Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121 results about "Diisodecyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diisodecyl phthalate (DIDP) is a commonly used plasticizer used in the production of plastic and plastic coating to increase flexibility. It is a mixture of compounds derived from the esterification of phthalic acid and isomeric decyl alcohols.

Pipette tip

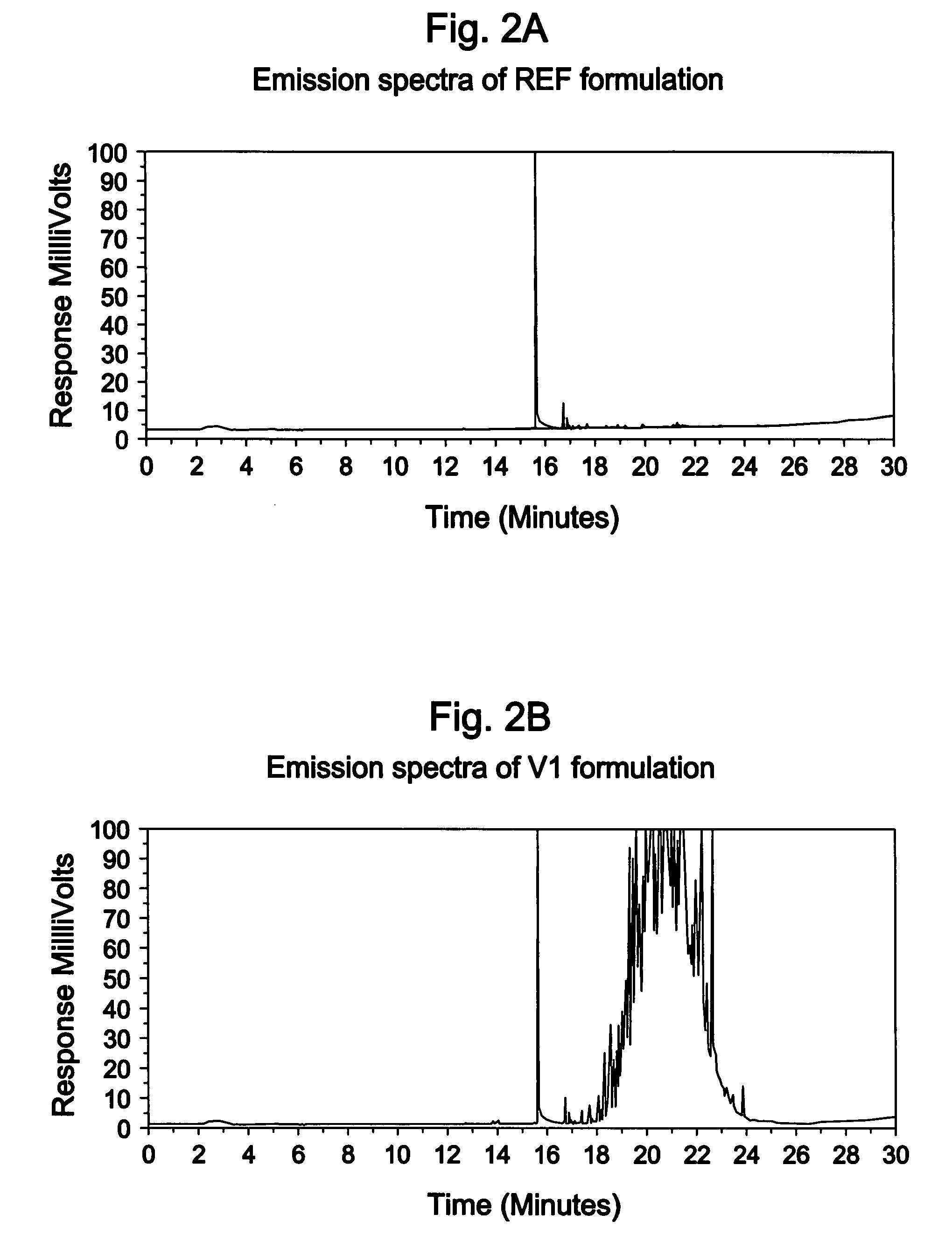

InactiveUS20090202392A1Reliable distributionAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipette1,3-Butanediol

A pipette tip formed by a polypropylene substrate coated with a water repellent agent. The water repellent agent contains a silicone resin containing at least one specific substance selected from the group consisting of diisononyl phthalate, diisodecyl phthalate, trioctyl trimellitate and poly (1,3-butanediol adipate). The total mass of the specific substance is 1-30 mass % of the silicone resin.

Owner:FUJIFILM CORP

Plasticiser compositions

C9 to C11 alkyl benzoates are used as plasticisers for polyvinyl chloride in particular in combination with plasticisers such as di-2-ethyl hexyl phthalate, diisononyl phthalate, di-2-propyl heptyl phthalate, diisodecyl phthalate or di-2-ethyl hexyl terephthalate. The use of the C9 to C11 alkyl benzoates provides low viscosity low volatility plasticisers, which are fast fusing with lower hot bench gelation temperature and which can be used to reduce the staining problems associated with use of di-2-ethyl hexyl phthalate and diisononyl phthalate. The low viscosity of the C9 to C11 alkyl benzoates allows the formulation of solvent free flexible PVC formulations meeting stringent VOC limitations.

Owner:EXXONMOBIL CHEMICAL CO INC

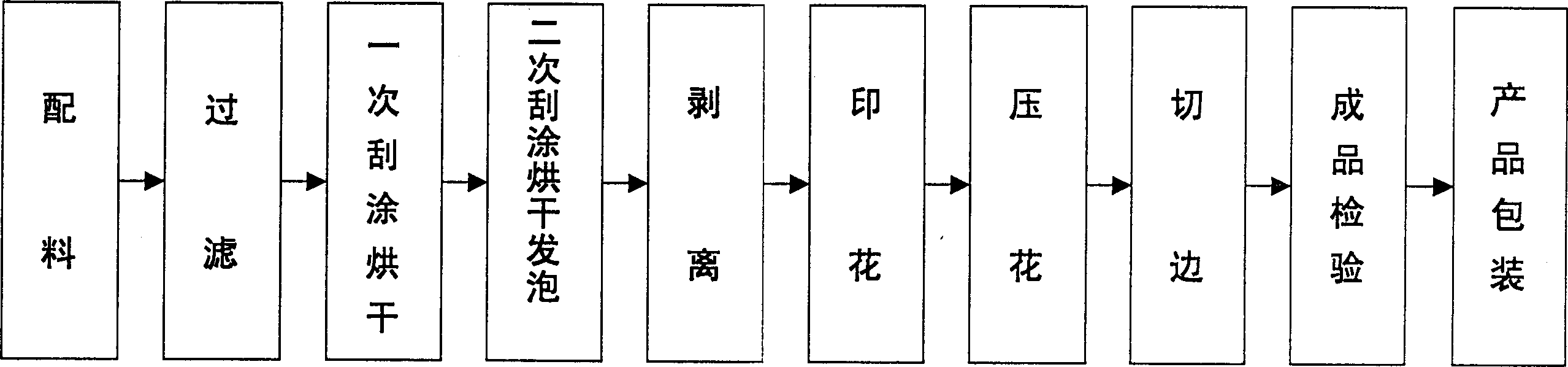

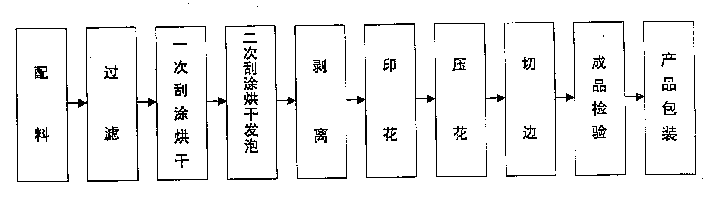

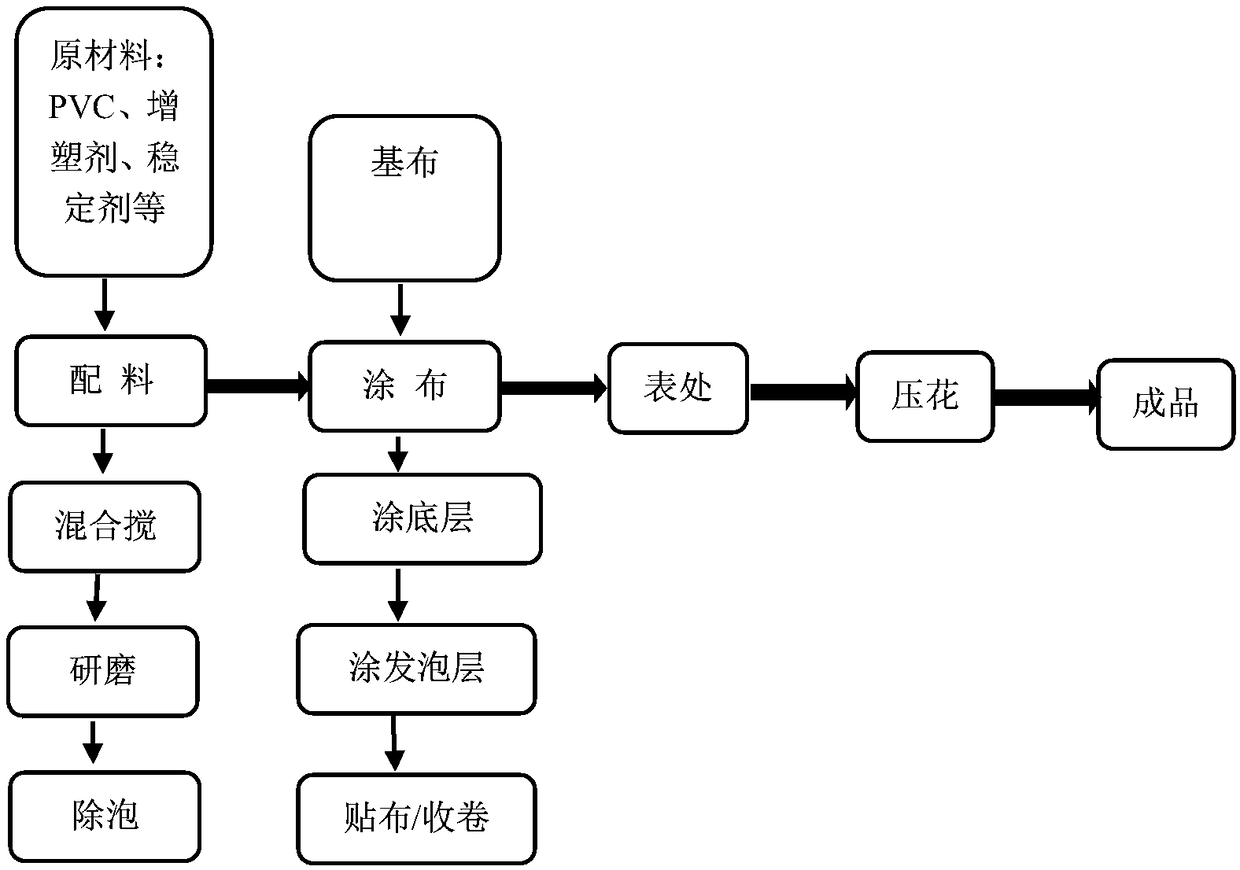

Decorative wall leather and its making method

InactiveCN1404989AImprove flame retardant performanceGood anti-mold and moisture-proof performanceSynthetic resin layered productsParaffin waxSurface layer

The decorative wall leather is formed from surface layer and bottom layer, the composition of surface layer comprises PVC base material 100, diisodecyl phthalate 30-60, chlorinated paraffin wax 0-25, barium-zinc liquid compound stabilizer 1-2, azoformamide 0-3, antimony oxide 0-5 and oil soluble dry film mildew inhibitor 0.2-1.5, and the composition of bottom layer contans PVC base material 100, diisodecyl phthalate 40-62, chlorinated paraffin wax 0-25, barium-zinc liquid compound stabilizer 1.5-3.5%, azoformamide 2-6, antimony oxide 2-8 and oil soluble dry film mildew inhibitor 0.2-2. Its preparation process includes the following steps: preparing materials, filtering, first knife coating, drying, secondary knife coating, drying, foaming, stripping, printing, embossing, edge-cutting, check finished product and packaging.

Owner:SICHUAN JINLU GRP

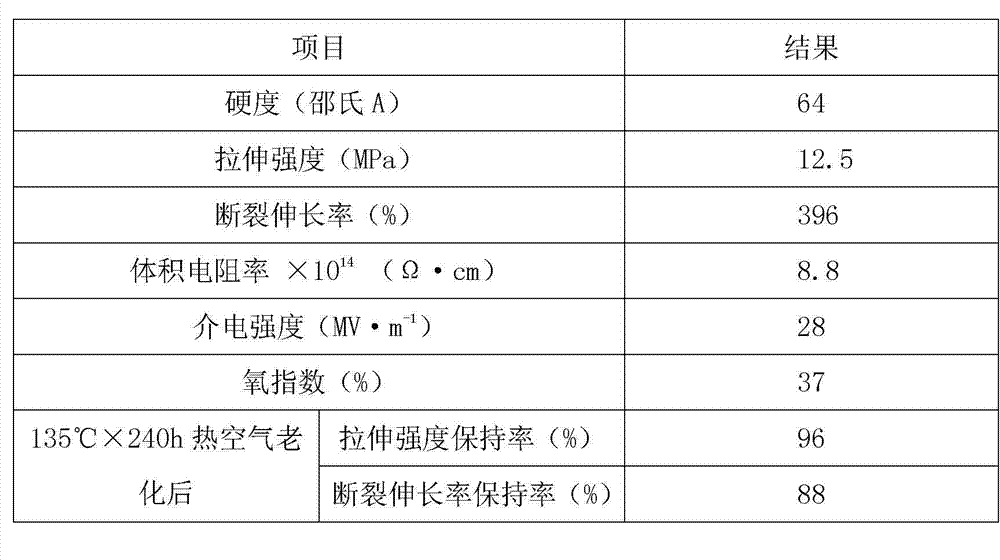

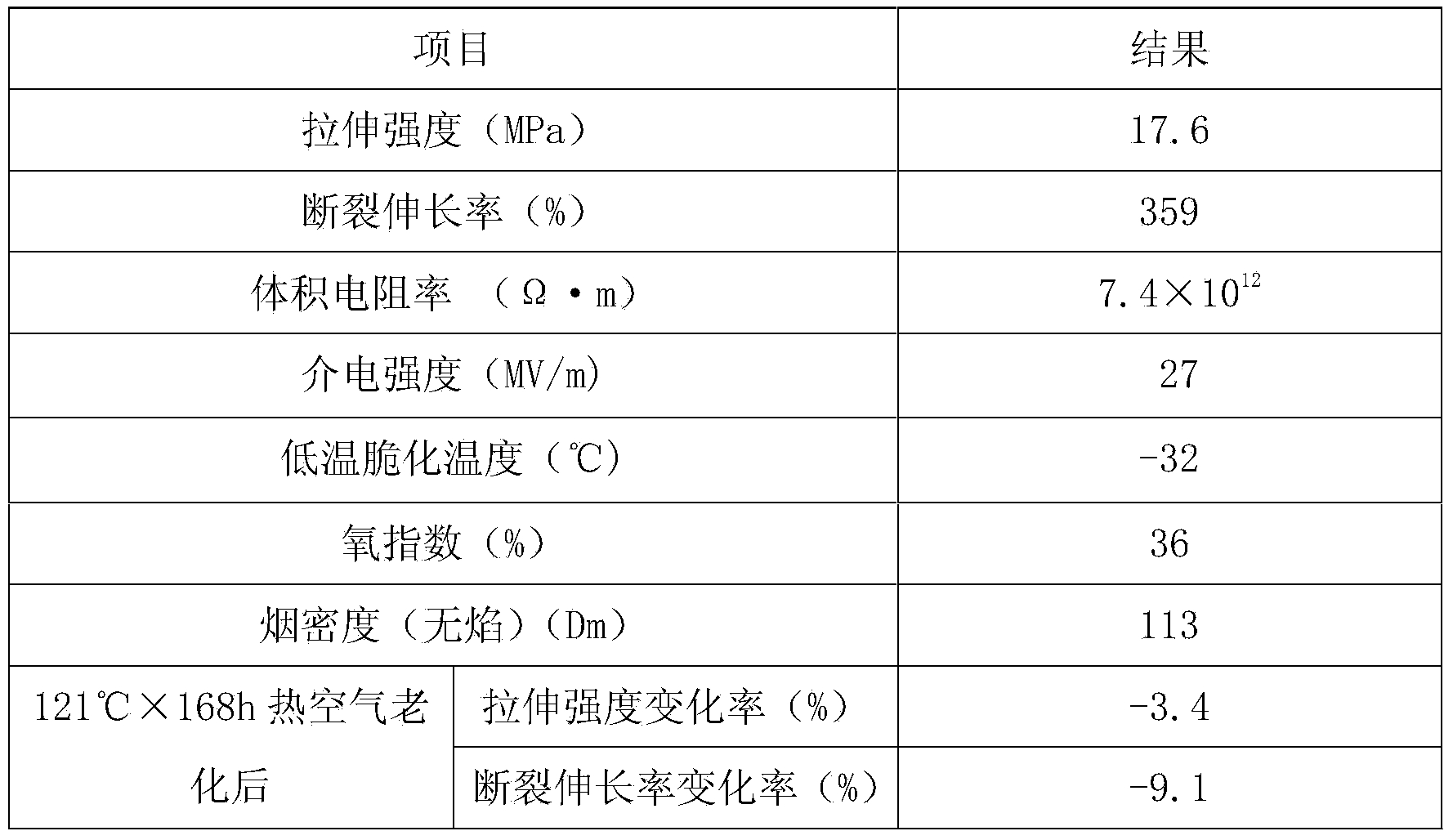

Incinerated pottery clay modified ethylene propylene diene copolymer cable material

ActiveCN102964699AImprove flame retardant performanceImprove heat resistanceParaffin waxPolymer science

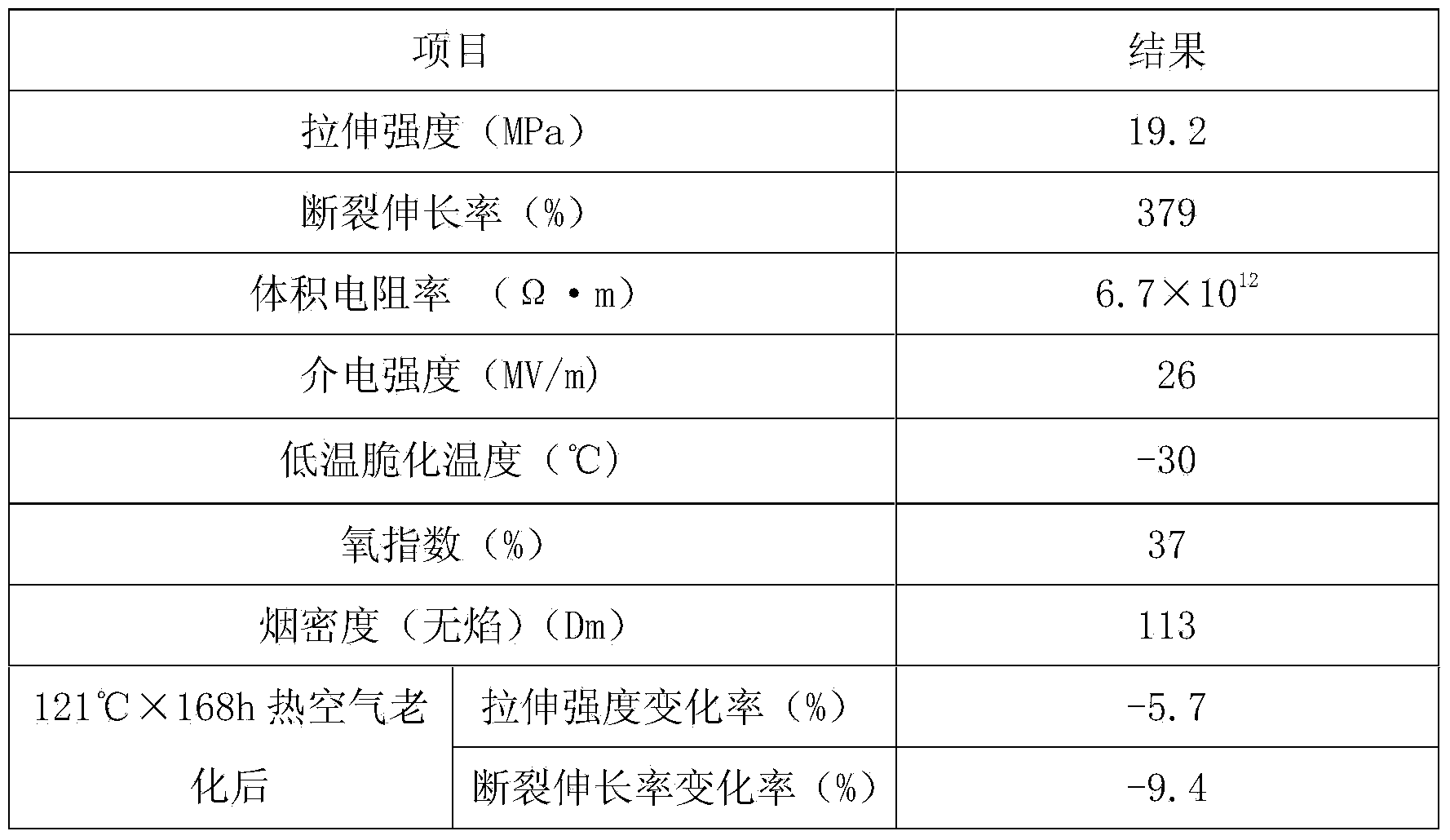

The invention discloses an incinerated pottery clay modified ethylene propylene diene copolymer cable material, which is prepared from the following raw materials in parts by weight: 100-120 parts of Lanxess Deutschland ethylene propylene diene copolymer 3950, 20-30 parts of nitrile butadiene rubber N41, 10-15 parts of chlorosulfonated polyethylene rubber CSM2305, 10-15 parts of diisodecyl phthalate; 2-5 parts of epoxidized triglyceride, 2-5 parts of triethyl citrate, 5-8 parts of chlorinated paraffin wax, 0.5-1.0 part of stearic acid, 2-3 parts of calcium stearate, 1-2 parts of sulphur, 3-5 parts of zinc oxide, 30-40 parts of incinerated pottery clay, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Plasticiser Compositions

C9 to C11 alkyl benzoates are used as plasticisers for polyvinyl chloride in particular in combination with plasticisers such as di-2-ethyl hexyl phthalate, diisononyl phthalate, di-2-propyl heptyl phthalate, diisodecyl phthalate or di-2-ethyl hexyl terephthalate. The use of the C9 to C11 alkyl benzoates provides low viscosity low volatility plasticisers, which are fast fusing with lower hot bench gelation temperature and which can be used to reduce the staining problems associated with use of di-2-ethyl hexyl phthalate and diisononyl phthalate. The low viscosity of the C9 to C11 alkyl benzoates allows the formulation of solvent free flexible PVC formulations meeting stringent VOC limitations.

Owner:EXXONMOBIL CHEM PAT INC

Diisodecyl phthalate preparation method

InactiveCN1733695ASimple processImprove product qualityOrganic compound preparationCarboxylic acid esters preparationNitrogenReaction temperature

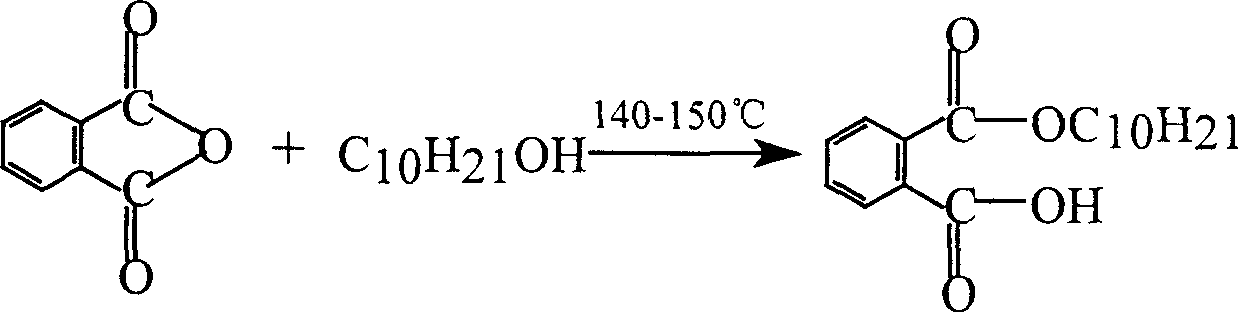

The invention relates to a process for preparing diisodecyl phthalate, which comprises using phthalic anhydride and isodecanol as raw material, at the presence of nitrogen, first carrying out esterification reaction, then carrying out diesterification reaction by using ipropyl titanate as catalyst, obtaining crude product of diisodecyl phthalate, finally carrying out dealcoholizing, alkaline cleaning, water scrubbing and steam extraction to obtain the end product.

Owner:CNPC JILIN CHEM GROUP CORP

Method for improving thermal stability of dibutyl/diisobutyl phthalate

ActiveCN102219688AImproves intrinsic thermal stabilityImprove thermal stabilityOrganic compound preparationCarboxylic acid esters preparationOrganic synthesisPolyvinyl chloride

The invention provides a method for r improving thermal stability of dibutyl / diisobutyl phthalate, and belongs to the technical fields of fine organic synthesis and application and machine shaping of macromolecular new materials. The method which improves the intrinsic thermal stability of plasticizers of dibutyl phthalate and diisobutyl phthalate by an inorganic carbonate heat treatment is characterized in that: protonic acid, such as sulfuric acid, is adopted to serve as an esterifying catalyst, coarse ester is thermally decomposed by anhydrous solid carbonates in a reaction system prepared through esterifying synthesis of benzoic anhydrides and n-butyl alcohol or isobutyl alcohol, the catalyst and byproducts generated in the reaction process are effectively removed, coloring byproducts in the esterifying reaction system can be effectively removed, the effect of improving the product stability is achieved, and the requirement on thermal treatment of polyvinyl chloride (PVC) products is met; compared with the conventional production methods, the method has the advantages that: process wastewater is reduced by two-thirds, the production period is shortened, and the aims of energy conservation and emission reduction are fulfilled.

Owner:JIANGNAN UNIV +1

Heatproof 105 DEG C polyvinyl chloride cable material and preparation method thereof

InactiveCN104109303AHigh mechanical strengthImprove thermal stabilityPlastic/resin/waxes insulatorsPolyvinyl chlorideAging resistance

The invention discloses a heatproof 105 DEG C polyvinyl chloride cable material and a preparation method thereof, the cable material comprises the following raw materials by weight: 100 parts of SG-3 pvc resins, 15-20 parts of bisphenol A polycarbonate, 8-12 parts of chlorinated polyethylene, 25-35 parts of tricapryl trimellitate, 10-15 parts of diisodecyl phthalate, 5-10 parts of pentaerythritol stearate, 10-15 parts of barium sulfate, 5-10 parts of nano wollastonite, 4-8 parts of composite filling material, 1-2 parts of AMTEOS, 5-8 parts of calcium zinc composite stabilizing agent, 1-2 parts of barium stearate, 1-2 parts of ethylene bis stearamide, 10-15 parts of zinc borate, 5-10 parts of decabromodiphenyl oxide and 0.5-1 part of anti-oxidant. The cable material has excellent mechanical strength, heat stability, weather resistance and ageing resistance, and good flame retardation effect, flare quenching can be rapidly carried out after flame disappears, other material can not be combusted, the smoke amount is little while the cable material is combusted, can be used under 105 DEG C for long-term, and the usage life of the cable can be increased.

Owner:ANHUI RONGJIU OPTICAL FIBER COMM

Mildew-proof and corrosion-resistant composite nano calcium silicate brick and production method thereof

The invention discloses a mildew-proof and corrosion-resistant composite nano calcium silicate brick, which is prepared by mixing an ethylene-vinyl acetate copolymer with a compounded plasticizer composed of diisodecyl phthalate, [beta]-diketone and ammonium polyphosphate. The brick is improved in mechanical performance and meanwhile is enhanced in anti-aging performance and processability and can enhance flexibility of cables. The ammonium polyphosphate has the effect of a condensed phase and is mixed with magnesium hydroxide to achieve excellent flame-retarding effect. In addition, the sintered brick is high in strength, is strong in bearing capability, is low in density, is low in heat conductivity coefficient and can satisfy use requirement, is wide in application range and is good in market prospect. The sintered brick can reduce environment pollution of industrial solid waste discharge, is low in cost and less in pollution, is less in damage on human body, is good in abrasion resistance, is strong in anti-aging performance and also achieves economic and social benefit of turning waste into resources.

Owner:CHANGZHOU WUJIN GOLDEN SUNSHINE ELECTRONICS

Sustainable poly(vinyl halide) mixtures for thin-film applications

InactiveUS20160260519A1High molecular weightGood strainPlastic/resin/waxes insulatorsCoatingsAccelerated agingHigh heat

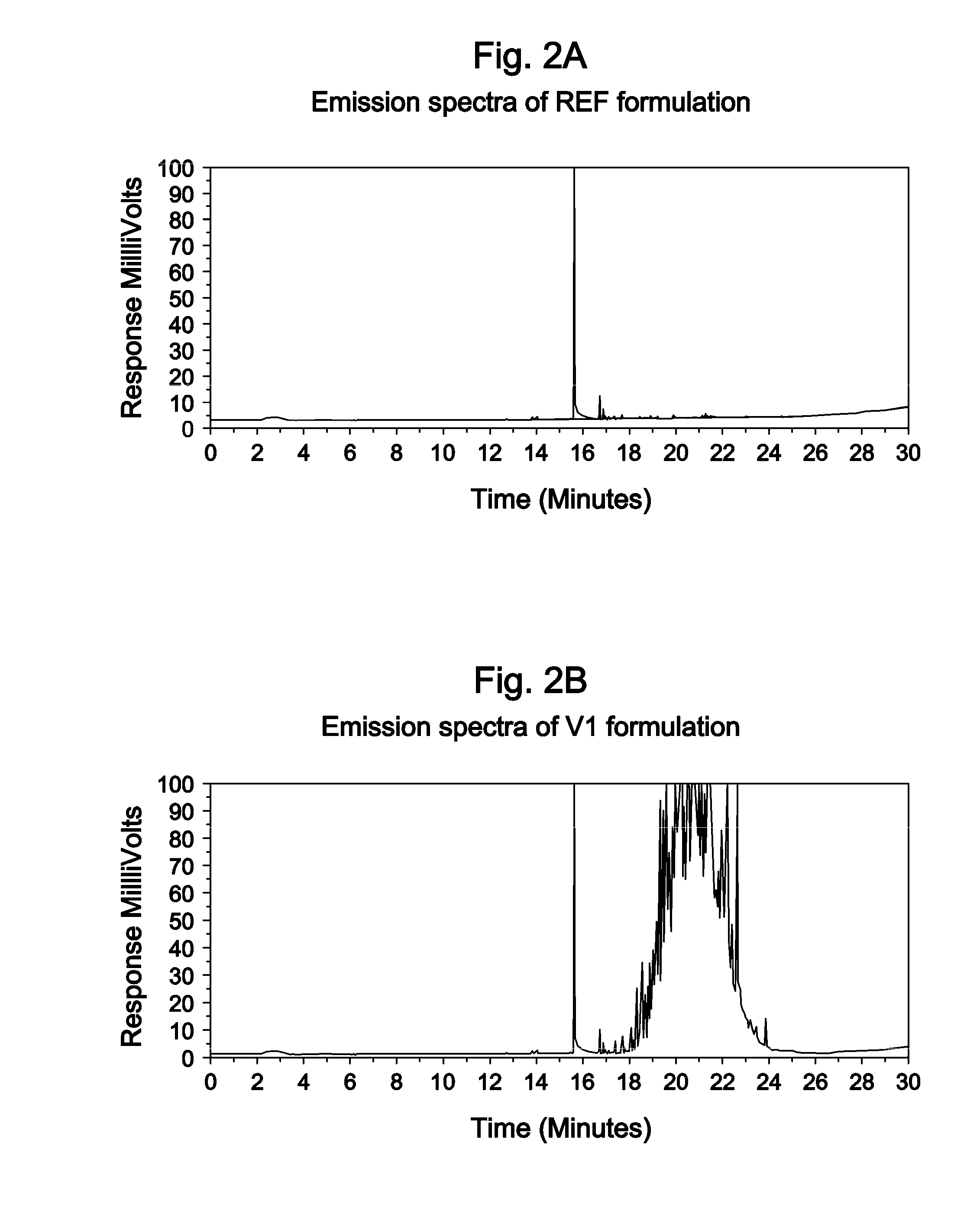

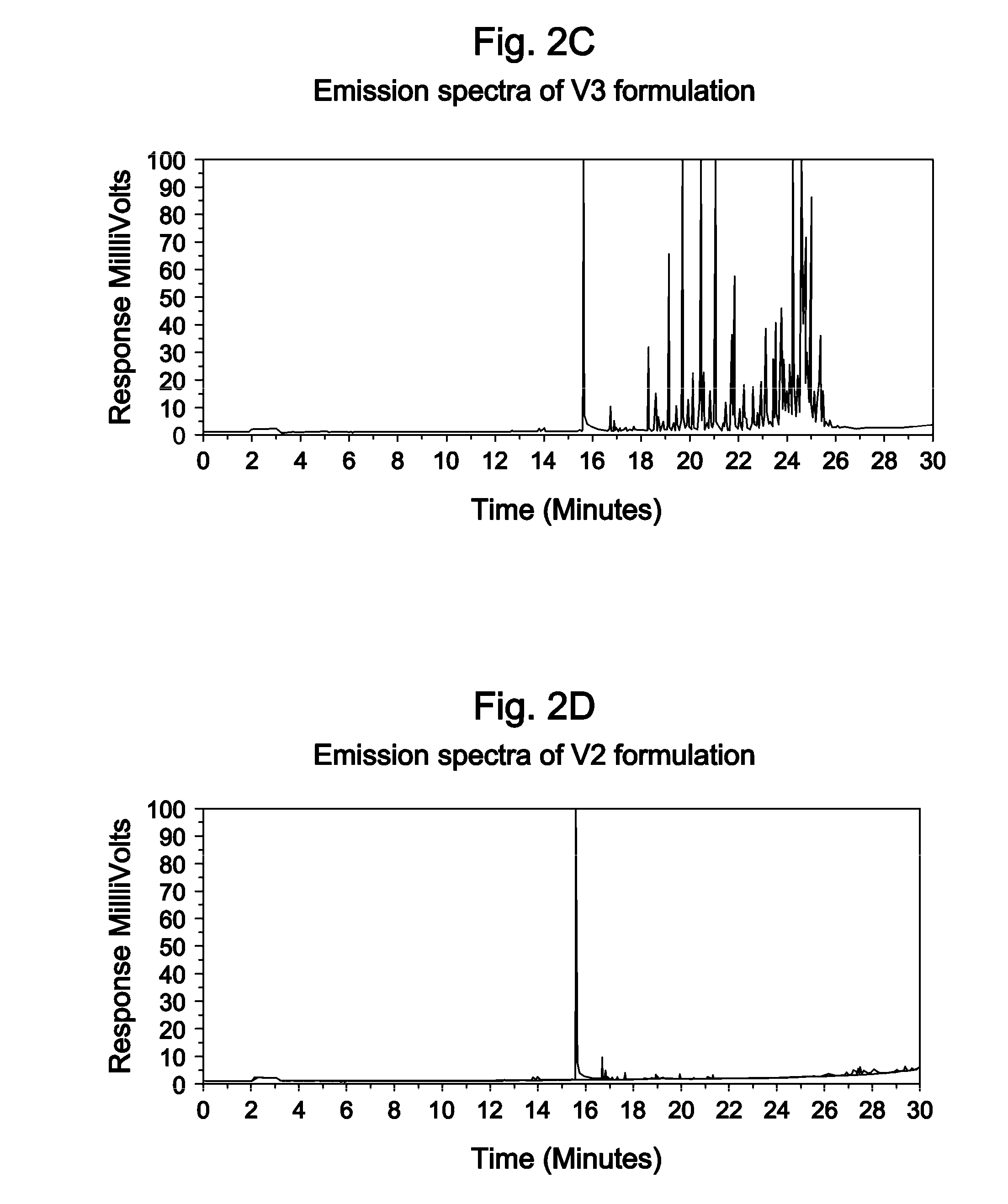

A mixture of poly(vinyl halide) and epoxidized benzyl fatty acid ester, preferably epoxidized benzyl soyate (EBS), is disclosed. The epoxidized benzyl fatty acid ester as a plasticizer replaces common high molecular weight phthalates, such as diisodecyl phthalate (DIDP), which are conventionally used for the manufacture of wire and cable insulation and jacketing. The epoxidized benzyl fatty acid ester, a bio-plasticizer, unexpectedly outperforms the higher molecular weight DIDP as demonstrated by superior retention of Strain at Break after accelerated aging at elevated temperatures.

Owner:POLYONE CORPORATION

Anti-rat-type PVC cable material and preparation method

ActiveCN104109305AGood anti-rat effectPrevent accident lossLinear low-density polyethylenePolyvinyl chloride

The invention discloses an anti-rat-type PVC cable material and a preparation method. The material is prepared by the following raw materials by weight: 75 to 95 of XS-2-type PVC, 20 to 30 of metallocene linear low-density PE, 5 to 10 of MBS, 10 to 20 of antimony trioxide , 8 to 12 of brucite powder, 20 to 30 of carbon block N330, 2 to 3 of a calcium zinc composite stabilizer, 0.5 to 1 of stearic acid, 2 to 3 of sulphur, 3 to 5 of zinc oxide, 10 to 15 of nano wollastonite powder, 12 to 18 of epoxidized soybean oil, 10 to 15 of chlorinated paraffin, 8 to 12 of dioctyl sebacate, 5 to 10 of diisodecyl phthalate, 2 to 3 of an anti-rat agent M-17, and 5 to 10 of composite filler. According to the cable material of the invention, excellent anti-rat performance is provided, fire accidents and economic loss caused by rat bite can be effectively prevented, the material is environmental-friendly and safe, the physical and mechanical performance is more reliable, good flame retardant performance is provided, and better low-smoke and low-toxic properties are provided.

Owner:安徽荣鹏智能装备有限公司

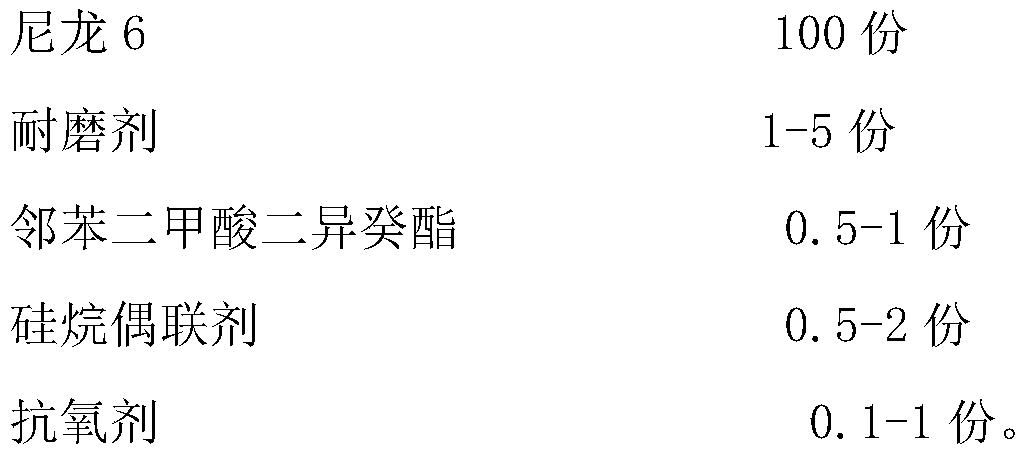

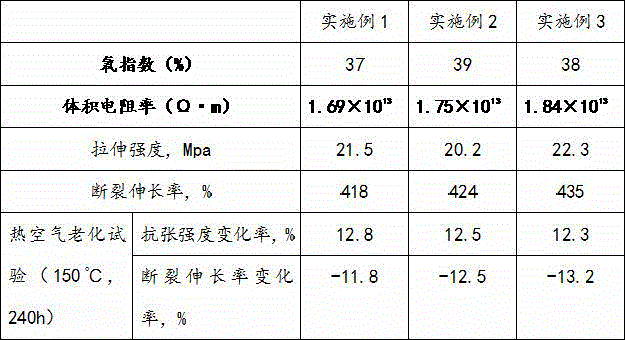

Nylon 6 composition with excellent wear resistance and preparation method of nylon 6 composition

ActiveCN110079077AImprove wear resistanceImprove low temperature impact performanceWear resistantNylon 6

The invention provides nylon 6 composition with excellent wear resistance and a preparation method of the nylon 6 composition. 100 parts of nylon 6, 1-5 parts of a wear-resistant agent, 0.5-1 part ofDIDP (di-iso-decyl phthalate) (which is 0 when not added), 0.5-2 parts of a silane coupling agent and 0.1-1 part of an antioxidant are added to a mixer to be stirred for 30-40 s at normal temperatureat low speed, and the obtained mixture after uniform mixing is added to a twin-screw extruder; granulation is performed after melt extrusion, and the nylon 6 composition with excellent wear resistanceis prepared. The used wear-resistant agent has a better wear-resistant effect than single wollastonite and alumina and excellent wear-resistant effect than common molybdenum disulfide, polytetrafluoroethylene and graphite wear-resistant agents in the market.

Owner:河北易牛工程塑料有限公司

Outdoor overhead ageing-resistant insulating polyolefin cable material and preparation method thereof

InactiveCN104945727AGood flexibilityHeat resistantPlastic/resin/waxes insulatorsKetoneP-Phenylenediamine

The invention discloses an outdoor overhead ageing-resistant insulating polyolefin cable material and a preparation method thereof. The outdoor overhead ageing-resistant insulating polyolefin cable material comprises, by weight, 60-80 parts of ethylene-vinyl acetate copolymer, 30-40 parts of chlorosulphonated polyethylene, 4-6 parts of isopropyl phenyl diphenyl phosphate, 4-5 parts of acetyl tri-n-butyl citrate, 8-10 parts of magnesium hydroxide, 40-50 parts of di-iso-decylphthalate, 6-8 parts of butadiene triethoxy silane, 2-4 parts of organic chromium complex, 6-8 parts of lead sulfate tribasic, 5-7 parts of p-phenylenediamine, 30-40 parts of nano calcium carbonate, 6-10 parts of beta-diketone, 12-14 parts of ammonium polyphosphate, 7-8 parts of silicone emulsion, 5-7 parts of fluoro-alkyl polyether modified polysiloxane, 7-9 parts of zinc stearate, 5-8 parts of nano calcium superoxide, 6-9 parts of paraffin and 8-12 parts of hexadecyl dimethyl amine. According to the outdoor overhead ageing-resistant insulating polyolefin cable material and the preparation method thereof, the added di-iso-decylphthalate plasticizer and the ethylene-vinyl acetate copolymer are matched, in this way, the aging resistance is improved, the processability is also improved, and the flexibility of a cable is improved; meanwhile, the ammonium polyphosphate has the condensation and phase neutralizing functions, and an extremely good frame retardant effect is achieved through the combination of the ammonium polyphosphate and the magnesium hydrate; the added chlorosulphonated polyethylene has the wear resistance, electric insulation resistance and other characteristics.

Owner:CHANGZHOU CITY WUJIN DISTRICT KAILIDA ELECTRONICS

Aging-resistant PVC (polyvinyl chloride) plastic and preparation method

InactiveCN107474425AThe construction process is simple and stableLow costPolyvinyl chlorideButylated hydroxytoluene

The invention discloses aging-resistant PVC (polyvinyl chloride) plastic and a preparation method. The aging-resistant PVC plastic is prepared from raw materials in parts by weight as follows: 90-110 parts of PVC resin, 1-2 parts of diisodecyl phthalate, 1-2 parts of chlorinated paraffin, 5-10 parts of talc powder, 1-3 parts of epoxidized soybean oil, 0.01-0.1 parts of butylated hydroxytoluene, 0.01-0.1 parts of an antibacterial agent and 0.01-0.1 parts of a heat stabilizer. The provided aging-resistant PVC plastic adopts a simple and stable construction process, is low in cost, has excellent mechanical property, flame resistance and antibacterial property and is resistant to aging and high temperatures and long in service life.

Owner:雄子(上海)新材料科技有限公司

Pottery clay modified cable material and preparation method thereof

InactiveCN106916380AImprove flame retardant performanceImprove heat resistanceRubber insulatorsTG - TriglycerideEPDM rubber

The invention provides a pottery clay modified cable material. The pottery clay modified cable material is prepared from the following raw materials in parts by weight: 100 to 120 parts of Germany Lanxess EPDM rubber 3950, 20 to 30 parts of nitrile rubber N41, 10 to 15 parts of chlorosulfonated polyethylene rubber CSM2305, 10 to 15 parts of diisodecyl phthalate, 2 to 5 parts of epoxidized triglyceride, 2 to 5 parts of triethyl citrate, 5 to 8 parts of chlorinated paraffin, 0.5 to 1.0 part of stearic acid, 2 to 3 parts of calcium stearate, 1 to 2 parts of sulfur, 3 to 5 parts of zinc oxide, 30 to 40 parts of calcined pottery clay, 20 to 30 parts of precipitated white carbon black, 5 to 15 parts of carbon black N660, 3 to 5 parts of zinc borate, 1 to 2 parts of an aluminate coupling agent DL- 411, 0.1 to 1 part of an ultraviolet screening agent UV-531, 1 to 2 parts of a crosslinking agent TAIC, 1 to 2 parts of 3-aminopropyl trimethoxysilane, 1 to 2 parts of an anti-aging agent OD, 1 to 2 parts of an anti-aging agent ODA, 1 to 2 parts of an anti-aging agent TPPD, 1 to 2 parts of an accelerator Na-22, 3 to 4 parts of an accelerator DM and 2 to 3 parts of aluminum hydroxide.

Owner:TIANCHANG HIGH TECH ENTREPRENEURSHIP SERVICE CENT

High-elasticity high-toughness polypropylene cable material for communication and preparation method thereof

InactiveCN106317622AImprove toughnessIncrease elasticityPlastic/resin/waxes insulatorsInsulated cablesPolypropyleneVolcanic ash

The invention discloses a high-elasticity high-toughness polypropylene cable material for communication and a preparation method thereof. The high-elasticity high-toughness polypropylene cable material for communication is prepared from the following raw materials in parts by weight: 70-90 parts of atactic polypropylene, 25-35 parts of thermoplastic elastomer SEEPS, 14-26 parts of butanediol cycloterephthalate, 15-25 parts of nano cellulose whisker, 12-20 parts of coumarone indene resin, 6-12 parts of hydroxyl aluminum distearate, 20-30 parts of siliceous shale, 16-24 parts of diisodecyl phthalate, 18-32 parts of asbestos tailing, 2-4 parts of cadmium stearate, 10-15 parts of flocking powder, 9-16 parts of basic magnesium sulfate whisker and 15-25 parts of volcanic ash. The toughness and elasticity of the material are improved; by adding the nano cellulose whisker, flocking powder, basic magnesium sulfate whisker and other raw materials into the system, the tensile strength and elongation at break of the material are enhanced; and the heat resistance, wear resistance and corrosion resistance of the material can also be improved.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

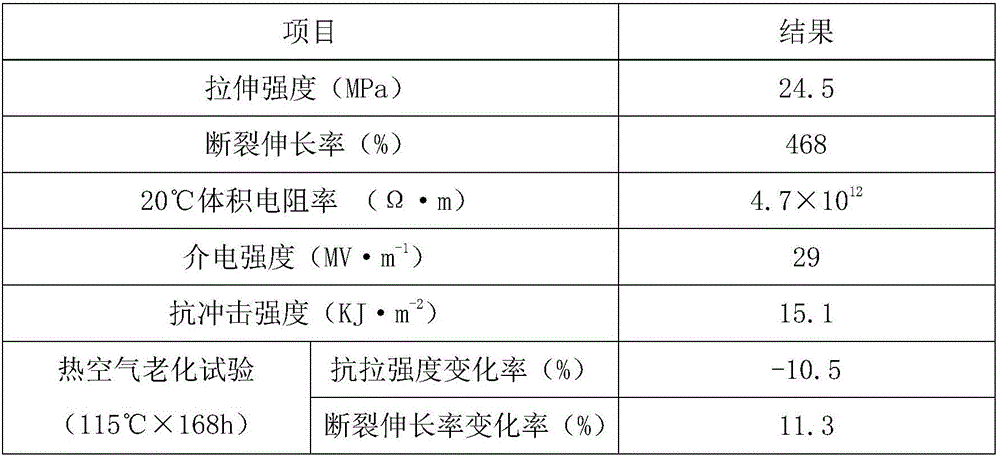

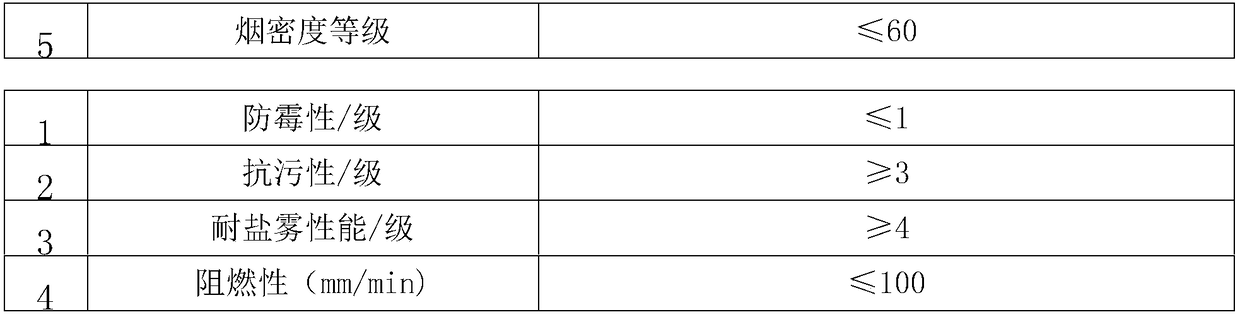

Yacht leather and preparation method thereof

InactiveCN108823992AGood anti-mildew effectImprove flame retardant performanceWaterborne vesselsCoatingsFoaming agentAluminium hydroxide

The invention relates to yacht leather. According to weight percentage, the yacht leather comprises a bottom layer and a foamed layer; raw materials of the bottom layer comprise 100 parts of a PVC (Poly Vinyl Chloride) resin powder, 60 to 90 parts of diisodecyl phthalate, 6 to 10 parts of zinc hydroxystannate, 25 to 40 parts of aluminium hydroxide, 0.5 to 2 parts of an ultraviolet absorbent, 2 to4 parts of a heat stabilizer, 1 to 3 parts of an anti-amine agent and 0.2 to 0.8 part of a mould inhibitor; and raw materials of the foamed layer comprise 100 parts of a PVC resin powder, 60 to 90 parts of diisodecyl phthalate, 2 to 4 parts of zinc hydroxystannate, 50 to 75 parts of aluminium hydroxide, 1 to 4 parts of a heat stabilizer, 0.2 to 0.5 part of a mould inhibitor, 1 to 6 parts of a foaming agent and 1 to 2 parts of a foam stabilizer. The product has good mildew resistance and good flame retardance, generates little smoke in the burning process, and has good salt spray corrosion resistance and stain resistance.

Owner:佛山市威仕达新材料有限公司

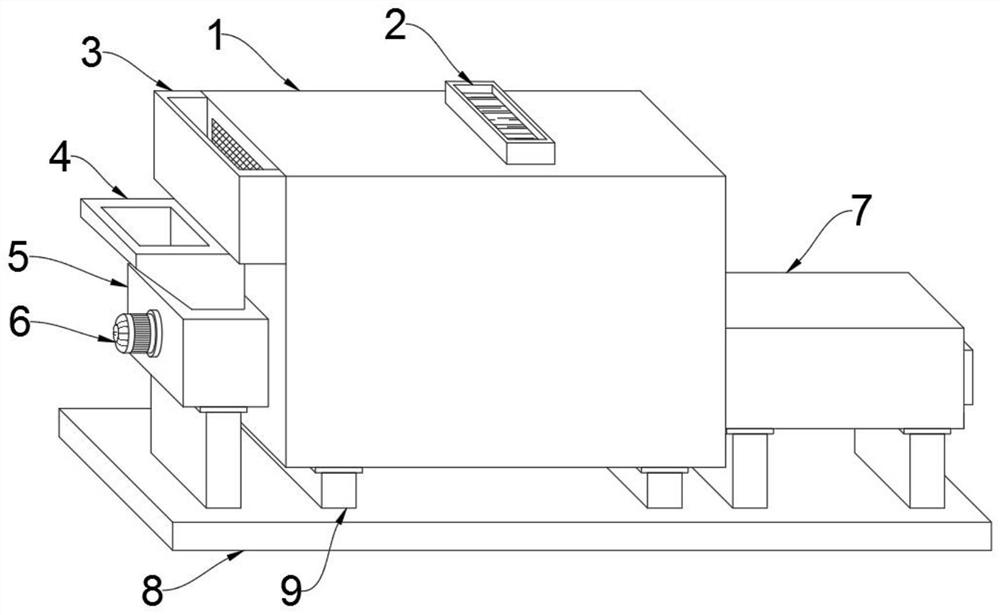

Cable material with high flame-retardant and fireproof performance and preparation method thereof

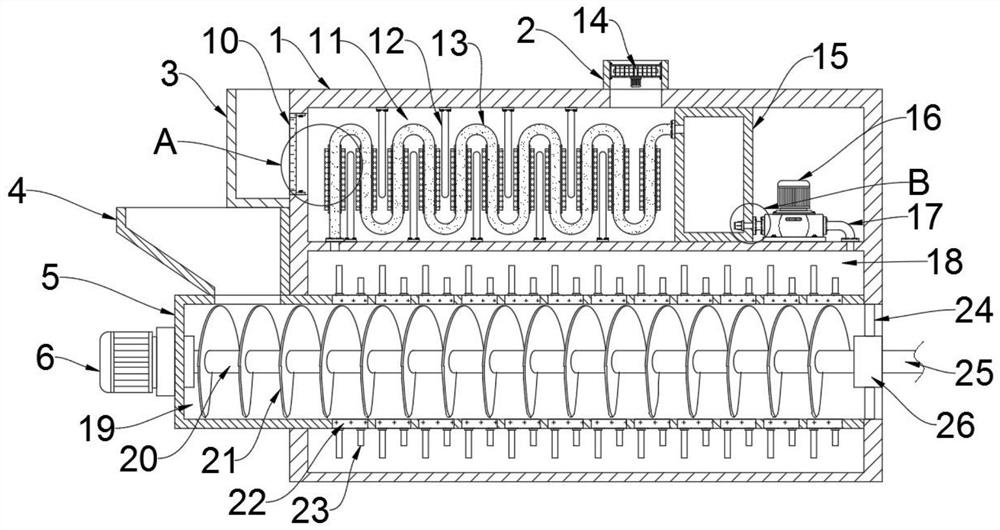

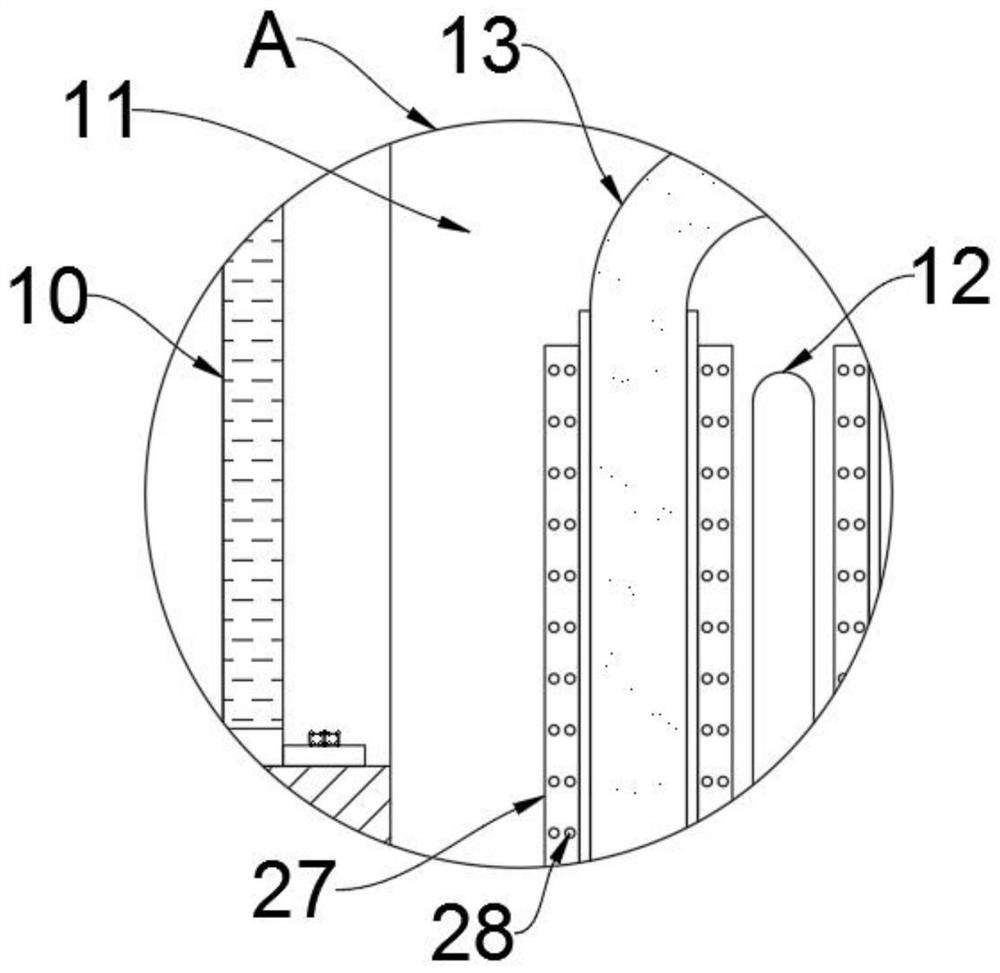

The invention discloses a cable material with high flame-retardant and fireproof performance and a preparation method thereof, relates to the technical field of cable materials, and aims to solve the problems that in the cable material preparation process in the prior art, after mixed raw materials are internally mixed, the temperature of the mixed raw materials is too high and needs to be reduced for granulation, but a natural cooling method is often adopted at present, a lot of time is wasted, and the preparation speed of the cable material is influenced. The cable material comprises the following components in parts by weight: 10-20 parts of polyvinyl chloride, 15-30 parts of silicone rubber, 2-4 parts of calcium carbonate, 1-2 parts of a stabilizer, 1-2 parts of an antioxidant, 2-4 parts of di-iso-decylphthalate, 2-4 parts of trioctyl trimellitate, 3-6 parts of diphenyl anthraquinone phosphine oxide, 1-2 parts of plant ash and 1-2 parts of an anti-aging agent. Wherein the cable material is prepared through a cable preparation device, and the cable preparation device comprises a cooling box body and a placement bottom plate.

Owner:武汉金牌电工股份有限公司

High-compressibility high-recovery PVC artificial leather

InactiveCN110846901APromote environmental protectionIncreased durabilityTextiles and paperPolymer scienceFoaming agent

Owner:佛山市威仕达新材料有限公司

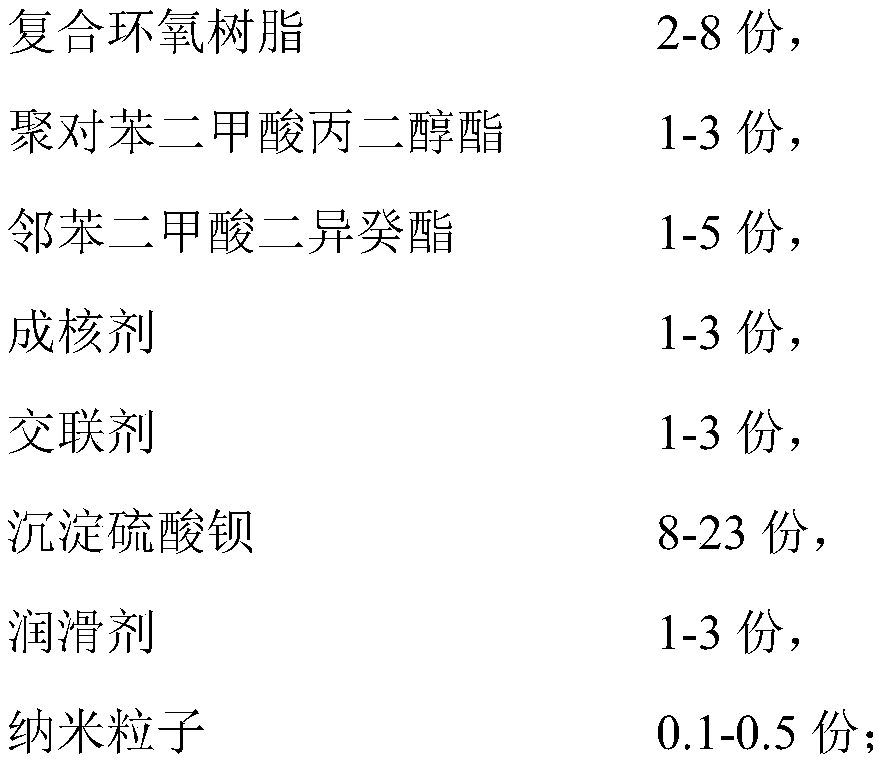

Low-temperature 3D printing material and preparing method thereof

The invention discloses a low-temperature 3D printing material. The low-temperature 3D printing material is prepared from, by weight, 70-85 parts of polycaprolactone, 2-8 parts of composite epoxy resin, 1-3 parts of polypropylene glycol terephthalate, 1-5 parts of diisodecyl phthalate, 1-3 parts of nucleating agent, 1-3 parts of cross-linking agent, 8-23 parts of precipitated barium sulphate, 1-3parts of lubricating agent and 0.1-0.5 part of a nanometer particle. The composite epoxy resin comprises bisphenol A type epoxy resin and bisphenol F type epoxy resin, and the weight ratio of the bisphenol A type epoxy resin to the bisphenol F type epoxy resin is (2-5):1. By means of the low-temperature 3D printing material, the crystal hardness and the surface gloss of the low-temperature 3D printing material can be improved.

Owner:ZHUHAI SUNLU IND

Damping pad rubber material and preparation method thereof

InactiveCN106543574AImprove aging resistanceImprove wear resistanceRubber materialMicrocrystalline wax

The invention discloses a damping pad rubber material and a preparation method thereof; the damping pad rubber material is prepared from, by weight, 22-53 parts of chlorinated butyl rubber, 16-32 parts of high-cis-butadiene rubber, 10-20 parts of fluoro-phosphazene rubber, 4-12 parts of diisodecyl phthalate, 3-10 parts of triallyl isocyanurate, 5-13 parts of calcined kaolin, 3-10 parts of microcrystalline wax, 2-7 parts of zinc dimethacrylate, 3-12 parts of calcium hydroxide, 8-15 parts of hexamethyl-disilazane, 1-5 parts of polyvinylsilicone oil, 6-13 parts of modified nano montmorillonite, 7-14 parts of glass fiber, 1-4 parts of an accelerant, 1-3 parts of a stabilizer, 3-7 parts of a vulcanizing agent, 5-10 parts of aromatic hydrocarbon oil, 2-6 parts of an antiaging agent, 2-8 parts of zinc oxide, 8-15 parts of bauxite, and 4-9 parts of chlorinated paraffin. Compared with the prior art, the damping pad rubber material of the invention has good aging resistance, wear resistance and damping performance.

Owner:ANHUI MEITENG SPECIAL ELECTRIC CABLE MATERIALS

PVC (polyvinyl chloride) cable material and preparation method thereof

InactiveCN105820467AExcellent flame retardantImprove flame retardant performancePlastic/resin/waxes insulatorsPolyvinyl chlorideChlorinated paraffins

The invention discloses a PVC cable material and a preparation method thereof. The raw material components are as follows: 90-110 parts of PVC resin, 5-10 parts of basic lead carbonate, and 25-30 parts of diisodecyl phthalate 15-20 parts of chlorinated paraffin, 0.8-1.5 parts of calcium stearate, 0.1-0.5 parts of bisphenol A, 8-12 parts of pottery clay, and 8-12 parts of calcium carbonate. The PVC cable material of the present invention is made of polyvinyl chloride resin, stabilizer, plasticizer, filler, and antioxidant through batching, high-speed kneading, single-screw extrusion, pelletizing, cooling, screening magnetic separation, metering, and packaging. It has good physical, chemical, electrical, flame retardant and electrical insulation properties.

Owner:ANHUI JIUHUA KIMRUN COPPER IND

High-strength modified plastic tray

The invention relates to a high-strength modified plastic tray which comprises 90 parts of plastic raw material, 8 parts of reinforcing fiber, 10 parts of glass fiber, 5 parts of combusted kaolin, 11 parts of polycarbonic acid resin, 12 parts of polyvinyl chloride, 4 parts of diisodecyl phthalate, 15 parts of polyethylene and 5 parts of methacrylate. The plastic tray has the advantages of high strength, high corrosion resistance, favorable weather resistance, high impact resistance and low tendency to damage when in use.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Plastic handle material for automobile door and preparation method of same

The invention discloses a plastic handle material for an automobile door, which is prepared from, by weight, 25-30 parts of polystyrene, 45-55 parts of phenolic resin, 8-10 parts of polymethacrylate, 7-11 parts of polyphenylene thioether, 12-16 parts of tetraphenyl tin, 22-25 parts of abietic acid, 8-10 parts of nano aluminum oxide, 14-18 parts of polyamide, 11-18 parts of polyvinyl formal fiber, 4-9 parts of di-n-octyl phthalate, 6-8 parts of diisodecyl phthalate, 7-11 parts of alkylphenol ethoxylates, 3-7 parts of talcum powder, 16-20 parts of barium sulfate, 5-7 parts of mica powder, 22-25 parts of carbon black, 4-9 parts of zinc borate, 3-9 parts of calcium silicate hydrate, 12-17 parts of nano molybdenum disulfide, 3-5 parts of zirconium oxide, 14-16 parts of triethylene tetramine, and 21-26 parts of boron nitride. The plastic handle material has high wear resistance, is anti-aging, is high in structural strength, is free of surface electroplating treatment and can be applied directly, thereby reducing processing steps and reducing cost.

Owner:芜湖天鸿汽车零部件有限公司

Attapulgite modification based air blower shell of automotive air conditioner and preparation method of air blower shell

InactiveCN106317831AGood weather resistanceImprove mechanical propertiesAgricultural engineeringShielding gas

The invention discloses an attapulgite modification based air blower shell of an automotive air conditioner and a preparation method of the air blower shell. The preparation method comprises the steps: (1) carrying out ball-milling on starch, silica gel, cyclodextrin, dodecyl ethoxy sulfobetaine, graphene and ornithine, so as to prepare modified starch; (2) carrying out calcination on attapulgite, graphite, molybdenite and sodium tungstate in the presence of shielding gas, so as to prepare a modified composition; (3) carrying out mixing on PC, PP, PA, rosin, hydroxyethyl cellulose, barium sulfate whiskers, titanate, simethicone, diisodecyl phthalate, zinc oxide, the modified starch and the modified composition, and carrying out molding, thereby preparing the attapulgite modification based air blower shell of the automotive air conditioner. The attapulgite modification based air blower shell of the automotive air conditioner, prepared by the method, has excellent weather resistance and mechanical properties; meanwhile, the preparation method has the advantages that the steps are simple, and the raw materials are readily available.

Owner:芜湖德鑫汽车空调有限公司

Automobile flame-retardant paint formula

InactiveCN104263043AImprove flame retardant performanceGood sun protectionFireproof paintsGlycerolLimonene

The invention relates to an automobile flame-retardant paint formula. The automobile flame-retardant paint formula comprises the following components: 10 parts of linseed oil, 32 parts of limonene, 4 parts of rosin diacid, 1 part of heat-resistant agent, 4 parts of triphenyl phosphate, 2 parts of triethanolamine, 8 parts of diisodecyl phthalate, 2 parts of dicumyl peroxide, 12 parts of unsaturated oleic acid, 5 parts of glycerol, 8 parts of rosin diacid, 2 parts of trimethylol propane, 1 part of silicon dioxide, 2 parts of organic soil, 9 parts of chlorinated polyethylene and 2 parts of acrylate type copolymer. Compared with the traditional finish paint, the paint provided by the invention has good flame retardance, sun-screening property, chemical resistance and wear resistance. Furthermore, the ignition point is high, open fire can be avoided, and the unit using amount is reduced, so that the using cost is effectively reduced.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Composite material with flame-retardant function

The invention discloses a composite material with flame-retardant function, which comprises the following components in parts by weight: 35-46 parts of propylene glycol monobutyl ether, 10-15 parts of n-propyl methacrylate, 3.5-9.5 parts of basic lead sulfite, 9-16 parts of 9,10-epoxy octyl stearate, 5-14 parts of silicon oil, 23-54 parts of ethylene copolymer elastomer, 15-21 parts of stearic acid, 35-67 parts of oxidized polyethylene ester, 3-6 parts of talcum powder, 18-36 parts of diisodecyl phthalate and 45-69 parts of acrylonitrile-styrene-butadiene copolymer. The composite material has the characteristics of flame retardancy and environmental protection, and is suitable for producing mechanical equipment, instruments, light equipment and other components.

Owner:QINGDAO JINXIU SHUIYUAN COMMERCE & TRADE

Solvent-resistant cable material for large power and preparation method thereof

InactiveCN105017580AReasonable designIncrease profitRubber insulatorsDiisodecyl phthalatePOLYETHYLENE WAX

The invention discloses a solvent-resistant cable material for large power and a preparation method thereof. The solvent-resistant cable material comprises, by weight, 1-2 parts of an antiager MB, 3-5 parts of epoxidized soybean oil, 4-6 parts of ethylene dimethacrylate, 30-50 parts of nitrile rubber, 2-4 parts of an ethene-propylene-butylene ternary copolymer, 2-4 parts of light calcium carbonate, 3-5 parts of zinc stearate, 2-5 parts of magnesium hydroxide, 3-4 parts of tetra[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol, 2-4 parts of calcined clay, 3-6 parts of polyethylene wax, 5-8 parts of diisodecyl phthalate, 2-4 parts of sodium pyrosulfite, 15-25 parts of isoprene rubber and a filler. The preparation method has a reasonable design, can be operated simply, and has a high raw material utilization rate. The solvent-resistant cable material has the characteristics of heat resistance, weatherability and solvent resistance and excellent wear resistance and can be widely used in the field of power cables.

Owner:ANHUI TELI SCI & TECH

Automobile air conditioner blower shell based on diatomaceous earth modification, and preparation method thereof

The invention discloses an automobile air conditioner blower shell based on diatomaceous earth modification, and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out ball milling on starch, silica gel, cyclodextrin, dodecyl ethoxy sulphobetaine, graphene and ornithine to obtain modified starch; (2) calcining diatomaceous earth, graphite, molybdenite and sodium wolframate in existence of a shielding gas to obtain a modified composition; and (3) carrying out mixing and molding on PC, PP, PA, rosin, hydroxy ethyl cellulose, glass fibers, titanate, dimethyl silicon oil, diisodecyl phthalate, zinc oxide, the modified starch and the modified composition to obtain the automobile air conditioner blower shell based on diatomaceous earth modification. The automobile air conditioner blower shell based on diatomaceous earth modification prepared by the method has excellent weather resistance and mechanical properties, and simultaneously the preparation method has simple steps and easily available raw materials.

Owner:芜湖德鑫汽车空调有限公司

Automotive exterior coating and preparation method thereof

The invention provides an automotive exterior coating and a preparation method thereof. The coating comprises the following components in parts by mass: 25-35 parts of nitrocellulose, 2-6.4 parts of di-iso-decylphthalate, 24-35 parts of phenolic resin, 30-42 parts of n-butyl methacrylate, 4-6.4 parts of polyacrylic resin, 7-13 parts of acetone, 20-28 parts of hydroxypropyl methacrylate, 7-14 parts of cyclohexanone, 1.5-4.5 parts of dibutyl phthalate, 45-60 parts of methylbenzene, 10-20 parts of non floating type aluminum silver paste and 0.6-1 part of benzoyl peroxide. The coating provided by the invention is very high in glossiness, can emit metal luster, and has very good protection and decoration effects on automotive exterior surfaces.

Owner:东莞市惠尔明高分子材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com