Method for preparing special type molybdenum powder

A technology of special molybdenum powder and molybdenum powder, which is applied in the field of preparation of special molybdenum powder for thermal spraying, mechanical processing industry and precision device pressing. It can solve the problems of fluidity, loose ratio, and particle size that are difficult to meet the requirements, and achieve easy control of the production process. , reduce sintering energy consumption, and improve the effect of microscopic appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

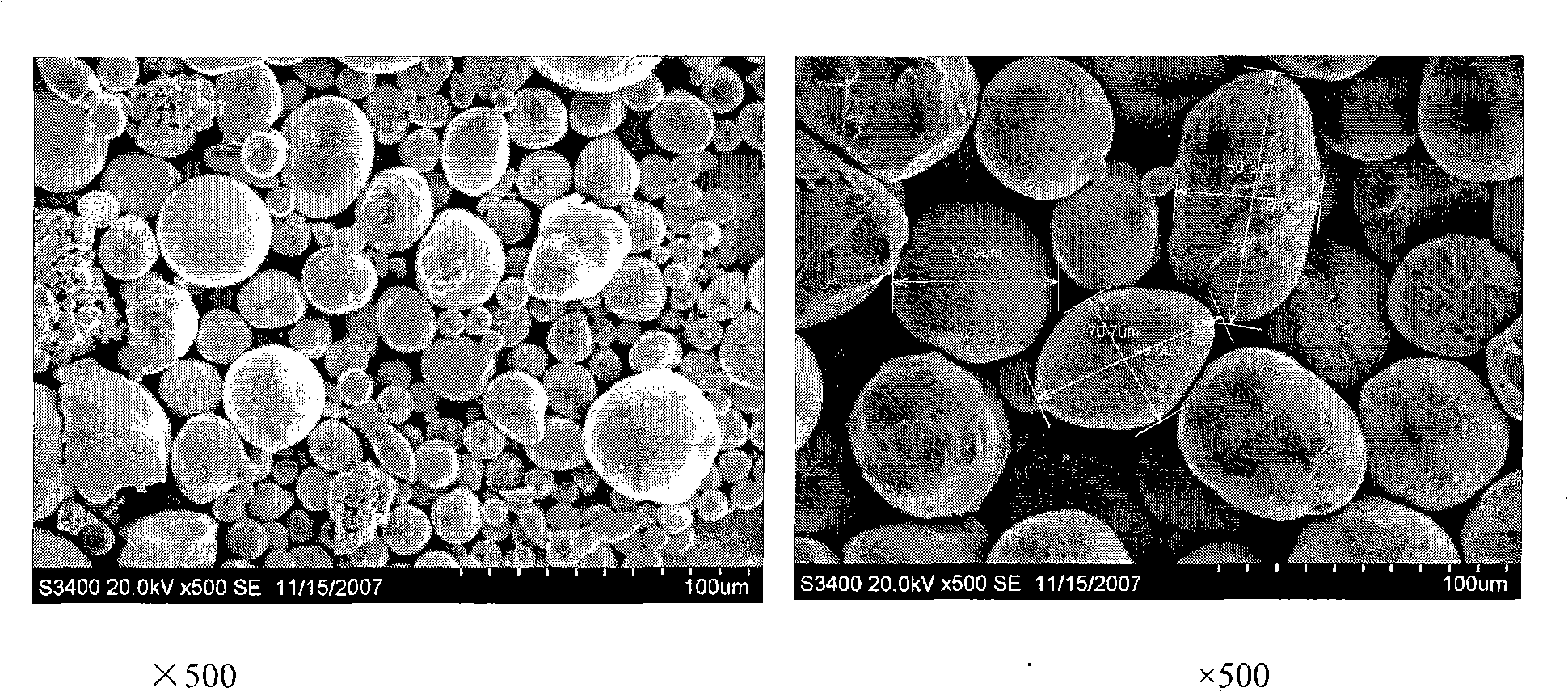

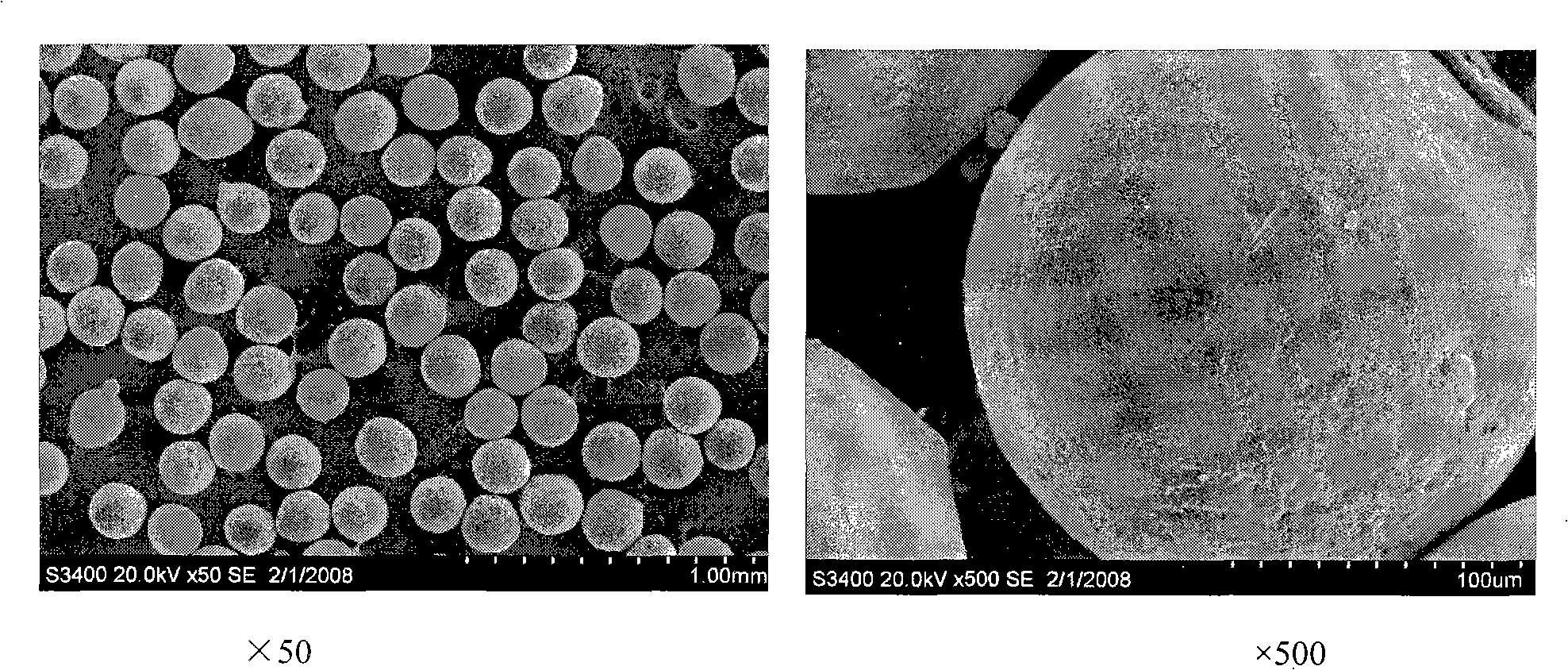

[0029] Take 2kg of MP-1 molybdenum powder that meets the Q / JDC013-2002 standard for use, its average Fischer particle size is 3.20μm, and its bulk density is 1.04g / cm 3 ;Sinter and granulate the weighed molybdenum powder in a muffle furnace under the protection of hydrogen, the sintering temperature is 980°C, and the time is 5hr; the molybdenum powder after sintering and granulation is sieved and classified, and the molybdenum powder with similar particle size is sintered in DH-1080 Plasma equipment is used for high temperature spheroidization treatment. The working current of the plasma spheroidization equipment is 350 amperes and the working voltage is 70 volts; the spheroidized molybdenum powder is reduced under the protection of hydrogen in the muffle furnace at a temperature of 800 ° C for 6 hours; the reduced molybdenum powder The special molybdenum powder of the present invention is obtained by sieving and classifying.

[0030] The detection index of special molybdenum ...

Embodiment 2

[0033] Take 5kg of MP-1 molybdenum powder that meets the Q / JDC013-2002 standard for use, its average Fischer particle size is 3.60μm, and its bulk density is 1.10g / cm 3 ; Sinter and granulate the weighed molybdenum powder in a muffle furnace under the protection of hydrogen. The sintering temperature is 1100°C and the time is 6hr; Plasma equipment for high temperature spheroidization treatment, plasma spheroidization equipment working current 400 amperes, working voltage 80 volts; spheroidized molybdenum powder is reduced under the protection of hydrogen in the muffle furnace, the temperature is 850 ° C, and the time is 8 hours; the reduced molybdenum powder The special molybdenum powder of the present invention is obtained by sieving and classifying.

[0034] The detection index of special molybdenum powder is as follows:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com