Deep impurity removal method for cell-grade lithium chloride

A deep impurity removal and lithium chloride technology, applied in the direction of lithium halide, etc., can solve the problems of fine initial sediment particle size, increased risk of scaling on the inner wall of pipelines and containers, and many times of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

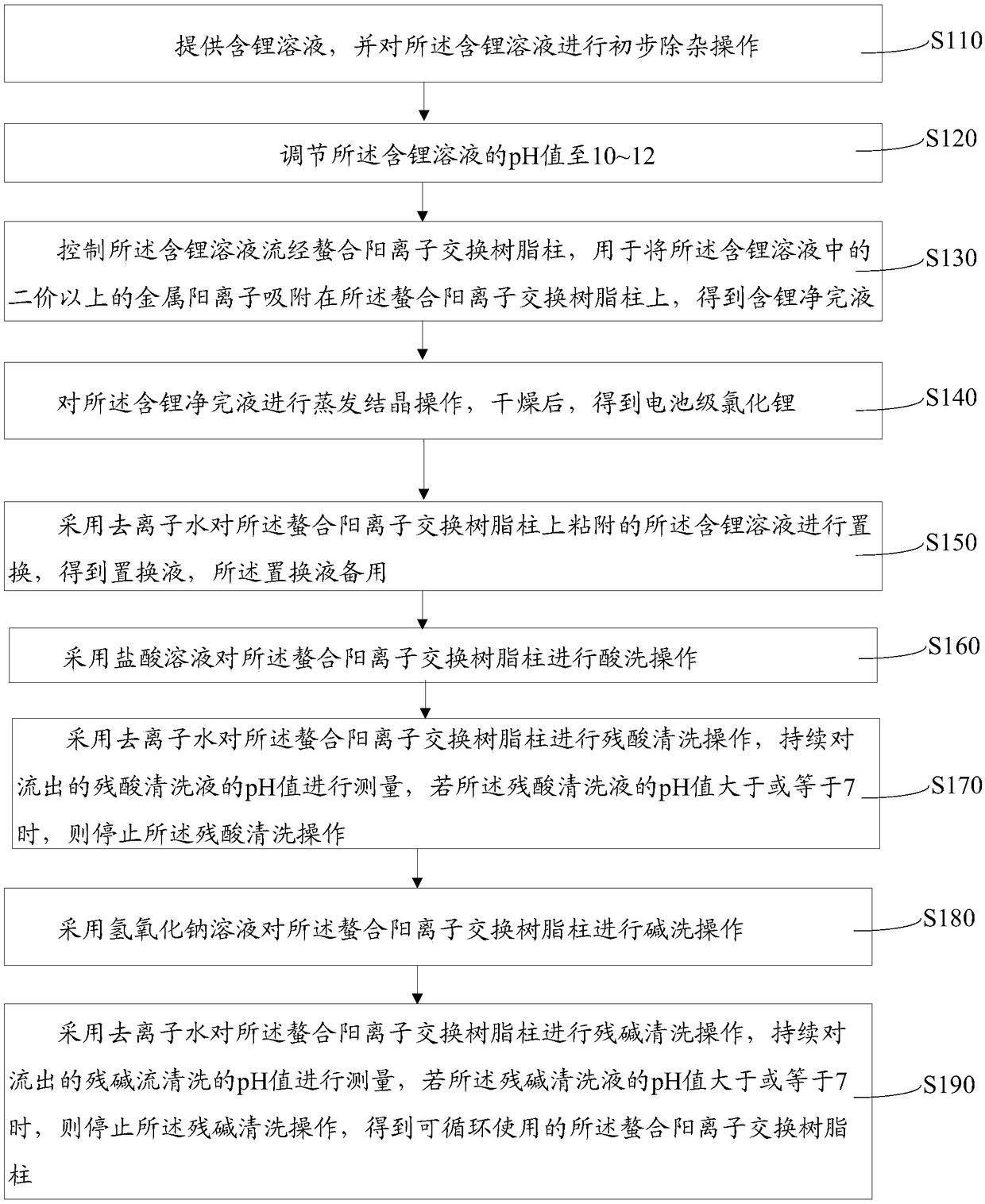

Image

Examples

Embodiment 1

[0101] Provide the lithium sulfate solution that 8kg spodumene leaching obtains, add 3kg sodium carbonate solution, carry out first filtration separation operation, obtain filtrate, then add 1kg mass fraction in filtrate and be 15% dilute sodium hydroxide solution, adjust pH value To 11, carry out vacuum filtration and separation to obtain the lithium sulfate solution after preliminary impurity removal;

[0102] The pH value of the lithium sulfate solution is adjusted to 12 by a sodium hydroxide solution with a mass fraction of 20%;

[0103] The lithium sulfate solution is flowed through the polystyrene aminophosphoric acid type chelating cation exchange resin column, and the flow time is 15min to obtain a lithium-containing clean solution;

[0104] Put the lithium-containing purified solution into the evaporation crystallization kettle, first turn on the internal circulation mode, then vacuumize, and at the same time slowly heat to evaporate the water in the lithium-containin...

Embodiment 2

[0111] Provide the lithium sulfate solution that 8kg lepidolite leaching obtains, add 4kg sodium carbonate solution, carry out first filtration and separation operation, obtain filtrate, add 2kg mass fraction again in filtrate and be 18% dilute sodium hydroxide solution, pH value is adjusted to 11. Carry out vacuum filtration and separation to obtain lithium sulfate solution after preliminary impurity removal;

[0112] The pH value of the lithium sulfate solution is adjusted to 12 by a sodium hydroxide solution with a mass fraction of 20%;

[0113] The lithium sulfate solution is flowed through the polystyrene aminophosphoric acid type chelating cation exchange resin column, and the flow time is 20min to obtain a lithium-containing clean solution;

[0114] Put the lithium-containing purified solution into the evaporation crystallization kettle, first turn on the internal circulation mode, then vacuumize, and at the same time slowly heat to evaporate the water in the lithium-co...

Embodiment 3

[0121] Provide the lithium sulfate solution that 8kg lepidolite leaching obtains, add 4kg sodium carbonate solution, carry out first filtration and separation operation, obtain filtrate, add 2kg mass fraction again in filtrate and be 18% dilute sodium hydroxide solution, pH value is adjusted to 11. Carry out vacuum filtration and separation to obtain lithium sulfate solution after preliminary impurity removal;

[0122] The pH value of the lithium sulfate solution is adjusted to 12 by a sodium hydroxide solution with a mass fraction of 20%;

[0123] The lithium sulfate solution is flowed through the polystyrene iminodiacetic acid type chelating cation exchange resin column, and the flow time is 20min to obtain a lithium-containing clean solution;

[0124] Put the lithium-containing purified solution into the evaporation crystallization kettle, first turn on the internal circulation mode, then vacuumize, and at the same time slowly heat to evaporate the water in the lithium-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com