Pre-vulcanized natural rubber latex/chitosan blended membrane material and preparation method thereof

A technology of natural latex and chitosan, applied in natural rubber coatings, chitin coatings, hyaluronic acid coatings, etc., can solve the problem that it is not suitable for ion deposition method or direct dipping method or casting method or extrusion latex products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

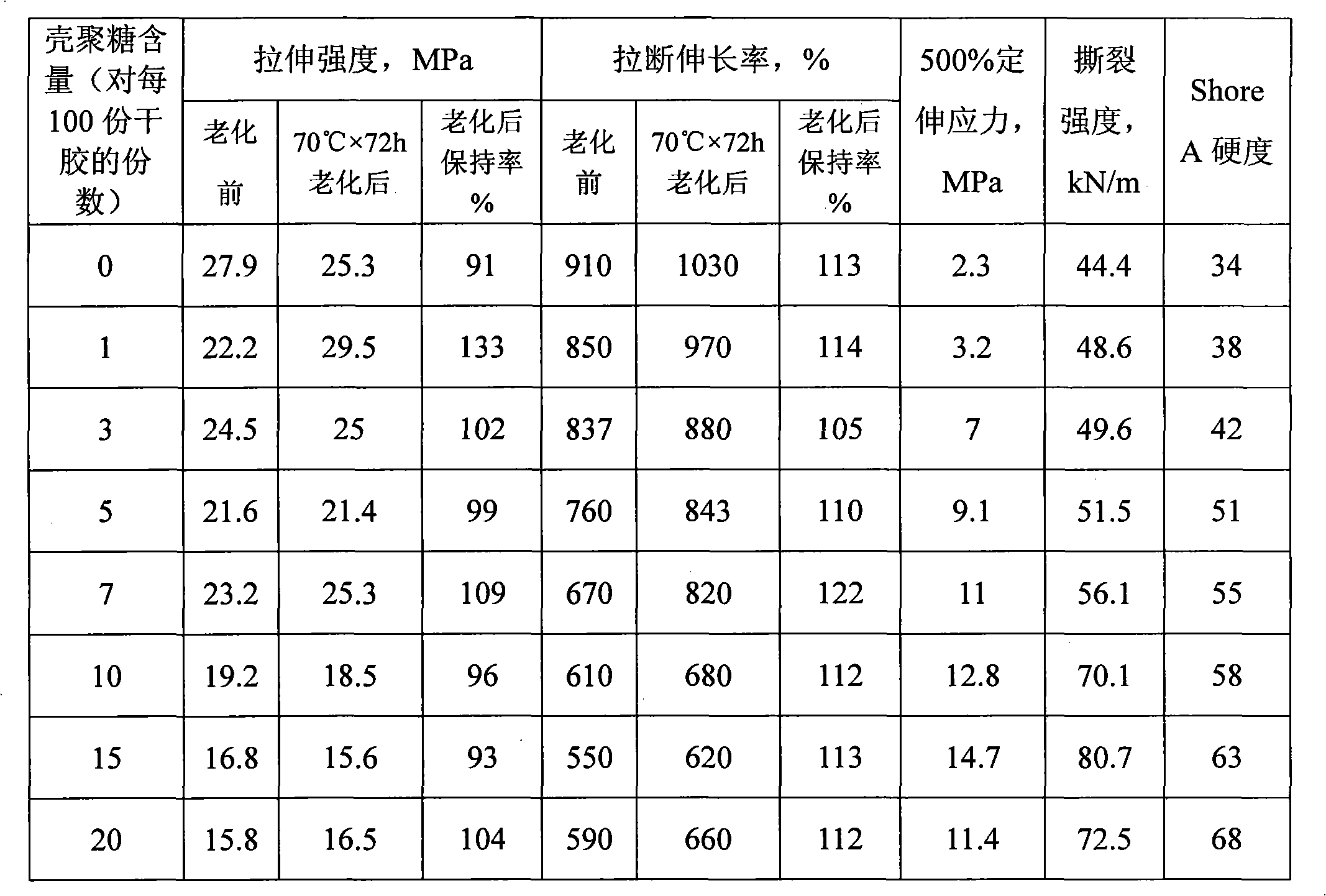

Examples

Embodiment 1

[0029] a. After stabilizing the concentrated natural rubber latex with a dry rubber content of 100 parts, add the mixed vulcanizing agent dispersion, heat at 60°C for 2 hours, and after standing for 3 days, filter to obtain pre-vulcanized natural rubber latex. The amount added is concentrated natural latex dry rubber 1.0% of anti-aging agent Wingstay L, spare.

[0030] b. Add 2.0 parts of fatty alcohol polyoxyethylene ether with a concentration of 10% to the pre-vulcanized latex prepared in "a", and continue stirring for 0.5h, then quickly add acetic acid with a concentration of 36% under high-speed stirring, and The pH is adjusted to 4 to obtain acidified pre-vulcanized natural rubber latex.

[0031] c. Dissolving 1 part, 3 parts and 5 parts of chitosan with a deacetylation degree greater than 90% with 1% acetic acid solution respectively to form a 2% chitosan acetic acid solution.

[0032] d. Add the chitosan dilute acetic acid solution prepared in "c" into the acidified pre-...

Embodiment 2

[0036] a. After stabilizing the concentrated natural rubber latex with a dry rubber content of 100 parts, add the mixed vulcanizing agent dispersion, heat at 60°C for 2 hours, and after standing for 3 days, filter to obtain pre-vulcanized natural rubber latex. The amount added is concentrated natural latex dry rubber 1.0% of anti-aging agent Wingstay L, spare.

[0037] b. Add 2.5 parts of fatty alcohol polyoxyethylene ether with a concentration of 10% to the pre-vulcanized latex prepared in "a", and continue stirring for 0.5 to 1.0 hours, then quickly add acetic acid with a concentration of 36% under high-speed stirring , adjust its pH to 4 to obtain acidified pre-vulcanized natural rubber latex.

[0038] c. Dissolving 7 parts and 10 parts of chitosan with a degree of deacetylation greater than 90% with 1% acetic acid solution respectively to form a 2% chitosan acetic acid solution.

[0039] d. Add the dilute chitosan acetic acid solution prepared in "c" into the acidified pr...

Embodiment 3

[0042] a. After stabilizing the concentrated natural rubber latex with a dry rubber content of 100 parts, add the mixed vulcanizing agent dispersion, heat at 60°C for 2 hours, and after standing for 3 days, filter to obtain pre-vulcanized natural rubber latex. The amount added is concentrated natural latex dry rubber 1.0% of anti-aging agent Wingstay L, spare.

[0043] b. Add 3.0 parts of fatty alcohol polyoxyethylene ether with a concentration of 10% to the pre-vulcanized latex prepared in "a", and continue stirring for 0.5 to 1.0 hours, then quickly add acetic acid with a concentration of 36% under high-speed stirring , adjust its pH to 4 to obtain acidified pre-vulcanized natural rubber latex.

[0044] c. Dissolving 15 parts and 20 parts of chitosan with a degree of deacetylation greater than 90% with 1% acetic acid solution respectively to form a 2% chitosan acetic acid solution.

[0045] d. Add the chitosan dilute acetic acid solution prepared in "c" into the acidified p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com