Recycling method of lithium ion battery positive electrode material fine powder

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor electrochemical performance of positive electrode materials, achieve gram capacity and good cycle stability, simple process, and recycling efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

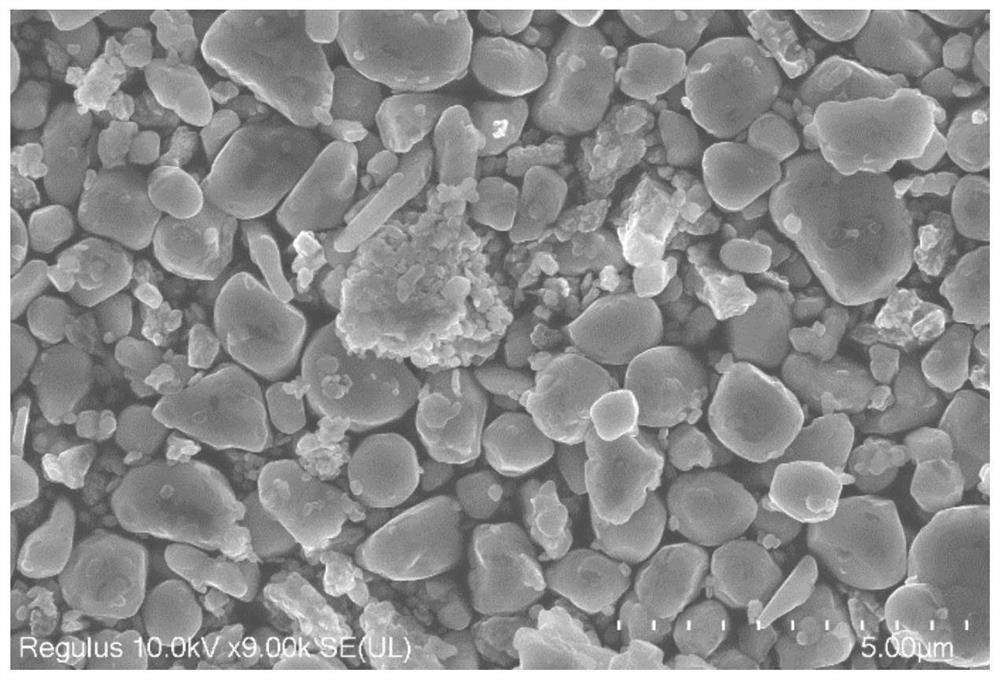

[0042] (1) Process fine powder of NCM622 cathode material (active ingredient is LiNi x co y mn z o 2 , x is 0.6, y is 0.2, z is 0.2, and the crystal form is single crystal) and grinding aid (magnesium oxide), polyurethane grinding balls are added in the ball milling tank according to the weight ratio of 1:0.02:1, with the ball milling frequency of 35Hz , ball milled for 2 hours to get fully dispersed fine powder, the particle size D 50 ≤1.0μm. Among them, the SEM image of NCM622 cathode material is as follows figure 1 shown. from figure 1 It can be seen that the particle size of the positive electrode material in the fine powder is 0.01 μm to 5 μm.

[0043] (2) Add the above-mentioned fine powder and HPMA (the number average molecular weight is 758, the pH value of 1% aqueous solution is 2.3), NaOH and deionized water are added in the reactor and stirred for 2h, the addition of HPMA is 0.1wt%, the addition of NaOH The addition amount is 4mol / L, the ratio of fine powder...

Embodiment 2

[0049] (1) Process fine powder of NCM622 cathode material (active ingredient is LiNi x co y mn z o 2 , x is 0.6, y is 0.2, z is 0.2, the crystal form is single crystal, the particle size is 0.01μm~5μm) and grinding aid (ethylene glycol), polyurethane grinding balls are added to the ball mill at a weight ratio of 1:0.04:1 In the tank, mill at a ball milling frequency of 35 Hz for 2 hours to obtain a fully dispersed fine powder with a particle size of D 50 ≤1.0μm.

[0050] (2) Add above-mentioned fine powder material and HPMA, NaOH and deionized water in the reactor and stir for 2h, wherein, the addition amount of HPMA is 0.15%, the addition amount of NaOH is 4mol / L, the ratio of fine powder material and water is 0.3:1, to obtain a mixed slurry where solid and liquid coexist.

[0051] (3) Pass the mixed slurry into a decanter centrifuge, set the speed of the centrifuge at 15000r / min, and separate the large-grained positive electrode material (3.4-3.7μm) and small-grained T...

Embodiment 3

[0056] (1) Process fine powder of NCM622 cathode material (active ingredient is LiNi x co y mn z o 2 , x is 0.6, y is 0.2, z is 0.2, the crystal form is single crystal, the particle size is 0.01 μm ~ 5 μm) and grinding aid (talc powder), polyurethane grinding balls are added to the ball milling tank according to the weight ratio of 1:0.05:1 In the process, ball milling at a ball milling frequency of 35 Hz for 2 hours yields fully dispersed fine powder with a particle size of D 50 ≤1.0μm.

[0057] (2) Add above-mentioned fine powder material and HPMA, NaOH and deionized water in the reactor and stir for 2h, wherein, the addition amount of HPMA is 0.15%, the addition amount of NaOH is 4mol / L, the ratio of fine powder material and water is 0.3:1, to obtain a mixed slurry where solid and liquid coexist.

[0058] (3) Pass the mixed slurry into a decanter centrifuge, set the speed of the centrifuge at 17000r / min, and separate the large-grained positive electrode material (3.3-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com