Optical semiconductor apparatus and method for producing the same

A technology of an optical semiconductor device and a manufacturing method, which is applied to semiconductor devices, electric solid-state devices, electrical components, etc., can solve problems such as increased processing time, and achieve the effects of eliminating chip spatter and shortening reflow soldering time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

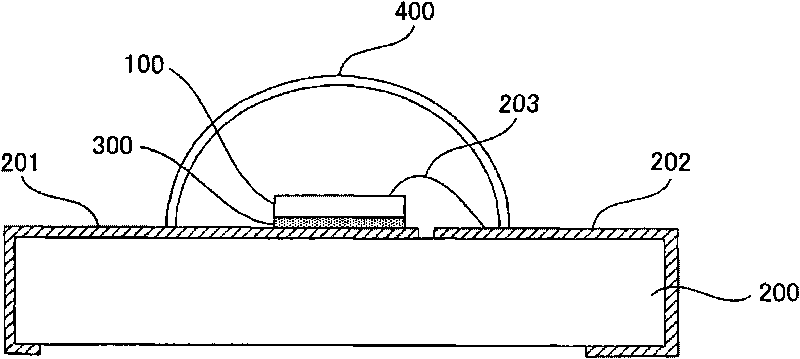

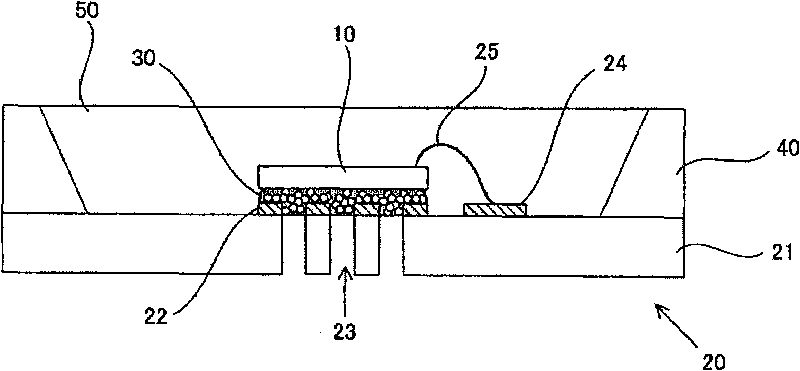

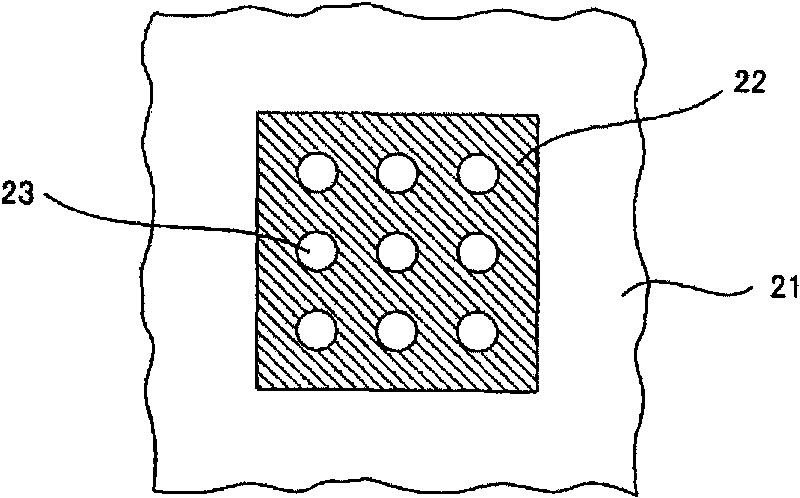

[0022] Next, embodiments of the optical semiconductor device of the present invention will be described with reference to the drawings. In addition, in the drawings shown below, substantially the same or equivalent constituent elements and parts are assigned the same reference numerals.

[0023] figure 2 It is a cross-sectional view showing the structure of an optical semiconductor device according to an embodiment of the present invention. image 3 It is a plan view of an underlayment forming part of a ceramic substrate constituting an optical semiconductor device.

[0024] The optical semiconductor device is composed of, for example, an LED chip 10 as an optical semiconductor element; a ceramic substrate 20 as a package substrate on which the LED chip 10 is mounted; a reflective member 40 disposed on the ceramic substrate 20 so as to surround the LED chip 10; and The light-transmitting resin portion 50 is provided to fill the space surrounded by the reflective member 40 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com