Low-temperature 3D printing material and preparing method thereof

A 3D printing, low-temperature technology, applied in the field of 3D printing materials, can solve the problems of gear occlusion, feeding slippage, increased friction between the wire and the inner wall of the feeding tube, and unsustainable feeding, so as to improve gloss, crystallization hardness and surface gloss Degree, the effect of improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A low-temperature 3D printing material, the preparation method comprising the following steps:

[0035] (1) Put 83 parts of polycaprolactone (molecular weight of 60000) (without prior drying treatment) and 1.5 parts of white silicone oil into a high-speed mixer, and mix them evenly at 2-38°C (the temperature should not exceed 38°C), Mixing time 5min;

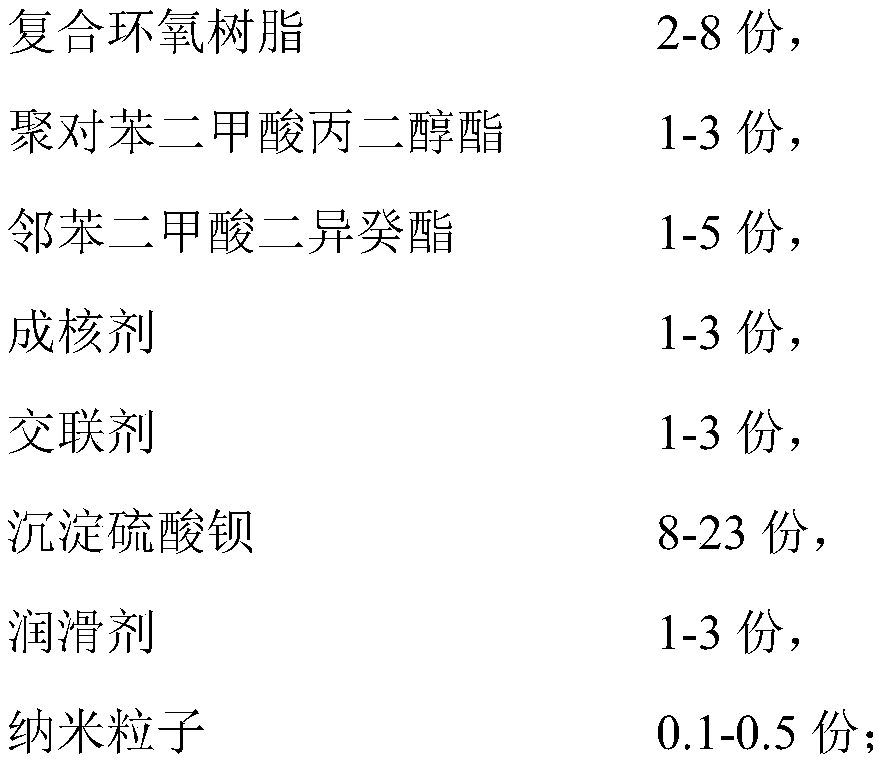

[0036] (2) Then add 2 parts of composite epoxy resin (the weight ratio of bisphenol A type epoxy resin and bisphenol F type epoxy resin is 2:1), 1 part of polytrimethylene terephthalate, 1 part of phthalate Diisodecyl diformate, 1.5 parts of nucleating agent, 2 parts of methylol acrylamide, 12 parts of precipitated barium sulfate (6000 mesh), 0.1 part of nanoparticles (nano-titanium dioxide (particle size 10-100nm) and nano-lanthanum oxide ( The weight ratio of the particle size (50-100nm) is 5:1), stir evenly at 5-38°C, and the stirring time is 5min;

[0037] (3) adding the material mixed in step (2) into a twin-screw ...

Embodiment 2

[0042] A low-temperature 3D printing material, the preparation method comprising the following steps:

[0043](1) Put 73 parts of polycaprolactone (molecular weight of 60000) (no need to dry in advance), 1.5 parts of white silicone oil into a high-speed mixer, and mix them evenly at 2-38°C (the temperature should not exceed 38°C), Mixing time 5min;

[0044] (2) Then add 5 parts of composite epoxy resin (the weight ratio of bisphenol A type epoxy resin and bisphenol F type epoxy resin is 5:1), 3 parts of polytrimethylene terephthalate, 3 parts of phthalate Diisodecyl diformate, 1 part of nucleating agent, 2.5 parts of methylol acrylamide, 22 parts of precipitated barium sulfate (8000 mesh), 0.5 part of nanoparticles (nano-titanium dioxide (particle size 10-100nm) and nano-lanthanum oxide ( The weight ratio of the particle size (50-100nm) is 10:1), and it is stirred evenly at 5-38°C, and the stirring time is 5 minutes;

[0045] (3) adding the material mixed in step (2) into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com