Differential pressure air speed detection and control device

A wind speed detection and control device technology, which is applied in the direction of detecting fluid flow by measuring pressure difference, manufacturing cigarettes, transportation and packaging, etc., can solve the problem that cannot solve the influence of the conveying speed of shredded tobacco, and does not detect the wind speed of the air supply and dust removal branch pipe of the cigarette machine, shredded tobacco Problems such as retention, to achieve the effect of maintaining high-precision detection for long-term operation, ensuring effective operation rate and reliability, and reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

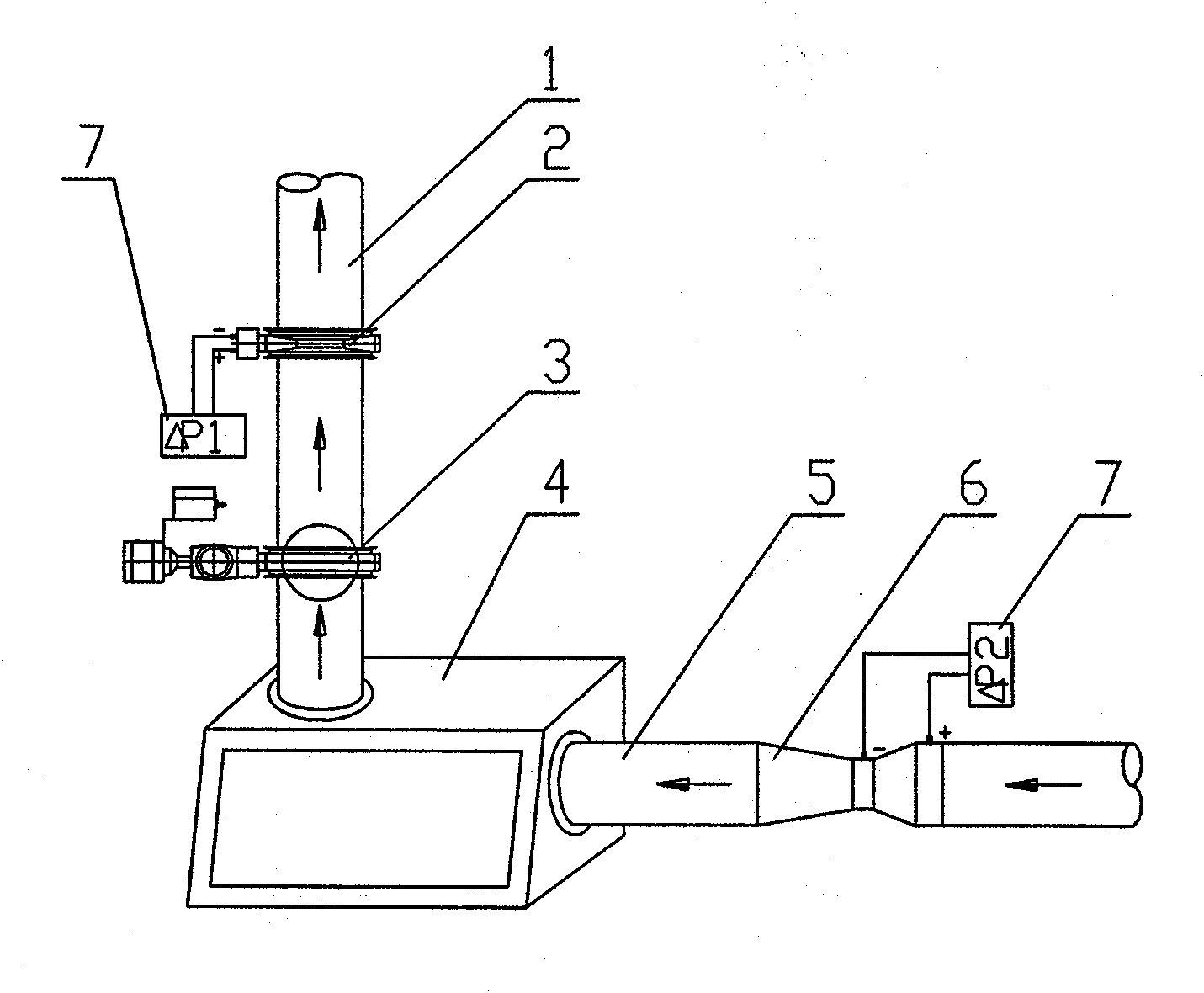

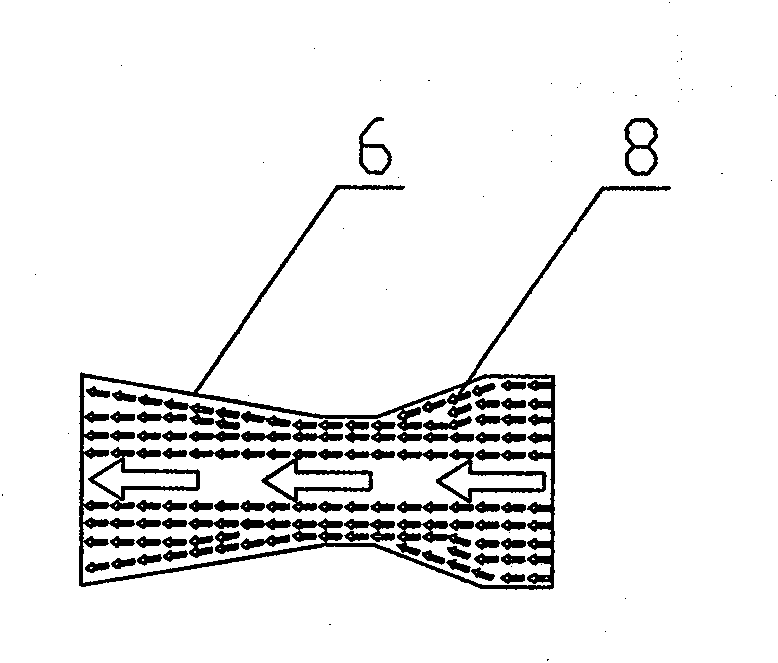

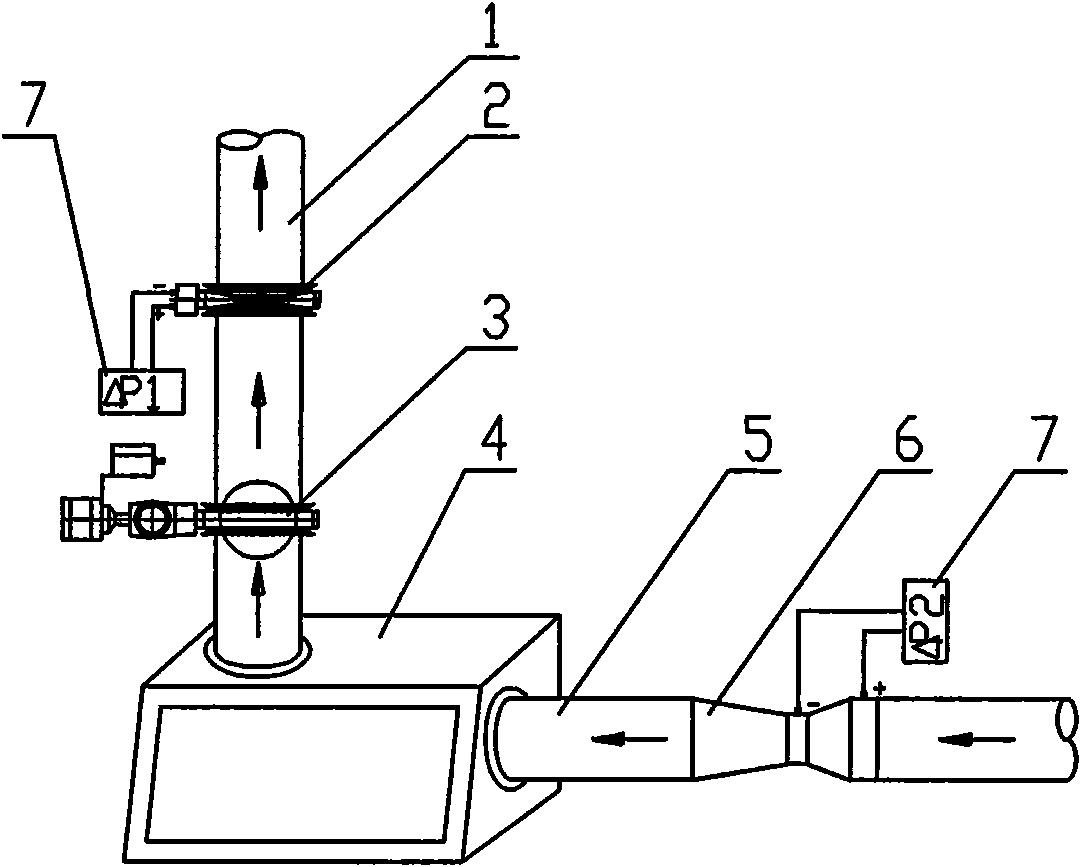

[0013] A differential pressure wind speed detection and control device, including an air supply dust removal branch pipe 1, an electric (pneumatic) regulating butterfly valve 3, a cigarette machine silk collecting box 4, a shredded tobacco conveying pipeline 5, and a differential pressure flowmeter, a differential pressure flowmeter It is a split-type venturi flowmeter, which consists of a split-type venturi flowmeter pressure measuring component 6 and a differential pressure sensor 7; it also includes a split-type orifice flowmeter, which consists of a split-type orifice flowmeter The pressure measuring assembly 2 of the split orifice flowmeter is composed of a differential pressure sensor 7 . In actual operation, when the cigarette machine wire collection box 4 needs shredded tobacco, its own pneumatic switch butterfly valve is opened, and the system negative pressure wind draws shredded tobacco from the pneumatic wire distribution machine into the shredded tobacco conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com