High-bulk papermaking method reconstruction tobacco leaf fiber composition and preparation method and application

A technology of reconstituted tobacco leaves and short fibers, applied in the application, preparation of tobacco, tobacco, etc., can solve the problems of reducing the CO emission of reconstituted tobacco leaves in the papermaking process, and achieve the effects of controllable woody gas, improved filler retention rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

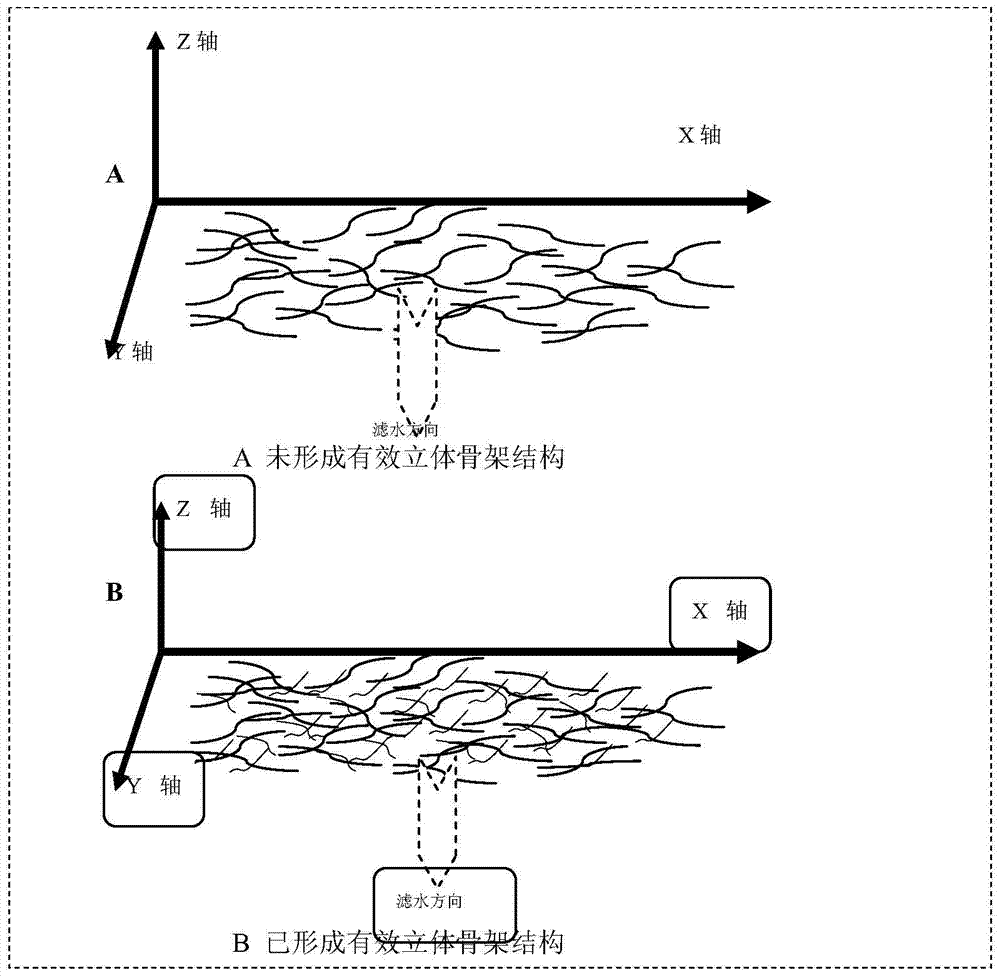

[0044] The long and short wooden fibers are used as the main skeleton of the substrate in the longitudinal and vertical directions, the high-efficiency defibrated tobacco stems are used as the auxiliary skeleton of the substrate in the transverse plane, and the finely pulped tobacco chips are used as the filler of the substrate. To ensure the normal operation of the paper machine, reconstituted tobacco leaves with good bulk and high coating rate. Schematic diagram of the distribution of long and short fibers during the water filtration process of the substrate figure 1 shown.

[0045] Tobacco stems and tobacco flakes are extracted by the method of "half-division and half-combination". Specifically, the tobacco stems are firstly extracted with hot water for 30 minutes, the extraction temperature is 60°C, and the solid-to-liquid ratio is 1:3; the rod-like defibrillator is used for defibrillation treatment, the mass volume concentration is 20%, the rotational speed is 1200rpm, a...

Embodiment 2

[0053] Tobacco stems and tobacco flakes are extracted by the method of "half-division and half-combination". Tobacco stems are firstly extracted with hot water for 30 minutes, the extraction temperature is 60°C, and the solid-to-liquid ratio is 1:3; the rod-like defibrillator is used for defibrillation treatment, the mass volume concentration is 28%, the rotational speed is 1800rpm, and the specific energy consumption is 90kW / h. Tobacco stems and tobacco flakes are mixed in a weight ratio of 6:4, extracted at a solid-to-liquid ratio of 1:6, squeezed and then subjected to secondary low-concentration beating with a beating concentration of 5% and a beating power of 120 to obtain smoke pulp.

[0054] The long wood fibers are selected from dolomites, and the short wood fibers are selected from eucalyptus. The long wood fibers and short wood fibers are mixed according to the mass ratio of 9:12. In the dolomites pulp, 82% of the fiber lengths are within the range of 0.8-4.0mm, and 80...

Embodiment 3

[0060] Tobacco stems and tobacco flakes are extracted by the method of "half-division and half-combination". Specifically, the tobacco stems are first extracted with hot water for 30 minutes, the extraction temperature is 60°C, and the solid-to-liquid ratio is 1:3; the rod-like defibrillator is used for defibrillation treatment, the mass volume concentration is 23%, the rotational speed is 1500rpm, and the specific energy consumption is 65kW / h, then the tobacco stems and tobacco chips are mixed according to the absolute dry weight ratio of 5:5, extracted with a solid-to-liquid ratio of 1:6, and after being squeezed dry, perform secondary low-concentration beating, the beating concentration is 4%, and the beating power is 120kW , to obtain smoke pulp.

[0061] The long wood fiber is made of twisted leaf pine, and the short wood fiber is made of eucalyptus. The long wood fiber and the short wood fiber are mixed according to the absolute dry mass ratio of 12:9. In the twisted le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com