High-strength molybdenum nickel boron ternary boride material and manufacturing preparation method thereof

A ternary boride, high-strength technology, applied in the field of molybdenum nickel boron ternary boride materials, can solve the problems of heavy metal dust, human health damage, affecting the continuity of materials, easy to generate dust, etc. The effect of grain growth and segregation reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

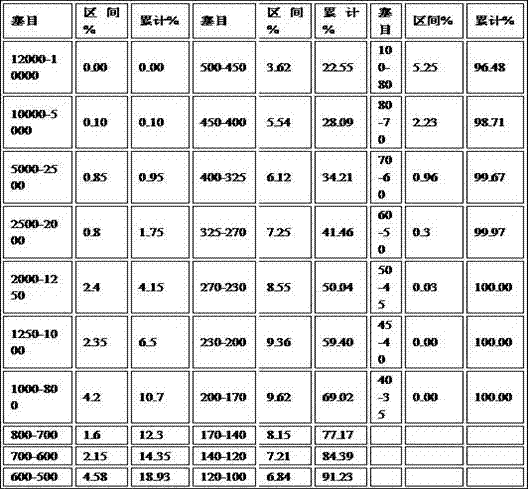

Image

Examples

Embodiment 1

[0022] Embodiment 1: A high-strength molybdenum-nickel-boron ternary boride material provided in this embodiment has the following element content percentages: boron (B) content is 3%, molybdenum (Mo) content is 40%; chromium (Cr) content is 8%, carbon (C) content is 0.2%, vanadium (V) content is 3%, niobium (Nb) content is 4%, tungsten (W) content is 0.5%, cerium The content of (Ce) is 0.3%, the content of manganese (Mn) is 3%, and the content of nickel (Ni) is 38%. Mo 2 NiB 2 The basic component of the base cermet is the hard phase Mo 2 NiB 2 with the binder phase Ni, Mo 2 NiB 2 Its crystal structure is orthorhombic system, which can be transformed into a tetragonal system after adding an appropriate amount of Cr and V. During the liquid phase sintering process, the crystal grains grow unevenly and produce sharp angles, resulting in the adhesion of the hard phase grains to the metal. The bonding of the junction phase is poor, which is not conducive to the improvement ...

Embodiment 2

[0039] Example 2: This example provides a high-strength molybdenum-nickel-boron ternary boride material and its preparation method, which are basically the same as Example 1, except that the elements and their mass percentages are as follows: boron (B) The content of molybdenum (Mo) is 5%, the content of chromium (Cr) is 1%, the content of carbon (C) is 0.5%, the content of vanadium (V) is 4%, niobium (Nb) The content of tungsten (W) is 1%, the content of cerium (Ce) is 1%, the content of manganese (Mn) is 1%, and the content of nickel (Ni) is 27.5%.

Embodiment 3

[0040] Example 3: A high-strength molybdenum-nickel-boron ternary boride material and its preparation method provided in this example are basically the same as in Example 1, except that the elements and their mass percentages are as follows: boron (B) The content of molybdenum (Mo) is 6%, the content of chromium (Cr) is 6%, the content of carbon (C) is 0.8%, the content of vanadium (V) is 0.5%, niobium (Nb) The content of tungsten (W) is 3%, the content of cerium (Ce) is 0.1%, the content of manganese (Mn) is 2%, and the content of nickel (Ni) is 41.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com