Preparation method of copper-chromium alloy powder and preparation method of copper-chromium alloy pig

A technology of copper-chromium alloy and powder, which is applied in the application field of the metal powder, can solve the problems of high gas content, complex process, coarse Cr particles, etc., and achieve the advantages of high gas content, uniform fine distribution, and high anti-welding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

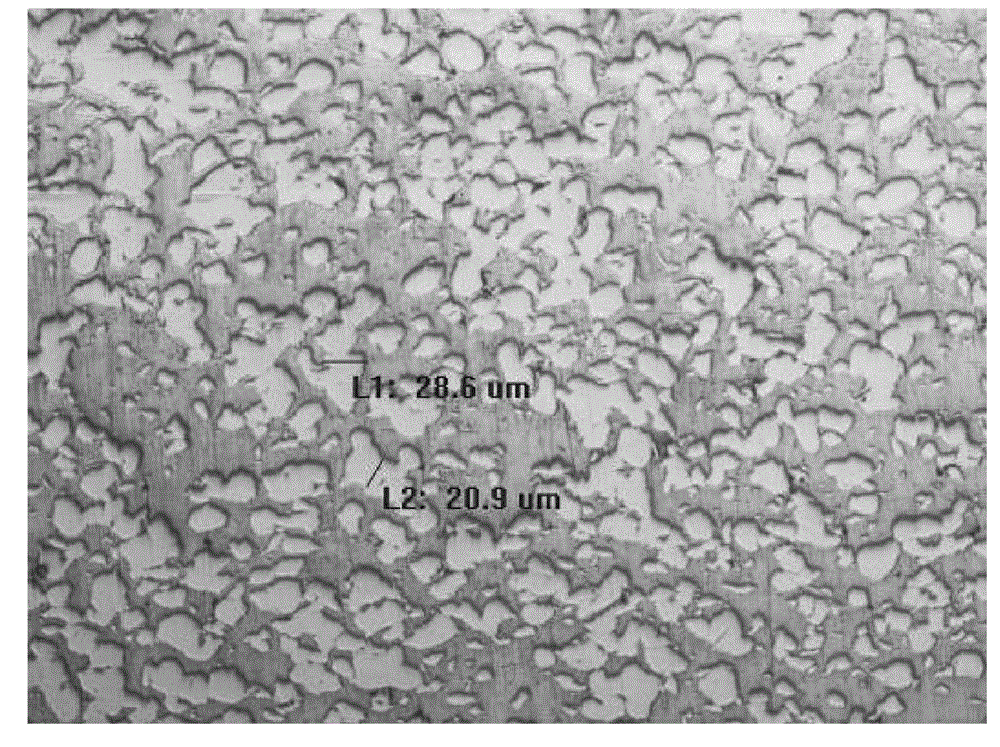

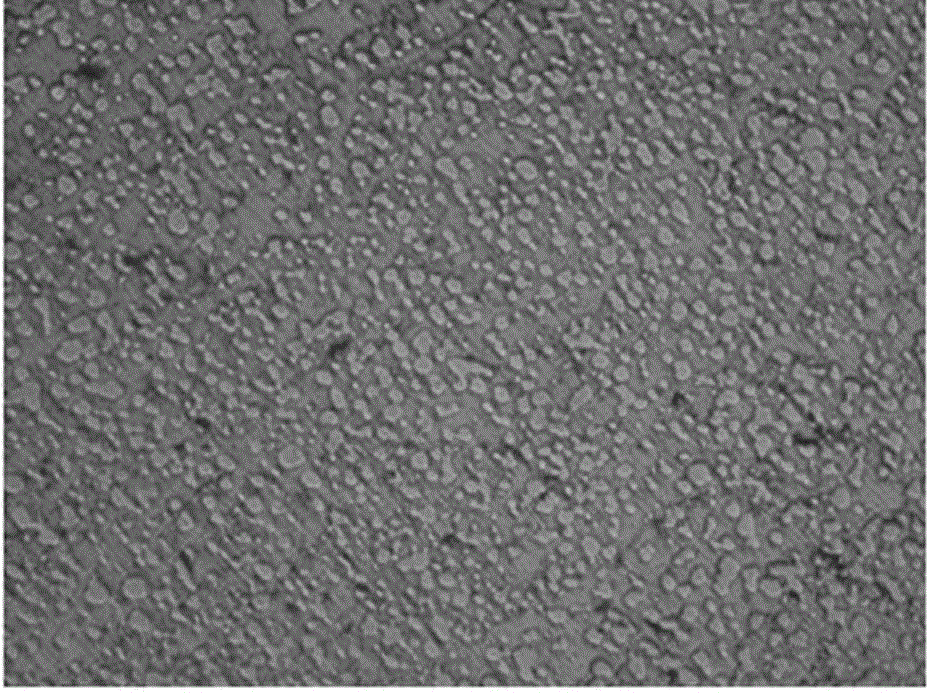

[0024] Take 5.25 kg of copper and 1.75 kg of chromium into the ceramic crucible of the vacuum induction melting furnace, and first evacuate to 10 -3 -10 -4 Pa, and then filled with an inert protective gas such as argon or nitrogen with a mass purity greater than 99%. Turn on the heating power to melt the raw materials by induction heating. And heat the molten alloy for 1 to 10 minutes. The smelted alloy liquid is introduced from the outlet into the guide tube of the atomization chamber with a diameter of 6.0mm, and flows from the guide tube into the atomization nozzle. Under the action of the high-pressure nitrogen gas flow at a pressure of 0.2MPa, Immediately after spraying from the atomizing nozzle, it is atomized into small droplets with a size of 1-1000 microns; the molten droplets are rapidly cooled and solidified into solid alloy powders of the same size during the falling process. Collect the powder and sieve it through a 150-micron sieve to remove particles larger t...

Embodiment 2

[0028] Put 4.9 kg of copper and 2.1 kg of chromium into the ceramic crucible of the vacuum induction melting furnace, and first evacuate to 6.0Χ10 -3 After Pa, it is filled with an inert protective gas such as argon with a mass purity greater than 99%. Turn on the heating power to melt the raw materials by induction heating. And heat the molten alloy for 1 to 10 minutes. The smelted alloy liquid is introduced from the outlet into the guide pipe of the atomization chamber with a diameter of 8.0mm, and flows from the guide pipe into the atomization nozzle. Under the action of the helium gas flow at a pressure of 0.3Mpa, the alloy liquid Immediately after spraying from the atomizing nozzle, it is atomized into small droplets with a size of 1-1000 microns; the molten droplets are rapidly cooled and solidified into solid alloy powders of the same size during the falling process. Collect the powder and sieve it through a 150 micron sieve to remove particles larger than 150 micron ...

example 3

[0032] Take 3.5 kg of copper and 3.5 kg of chromium into the ceramic crucible of the vacuum induction melting furnace, and first evacuate to 4.0Χ10 -3 Pa is filled with an inert protective gas such as helium with a mass purity greater than 99%. Turn on the heating power to melt the raw materials by induction heating. And keep the molten alloy for 10 minutes. The smelted alloy liquid is introduced from the outlet into the guide tube of the atomization chamber with a diameter of 7.0mm, and flows from the guide tube into the atomizing nozzle. Under the action of the helium gas flow at a pressure of 0.4Mpa, the alloy liquid Immediately after spraying from the atomizing nozzle, it is atomized into small droplets with a size of 1-1000 microns; the molten droplets are rapidly cooled and solidified into solid alloy powders of the same size during the falling process. Collect the powder and sieve through a 150 micron sieve to remove particles larger than 150 micron in size, then put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com