Decorative wall leather and its making method

A decorative and wall leather technology, applied in the production process of artificial leather materials for walls, can solve the problems of low flame retardancy, easy aging, poor light resistance, etc., and achieve good mildew and moisture resistance and long anti-aging life , The effect of short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

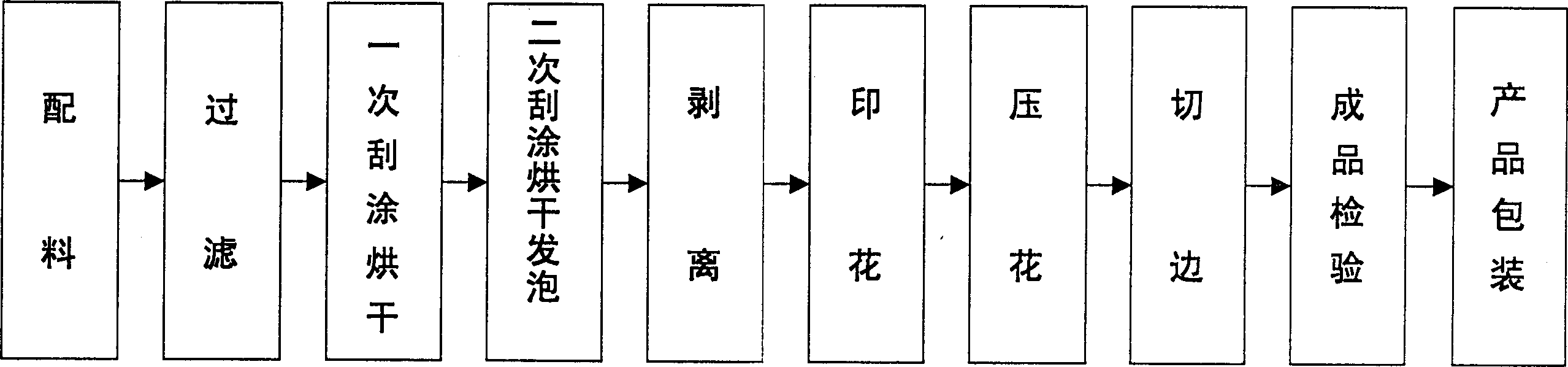

Image

Examples

Embodiment Construction

[0026] A decorative wall leather composition, the composition of the inner surface and the bottom layer is compounded by a scraping process, and the preferred raw material components (parts by weight) used to form the composition of the surface layer: PVC base material 100 wherein: Emulsion polyvinyl chloride (K=70~80) 70

[0027] Emulsion method polyvinyl chloride (K=62~67) 30 diisodecyl phthalate 35 chlorinated paraffin (52°C) 20 barium-zinc liquid composite stabilizer 2 azodicarbonamide 2 heavy calcium carbonate 20 oxidation Antimony (containing antimony 95%) 3 oil-soluble dry film antifungal agent 1 silicone oil 1 non-azo heavy metal-free organic and inorganic pigment 20 used to form the preferred raw material components (parts by weight) of the bottom composition: PVC base material 100 wherein : Emulsion polyvinyl chloride (K=70~80) 0

[0028] Emulsion method polyvinyl chloride (K=62~67) 100 diisodecyl phthalate 40 chlorinated paraffin (52°C) 25 barium-zinc liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com