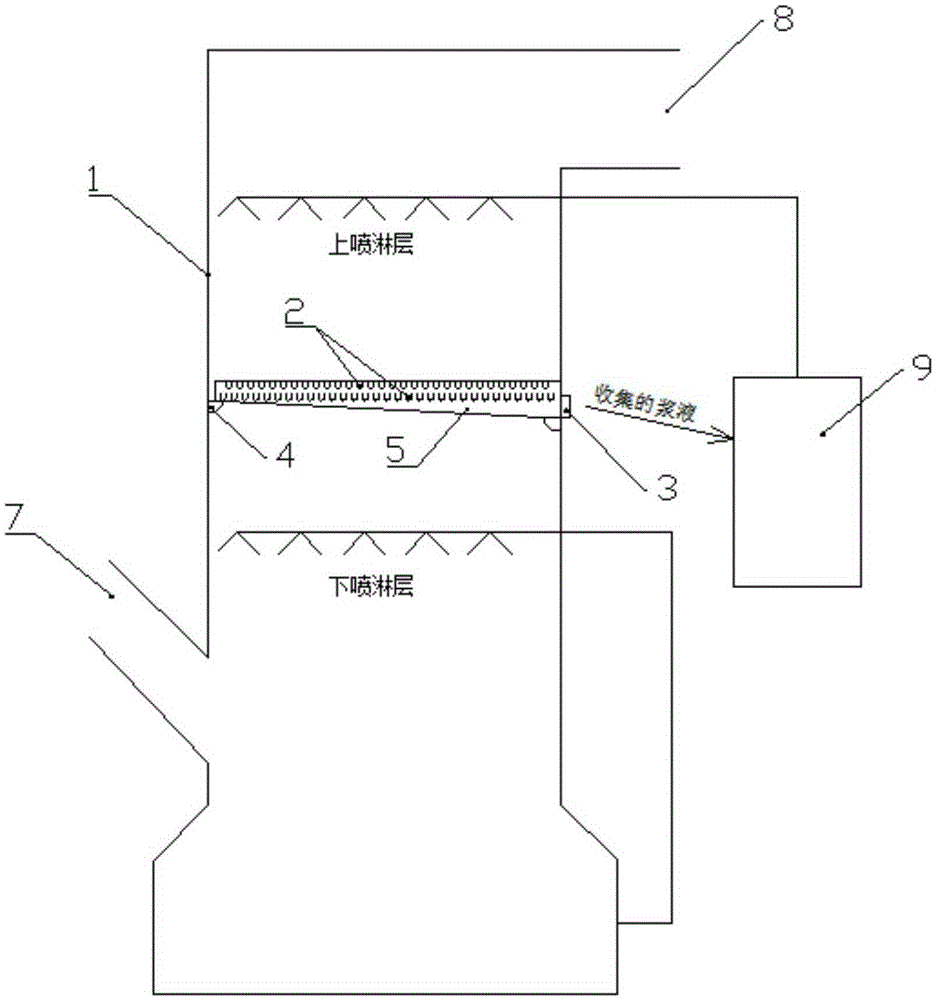

Single-tower dual-cycle wet flue gas desulfurization tower and tube groove type liquid collection device

A tube-trough, liquid-collecting technology, applied in the field of flue gas desulfurization, can solve the problems of uneven distribution of flue gas flow rate, insufficient gas-liquid contact, and reduced mass transfer capacity, and achieves good gas-liquid contact effect, avoids short circuits, The effect of reducing drag loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

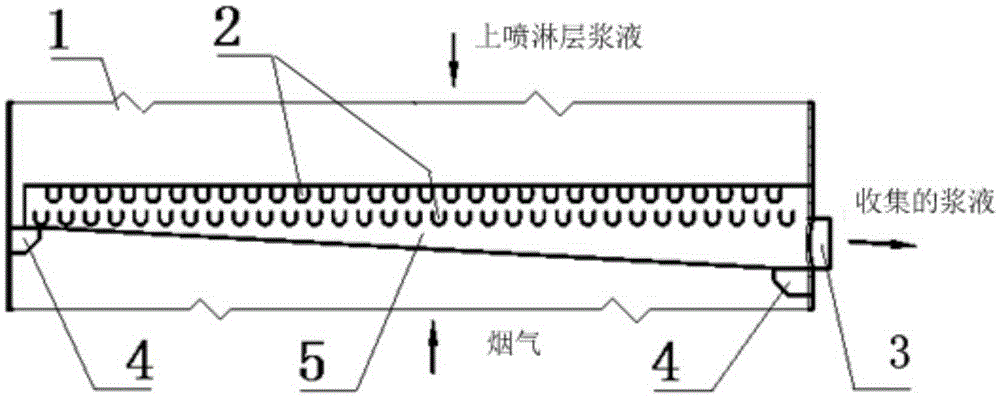

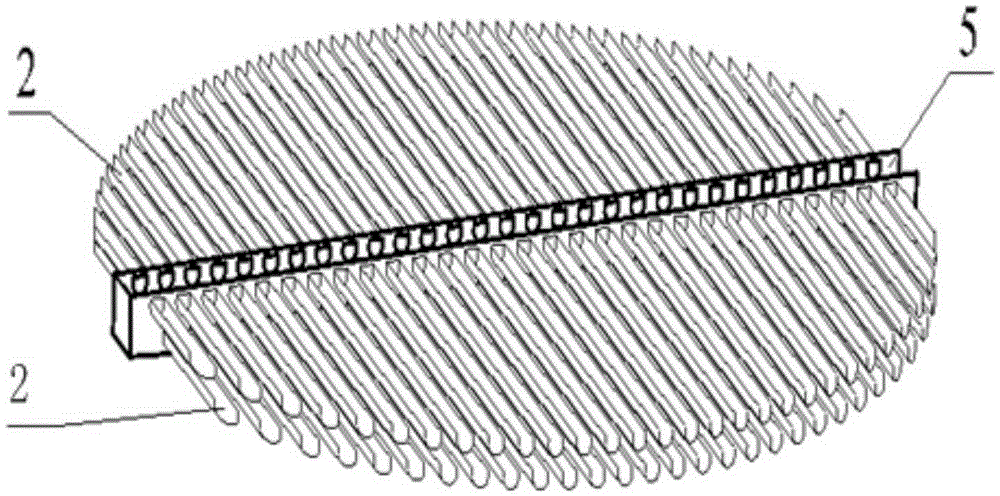

[0030] Such as image 3 shown. A pipe-groove type liquid collection device, comprising several liquid-collecting pipe grooves 2, the liquid-collecting pipe groove 2 is a long semi-circular pipe groove with an open top, the liquid-collecting pipe groove 2 is provided with two layers in the longitudinal direction, and the two-layer liquid collecting pipe The grooves 2 are arranged in a staggered manner, and the liquid collecting pipe grooves on the same layer are evenly arranged. The distance between two adjacent liquid collecting pipe grooves on the same layer is equal to the width of the opening of the liquid collecting pipe grooves, so as to realize the collection of the upper spray layer slurry At the same time, the system resistance is reduced, and the gap between the collecting pipe grooves 2 forms a flue gas channel.

[0031] In order to make the flue gas pass smoothly through the liquid collecting pipe grooves arranged in the groove grid type and reduce the resistance l...

Embodiment 2

[0041] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are: Figure 4 As shown, the liquid collecting pipe groove 2 is distributed symmetrically on both sides of a support rod 6 , and the diversion groove 5 surrounds the end of the liquid collecting pipe groove 2 away from the supporting rod 6 . The diversion groove 5 is located at the outer end of the collecting pipe groove 2 and communicates with all the collecting pipe grooves 2 at the same time. One end of the collecting pipe groove 2 communicating with the diversion groove 5 is lower than the other end, so that the collecting pipe groove 2 form a "Λ" shape arrangement as a whole.

[0042] In order to avoid affecting the flue gas flow while ensuring that the slurry is easy to flow, the bottom surface of the diversion groove 5 includes an inner bottom surface in contact with the slurry and an oute...

Embodiment 3

[0045] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are: Figure 5 As shown, the overall collection pipe groove 2 is inclined in the same direction, and the diversion groove 5 is located at the lower end of the liquid collection pipe groove 2 and communicates with all the liquid collection pipe grooves 2 at the same time.

[0046] In this embodiment, the diversion groove 5 is located at the edge of the entire pipe groove liquid collection device. In order to avoid affecting the flow of flue gas and ensure that the slurry is easy to flow, the bottom surface of the diversion groove 5 includes the bottom surface of the inner layer that is in contact with the slurry As for the bottom surface of the outer layer in contact with the flue gas, the bottom surface of the inner layer is an inclined surface, and the bottom surface of the outer layer is a horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com