Blade tip coupled cooling experiment system for turbine blades of gas turbine

A technology of turbine blades and experimental systems, which is applied in gas turbine engine testing, jet engine testing, etc., can solve the problems of single external film cooling research content and affect the film flow structure, so as to save research costs and enhance flow mixing. Mixed, Experimental Study of Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

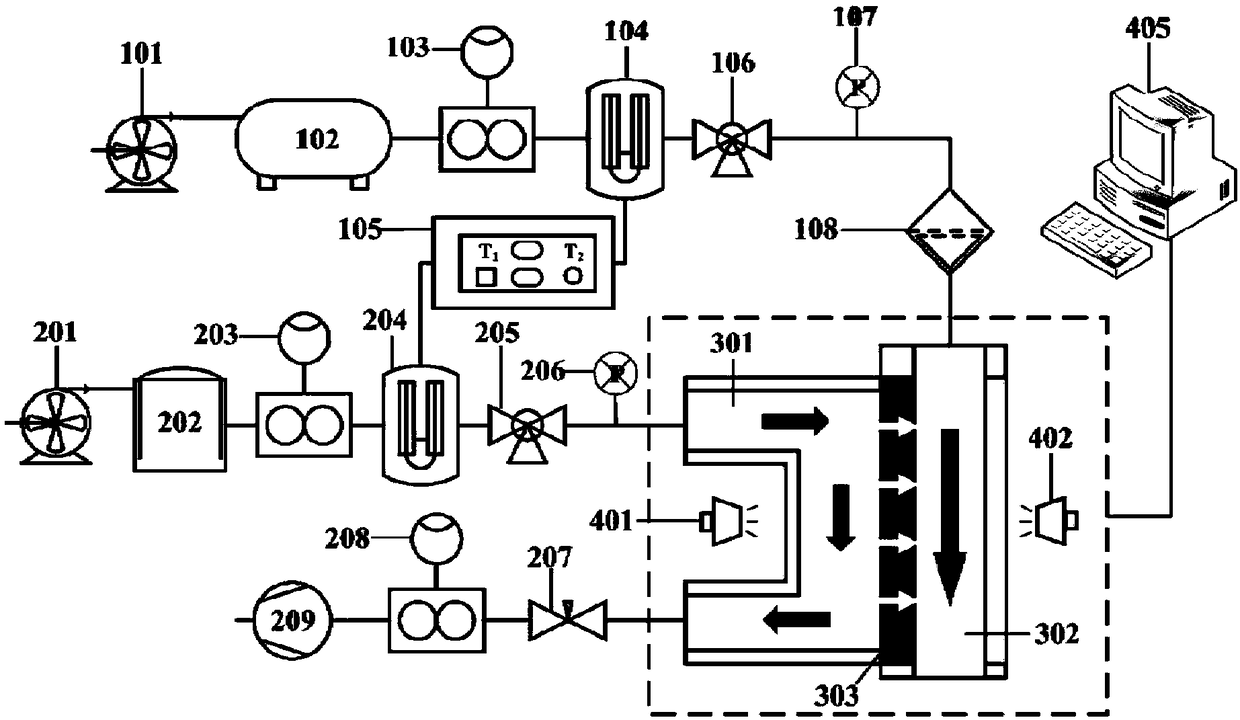

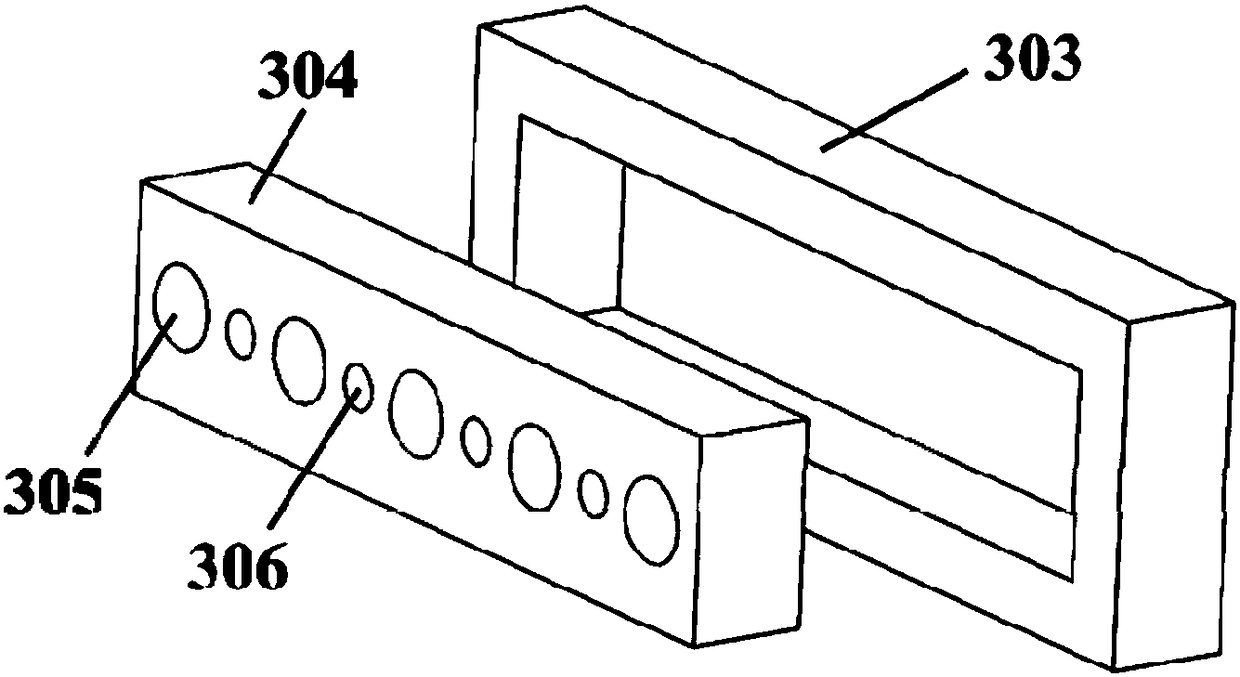

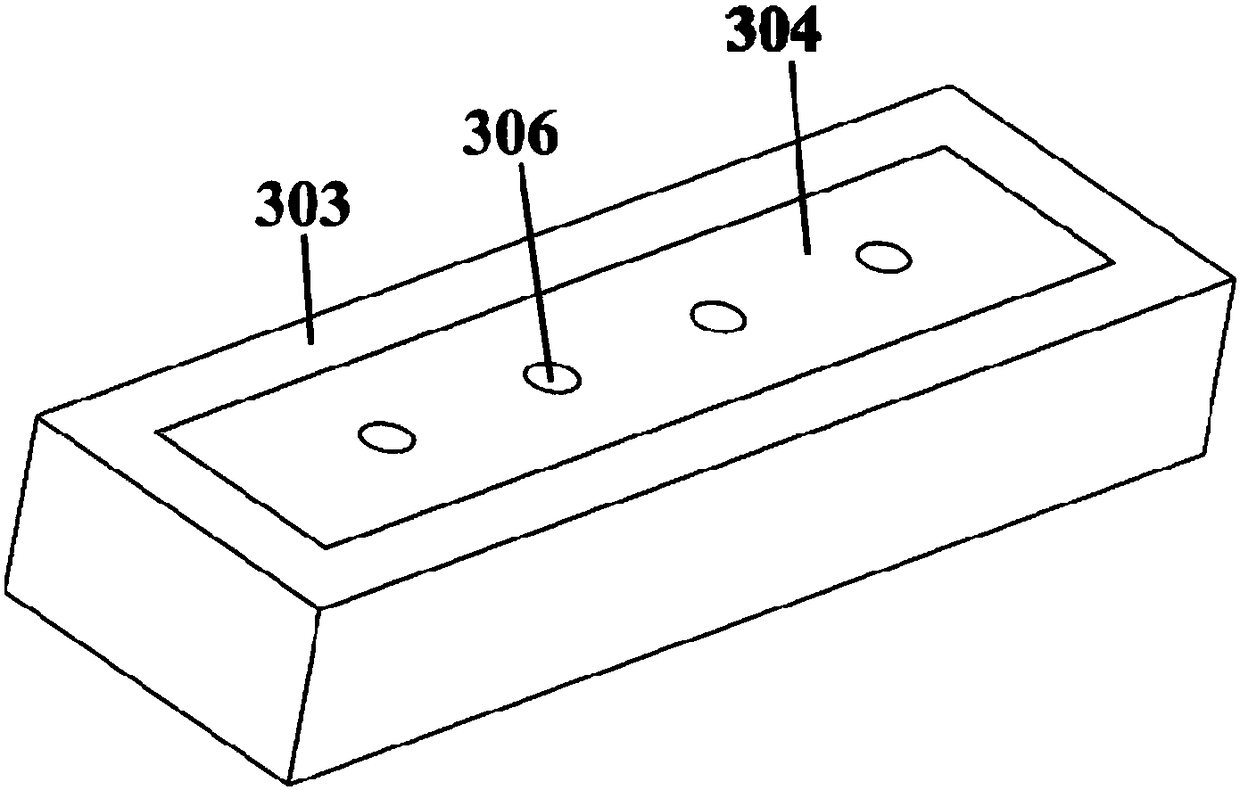

[0043] see figure 1 The present invention provides a blade tip coupling cooling experiment system for a turbine blade of a gas turbine, which includes a high-temperature mainstream passage, a U-shaped cooling passage, an experimental test section, and a data acquisition and analysis system.

[0044] refer to figure 1 , the high-temperature mainstream path includes a mainstream gas pump 101, a mainstream gas stabilizing tank 102, a mainstream gas flow meter 103, a mainstream gas heater 104, a temperature control box 105, a mainstream three-way solenoid valve 106, a mainstream gas pressure gauge 107 and a mainstream gas rectifying filter Net 108. The air at room temperature enters the high-temperature main channel through the main air pump 101, and after being pressure-compensated by the main flow tank 102, it flows stably into the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com