Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1673results about "Evaporation by spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

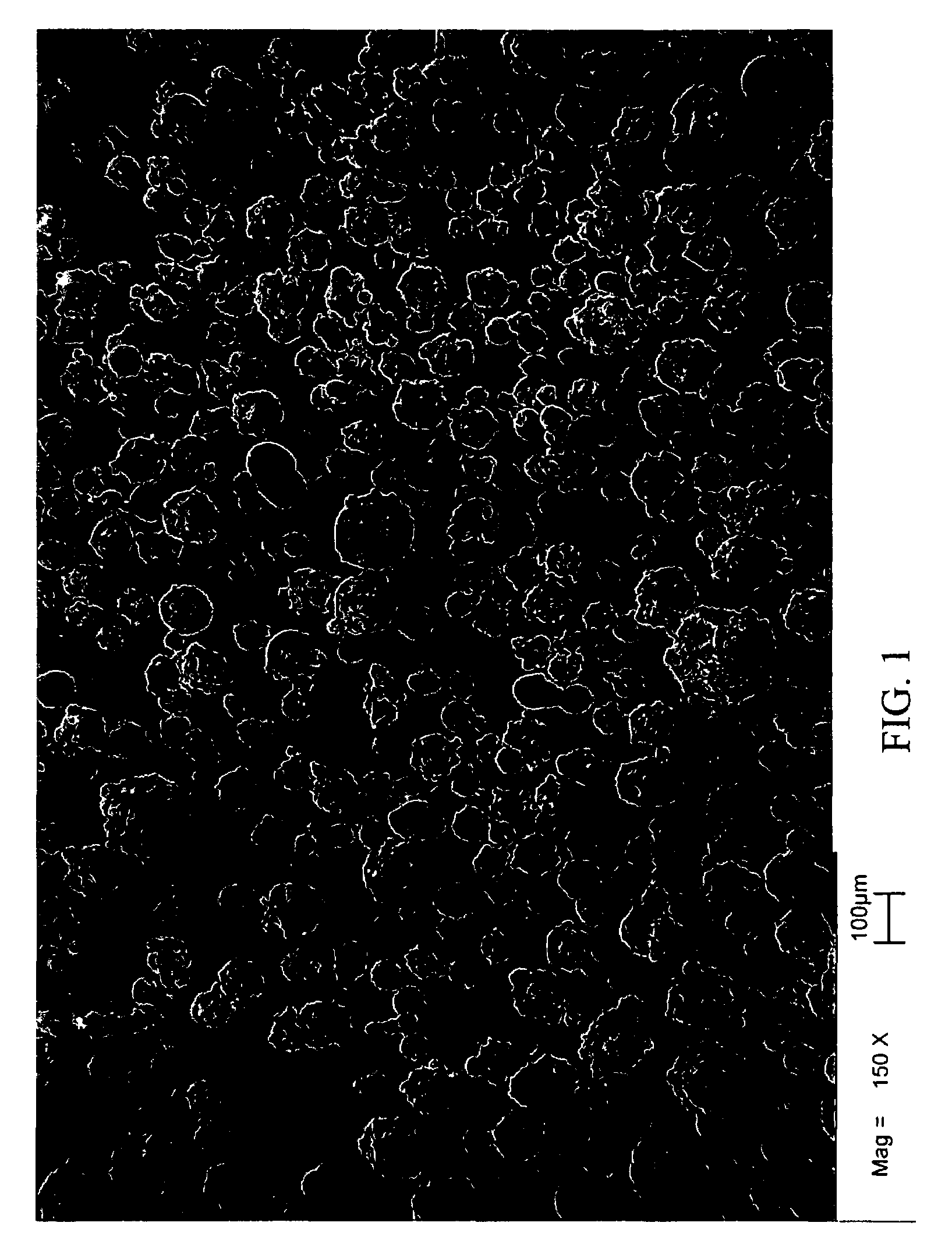

Methods for making pharmaceutical formulations comprising microparticles with improved dispersibility, suspendability or wettability

InactiveUS20050079138A1Good dispersibilityImproved suspendabilityPowder deliveryGranulation by liquid drop formationPowder mixtureMicroparticle

Methods are provided for making a dry powder blend pharmaceutical formulation, comprising the steps of: (a) providing microparticles which comprise a pharmaceutical agent; (b) blending the microparticles with at least one excipient in the form of particles to form a powder blend; and (c) jet milling the powder blend to form a dry powder blend pharmaceutical formulation having improved dispersibility, suspendability, or wettability as compared to the microparticles of step (a) or the powder blend of step (b). The method can further include dispersing the dry powder blend pharmaceutical formulation in a liquid pharmaceutically acceptable vehicle to make an formulation suitable for injection. Alternatively, the method can further include processing the dry powder blend pharmaceutical formulation into a solid oral dosage form. In one embodiment, the microparticles of step (a) are formed by a solvent precipitation or crystallization process.

Owner:ACUSPHERE INC

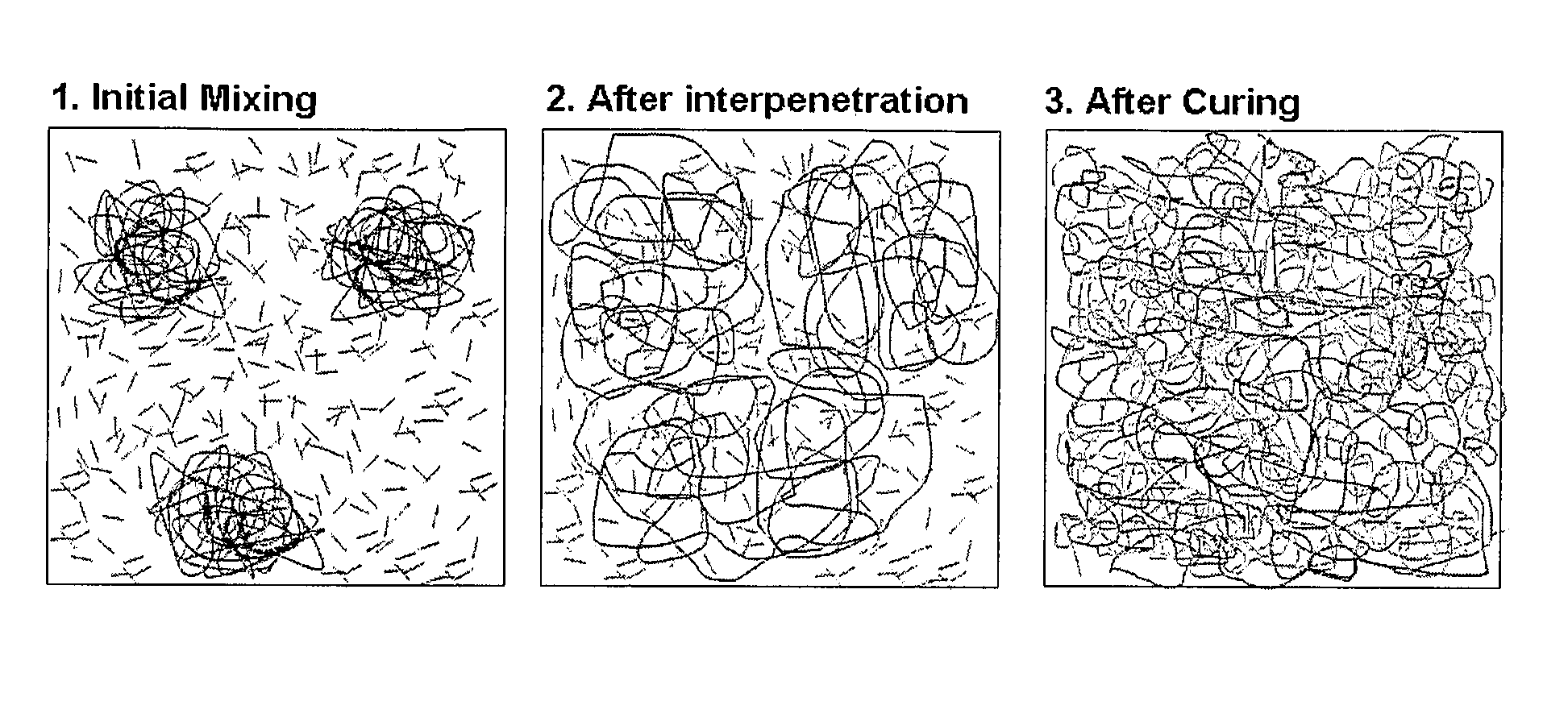

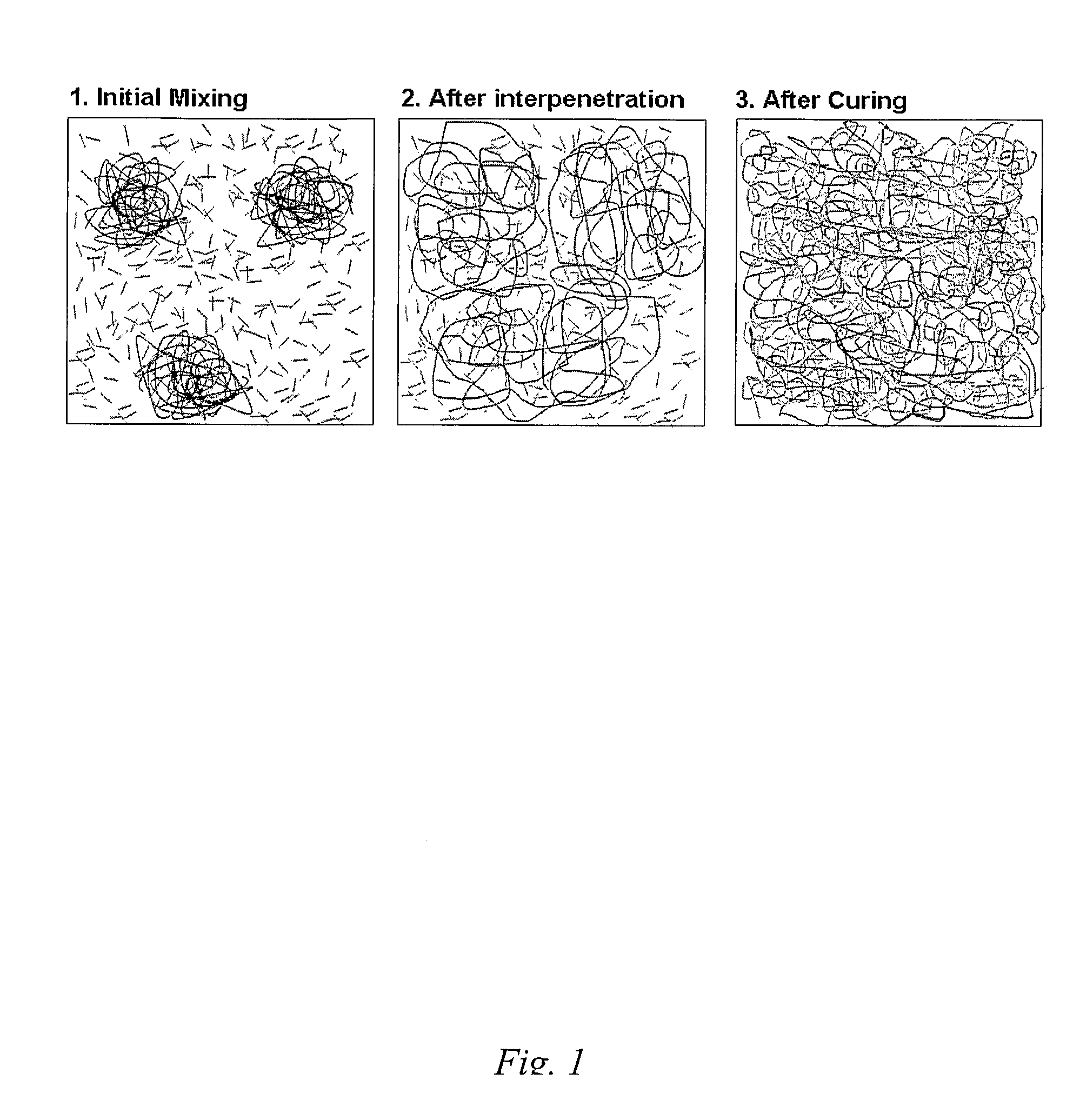

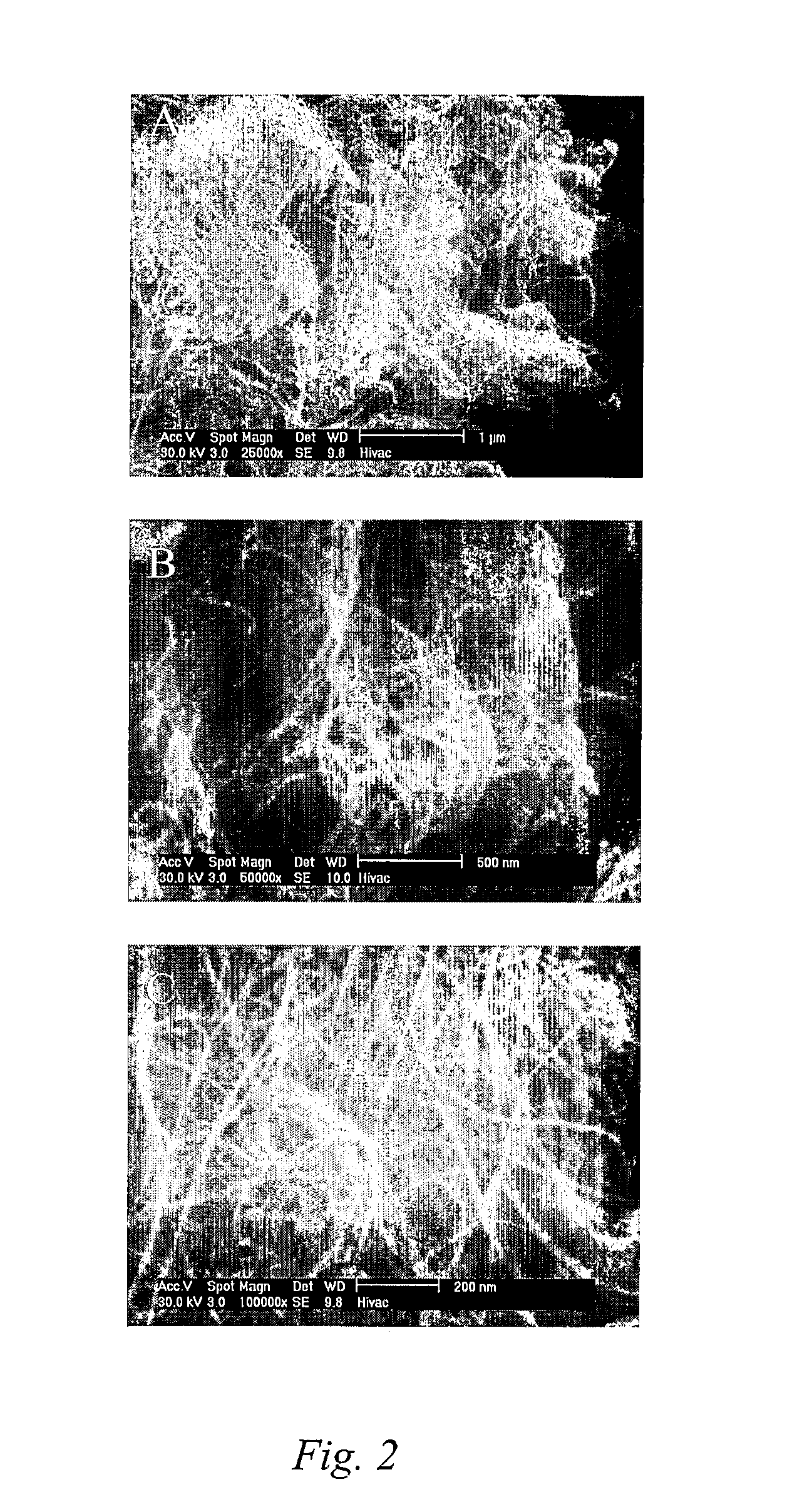

Polymer / Carbon-Nanotube Interpenetrating Networks and Process for Making Same

ActiveUS20080048364A1Improve propertiesHigh strengthPigmenting treatmentMaterial nanotechnologyCross-linkConductive polymer composite

The present invention is directed to new methods for combining, processing, and modifying existing materials, resulting in novel products with enhanced mechanical, electrical and electronic properties. The present invention provides for polymer / carbon nanotube composites with increased strength and toughness; beneficial for lighter and / or stronger structural components for terrestrial and aerospace applications, electrically and thermally conductive polymer composites, and electrostatic dissipative materials. Such composites rely on a molecular interpenetration between entangled single-wall carbon nanotubes (SWNTs) and cross-linked polymers to a degree not possible with previous processes.

Owner:RICE UNIV

Dry powder which retains savor and flavor and method for producing the same

InactiveUS20050031769A1Avoid and reduce occurrenceLess occurrenceFruit and vegetables preservationFood shapingSolubilityProduct gas

In order to provide a spray dry method capable of producing a dry powder retaining the savor and flavor of a raw material and having solubility without any thermal deterioration, at a mass scale, a method for producing a dry powder keeping savor and flavor from a hydrous liquid material containing a savory and flavorful component and, preferably, a hygroscopic component by spray drying is disclosed, the method including spray drying the hydrous liquid material at the microfine liquid droplet state in gas atmosphere at the outlet temperature of a spray dryer at 20 to 90° C. and the outlet relative humidity of 1% RH to 40% RH, to prepare a dry powder of a mean particle size of 0.1 μm to 15 μm.

Owner:AJINOMOTO CO INC

Sulfoalkyl ether cyclodextrin compositions and methods of preparation thereof

A particulate SAE-CD composition is provided. The SAE-CD composition has an advantageous combination of physical properties not found in known solid forms of SAECD. In particular, the SAE-CD composition possesses an advantageous physicochemical and morphological property profile such that it can be tailored to particular uses. The SAE-CD composition of the invention has improved flow and dissolution performance as compared to known compositions of SAE-CD.

Owner:CYDEX PHARMACEUTICALS INC

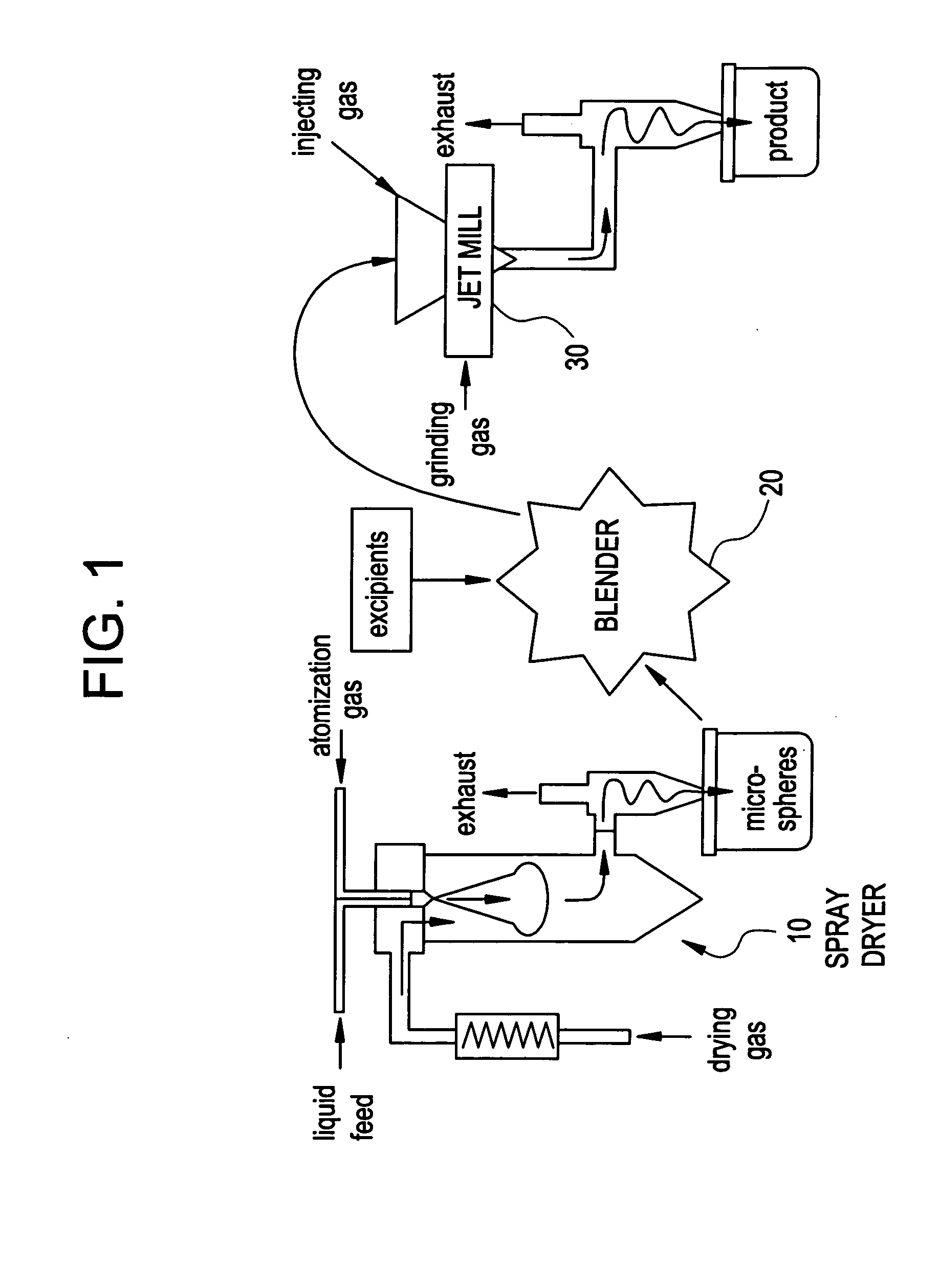

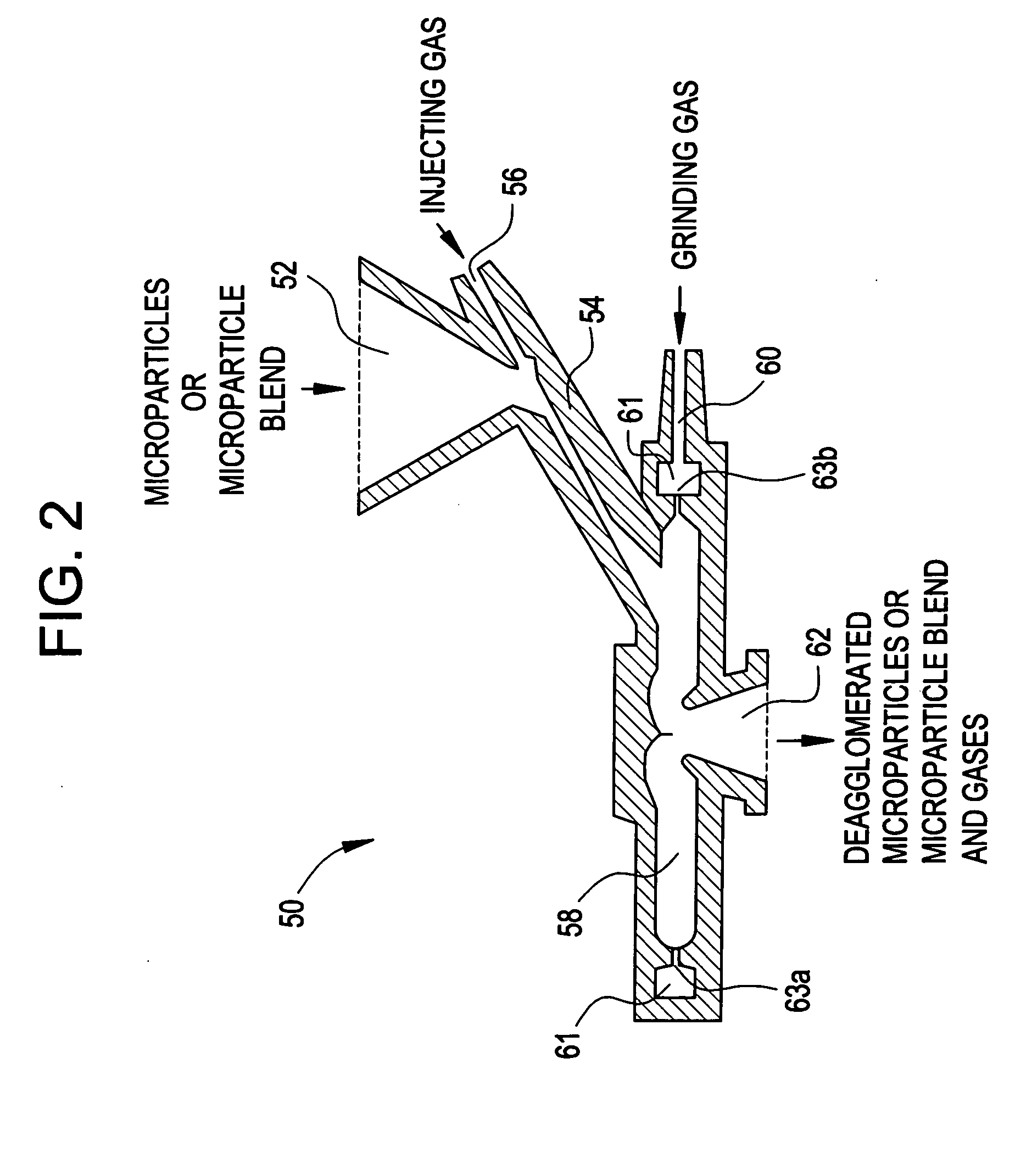

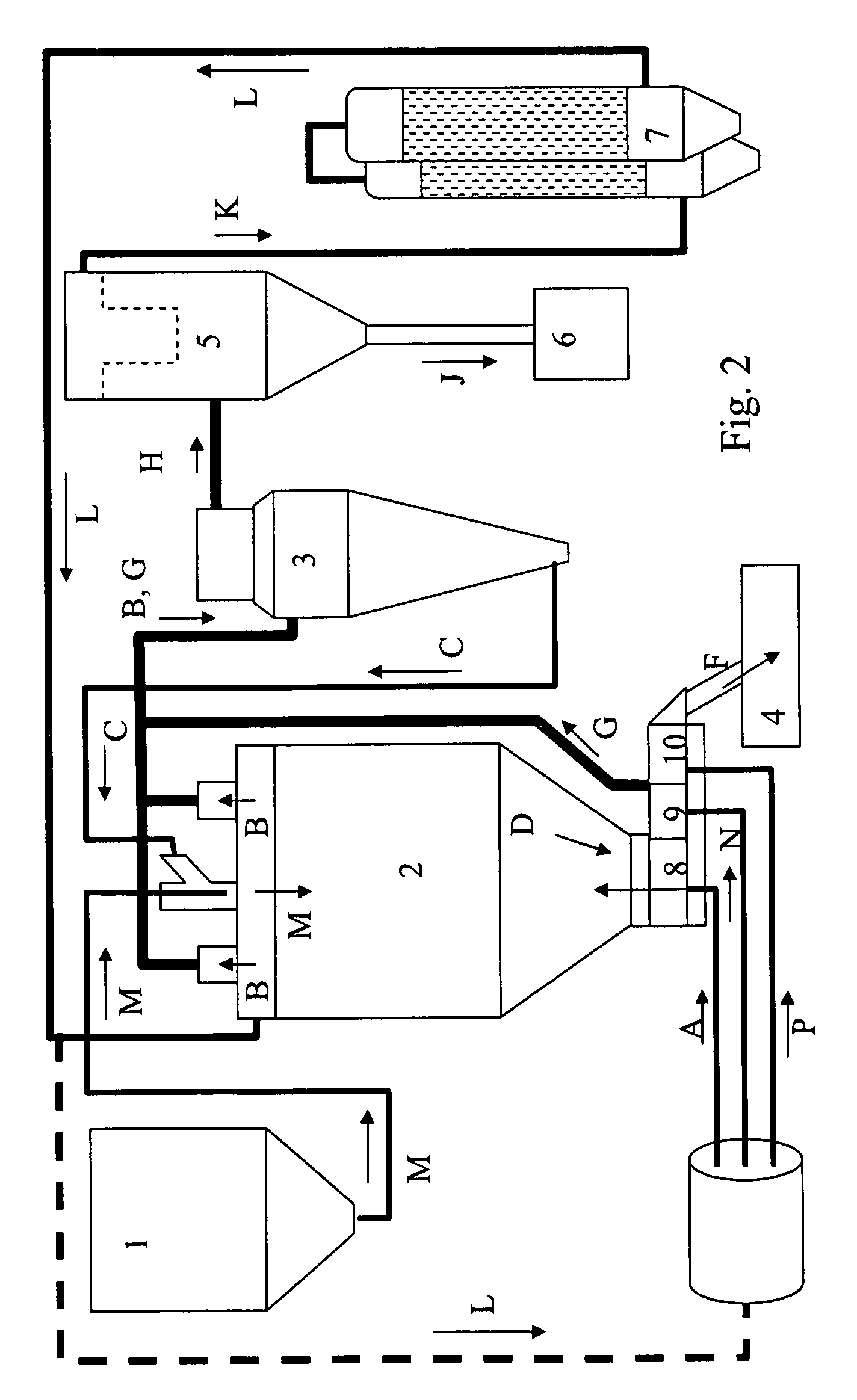

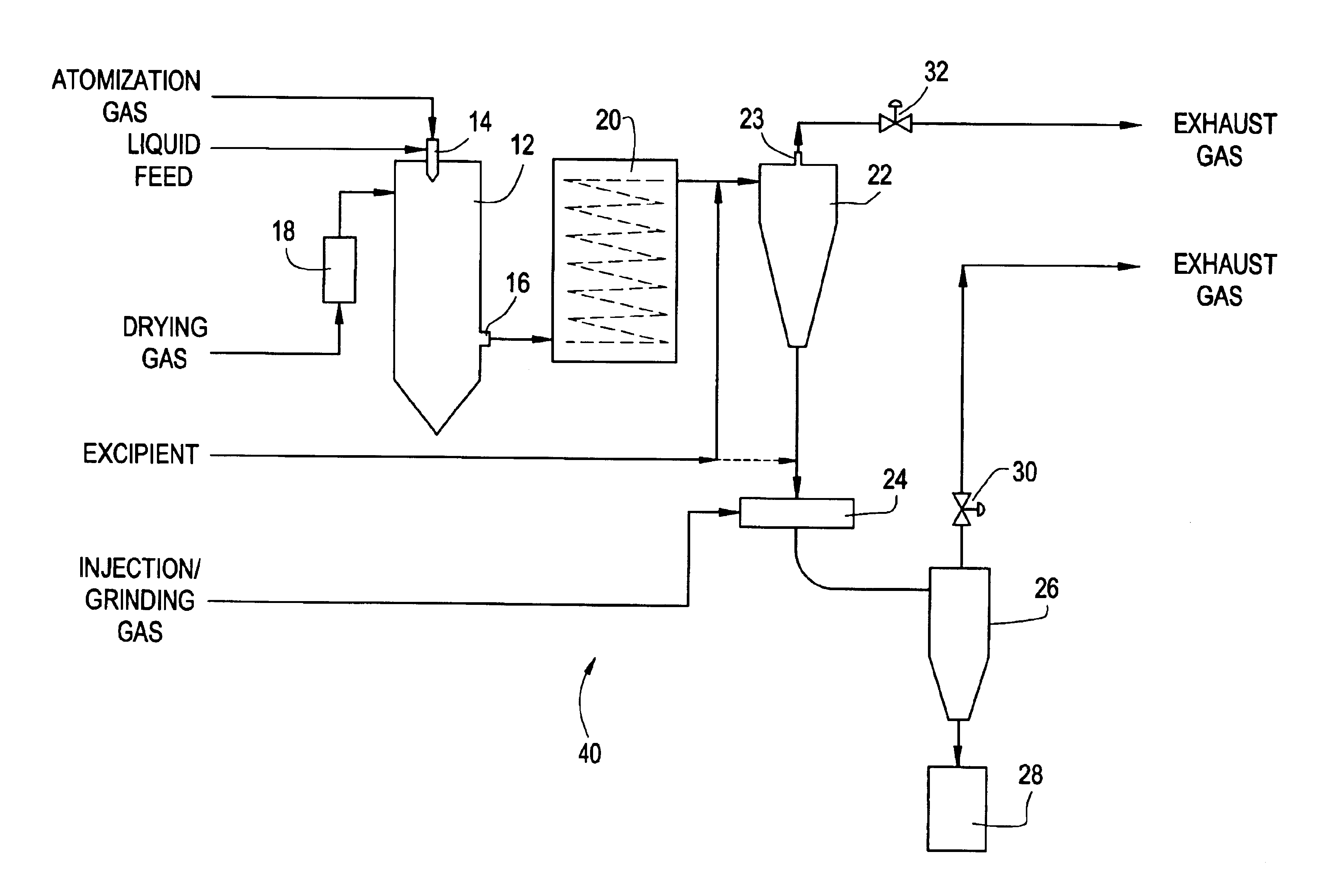

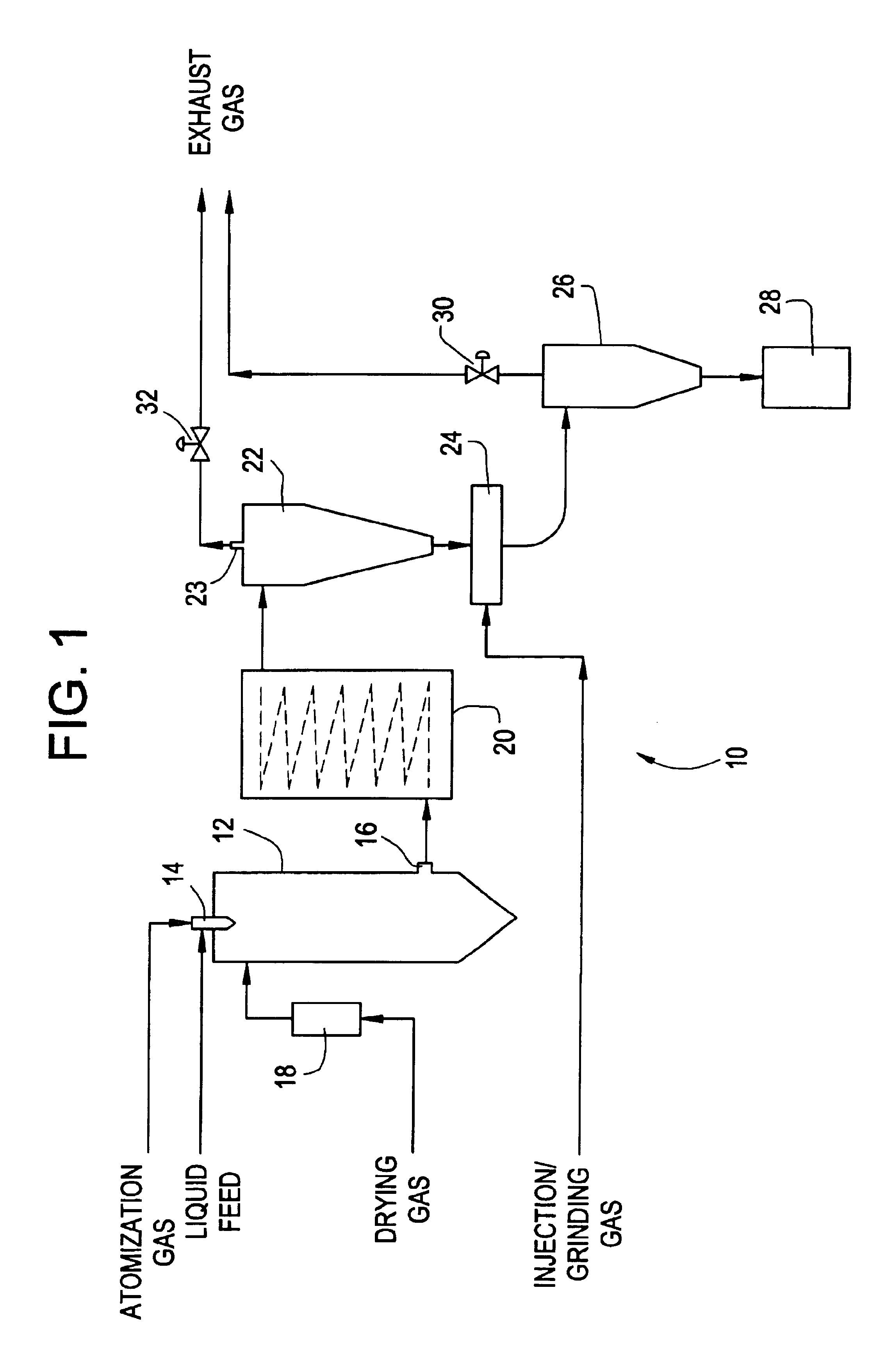

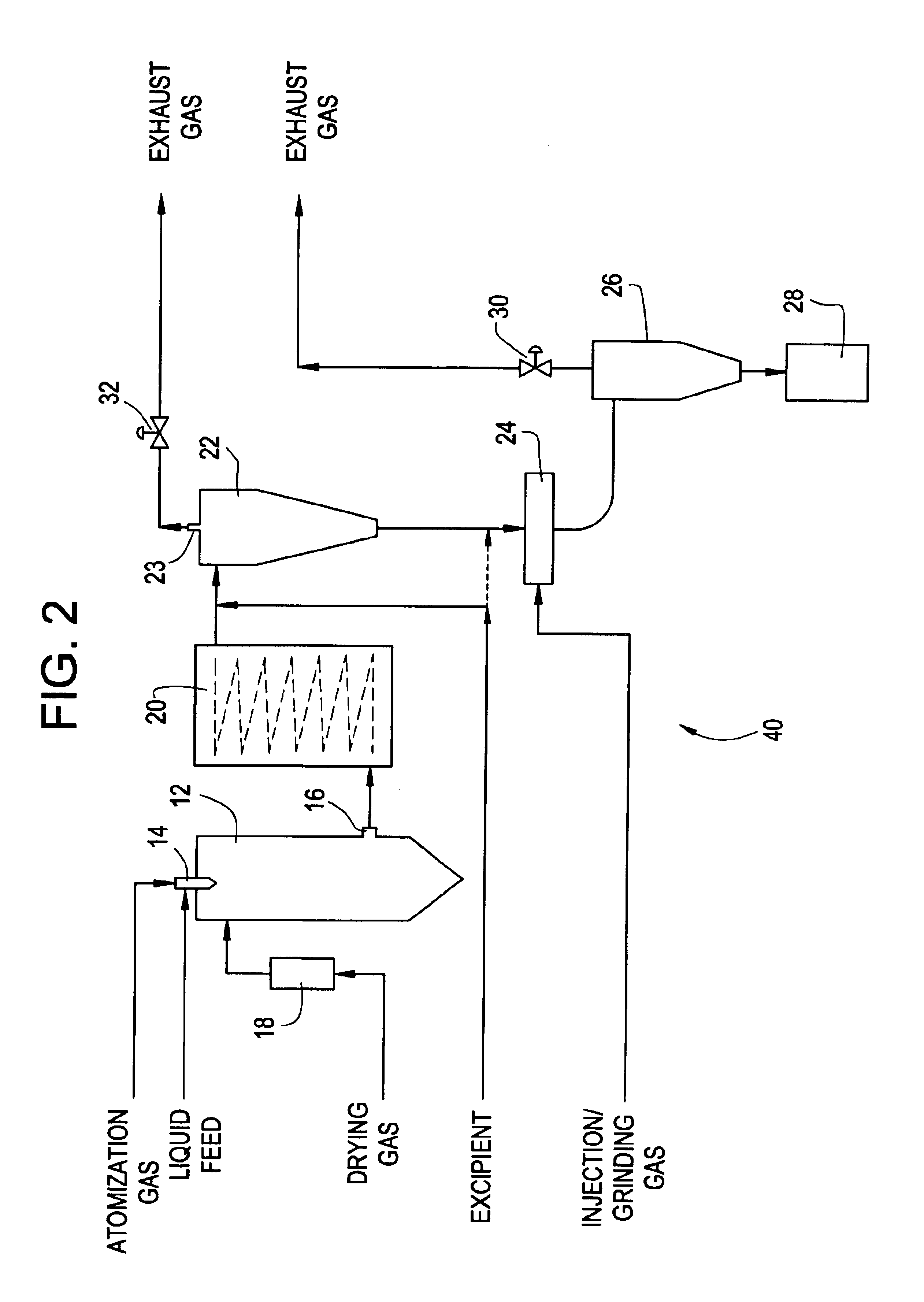

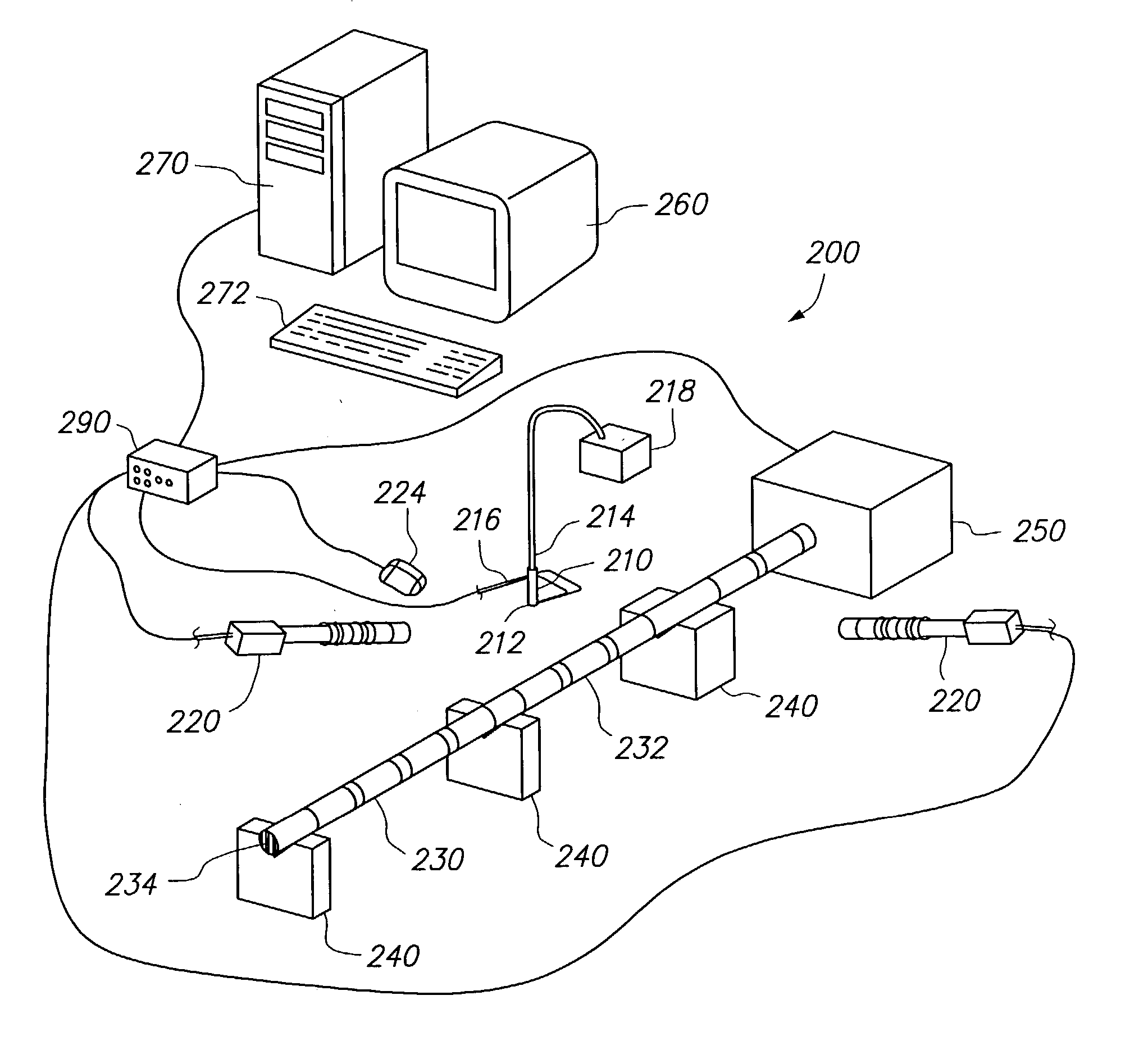

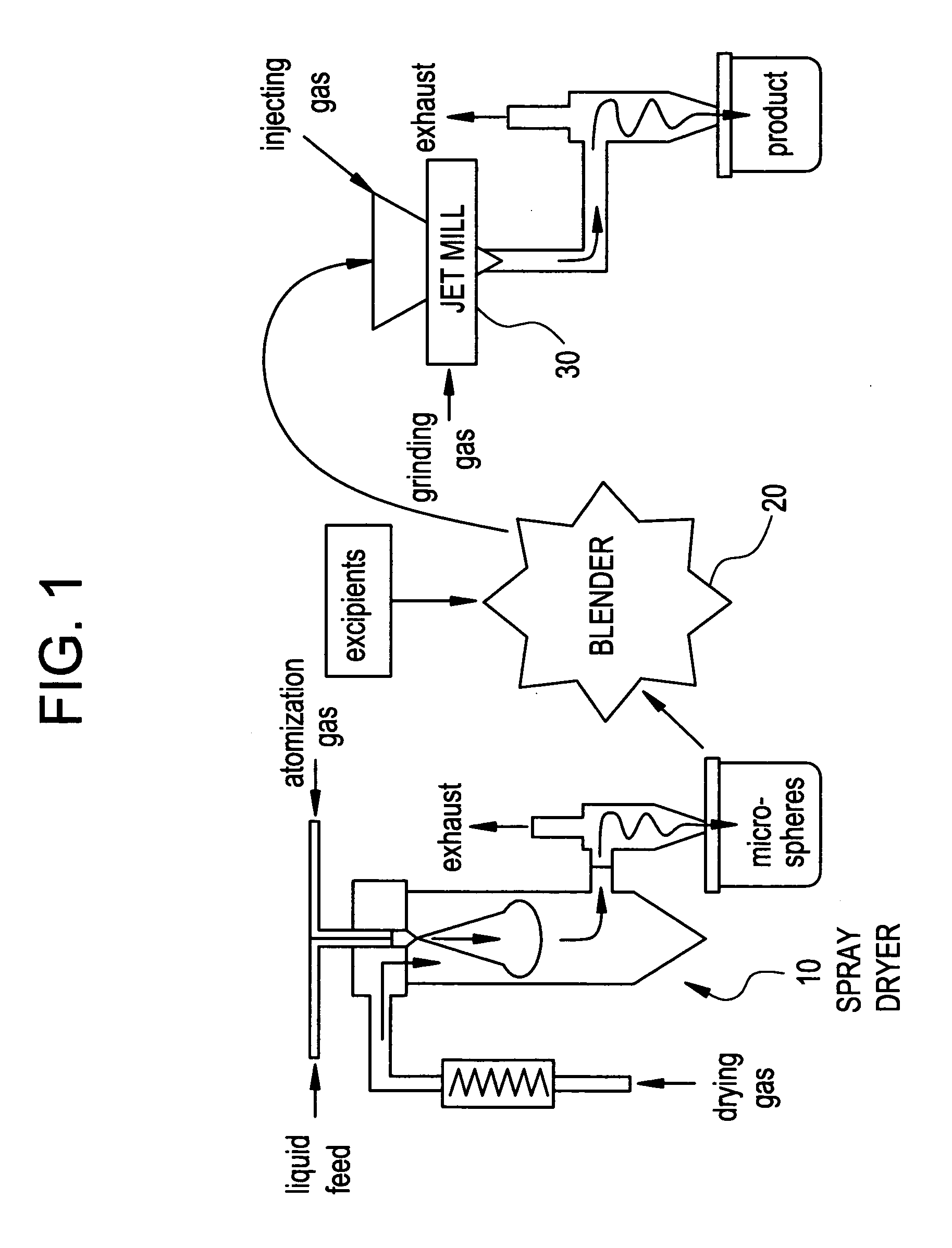

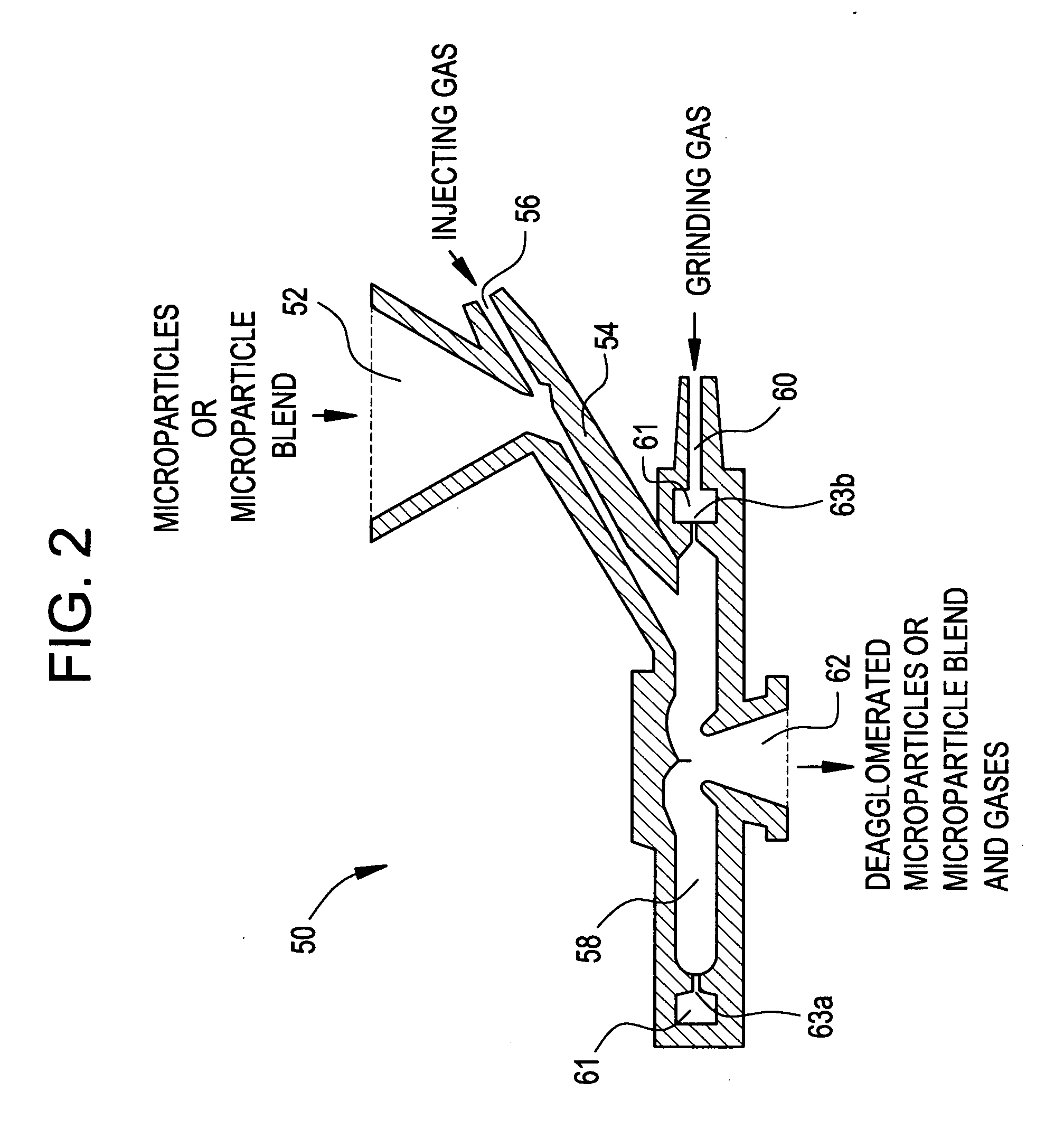

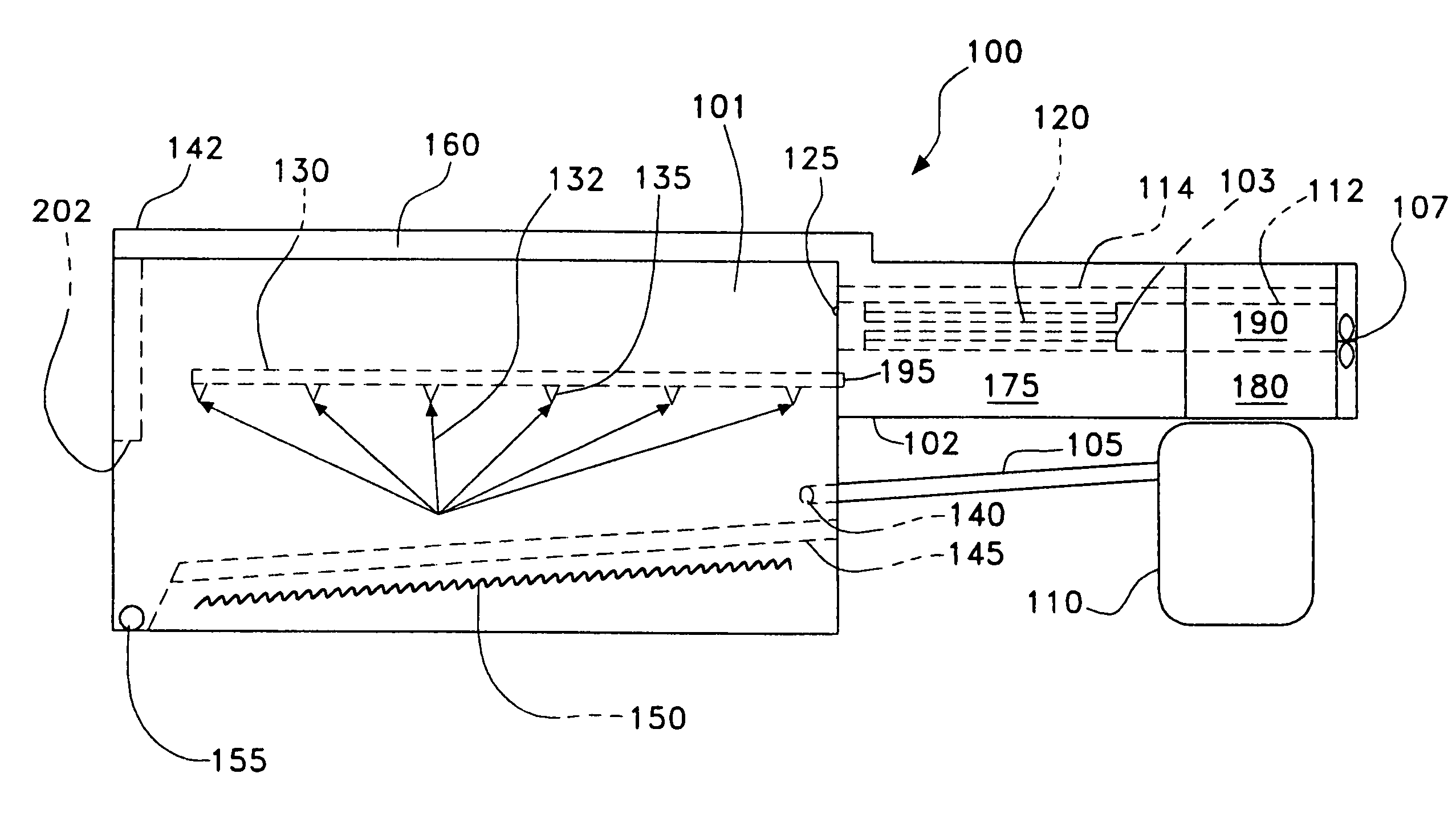

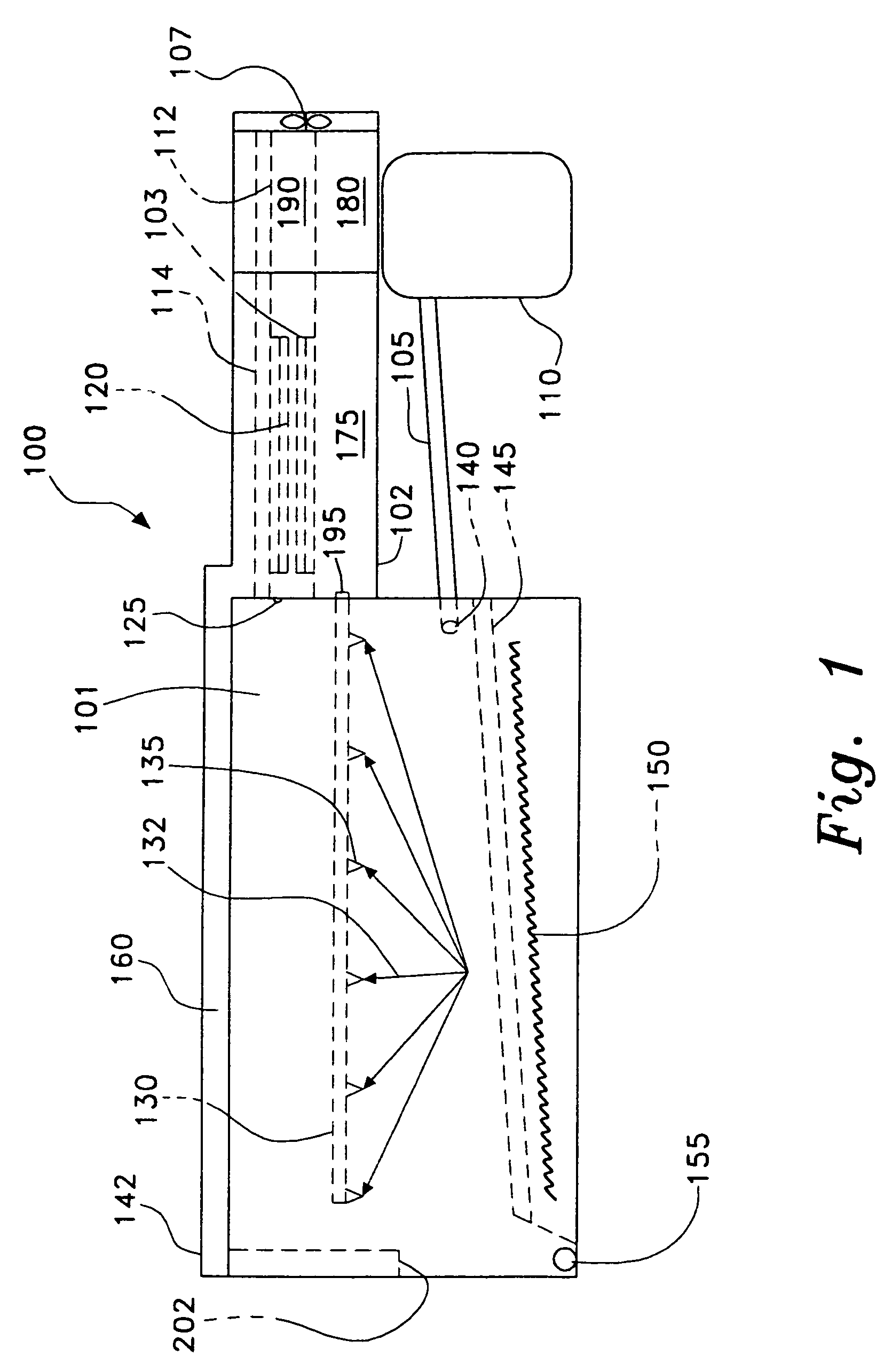

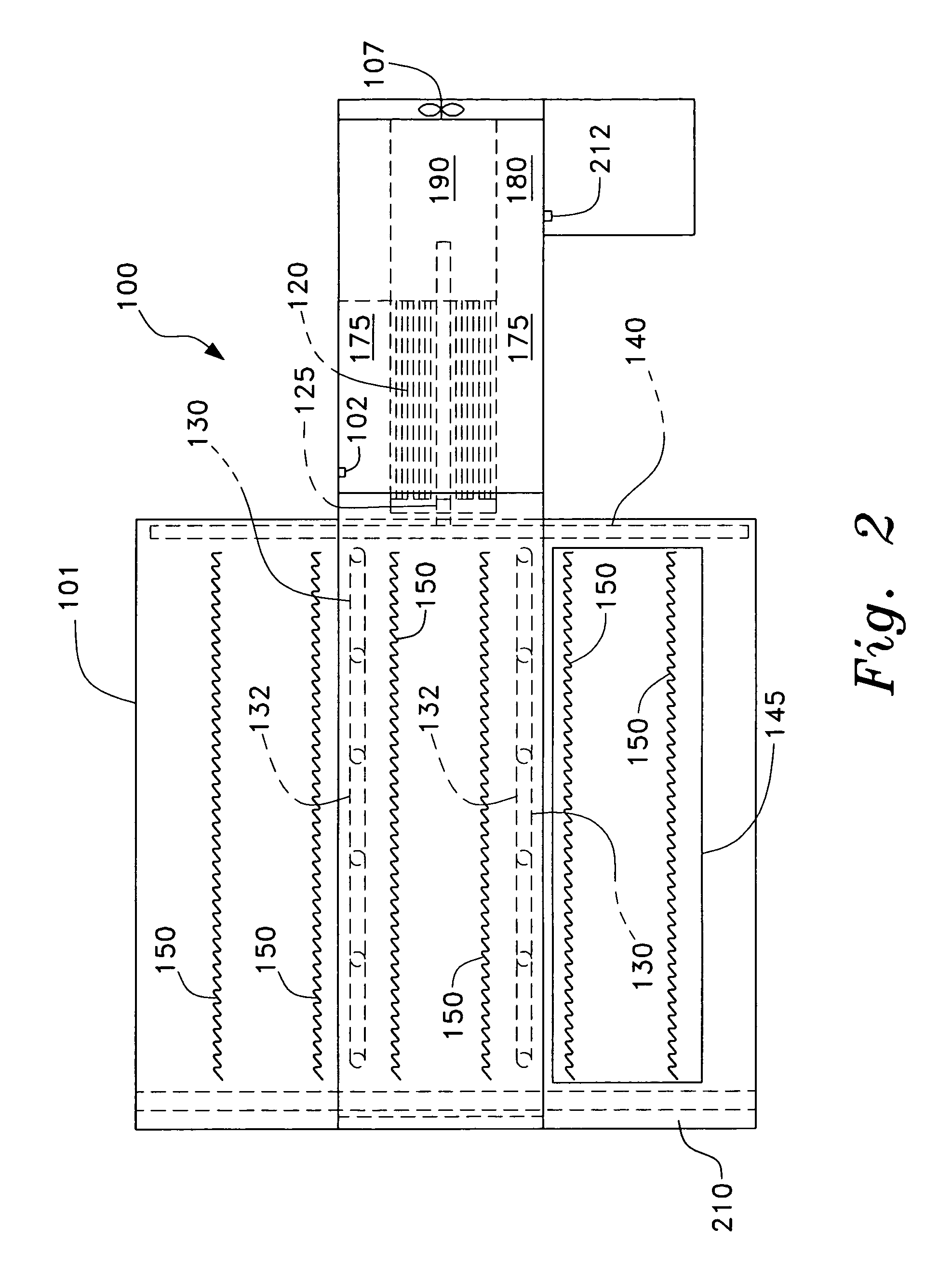

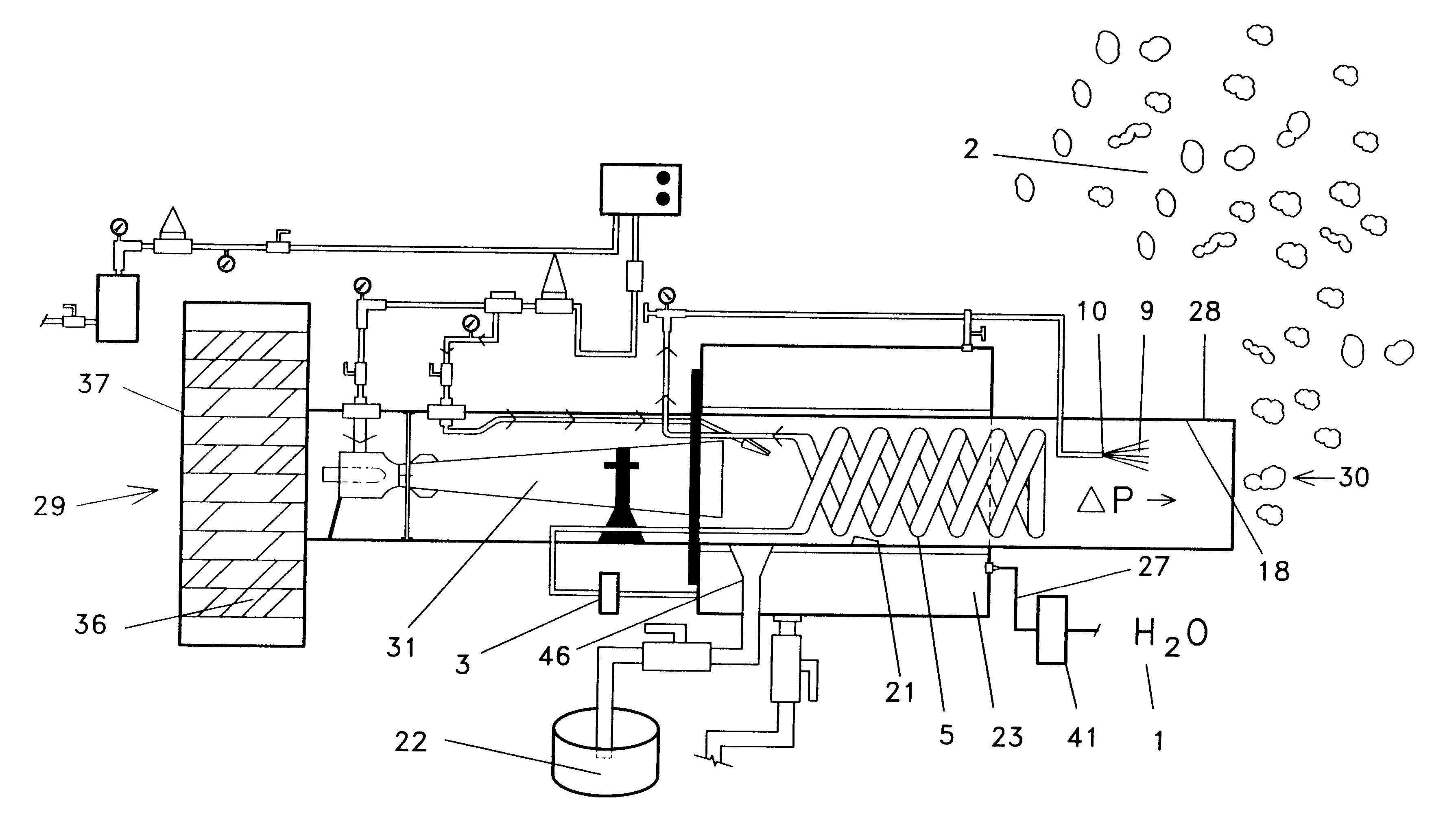

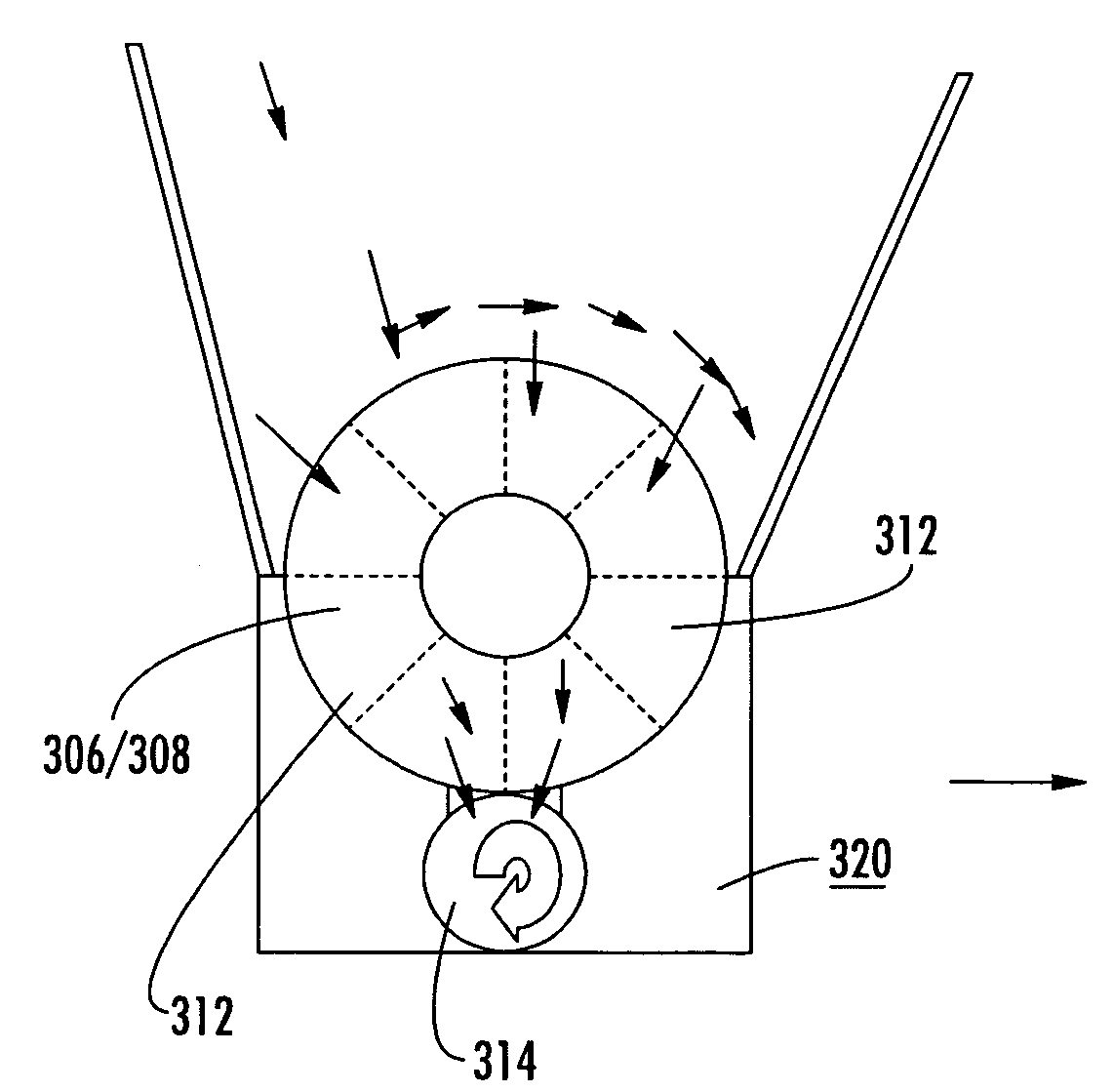

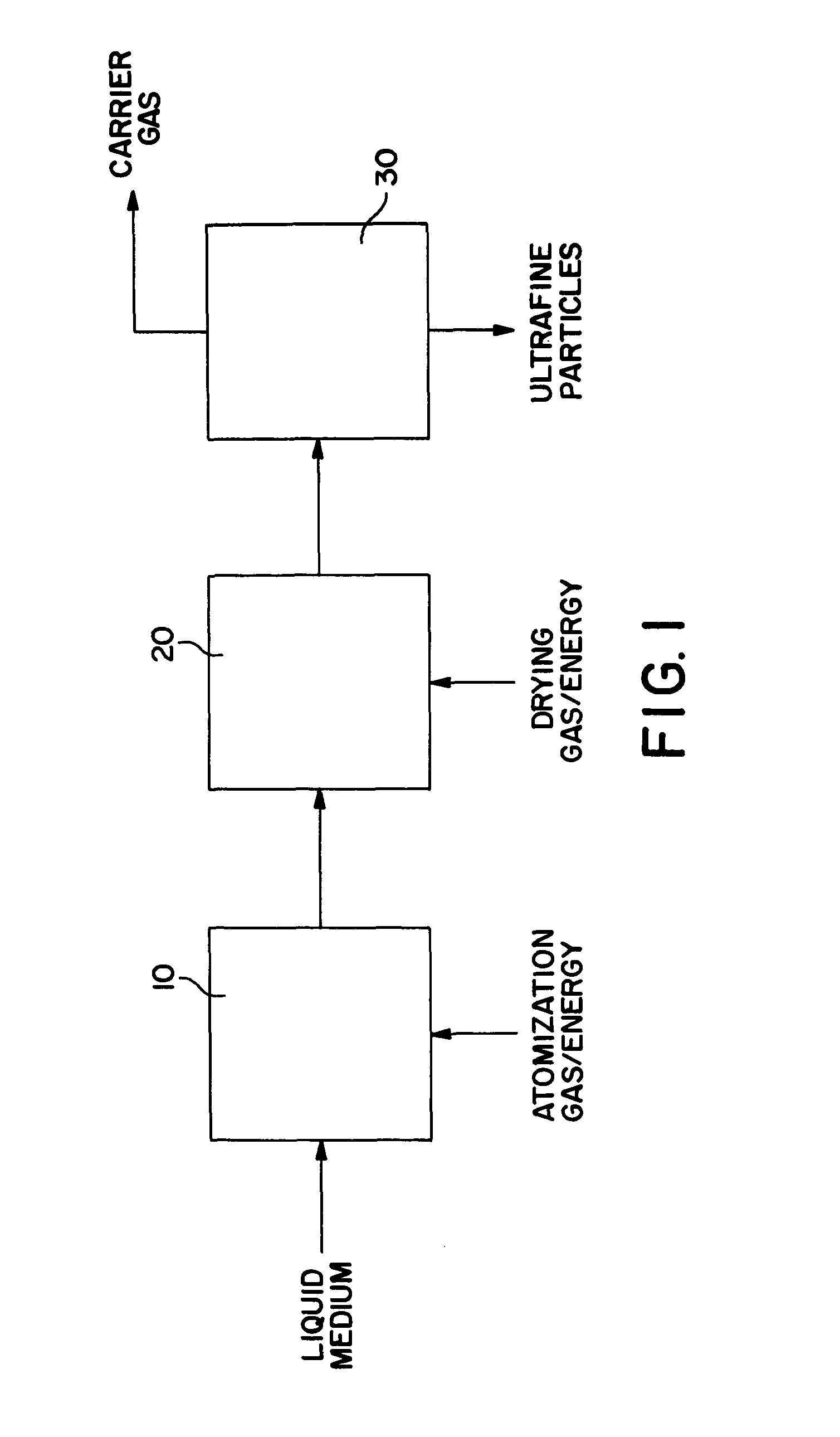

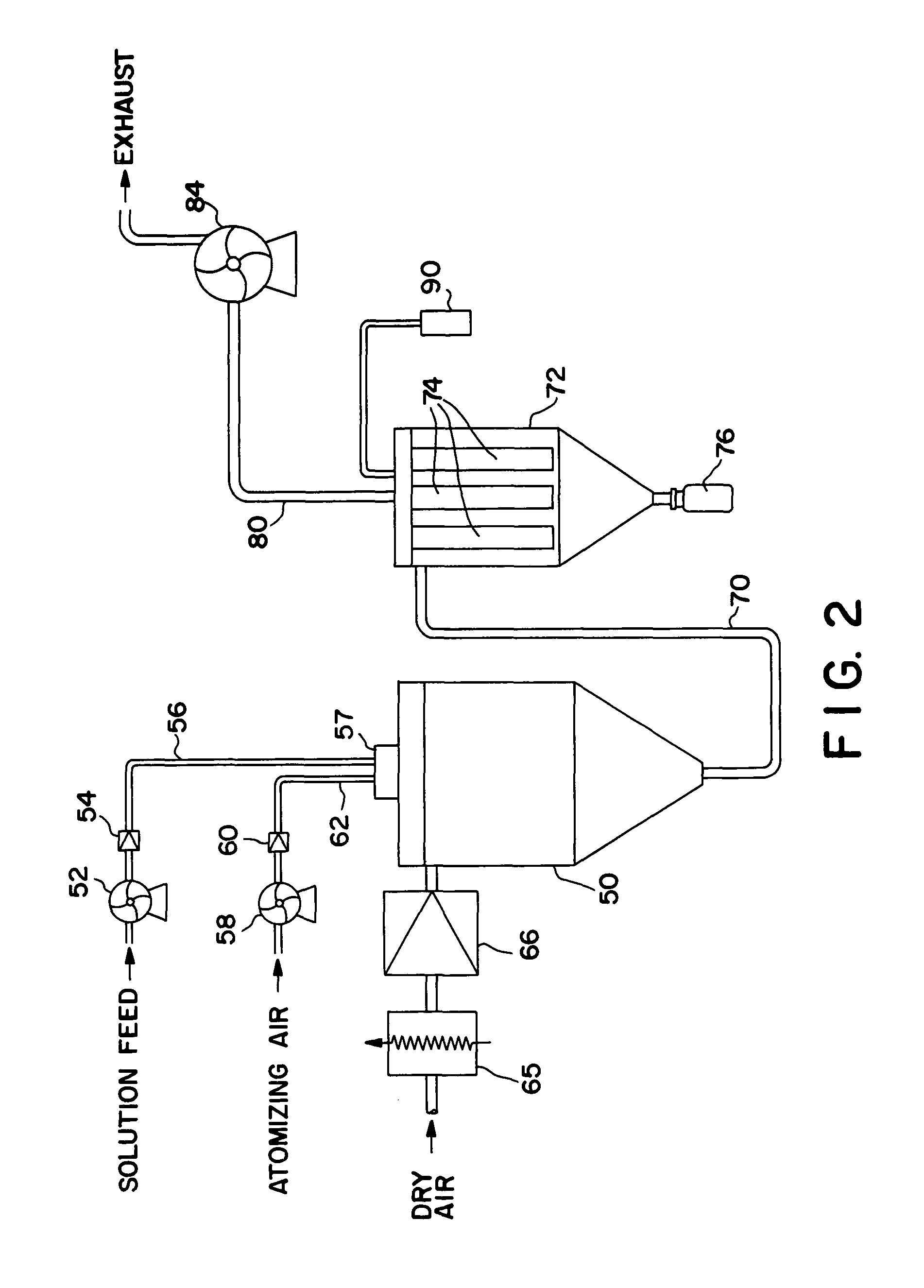

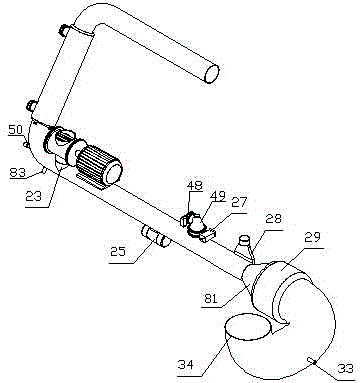

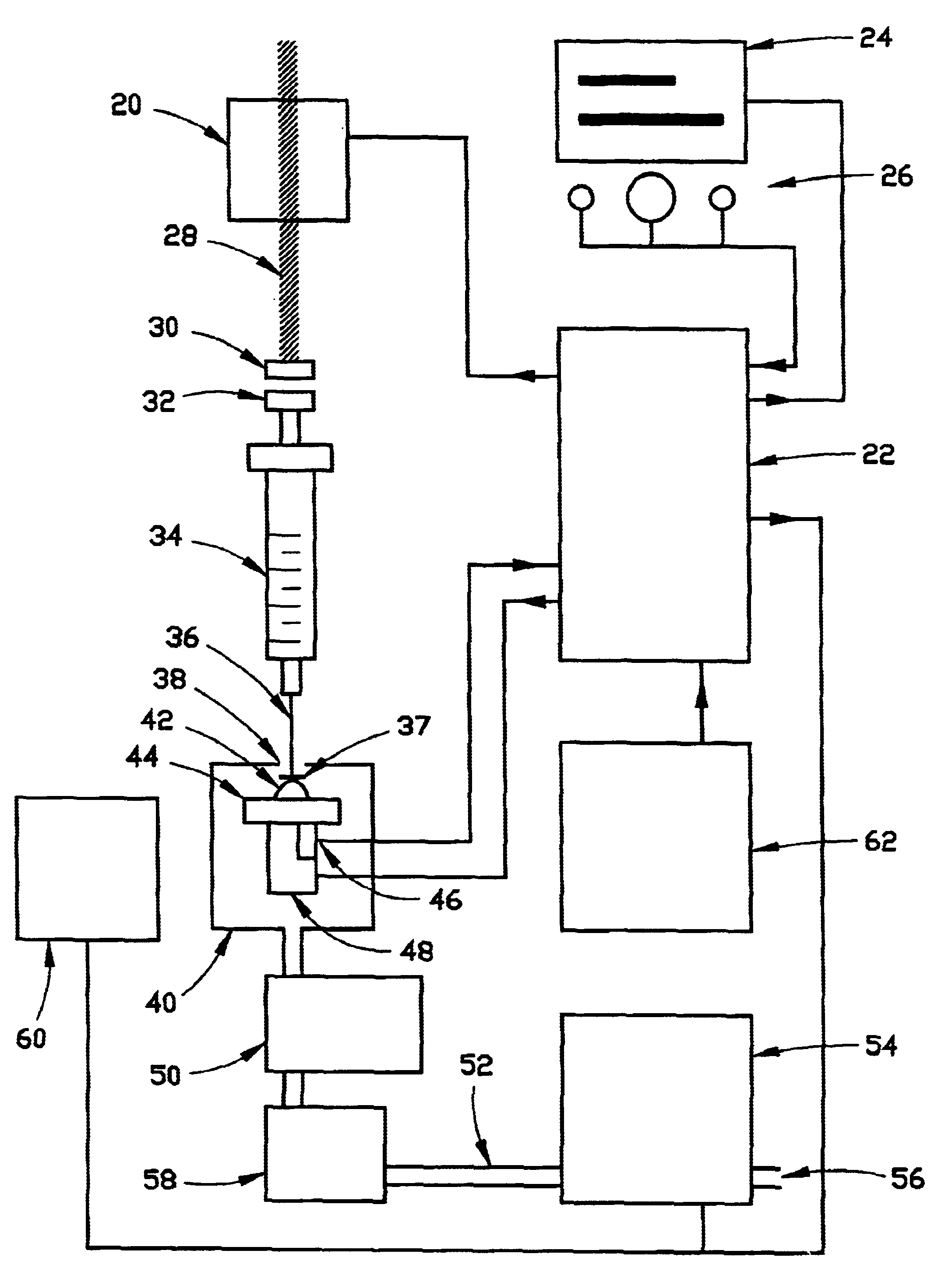

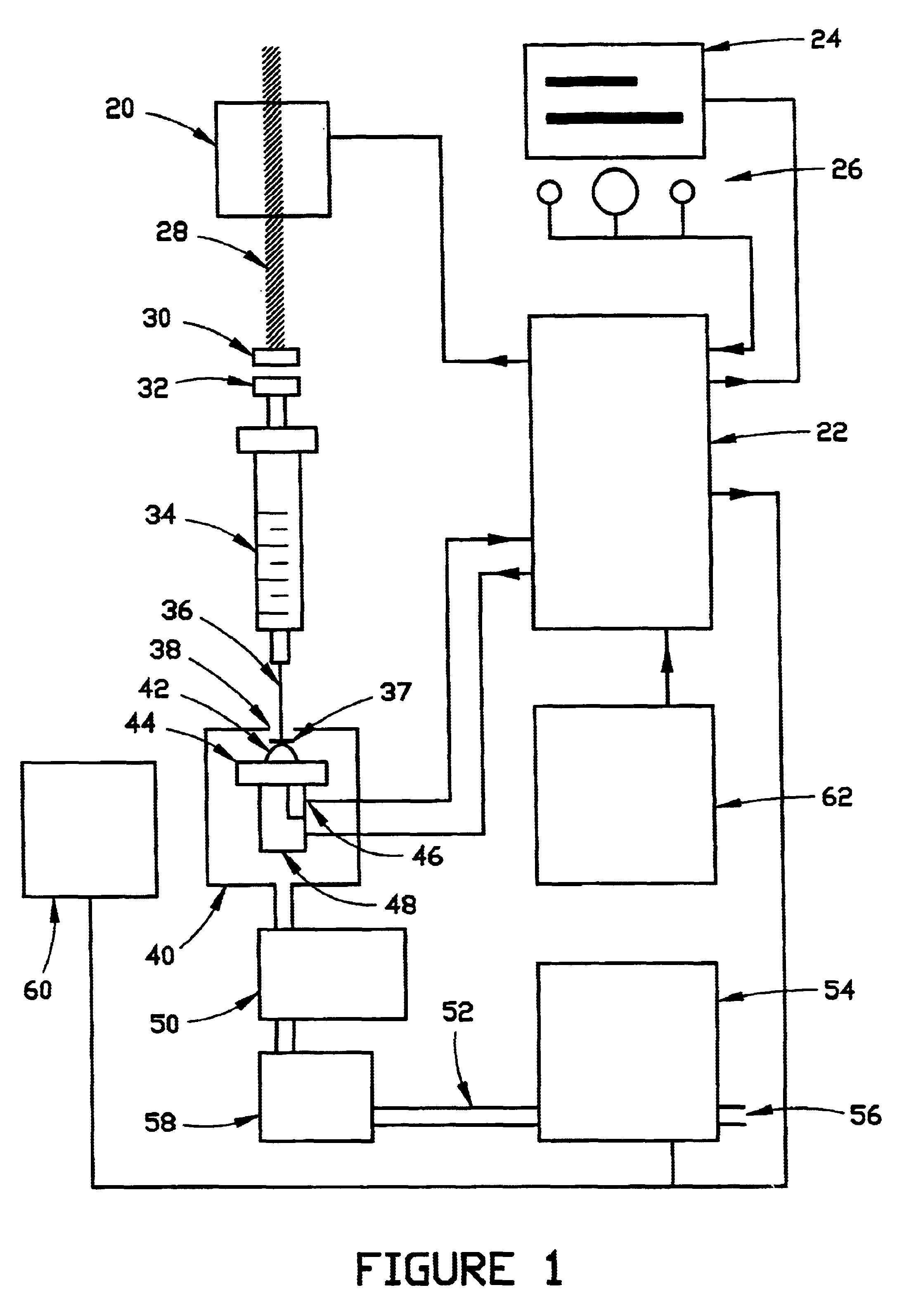

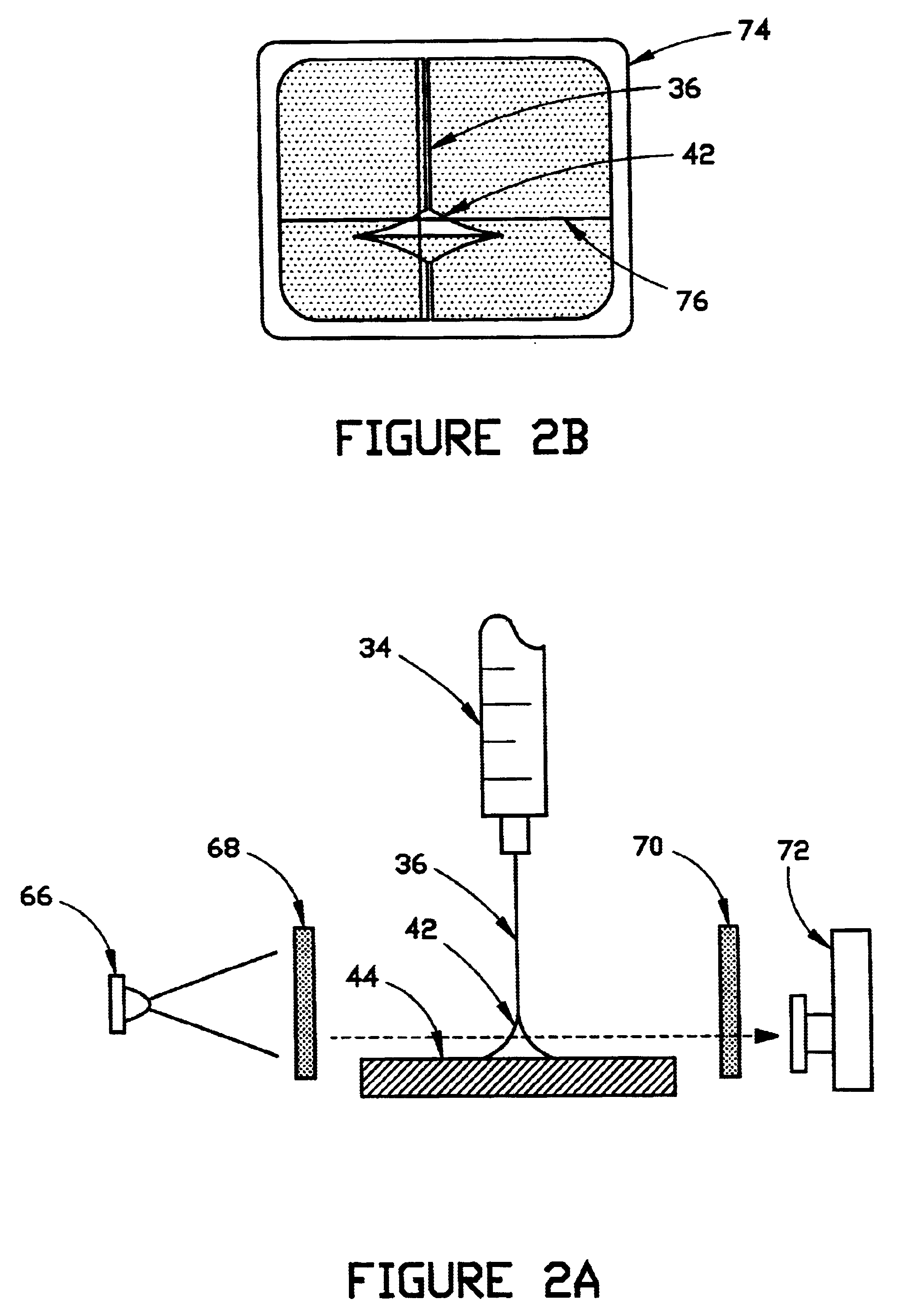

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6918991B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

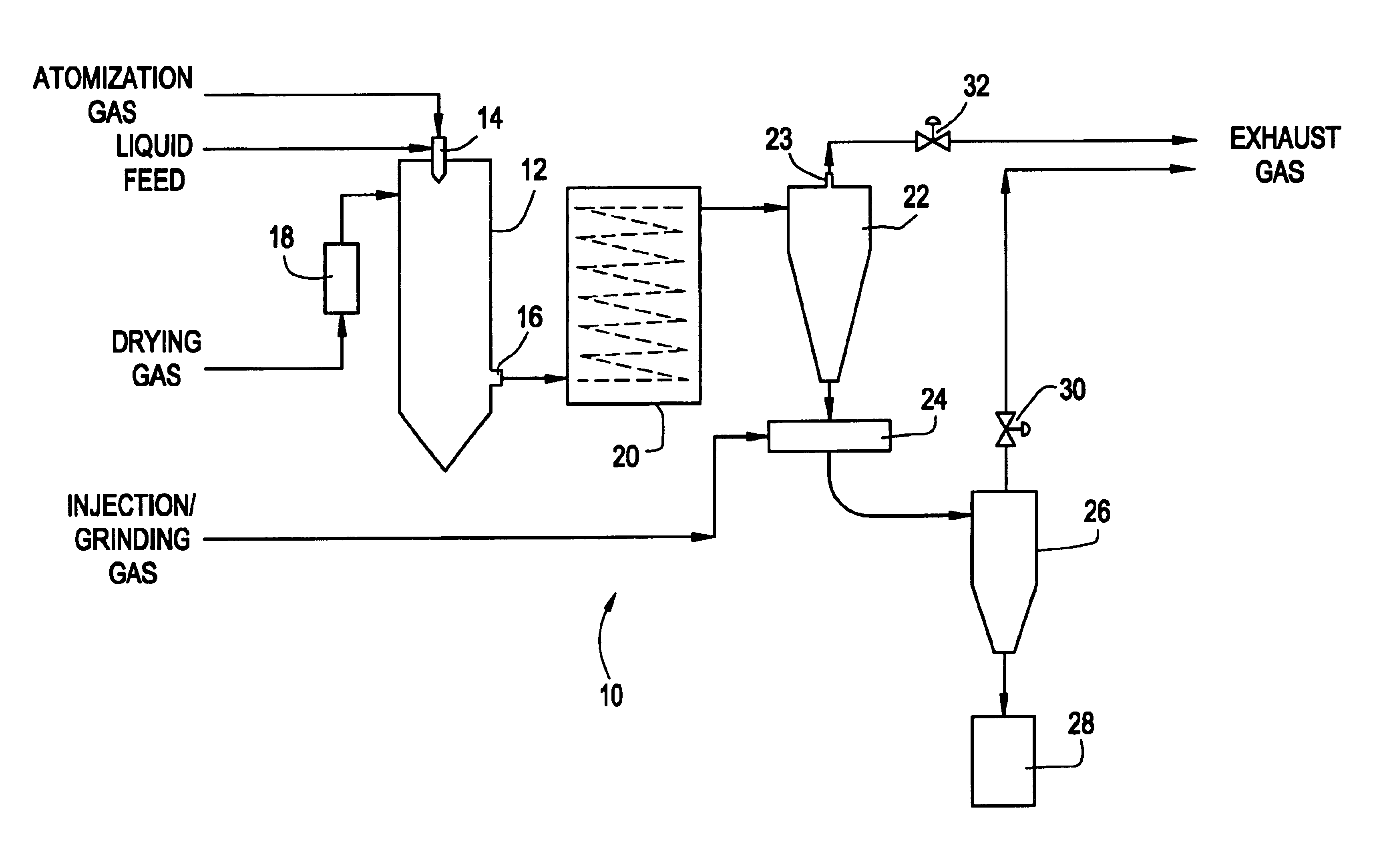

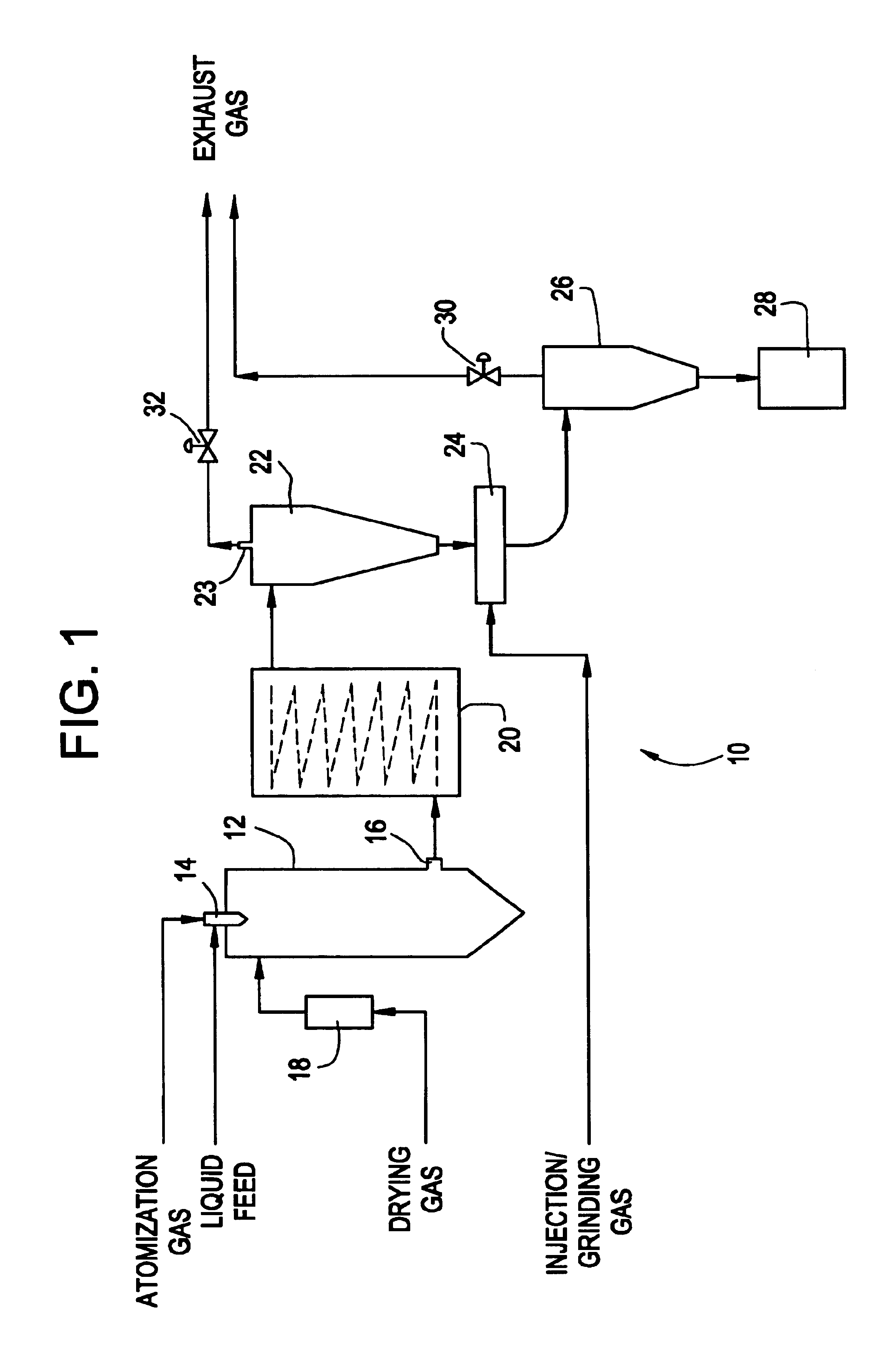

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

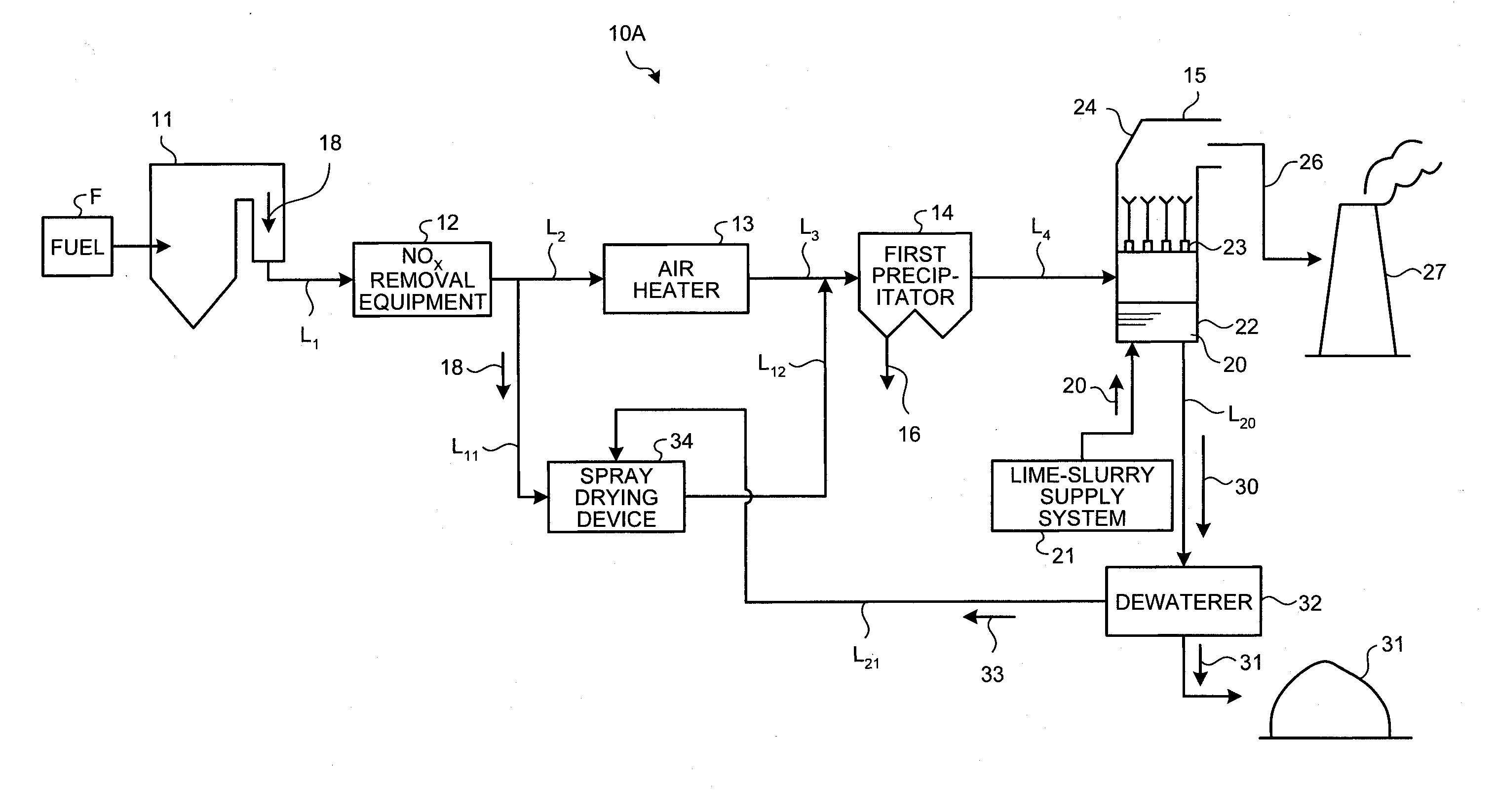

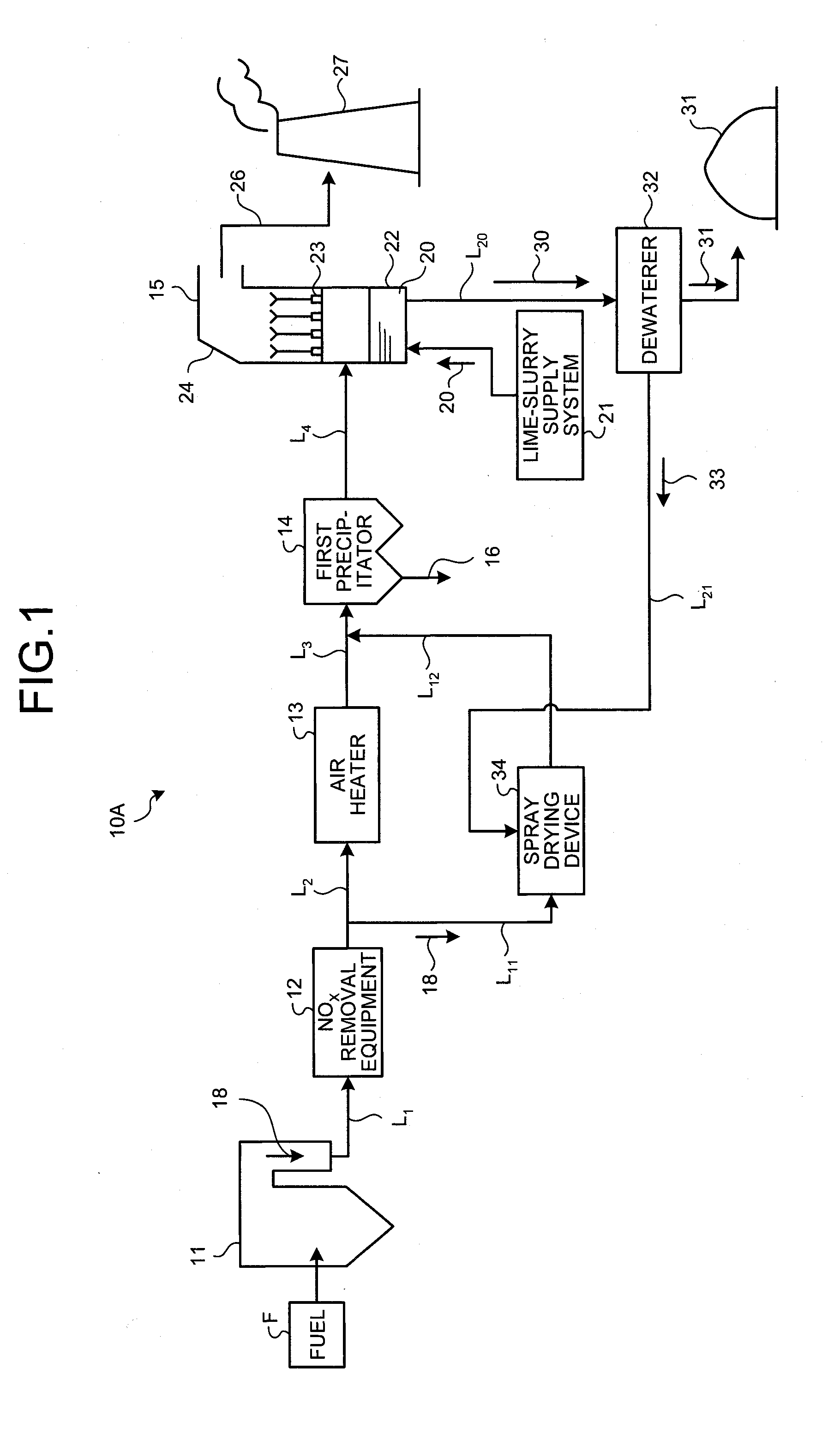

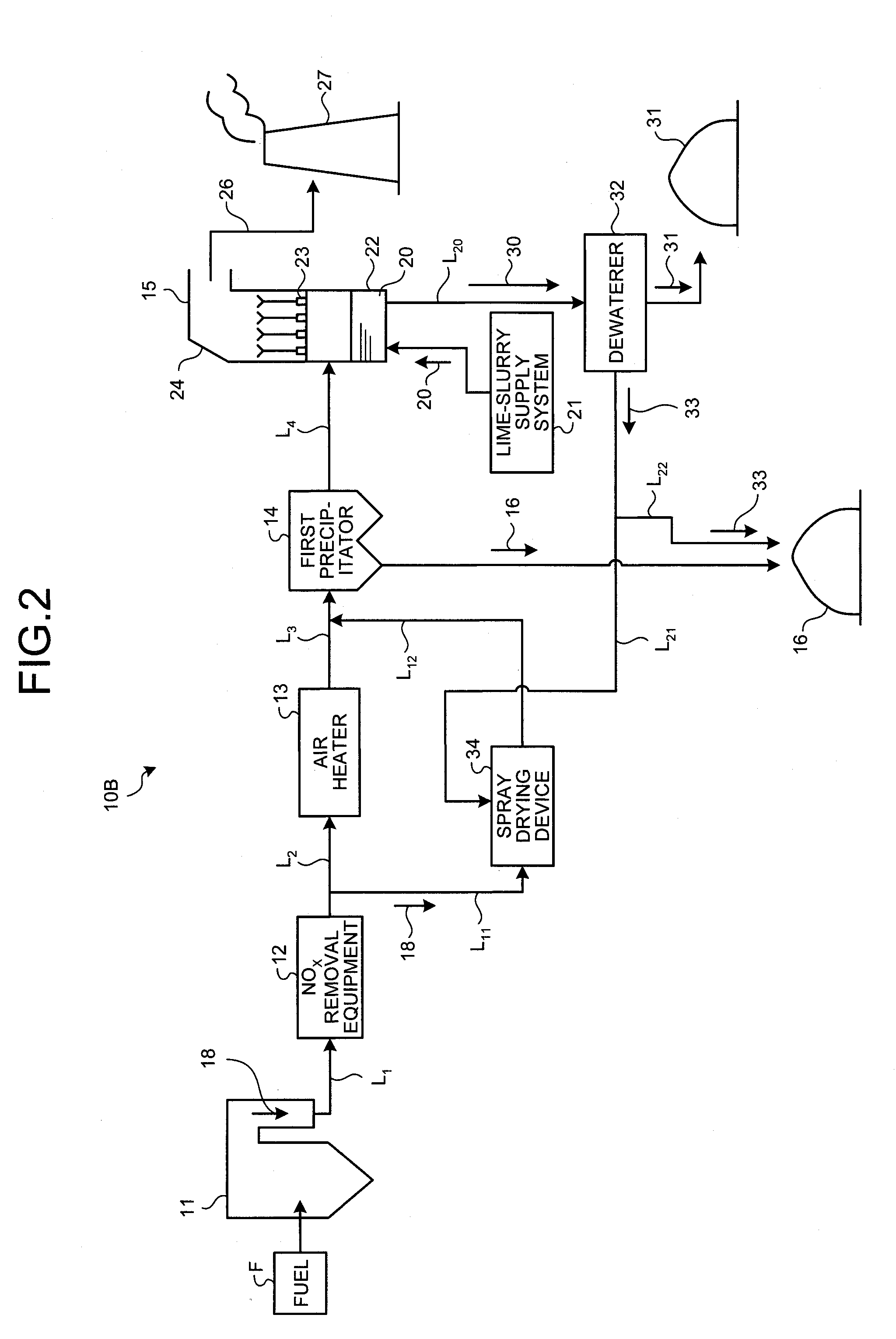

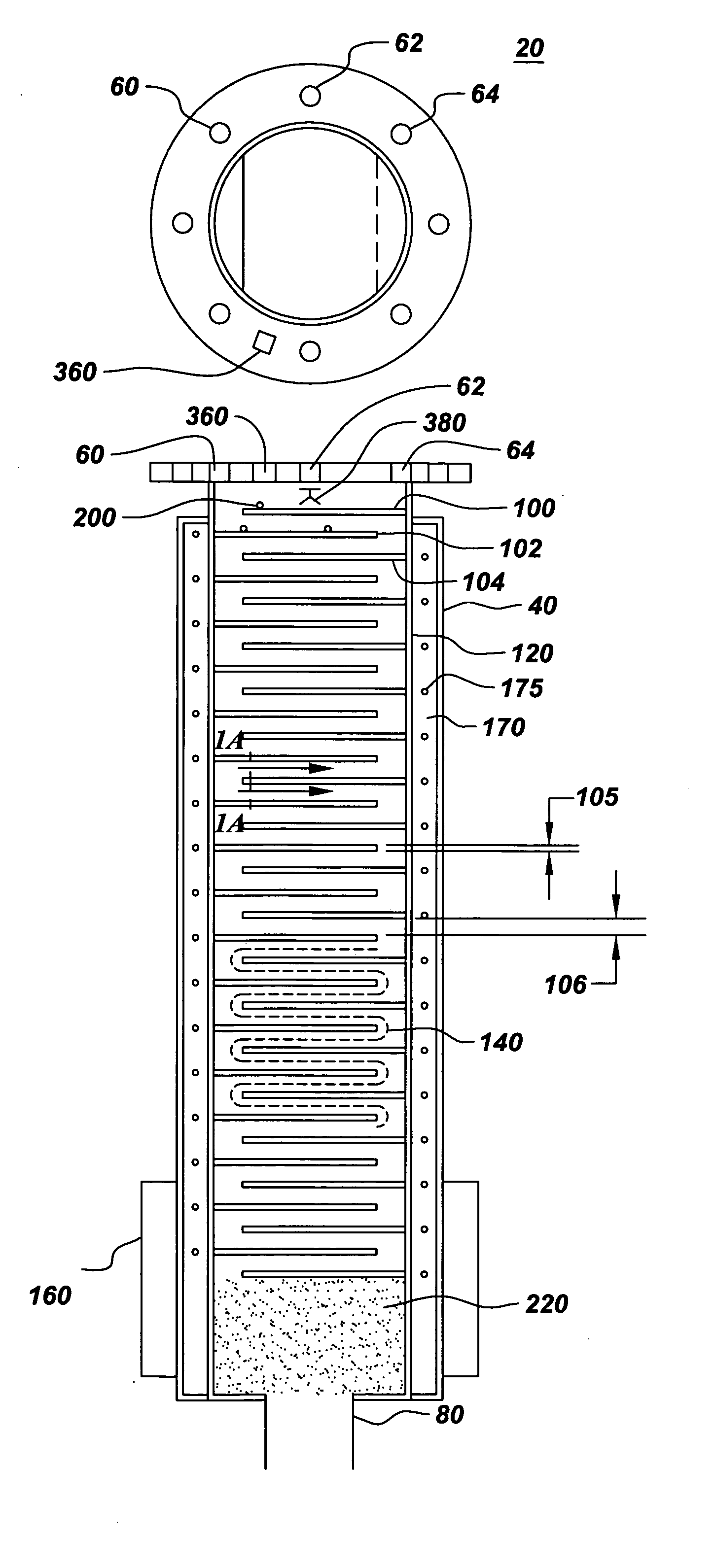

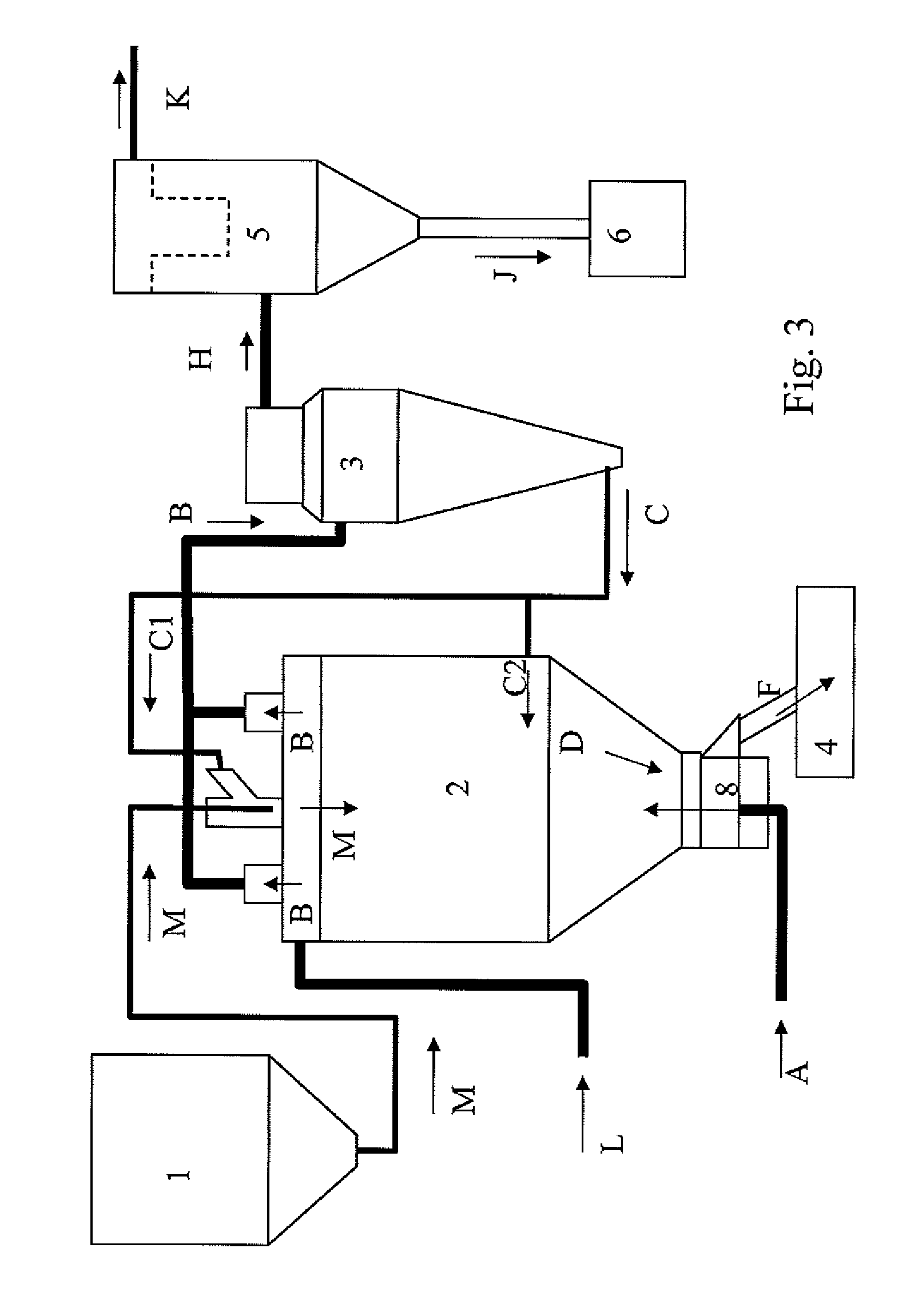

Air pollution control system and air pollution control method, spray drying device of dewatering filtration fluid from desulfurization discharged water, and method thereof

ActiveUS20120240761A1Improve performanceStable atomizationGas treatmentLiquid degasificationControl systemFlue gas

Owner:MITSUBISHI POWER LTD

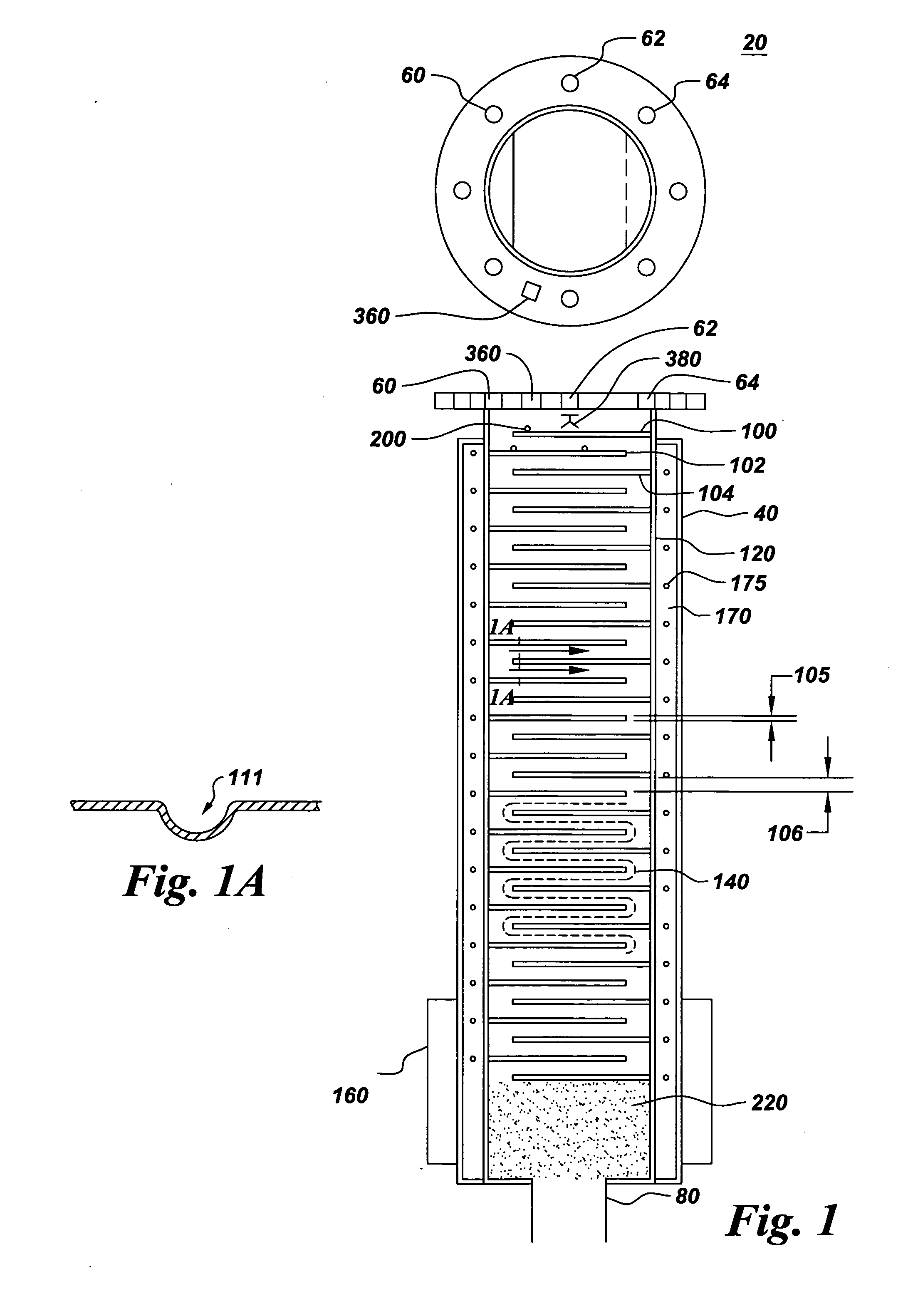

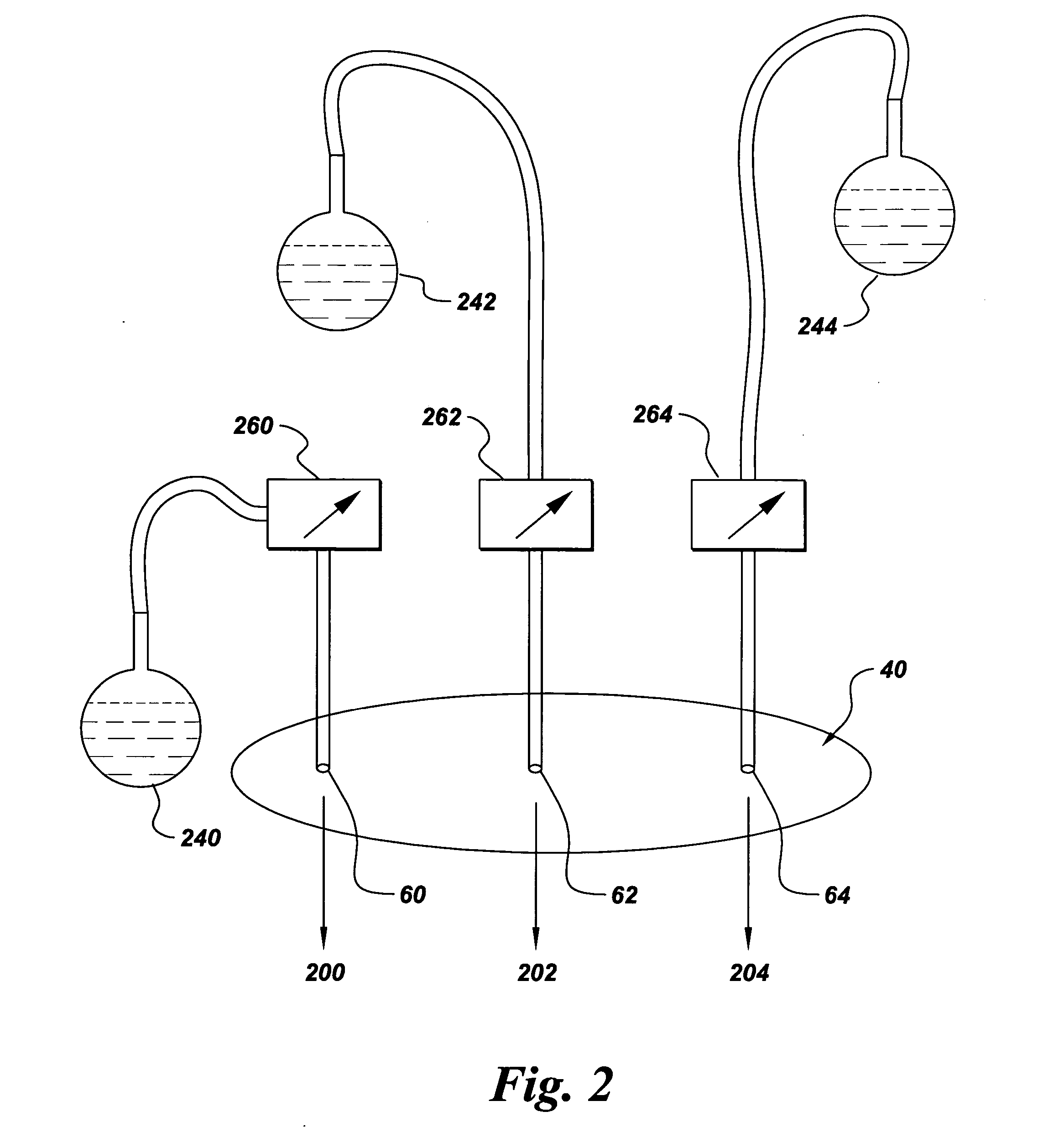

Apparatus for the evaporation of aqueous organic liquids and the production of powder pre-forms in flame hydrolysis processes

InactiveUS20050205215A1Drying using combination processesEvaporator liquid feederOrganic liquidsEvaporation

An organic liquid evaporation system is disclosed. The organic liquid evaporation system comprises a housing having at least one inlet and at least one outlet. At least a first evaporator plate radially extending from a sidewall of the housing, and at least a second evaporator plate radially extending from a sidewall of the housing define a serpentine flow path within the housing. A heating source is in thermal communication with the first evaporator plate and the second evaporator plate, wherein the heating source provides heat to the first and second evaporator plates to evaporate organic liquid introduced within the inlet to produce a vapor through the outlet. A method for preparing powder pre-forms and oxide soot using the organic liquid evaporation system is also disclosed.

Owner:GENERAL ELECTRIC CO

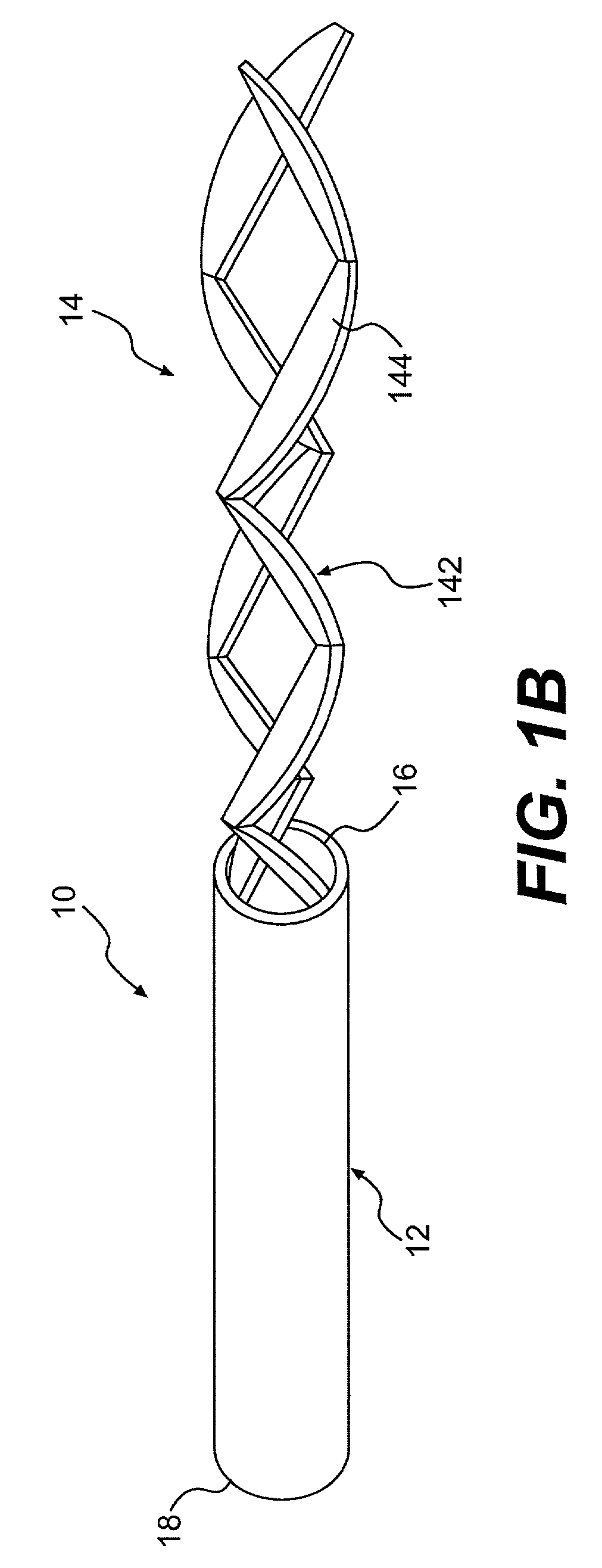

Method and apparatus for loading a beneficial agent into an expandable medical device

The present invention relates to method and apparatus for dispensing a beneficial agent into an expandable medical device. The method includes the step of placing an expandable medical device on a mandrel, the medical device forming a cylindrical device having a plurality of openings and dispensing a beneficial agent into the plurality of openings.

Owner:INNOVATIONAL HLDG LLC

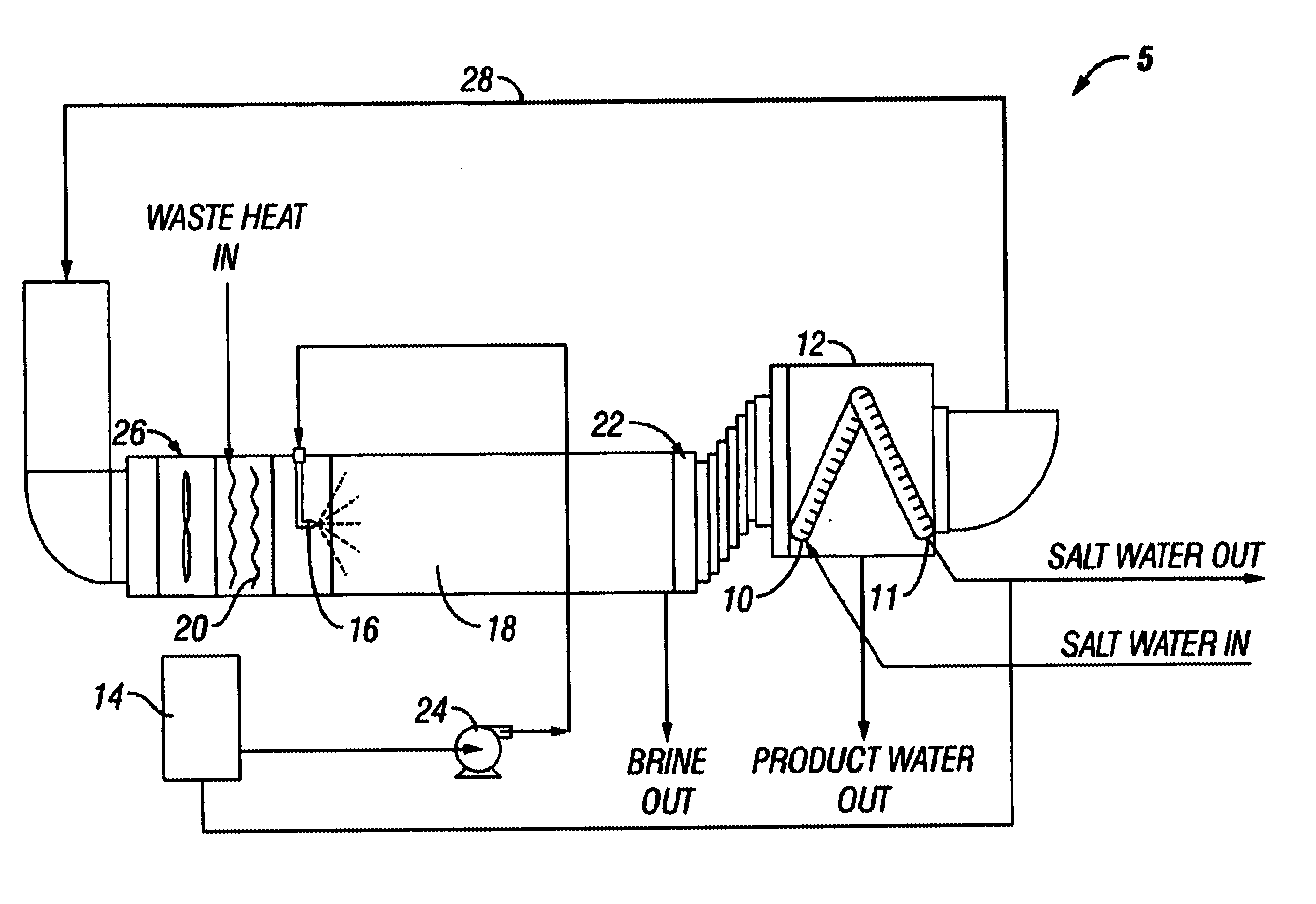

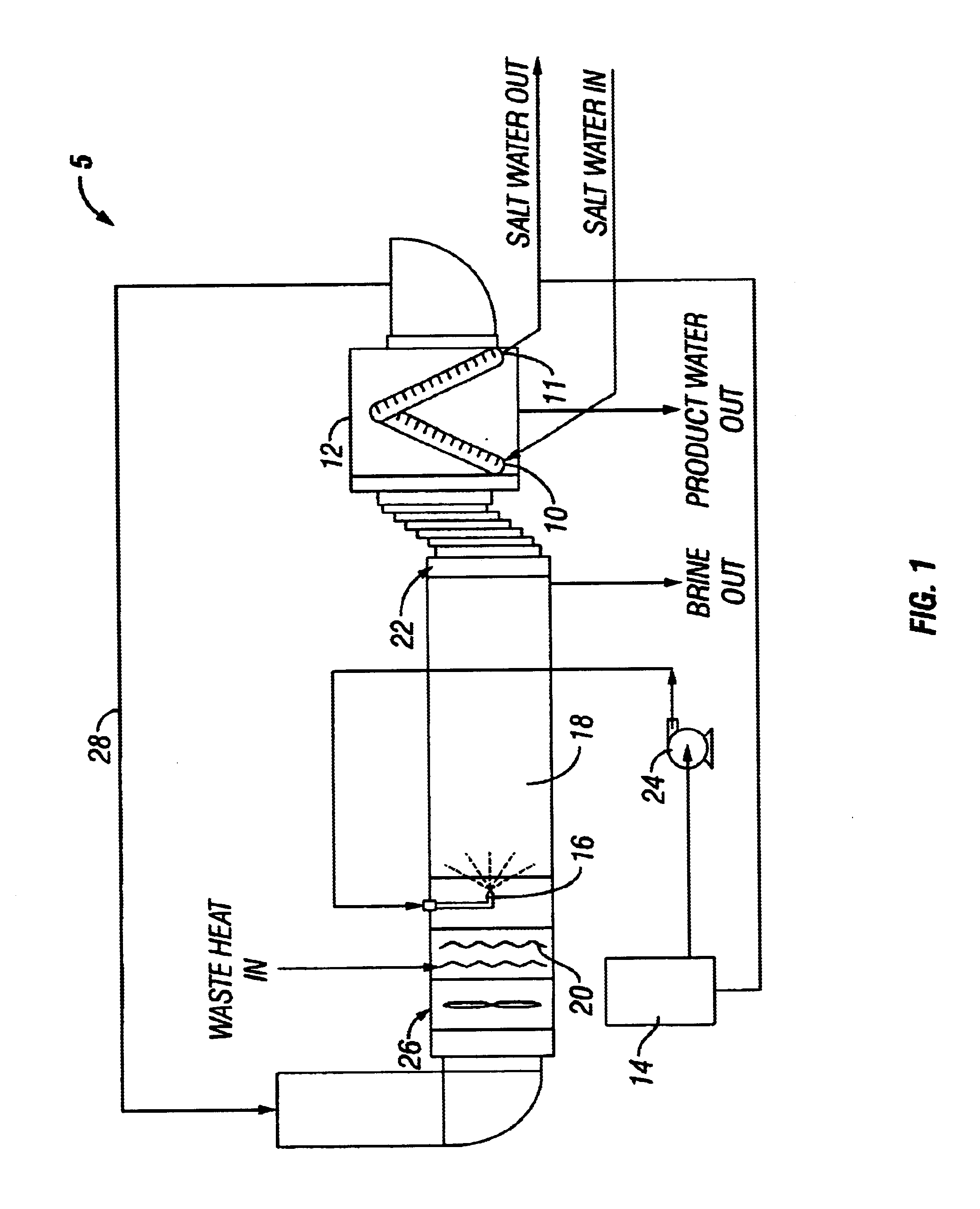

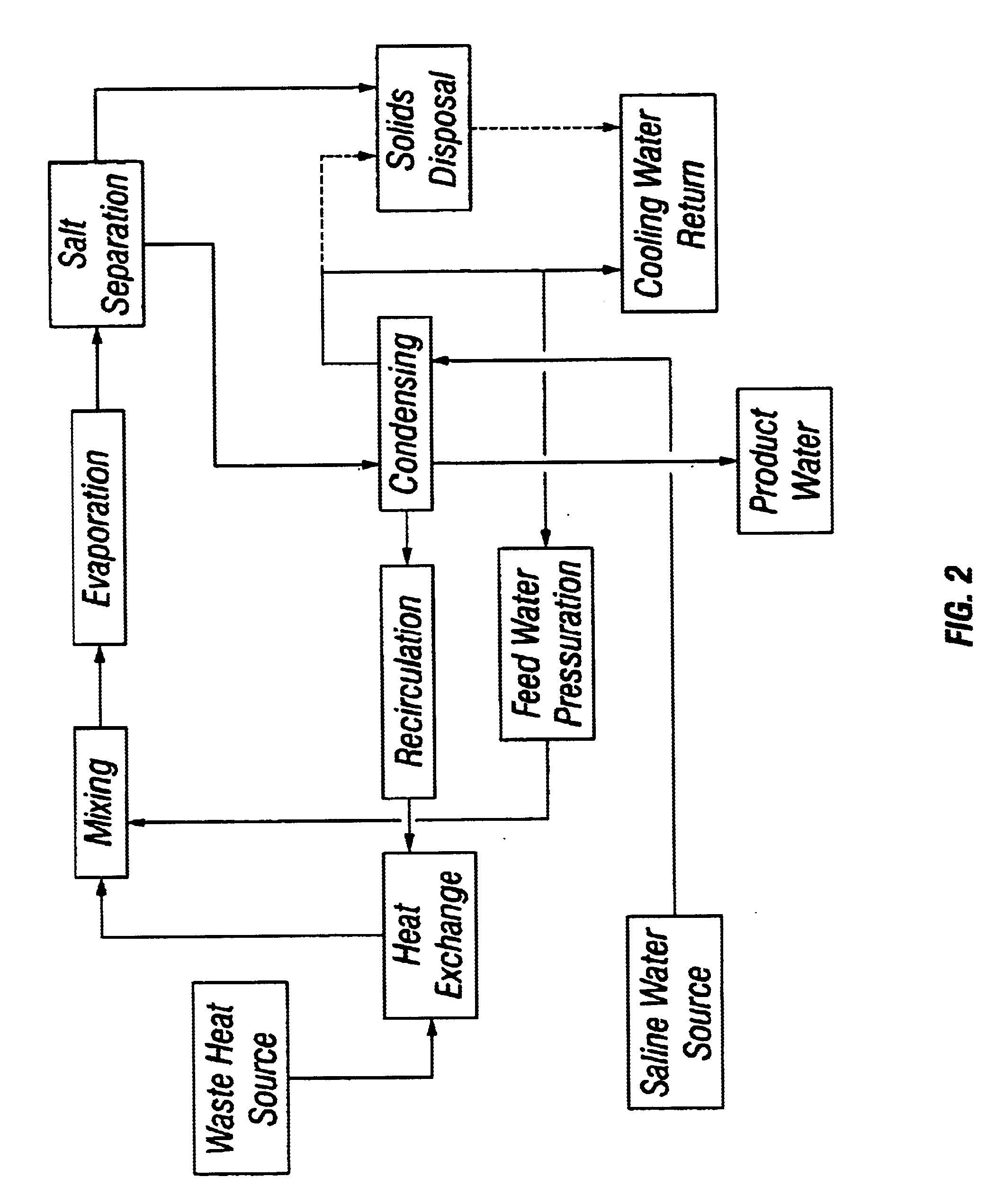

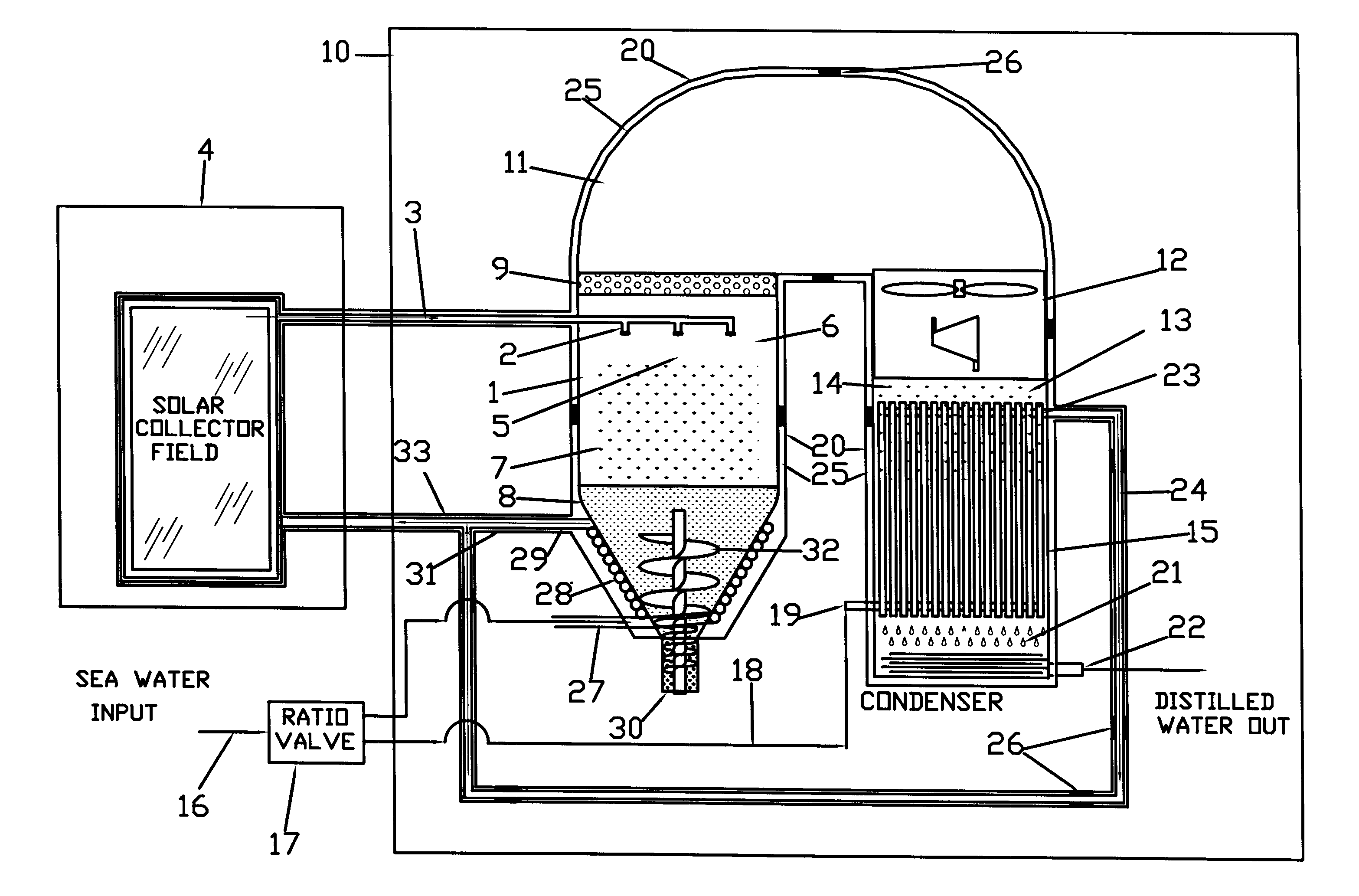

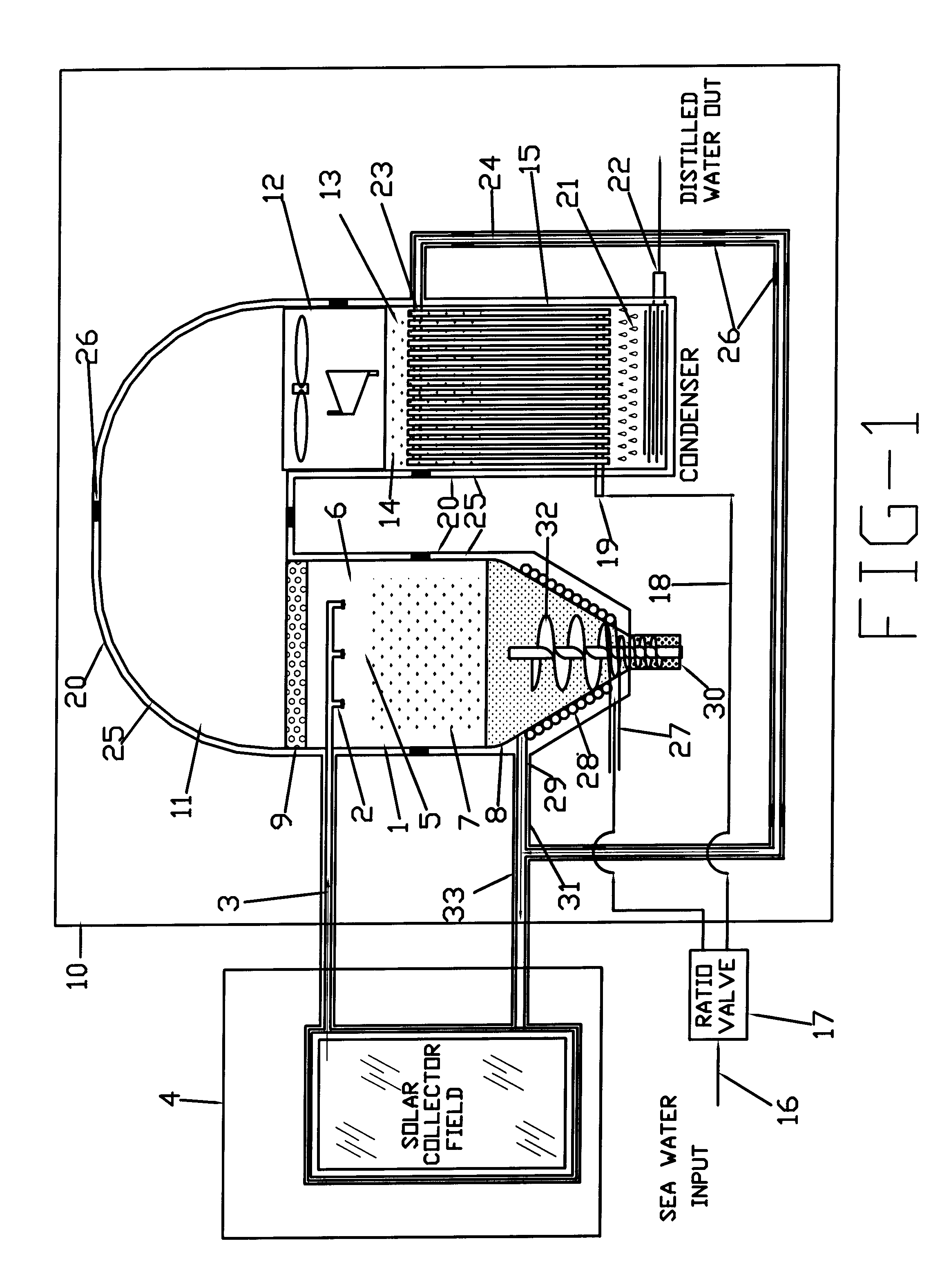

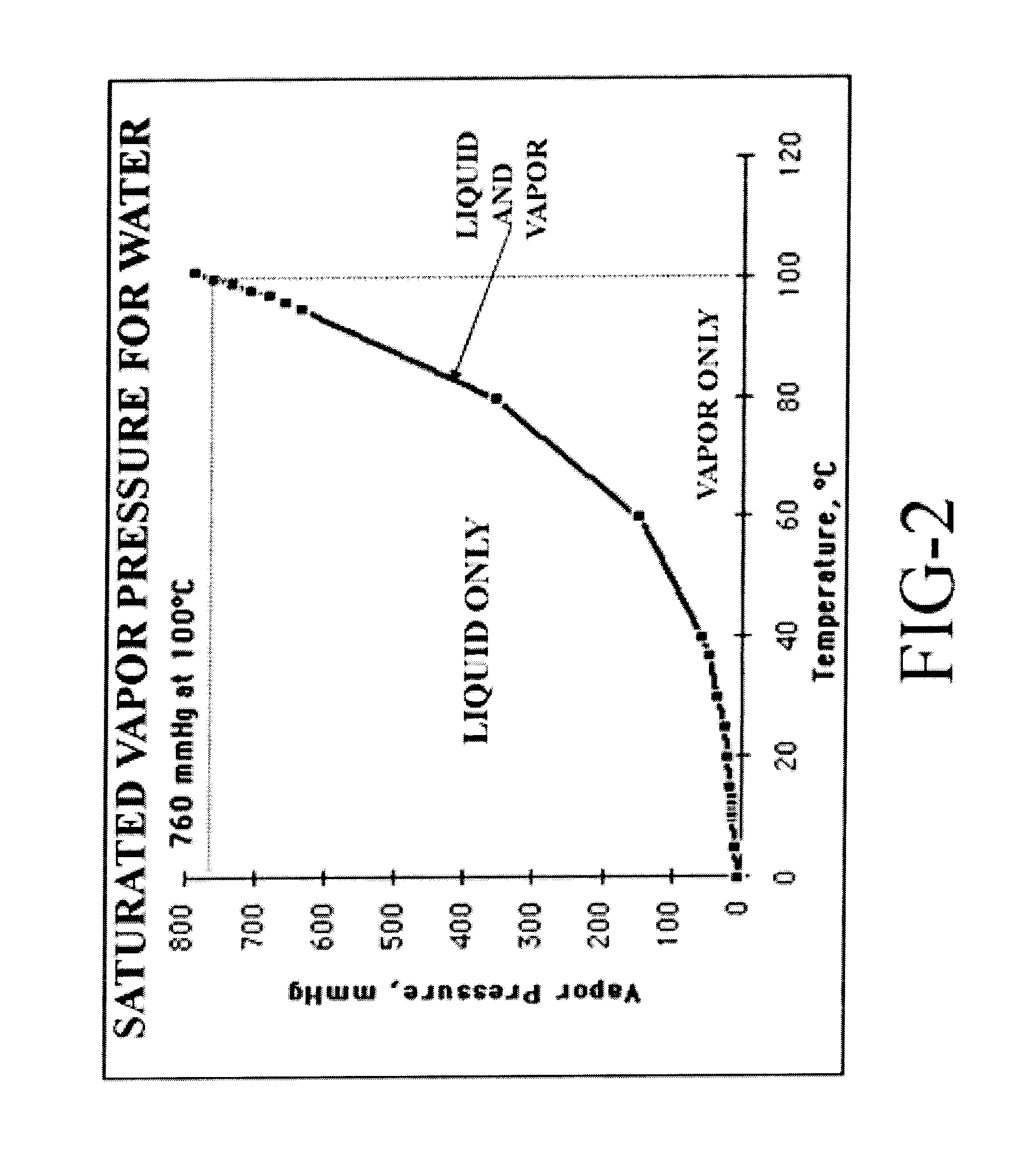

Apparatus and method for thermal desalination based on pressurized formation and evaporation of droplets

A method for removing dissolved solids, particularly salts, from water. An apparatus for performing the inventive method is disclosed. The aqueous solution to be treated, for example sea water, is atomized using special non-pneumatic nozzles, and sprayed into an evaporation chamber through which air, heated by waste heat, is blown. The micro-droplets undergo rapid evaporation in the chamber, resulting in the separation of the salt solids from the vapor phase of the water. The mixture of suspended solids and water vapor is filtered to remove and collect the salts, and the water vapor is condensed to collect the salt-free water.

Owner:AQUASONICS RSE INC

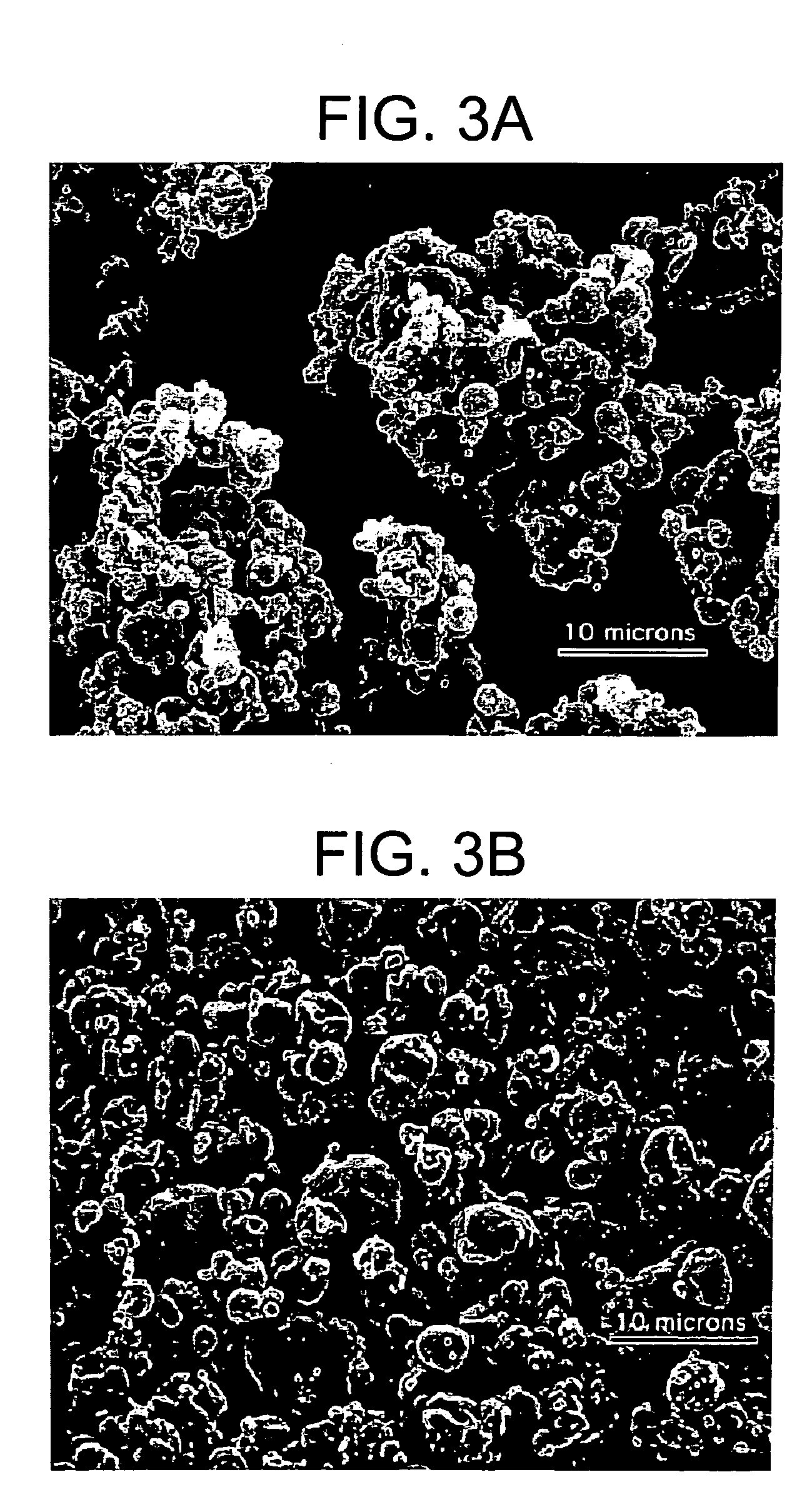

Methods for making pharmaceutical formulations comprising deagglomerated microparticles

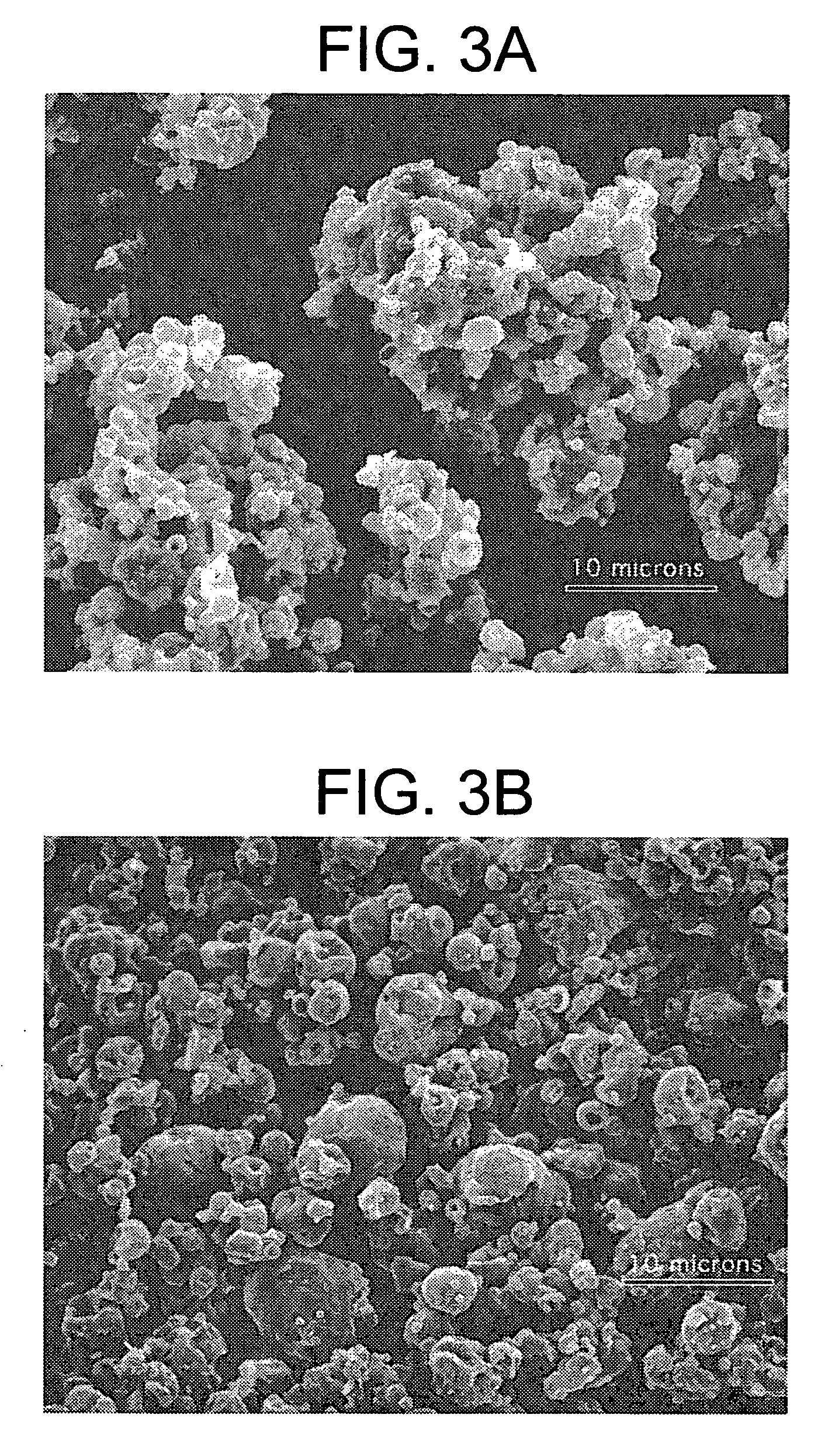

InactiveUS20060093678A1High crystallinityReduce contentPowder deliveryGranulation by liquid drop formationMicroparticleVolume average

Methods are provided for making a dry powder blend pharmaceutical formulation comprising (i) forming microparticles which comprise a pharmaceutical agent; (ii) providing at least one excipient in the form of particles having a volume average diameter that is greater than the volume average diameter of the microparticles; (iii) blending the microparticles with the excipient to form a powder blend; and (iv) jet milling the powder blend to deagglomerate at least a portion of any of the microparticles which have agglomerated, while substantially maintaining the size and morphology of the individual microparticles. Jet milling advantageously can eliminate the need for more complicated wet deagglomeration processes, can lower residual moisture and solvent levels in the microparticles (which leads to better stability and handling properties for dry powder formulations), and can improve wettability, suspendability, and content uniformity of dry powder blend formulations.

Owner:CHICKERING DONALD E III +6

Methods and apparatus for making particles using spray dryer and in-line jet mill

InactiveUS6921458B2Reduce processing timeDrying solid materials with heatGranulation by liquid drop formationPolymer scienceEmulsion

Methods and apparatus are provided for making particles comprising: (a) spraying an emulsion, solution, or suspension, which comprises a solvent and a bulk material (e.g., a pharmaceutical agent), through an atomizer and into a primary drying chamber, having a drying gas flowing therethrough, to form droplets comprising the solvent and bulk material dispersed in the drying gas; (b) evaporating, in the primary drying chamber, at least a portion of the solvent into the drying gas to solidify the droplets and form particles dispersed in drying gas; and (c) flowing the particles and at least a portion of the drying gas through a jet mill to deagglomerate or grind the particles. By coupling spray drying with “in-line” jet milling, a single step process is created from two separate unit operations, and an additional collection step is advantageously eliminated. The one-step, in-line process has further advantages in time and cost of processing.

Owner:ACUSPHERE INC

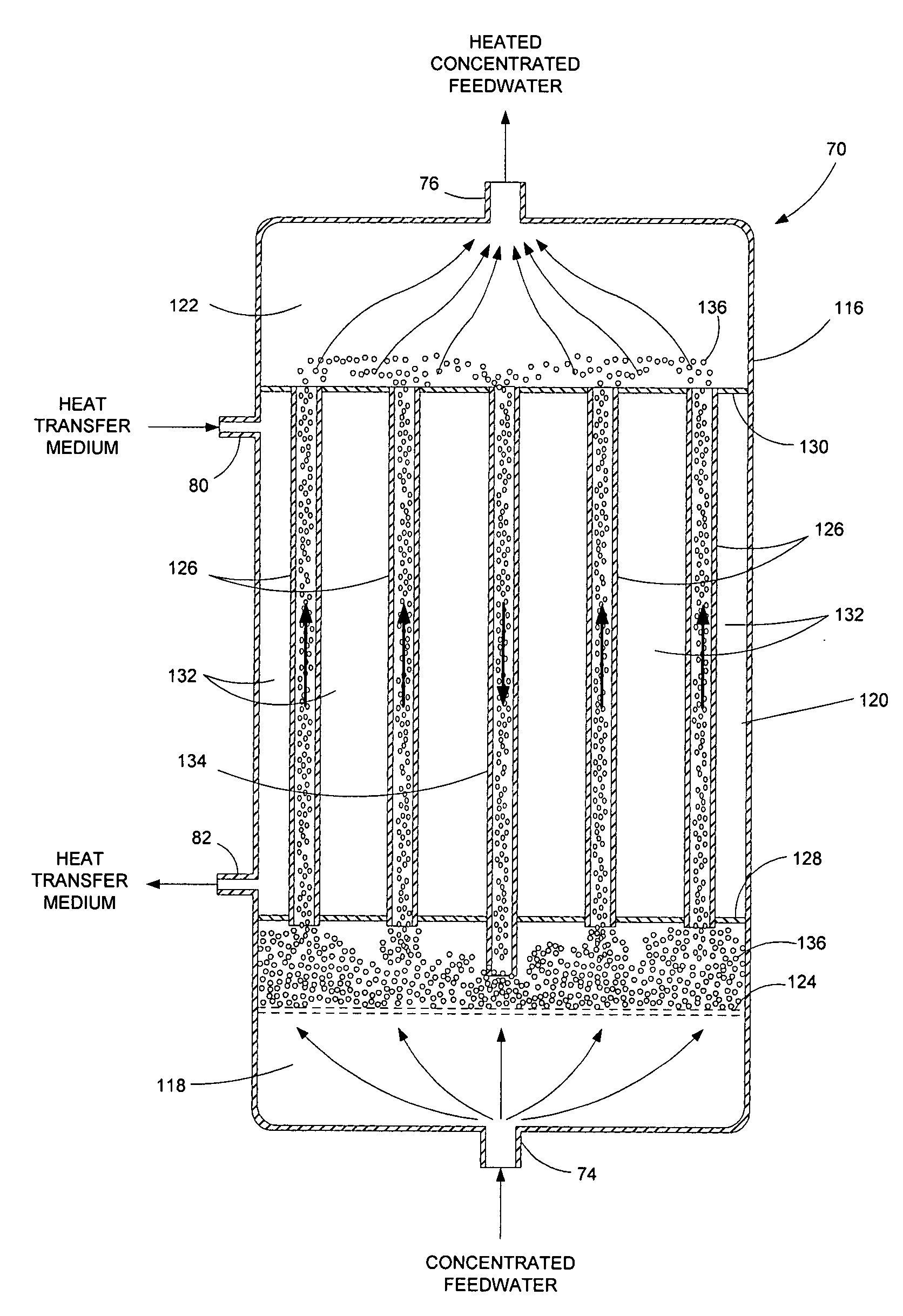

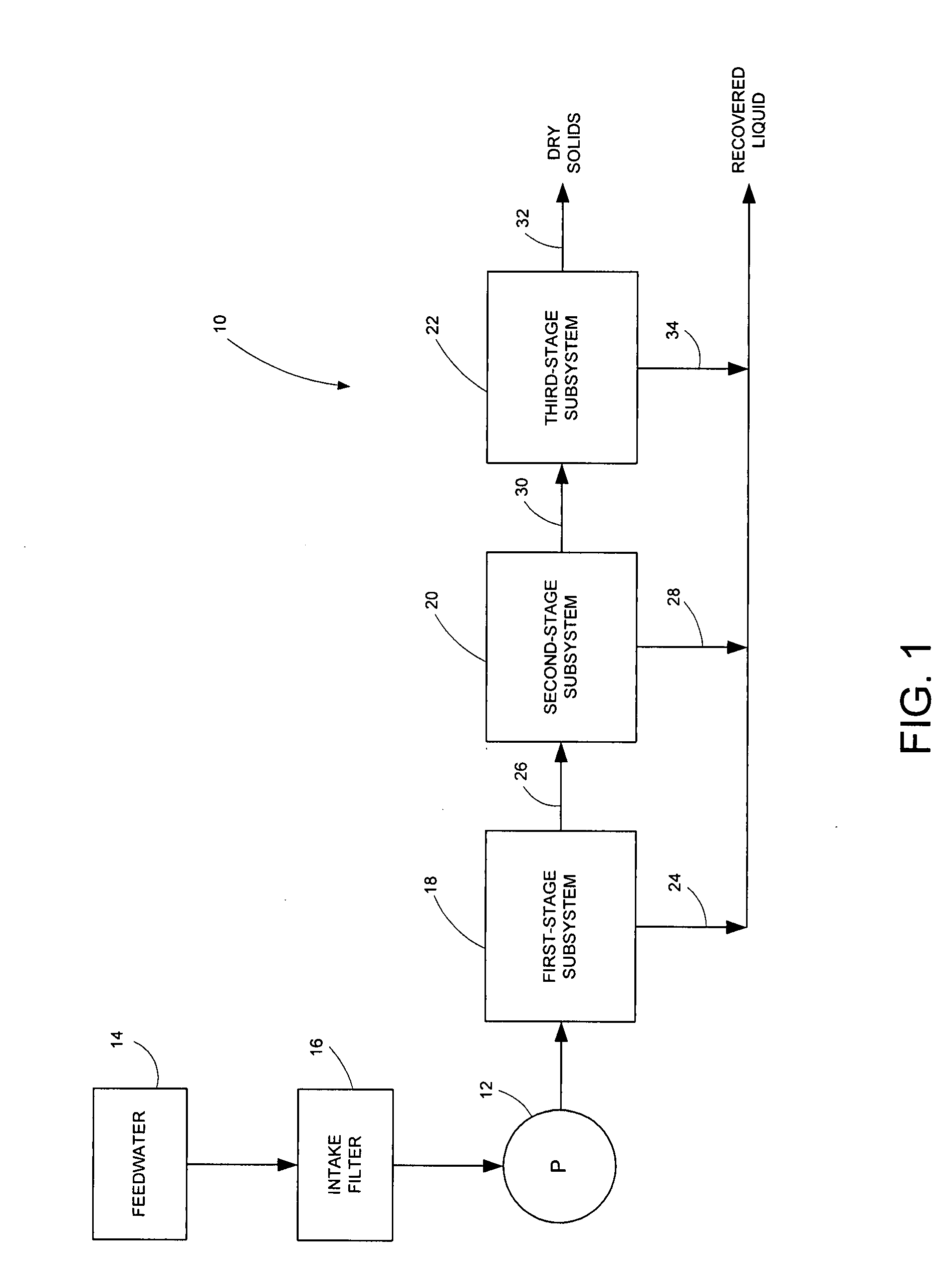

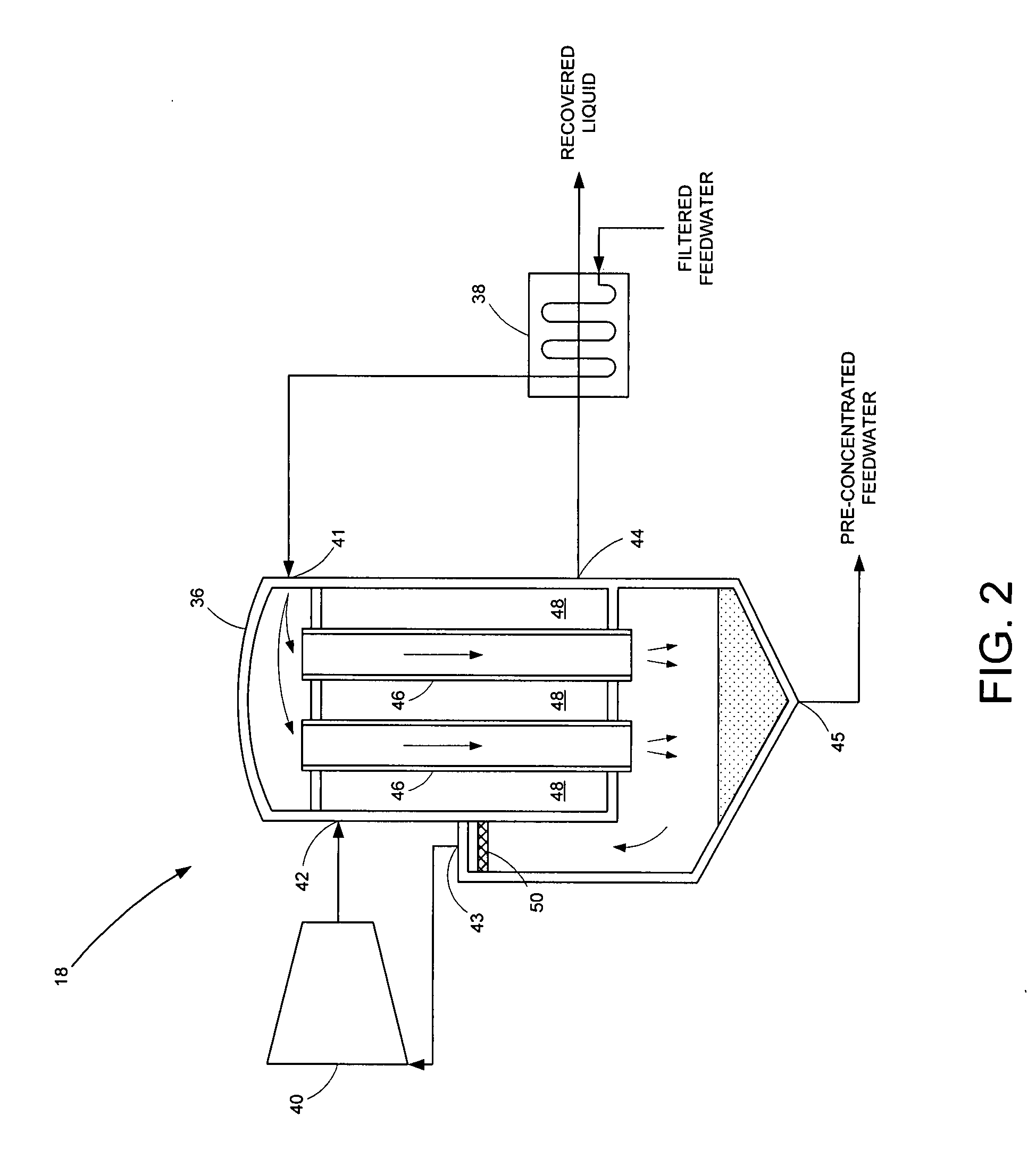

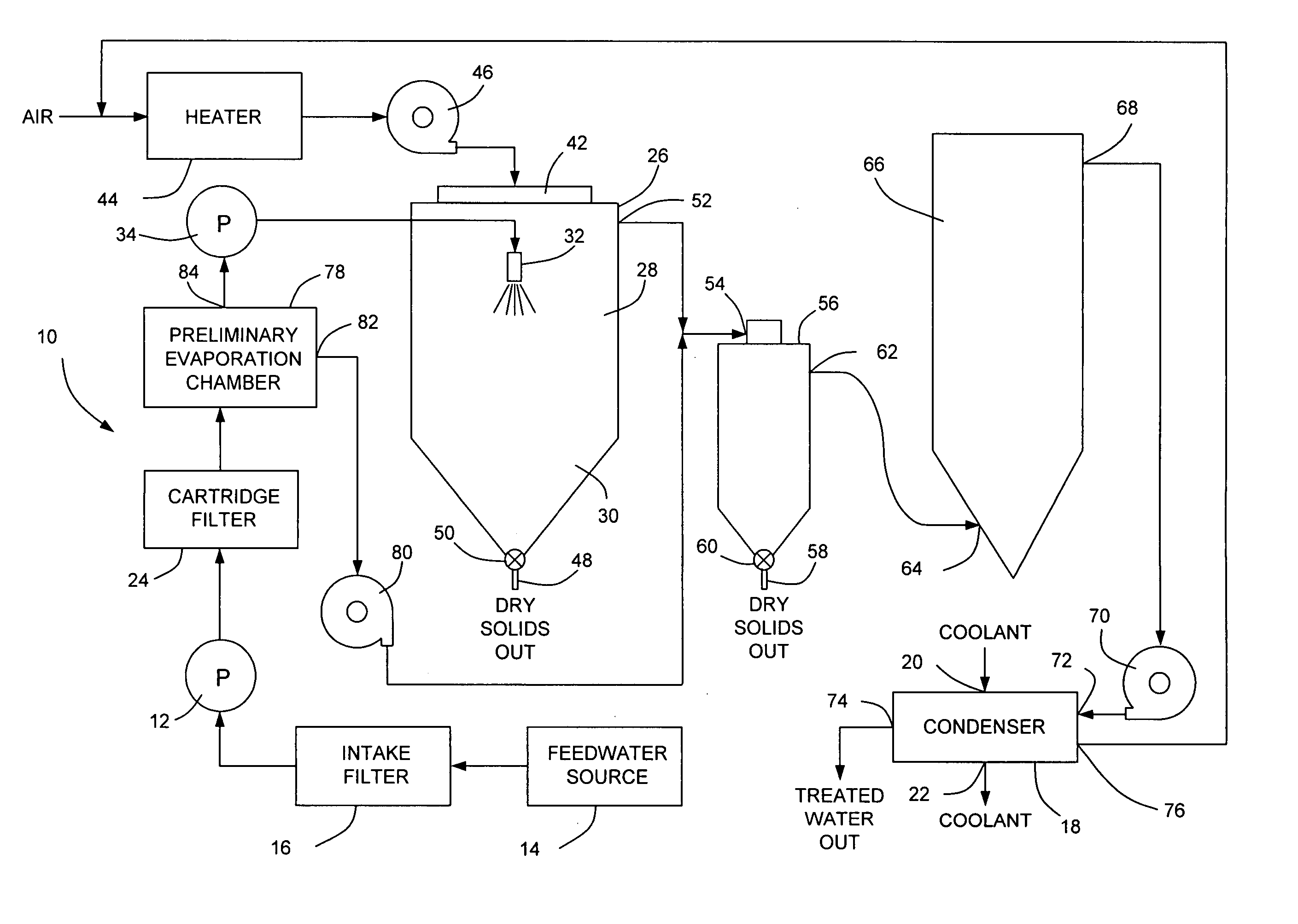

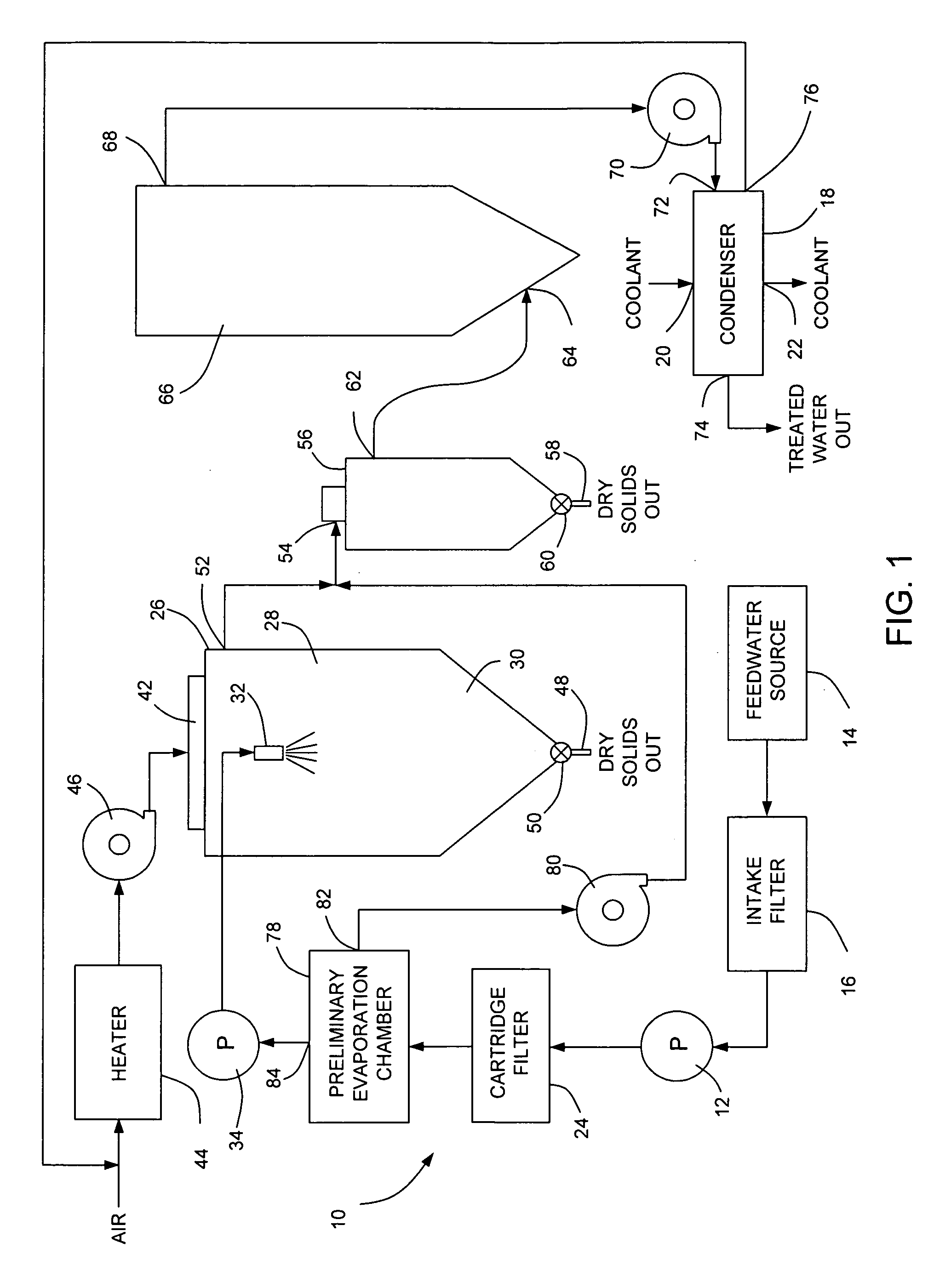

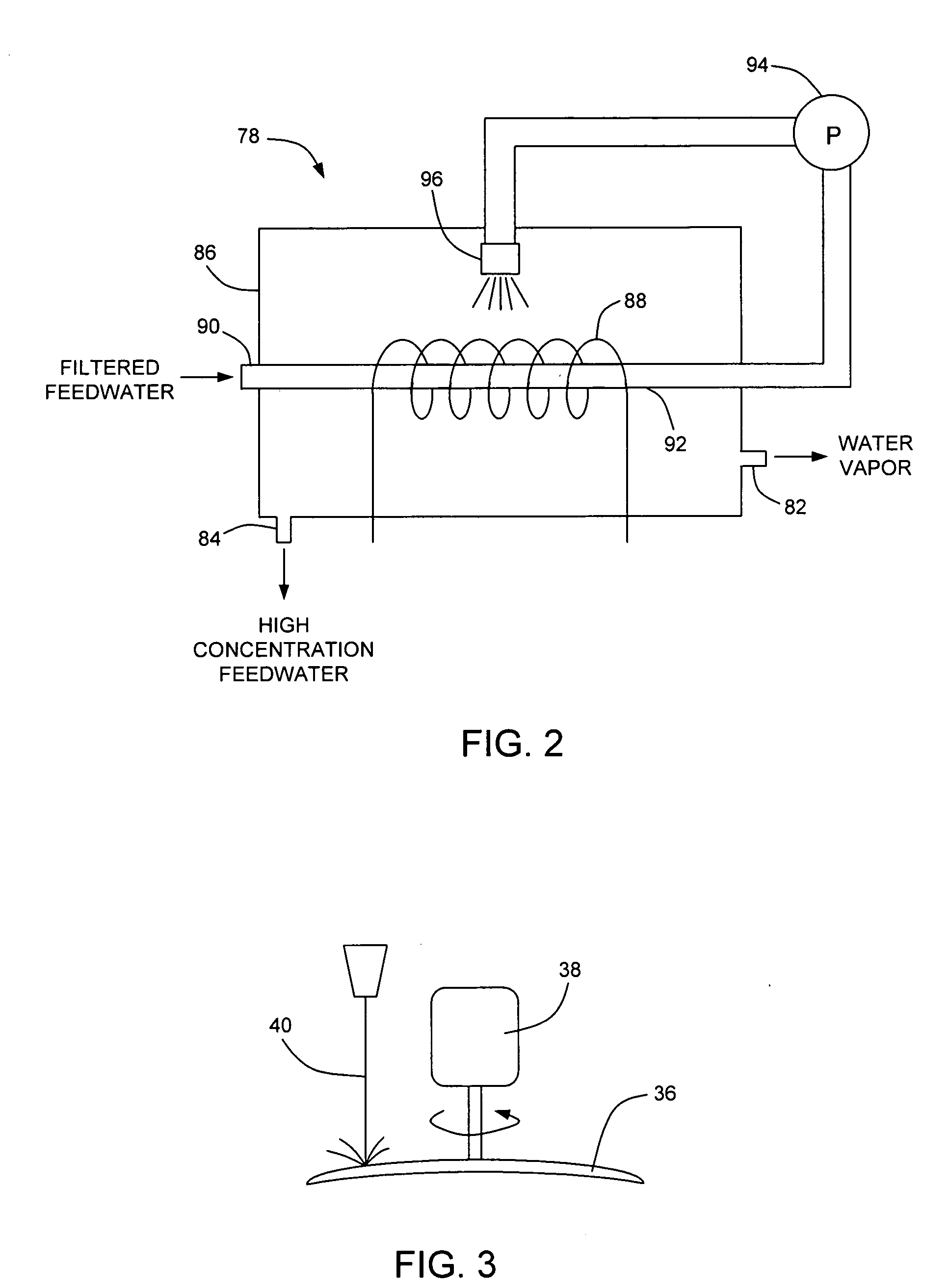

Method and system for treating feedwater

InactiveUS20090020481A1Easy to understandLiquid degasificationSedimentation separationFluidized bedSlurry

A system for treating feedwater includes a fluidized bed heat exchanger unit connected to receive feedwater and a flash concentrator column connected to receive feedwater discharged from the fluidized bed heat exchanger unit. A spray dryer is provided to receive a solids / liquid slurry discharged from the flash concentrator column. Feedwater can be treated by converting dissolved solids in the feedwater to suspended solids, vaporizing a portion of the feedwater to produce a solids / liquid slurry, and separating solids from the solids / liquid slurry.

Owner:WATERVAP +1

Sulfoalkyl Ether Cyclodextrin Compositions and Methods of Preparation Thereof

A particulate SAE-CD composition is provided. The SAE-CD composition has an advantageous combination of physical properties not found in known solid forms of SAECD. In particular, the SAE-CD composition possesses an advantageous physicochemical and morphological property profile such that it can be tailored to particular uses. The SAE-CD composition of the invention has improved flow and dissolution performance as compared to known compositions of SAE-CD.

Owner:CYDEX PHARMACEUTICALS INC

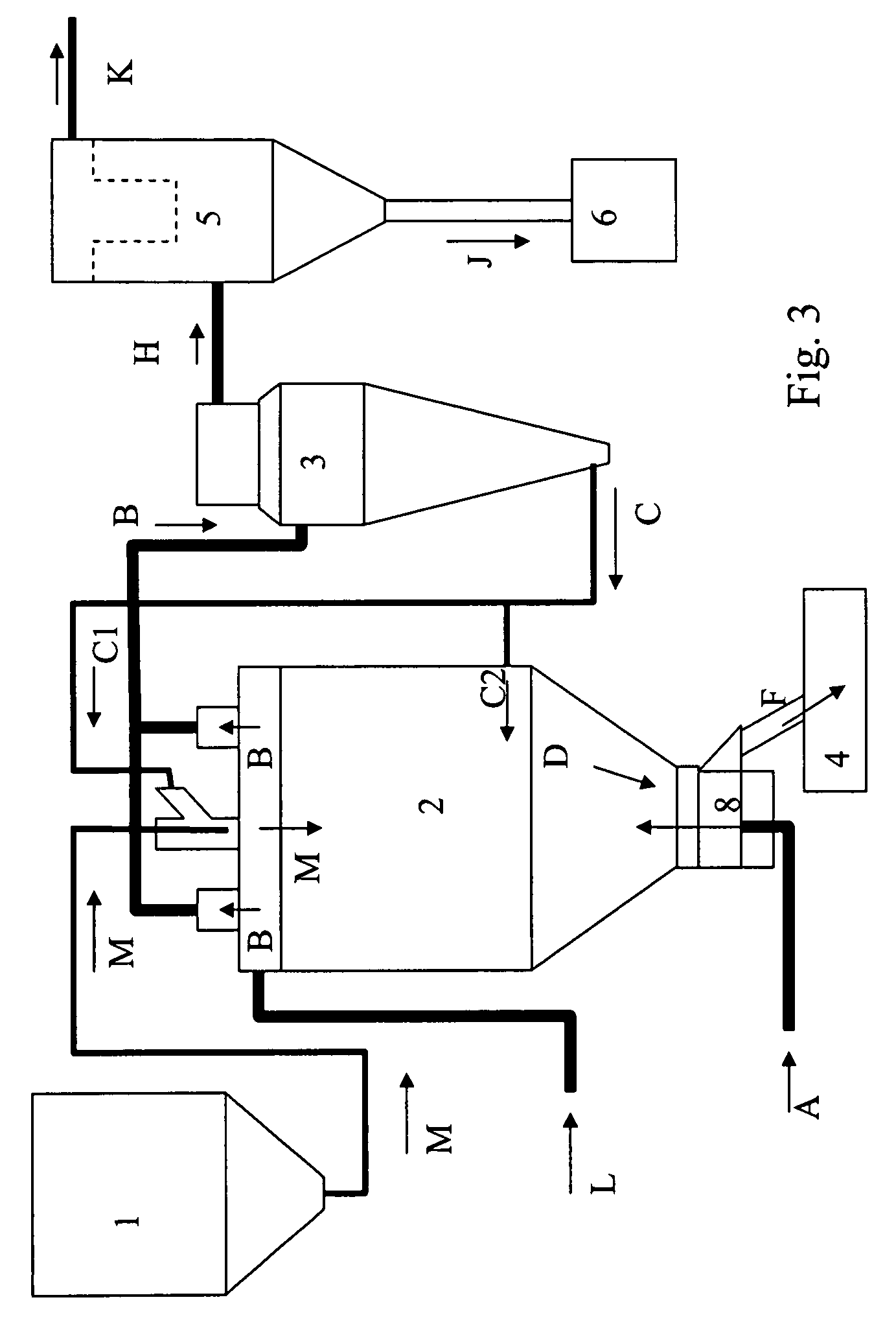

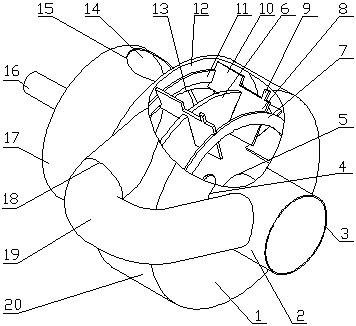

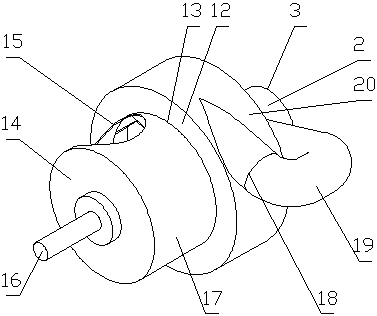

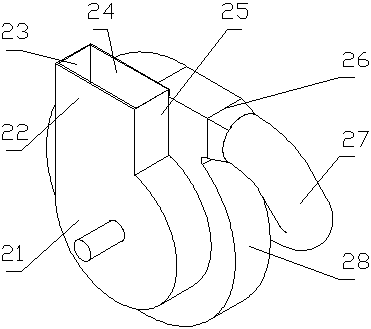

Mill for drying and pulverizing high-moisture and high-viscosity material and application method thereof

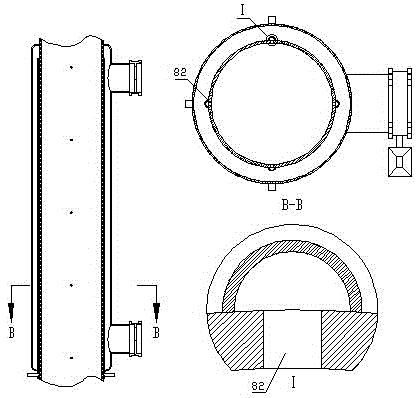

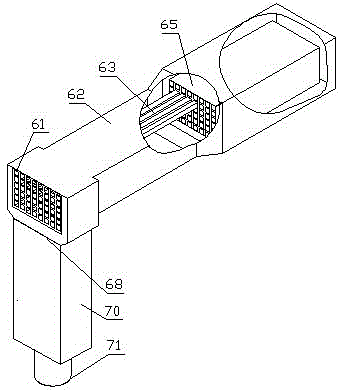

ActiveCN107694135ASolve the problem of hanging on the wallSolve the problem of dry millingEvaporator accessoriesGrain treatmentsImpellerEngineering

The invention provides a Yunjie mill. The Yunjie mill adopts a Yunjie mill main engine composed of a shell body, a rotor with a powder mill and a grading function and an inner circulating pipe, so that materials are pulverized and dried at the same time in a high-speed circulating flowing process in an inner circulating channel composed of an inner circulating pipe, a pulverizing impeller, a spacebetween the pulverizing impeller and an inner wall of a barrel body and the like; a wall remaining problem of the inner circulating channel is solved by utilizing an impact effect of a high-speed material flow; the wall remaining problem of an outer circulating channel is solved by controlling the moisture content of materials, discharged by the main engine, through a grading impeller; the defects of equipment in the inventive patent 2015110139212 are overcome and a method and a product of the inventive patent 2015110139212 are economically realized; the invention provides an application method of the Yunjie mill, so that the drying and pulverizing problem of high-moisture and high-viscosity materials including vegetable materials, meat, liquid materials and the like is solved; a solutionwith good economical efficiency is provided for processing feed and preparing a medicine which takes a volatile component as a functional component.

Owner:KUNMING TEKANG TECH CO LTD

Salt water distillation system

The salt water distillation system includes a sprinkler to form a mist of salt water over a distillation plate. The distillation plate is heated by applying electrical current to a heating coil. The steam is transferred to a condensation chamber and condensed fresh water is collected. During the desalination process, salt impurities are deposited on the hot distillation plate. A sludge remover, i.e., a steam head and movable ram, is provided to clean the distillation plate of the salt impurities. An exhaust fan is provided to cool fresh water condensate and lower air pressure in the system. Heat transferred from the steam during condensation is used to pre-heat the salt water to increase efficiency of the system.

Owner:RIVES MICHAEL L +1

Sulfoalkyl Ether Cyclodextrin Compositions and Methods of Preparation Thereof

A particulate SAE-CD composition is provided. The SAE-CD composition has an advantageous combination of physical properties not found in known solid forms of SAE-CD. In particular, the SAE-CD composition possesses an advantageous physicochemical and morphological property profile such that it can be tailored to particular uses. The SAE-CD composition of the invention has improved flow and dissolution performance as compared to known compositions of SAE-CD.

Owner:CYDEX PHARMACEUTICALS INC

Method for making homogeneous spray-dried solid amorphous drug dispersions using pressure nozzles

InactiveUS7780988B2Large particle sizeReduce the ratioPowder deliveryMetabolism disorderSolid massProcess conditions

Homogeneous solid amorphous dispersions of drugs in concentration-enhancing polymers are formed in desirable larger particle sizes with minimal fines by using an atomizer and process conditions capable of producing droplets having an average diameter of at least 50 microns and a D10 of at least 10 microns.

Owner:LONZA BEND INC

Method and apparatus for producing dry particles

Owner:CIVITAS THERAPEUTICS

Method for manufacturing toner, toner, fixing device, and image forming apparatus

A toner having high mechanical strength and being capable of exhibiting a sufficient fixing property in a wide temperature range, and a method for manufacturing such a toner are provided. Further, a fixing device and an image forming apparatus in which such a toner can be suitably used are also provided. The method for manufacturing a toner comprises a step of spreading a dispersion liquid, in which a dispersoid containing polyester-based resin is dispersed in a dispersion medium, into a laminar flow by pressing it against a smooth surface using a gas flow and then jetting the dispersion liquid in the form of fine particles and a step of solidifying the fine particles of the dispersion liquid while they are being conveyed in a solidifying section. The polyester-based resin includes block polyester mainly composed of a block copolymer, and amorphous polyester having crystallinity lower than that of the block polyester. The block polyester has a crystalline block obtained by condensation of a diol component with a dicarboxylic acid component, and an amorphous block having crystallinity lower than that of the crystalline block.

Owner:SEIKO EPSON CORP

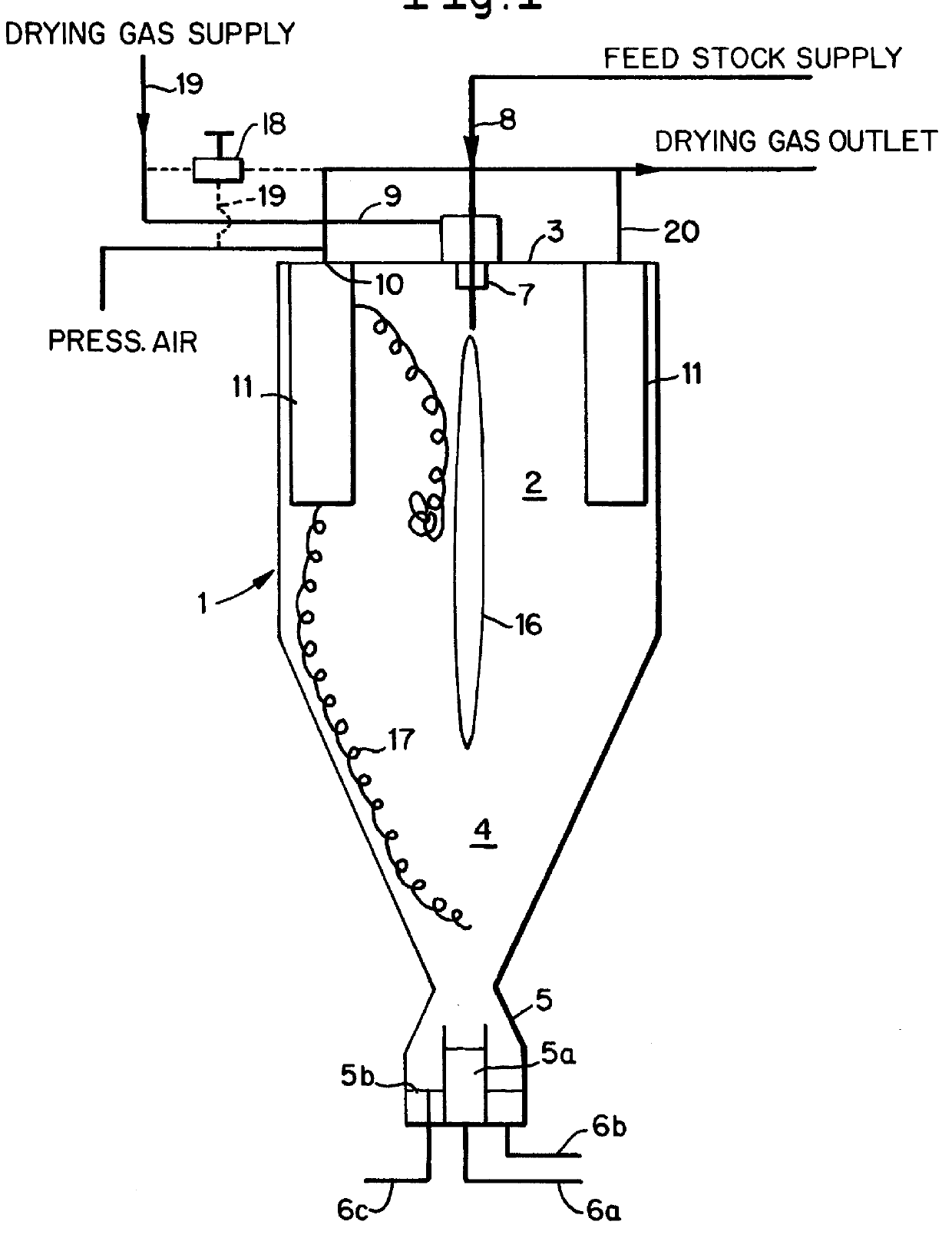

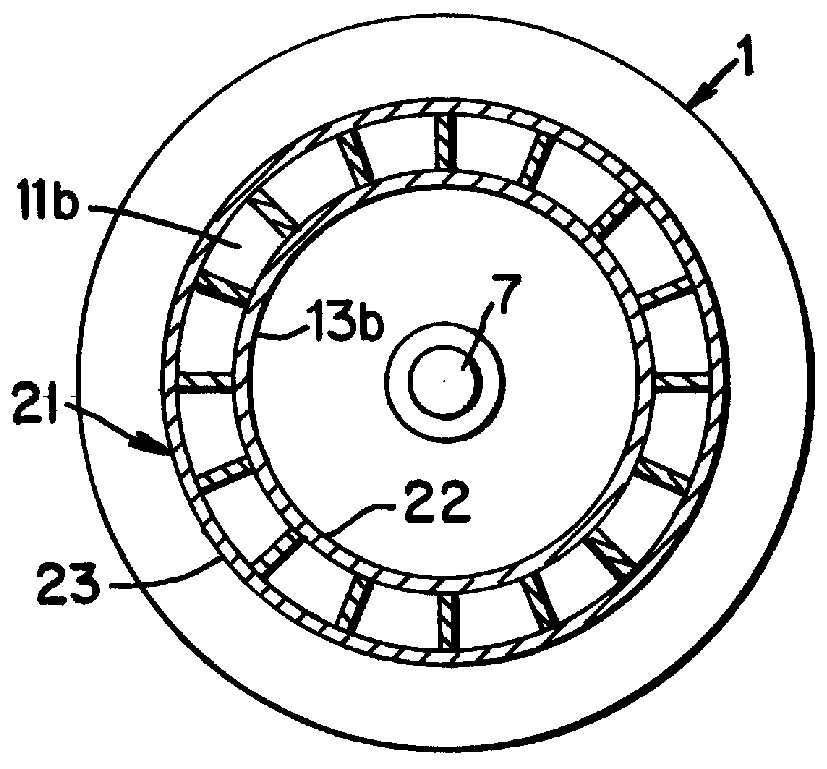

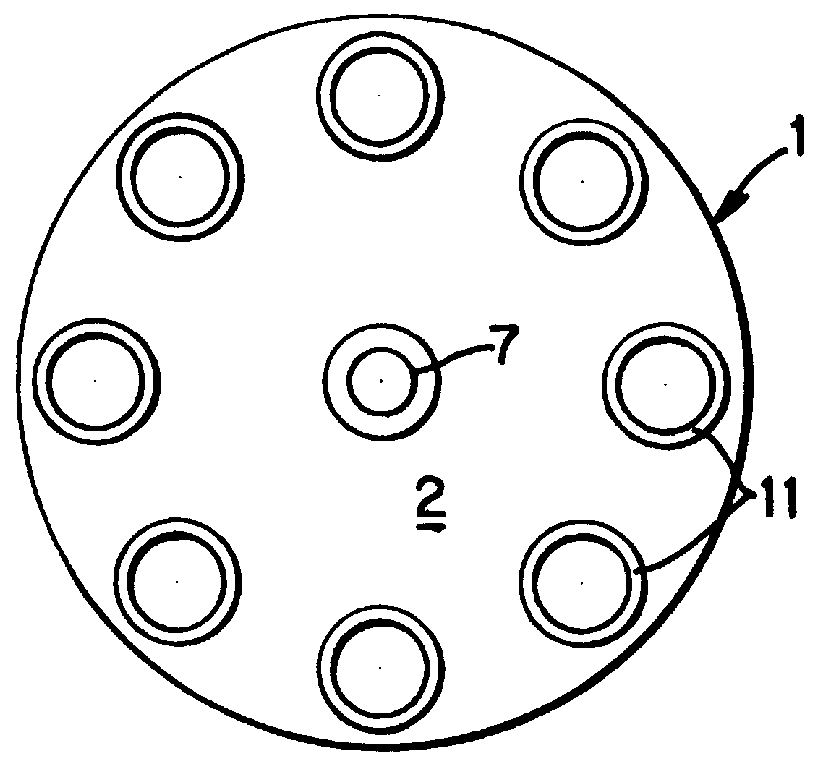

Spray drying method and apparatus and cleaning method for such an apparatus

InactiveUS6058624ALess complicated and more compact overall structureEasy to cleanDrying using combination processesDrying solid materials with heatEngineeringCleaning methods

PCT No. PCT / DK97 / 00078 Sec. 371 Date Feb. 25, 1997 Sec. 102(e) Date Feb. 25, 1997 PCT Filed Feb. 20, 1997 PCT Pub. No. WO97 / 14288 PCT Pub. Date Apr. 24, 1997In fluidized spray drying of a feedstock to produce an agglomerate product by means of at least one spraying device (7) arranged in the upper part (2) of a vertically disposed drying chamber (1), in a lower part of which a fluid-bed is accommodated, a drying gas introduced into a processing zone (16) of the chamber (1) is exhausted through an integrated arrangement of filter elements (11) in the upper chamber part (2) to retain and allow agglomeration of the particles carried by the flow of drying gas on the filter elements (11). By intermittent supply of reverse flow gas pulses to the filter elements (11) the retained particles are released and returned to agglomeration zones (16, 17). The drying gas is introduced at a rate producing at the filter walls (13) a flow rate amounting to at least 150 cubic meters per hour per square meter of filter wall surface. In the non-operative condition of the spray drying apparatus the filter elements (11) may be cleaned-in-place by supplying a cleaning liquid to the interior of the elements.

Owner:NIRO

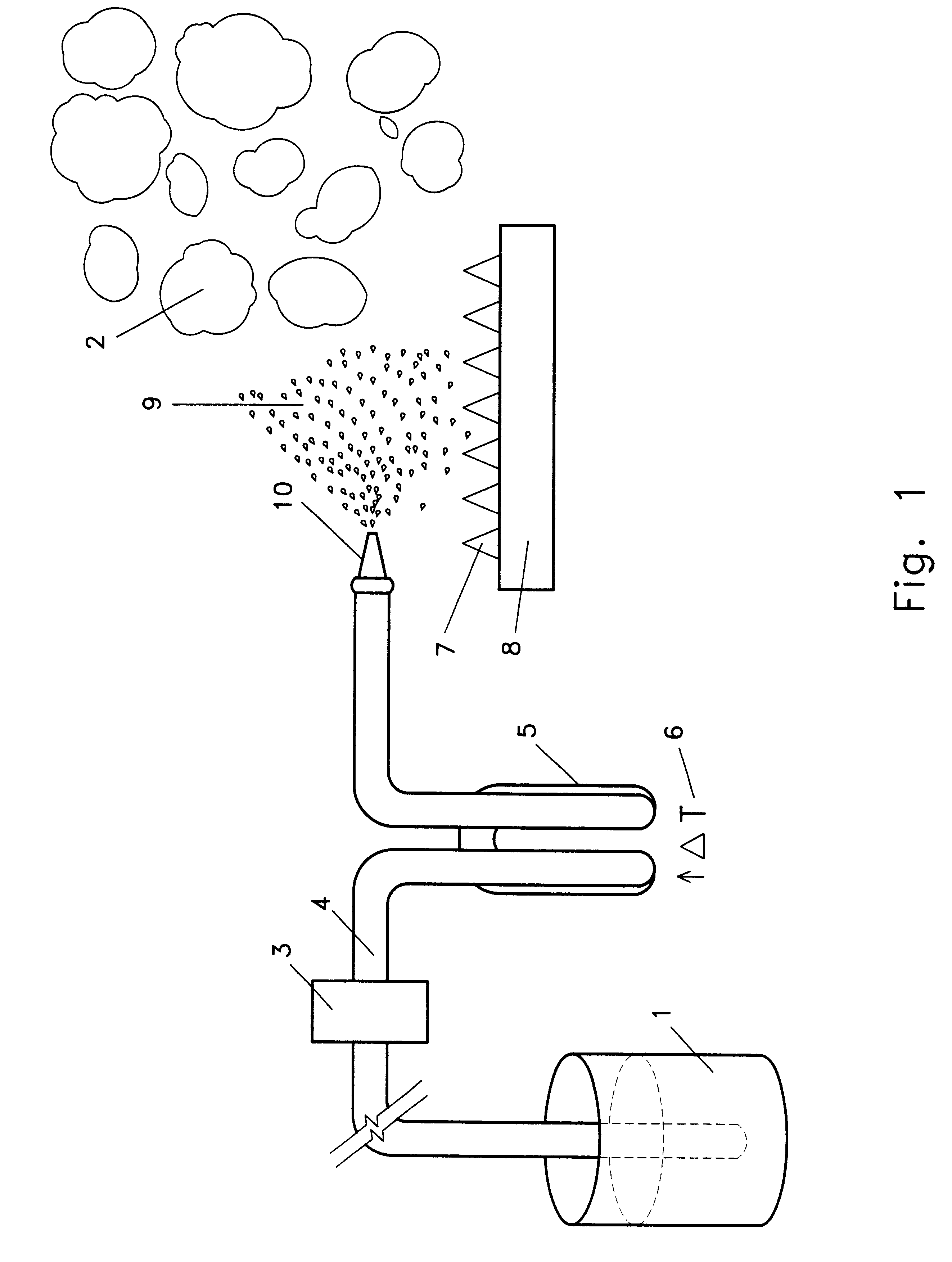

Accelerated water evaporation system

InactiveUS6637379B2Lower the volumeCost effectiveCombustion enginesFlash steam boilersGas to liquidsEvaporation

A liquid to gas converter to convert liquids (1) to gas (2) that can include a liquid pressurization element (3), a liquid preheating element (5), and a nozzle (10) to disperse liquids into energy (7) generated by an energy source (8). The gas to liquid converter can be located inside an enclosure (17) and substances dissolved in the liquid can accumulate as solids (13) on deposition surface (12) of the enclosure as the liquid (1) converts to gas Cis (2). Condensation of a portion of the gas (2) generated can be combined with the solids (13) for continuous removal of such solids (13) from the enclosure (17). A gas expansion compensator can generate a pressure gradient (24) to move the volume of gas generated from the liquid from the enclosure (17).

Owner:RESOURCE WEST

Large scale insulated desalination system

ActiveUS20120085635A1Improve distillation efficiencyLower energy requirementsGeneral water supply conservationAuxillariesDistillationBrackish water

An apparatus and method for the distillation of ocean and brackish water that includes insulation means for preventing heat from escaping to the atmosphere is disclosed. The insulation means comprises a second wall surrounding the basic assemblies of a desalination system in which the space between the second wall and basic assemblies is under low partial vacuum and is partially or totally filled with an insulation material for structural support. The system provides a means for flash evaporation of heated input water and condensing the resultant vapors into pure distilled water. A means for recapturing and using the heat of condensation as well as heat from the salt byproduct to preheat the input contaminated water is also disclosed.

Owner:FLO ONICS LLC

Method and system for separating solids from liquids

A method and system for treating feedwater includes evaporating a portion of the feedwater in a first evaporation chamber so as to separate water vapor from the remaining feedwater. Droplets of the remaining feedwater are dispersed into a stream of hot air produced in a second evaporation chamber. The droplets evaporate and solids in the feedwater precipitate. The precipitated solids are collected in the lower section of the second evaporation chamber. Water vapor discharged from both evaporation chambers can be treated in a cyclone separator to remove residual solids therefrom. The cleansed water vapor output from the cyclone separator can be condensed to recover clean water. Dry solids can be discharged from the second evaporation chamber and the cyclone separator for recovery.

Owner:WATERVAP

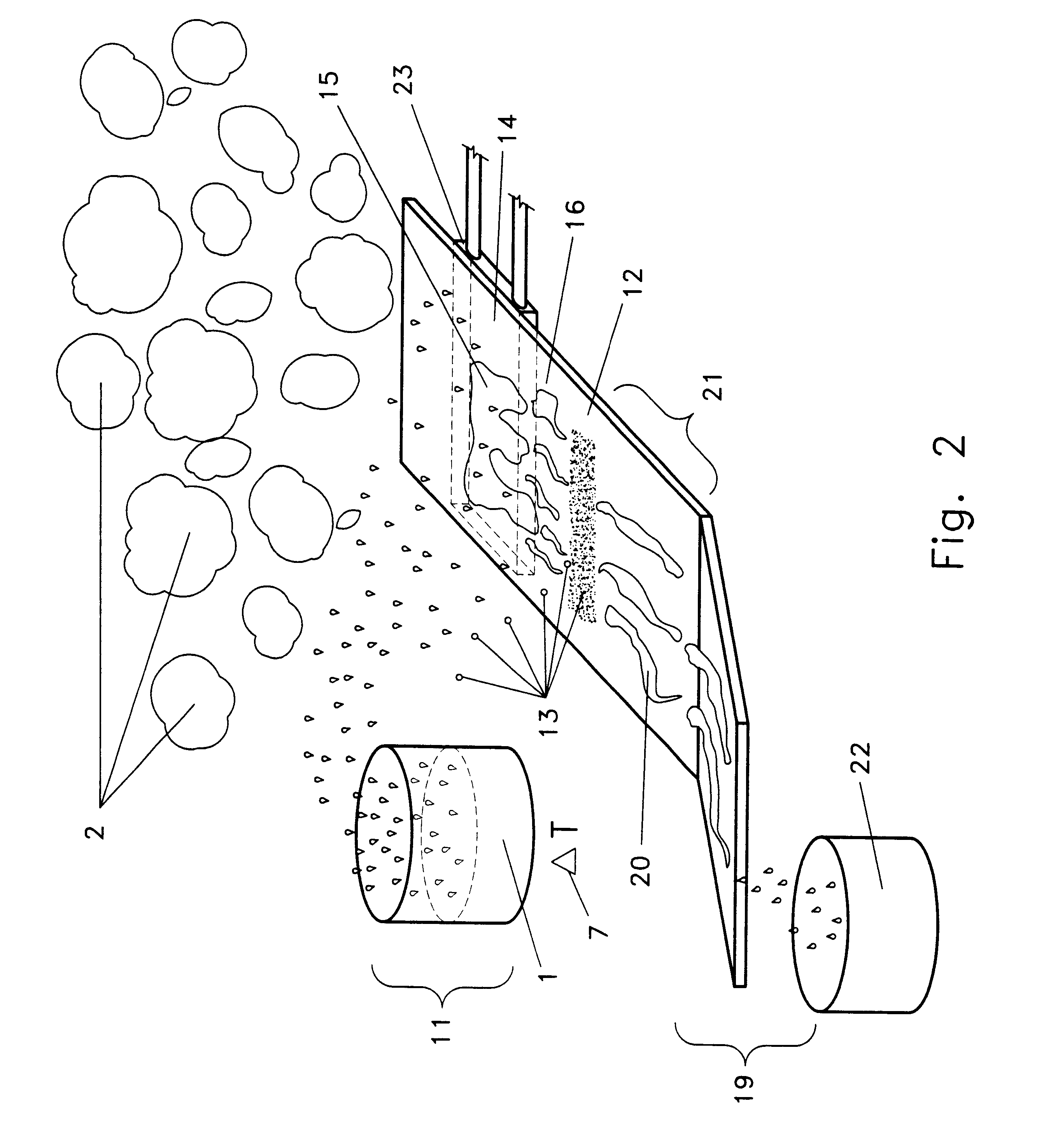

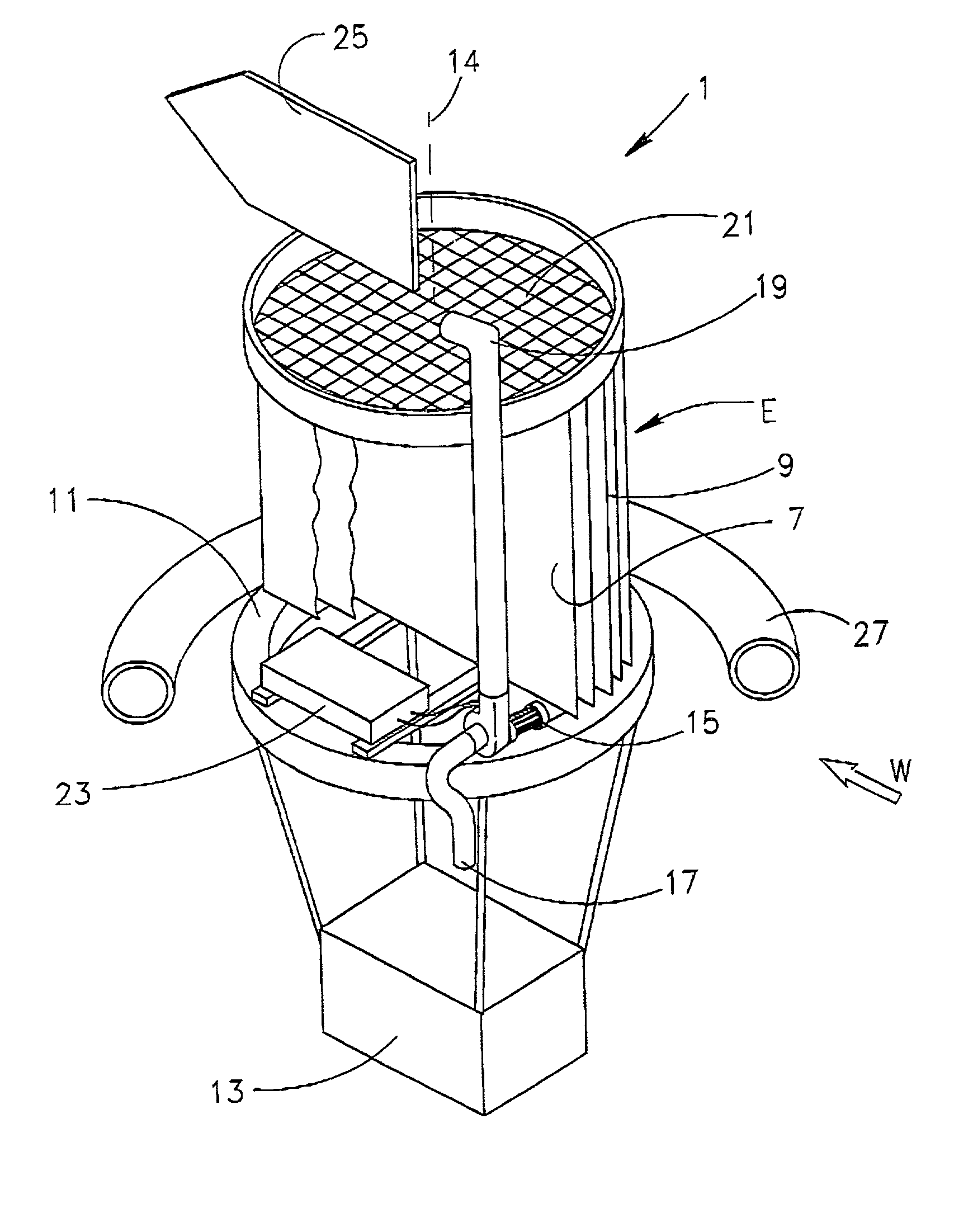

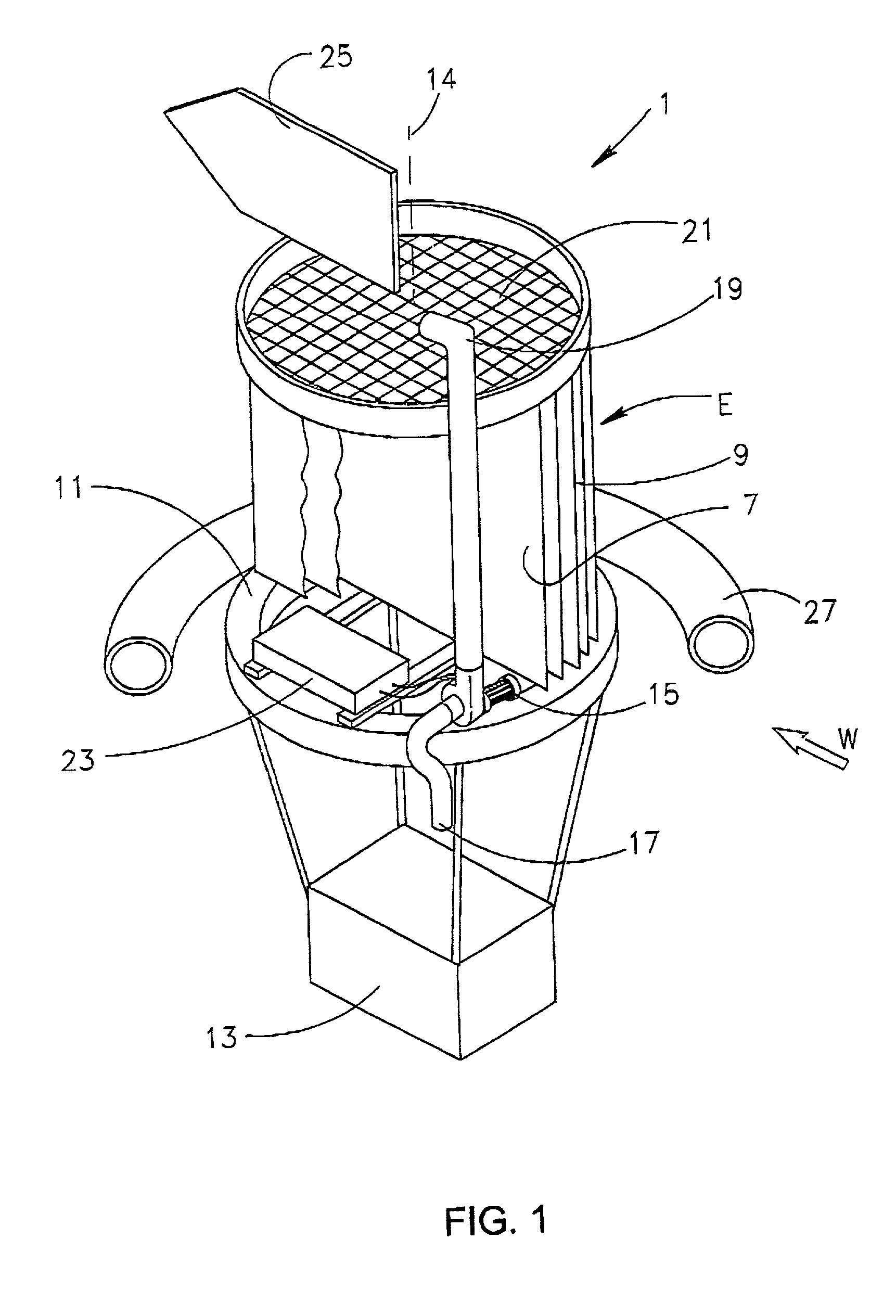

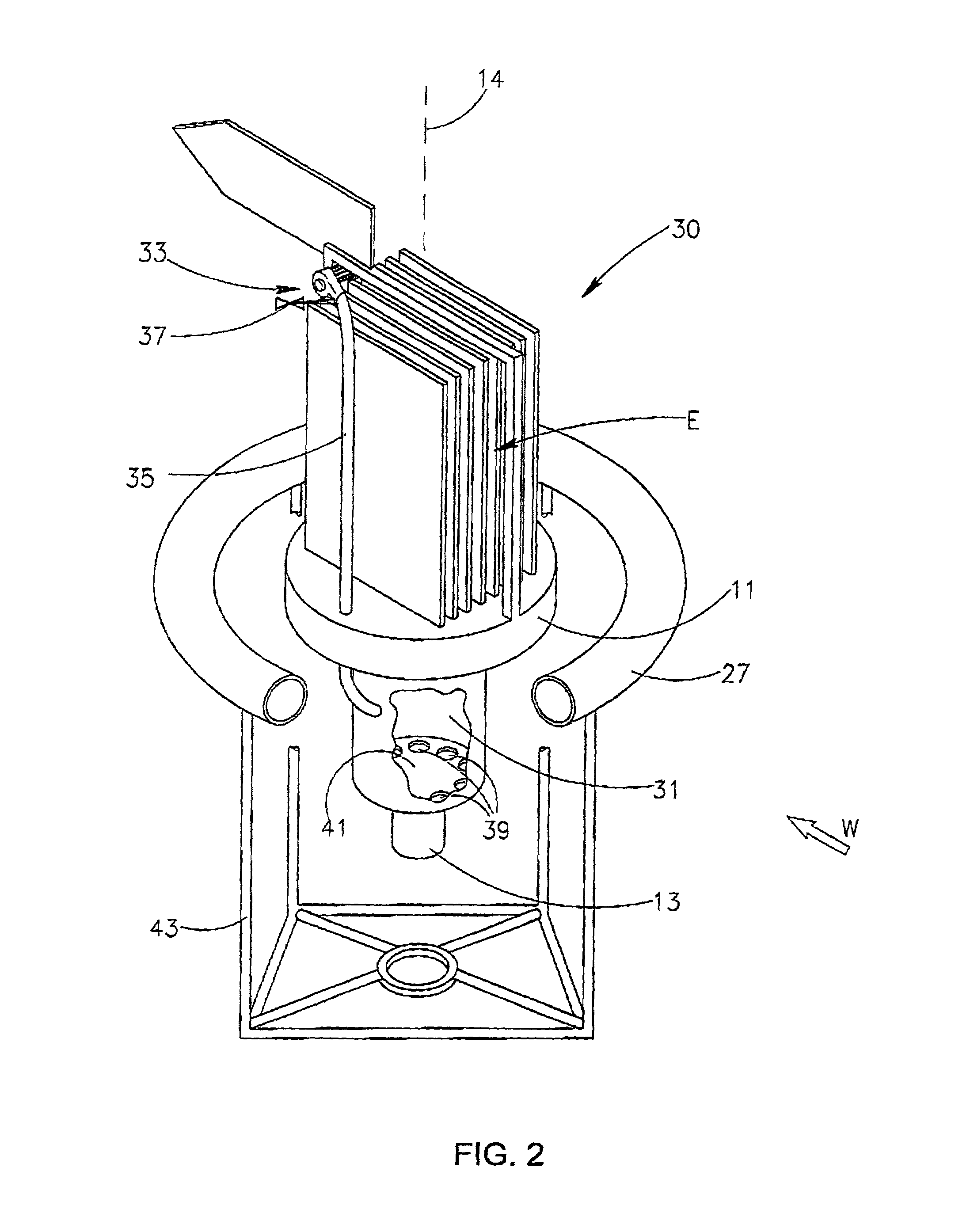

Evaporation device

InactiveUS7166188B2Increase evaporation rateIncrease surface areaDrying solid materials with heatGeneral water supply conservationEvaporationChemistry

An evaporation device for increasing evaporation from a surface of a body of liquid, comprises at least one evaporation element having at least one evaporation surface wettable by the liquid and at least partially exposable to wind when wetted, so as to allow evaporation of the liquid from the evaporation surfaces whereby the total evaporation area of the surface of the body of liquid is increased.

Owner:B G NEGEV TECH & APPL LTD +1

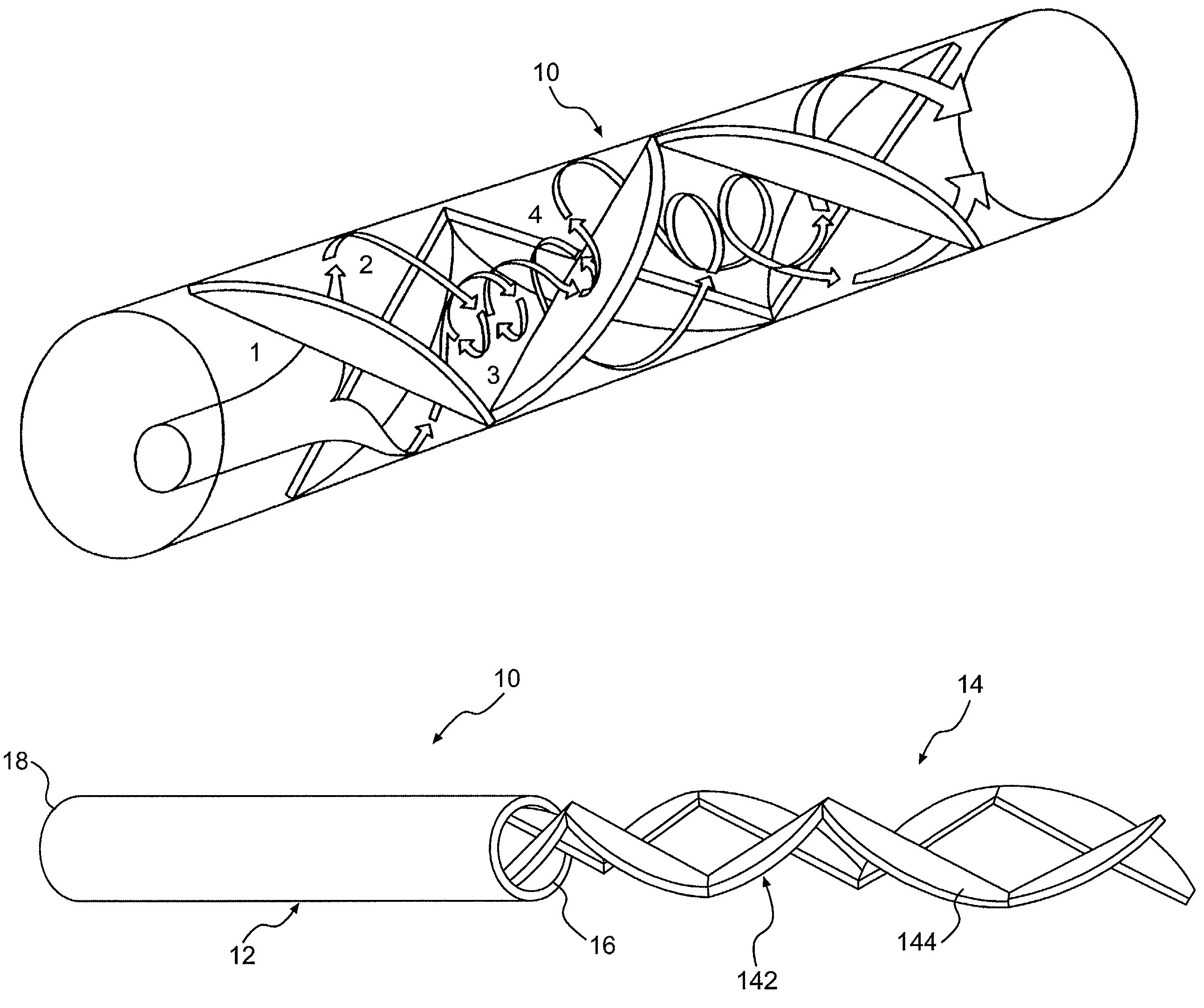

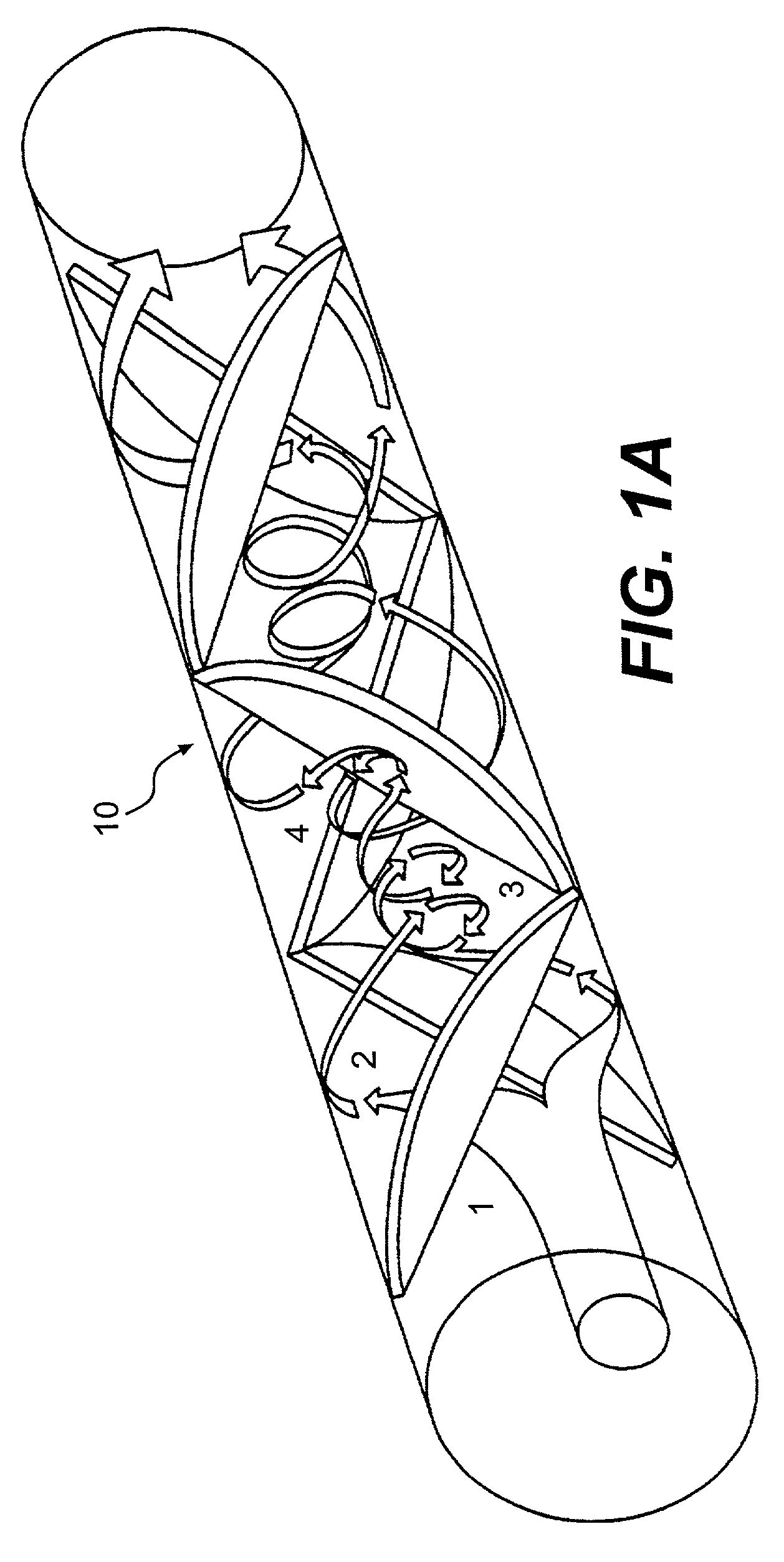

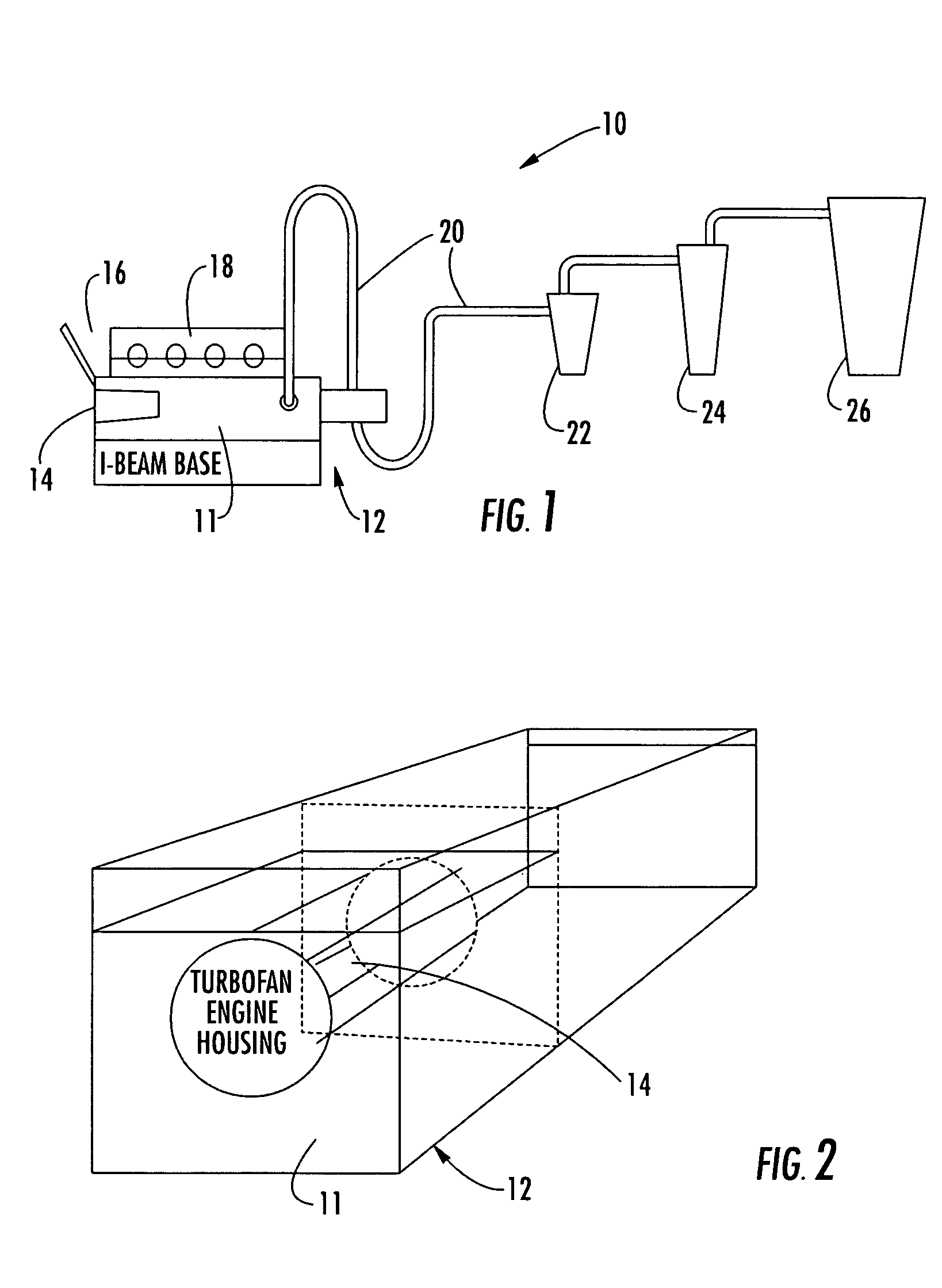

Air dryer system and method employing a jet engine

InactiveUS6944967B1Operate operating costQuality improvementDrying gas arrangementsDrying machines with non-progressive movementsJet engineTurbofan

An air dryer and process employs a jet engine for producing high quality dried products. A turbofan jet engine in an air-drying system uses both thermal and non-thermal air-drying. The turbofan jet engine is housed within an air distribution chamber for directing exhaust air and bypass air from the jet engine into a product drying tube, where it is dried through a combination of thermal drying from heat content in an engine exhaust, and by the kinetic energy of air flowing past the product traveling through the drying tube, that may include a physical impediment for retarding retard the speed of the product solids flowing in the air stream through the tube.

Owner:STAPLES WESLEY A

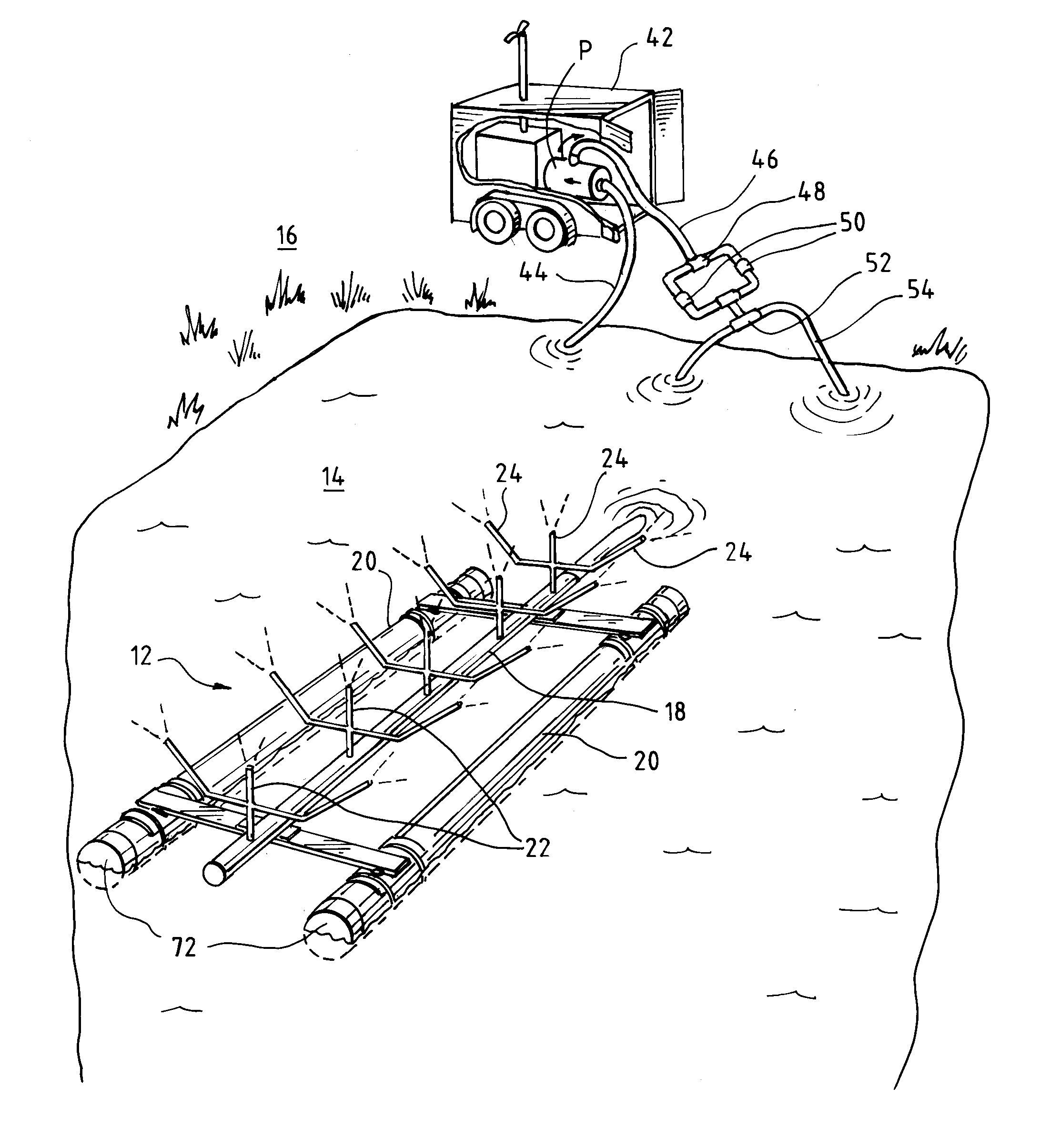

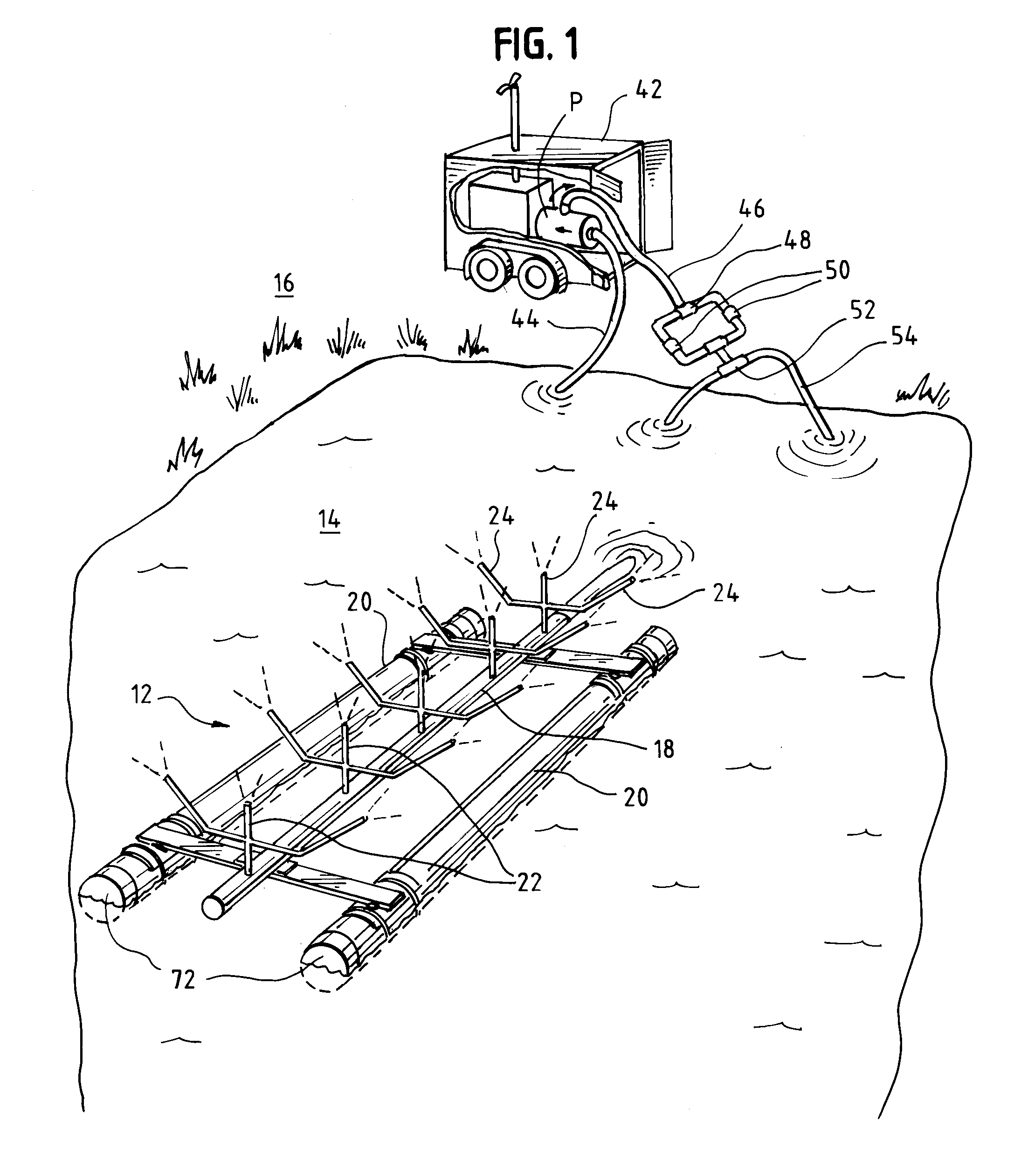

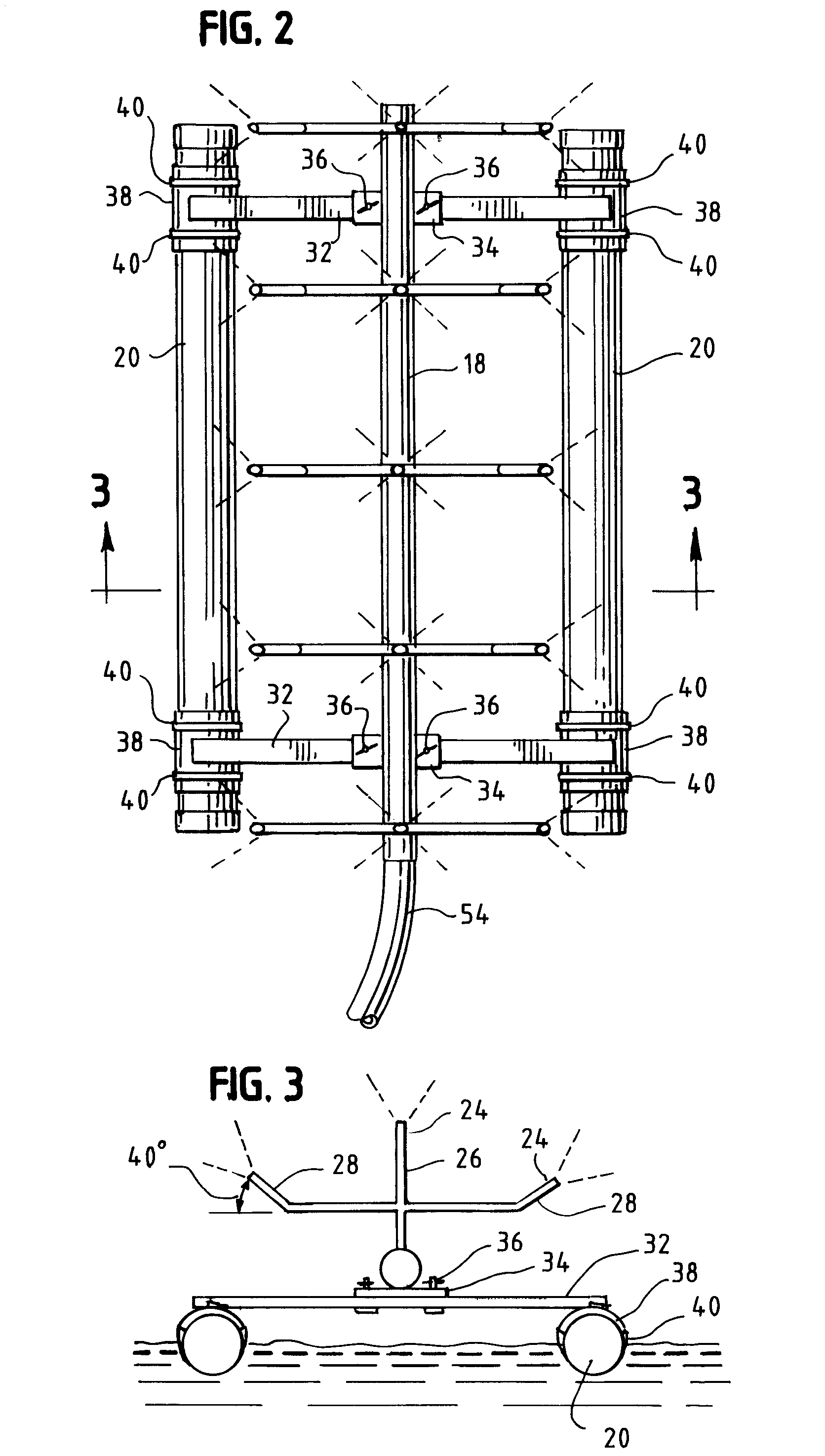

Modular floating water evaporation system

InactiveUS7604710B2Surface area availableMinimize impactDrying using combination processesSolid waste disposalMarine engineeringEvaporation

A floating water evaporation system for use in disposing of excess water from oil and gas drilling operations is provided. One or more nozzle arrays float on the surface of a wastewater pond a distance away from the pond shoreline. Each nozzle array includes a series of upright risers that extend above a water reservoir tank. Spray nozzles are mounted on each riser. The water reservoir tank is mounted between floating pontoons that elevate the nozzles a distance above the surface of the pond. Water from the pond is pumped through the nozzles to create a patterned spray of small evaporable droplets.

Owner:EVAPORITE SYST

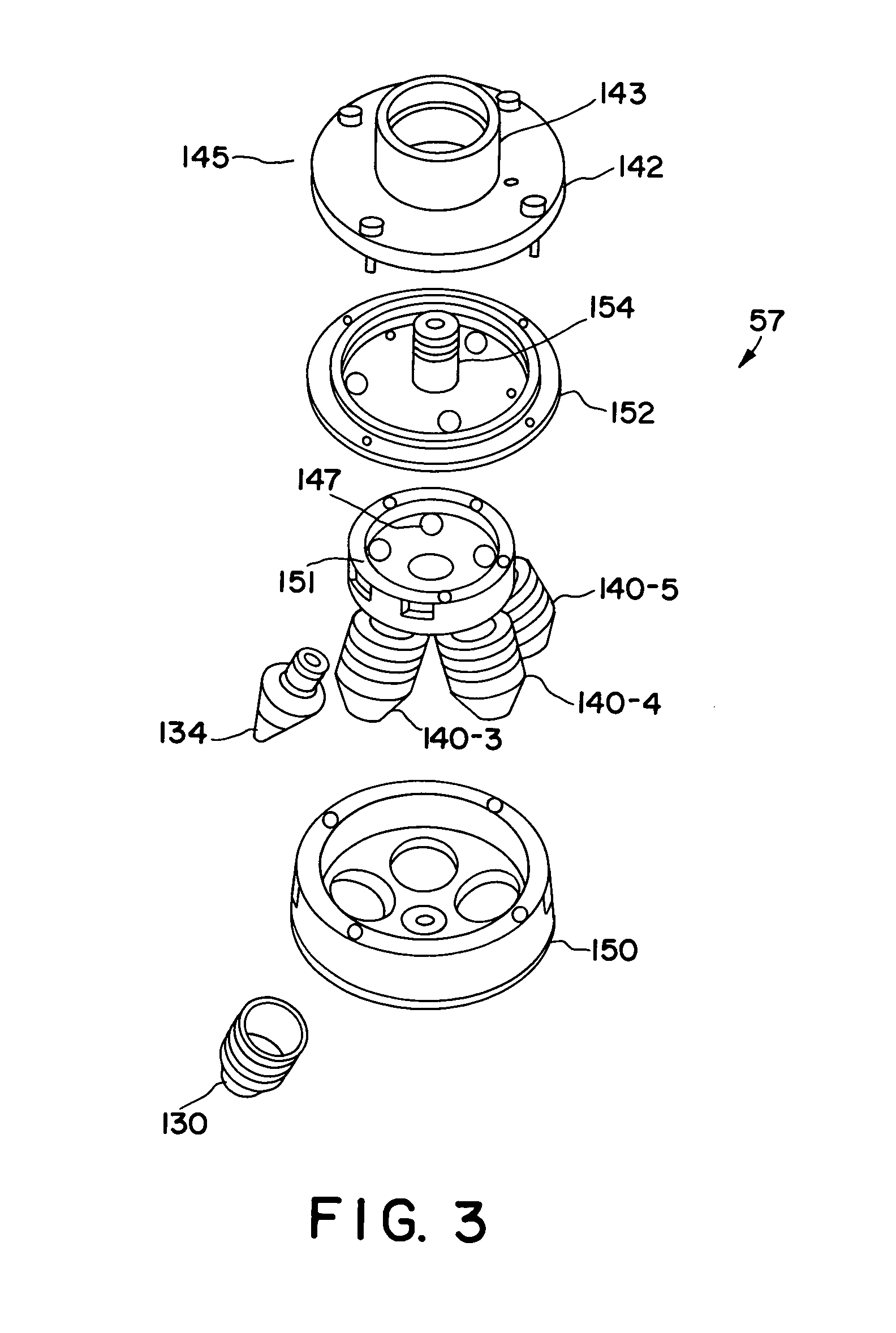

Spray drying methods and related compositions

ActiveUS8524279B2Enabling controlMinimize interactionOrganic active ingredientsPowder deliveryPowder mixtureSpray nozzle

A method and apparatus are provided for atomizing a liquid under dispersal conditions suitable for spray drying at a commercial plant scale. In one embodiment, a liquid atomizer has a structural body adapted for connection with a spray dryer and a plurality of atomizing nozzles. Each of the atomizing nozzles includes a liquid nozzle adapted to disperse a supply of liquid and a gas nozzle adapted to disperse a supply of gas. In another embodiment, a process for producing a powder blend of at least two target substances in a single processing step is provided.

Owner:NOVARTIS AG

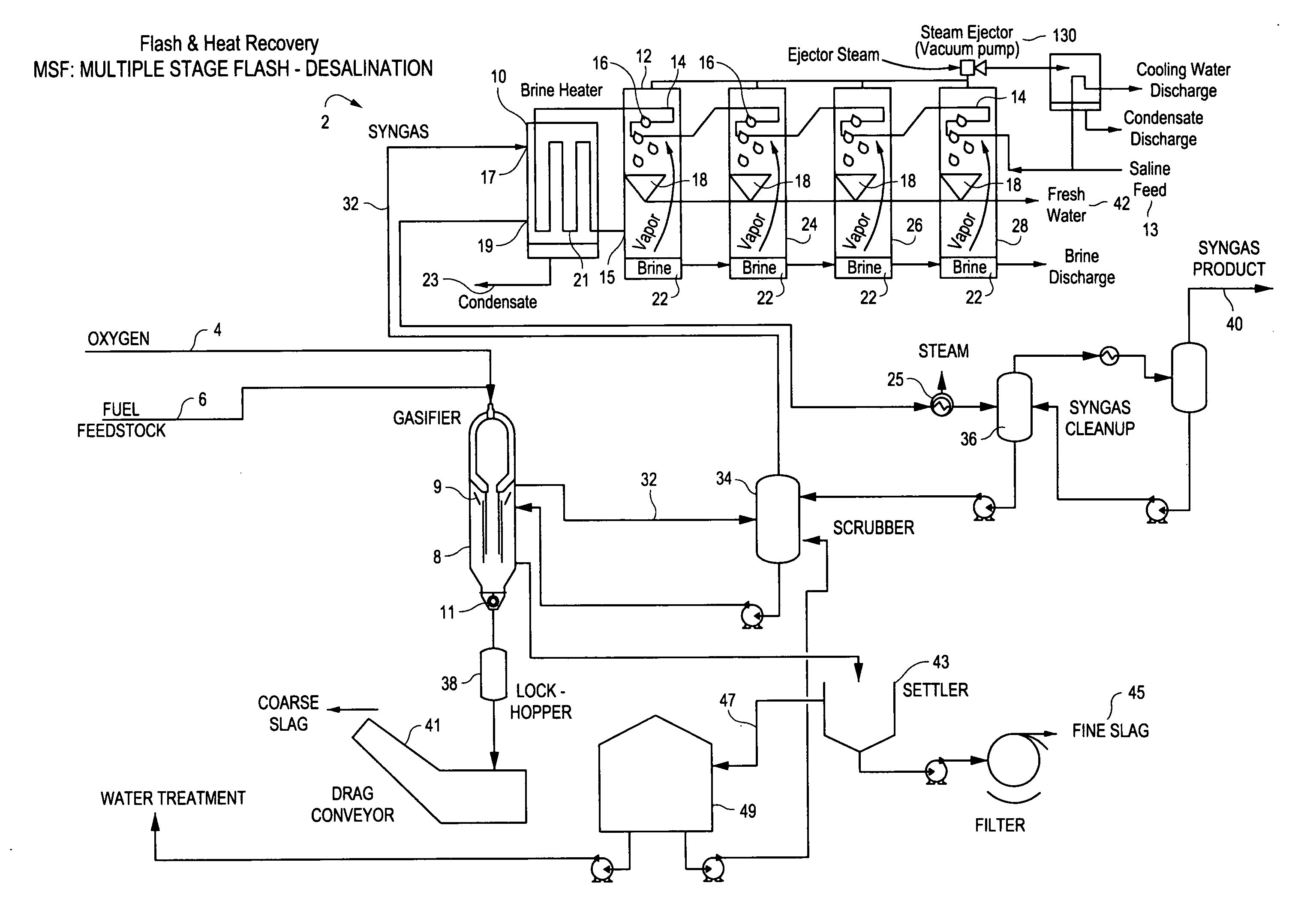

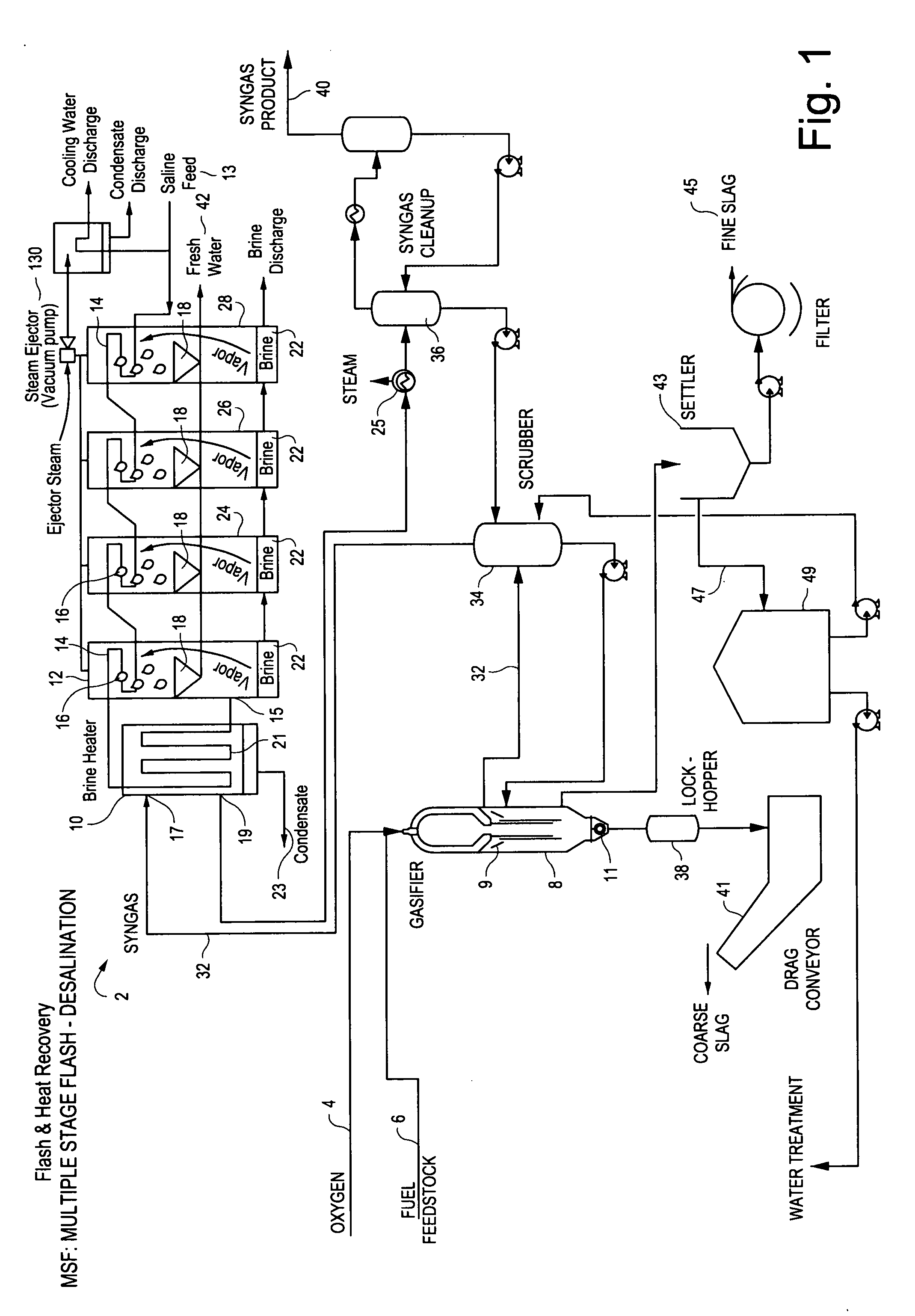

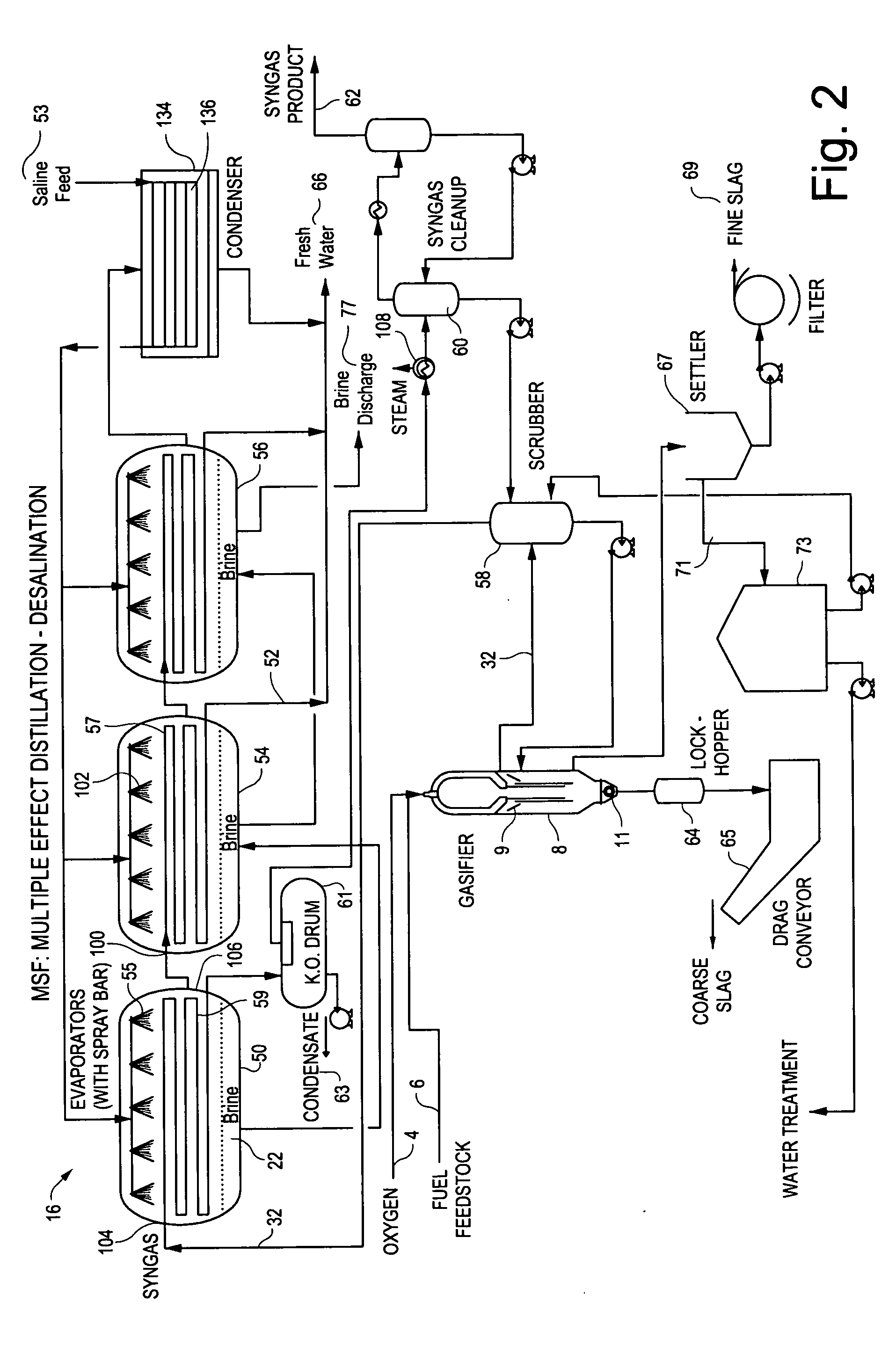

Salt water desalination using energy from gasification process

InactiveUS20110162952A1Improve thermal efficiencyLow costAuxillariesGeneral water supply conservationProcess systemsSaline water

System and process for producing no-salt water by desalination of salt water, by heating salt water directly with heated synthetic gas produced in a gasification reaction or by using steam produced using heated synthetic gas, to evaporate the salt water and produce no-salt water.

Owner:GENERAL ELECTRIC CO

Entire closed-loop circulating fluidized bed as well as usage and application method thereof

ActiveCN105641961AImprove utilizationFast exchangeDrying solid materials with heatDrying gas arrangementsDistillationHigh energy

The invention provides an entire closed-loop circulating fluidized bed as well as usage and an application method thereof. Third generation circulating fluidized bed equipment is improved, the problems of high energy consumption and high processing cost and the like caused by moisture and slow heat exchange speed between materials and working mediums in prior process methods, such as drying, crushing, evaporation, distillation, condensation, gasification, liquefaction, and other operations are solved; entire closed circulation work and rapid normal temperature work of scaled materials are economically realized, and an economically feasible solution scheme is provided for developing works, such as improvements of output and quality of foodstuff, medicine, chemical products and other basic raw material products, as well as energy saving and consumption reduction, cleaning production, etc.

Owner:KUNMING TEKANG TECH CO LTD

Micro liquid evaporator

InactiveUS6620620B1Accurate measurementReduce the amount requiredAnalysis using chemical indicatorsLevel controlBoiling pointEvaporation

The drop-by-drop evaporation of a liquid or solution is controlled by monitoring the disappearance of each successive droplet and by actuating the deposition of the next droplet until the desired volume is deposited. In the case of a solution, non-volatile residue (NVR) is collected on a deposition surface plate as a relatively small mound. One of a variety of methods may be employed to measure the evaporative behavior of each droplet and to key the deposition procedure. The process is preferably carried out employing a clean deposition surface plate that is maintained at or below the boiling point of the particular liquid or solvent being deposited. The environment is preferably controlled so that inadvertent contamination is precluded from interfering, and thus the method permits the automatic, micro-processor controlled evaporation of liquids with the resultant deposition of non-volatile residues from solutions within relatively short periods of time. The deposited residue may then be quantified at levels down to and below about 1 ug / mL (1 mg / L) by one of several means for determining the amount of non-volatile residue remaining.

Owner:ERA SYSTEMS CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com