High-purity low-aluminum type spherical beta silicon nitride powder as well as manufacturing method and application thereof

A silicon nitride powder, spherical-like technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of reduced reliability, chips restricting the development of electronic products, and the use temperature cannot be higher than 80 °C, and achieves The effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1 The improved combustion synthesis method prepares the method for the beta silicon nitride of high sphericity, low Al

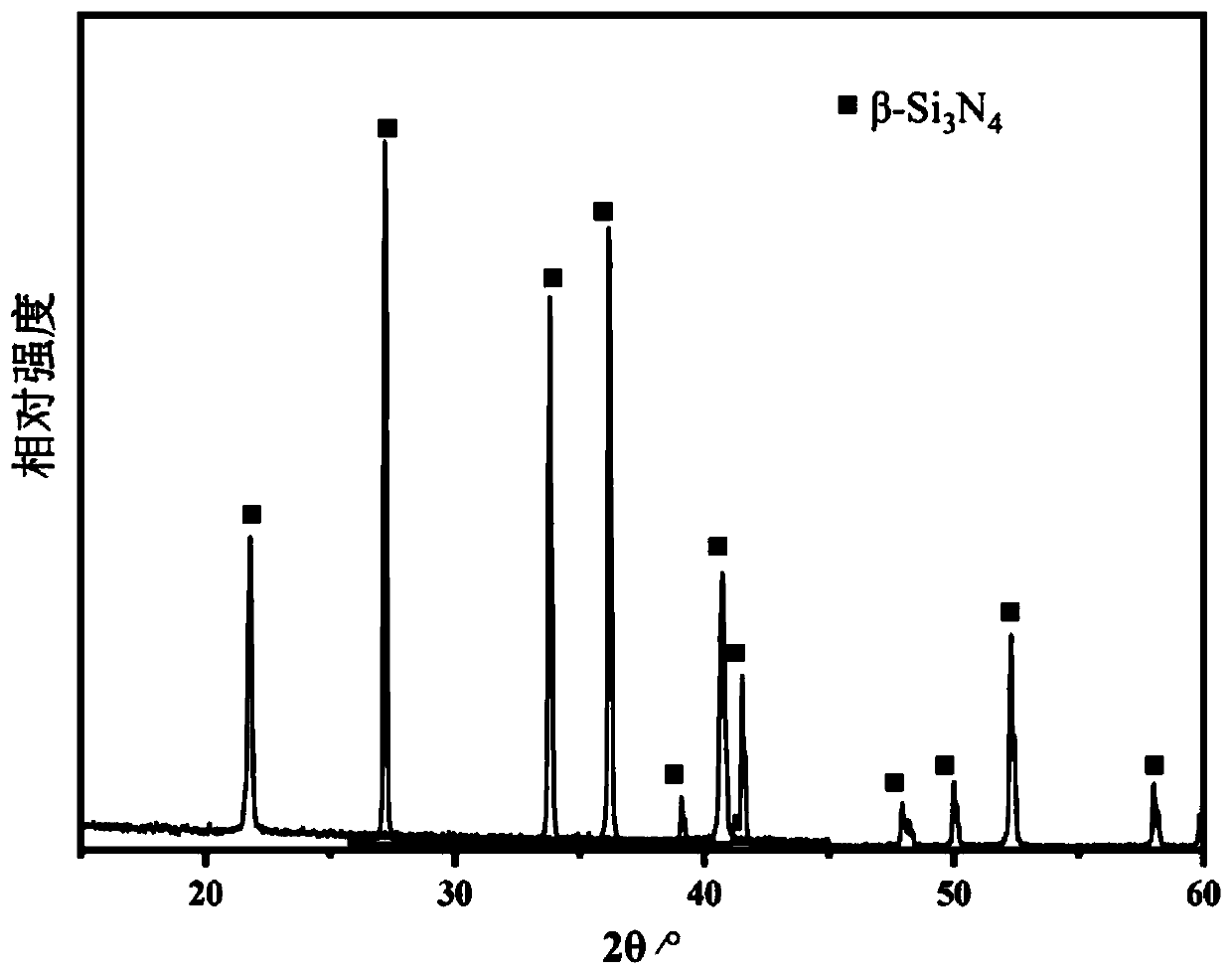

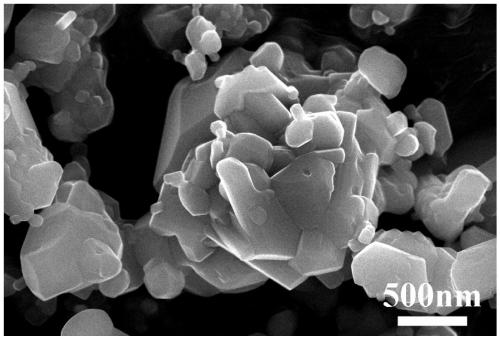

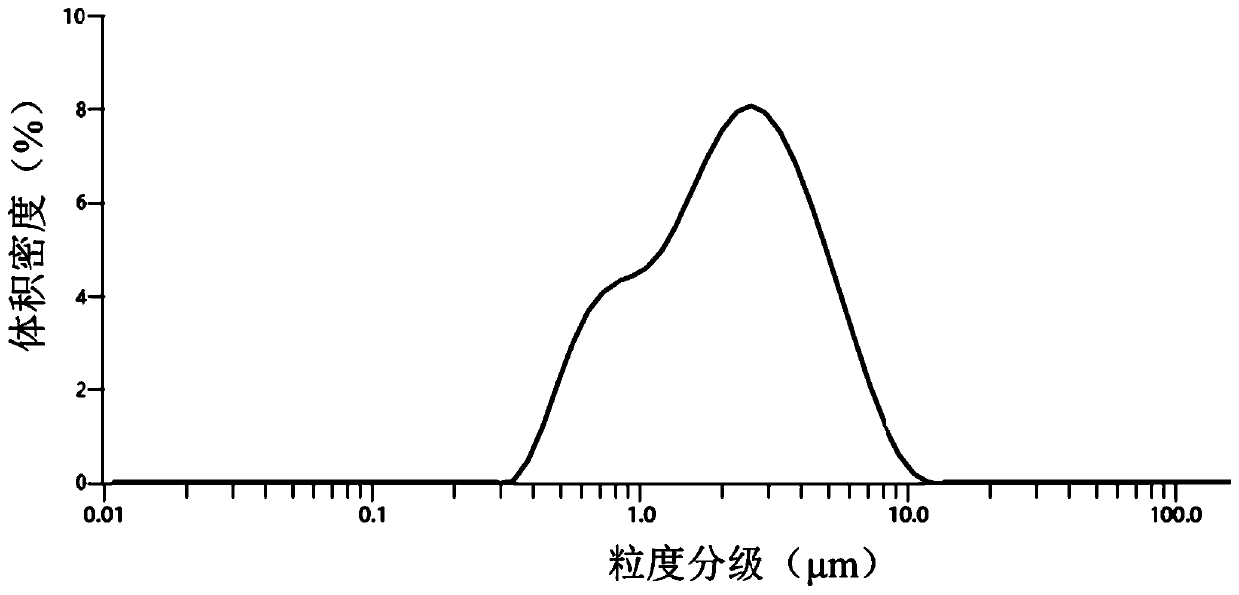

[0095] The silicon powder is pickled with hydrofluoric acid and nitric acid to obtain low-aluminum high-purity silicon powder (2 Content>99.999vol%)N 2 Under the atmosphere, ignite at one end to initiate a self-propagating reaction, and the reaction is completed when the sample is extended from one end to the other end, and the β-silicon nitride powder is obtained. The XRD of the powder is as follows: figure 1 shown (by figure 1 It can be seen that the silicon nitride obtained in Example 1 is almost all β-phase); the resulting product is ball-milled in a non-Al lining such as nylon or polyurethane, and the balls are made of silicon nitride balls, milled for 4 hours to obtain a particle size of 2.15 μm , β-silicon nitride powder with a sphericity of 0.89, the powder morphology and particle size are as follows figure 2 and 3 As shown; the...

Embodiment 2

[0096] Example 2 The method for preparing high sphericity and low Al beta silicon nitride by improved carbothermal reduction method

[0097] Using low-aluminum carbon powder (<500ppm) and low-aluminum amorphous silicon oxide (<500ppm) powder as raw materials with a mass ratio of 1:2, add low-aluminum calcium carbonate additive (<500ppm), and the addition ratio accounts for 10mol of the total mass of raw materials %. The above raw materials were mixed with water, prepared into a slurry with a solid content of 30vol%, ball milled for 24 hours, dried and ground. The above raw materials were placed in a gas pressure sintering furnace for carbothermal reduction reaction at a temperature of 1800° C., a nitrogen pressure of 4 MPa, and a reaction time of 2 h. The obtained product was placed in a muffle furnace, kept at 650°C for 5 hours to remove excess carbon, and a high-purity β-silicon nitride powder with a sphericity of 0.93, a particle size of 9.02 μm, and an aluminum content of...

Embodiment 3

[0098] Example 3 Improved granulation and sintering method to prepare high sphericity, low Al β silicon nitride method

[0099] Using low-Al α-silicon nitride (<500ppm) powder as raw material, add 5wt% of low-alumina yttrium oxide (<500ppm) and 5wt% of low-alumina alumina (<500ppm) additives, the addition ratio accounts for the total mass of raw materials 1wt% dispersant and 2wt% binder PVB were formulated into a slurry with a solid content of 30vol%, and ball milled for 24 hours to mix evenly. The ball-milled slurry is subjected to spray granulation to prepare spherical α-silicon nitride granulated powder. The various parameters of the spray granulation process used are: the hot air inlet temperature is 150°C, the exhaust air temperature is 50°C, and the rotational speed of the centrifugal disk of the atomizer is 6000rpm. The granulated powder was placed in a crucible, and sintered in a gas pressure sintering furnace at a temperature of 1800° C., a nitrogen pressure of 4 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com