Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57results about How to "Improve filler retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treated filler or pigment containing natural carbonate

InactiveUS6666953B1Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

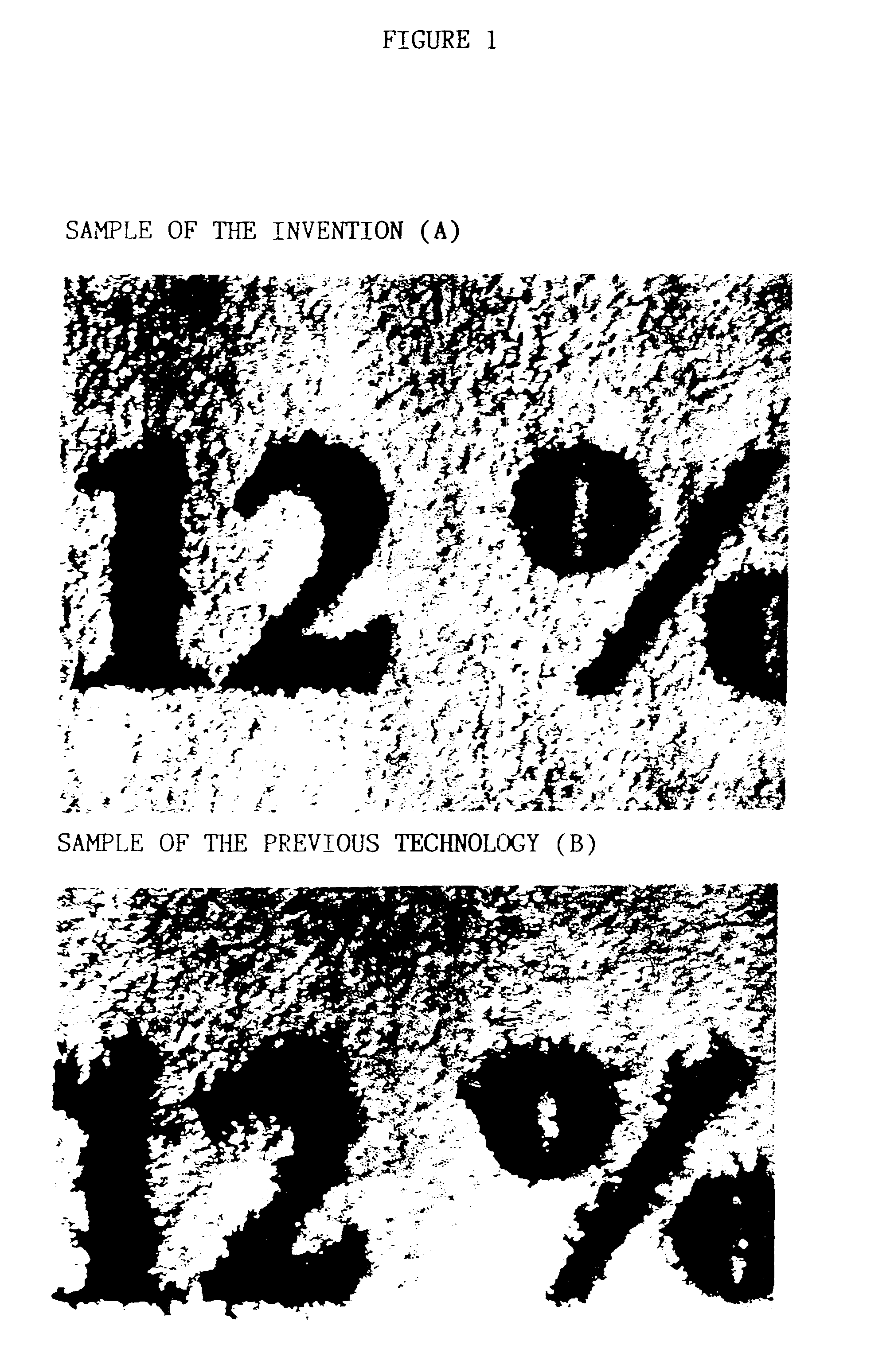

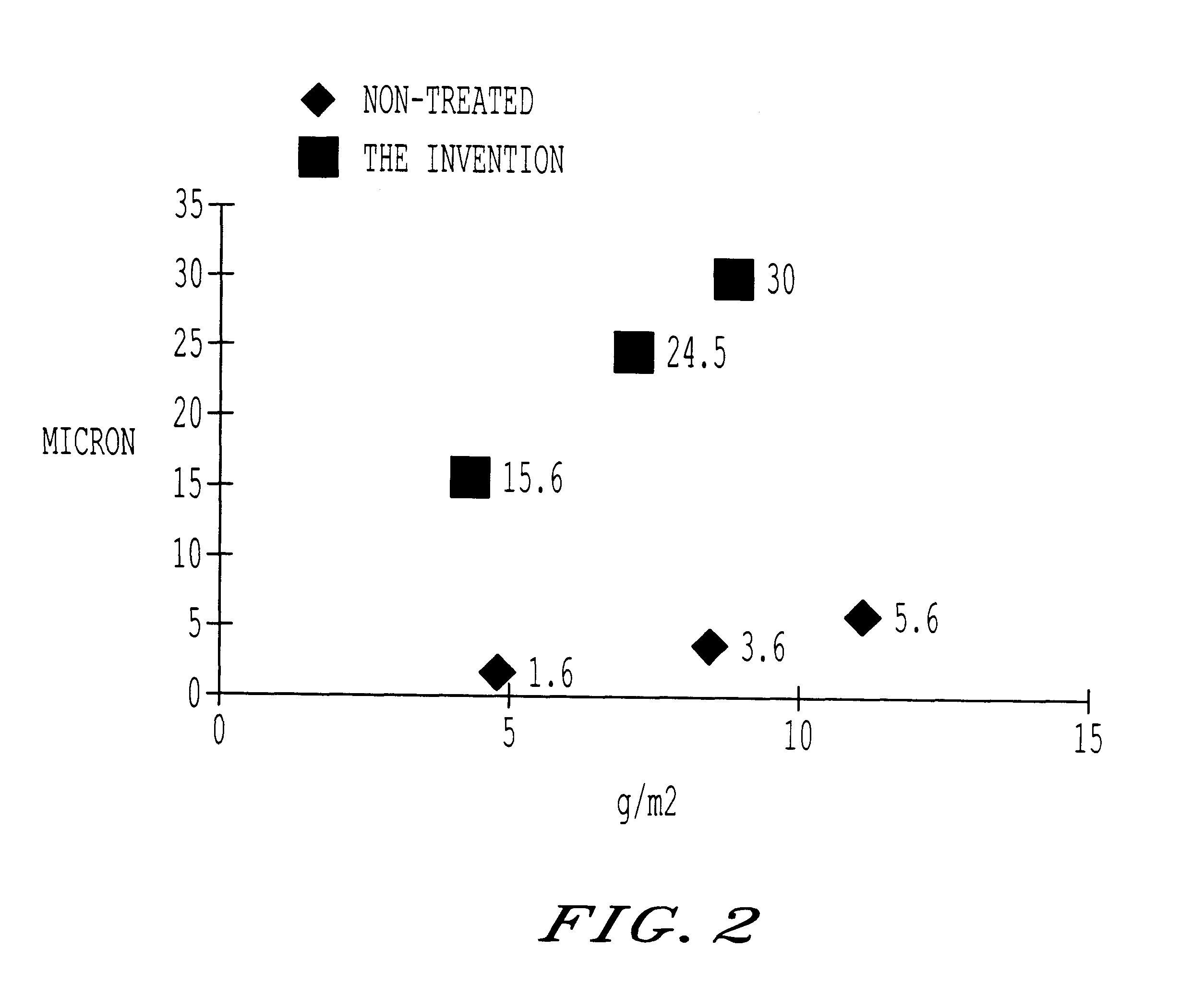

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O<+> ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibers or similar, treated with one or more medium-strong or strong providers of H3O<+> ions in the presence of gaseous CO2. Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA DEV AG

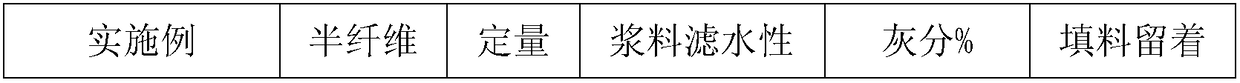

Method for improving retention of sizing agent fiber and filler in production of tobacco sheets through paper-making process

The invention relates to a method for improving the retention of sizing agent fiber and filler in production of tobacco sheets through the paper-making process. According to the technical requirements, natural potato starch is selected and used as a wrapping agent, and then the surface of the filler is wrapped or the filler is partially wrapped in the wrapping agent; a charge control agent is selected and used for regulating the charge on the surface of the sizing agent fiber, then the filler wrapped in the wrapping agent is added to a tobacco sizing agent, and production of the tobacco sheets through the paper-making process is conducted for improving the retention of the fiber and the filler. The method is applied to the production technology of the tobacco sheets through the paper-making process; by means of the method, the retention of the fiber and the filler in the sizing agent can be remarkably improved, loss of fine fiber and filler is reduced, the utilization rate of raw materials is increased, and the quality of the tobacco sheets is not affected. The method has the advantages that operation is simple, equipment is common and pollution is avoided.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD +1

Filler or pigment or processed mineral for paper, in particular a pigment containing natural CaCO3, its manufacturing process, preparations containing it and their applications

InactiveUS7638017B2Reduce weightReduce wearNatural cellulose pulp/paperSpecial paperPhysical chemistryKaolin clay

The invention concerns a pigment, filler or mineral containing a natural calcium carbonate, treated with one of more providers of H3O+ ions and gaseous CO2, allowing a reduction in the weight of paper for a constant surface area without loss of physical properties when it is used as a pigment or coating filler for the said paper. In particular, the invention concerns a pigment, filler or mineral containing a natural calcium carbonate or dolomite or mixtures of talc and calcium carbonate, of kaolin and carbonate or carbonate alone or in combination with natural and / or synthetic fibres or similar, treated with one or more medium-strong or strong providers of H3O+ ions in the presence of gaseous CO2.Applications are particularly in the paper industry, obtaining in particular good sheet properties i.e. a reduction its weight for a given surface area.

Owner:OMYA INT AG

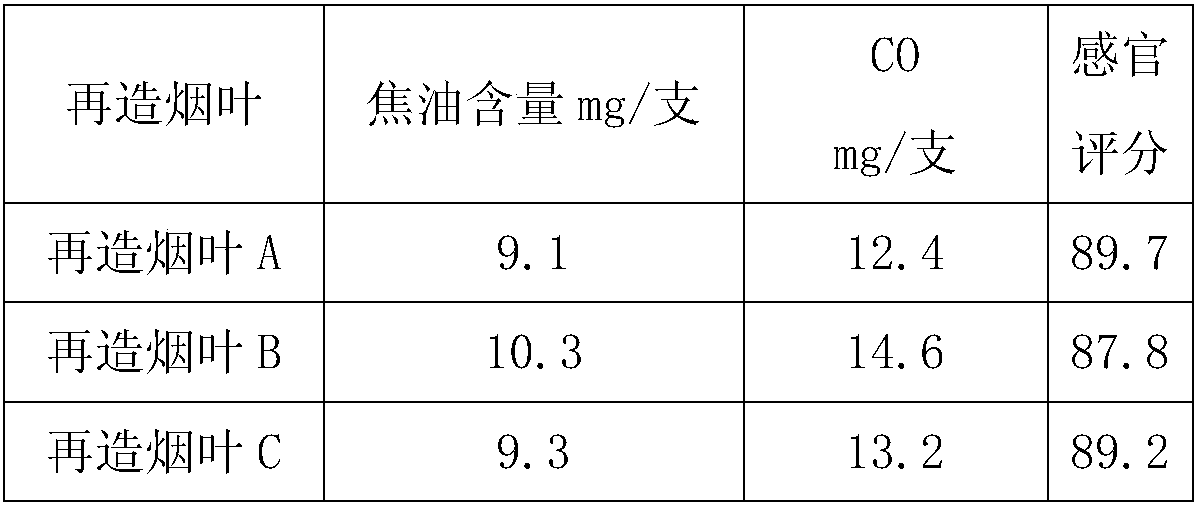

High-bulk papermaking method reconstruction tobacco leaf fiber composition and preparation method and application

ActiveCN106993820AAchieve absorbency and bulkImprove filler retentionTobacco preparationCo releaseTobacco leaf

The invention belongs to the special papermaking production field, and specifically relates to a high-bulk papermaking method reconstruction tobacco leaf fiber composition and a preparation method and application; the reconstruction tobacco leaf comprises a tobacco raw material, wood long fibers and wood short fibers, and is prepared by mixing said compositions; the short fibers are arranged in a Z-type in a water filtering process, thus effectively improving the bulk property and spreading rate while fully ensuring the substrate tensile strength and paper machine operationability, improving filling material retention rate and product yield, reducing production cost, improving product fully combustion level, and reducing CO release amount.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Swollen starch-latex compositions for use in papermaking

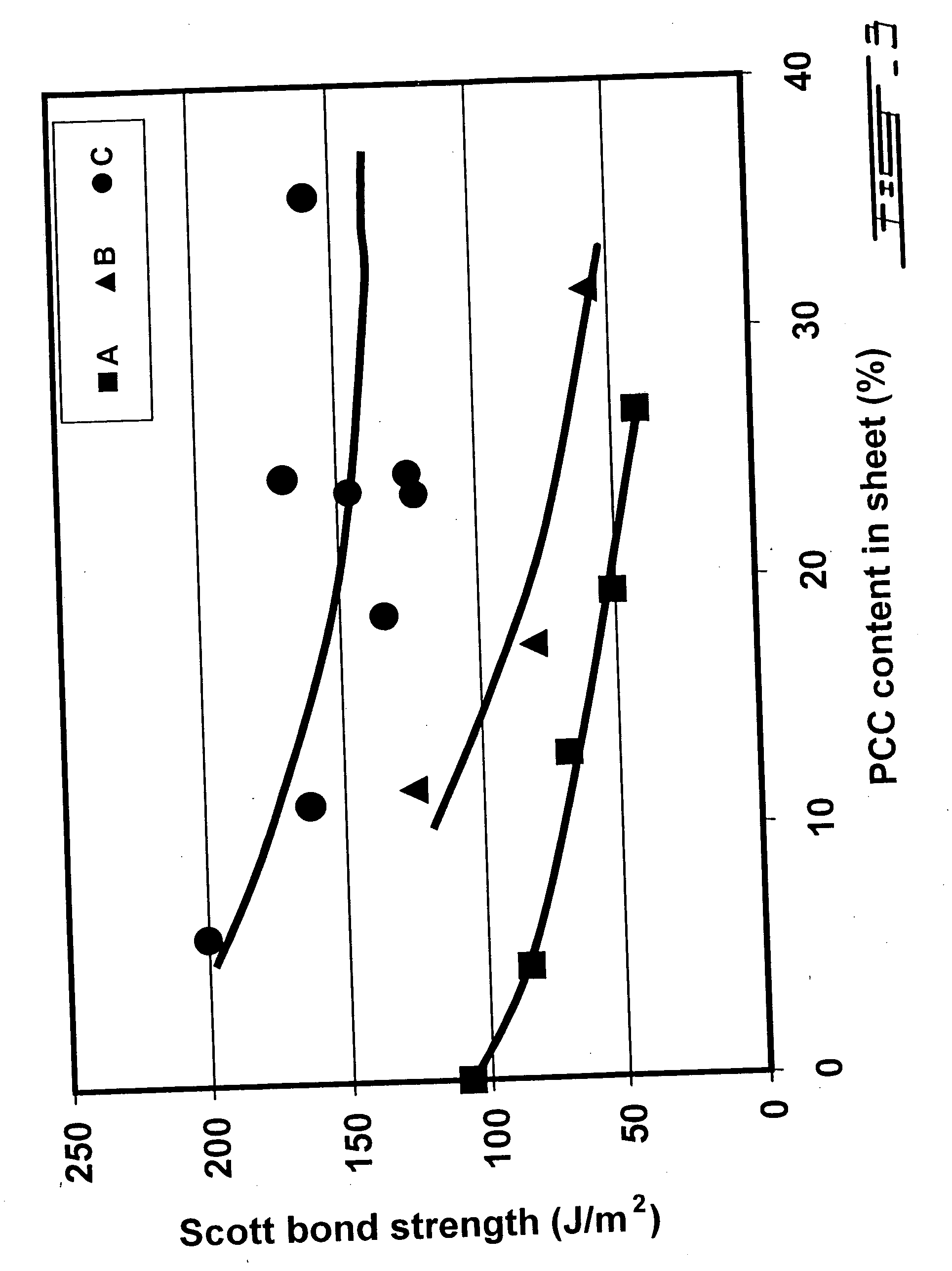

ActiveUS20050252629A1Improve filler retentionHigh retention rateNatural cellulose pulp/paperSpecial paperPapermakingPaperboard

A novel filler treatment comprising the preparation of swollen starch-latex compositions, prepared in the presence or absence of co-additives, and the addition of the said composition to a filler suspension, has been developed. Use of the treated filler during papermaking improves filler retention and produces filled papers where addition of the filler has only a minimal negative effect on strength properties. The swollen starch-latex compositions can be prepared in a batch or jet cooker, or by mixing with hot water under controlled conditions (i.e., temperature, pH, mixing, mixing time) in order to make the starch granules swell sufficiently to improve their properties as a filler additive but avoiding excess swelling leading to their rupture. The swollen starch-latex composition is then rapidly mixed with the filler slurry, preferably in a static mixer, and added to the papermaking furnish at a point prior to the headbox of the paper machine. The starch-latex composition can be used with wood-free or wood-containing furnishes. The treated filler is easily retained in the web during papermaking, improves drainage, and gives sheets having good formation. Sheets made with the treated fillers have higher bonding and tensile strengths than sheets produced using filler treated with either swollen starch alone or latex alone. Retention and drainage are further improved when conventional retention aid chemicals are added to the furnish containing the treated filler. The use of swollen starch-latex compositions could allow the papermaker to increase the filler content of the paper without sacrificing dry strength properties or increasing the amount, and hence the cost, of the retention aid added. The combination of swollen starch and latex could be used as furnish additives in the manufacture of both filled grades and grades that contain no filler such as sack papers and paperboard products.

Owner:FPINNOVATIONS INC

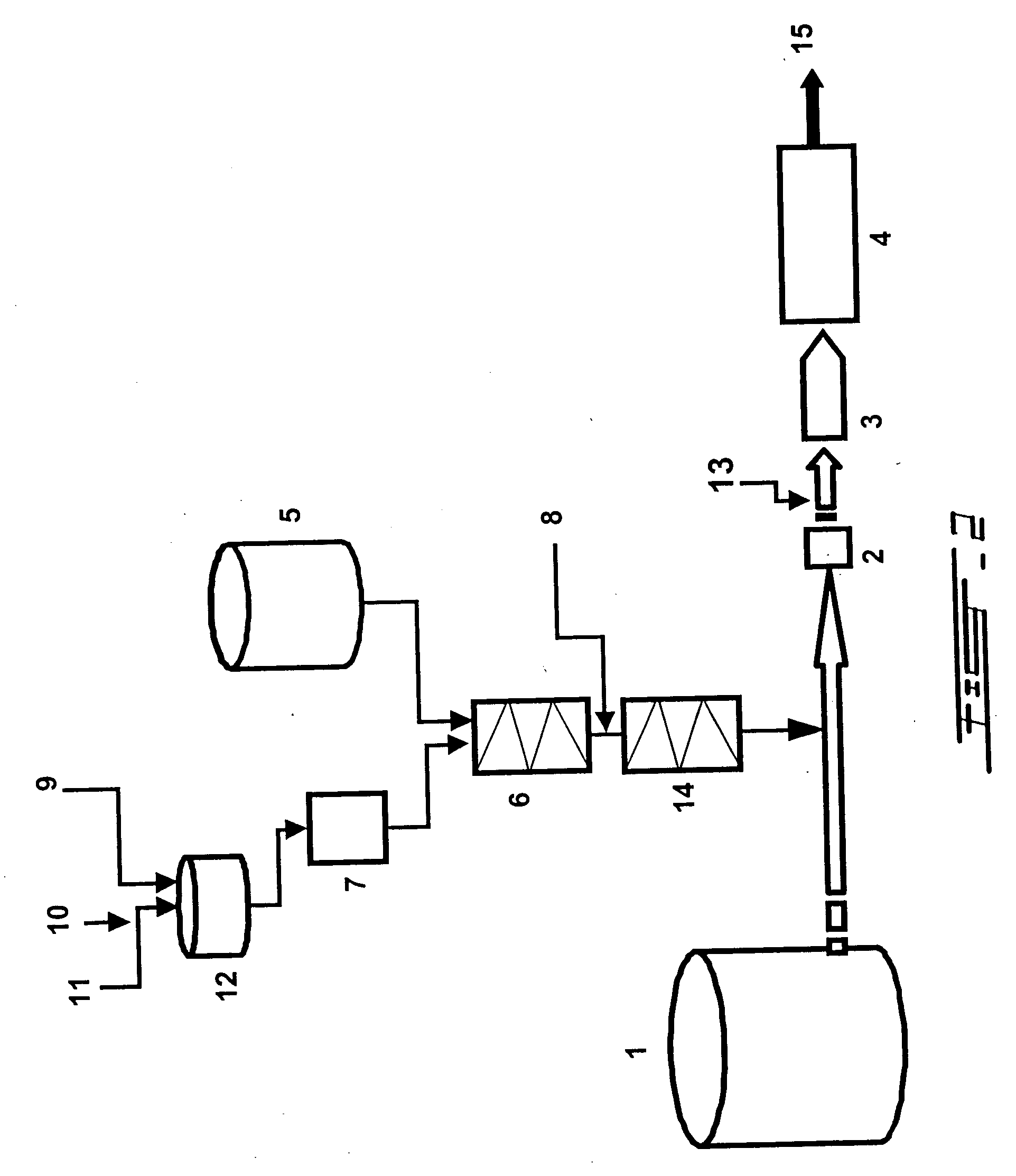

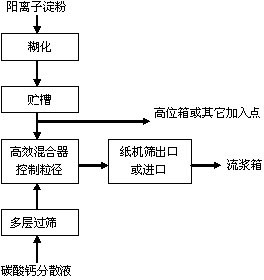

Method for fill feeding in papermaking

ActiveCN102677543AImprove stabilityFine granularityPulp material addition processesFiberFlocculation

The invention discloses a method for fill feeding in papermaking, which is characterized by comprising the following steps of: (1) firstly gelatinizing quaternary ammonium type cation starch, diluting to 1-3 percent concentration, conveying to a high-efficient mixer by a piston pump; conveying calcium carbonate with 10-30 percent concentration to the high-efficient mixer by a centrifugal pump; and (2) completing pre-flocculation of the quaternary ammonium type cation starch and the calcium carbonate in the high-efficient mixer, conducting multilayer filtering on the pre-flocculation bodies in the mixer, thus obtaining the pre-flocculation bodies with proper granules. With the adoption of the method, on the premise that the strength property of paper is guaranteed, the ash content can be effectively improved, the ash content of facial gummed paper can be improved from 25% to 35%, and the dry steam consumption can be reduced by 10%, moreover, the fiber materials can be greatly reduced, thus the method has wide application prospects.

Owner:YUEYANG FOREST & PAPER CO LTD +1

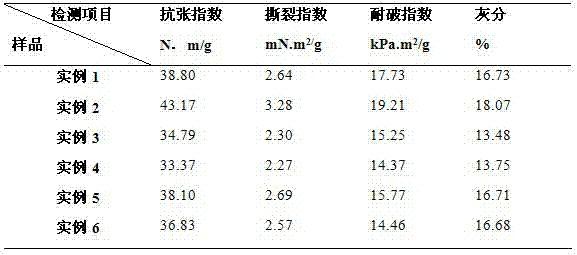

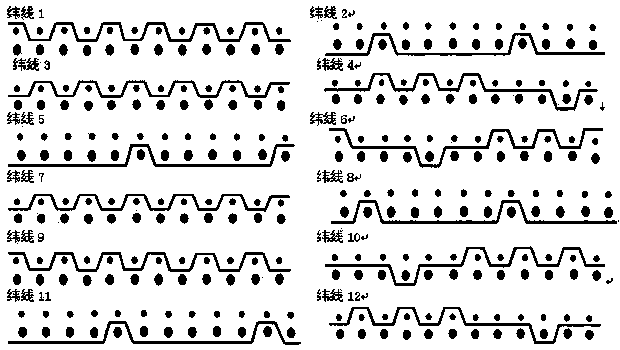

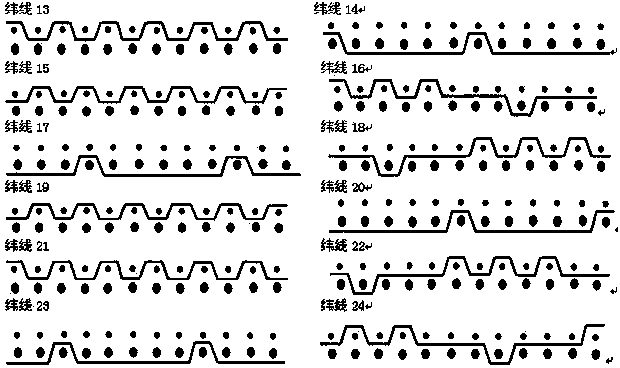

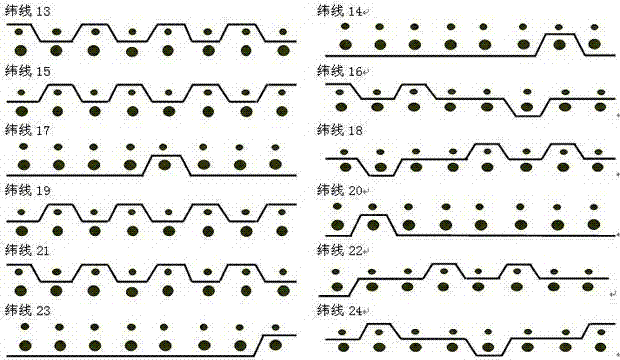

Manufacture method of secondary-seaming ternary-papermaking forming net

The invention discloses a manufacture method of a secondary-seaming ternary-papermaking forming net. Sixteen heald frames are adopted to interweave polyester or nylon monofilaments into three layers of different weaving structures into a whole, the three layers of different weaving structures comprise a paper-forming layer, an intermediate connecting layer and a machine layer, the minimum tissue unit comprising sixteen polyester monofilaments as warps and thirty-two polyester or nylon monofilaments as wefts, the warp number ratio of the paper-forming layer to the machine layer is 1:1, the weft number ratio of the paper-forming layer to the machine layer is 2:1, and the intermediate connecting layer comprises one half of total wefts and is characterized by being formed by the secondarily seaming of the self warp seaming and the self weft seaming of the paper-forming layer. The invention has the advantages of smooth papermaking surface, firm interlayer binding force, no internal abrasion or net elongation and compact and even net structure, and the machine layer has wear resistance, small thickness, long service life and strong dewatering performance.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Preparation method of bamboo fiber paper cups

InactiveCN108824071AGood oil resistanceGood resistance to organic solventsPaper coatingReinforcing agents additionPolypropyleneGuar gum

The invention discloses a preparation method of bamboo fiber paper cups. The invention relates to a bamboo fiber paper cup and a production process thereof. The bamboo fiber paper cup mainly structurally comprises a hollow fiber cup body, and is characterized in that the cup body comprises an outer layer, an inner layer, a hollow layer arranged between the outer layer and the inner layer and a coating layer above the inner layer. The outer layer and the inner layer are prepared from the following components in parts by weight: bleached bamboo fibers, dahurian larch fibers, modified starch, chitosan, talc powder, a dispersant, guar gum, glyceride hydrolase and a wet-strength agent. The hollow layer is prepared from the following components in parts by weight: polypropylene hollow short fiber pulp, dahurian larch fibers, chitosan, talc powder and a dispersant. According to the above settings, the outer layer and the inner layer are produced by employing bamboo fibers. The bamboo fiber pulp not only is environment-friendly, but also has the characteristics of being excellent in antibacterial property, bacteriostatic and free of peculiar smells. The hollow fiber layer has the functionsof being light in weight, heat insulative and warm-keeping. The bamboo fiber paper cup serving as a hot drink paper cup and a cold drink paper cup simultaneously is relatively safe.

Owner:安徽永豪新材料科技有限公司

Whitewater processing method

ActiveCN103086534AReduce concentrationReduce turbidityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCationic polymerizationPapermaking

The invention relates to a whitewater processing method comprising the steps that: the pH value of the whitewater is regulated to 8-14; a certain amount of a mixed solution of a flocculating agent and a cationic polymer is added to the whitewater, until the total mass concentration of the flocculating agent and the cationic polymer in the whitewater is 1000-3000ppm. In the mixed solution, the mass concentration of the flocculating agent is 1-5%, and the mass concentration of the cationic polymer is 0.1-0.5%. According to the invention, papermaking whitewater is processed by using the whitewater processing method provided by the invention, and is then used in preparing slurry. Therefore, paper one-time retention rate and filler retention rate can be substantially improved, and paper bursting index and tensile strength index are improved to a certain extent. Also, when the slurry is used in papermaking, concentration, turbidity, conductivity, and COD of collected under-mesh whitewater are greatly reduced, such that whitewater recycling time can be increased.

Owner:GOLD EAST PAPER JIANGSU

Papermaking modified calcium carbonate and method for preparing same

InactiveCN107419595AImprove suspension stabilityEasy to controlInorganic compound additionFiberSodium stearate

The invention belongs to the technical field of calcium carbonate technologies, and discloses papermaking modified calcium carbonate. The papermaking modified calcium carbonate mainly comprises, by weight, 100-200 parts of light calcium carbonate, 10-15 parts of bamboo pulp fibers, 30-40 parts of cationic starch, 1-3 parts of sodium stearate, 0.01-0.05 part of sodium polyacrylate, 1-3 parts of bentonite, 0.1-0.8 part of chitosan, 0.01-0.05 part of hardening agents, 0.2-0.8 part of antioxidants, 0.5-1.5 parts of dispersing agents and 0.5-1.5 parts of coupling agents. The invention further provides a method for preparing the papermaking modified calcium carbonate. The papermaking modified calcium carbonate and the method have the advantages that the papermaking modified calcium carbonate can be uniformly dispersed and is high in retention and tear-resistant strength and good in suspension stability; the method includes simple processes, is safe and reliable and is easy to control, convenient to implement, suitable for large-scale production and low in production cost, and the like.

Owner:广西华洋矿源材料有限公司

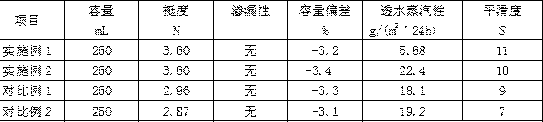

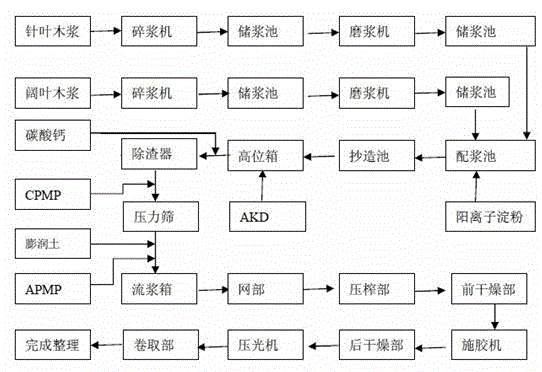

Method for producing highly quantitative two-side offset paper

ActiveCN103603225AImprove water filtration performanceReduce poor qualityChemical/chemomechanical pulpPaper-making machinesSulfatePulp and paper industry

The invention belongs to papermaking technologies and relates to a method for producing highly quantitative two-side offset paper. The method comprises the following steps: sequentially performing pulping, size mixing, sizing, manufacturing paper with pulp, pre-drying, surface sizing, after-drying, press polish and rolling on basic raw materials such as bleached sulfate needlebush pulp and bleached sulfate broadleaf wood pulp, and finally finishing into paper; and allowing the materials in the pulping process to sequentially pass through a pulper, a pulp storage pool, a pulp grinder and the pulp storage pool according to a material transfer sequence, wherein in the pulping process, the pulping beating degree of the bleached sulfate needlebush pulp in the basic raw materials is required to be 25-320SR, and the pulping beating degree of the bleached sulfate broadleaf wood pulp is required to be 24-330SR. According to the method, the highly quantitative two-side offset paper can be manufactured with pulp, and the manufactured paper is high in surface strength, high in internal binding force, high in smoothness and small in two-side difference.

Owner:ZHENJIANG DADONG PULP & PAPER

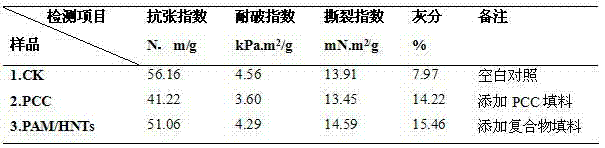

Preparation method and application of polyacrylamide/keramite nanotube composite papermaking filler

InactiveCN102644214AIncrease dosageReduced impact strengthPaper/cardboardInorganic compound additionPapermakingAqueous solution

The invention relates to a preparation method and application of a polyacrylamide / keramite nanotube composite papermaking filler. The preparation method comprises the following steps of: adding a keramite nanotube into aqueous solution of acrylamide monomer or mixed solution of water and ethanol of acrylamide, then loading acrylamide monomer molecules to a cavity of the keramite nanotube by using vacuum negative pressure, and preparing the keramite nanotube / acrylamide composite monomer; and then through a free radical solution polymerization reaction, polymerizing the keramite nanotube / acrylamide composite monomer, and a polyacrylamide molecule chain penetrating through the keramite nano cavity, so as to prepare the olyacrylamide / keramite nanotube composite papermaking filler. The olyacrylamide / keramite nanotube composite papermaking filler is added into the papermaking pulp, so that the amount of fillers in the paper can be increased; and the effect on physical strength of the paper caused by adding the fillers can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

Process for production of paper

ActiveUS8784611B2High retention rateImprove filler retentionNanotechNatural cellulose pulp/paperCardboardWater soluble

The invention relates to a process for the production of paper or board comprising: adding a retention system to a stream of stock entering a paper machine head box, directing the stream of stock to a wire, de watering the stream of stock on the wire to form a paper web, and drying the paper web, wherein the retention system comprises a water-soluble cationic polymer, and nanocellulose acting like a micro particle, wherein the nanocellulose is added in an amount of less than 1% as active substance based on dry solids weight of the stock.

Owner:KEMIRA OY

Production method of lightweight paper

InactiveCN109680536AHigh yieldHigh opacityWater-repelling agents additionChemical and mechanical pulp mixtureSulfatePaper manufacturing

The invention discloses a production method of lightweight paper. The production method comprises a wood pulp proportioning step and a mixing step. Needle BCMTP chemimechanical pulp and needle bleached chemical wood pulp are proportioned and pulped; a neutral sizing agent, cationic starch, cationic polyacrylamide and talcum powder are used; then a paper manufacturing process is performed. Importedneedle wood pulp and broadleaf wood bleached sulfate pulp are respectively pulped and blended, and various additives are added; the blend is conveyed into an approaching system for dehydration forming through a wet part and then is further dehydrated through a squeezing part; after pre-drying, semi-dry calendaring and surface sizing are performed, the product is dried through a drying part; the product is baked at low temperature, subjected to soft calendaring finishing and wound. First of all, high bulkiness is achieved, and the flatness and the tensile strength of paper are not affected, sothe production method is suitable for high-speed printing; secondly, no flourescent brightener is contained; compared with common coated paper, offset paper and lightweight paper, the lightweight paper produced according to the method is relatively dark and has a color close to the primary color of wood pulp, so that visual fatigue cannot be caused by long-time reading.

Owner:SHANDONG TIANYANG PAPER

Modified filler composition, method for making same, pulp and paper using same

InactiveUS20140216673A1Large specific surface areaHigh strengthSpecial paperPaper after-treatmentCellulosePapermaking

A modified filler composition used in papermaking is provided. The modified filler composition contains nanofibrillated cellulose having a carboxyl content of about 0.05 to about 1.5 mmol / g, and filler having positive charge.

Owner:GOLD EAST PAPER JIANGSU

Composite special type filler combination method

The invention discloses a complex method for compounding a special filling, comprising the following steps that: the special filling is dispersed into a dispersed suspending liquid with a mass concentration ranging from 1 to 30 percent, the dispersed suspending liquid is mixed with a macromolecule water solution with a mass concentration ranging from 1 to 25 percent to obtain a mixture, the mixture and an acidic electrolyte bath solution are mixed evenly, or a fatty acid is added into the mixture and is mixed evenly to obtain a solution, and then the solution and the acidic electrolyte bath solution are mixed evenly; after let stand, an upper layer of clear solution is eliminated, a lower layer of white substance is the special compounded filling. The complex method can improve the hydrophilicity of the special filling and the fiber, increases the use amount of the special filling and obviously improves the intensity of the paper. The complex method can improve the retention of the filling, increase the whiteness of the paper, reduces the waste water processing load and further saves the fiber use amount.

Owner:GUANGDONG IND TECHN COLLEGE

Inorganic powder highly filled polyolefin fiber paper and production method thereof

PendingCN108864521AEasy to distributeHigh surface glossWater-repelling agents additionPaper-making machinesSurface finishPolymer science

The invention discloses inorganic powder highly filled polyolefin fiber paper and a production method thereof. The polyolefin fiber paper is prepared from the raw materials in proportion: 10% to 20% of polyolefin, 0.1% to 2% of coupling agent, 0.1% to 1% of dispersing agent, 1% to 10% of compatibilizer, 0.1% to 2% of plasticizer, 1 to 5% of hot-melt type adhesive, 0.1% to 2% of surface active agent, 0.1% to 1.5% of rheology modifier and 75% to 85% of inorganic powder. The production method comprises the steps of evenly mixing and stirring polyolefin and the rheology modifier under the assistance of a technology to improve a melt index and fluidity of polyolefin; sequentially adding the compatibilizer and the plasticizer to be evenly stirring and mixed; then sequentially adding the activated inorganic powder and the activated hot-melt type adhesive and evenly mixing and stirring; processing through the work procedures of mixing, kneading, drawing fiber, preparing a finished product fromfiber stuff and the like to obtain the inorganic powder highly filled polyolefin fiber paper. According to the inorganic powder highly filled polyolefin fiber paper disclosed by the invention high filling of inorganic powder is achieved, a resin use amount is reduced, tensile strength, impact strength and surface smoothness of the product are enhanced, and a filler retention rate is improved.

Owner:福建省大投科技有限公司

Preparation method of tipping paper body paper

InactiveCN107190570AHigh mechanical strengthHigh whitenessSpecial paperWater-repelling agents additionTithonia longiradiataTar

The invention discloses a preparation method of tipping paper body paper. The preparation method comprises the following steps: respectively pulping softwood pulp and hardwood pulp, uniformly mixing to obtain tipping paper pulp, collectively adding calcium carbonate and nano titanium dioxide into a sodium hydroxide solution, growing a titanium dioxide naontube on the surface of the calcium carbonate by hydrothermal reaction, drying to obtain tipping paper filler, then mixing the tipping paper pulp, the tipping paper filler, a sizing agent and a retention aid, making molding, drying, and calendaring to obtain the tipping paper body paper. The tipping paper body paper prepared by the method has excellent mechanical strength and appearance quality, also has an efficacy of reducing tar and harm, and is applicable to a top-grade cigarette packaging material.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Method for complexing composite calcium carbonate filling material

InactiveCN101240515AReduce dosageDosage solidPaper/cardboardInorganic compound additionFiberAcid electrolyte

The invention discloses a composite method for a composite calcium carbonate filler, comprising following steps: dispersing calcium carbonate to be suspending liquid with a mass concentration of 1-50, mixing it evenly with high molecule aqueous solution with a mass concentration of 1-30to obtain a blend, the mass ratio of calcium carbonate to the high molecule aqueous solution is 50:1-1:5; mixing above blend with acidic electrolyte solution, the volume ratio of the acidic electrolyte solution to the blend is 1:1-10:1, mixing evenly, standing, removing supernatant liquor, the white lower layer matter is the composite pearl filler. The invented method can increase fibrous hydrophilicity, increase filler retention, enhance paper intensity and whiteness, and saving fabric.

Owner:GUANGDONG IND TECHN COLLEGE

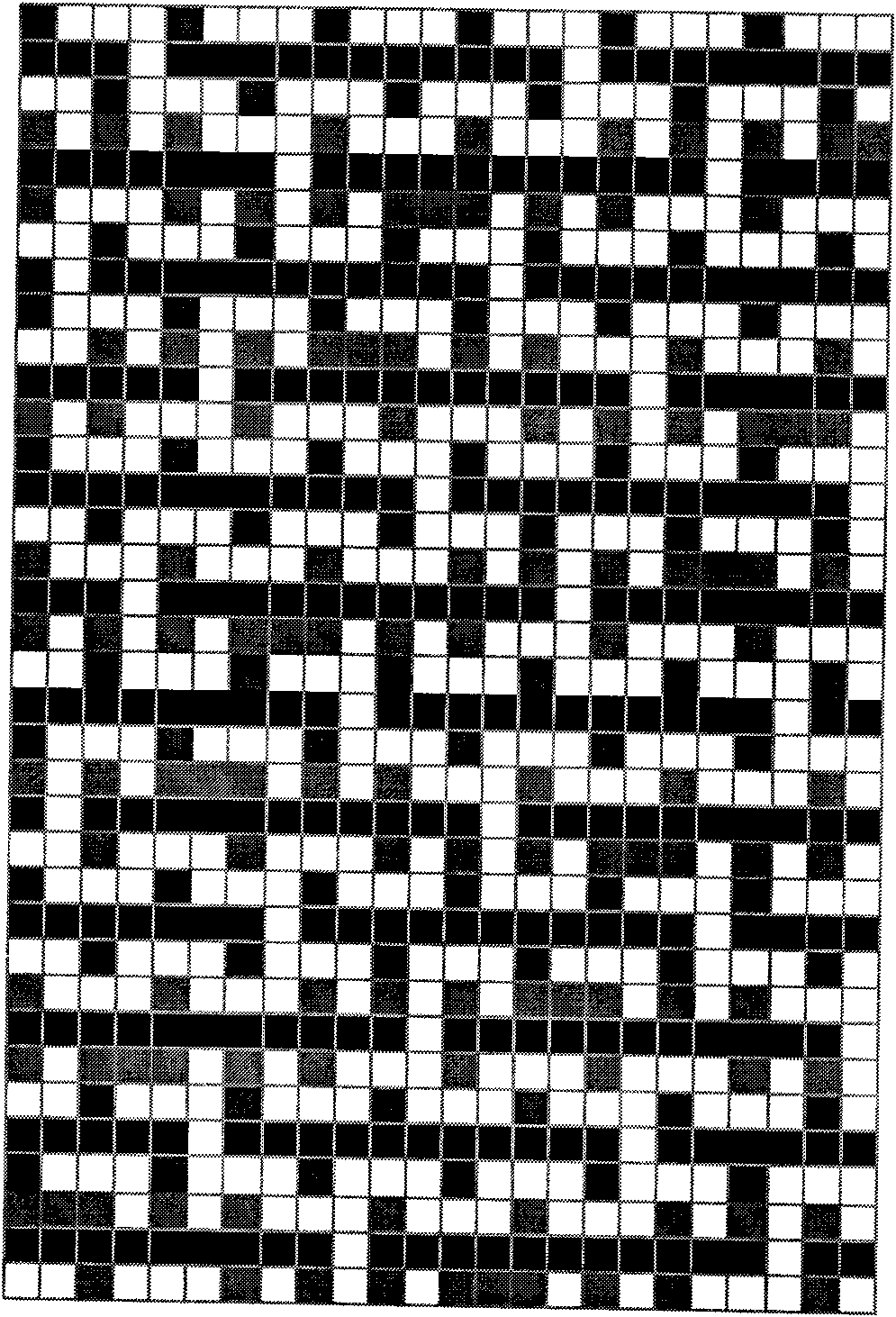

High-grade daily used paper-polyester fibres three-layer wire-cloth

The invention provides 24 harness self-binding polyester three-layer wire-cloth, wherein polyester and nylon monofilament is interwoven to be composite intertexture of a structural connection whole body of a paper forming layer, an intermediate connection layer and a machine layer by 24 pieces of harness frames, the minimum organization unit is composed of 24 polyester monofilaments as a warp thread and 36 polyester or nylon monofilament as a weft thread. Number ratio of warp threads of the paper forming layer to that of the machine layer is 1:1, and number ratio of weft threads is 3:2; the number of weft threads is 2 / 6 of total number of the weft threads; the paper forming layer employs plain weave method, and the machine layer employs 6 harness weave method. The invention has advantages of high fibre supporting index, high retention of fibre and fillers, uniform forming of page, easy peeling of page from net, flattening paper forming, firm combination of upper and lower layers, good abrasive resistance and long service life.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Preparation method and application of tobacco cationic hemicellulose

ActiveCN108077996AImprove water filtration performanceGood filterabilityTobacco treatmentWater filterSlurry

The invention provides a preparation method and application of tobacco cationic hemicellulose. The preparation method includes the specific steps that solid phase materials are extracted from waste tobacco raw materials and then mixed with an alkali solution for heating and stirring to collect the filtrate, ethanol is added for filtering to collect precipitate, the precipitate is dried to obtain tobacco hemicellulose, sodium hydroxide is added for stirring and carrying out a reaction, a cationic surfactant is slowly added for carrying out a reaction for 1-3 hours, a weak acid is added for neutralizing, precipitation is carried out by ethanol, and then the precipitate is collected after filtering, washed with ethanol and dried to obtain the tobacco cationic hemicellulose. The tobacco cationic hemicellulose prepared by the method can be used as a retention aid for slurry of reconstituted tobaccos, can effectively improve the filler retention rate, the water filtering performance of the slurry and the ability for absorbing anion interference substances and reduce the load of plain boiled water and waste water, is easily biodegradable, improves the combustion performance of the reconstituted tobaccos, reduces the released amount of tar and CO and improves the sensory quality of cigarettes to a certain extent.

Owner:HUBEI CHINA TOBACCO IND

Composition method for composite talcum powder

InactiveCN101260251AReduce dosageDosage solidInorganic compound additionPigment treatment with macromolecular organic compoundsFiberMetallurgy

The invention discloses a composite method for a composite talcum powder filler, the method comprises the following steps of: dispersing talcum powder into dispersing suspension with 1 to 50 percent mass concentration, after mixing evenly with macromolecular water solution with 1 to 30 percent mass concentration, mixing the talcum powder with acidic electrolyte solution, and stirring evenly; or adding fatty acid and mixing evenly, then mixing with the acidic electrolyte solution, and stirring evenly; after standing the stirred evenly liquid and removing an upper layer of clear liquid, a lower layer of white substance is the composite talcum powder filler. The composite method for the composite talcum powder filler can improve hydrophilicity of the talcum powder and fiber, increase amount of the talcum powder as well as strength of paper, the composite method for the composite talcum powder filler also has the advantages of improving filler levels, increasing paper brightness, reducing wastewater treatment load and further saving the using amount of the fiber.

Owner:GUANGDONG IND TECHN COLLEGE

Twenty-four- heald composite fiber polyester three-layer papermaking net

The invention discloses a twenty-four-heald composite fiber polyester three-layer papermaking net which is an integrated composite intertexture formed by using twenty-four healds to interweave polyester or nylon single yarn. The twenty-four-heald composite fiber polyester three-layer papermaking net comprises a paper forming layer, a middle connecting layer and a machine layer, wherein the paper forming layer, the middle connecting layer and the machine layer are different in weaving structure, the 1 / 1 plain weaving method is adopted for the paper forming layer, the six-heald weaving method is adopted for the machine layer, and the middle connecting layer comprises a pair of connecting wefts which are used for connecting the paper forming layer and the machine layer. Due to the fact that the 1 / 1 plain weaving method is adopted for the paper forming layer, the fiber supporting index is made to be improved, meshes are even and smooth, the retention rate of fiber and padding of paper is improved, paper page forming is even, and a paper page can be stripped off the net easily. The pair of connecting wefts is used for connecting the paper forming layer and the machine layer, so that the upper layer and the lower layer are connected with each other more firmly. The six-heald weaving method is adopted for the machine layer, so that the span of wefts of the machine layer is increased, abrasive resistance of the forming net is improved, and service life is longer.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Method for complexing composite calcium carbonate filling material

InactiveCN100590257CReduce dosageDosage solidPaper/cardboardInorganic compound additionFiberAcid electrolyte

The invention discloses a composite method for a composite calcium carbonate filler, comprising following steps: dispersing calcium carbonate to be suspending liquid with a mass concentration of 1-50,mixing it evenly with high molecule aqueous solution with a mass concentration of 1-30to obtain a blend, the mass ratio of calcium carbonate to the high molecule aqueous solution is 50:1-1:5; mixingabove blend with acidic electrolyte solution, the volume ratio of the acidic electrolyte solution to the blend is 1:1-10:1, mixing evenly, standing, removing supernatant liquor, the white lower layermatter is the composite pearl filler. The invented method can increase fibrous hydrophilicity, increase filler retention, enhance paper intensity and whiteness, and saving fabric.

Owner:GUANGDONG IND TECHN COLLEGE

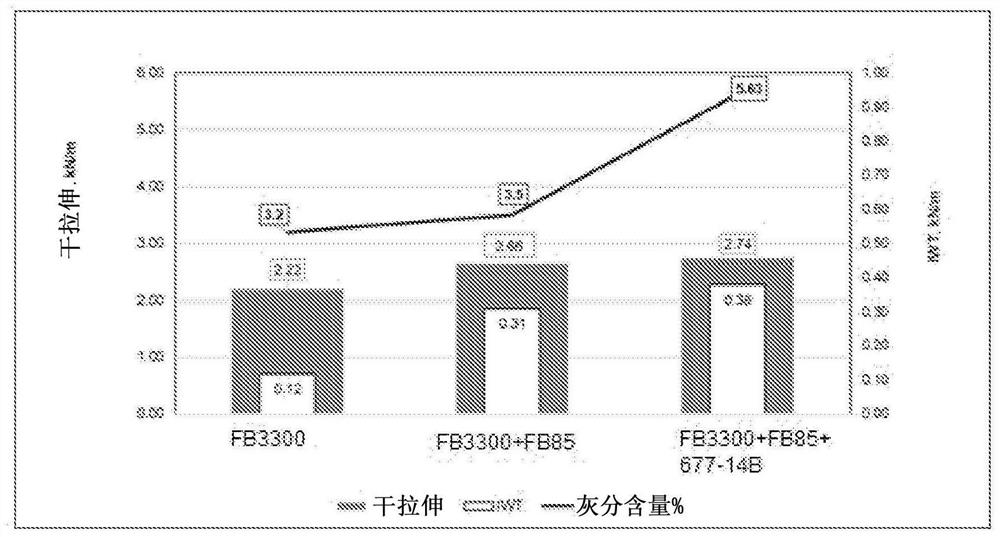

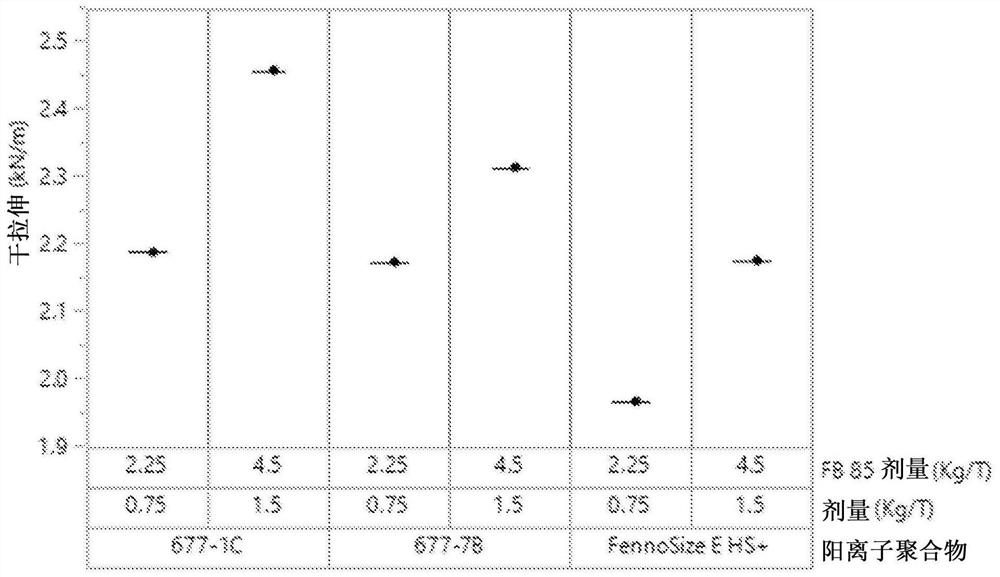

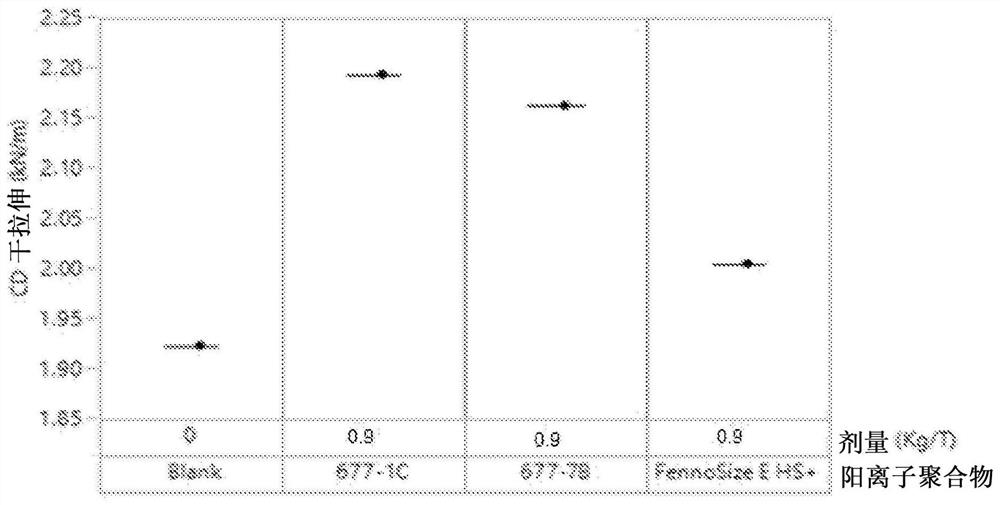

Process for manufacture of paper or paperboard and paper or paperboard obtained from this process and use of cationic emulsion polymers in manufacture of paper or paperboard

ActiveCN114174591AImprove dehydration rateImprove performancePaper recyclingReinforcing agents additionFiberPolymer science

Owner:KEMIRA OY

Method for improving filler retention rate and paper evenness under the condition of high shear force

ActiveCN109082932AImprove filler retentionImprove uniformityRetention agents additionFiberMontmorillonite

The invention provides a technical method for improving the filler retention rate and paper evenness of a high-speed paper machine and improving the paper forming strength by using a chitosan / montmorillonite binary particle retention aid system or a chitosan / cationic polyacrylamide / montmorillonite ternary retention aid system. The bio-based chitosan / montmorillonite microparticle retention aid system of the invention adopts chitosan with a deacetylation degree of 80-95 %, the dosage of chitosan is 0.03-0.1 % of the mass of the absolutely dry fiber raw material, the dosage of montmorillonite is0.1-0.5 % of the mass of the absolute dry fiber raw material, the cationic polyacrylamide is 0.03-0.1 % of the mass of the absolutely dry fiber. According to the method, the filler retention is improved under the condition of high shear force, the paper evenness is improved, and the problem that the paper strength is reduced due to the increase of ash content is solved.

Owner:NANJING FORESTRY UNIV

High-speed wide 16-heald mesh-mark-free three-layer paper making mesh

InactiveCN103882755AImprove wear resistanceExtended service lifeMachine wet endPolyesterMechanical engineering

The invention discloses a high-speed wide 16-heald mesh-mark-free three-layer paper making mesh. The high-speed wide 16-heald mesh-mark-free three-layer paper making mesh is integrated composite intertexture which is formed by interweaving polyester or nylon monofilaments through 16 heald frames, and the high-speed wide 16-heald mesh-mark-free three-layer paper making mesh comprises the three different woven structures of a finished paper layer, a middle connecting layer and a machine layer. A 1 / 1 plain weaving method is adopted by the finished paper layer, an eight-heald weaving method is adopted by the machine layer, the middle connecting layer comprises a pair of connecting weft yarns, and the finished paper layer and the machine layer are connected. Due to the fact that the 1 / 1 plain weaving method is adopted by the finished paper layer, the fiber supporting index is improved, meshes are even and smooth, the fiber and packing retention of paper is improved, paper forming is even, the paper can be separated from the mesh easily, and the finished paper is smoother. The connecting weft yarns are used for being connected with the two layers, and the upper layer and the lower layer are combined more firmly. The eight-heald weaving method is adopted by the machine layer, the span of the weft yarns of the machine layer is increased, the abrasion resistance of the forming mesh is improved, and the service life is longer.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

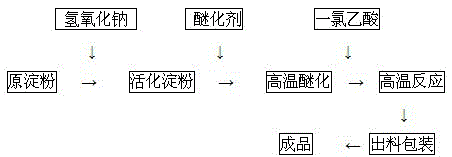

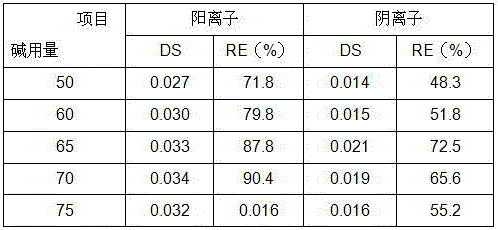

Method for preparing carboxy-type amphoteric starch in one step by semi-dry process

The invention discloses a method for preparing carboxyl-type amphoteric starch in one step by a semi-dry process, which is characterized in that: firstly adding a cationic reagent 3-chloro-2-hydroxypropyl-trimethylammonium chloride to carry out etherification reaction on the original starch, After the etherification reaction, directly add the anionizing reagent monochloroacetic acid to carry out the carboxymethylation reaction. Both anionization and cationization reactions are carried out in one kettle to prepare carboxy-type amphoteric starch in one step, and the production process is uninterrupted. The invention can effectively solve the shortcomings of wet process and dry process. Cationic and anionic groups are connected in the same starch chain, so that the product has the characteristics of cationic starch and anionic starch, and various performances are improved; the reaction time can be shortened from 8 hours to 6 hours; due to the shortened process, energy saving and consumption reduction, so that The product cost can be saved by about 12%.

Owner:抚州新天下知识产权咨询管理有限公司

Manufacturing method and product of high surface strength offset printing paper

ActiveCN103526630BImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

A kind of preparation method of offset paper

ActiveCN108560308BImprove retentionControllable dehydration rateSpecial paperWater-repelling agents additionPapermakingHigh intensity

The invention relates to an offset paper preparation method. The method comprises the steps that pulping is conducted with wood pulp, a sizing agent is added, filler is added, a retention agent is added, wet paper sheet papermaking is conducted, drying is conducted, and glaced finish is conducted to obtain paper. A quintuple retention system is used, in the step of adding the retention agent, polyacrylamide, bentonite and high polymer are cooperatively used, compared with the sizing agent weight, polyacrylamide is added first at the weight ratio being 3-8%, then 0.1-0.5% of bentonite is added,stirring is conducted, and finally 0.1-1% of high polymer is added, wherein the high polymer is prepared from polyacrylate, polymethacrylate, polycarboxymethyl acrylate at the ratio being 20-40%:30-40%:20-50%. The offset paper prepared on the basis of the quintuple retention system has the advantages of being high in strength, whiteness and smoothness and the like.

Owner:JILIN CHENMING PAPER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com