Rapid gas hybrid reactor for high temperature cracking and application thereof

A reaction device and gas technology, applied in chemical methods for reacting gas medium with gas medium, mixers, feeding devices, etc., can solve the problems of large pressure loss, complex structure, insufficient reaction, etc., and achieve fast mixing speed , The effect of small resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Reaction gas: water vapor and chlorodifluoromethane; the inlet of the gas delivery pipe is connected with the heating furnace, and the outlet of the reaction pipe is connected with the quencher.

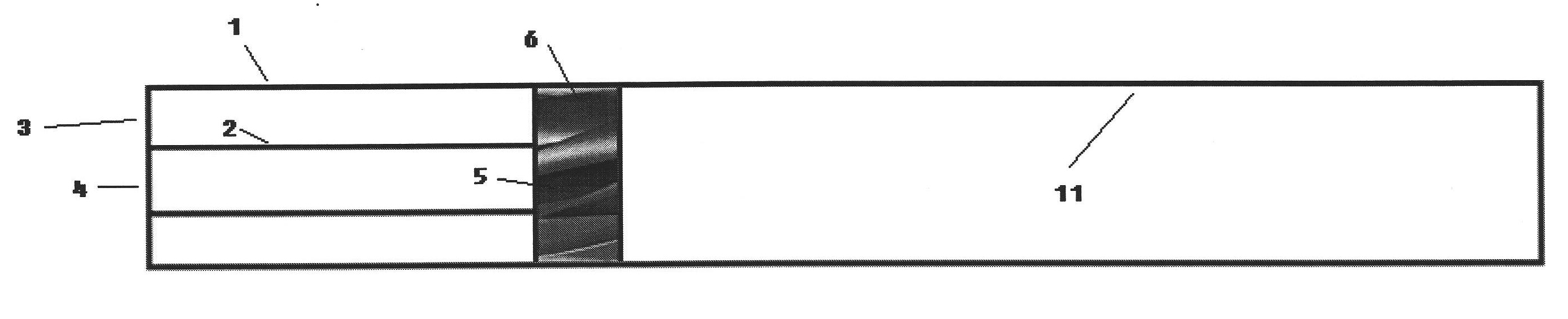

[0028] A gas rapid mixing reaction device for pyrolysis, comprising a gas delivery tube, a mixing nozzle and a reaction tube 11; the gas delivery tube communicates with the reaction tube 11 through the mixing nozzle; it is characterized in that the gas delivery tube is a Concentric double-layer circular tube, divided into delivery inner tube 2 and delivery outer tube 1;

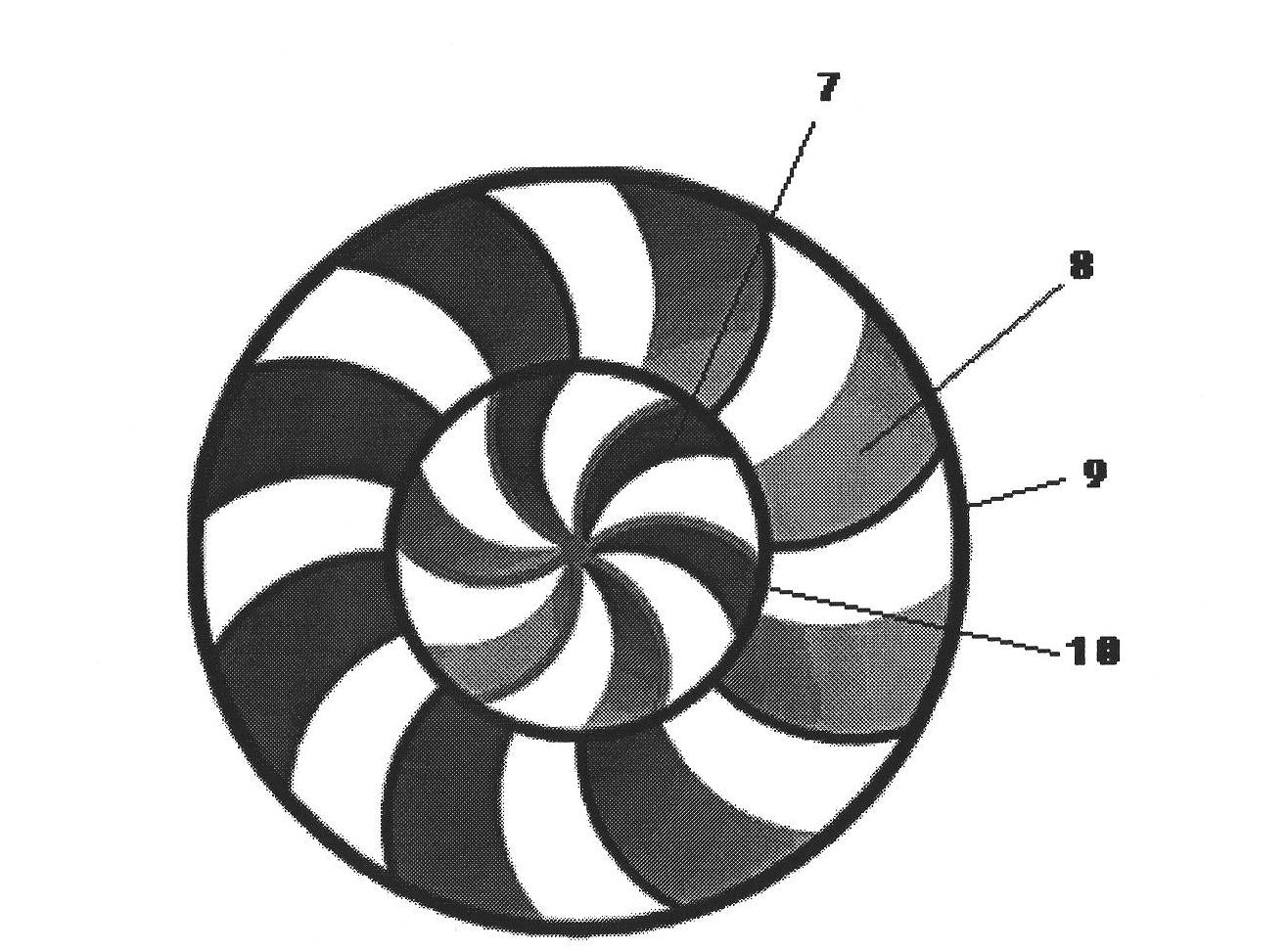

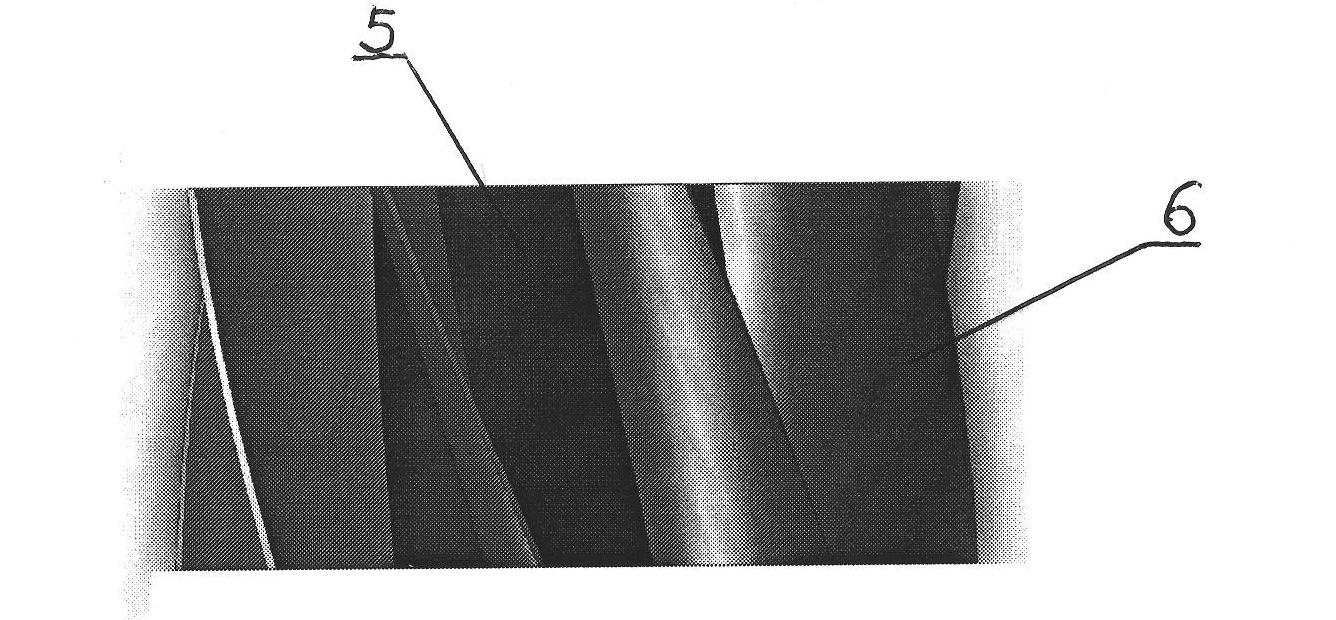

[0029] The mixing nozzle includes a concentric double-layer circular tube, which is divided into a nozzle inner tube 10 and a nozzle outer tube 9; The pipe annulus between is provided with annular turbine 6, and the rotation direction of inner turbine 5 and annular turbine 6 is opposite; The outer edge of turbine sheet 7 of inner turbine is fixedly connected with the inner wall of nozzle inner pipe 10; The ou...

Embodiment 2

[0035] Utilize the process steps of the preparation tetrafluoroethylene of the gas rapid mixing reaction device described in embodiment 1 to mix water vapor and difluorochloromethane:

[0036] 1) The superheated steam at 950°C enters the annular turbine 6 of the mixing nozzle through the pipe annulus formed by the inner pipe 2 and the outer pipe 1, and the flow rate is 1.5m 3 / s; 450°C difluorochloromethane enters the inner turbine 5 of the mixing nozzle from the delivery inner pipe 2, and the flow rate is 0.25m 3 / s;

[0037] 2) The superheated steam spins out through the annular turbine 6, and the difluorochloromethane spins out through the inner turbine 5, and the two gases spin out at opposite angles, and enter the reaction tube 11 after being fully mixed;

[0038] 3) After the water vapor and chlorodifluoromethane in step 2) are fully reacted in the reaction tube 11, they are cooled by quenching air, deacidified, dehydrated and washed to obtain tetrafluoroethylene.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com