Buffering material-receiving device for coal mine

A technology of material receiving device and buffer device, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low service life of radial shaft, high maintenance cost, increased running resistance, etc., and reduce daily repair and maintenance costs , Eliminate material splash and bulk material, prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

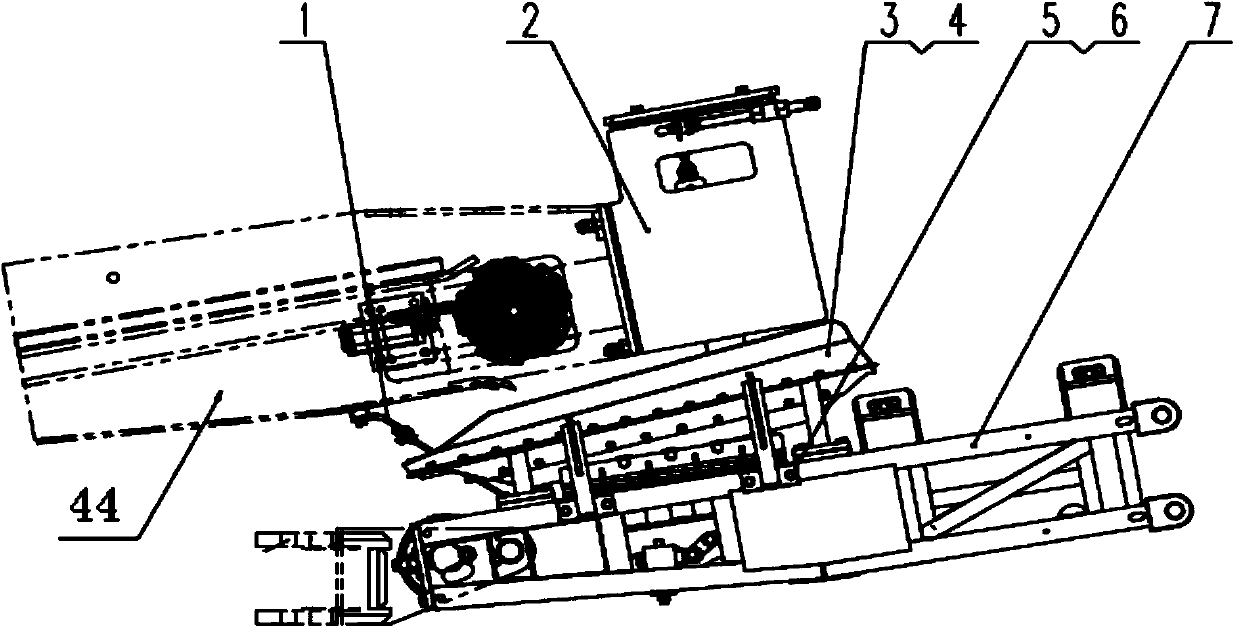

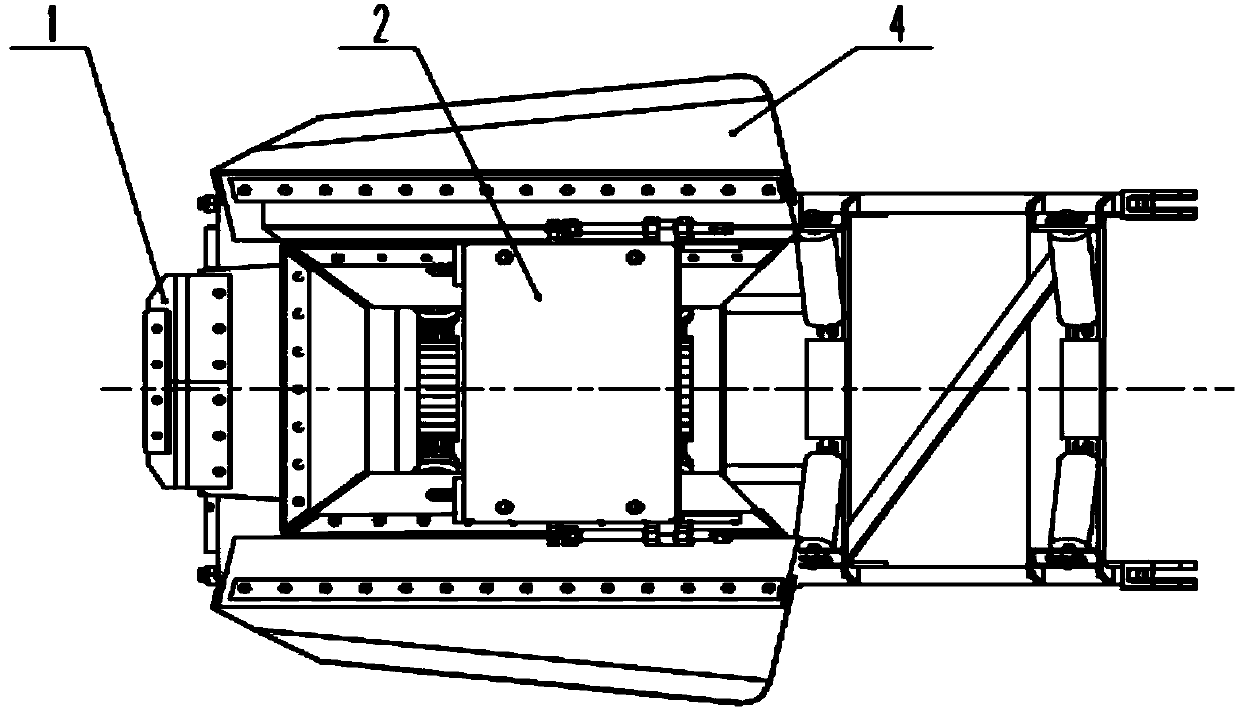

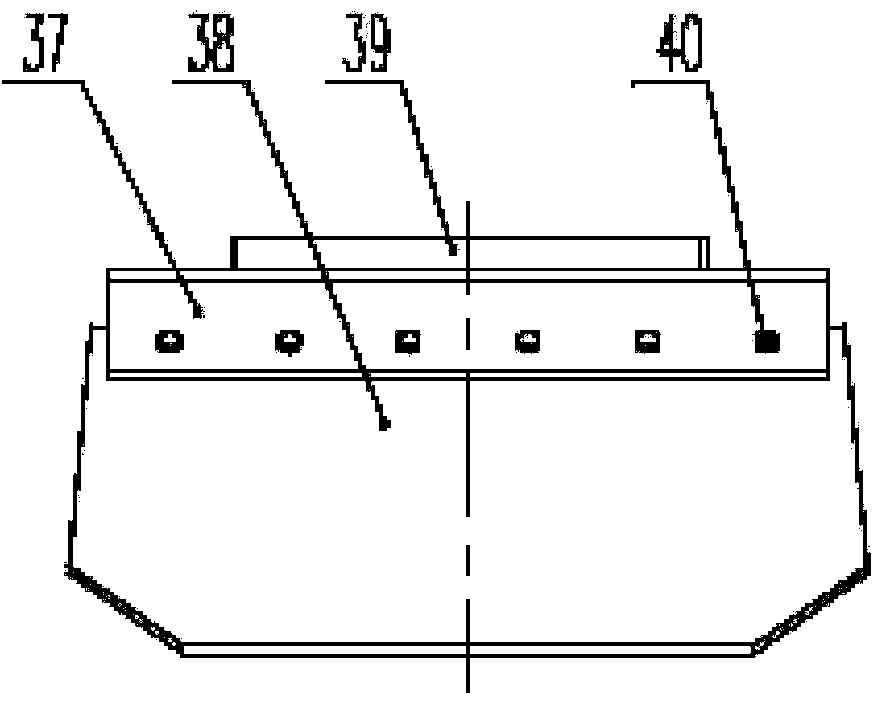

[0023] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 , a buffer device 2 is connected to the discharge end of the first conveyor 44, a buffer idler 10 is provided at a position aligned with the outlet of the buffer device 2 on the tail part 7 of the second conveyor, and a rear end of the tail part 7 of the second conveyor is provided The stopper device 1, the left stopper device 3 is provided on the left side aligned with the buffer device 2 on the tail part 7 of the second transport machine, and the right stop device 4 is provided on the right side aligned with the buffer device 2 on the tail part 7 of the second transport machine , The back gauge device 1, the left gauge device 3 and the right gauge device 4 form a funnel-shaped structure with an opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com