Method for producing optical sheet, optical sheet, and method for producing lenticular lens sheet

a manufacturing method and technology for lenticular lenses, applied in the field of manufacturing methods for lenticular lenses, can solve the problems of high thickness accuracy, difficult to produce thin sheets having such shapes, and inability to achieve such thickness distribution, etc., to achieve high thickness accuracy, low manufacturing cost, and high shaping/transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

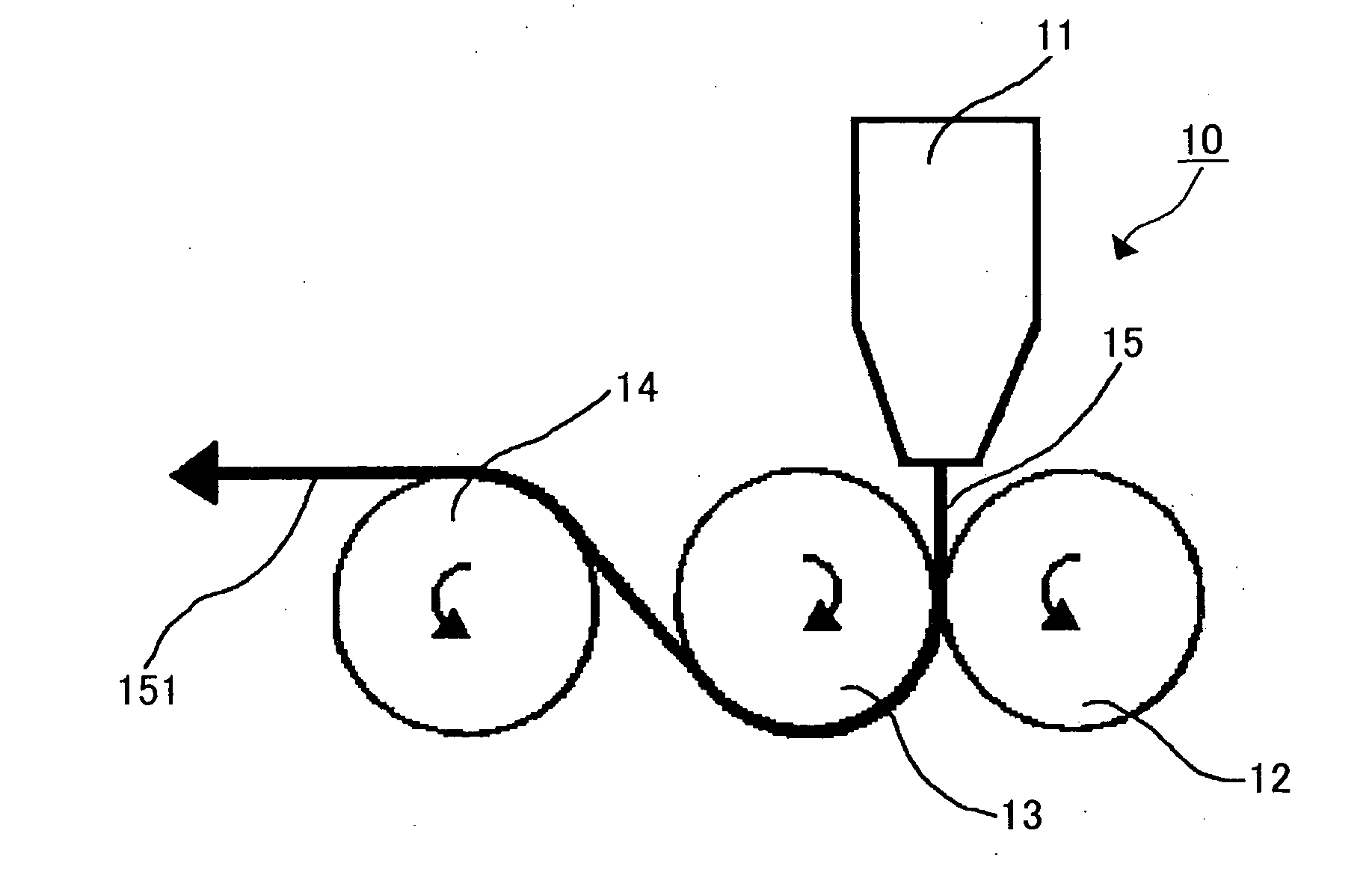

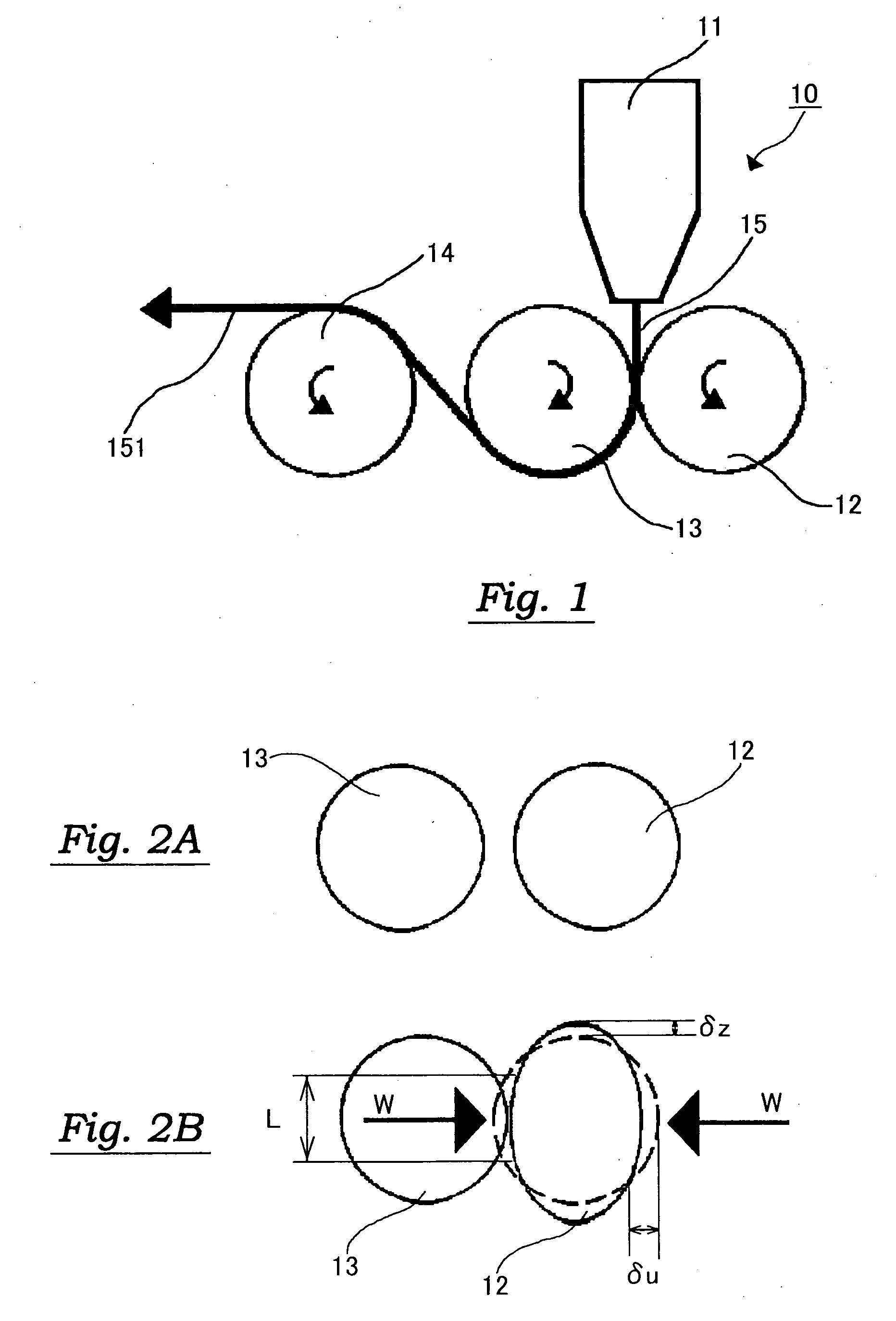

[0047] Referring now to FIG. 1, a manufacturing method for a lenticular lens sheet is described first. FIG. 1 is a sectional view showing a manufacturing apparatus for a lenticular lens sheet.

[0048] As shown in FIG. 1, a lenticular lens sheet manufacturing apparatus 10 includes a die 11, a first roll 12, a second roll 13, and a third roll 14.

[0049] The die 11 is a discharging member for discharging a resin 15 in a molten form by use of an extruder. A temperature of the resin 15 discharged from the die 11 preferably exceeds 230° C., more specifically, ranges from 250° C. to 290° C. With the resin temperature below 230° C., the melt viscosity of the resin is too high, leading to insufficient transferability of a shaping roll in some cases. In contrast, the resin temperature above 290° C. may accelerate thermal decomposition of the resin, resulting in a discolored and whitish resin.

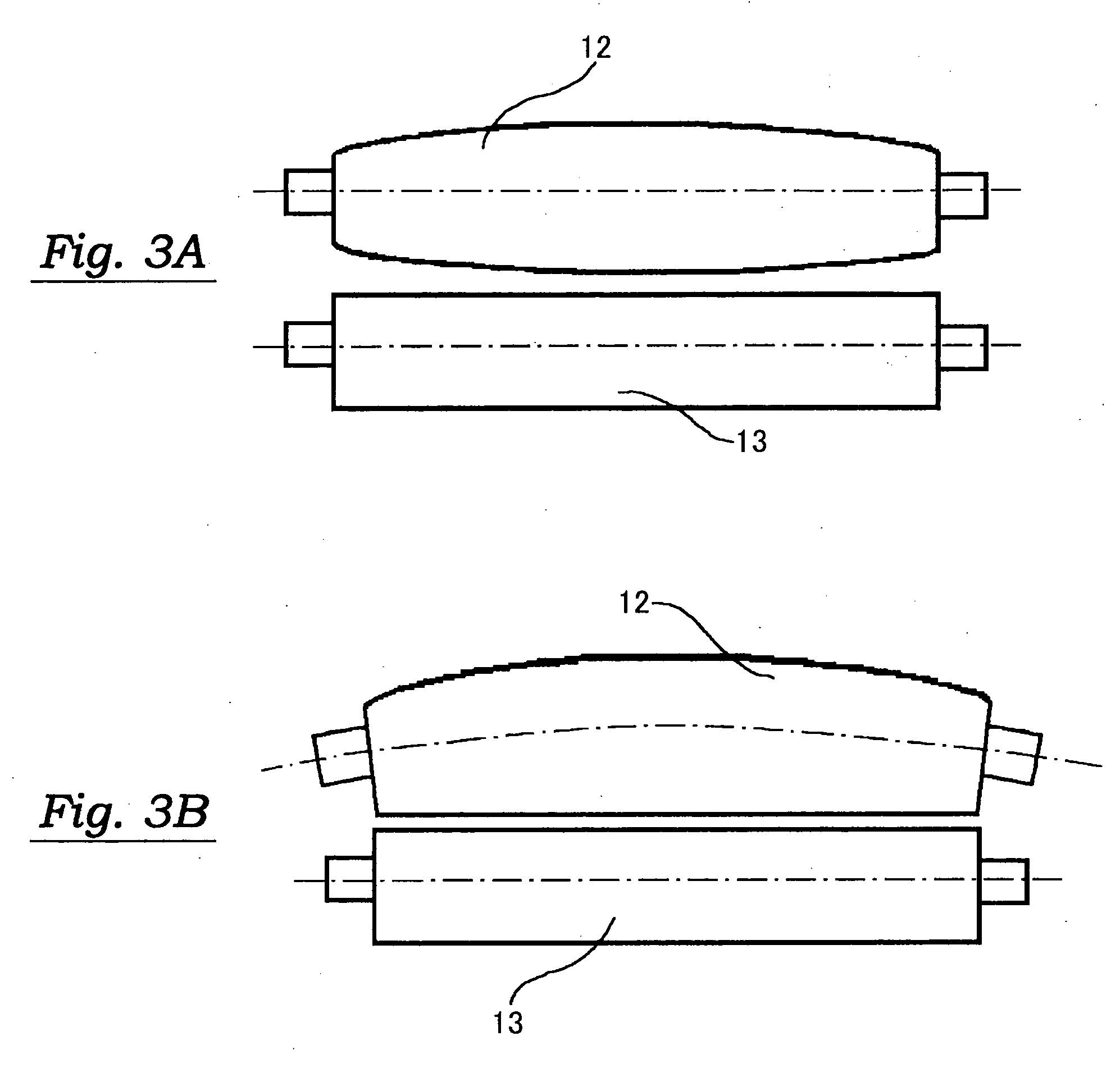

[0050] The first roll 12 is a touch roll for pressing the molten resin 15 against the second roll 13. ...

second embodiment

[0078] When an elastic metal roll exhibiting an elastic behavior is used as the first roll 12, any optical sheet embossed on both sides can be formed by engraving a given shaping pattern on the first roll 12 as well.

[0079] Besides, the degree of freedom in design of an optical pattern to be transferred can be enhanced by attaching a mold plate around the second roll 13 by means of an adhesive. In addition, the heat insulating property of the second roll 13 can be improved, and an optical function sheet can be formed with the high thickness accuracy, high transferability, and the like.

third embodiment

[0080] In a third embodiment, a description is given of an overall process of a manufacturing method for a lens sheet according to this embodiment with reference to FIG. 4. FIG. 4 is a schematic diagram showing a structural example of an entire lens sheet manufacturing apparatus.

[0081] In FIG. 4, reference numeral 10 denotes the lenticular lens sheet manufacturing apparatus; 11, the die; 110, an extruder; 12, the first roll; 13, the second roll; 14, the third roll; 140, a fourth roll; and 141 and 142, conveying rolls. As mentioned below, an elastic roll is used as the first roll 12.

[0082] The lenticular lens sheet manufacturing apparatus 10 mainly carries out the following extrusion-molding step. To elaborate, the die 11 first discharges the molten rein 15 by means of the extruder 110 to the air gap between the first roll 12 and the second roll 13. The discharged resin 15 is pressed against the second roll 13 by the first roll 12. At this time, the second roll 13 transfers the opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com