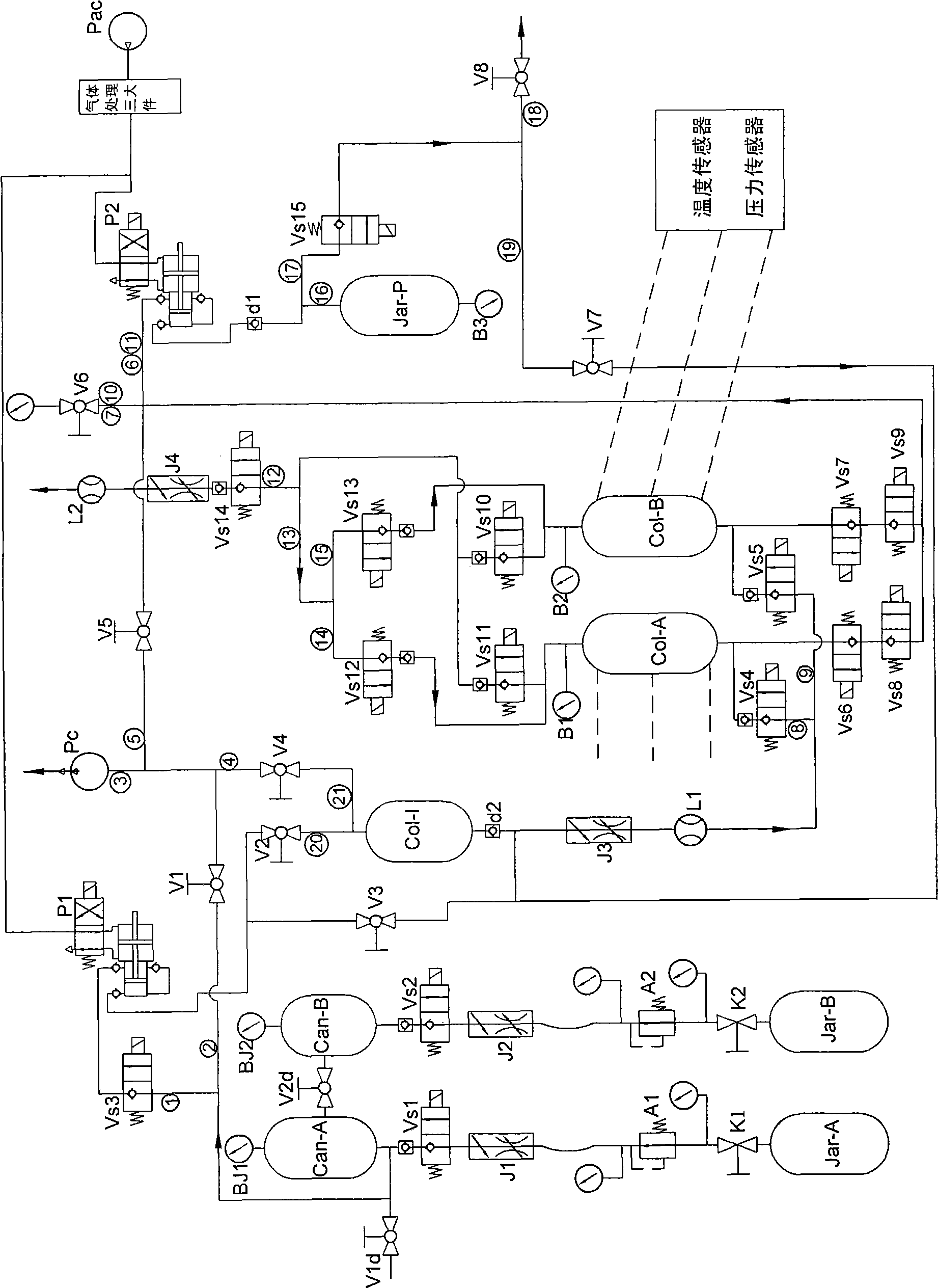

Double-column self-control variable-pressure adsorption experiment system with self-pressurization system

A technology of pressure swing adsorption and experimental system, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large volume, inability to meet the analysis and experimental parameters, high cost of use, etc., and achieve strong operability , The interface of the control system is clear, and the effect of monitoring the operating status of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

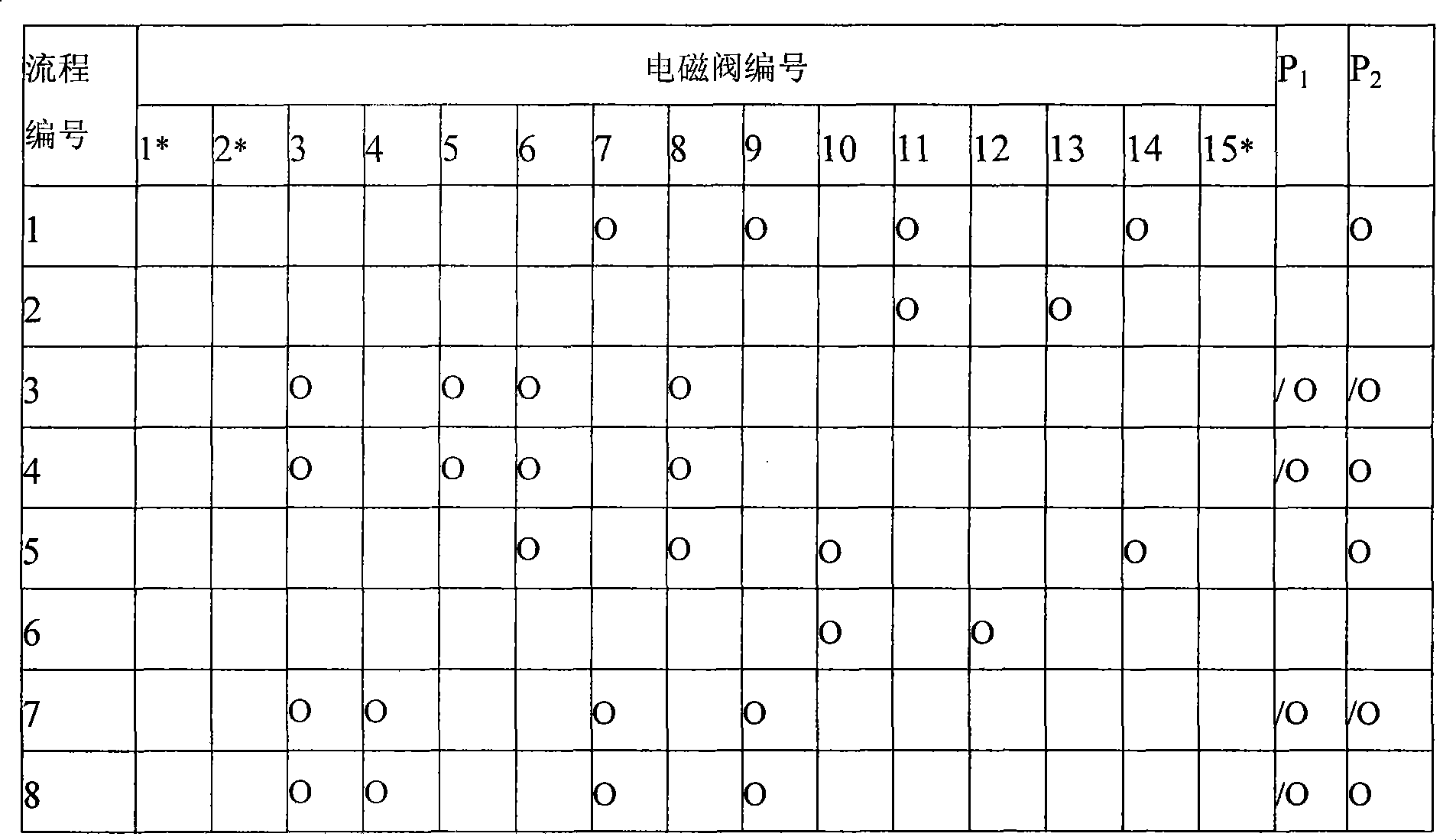

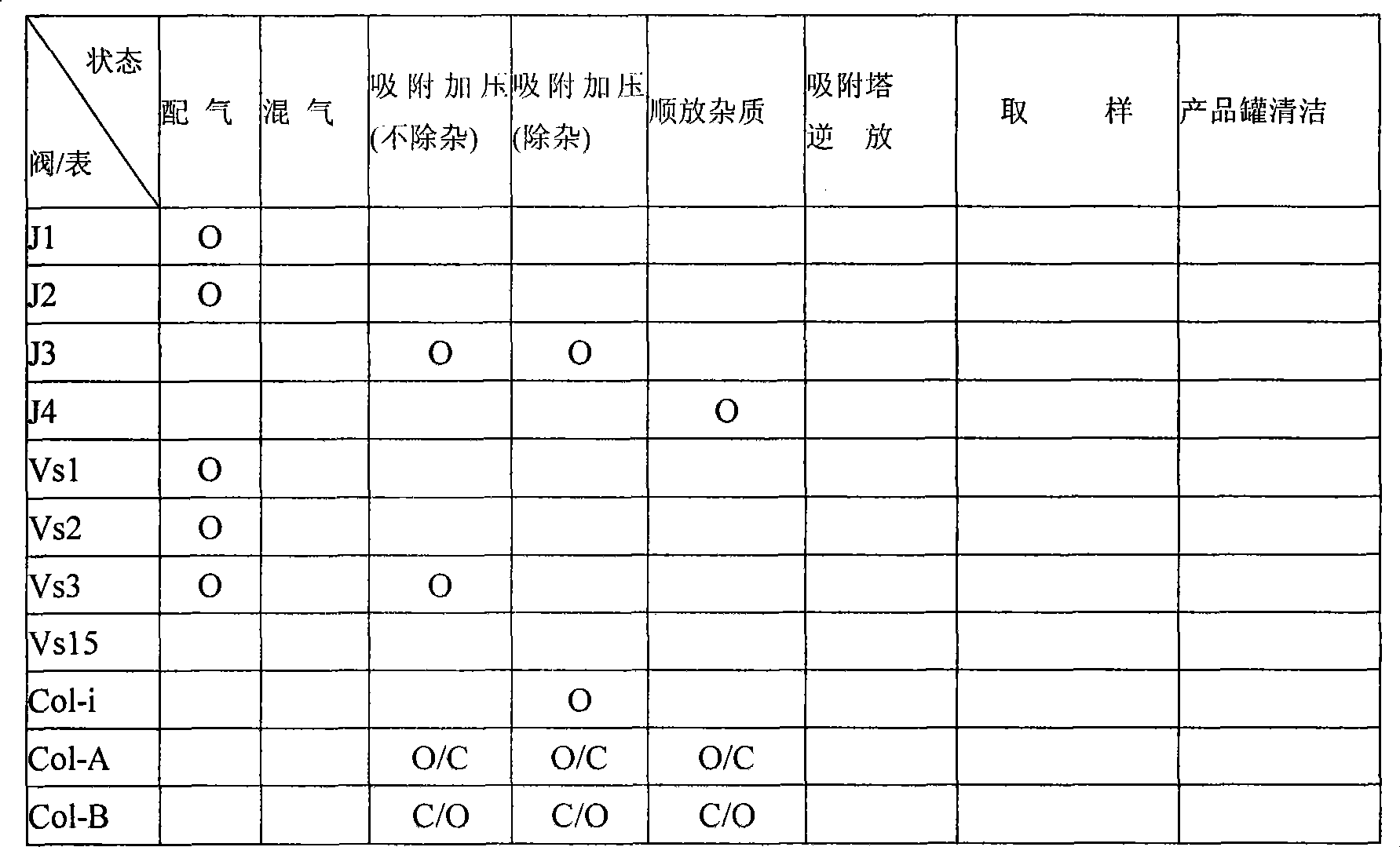

Method used

Image

Examples

Embodiment

[0031] Embodiment: The following is a detailed description of the working process of this experimental system with the methane separation process as a specific example:

[0032] 1. Purpose of the experiment:

[0033] Separation of methane and nitrogen mixed in a quantitative ratio, using the PSA pressure swing adsorption method to separate the mixed gas, by adjusting the pressure change during the adsorption process, to change the adsorption capacity of the adsorbent to the gas to achieve the purpose of absorbing or releasing the gas. Separation and purification of the required gas provide reference and reference for industrial adsorption separation application data and process flow.

[0034] 2. Experiment preparation:

[0035] 1. Raw material gas: methane and nitrogen

[0036] Methane and nitrogen are used as raw material gas to be quantitatively input into the gas distribution tank Can-A and the gas distribution tank Can-B respectively through the pipeline and the switch, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com