Autoclave curing-free, light and ultrahigh-strength concrete and preparation method thereof

An ultra-high-strength concrete and steam-free technology, which is applied in the field of building materials, can solve the problems of prefabricated components such as size and weight, large shrinkage, and blockage of existing roads, so as to achieve excellent work performance and durability, improve durability, and improve The effect of flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

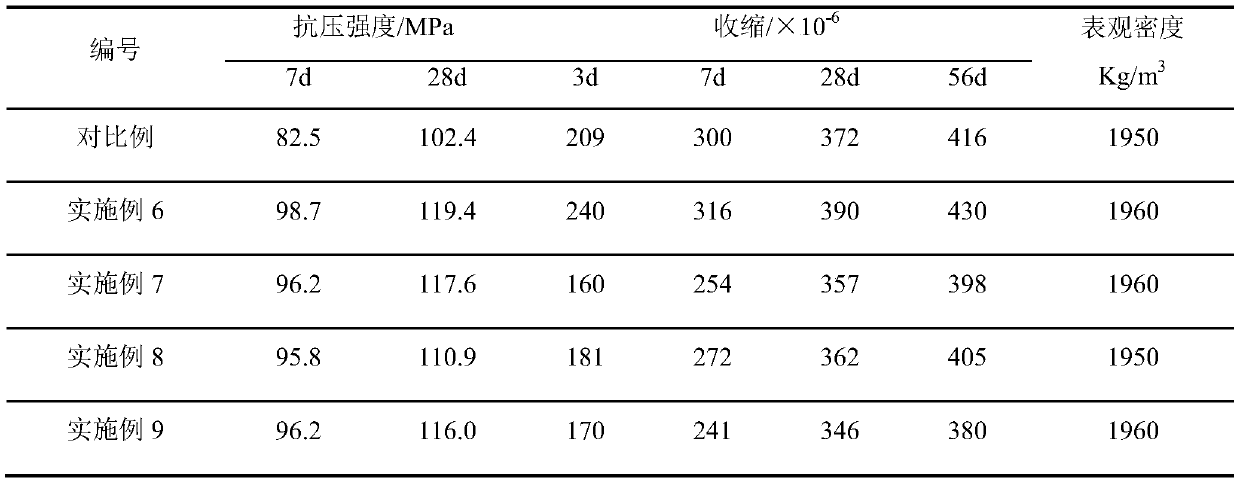

Examples

Embodiment 1

[0070] A preparation method of high-strength porous microspheres, the specific steps are:

[0071] 1) Coal gangue powder, soft kaolin powder, dolomite powder and limestone powder are mixed uniformly in a mixer in a mass ratio of 75:10:12:3;

[0072] 2) Add water with 30% of the total mass of the powder, and stir with the evenly mixed powder in a planetary mixer for 200 seconds, then let it stand for 2 hours to obtain a mud base for firing high-strength porous microspheres;

[0073] 3) Put the obtained mud base into a ball forming machine to prepare a continuously graded spherical plastic mud mass of 4.75mm to 9.5mm, and place it at room temperature for 8 hours;

[0074] 4) Calcining the plastic mud mass in step 3), the calcination system is: heat up to 110°C at a heating rate of 5°C / min for pre-calcination, and keep it warm for 20 minutes; continue to heat up to 900°C at a heating rate of 5°C / min ℃ for calcination, and keep it warm for 15 minutes; then increase the temperature ...

Embodiment 2

[0076] A preparation method of interface modified emulsion A, the concrete steps are:

[0077] 1) Dissolve sodium hydroxide in deionized water, heat to 60°C, add emulsifier alkylphenol polyoxyethylene polyoxypropylene ether and dissolve evenly to obtain mixed solution I;

[0078] 2) heating and melting palmitic acid at 60° C. to obtain palmitic acid liquid;

[0079] 3) Slowly add the mixed solution I into the palmitic acid liquid, carry out saponification reaction at 80° C., and stir for 30 minutes;

[0080] 4) Cool the soap liquid obtained in step 3) to 25°C, slowly add ammonia water under stirring until the ammonia water is added, and a uniform emulsion is obtained;

[0081] 5) Slowly add 200-mesh natural zeolite powder into the emulsion prepared in step 4), and stir until the zeolite powder is evenly dispersed to obtain an interface-improving emulsion A agent.

[0082] Among them, the mass ratio of palmitic acid, ammonia water, sodium hydroxide, deionized water, 200 mesh ...

Embodiment 3

[0084] A preparation method of interface modified emulsion B, the concrete steps are:

[0085] 1) Add polyvinyl alcohol with a degree of alcoholysis of 80% to 1 / 2 mass of deionized water, heat and dissolve in a water bath at 80°C to obtain a polyvinyl alcohol solution;

[0086] 2) Slowly pour xanthan gum into the polyvinyl alcohol solution obtained in step 1), and then add the remaining deionized water and stir to obtain the interface-improving emulsion B agent.

[0087] The mass ratio of polyvinyl alcohol, deionized water, and xanthan gum having an alcoholysis degree of 80% is 22:75:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com