Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Good "processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

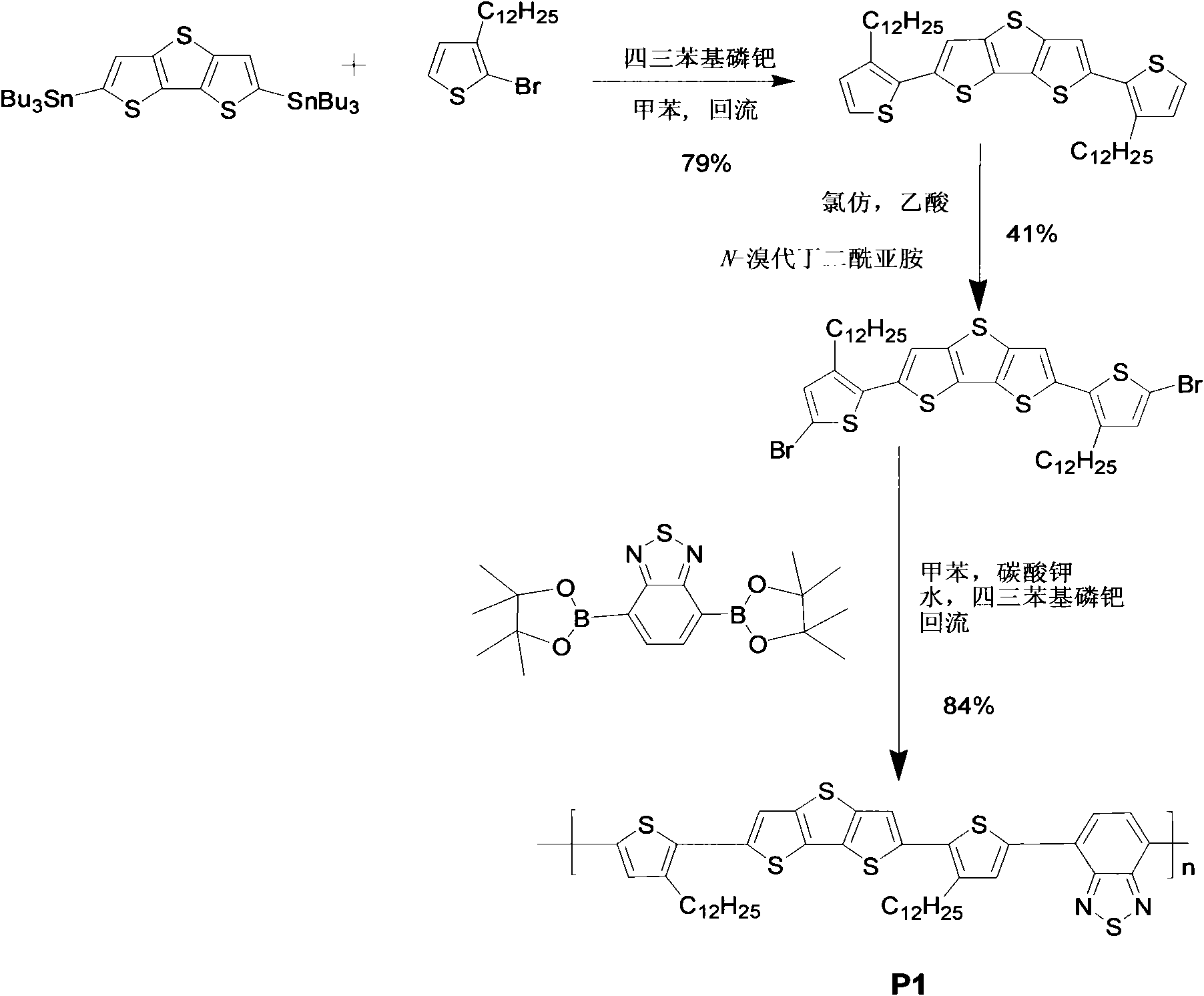

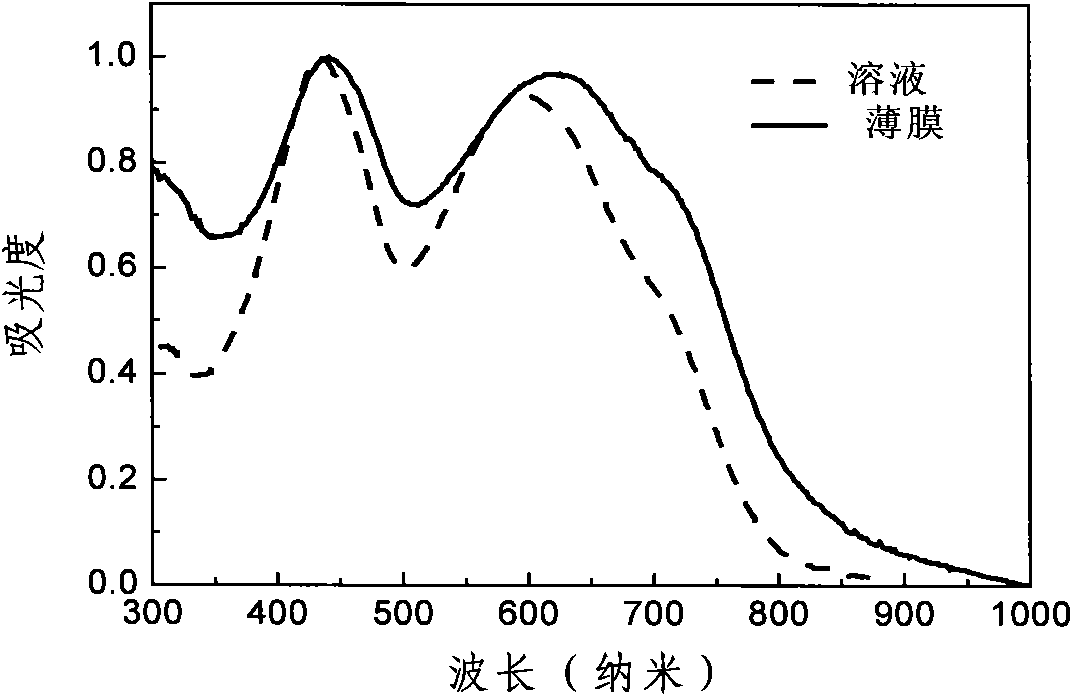

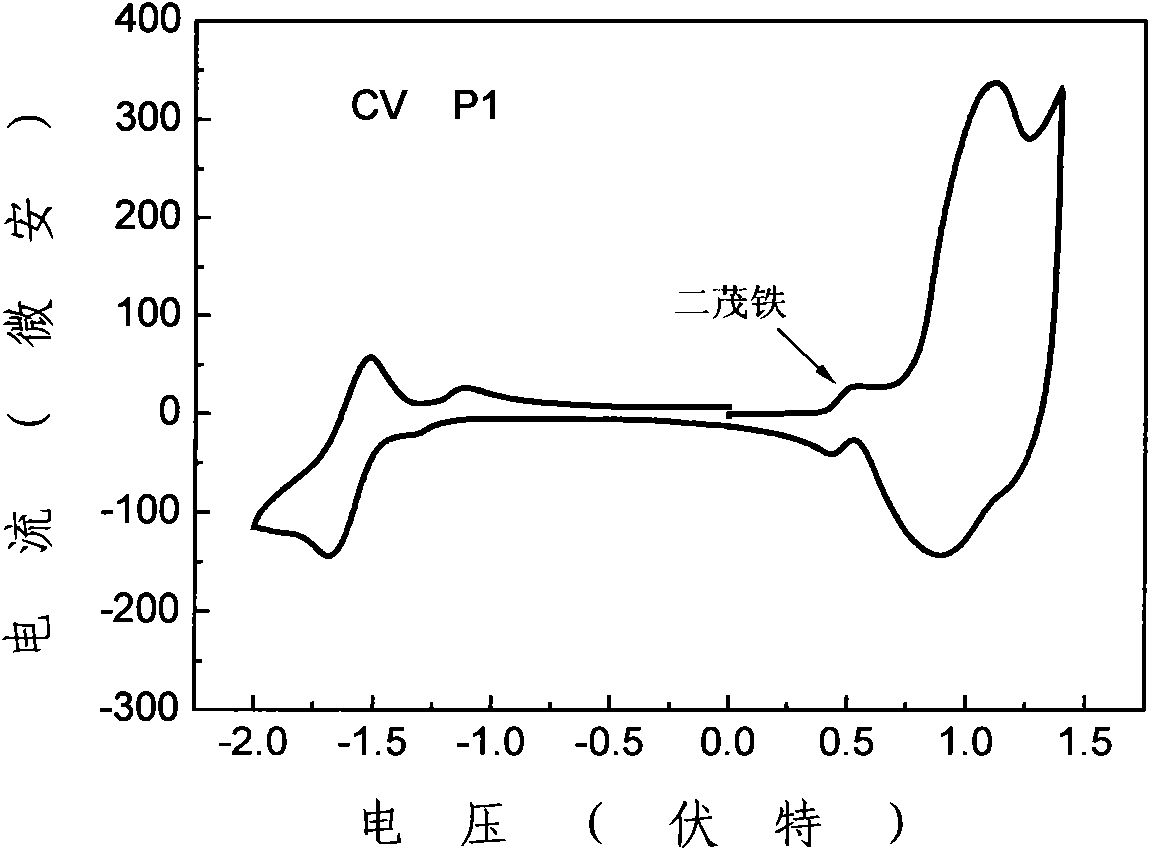

Conjugated polymer based on condensed ring thiophene and diazosulfide as well as preparation method and application thereof

ActiveCN101671428AGood processabilityGood thermal stabilitySolid-state devicesSemiconductor/solid-state device manufacturingTransmission performanceOrganic semiconductor

The invention relates to a conjugated polymer based on condensed ring thiophene and diazosulfide, a preparation method and an application of the conjugated polymer as an active layer material in organic optoelectronic devices, such as polymer solar energy cells, organic field effect transistors and organic light emitting diodes. The conjugated polymer based on condensed ring thiophene and diazosulfide has an excellent sunlight capture ability and a hole transmission ability, and the conjugated polymer solution has good processability, thermostability, charge transmission performance and lightadsorption and is an ideal organic semiconducting material in the organic electronic devices, such as solar energy cells, field effect transistors and light emitting diodes. A general formula of the conjugated polymer is shown as above.

Owner:INST OF CHEM CHINESE ACAD OF SCI

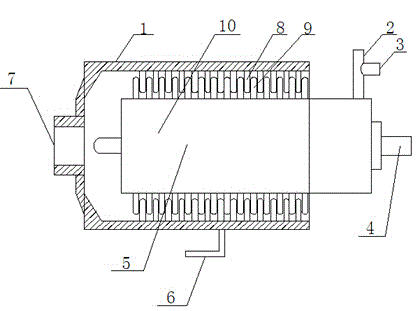

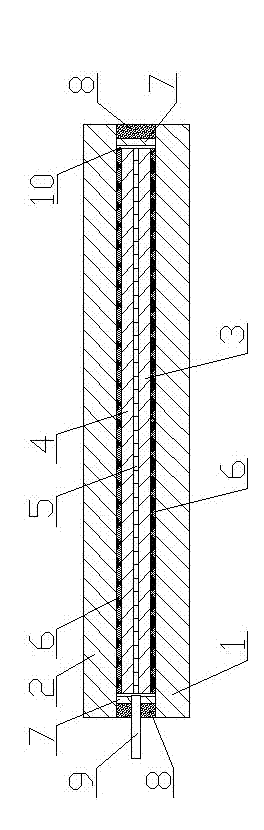

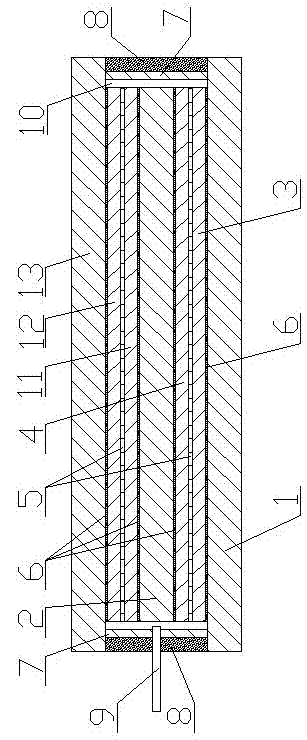

Micro-nano bubble generating device

InactiveCN104803467AReduce energy consumptionSimple structureWater/sewage treatment by substance additionWater/sewage treatment using germicide/oligodynamic-processMicro nanoMicro bubble

The invention provides a medical cleaning device, and relates to a micro-nano ozone bubble device, in particular to a micro-nano bubble generating device. The micro-nano bubble generating device comprises a foam maker and an ozone generator, wherein the foam maker is connected with the ozone generator through a pipeline; the foam maker comprises an inlet end, an outlet end, a power output device and a rotary stirring device; the inlet end is arranged at one end of the foam maker, and the outlet end is arranged at the other end, opposite to the inlet end, of the foam maker; the power output device is connected with the rotary stirring device and arranged outside the foam maker; the rotary stirring device is arranged inside the foam maker. The micro-nano bubble generating device is low in energy consumption, and can generate lots of micro bubbles; under the condition that the water pump power and the water flow pressure are not increased, more micro bubbles can be generated, and can reach micro-nanoscale. The device is simple in structure, excellent in processing and assembly performance, and simple and convenient to use and operate.

Owner:刘芮萌

Peppermint composite cellulose fibers and preparation method thereof

ActiveCN104593893AGood antibacterial effectComfortable to wearArtificial filaments from viscosePeppermintsAntibacterial activity

The present invention provides peppermint composite cellulose fibers, which contain 1-12 wt% of a peppermint extract component and 0.5-3 wt% of peppermint odor essential oil slow-release microcapsules, wherein the dry breaking strength of the fibers is 1.0-3.0 cN / dtex, the wet breaking strength of the fibers is 0.8-1.6 cN / dtex, the dry elongation at break is 16-24%, the residual sulfur content is less than or equal to 18 mg / 100 g, the antibacterial activity logarithm value is more than 2.0, and the bactericidal activity logarithm value is more than 0. The peppermint composite cellulose fiber preparation method comprises: peppermint extract adding liquid preparation, degenerated viscose glue preparing, peppermint blending viscose glue preparing, spinning and post-treating, and filament drafting and post-treating so as to obtain the peppermint composite cellulose fibers. The peppermint composite cellulose fibers of the present invention have characteristics of good wearability, textile processability, antibacterial function, bacterial inhibition function, lasting and fresh peppermint aroma, lasting odor, good textile processing performance, and significant antibacterial function.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

Fire-retardant composite materials

InactiveUS20120164373A1Good mechanical propertyGood processabilitySynthetic resin layered productsThin material handlingEpoxideFire retardant

A prepreg for the manufacture of a fibre-reinforced composite material, the prepreg including:i. an epoxy-resin matrix including:a. at least one non-halogenated epoxide-containing resin which has been chemically modified with at least one of a nitrogen- and / or phosphorous-containing molecule which has been chemically reacted with the epoxide-containing molecule;b. at least one toughening additive comprising an elastomeric or thermoplastic material chemically reacted with the at least one epoxide-containing resin;c. at least one mineral filler to provide fire-retardancy; andd. at least one catalyst for curing the epoxide-containing resin; andii. a fibrous reinforcement at least partially impregnated by the epoxy resin matrix.

Owner:GURIT (UK) LTD

Organic electronic devices and polymers, including photovoltaic cells and diketone-based and diketopyrrolopyrrole-based polymers

InactiveUS20110114184A1Extend conjugation lengthGood processabilityGroup 4/14 element organic compoundsSolid-state devicesPyrroleComposite material

Polymers which can be used in p-type materials for organic electronic devices and photovoltaic cells. Compounds, monomers, dimers, trimers, and polymers comprising:wherein A1 and A2 each independently comprise a fused ring system comprising at least two fused rings directly covalently linked to the pyrrole rings. Good photovoltaic efficiency and lifetime can be achieved. The R group can provide solubility, environmental stability, and fine tuning of spectroscopic and / or electronic properties. Different polymer microstructures can be prepared which encourage multiple band gaps and broad and strong absorptions. The carbonyl can interact with adjacent thiophene rings to provide backbone with rigidity, induce planarity, and reduce and / or eliminate intramolecular chain twisting defects.

Owner:SOLVAY USA

Manufacturing method of titanium-steel-titanium two-sided composite plate

ActiveCN102773670AReasonable process designLow requirements for welding conditionsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-steel-titanium two-sided composite plate. The manufacturing method comprises the following processing steps: (1) four titanium plates with the same dimension and three steel plates with the same dimension are selected respectively, and rust and oxide layer removal processing is performed on the surfaces of the titanium plates and the steel plates; (2) a multilayer combination blank with three layers of steel plates, four layers of titanium plates and four layers of transition layers is formed through assembly, and gaps are arranged between the peripheries of the titanium plates and barrier strips in the combination blank; (3) the combination blank is pressed tightly and enables the barrier strips to be welded to a first steel plate and a third steel plate so as to enable the first steel plate, the second steel plate and the inner portions of the barrier strips to form a closed cavity, holes are drilled on the barrier strips, steel tubes are welded in the holes, and the steel tubes are communicated with the closed cavity; (4) the combination blank is sent to a heating furnace to be heated and vacuumized; (5) the combination blank is sent to a rolling mill to be rolled after the outer ends of the steel tubes are sealed; and (6) one titanium-steel-titanium two-sided composite plate and two titanium-steel single-sided composite plates are obtained by slitting the combination blank after the combination blank is rolled. The manufacturing method of the titanium-steel-titanium two-sided composite plate is reasonable in design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

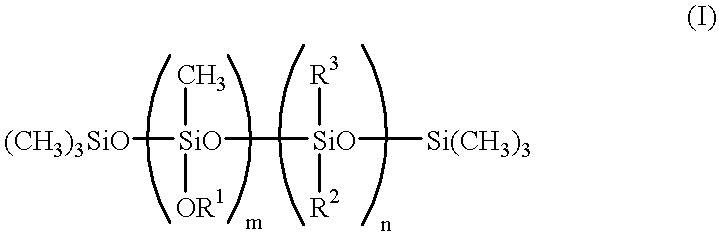

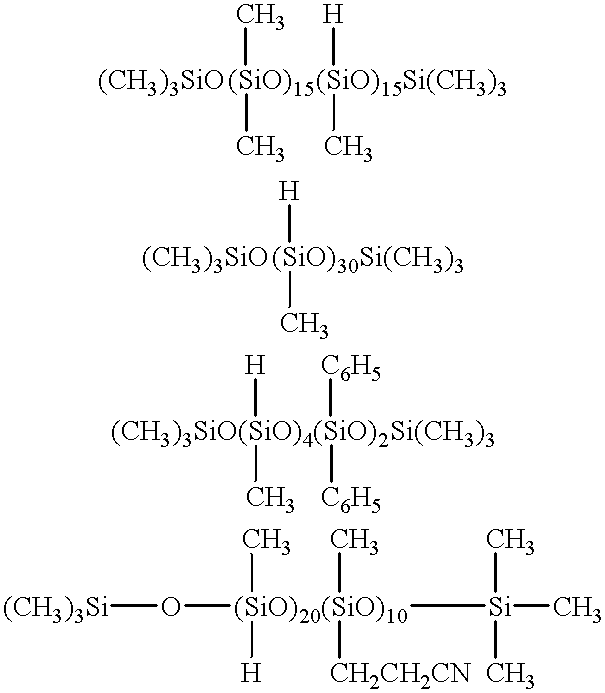

Rubber composition

InactiveUS6180703B1Good processabilityExcellent propertySolesLayered productsDegree of polymerizationElastomer

Rubber compositions for footwear, conveyor belt covers, rolls, hoses, cables, rubberized fabrics, and grips containing (A) an elastomer, (B) 5 to 150 parts by weight of a filler, and (C) a polysiloxane represented by the formula (I):wherein R1, R2, R3, m, and n are as defined in the specification, having an average degree of polymerization of 3 to 1000 in a specific ratio with respect to the filler (B) and footwear, conveyor belt covers, rolls, hoses, cables, rubberized fabrics, and grips comprising these rubber compositions.

Owner:YOKOHAMA RUBBER CO LTD

Adhesive film

InactiveUS20050247402A1Good processabilityCharacteristic having strengthLamination ancillary operationsSynthetic resin layered productsDouble bondCarbonyl group

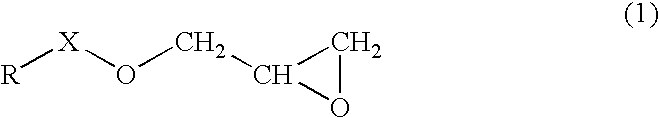

The present invention provides an adhesive film obtainable by irradiating electron beam on a molded article obtainable by molding a resin composition comprising components (A) and (B), the storage method of the film and a laminate comprising the adhesive film and an adherent. Component (A) is an epoxy group-containing copolymer obtainable by polymerizing, wherein (a1) is ethylene and / or propylene, and (a2)is a monomer represented by formula (1): (wherein R represents a hydrocarbon group of a carbon number of 2 to 18 having a double bond, wherein at least one of hydrogen atoms of the hydrocarbon group may be substituted with a halogen atom, a hydroxyl group or a carboxyl group, and X represents a single bond or a carbonyl group). Component (B) is a copolymer obtainable by polymerizing (b1) and (b2), wherein (b1) is ethylene and / or propylene, and (b2) is α,β-unsaturated carboxylic acid anhydride.

Owner:SUMITOMO CHEM CO LTD

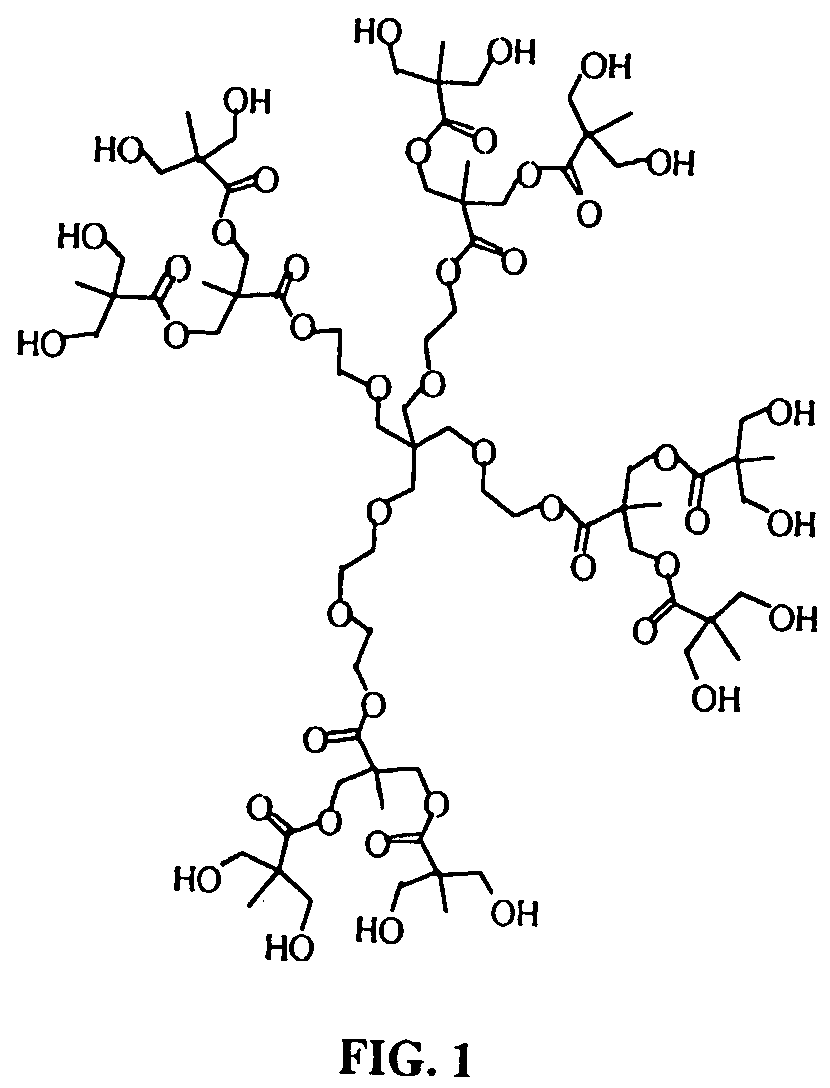

Composites and methods for their production

InactiveUS20050038167A1Good processabilityHigh massMaterial nanotechnologySpecial tyresMolar massPolymer chemistry

Intercalates and exfoliates formed from layered materials and dendritic polymers are disclosed, together with the uses of these materials, e.g. in producing composite materials. The dispersion of layered materials in a dendritic polymer matrix (hyperbranched polymers, star shaped polymers or star branched polymers) or has not been disclosed in the prior art. The high number of end-groups per molecule of dendritic polymer combined with their unique globular architectures leads to large intergallery spacings when intercalated in layered silicates and particularly facile exfoliation in spite of the high molar mass of the dendritic polymer. The excellent processability and potential high reactivity of dendritic polymers makes them extremely promising for thermoset applications, and coatings.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Weather-resistant film for the yellow coloration of retro-reflective moulded bodies

InactiveUS7754317B2High resistanceGood processabilitySynthetic resin layered productsReflex reflectorsAnthraquinone dyePhotochemistry

Owner:EVONIK ROEHM GMBH

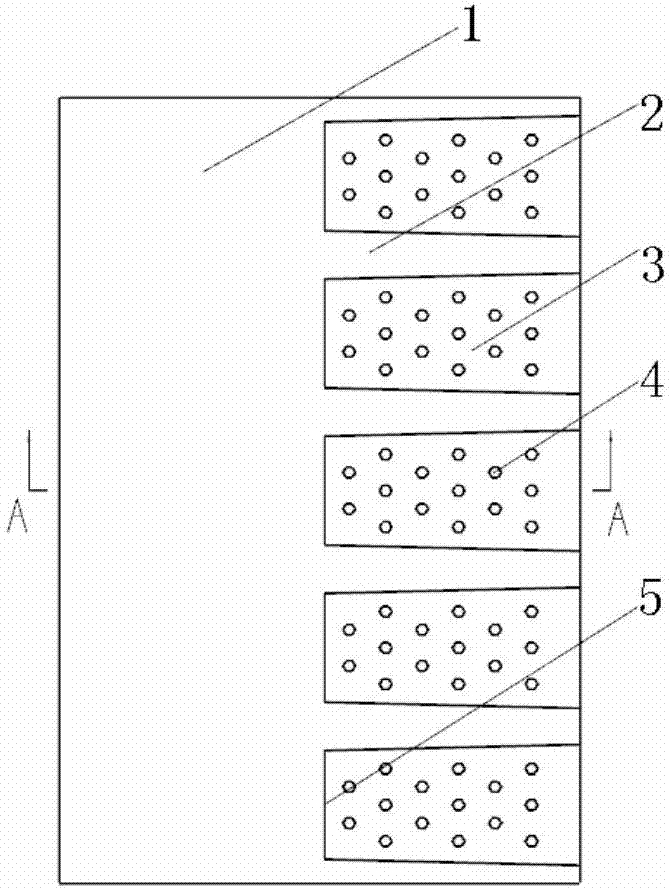

Turbine blade trailing edge turbulent flow half-wedge type seam cooling structure with array pin fins

InactiveCN107035421AImprove cooling effectImprove heat transfer effectBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention discloses a turbine blade trailing edge turbulence half-slit cooling structure with an array of pin ribs. The array of pin ribs is applied to the half-slit wall surface, and the flow turbulence structure is passed without increasing the outflow of the gas film. Improve the convective heat transfer coefficient and heat transfer area of the air film, and enhance the convective heat transfer intensity of the half-slit air film cooling, thereby improving the comprehensive cooling effect of the trailing edge of the blade. Turbine blade trailing edge turbulent half-split cooling structure with continuous array of needle ribs cuts off part of the wall on the pressure surface of the blade trailing edge, retains the wall on the suction side of the blade trailing edge and separates the partition ribs to form multiple half-splits Slit structure, the cooling air flow is ejected from the cold flow outlet and covers the split wall of the trailing edge to form a cooling air film. The structure is simple; the maximum temperature and average temperature of the suction surface can be effectively reduced, and high-temperature ablation of the suction surface of the turbine blade can be avoided. The straight rib structure is arranged on the half-slit wall surface, which has good heat transfer characteristics and good processing feasibility.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Heat-resistant austenitic stainless steel sheet

ActiveCN105051233AExcellent oxidation resistanceGood processabilityFurnace typesHeat treatment furnacesAustenitic stainless steelHeat resistant

This heat-resistant austenitic stainless steel sheet contains, in mass%, 0.05-0.15% of C, 1.0-3.5% of Si, 0.5-2.0% of Mn, 0.04% or less of P, 0.01% or less of S, 23.0-26.0% of Cr, 10.0-15.0% of Ni, 0.50-1.20% of Mo, 0.1% or less of Ti, 0.01-0.10% of Al and 0.10-0.30% of N, with the total of C and N (C + N) being 0.25-0.35% and with the balance made up of Fe and unavoidable impurities. This heat-resistant austenitic stainless steel sheet can be used in a high temperature environment where the highest temperature reaches 1,100°C.

Owner:NIPPON STEEL STAINLESS STEEL CORP

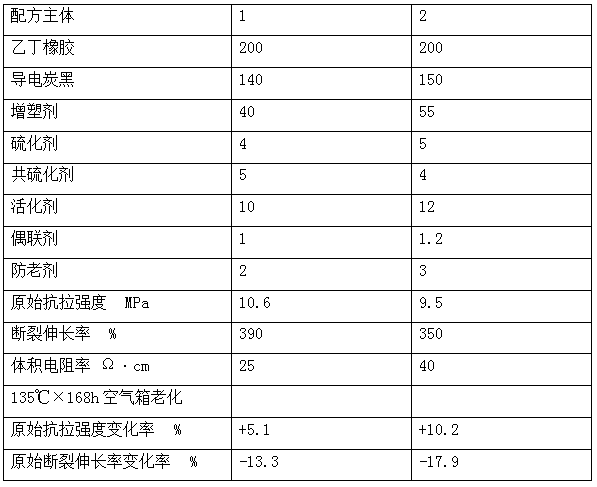

Semiconductor shielding cable material

ActiveCN102838801AGood filling effectImprove heat resistancePlastic/resin/waxes insulatorsShielded cableVulcanization

The invention relates to a semiconductor shielding cable material, and belongs to the technical field of cable materials. The semiconductor shielding cable material comprises the following components in parts by weight: 100 parts of butyl rubber, 50-120 parts of conducting carbon black, 20-45 parts of plasticizing agent, 1.0-6.0 parts of vulcanizing agent, 1.0-6.0 parts of co-vulcanizing agent, 1.0-10 parts of activating agent, 0.2-0.5 part of coupling agent, and 0.5-5.0 parts of anti-aging agent. The semiconductor shielding cable material has the advantages that the formula not only is low in cost, but also is simple in component; the butyl rubber with low cost, low viscosity and high fallibility is adopted as a base material, the vulcanization system matched with the butyl rubber is selected, and the conducting carbon black with good conductivity and processing performance is added, so that the defects of bad processing performance and high price in the prior art are overcome.

Owner:SICHUAN MINGXING CABLE

Proton exchange membrane

The invention belongs to the technical field of a fuel cell, in particular to a proton exchange membrane. The proton exchange membrane is prepared from a combination comprising a sulfonated poly ether ether ketone solution, sulfonated polyphenylene oxide sppo, a polyaniline filter liquid, heteropoly acid and a titanium dioxide fluid. The proton exchange membrane has the advantages of favorable mobility and processability; with the combination of the titanium dioxide fluid, the sulfonated poly ether ether ketone solution, the sulfonated polyphenylene oxide sppo and the polyaniline filter liquid, the reduction of proton conductivity can be reduced, the methanol permeability of the composite proton exchange membrane is effectively reduced, the comprehensive performance of the proton exchange membrane is improved, the methanol permeation problem when an Nafion membrane is used for a direct methanol fuel cell (DMFC) is solved, the proton conductivity is also not reduced, and the requirement for PEM used by the DMFC is met; and the proton exchange membrane can be used for the DMFC and also can be used for an alcohol fuel cell such as a direct ethanol fuel cell.

Owner:SHANDONG XINGHUO SCI TECH INSTITYTE

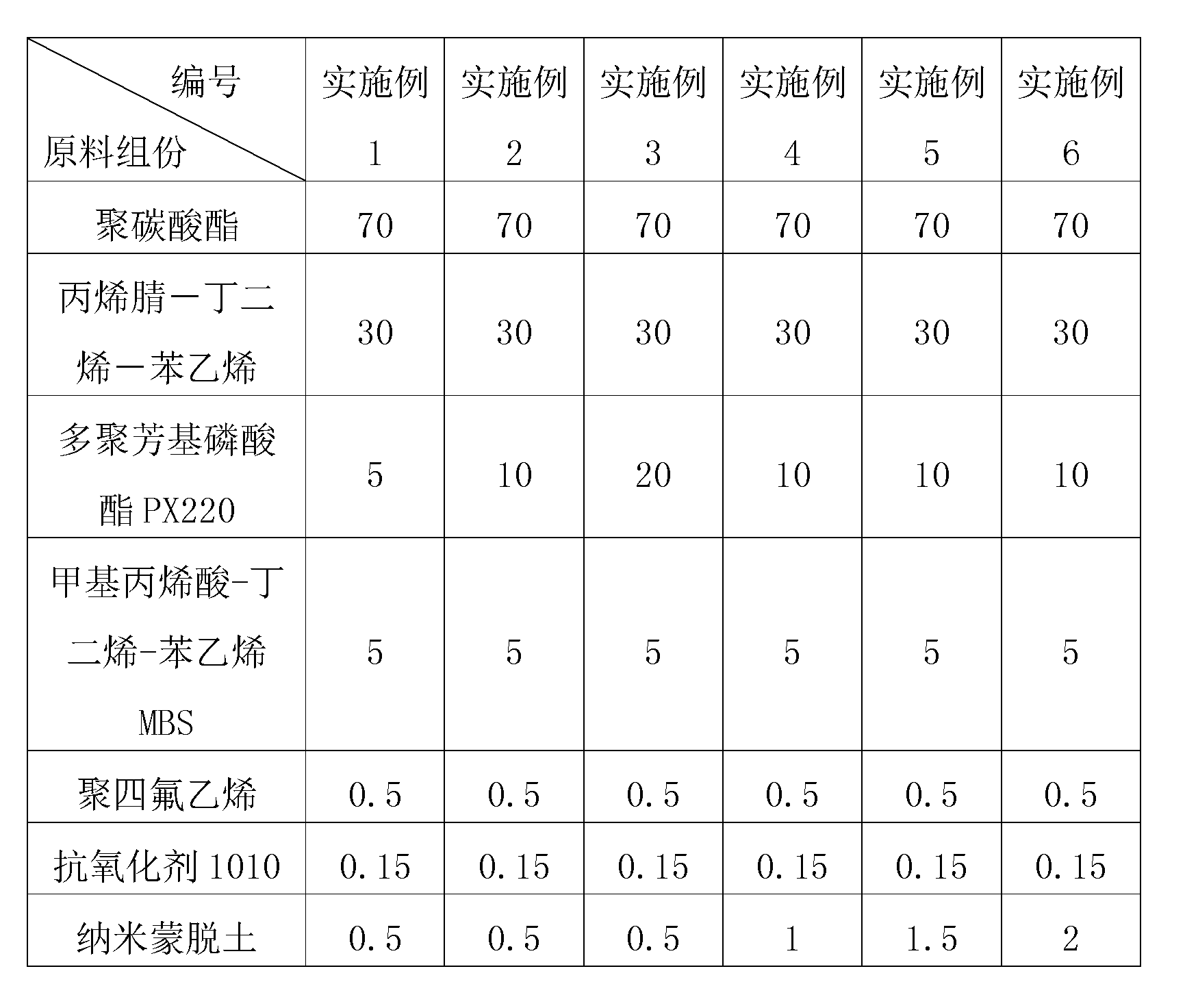

High-performance halogen-free flame-retardant PC/ABS alloy material and preparation process thereof

The invention discloses a high-performance halogen-free flame-retardant PC / ABS alloy material and a preparation process thereof. Raw materials for the material comprise main materials and accessory materials, wherein the main materials comprise, by weight, 70 parts of polycarbonate and 30 parts of acrylonitrile-butadiene-styrene, and the accessory materials comprise, on the basis of 100 parts of the main materials, 5 to 20 parts of a fire retardant, 0 to 5 parts of a compatilizer, 0 to 0.5 part of polytetrafluoroethylene and 0 to 0.15 part of an anti-oxidant. The alloy material prepared in the invention has a unique self-extinguishing character, good processability, compatibility and thermal stability; the addition amount of the fire retardant in the whole alloy material is obviously decreased compared with the addition amount of a fire retardant in the prior art, good flame resistance is obtained while other performances of the alloy material are not influenced, and obviously decreased addition amount of the fire retardant is beneficial for environmental protection.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

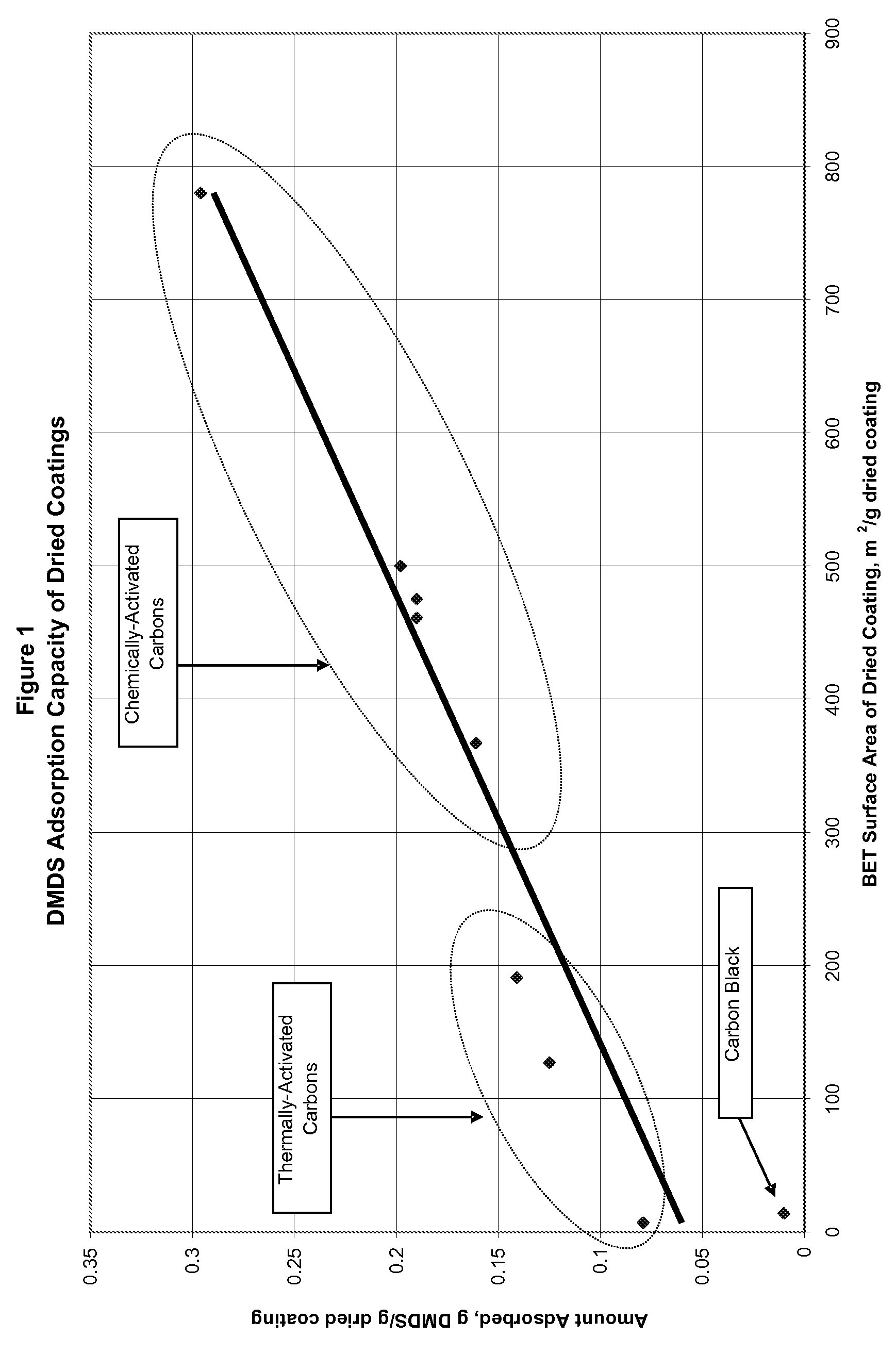

Adsorptive coating formulation

InactiveUS20090075060A1Good adsorption performanceGood processabilityAntifouling/underwater paintsLayered productsActivated carbonCoating

A coating formulation is disclosed that is capable of imparting, onto the treated substrate, an excellent adsorption performance, good print appearance, and enhanced rub-off resistance. Furthermore, the disclosed formulation has good ink stability and offers high quality print appearance throughout long printing runs of high speeding printing applications. The formulation comprises an activated carbon having a particle size of less than 1 micron and a binder, wherein an amount of the binder by weight is in a range of about 30 parts to 100 parts per 100 parts of the activated carbon, and the formulation has a dry basis BET Surface Area of greater than 100 m2 / g.

Owner:MEADWESTVACO CORP

Thermoformed articles made from reactive extrusion products of biobased materials

ActiveUS20110135863A1Good performanceGood processabilityCapsWrappers shrinkageChemistryPolylactic acid

The present invention is directed to a method of producing a themoformable composite by crosslinking PHA and PLA together in the presence of an additive to produce PHA and PLA blend and resins having: (a) a Ts value of up to about 180° C.; and (b) a heat distortion index of up to about 160° C. The themoformable composite is used to make a food or beverage cup, lid, cutlery item, foodservice item, molded tray, or food storage container. The thermoformable composite comprises from about 5% to about 95% by weight of polylactic acid (PLA), from about 5% to about 95% by weight polyhydroxyalkanoate (PHA) polymer, and from about 0.01% to about 60% additives wherein the PLA and PHAs being crosslink together by intermolecular means to enhance performance and processability

Owner:GRAPHIC PACKAGING INT

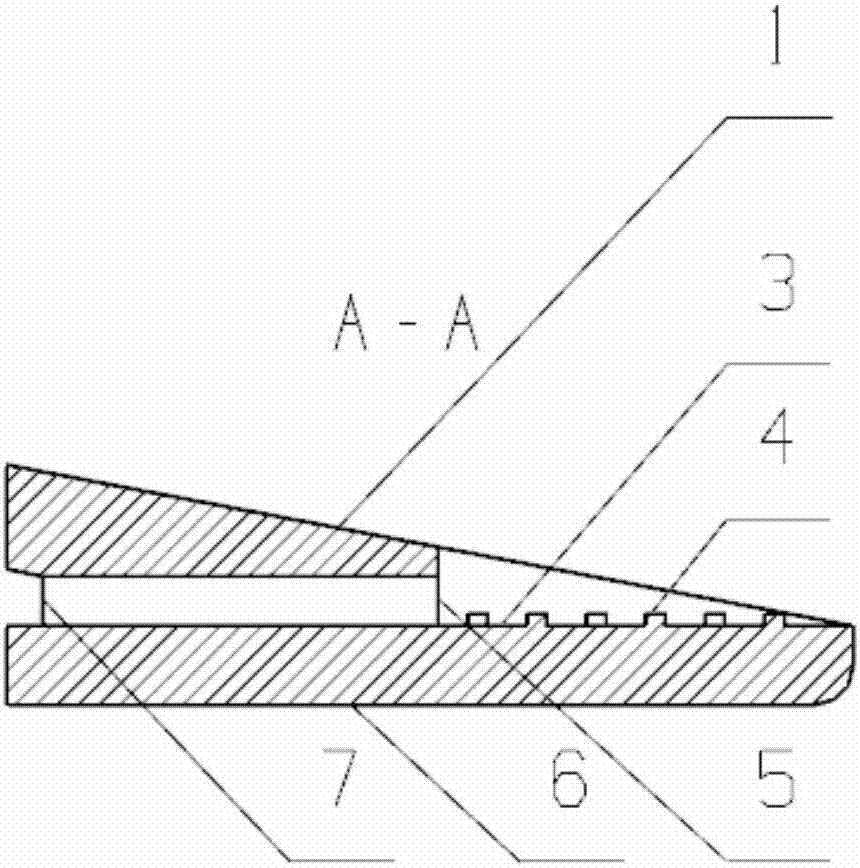

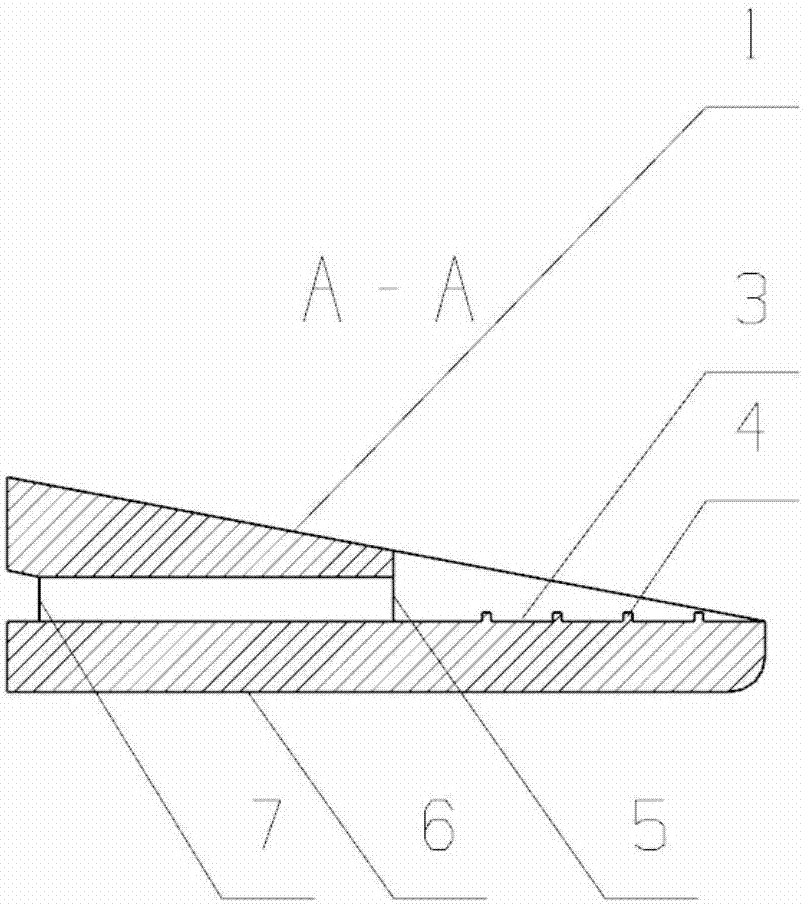

Turbine blade tail edge turbulence half-crack cooling structure with continuous straight ribs

InactiveCN107013255AAvoid high temperature ablationImprove cooling effectEngine fuctionsBlade accessoriesTurbine bladeCooling effect

The invention discloses a turbine blade trailing edge turbulence semi-slit cooling structure with continuous straight ribs. The straight rib structure is applied to the wall surface of the trailing edge half-slit. The flow structure improves the convective heat transfer coefficient and heat transfer area of the air film, and enhances the convective heat transfer intensity of the half-slit air film cooling, thereby improving the comprehensive cooling effect of the trailing edge of the blade. The turbulent half-split cooling structure is to cut off part of the wall surface on the pressure surface of the blade trailing edge, and retain the wall surface on the side of the suction side of the blade trailing edge and the spaced partition ribs to form a plurality of half-slit structures. The design is reasonable and the structure is simple; its characteristics are The cooling air flow is ejected from the cold flow outlet and covers the half-slit wall surface to form a cooling air film, which can effectively reduce the maximum and average temperature of the suction surface and avoid high-temperature ablation of the suction surface of the turbine blade. A simple straight rib structure is arranged on the half-slit wall surface, which has good heat transfer characteristics and good processability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Thermosettable composition containing a glycidylether based on trimethyolpropane octadecaethoxilate

A thermosettable composition including (a) a thermosetting resin and (b) at least one toughening agent; wherein the at least one toughening agent is a glycidyl ether based on trimethylolpropane octadecaethoxilate (TMP-18EO).

Owner:DOW GLOBAL TECH LLC

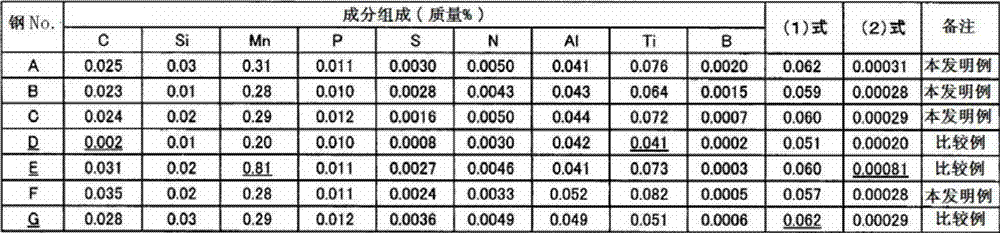

High-tension/hot-rolled steel sheet having excellent workability, and method for producing same

ActiveCN102959117AGood processabilityGood effectHot-dipping/immersion processesFurnace typesSheet steelHot rolled

Provided is a high-tension / hot-rolled steel sheet which has both strength and workability (stretch flangeability). The high-tension / hot-rolled steel sheet has: a composition comprising, by mass%, 0.005% to 0.050% of C, 0.2% or less of Si, 0.8% or less of Mn, 0.025% or less of P, 0.01% or less of S, 0.01% or less of N, 0.06% or less of Al, and 0.05% to 0.10% of Ti such that S, N, and Ti satisfy Ti>=0.04+(N / 1448+S / 3248), and with Fe and inevitable impurities as the balance; a matrix in which the ferrite phase is 95% or more by surface area percentage with respect to the overall structure; a structure in which carbide microparticles comprising Ti and having an average grain size of less than 10 nm are dispersed and precipitated, and the volume ratio of the carbide microparticles with respect to the overall structure is 0.0007 or greater; a tensile strength of 590 MPa or greater; and excellent workability.

Owner:JFE STEEL CORP

Flame retarding aging resistant polyvinyl chloride cable material and preparation method thereof

InactiveCN104861330AExcellent mechanical properties and flame retardant propertiesGood processabilityPlastic/resin/waxes insulatorsPolymer chemistryZinc

The invention discloses a flame retardant aging resistant polyvinyl chloride cable material and a preparation method thereof. The flame retardant aging resistant polyvinyl chloride cable material comprises the following components by mass: 60%-75% of polyvinyl chloride, 8%-15% of decabromo diphenylethane, 2%-4% of antimony trioxide, 1%-2% of a calcium zinc stabilizer, 10%-15% of a plasticizer, 1%-3% of a light stabilizer, 0.1%-0.5% of an antioxidant and 0.5%-1 % of a lubricant, the plasticizer is one or one than one of bis(2-propylheptyl) phthalate, dioctyl terephthalate, trioctyl trimellitate and dioctyl sebacate. The beneficial effect is that the flame retardant aging resistant polyvinyl chloride cable material has excellent flame retardant properties and mechanical properties, good processability, strong aging resistance, low cost and simple preparation process.

Owner:殷培花

High-toughened chloroethylene grafted copolymer and preparation method thereof

The invention discloses a high-toughened chloroethylene grafted copolymer and a preparation method thereof, and belongs to the field of high polymer materials. The high-toughened chloroethylene grafted copolymer is characterized in that the graft copolymerization process is divided into two stages for preparing the chloroethylene grafted copolymer, wherein the first stage is to prepare acrylate rubber latex which adopts a core-shell structure and is rich in unsaturated double bond active grafting sites on the surface; the second stage is to carry out graft copolymerization to 1-10% of the acrylate rubber latex and 90-99% of chloroethylene in mass fraction; the acrylate monomer is copolymerized with the crosslinking monomers containing two or more non-conjugated double bonds to prepare the crosslinked polymer latex as a core, and then the crosslinking monomers are polymerized on the surface of the core to form a shell, so as to prepare the acrylate rubber latex, the average grain diameter of which is 0.080-0.500 microns. The copolymer resin prepared by the preparation method disclosed by the invention is excellent in shock strength and processability; the extra impact modifier is not required to be used.

Owner:CHINA PETROLEUM & CHEM CORP

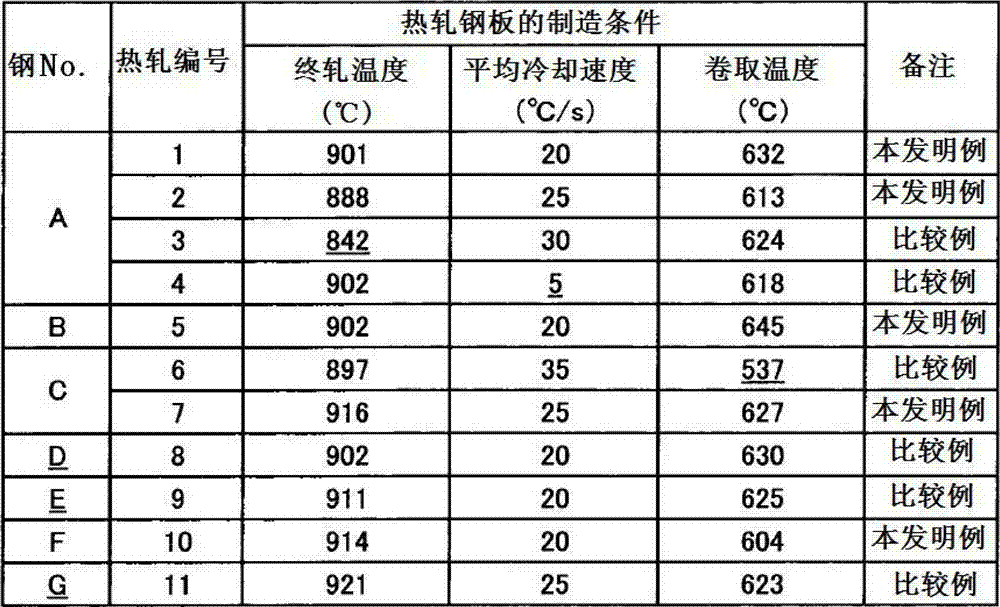

Exhaust pump

ActiveUS20130164124A1Good processabilityEasily balancePump componentsStatorsEngineeringMechanical engineering

Provided is an exhaust pump that is suitable for enhancing durability, processability of connecting opening portions in a pump production stage, and evacuation performance. An exhaust pump includes: a cylindrical rotating member; a support unit of the cylindrical rotating member; a driving unit for rotationally driving the cylindrical rotating member; an outer cylindrical fixed member disposed so as to surround the outer periphery of the cylindrical rotating member; an inner cylindrical fixed member disposed so as to be surrounded by the inner periphery of the cylindrical rotating member; a helical outer thread groove exhaust passage provided between the cylindrical rotating member and the outer cylindrical fixed member; a helical inner thread groove exhaust passage provided between the cylindrical rotating member and the inner cylindrical fixed member; connecting opening portions that are opened in the cylindrical rotating member and that lead a part of gas existing in the vicinity of the outer periphery of the cylindrical rotating member towards the inner thread groove exhaust passage. A gap between an upstream end of the connecting opening portions and lowermost stage rotor blades provided at the outer periphery of the cylindrical rotating member which is located upstream of the connecting opening portions has a dimension equal to or greater than a dimension that enables insertion, into the gap, of a tool for opening the connecting opening portions.

Owner:EDWARDS JAPAN

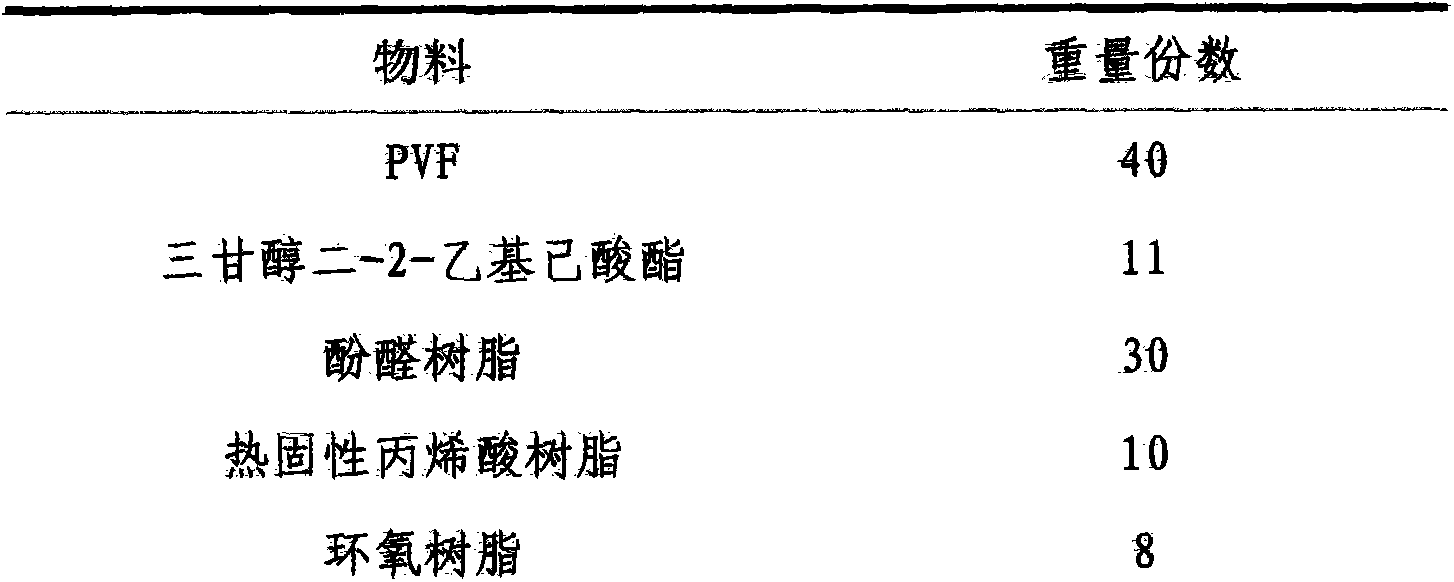

Thermosetting membrane for adhesion of bulletproof fiber and processing method of thermosetting membrane

InactiveCN103450822AImprove performanceSimple production processNon-macromolecular adhesive additivesFilm/foil adhesivesAviationCarbon fibers

The invention discloses a thermosetting membrane for the adhesion of bulletproof fiber and a processing method of the thermosetting membrane, and belongs to the field of high-molecular materials. The thermosetting membrane is prepared from the following materials in parts by weight: at least (a) 40-50 parts of film-forming resin, (b) 13-15 parts of plasticizing agents for the film-forming resin, (c) 30-45 parts by weight of curable resin, (d) 5-10 parts of cured resin curing agents and (e) 0.05-2 parts of surface treating agents. The method disclosed by the invention can be used for preparing the thermosetting membrane with good film-forming property, the uniform accuracy of + / - 0.001 mm, the crosslinking degree less than 5% and the thickness of 0.05-0.2 mm, has the advantages of simple preparation process, no solvent volatilization, good sizing uniformity, uniformity in interface adhesion, and the like and fundamentally overcomes the defects of low production efficiency, serious environment pollution, poor sizing uniformity, product fiber embrittlement and the like which are brought by using a wet method process of a liquid adhesive material. The thermosetting membrane disclosed by the invention is mainly applied to the adhesion of single materials, namely bulletproof aramid fiber materials, carbon fibers and the like, or composite materials and is applied to the fields of aviation, war industry, civil use and the like in production of bulletproof clothes, bulletproof helmets and the like.

Owner:宣英男 +1

Calotropis gigantean fiber composite fiber fabric and manufacturing method thereof

The invention relates to a calotropis gigantean fiber composite fiber fabric and a manufacturing method thereof; the fabric is formed by evenly feeding and spinning 30-70wt% calotropis gigantean fibers with 70-30wt% cotton fibers; the method comprises the following steps: using a single face machine and dual-face machine to process the blended yarns through a Siro compact spinning method, thus forming a fabric primary product; pre-setting treatment before dyeing; preprocessing before dyeing; dyeing; neutralizing; soaping; dye fixation; drying and setting process, thus forming the calotropis gigantean fiber composite fiber fabric. Compared with the prior art, the calotropis gigantean fiber composite fiber fabric is light in wearing, can further enhance hygroscopic, permeability and thermal insulation performance, and the fabric is excellent in fiber weaving processing and wearability performance.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

Resin composition for molding material and molded article made therefrom

ActiveCN1860174AGood processabilityExcellent hardness and tear strengthMethyl methacrylatePolymer chemistry

A resin composition for molding materials which comprises: an acrylic polymer comprising primary particles which have a core / shell structure comprising a core polymer and a shell polymer and in which the core polymer and shell polymer comprise methyl methacrylate monomer units and the content of methyl methacrylate monomer units in the core polymer is lower than that of methyl methacrylate monomer units in the shell polymer; and a plasticizer. The resin composition has high moldability during molding and gives a molded article having high hardness and high tear strength and reduced in plasticizer bleeding.

Owner:MITSUBISHI CHEM CORP

Double-component fluorine-containing hydrophobic coating as well as preparation and using method thereof

The invention relates to a double-component fluorine-containing hydrophobic coating as well as a preparation method thereof. The preparation method comprises a step of combining fluorine-containing polyacrylates with organic nano-particles to form the all-organic super-hydrophobic coating. The coating includes the following components in percentage by mass: the component A is 5 percent to 50 percent of fluorine-containing polyacrylates resin, 50 percent to 75 percent of organic nano or micro materials, 0.1 percent to 2 percent of fluorine-containing alcohol and 5 percent to 20 percent of solvent; and the component B is a curing agent. The component A is mixed with the component B according to a certain mass ratio, so that the coating is prepared. The coating can cover various substrates, and can be cured to generate the hydrophobic coating, and thus, the substrates are high in superhydrophobicity.

Owner:GUODIAN NEW ENERGY TECH INST

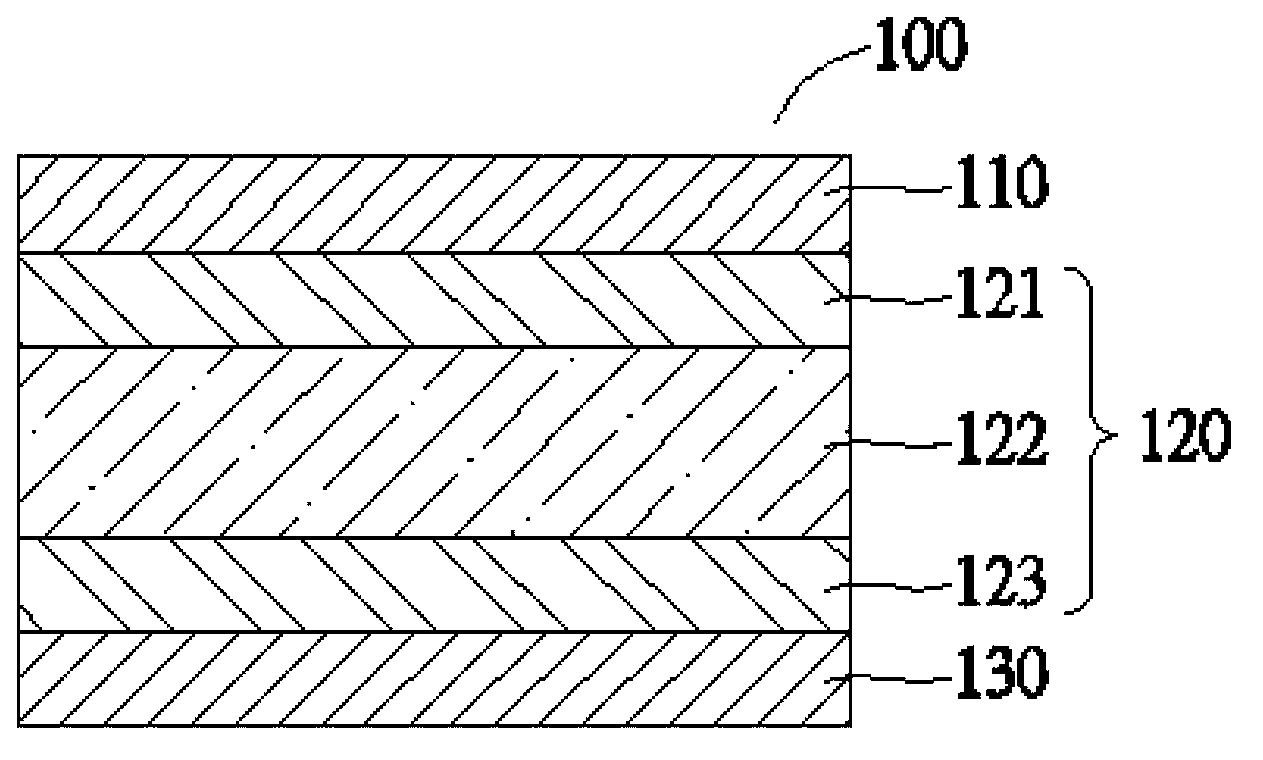

High-frequency substrate structure and manufacturing method thereof

InactiveCN103635015AGood processabilityLow dielectric constantCircuit susbtrate materialsMultilayer circuit manufactureComposite filmDielectric loss

The invention disclose a high-frequency substrate structure and a manufacturing method thereof. The high-frequency substrate structure comprises a composite film that is formed by a first sublayer, a second sublayer and a third sublayer. The first sublayer, the second sublayer and the third sublayer are laminated in sequence; and at least one of the first sublayer, the second sublayer and the third sublayer is a fluorine type polymer layer. In addition, the high-frequency substrate structure also includes a first metal layer and a second metal layer. The first metal layer is formed at the first sublayer that is clamped between the second sublayer and the first metal layer; and the second metal layer is formed at the third sublayer that is clamped between the second sublayer and the second metal layer. According to the invention, the manufacturing process machinability of the high-frequency substrate structure is good; and on the basis of testing results, the high-frequency substrate structure has the advantages of low dielectric constant, low dielectric loss and good heat resistance.

Owner:KUSN APLUS TEC CORP

Rubber composition, method of producing the same and tire using the same

InactiveUS20050215697A1High fill ratioGood processabilityOther chemical processesSpecial tyresAluminiumButadiene-styrene rubber

A rubber composition comprises a diene rubber component, a filler and a softening agent, in which a given amount of a filler is compounded based on 100 parts by mass of a diene rubber component, and a softening agent is included in a given amount per the filler, and not less than 60% by mass of the diene rubber component is a solution-polymerized styrene-butadiene copolymer rubber having a mass average molecular weight of not less than 1,000,000, and the filler is selected from the group consisting of carbon black, silica and an inorganic agent of a formula (I): mM.xSiOy.zH2O (wherein M is at least one metal selected from the group consisting of aluminum, magnesium, titanium and calcium, or an oxide of such a metal or a hydroxide of such a metal, m is a number of 1-5, x is a number of 0-10, y is a number of 2-5 and z is a number of 0-10), wherein each of the filler and the softening agent is charged in at least two fractions.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com