Ultrahigh-performance concrete doped with steel residues and preparation method of ultrahigh-performance concrete

An ultra-high-performance concrete technology, applied in the field of materials, can solve problems such as water pollution, soil occupation, and pollution, and achieve the effects of large amount of steel slag mixing, good fluidity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

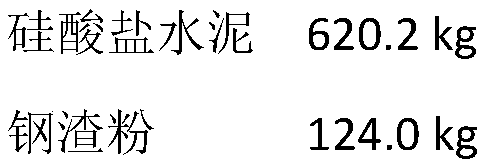

[0030] Each component is uniformly mixed according to the following ratio to obtain the ultra-high performance concrete mixed with steel slag of the present invention:

[0031]

Embodiment 2

[0033] Each component is uniformly mixed according to the following ratio to obtain the ultra-high performance concrete mixed with steel slag of the present invention:

[0034]

Embodiment 3

[0036] Each component is uniformly mixed according to the following ratio to obtain the ultra-high performance concrete mixed with steel slag of the present invention:

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com