Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Uniform mesh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

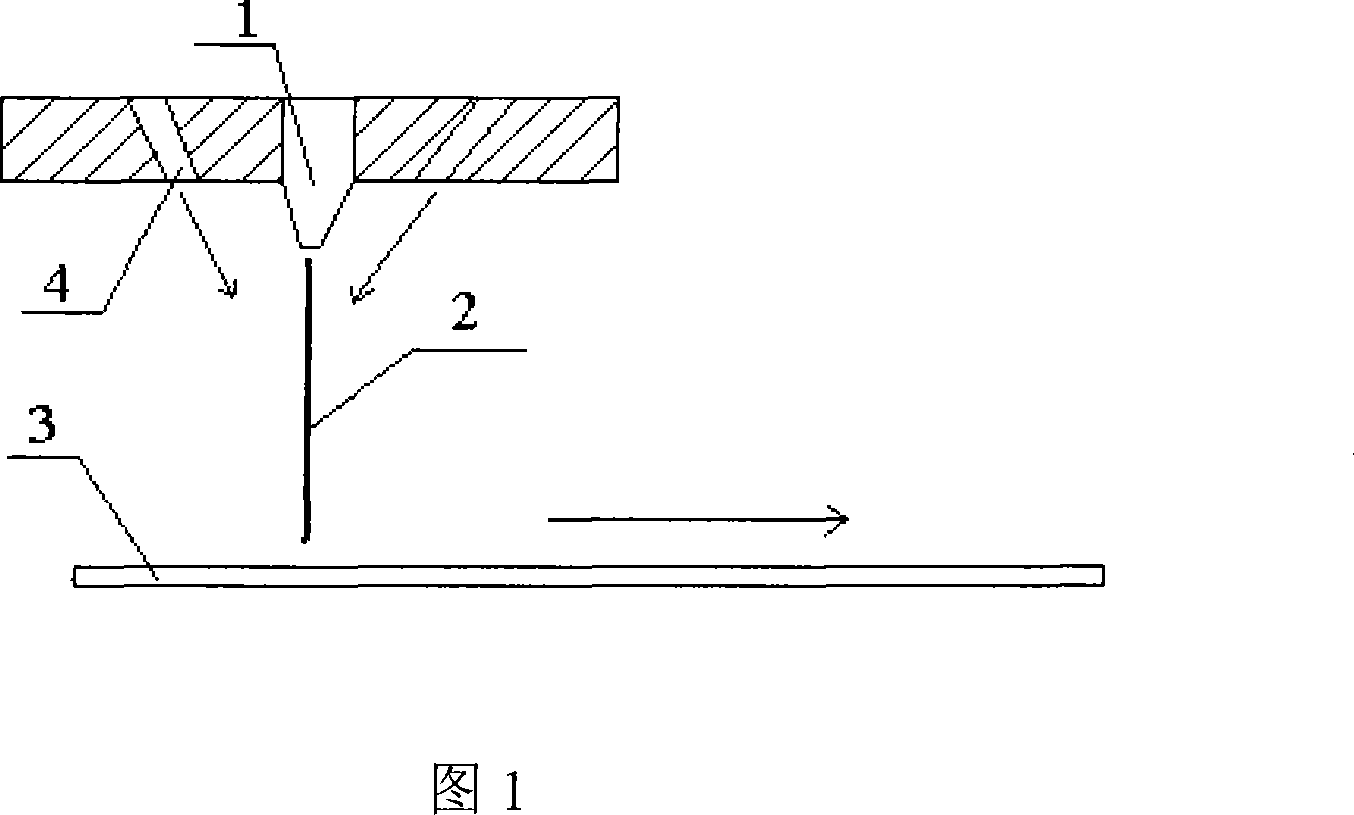

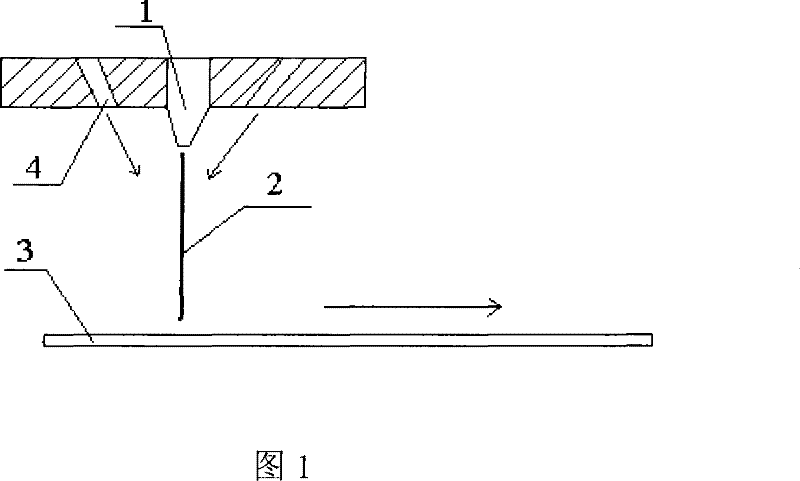

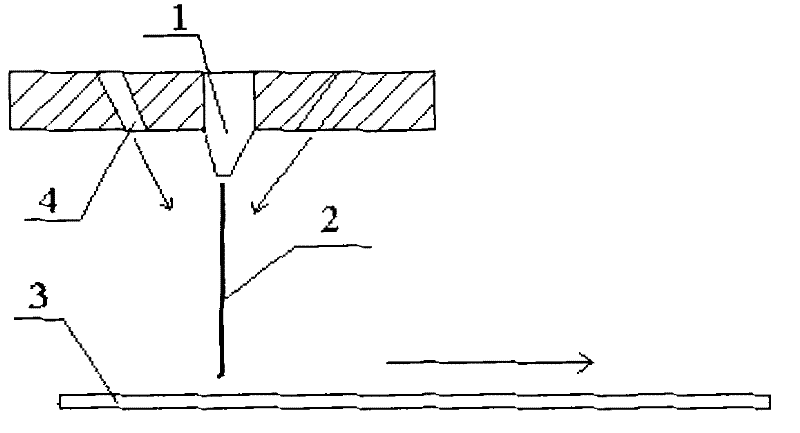

Method for preparing hot melt adhesive net film

ActiveCN101240148AStrong crystallization speedUniform meshFilm/foil adhesivesMelt spinning methodsComposite materialL&D process

A method for producing a hot melt adhesive omentum includes the processes such as melting hot melt adhesive raw materials, adding crystal nucleation agents, extruding, spining, drawing airflow, forming web and the like. The hot melt adhesive omentum with apertures in a uniform diameter and a stable weight is obtained by adding specific nucleation agents in a prescribed amount and controlling the temperature of the hot melt adhesive omentum and extruding speed. The processes with a increase in production efficiency are performed continuously in a production flow, suitable for industrial production.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD

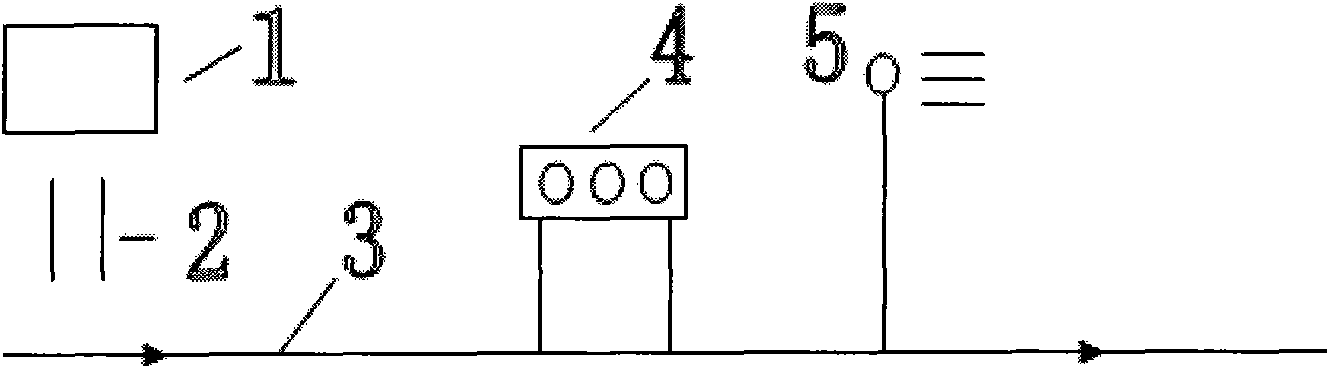

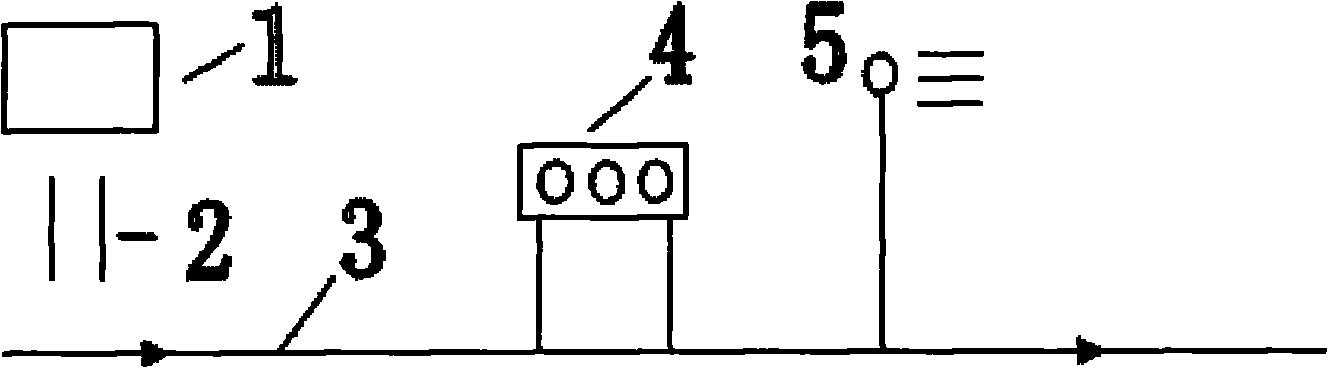

Method for preparing hot-melt adhesive net film

ActiveCN101967733AIncrease productivityReduce manufacturing costNon-woven fabricsHot-melt adhesiveMelting temperature

The invention provides a method for preparing a hot-melt adhesive net film. The method comprises the following steps of: melting a hot-melt adhesive serving as a raw material; squeezing and spinning; heating and crystallizing by infrared light; and solidifying the material to form a net by spraying and the like. The hot-melt adhesive net film with uniform aperture and stable gram weight is prepared by controlling the melting temperature of the hot-melt adhesive, the spinning speed, the speed of a conveying belt, infrared temperature and spray. The steps are continuously finished in a production flow, so that the production efficiency is greatly improved, and the method is suitable for industrial production.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

Process for producing meshed double-faced spraying and painting advertisement cloth

InactiveCN102660837AUniform meshOrganizational structure is stableFibre typesWarp knittingPolyesterEpoxy

The invention relates to a process for producing meshed double-faced spraying and painting advertisement cloth. The process comprises the following steps of: weaving polyester yarns by using a three-guide bar warp knitting machine in a knitting mode of threading 19 yarns with one vacant stitch, performing slurry immersing treatment on slurry, and sizing, cutting edges, and rolling to manufacture the meshed double-faced spraying and painting advertisement cloth, wherein the slurry consists of the following components in percentage by weight: 8 to 12 percent of epoxy resin curing agent, 1 to 2 percent of benzoxazole fluorescent whitening agent, 0.1 to 0.2 percent of silicone oil emulsion defoamer, 1.5 to 3 percent of parahydroxybenzoate ester, 1.5 to 2.5 percent of rutile nano titanium dioxide, 0.03 percent of pigment and the balance of water. The meshed double-faced spraying and painting advertisement cloth has the advantages of high strength, firm tissue structure, high ink absorption performance, no deflection of grids, environment friendliness and the like, and has the characteristic that a display effect of double-faced patterns is good after the advertisement cloth is subjected to single-faced spraying and painting.

Owner:浙江华生科技股份有限公司

Chitosan collagen and calcium alginate compounded spongy biological dressing and its preparation

InactiveCN1167366CGood biocompatibilityStrong adhesionAbsorbent padsBandagesFreeze-dryingBiological dressing

Owner:JIANGXI RUIJI BIOTECH CO LTD

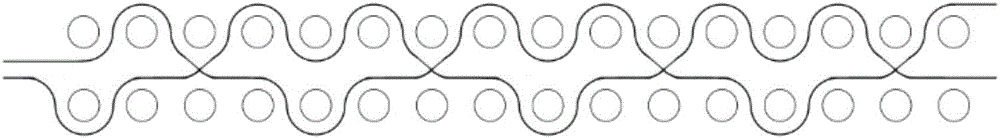

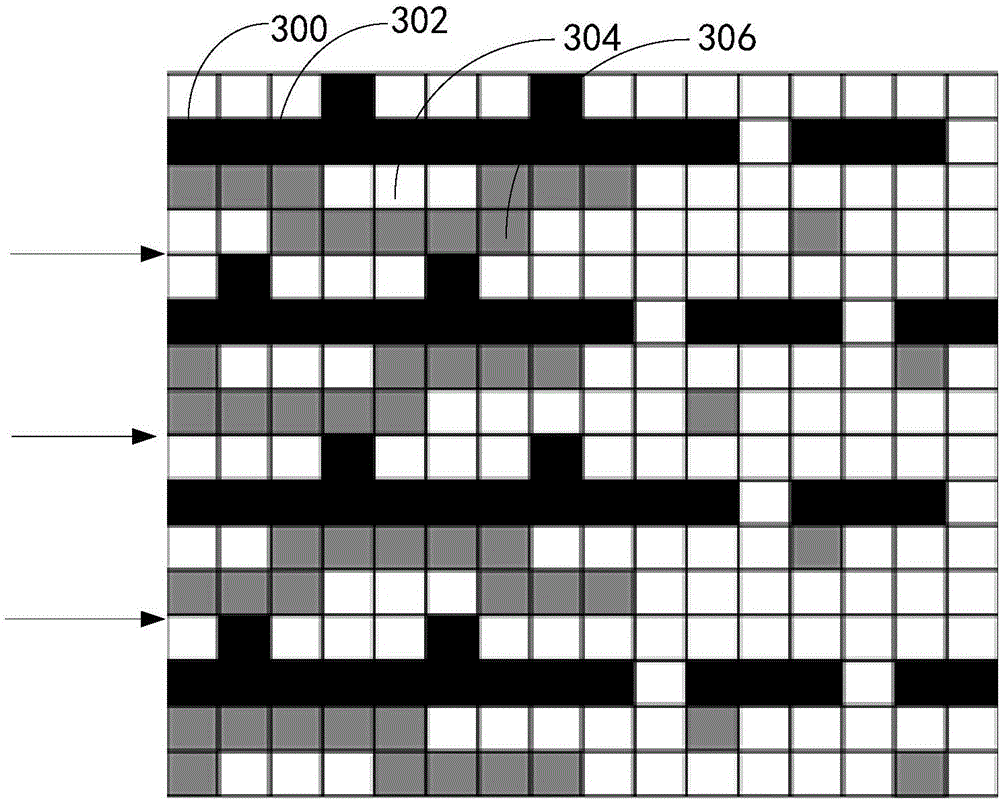

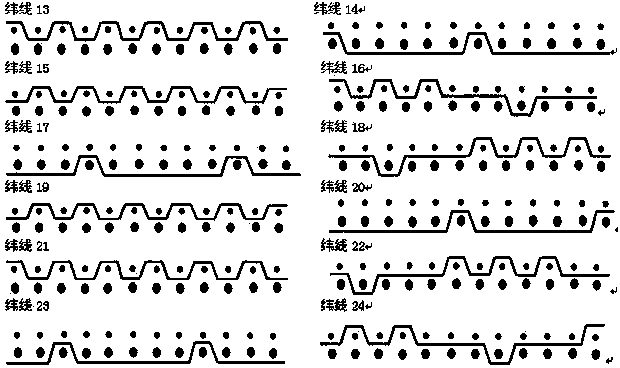

Weft self-binding forming net

InactiveCN106133239AImprove bindingLarge spanHeating/cooling textile fabricsMachine wet endSurface layerPulp and paper industry

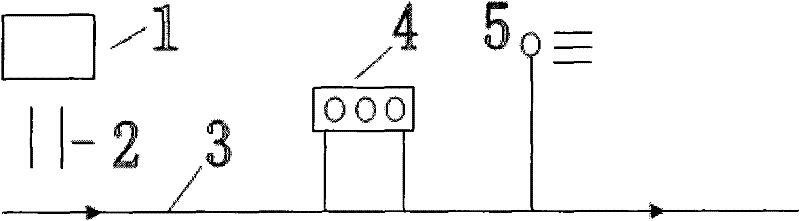

The present invention discloses a weft self-binding forming net, which belongs to the technical field of net forming for papermaking. The forming net comprises a surface layer, a bottom layer and connection lines, wherein, the surface layer has a plain weave structure that is alternately intertwined with a surface warp and a surface weft; the bottom layer has a satin structure that is alternately intertwined with a bottom warp and a bottom weft; and the connection lines are set in pairs to connect the surface layer and the bottom layer in horizontal direction. The connection lines are intertwined between an upper net and a lower net reguraly, making the two nets connected; relative moving and sliding are prevented to avoid internal wear; the forming mesh has uniform mesh size and high paper quality; a longer service life is provided by preventing wear in a three-tier net.

Owner:许长云 +1

The preparation method of hot melt adhesive omentum

ActiveCN101240148BAppropriate crystallization speedStrong toughnessFilm/foil adhesivesMelt spinning methodsHot meltSpin speed

The invention provides a preparation method of a hot-melt adhesive omentum, which comprises the steps of melting hot-melt adhesive raw materials, adding a crystallization nucleating agent, extruding, spinning, air-flow drafting, spinning and forming a web, and the like. By adding a certain amount of special nucleating agent and controlling the melting temperature and spinning speed of the hot melt adhesive, a hot melt adhesive film with uniform pore size and stable weight is prepared. The above processes are all continuously completed in one production process, the production efficiency is greatly improved, and it is suitable for industrial production.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD

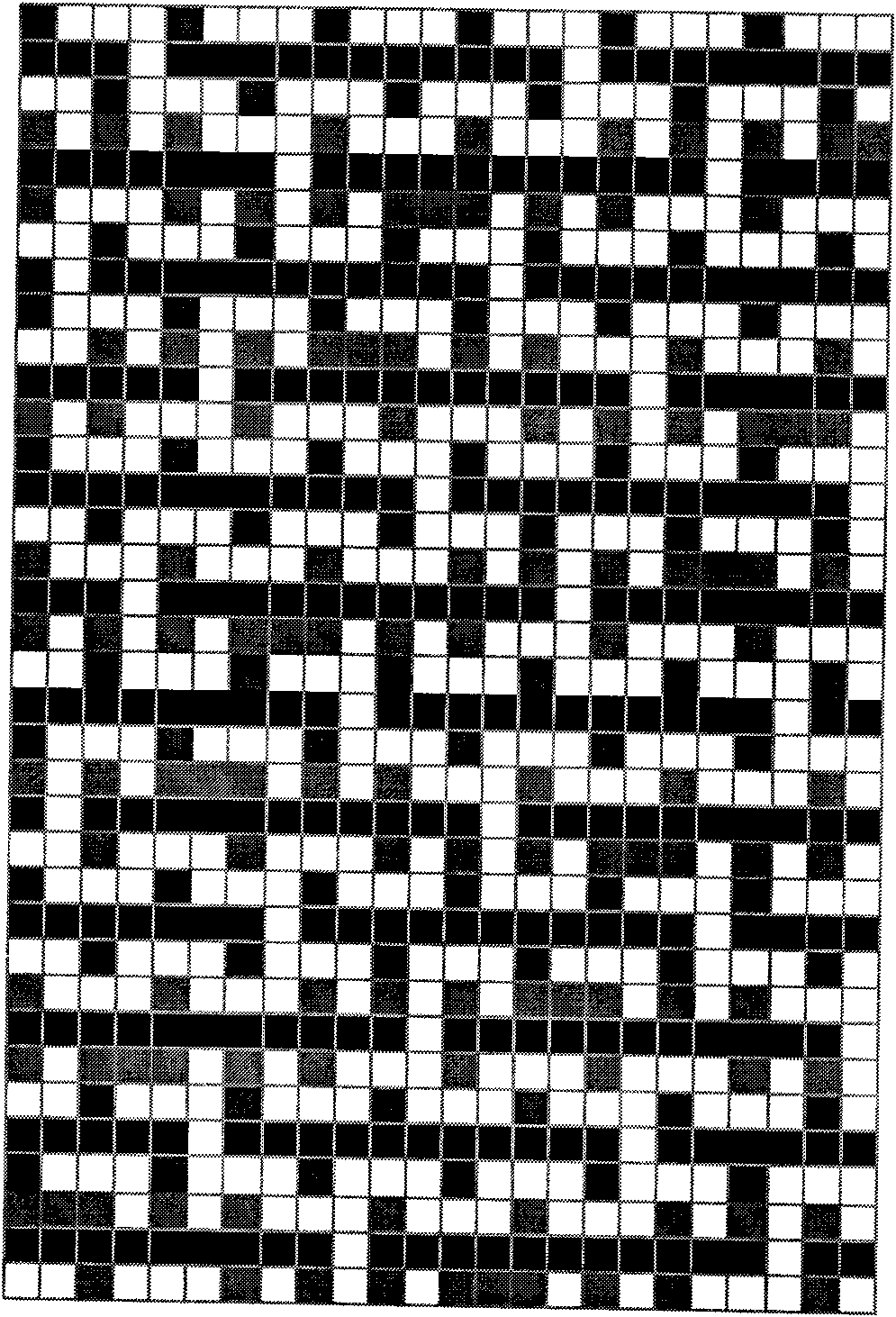

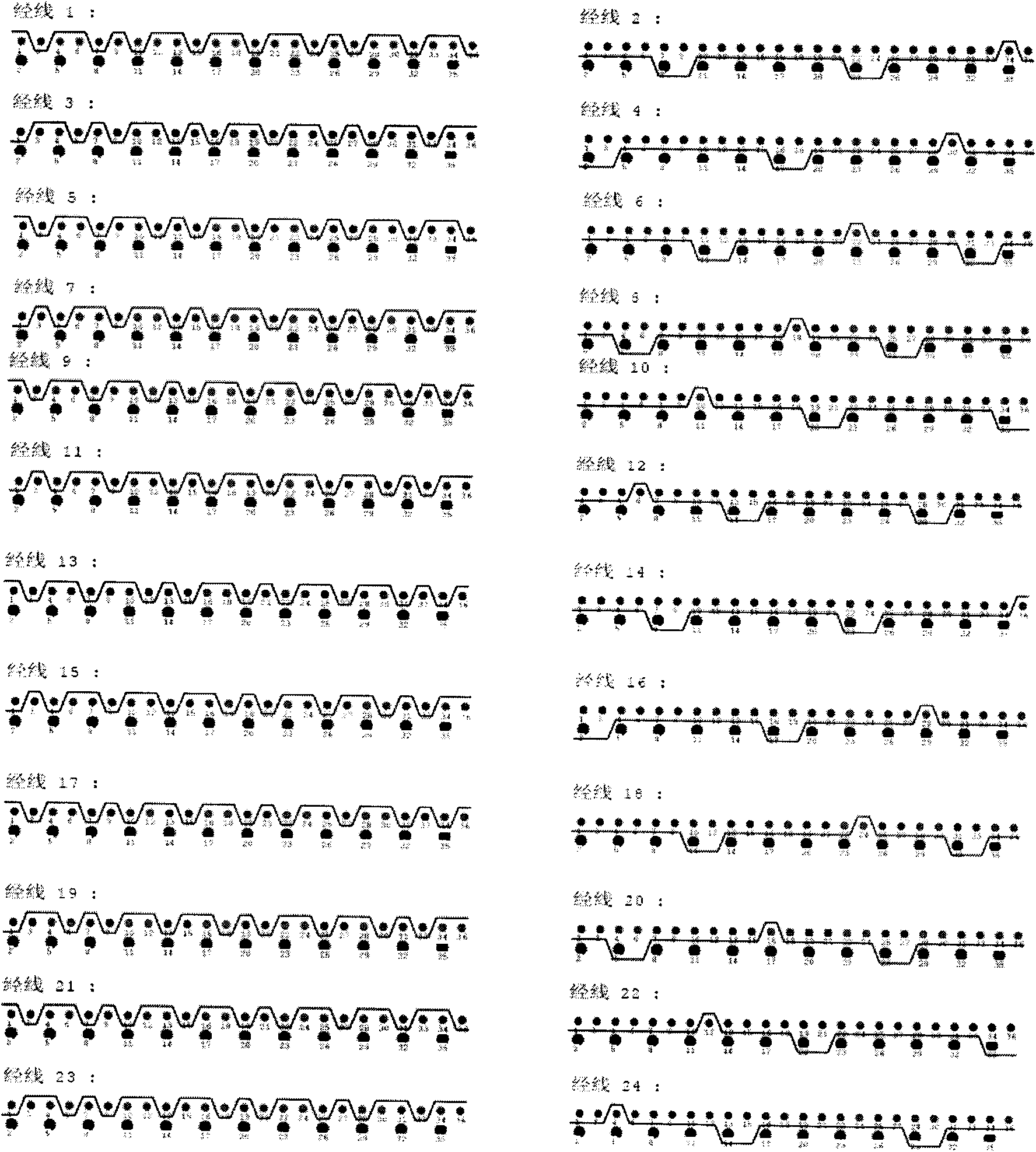

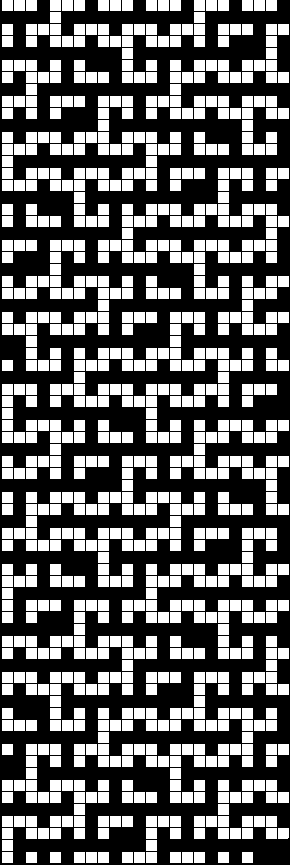

High-grade daily used paper-polyester fibres three-layer wire-cloth

The invention provides 24 harness self-binding polyester three-layer wire-cloth, wherein polyester and nylon monofilament is interwoven to be composite intertexture of a structural connection whole body of a paper forming layer, an intermediate connection layer and a machine layer by 24 pieces of harness frames, the minimum organization unit is composed of 24 polyester monofilaments as a warp thread and 36 polyester or nylon monofilament as a weft thread. Number ratio of warp threads of the paper forming layer to that of the machine layer is 1:1, and number ratio of weft threads is 3:2; the number of weft threads is 2 / 6 of total number of the weft threads; the paper forming layer employs plain weave method, and the machine layer employs 6 harness weave method. The invention has advantages of high fibre supporting index, high retention of fibre and fillers, uniform forming of page, easy peeling of page from net, flattening paper forming, firm combination of upper and lower layers, good abrasive resistance and long service life.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Method for preparing hot-melt adhesive net film

The invention provides a method for preparing a hot-melt adhesive net film. The method comprises the following steps of: melting a hot-melt adhesive serving as a raw material; squeezing and spinning; heating and crystallizing by infrared light; and solidifying the material to form a net by spraying and the like. The hot-melt adhesive net film with uniform aperture and stable gram weight is prepared by controlling the melting temperature of the hot-melt adhesive, the spinning speed, the speed of a conveying belt, infrared temperature and spray. The steps are continuously finished in a production flow, so that the production efficiency is greatly improved, and the method is suitable for industrial production.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

Preparation method for high-strength wear-resistant leather

InactiveCN109536647AHigh strengthImprove wear resistanceTanning treatmentLeather surface finishingCollagen fiberFiber strength

The invention mainly relates to the technical field of leather processing, and discloses a preparation method for high-strength wear-resistant leather. The preparation method comprises the steps of retanning, primary drying, primary coating, secondary coating and secondary drying. The preparation method for the high-strength wear-resistant leather has the advantages that the method is simple, andthe obtained leather is soft, breathable, high in strength and high in wear resistance, does not uses harmful chemical components and is healthy and environmentally-friendly; a tanned leather materialis put into a chrome tanning agent for rotary drum retanning, so that the synthesis of collagen fibers in the leather is promoted, and the leather is uniform and soft in texture; after retanning, theleather is subjected to primary drying, so that the moisture is rapidly reduced before high-temperature drying, the porosity of the surface of the leather material is decreased, the uniformity of theleather material is improved, the temperature is decreased for drying, so that the moisture in the leather material is slowly lost, mesh structures inside the leather material are increased, and thefiber strength is improved, so that the leather material is breathable, warm-keeping and comfortable to wear.

Owner:亓明芳

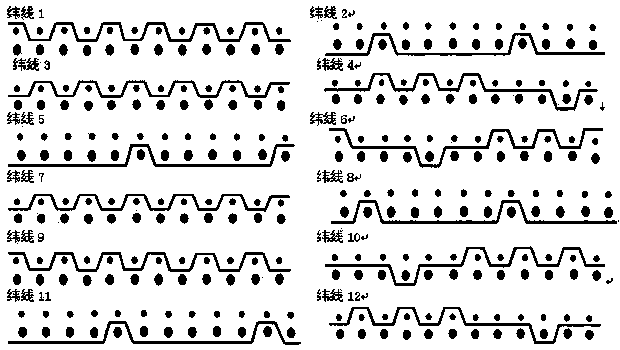

Forming mesh specially used for high-speed household paper and papermaking equipment

ActiveCN107177997AIncreased fiber support indexUniform meshLayered productsMachine wet endFiberPapermaking

The invention discloses a forming mesh specially used for high-speed household paper and papermaking equipment. The forming mesh comprises a paper-forming layer, an intermediate connection layer and a machine layer, wherein the paper-forming layer is formed by weaving paper-forming layer warps and paper-forming layer wefts according to a 4-satin weaving method; and the machine layer is formed by weaving machine layer warps and machine layer wefts according to a four-satin weaving method. By virtue of the way, the implementation way provided by the invention can improve fiber support index of a paper surface.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

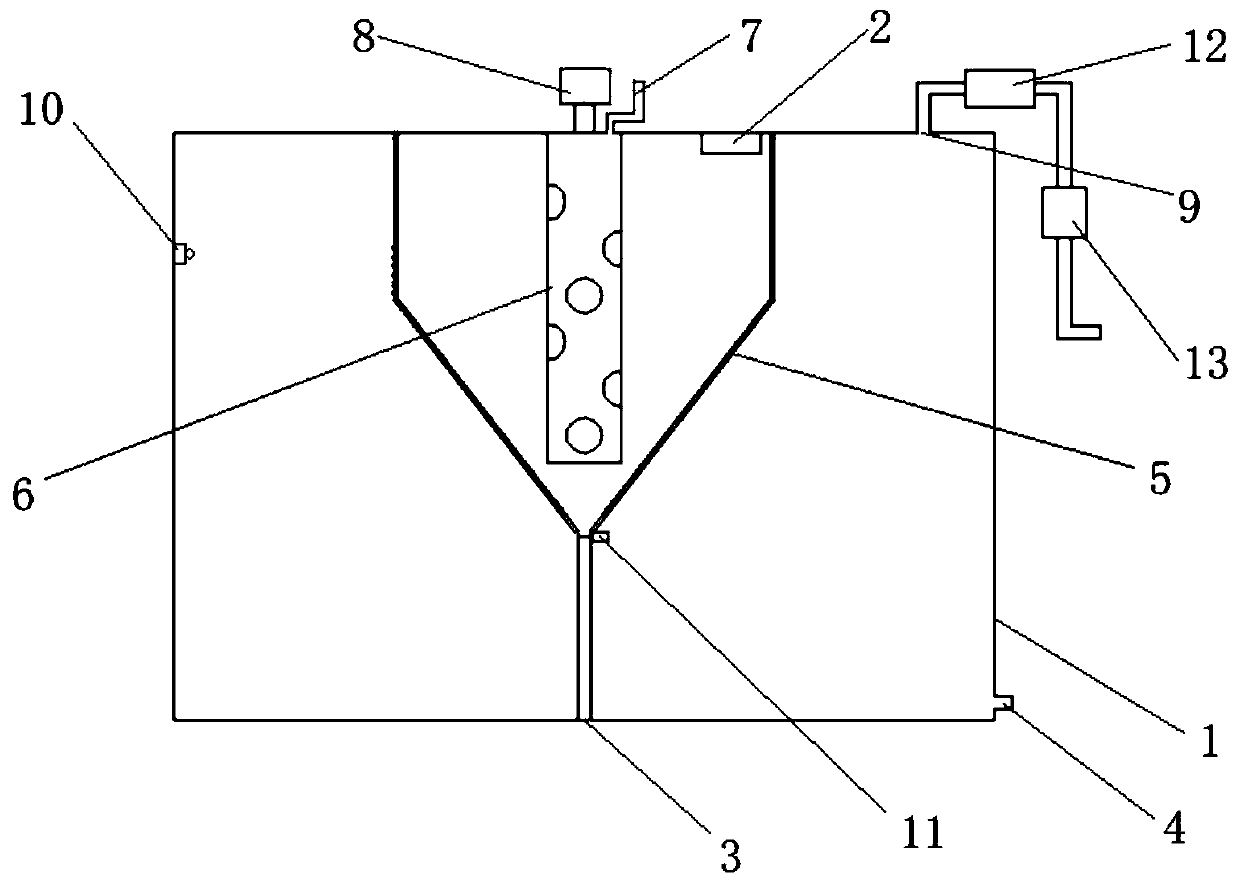

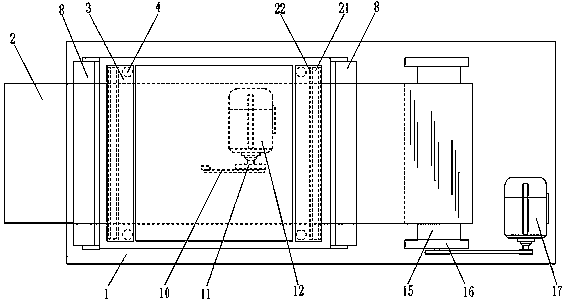

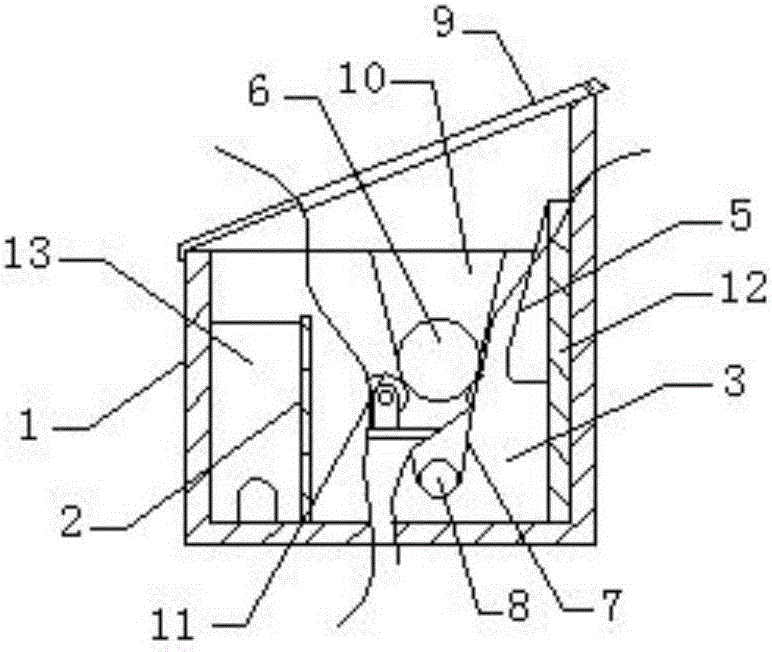

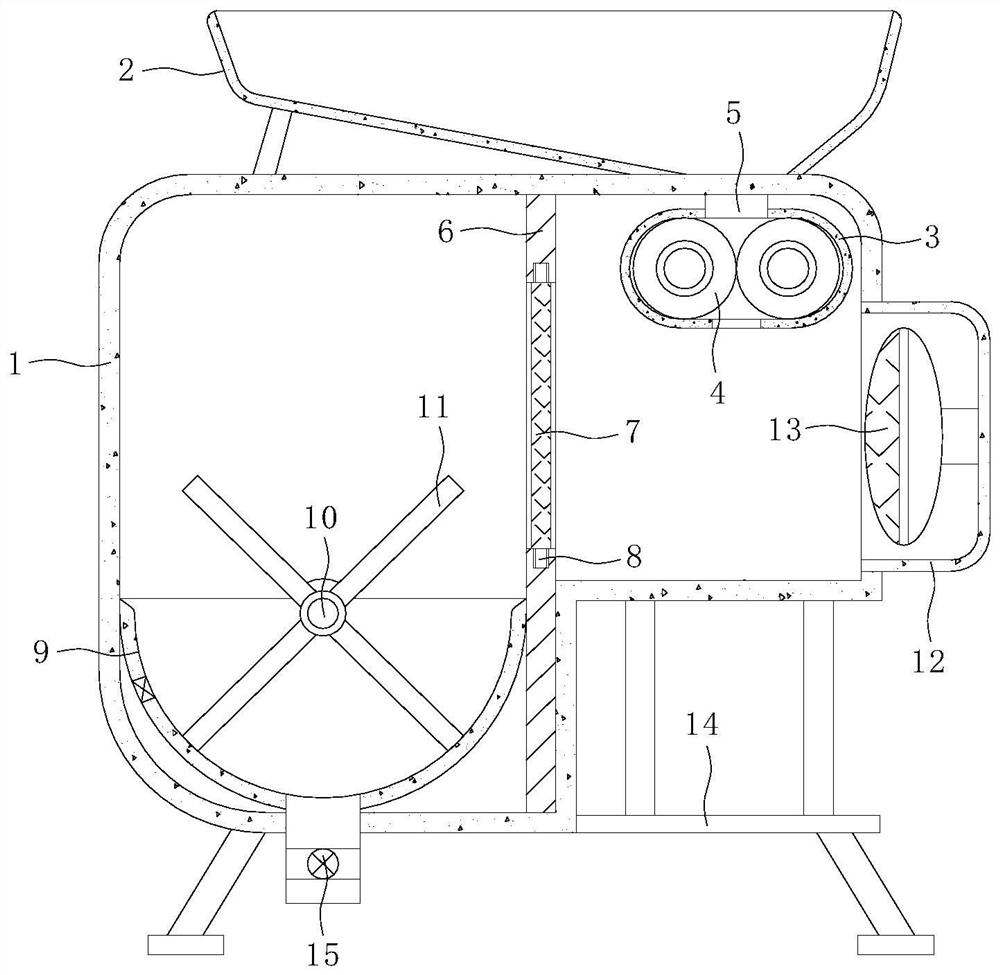

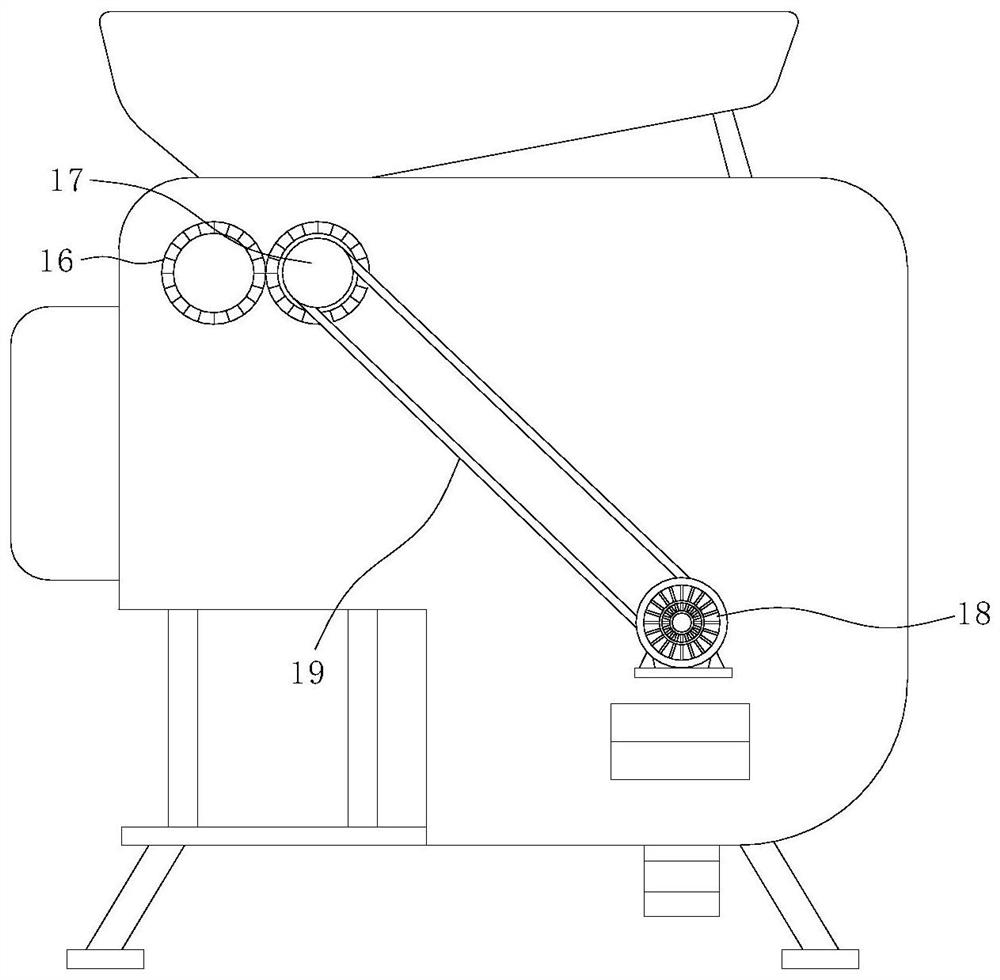

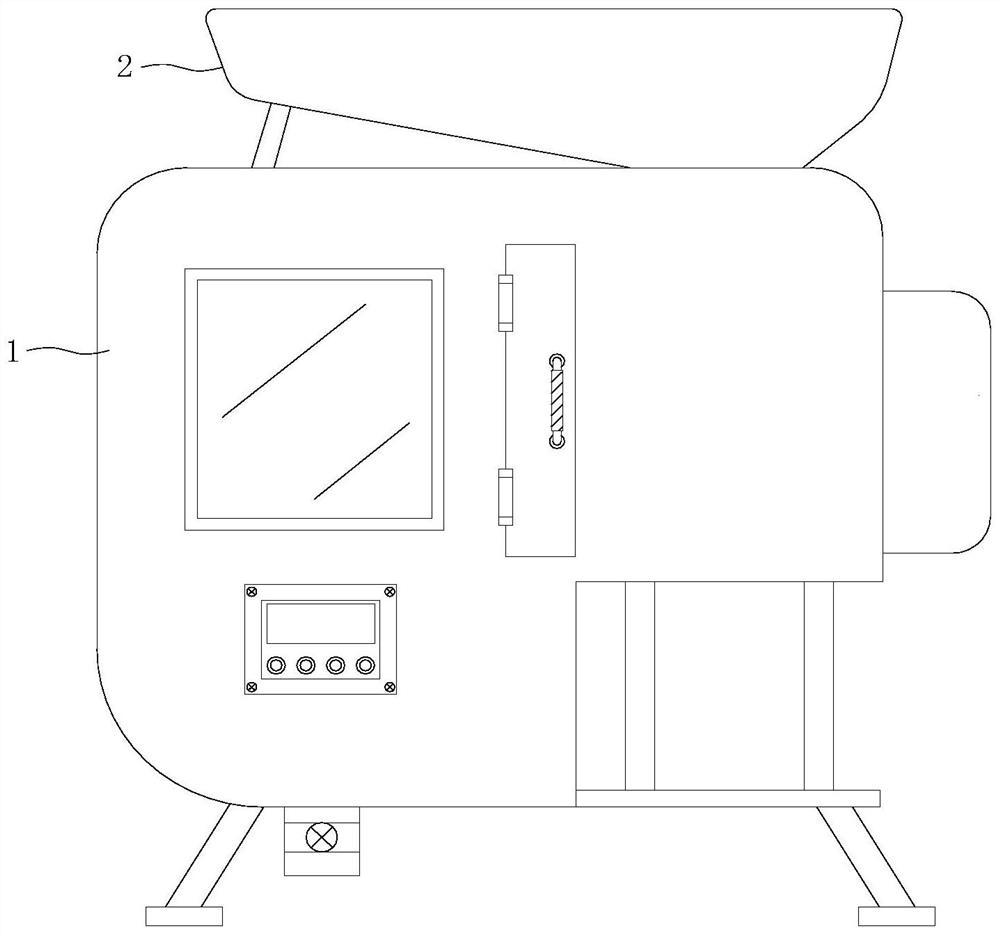

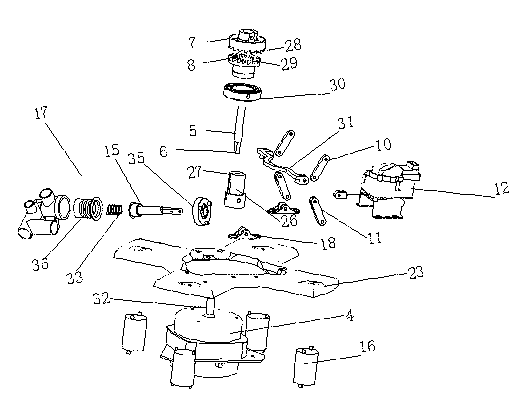

Titanium alloy tiny powder gas screening device

InactiveCN109877042ANo frequent replacementEfficient separationGas current separationTitanium alloyFine powder

The invention relates to a titanium alloy tiny powder gas screening device which comprises a closed container (1). A powder feeding opening (2) is formed in the top of the closed container (1). A rough powder outlet (3) and a fine powder outlet (4) are formed in the bottom of the closed container (1). A funnel-like screen (5) is arranged in the closed container (1). A sleeve (6) with a hole formedin the surface is arranged on the inner side of the funnel-like screen (5). An inert gas input opening (7) is formed in the top end of the sleeve (6). A motor (8) is connected with and drives the sleeve (6) to rotate. The closed container (1) is further provided with a gas exhausting opening (9). Inert gas is adopted for generating corresponding circulating airflow, no residual powder exists on the surface of the screen all the time, the situation that the powder gathers on the surface of the screen, and the screen is blocked is avoided, the screening efficiency is reduced, screening is uniform, safe and efficient, meanwhile, the screen does not need to be replaced frequently, and the device is simple and easy to use.

Owner:苏州双恩智能科技有限公司

Twenty-four- heald composite fiber polyester three-layer papermaking net

The invention discloses a twenty-four-heald composite fiber polyester three-layer papermaking net which is an integrated composite intertexture formed by using twenty-four healds to interweave polyester or nylon single yarn. The twenty-four-heald composite fiber polyester three-layer papermaking net comprises a paper forming layer, a middle connecting layer and a machine layer, wherein the paper forming layer, the middle connecting layer and the machine layer are different in weaving structure, the 1 / 1 plain weaving method is adopted for the paper forming layer, the six-heald weaving method is adopted for the machine layer, and the middle connecting layer comprises a pair of connecting wefts which are used for connecting the paper forming layer and the machine layer. Due to the fact that the 1 / 1 plain weaving method is adopted for the paper forming layer, the fiber supporting index is made to be improved, meshes are even and smooth, the retention rate of fiber and padding of paper is improved, paper page forming is even, and a paper page can be stripped off the net easily. The pair of connecting wefts is used for connecting the paper forming layer and the machine layer, so that the upper layer and the lower layer are connected with each other more firmly. The six-heald weaving method is adopted for the machine layer, so that the span of wefts of the machine layer is increased, abrasive resistance of the forming net is improved, and service life is longer.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

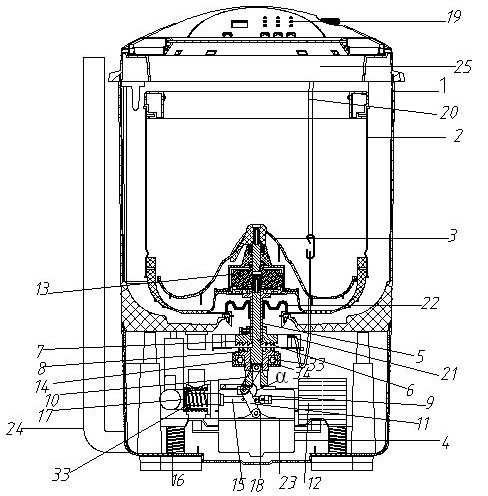

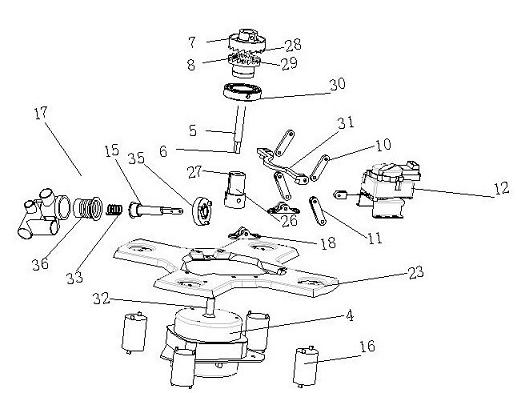

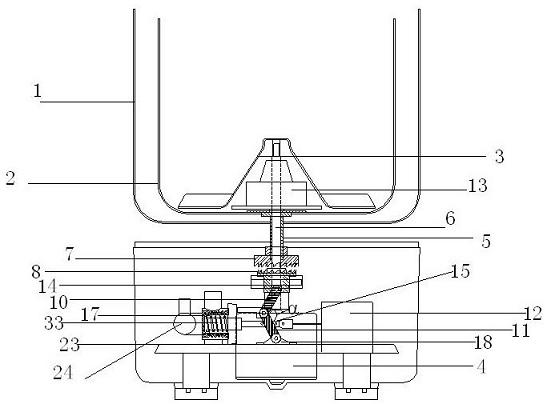

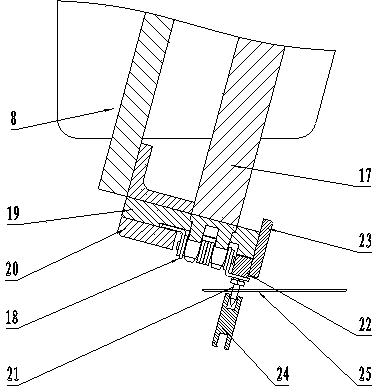

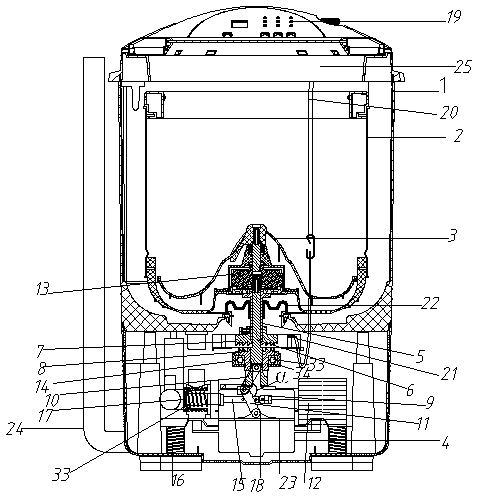

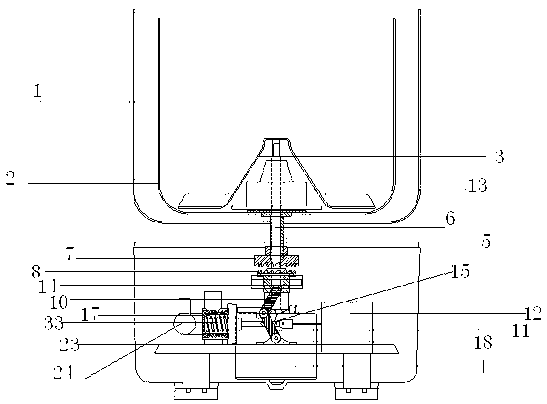

Washing machine with simple clutch

InactiveCN102535104ASimple structureEasy to controlOther washing machinesTextiles and paperImpellerClutch

The invention discloses a washing machine with a simple clutch. The washing machine comprises a box body, a spin dryer barrel, an impeller, a motor, a clutch part and a water draining system, wherein the motor is used for supplying a washing and dehydrating driving force; the washing machine is characterized in that the clutch part comprises a spin drying shaft sleeve and a spindle; the spin drying shaft sleeve is connected with the spin dryer barrel; the spindle passes through the spin drying shaft sleeve; the impeller is driven to rotate by one end of the spindle; the other end of the spindle is connected with the motor; an upper clutch is arranged on the spin drying shaft sleeve; a lower clutch is arranged on the spindle; and a lifting component is connected with the upper clutch and / or the lower clutch. The washing machine with the simple clutch has the characteristics that: washing and dehydrating are finished in one barrel, thereby being convenient and quick; an upper and lower clutch mechanism is adopted, the structure is simple, the control is accurate and the production cost is low; and the upper and lower clutches are clutch gears, the uniform teeth are compactly engagedand are difficult to separate and firmly clamp, the design is reasonable and the service life is long.

Owner:金碧辉

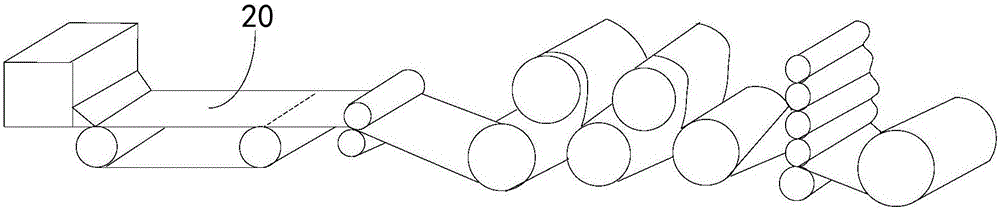

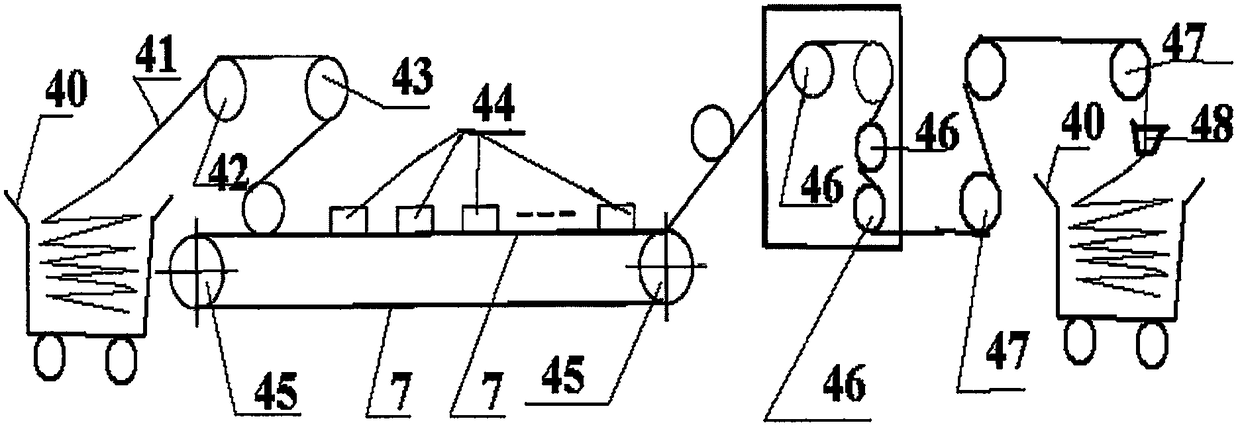

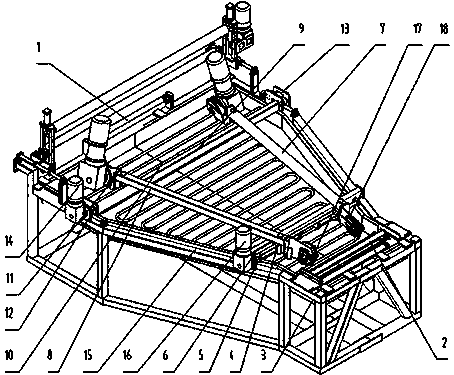

Electromechanical integrated rapid flat screen printing equipment

ActiveCN108162575AThe operating range can be adjustedHigh degree of automationScreen printersPrinting press partsScreen printingWater vapor

The invention relates to automatic rapid printing electromechanical equipment of textiles, in particular to electromechanical integrated rapid flat screen printing equipment. The equipment mainly comprises a silk screen, a dye groove, a cam, a right travel switch, edge suction devices, amplitude-opening threaded rollers, printing units and the like; after cloth is sucked by the edge suction devices, the cloth enters the printing units after passing through the amplitude-opening threaded rollers; each printing unit comprises the cam, a servo motor, a travel switch and the like, the number of the edge suction devices is two, and the cloth passes below the printing units and runs above a conveying belt simultaneously; the cloth is printed and then passes between four drying drums, and the drying rollers are provided with water vapor. The cam is adopted, so that the structure is simple, and compact, and the design is convenient; and therefore, in the printing process, only proper cam profiles are made, any preset movement rule of a scraper can be obtained, the running amplitude of the scraper can be adjusted, and the scraper can adapt to the cloth with different widths.

Owner:台州同兴印染有限公司

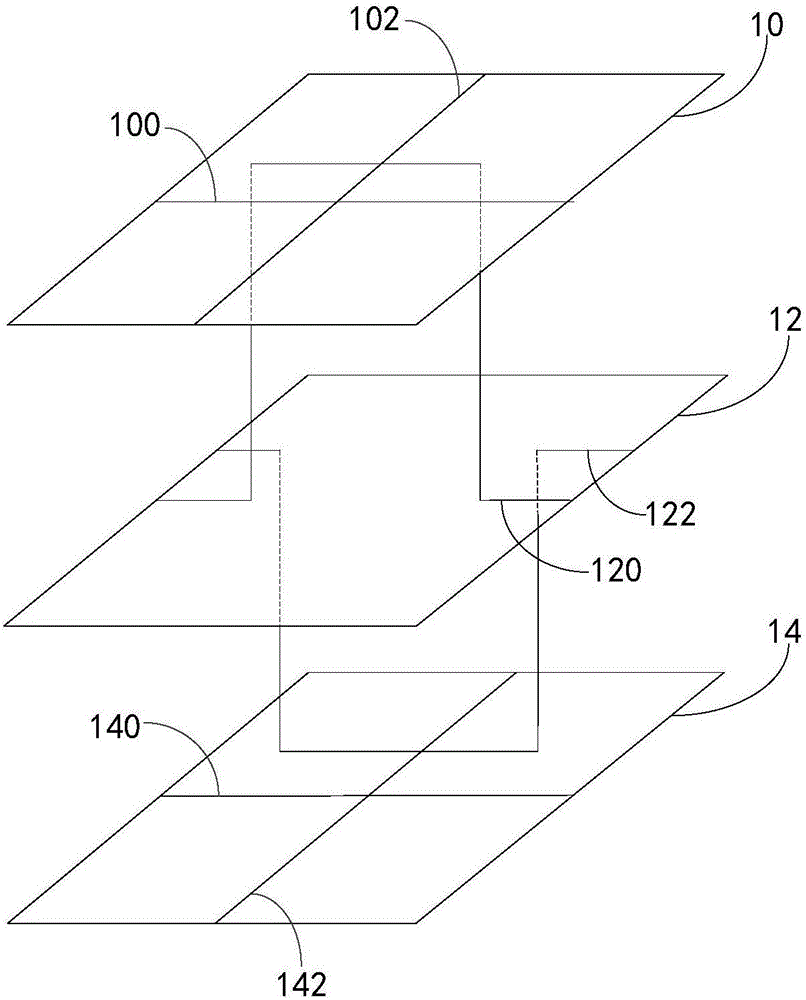

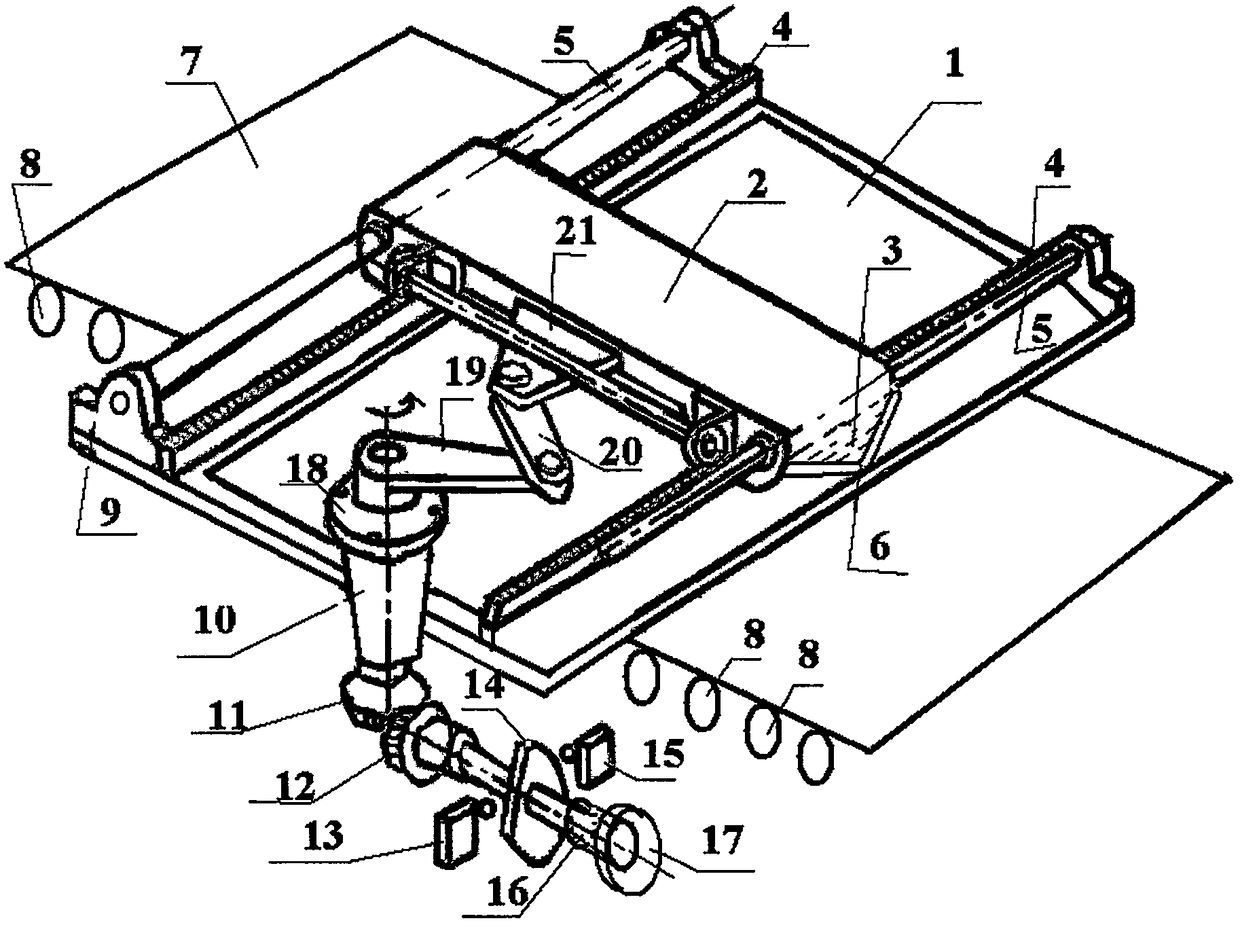

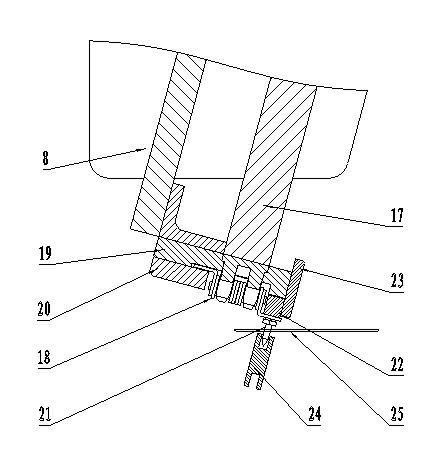

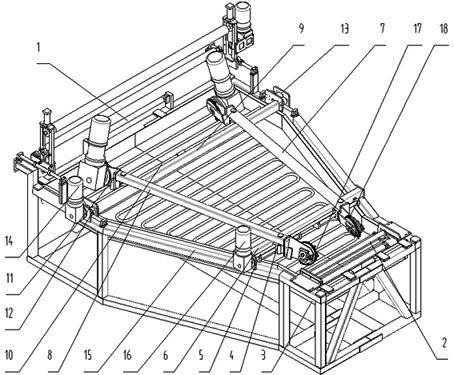

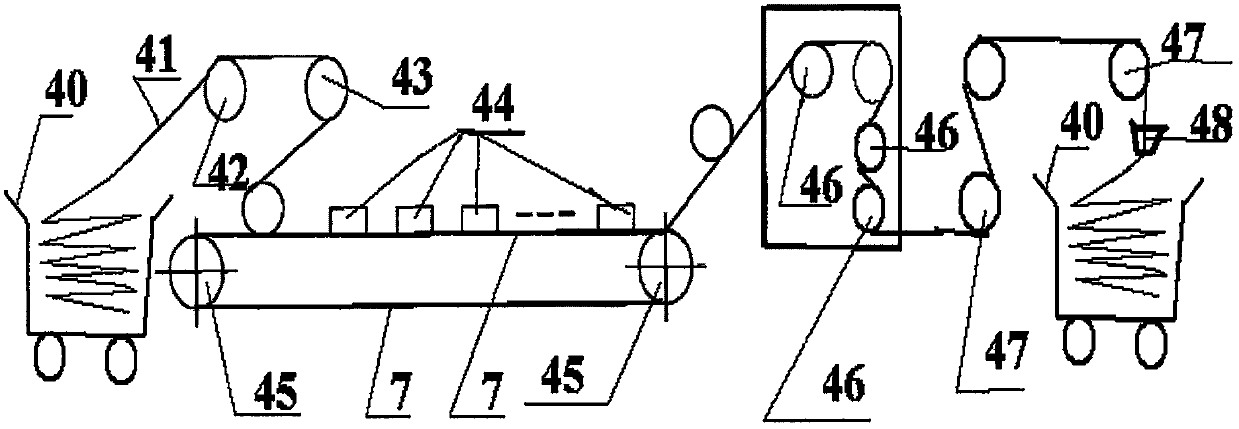

Adjustable plastic netting material transversal stretching device

The invention provides an adjustable plastic netting material transversal stretching device. The device is characterized in that a heat oven is arranged on a frame, a rear guide roller and a pull out roller are provided at the rear part of the frame, a front guide roller is arranged at the front of the frame, a front beam is transversally fixed at the front of the frame, a left dolly and a right dolly are supported on two sides of rear part of a support in a floating mode and the rear beam is supported by the left dolly and the right dolly, the front parts of a right spreading support and a left spreading support are supported on the front beam and the rear parts of the right spreading support and the left spreading support are supported on the rear beam, the front and back ends of the right spreading support and the left spreading support are provided with sprocket wheels and a chain is hanged between the front sprocket wheel and the back sprocket wheel, a needle-shape screw is fixedon a chain link of the chain, the rear sprocket wheels of the right spreading support and the left spreading support are connected with a driving motor. According to the invention, the production problem of precise biaxial orientation stretching net is effectively solved, and the plastic high-molecular biaxial orientation stretching net can be continuously produced, the netting material has the advantages of uniform mesh, smooth surface, high tensile strength and good elasticity.

Owner:SHANDONG TONGJIA MACHINERY

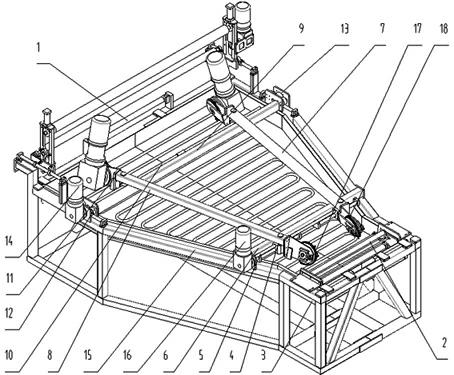

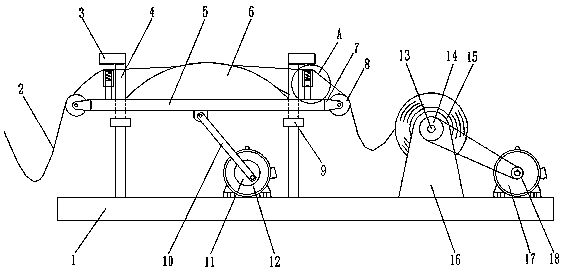

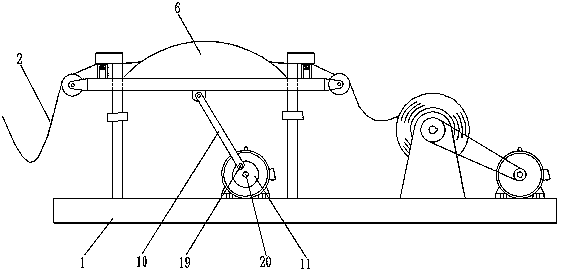

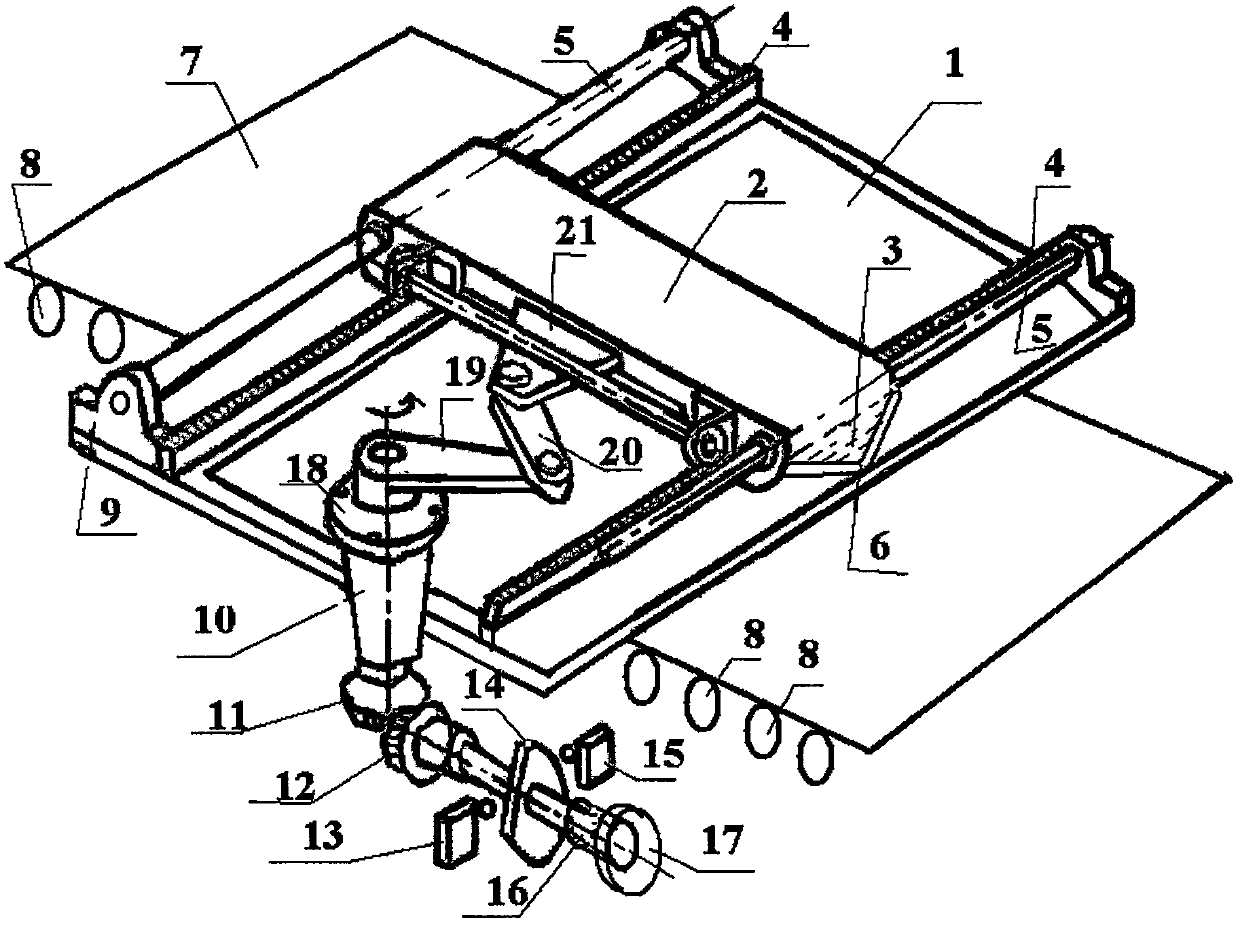

Fabric expanding and conveying system for tire chord fabric drawing zone

PendingCN111501166AAchieve stretching and wrinkle removalEven by forceLoomsAuxillary apparatusReciprocating motionElectric machinery

The invention discloses a fabric expanding and conveying system for a tire chord fabric drawing zone. The system comprises a base, wherein two groups of guide rods are perpendicularly connected to thebase, a crossbeam is connected to the top of each group of guide rods, a platform is connected to the guide rods in a sliding mode, a support lug is arranged on the lower end face of the platform, anarched bulge is arranged on the upper end face of the platform, locating components are arranged on the platform and located at outer sides of the two groups of guide rods respectively, tops of the locating components correspond to bottoms of the crossbeams in position, a first motor is mounted on the base and located between the two groups of guide rods, a transmission disk is mounted on a rotary shaft of the first motor, an eccentric shaft is arranged on the transmission disk, and the eccentric shaft is in transmission connection with the support lug at the lower end of the platform througha connecting rod. According to the system, the first motor drives the transmission disk to rotate, and up-and-down reciprocating motion of the platform is realized under the cooperation of the transmission disk and the connecting rod; and during the reciprocating motion of the platform, a chord fabric is firstly fixed through the locating components and then is supported upwardly by the bulge above the platform, so that expansion and wrinkle removal on the chord fabric are realized.

Owner:东营诺欧橡胶有限公司

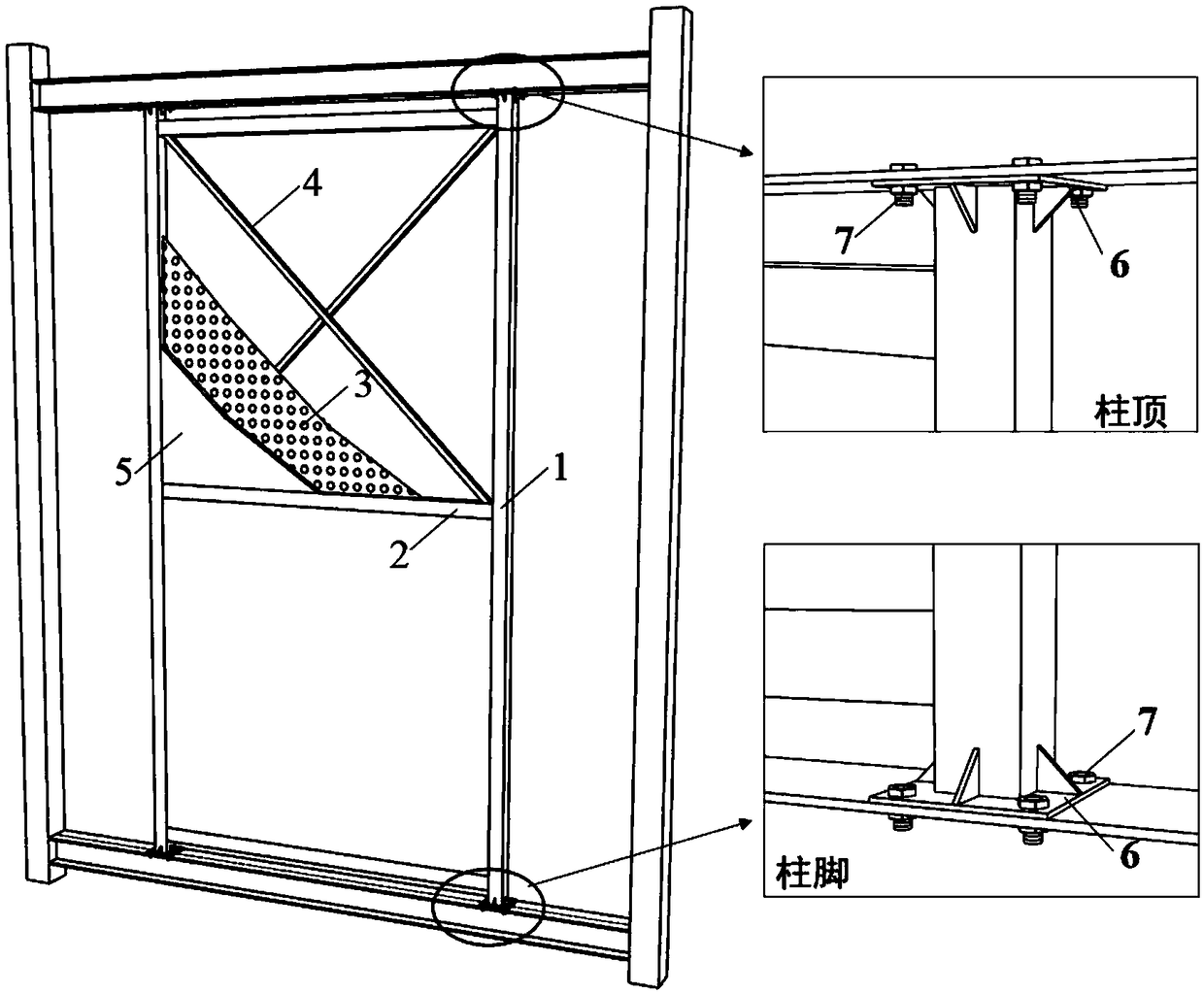

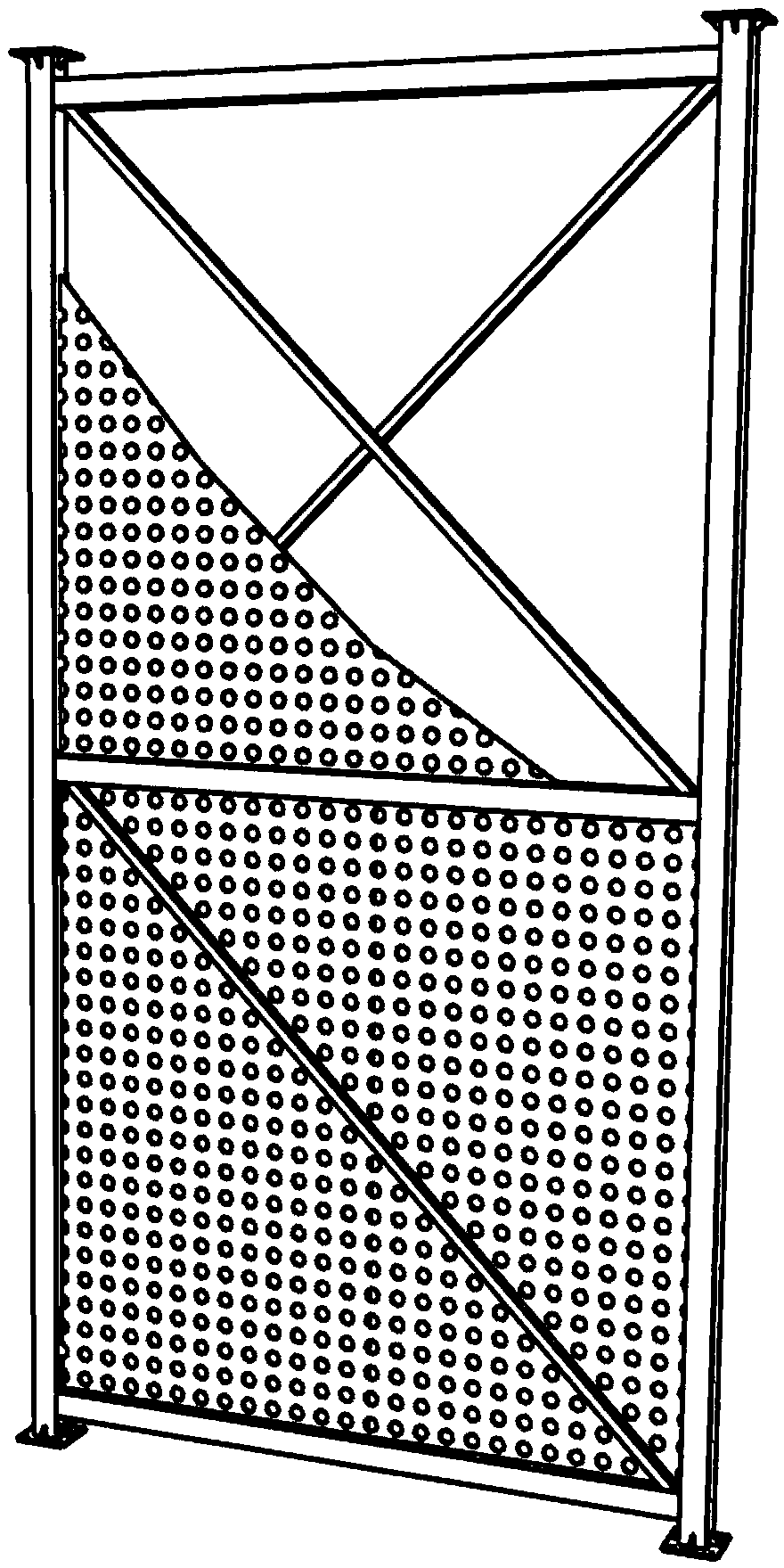

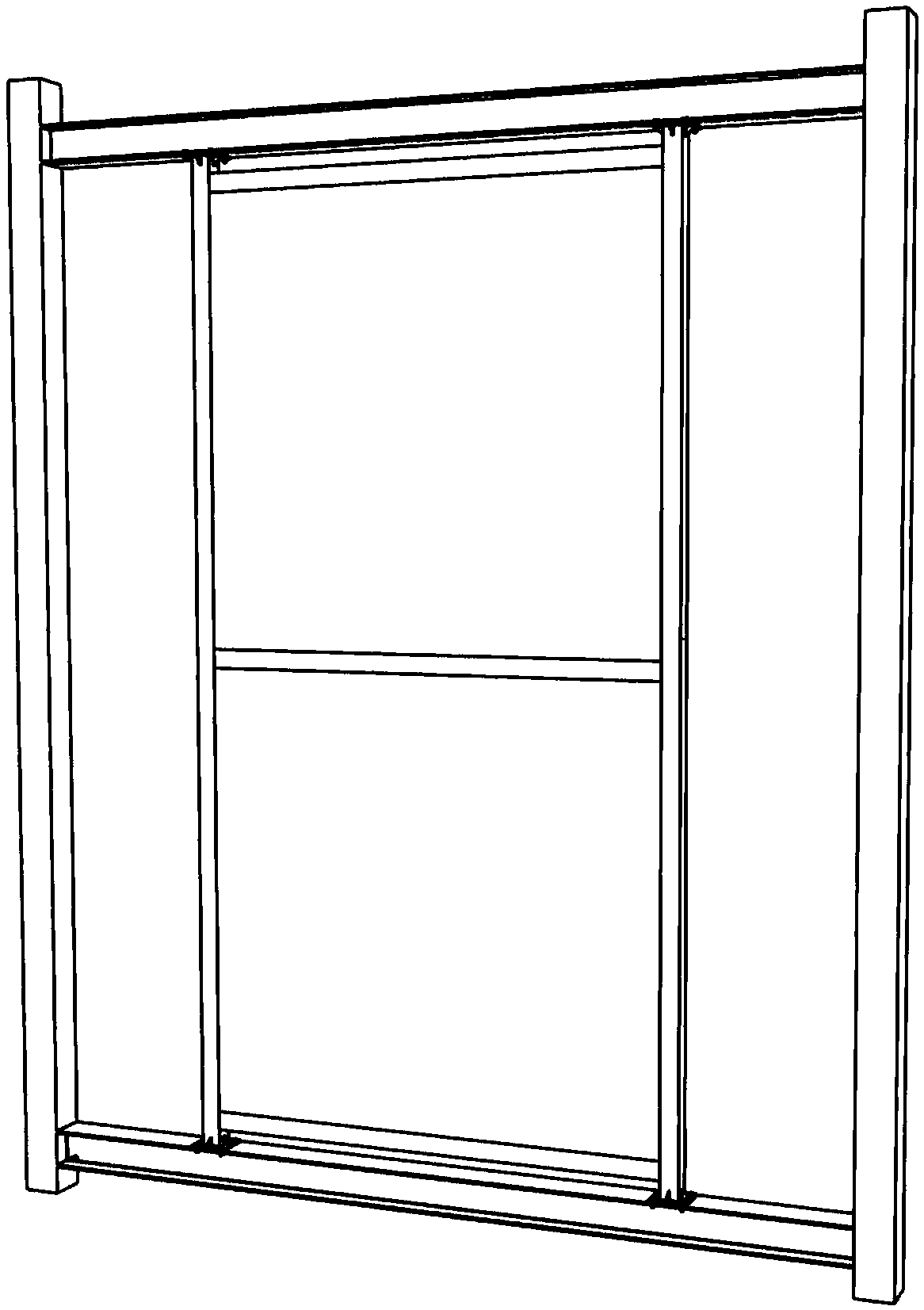

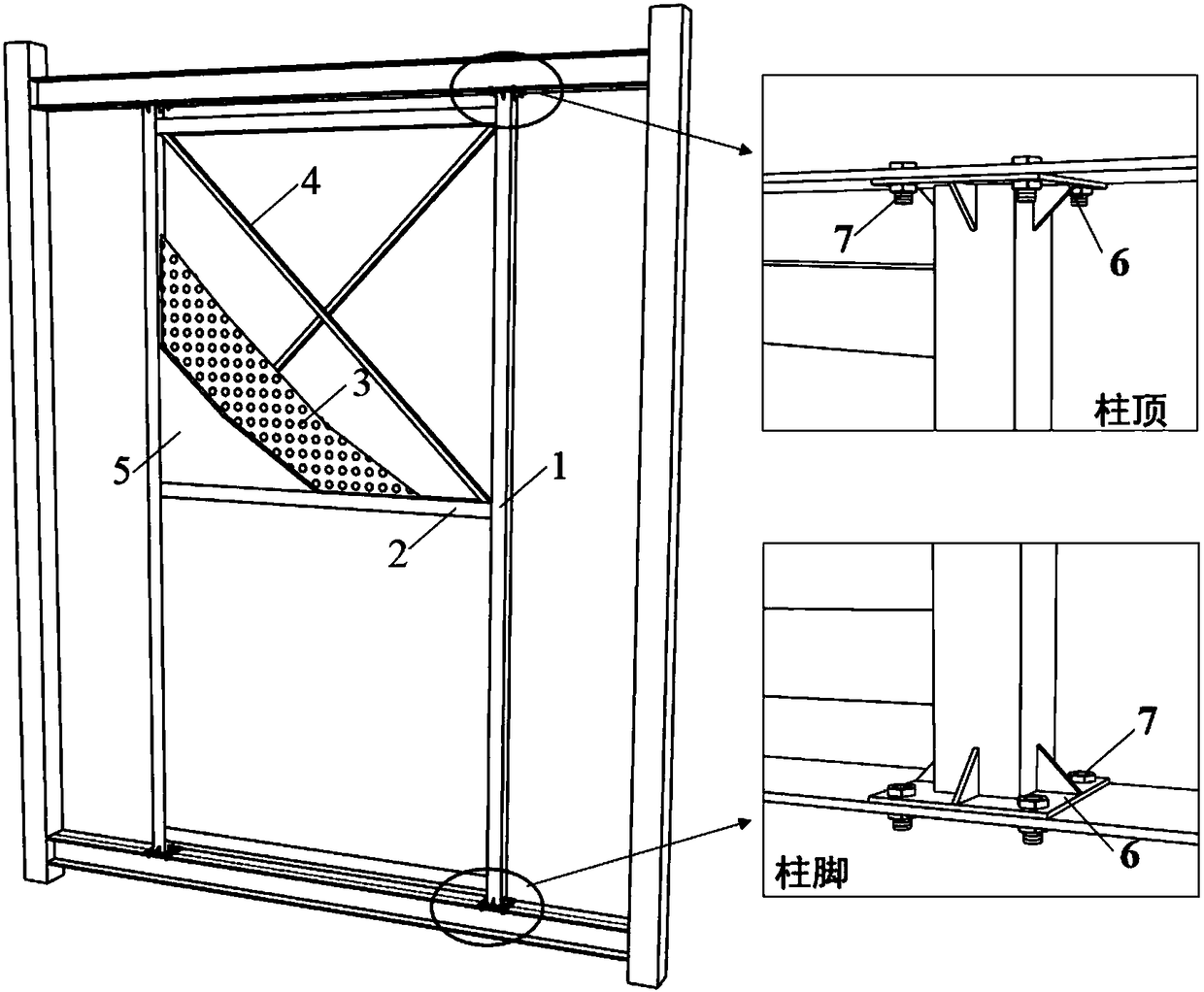

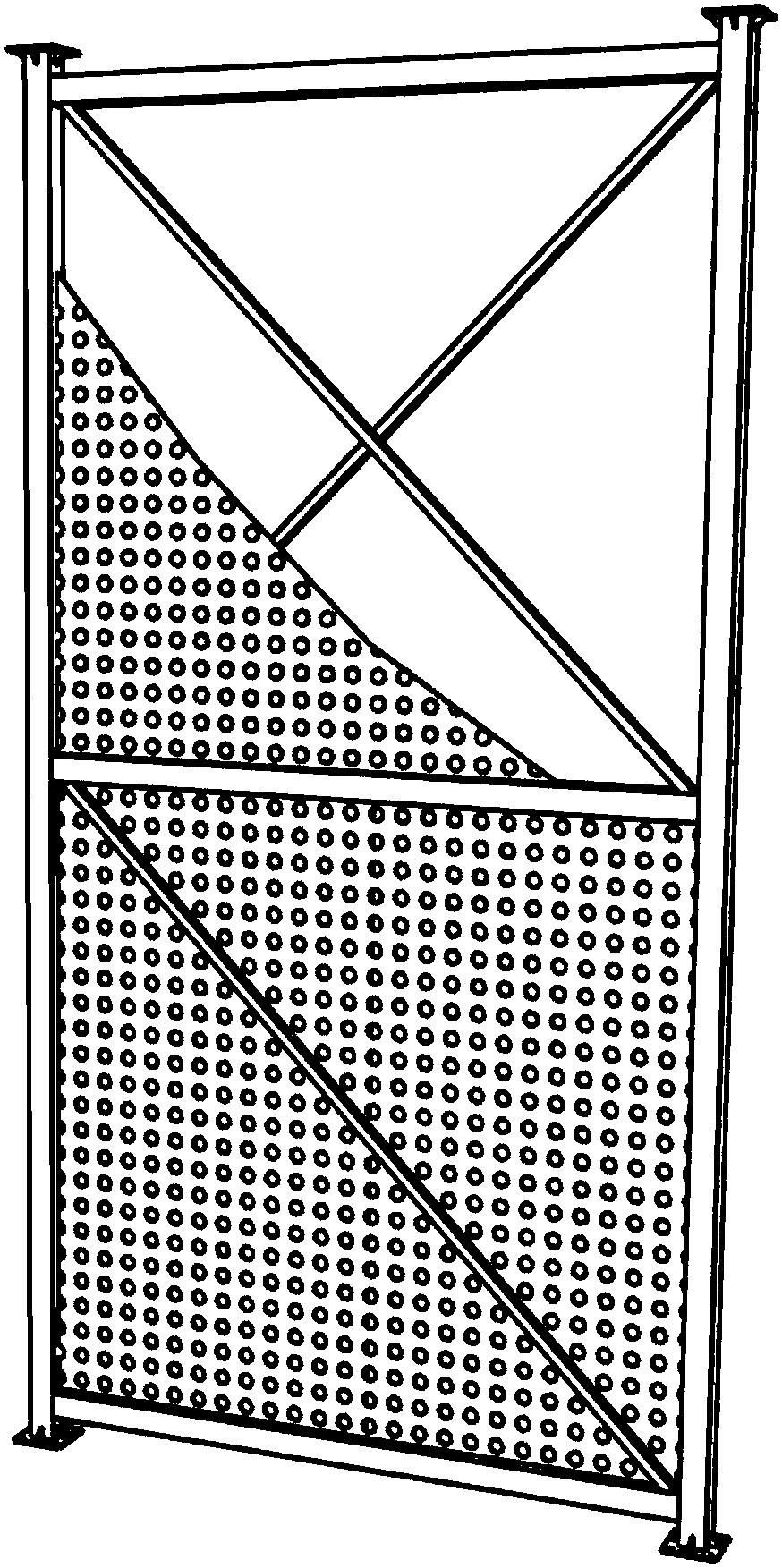

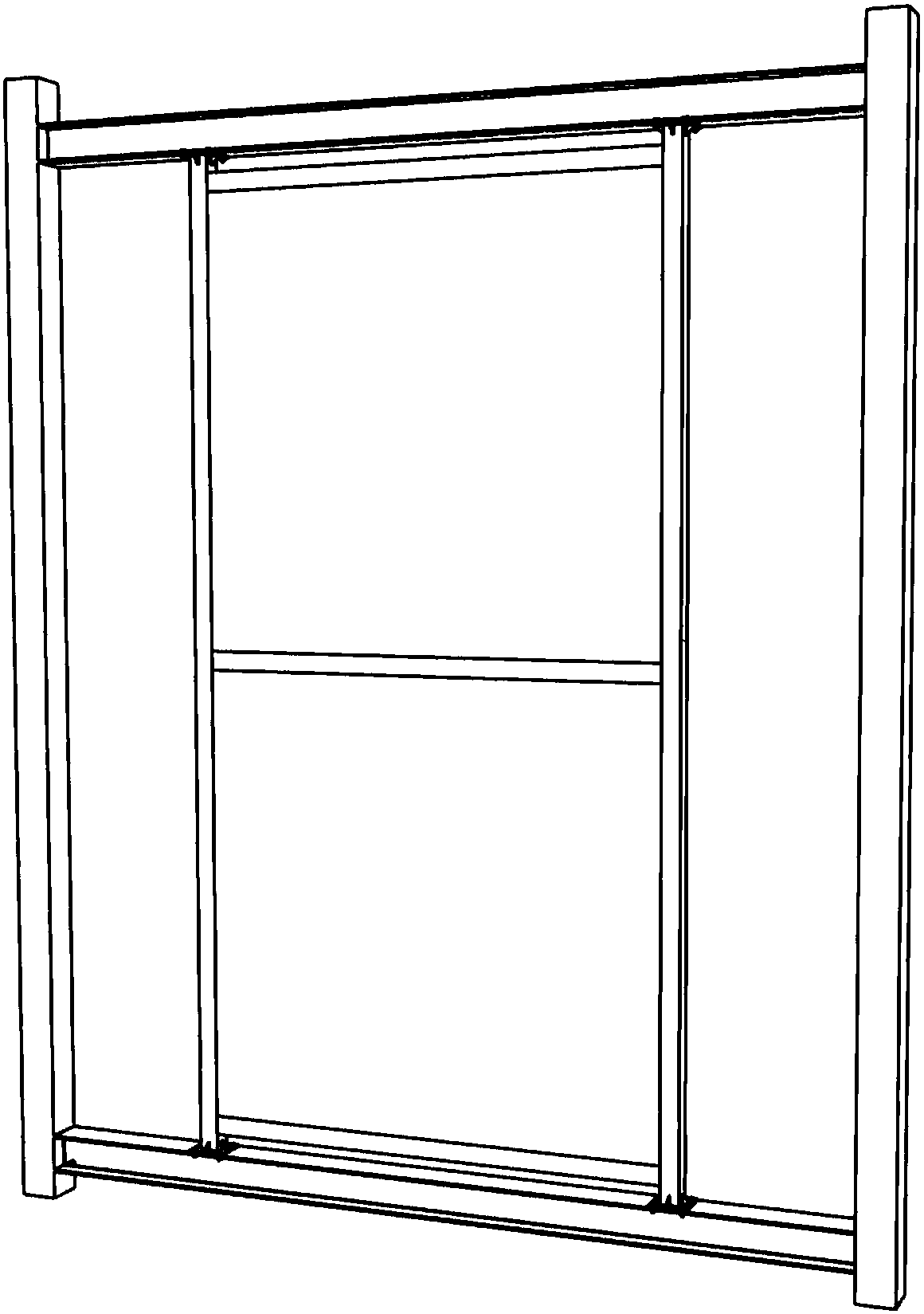

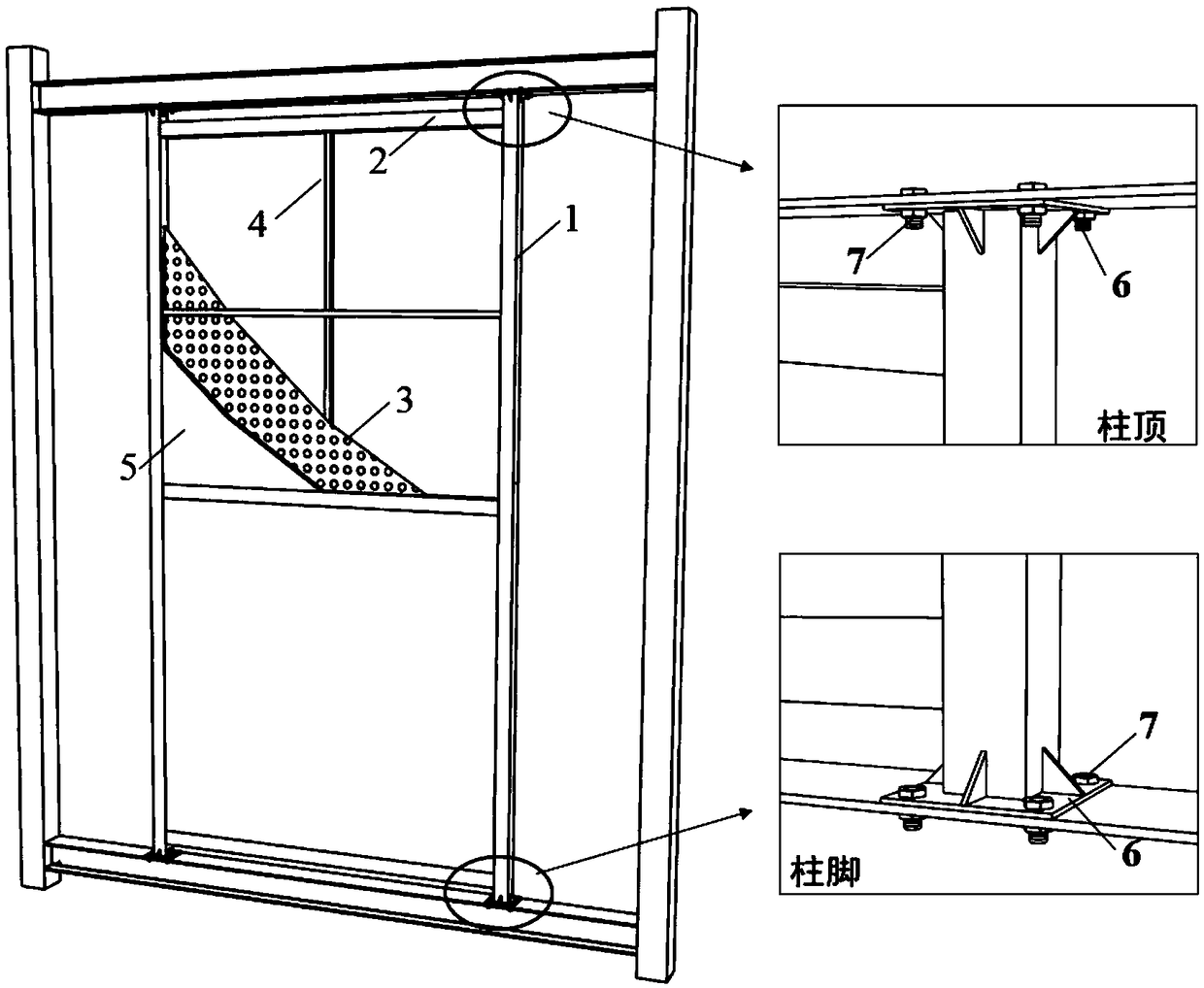

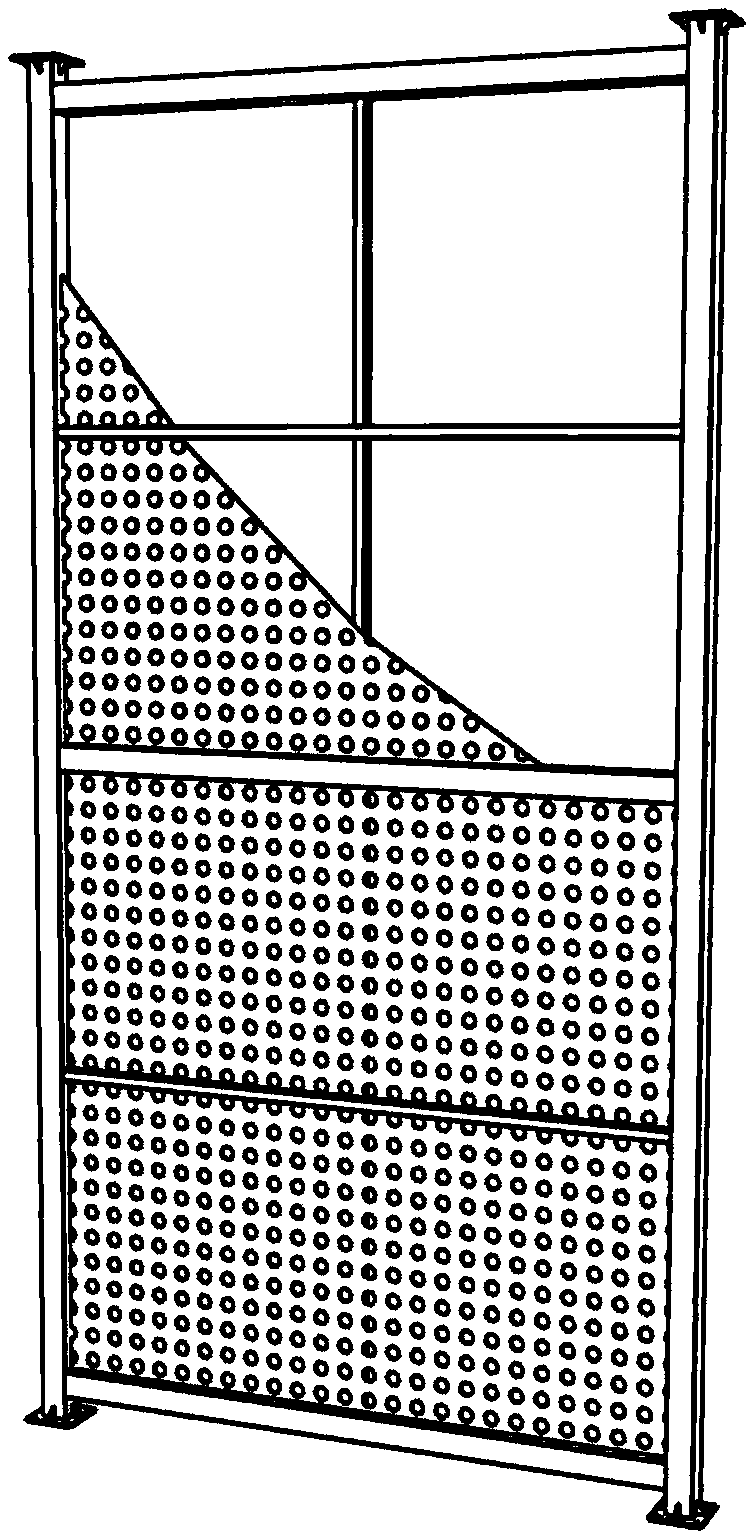

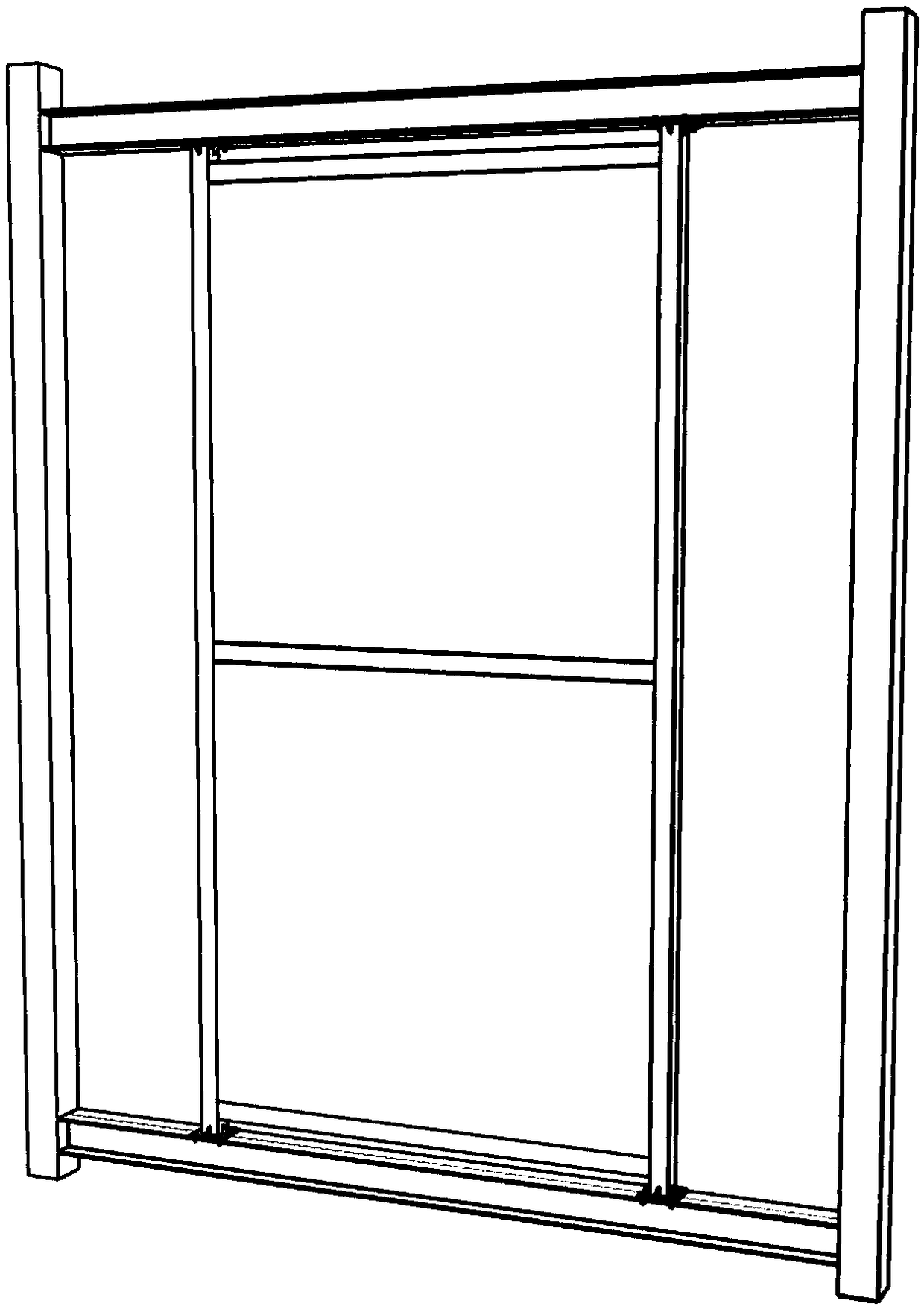

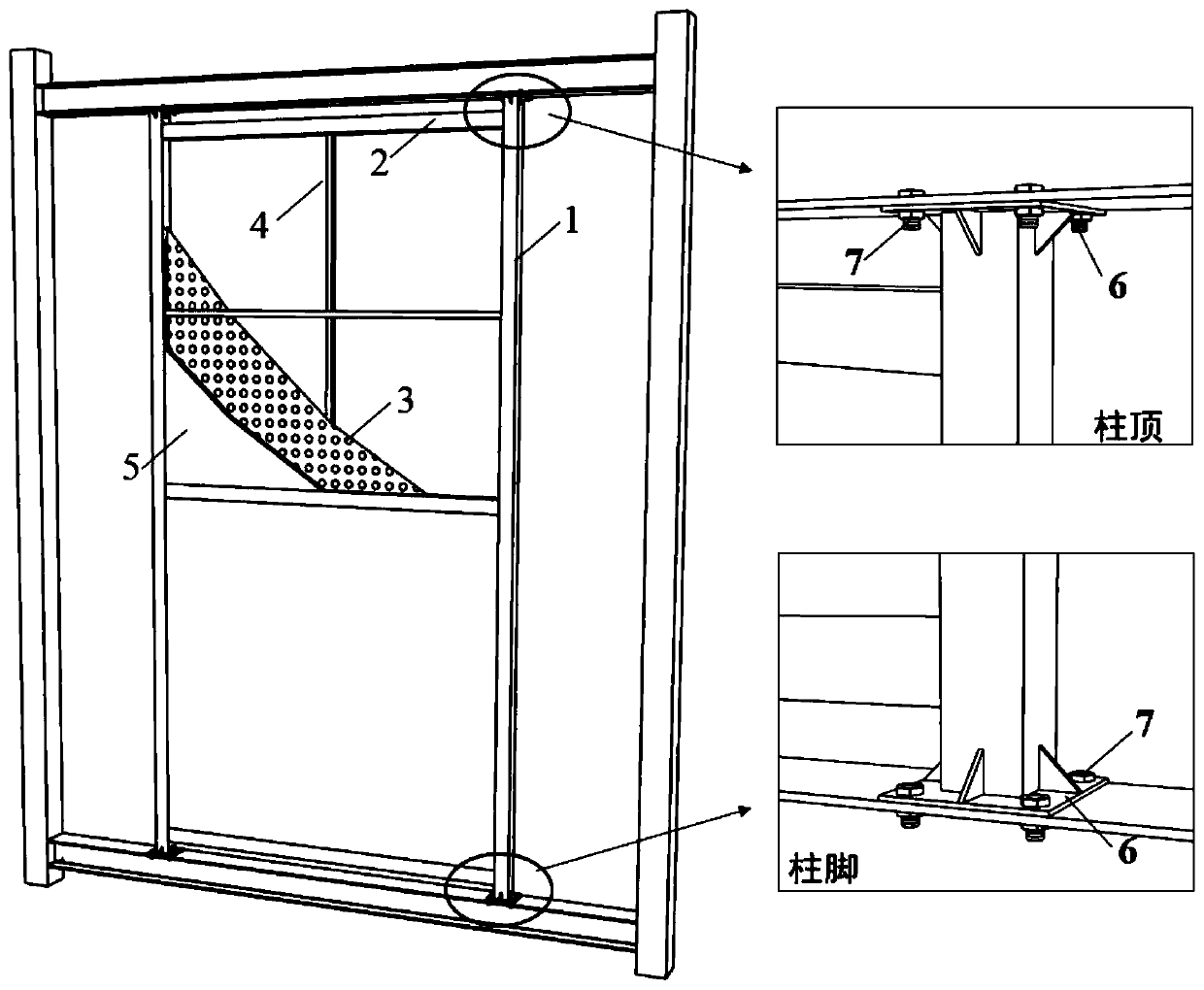

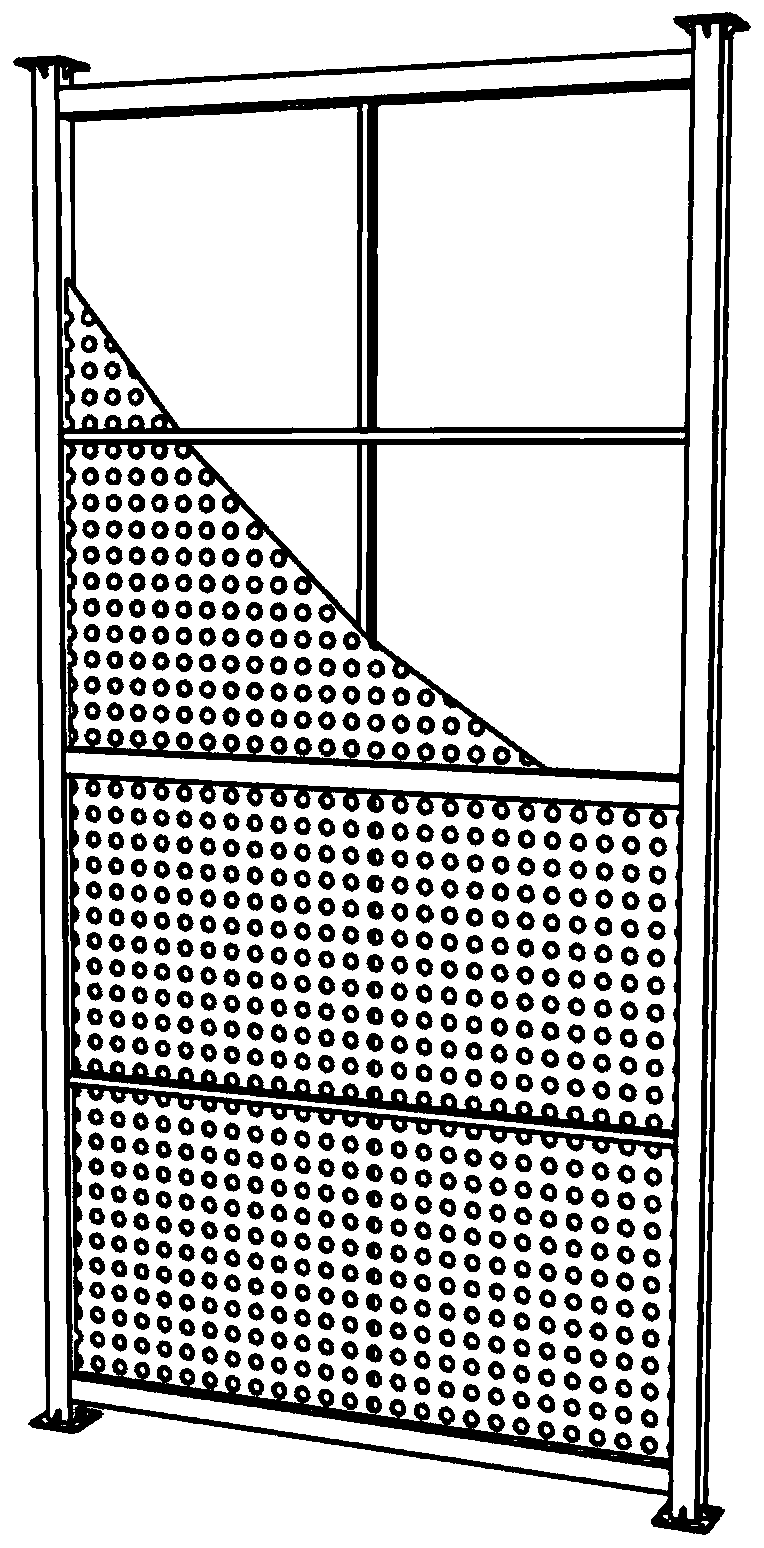

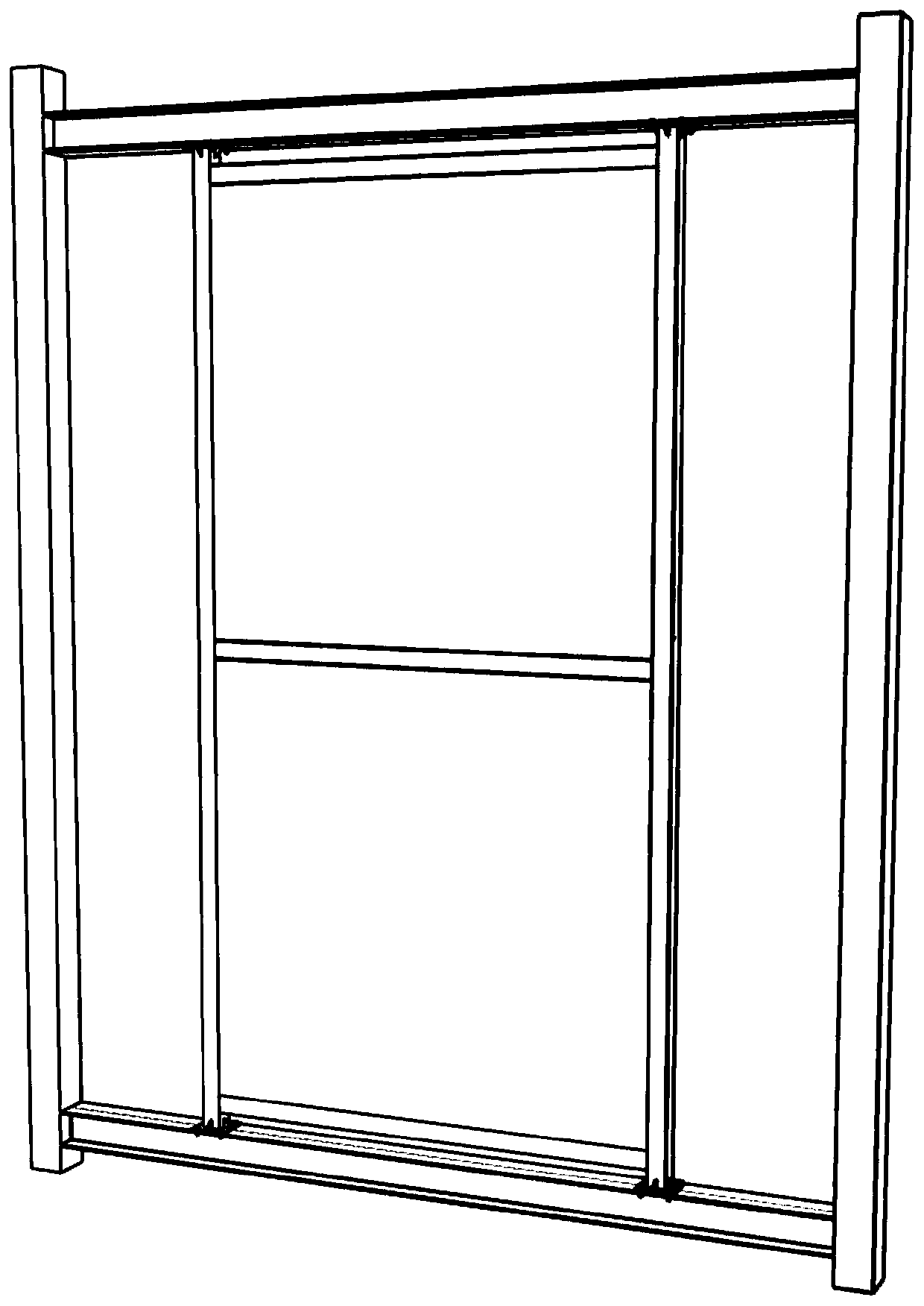

Prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall

ActiveCN108643390ASolve the current situation of lack of anti-seismic measures and weak anti-seismic abilityImprove carrying capacityWallsSteel tubeOut of plane

The invention relates to a prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall. A concrete filled steel tube frame column, a concrete filled steel tubeframe beam and concrete filled steel tube truss ribs together form a wallboard concrete filled steel tube truss stress system, a composite wall steel skeleton is formed by the wallboard concrete filled steel tube truss stress system and a punching thin steel plate, and the integrality of a wallboard is improved. Novel light insulation material foamed concrete is used for pouring the wallboard, theprefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is formed after maintenance, and the composite wall can be assembled to an external structure onlyby connecting bolts. The prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is integrated in heat preservation, has good bending resistance, shear capacity and out of plane stiffness, the anti-seismic property is good, meanwhile, the wallboard is manufactured in a factory and assembled on site, the common quality problems caused by site constructioncan be effectively resolved, the construction efficiency of the project is greatly improved, the amount of labor used of engineering is reduced, and the prefabricated truss type light steel frame-punching thin steel plate-foamed concrete composite wall is suitable for wide application in the structure of low-rise multi-storey rural houses in villages and towns.

Owner:BEIJING UNIV OF TECH

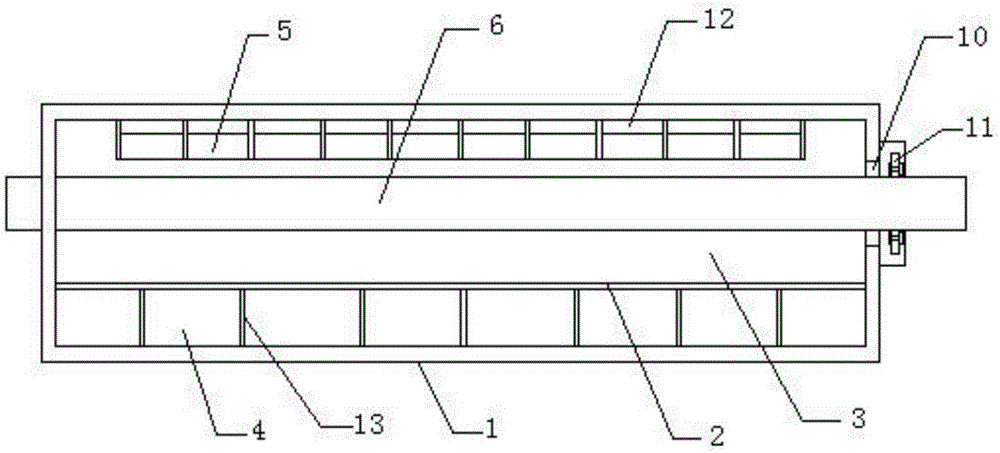

Nickel mesh coating bath

InactiveCN106435657AImprove space utilizationEasy to assemble and disassembleCellsTanksAperture ratioNickel coating

The invention discloses a nickel mesh coating bath, and relates to the technical field of nickel mesh production. The nickel mesh coating bath comprises a bath body, a longitudinal partition plate is arranged in the bath body and divides the bath body into an inner bath and an overflow bath, a cloth bag is arranged on the bath wall of one side of the inner bath and is far away from the overflow bath, nickel beads or nickel blocks are placed in the cloth bag, a mesh winding roller is arranged at two ends of the inner bath, a coating film is sleeved on the mesh winding roller, a pressure rod is arrange don the coating film, the bath wall of one side of the bath body is higher than that of the other side of the bath body, a bath body sealing cover is hinged at the top of the bath wall of the high side of the bath body, and a pumping pipeline is arranged on the bath wall of the high side of the bath body and communicated with an acid mist washing tower. According to the nickel mesh coating bath, utility rate of spaces is high, acid mist generated by bath solution in the nickel coating process is pumped by the aid of a side induced draft mode and recovered and treated, production safety is improved, environmental pollution is avoided, the aperture ratio of a nickel mesh is increased, and mesh openings are uniform.

Owner:湖北海富镍网科技股份有限公司

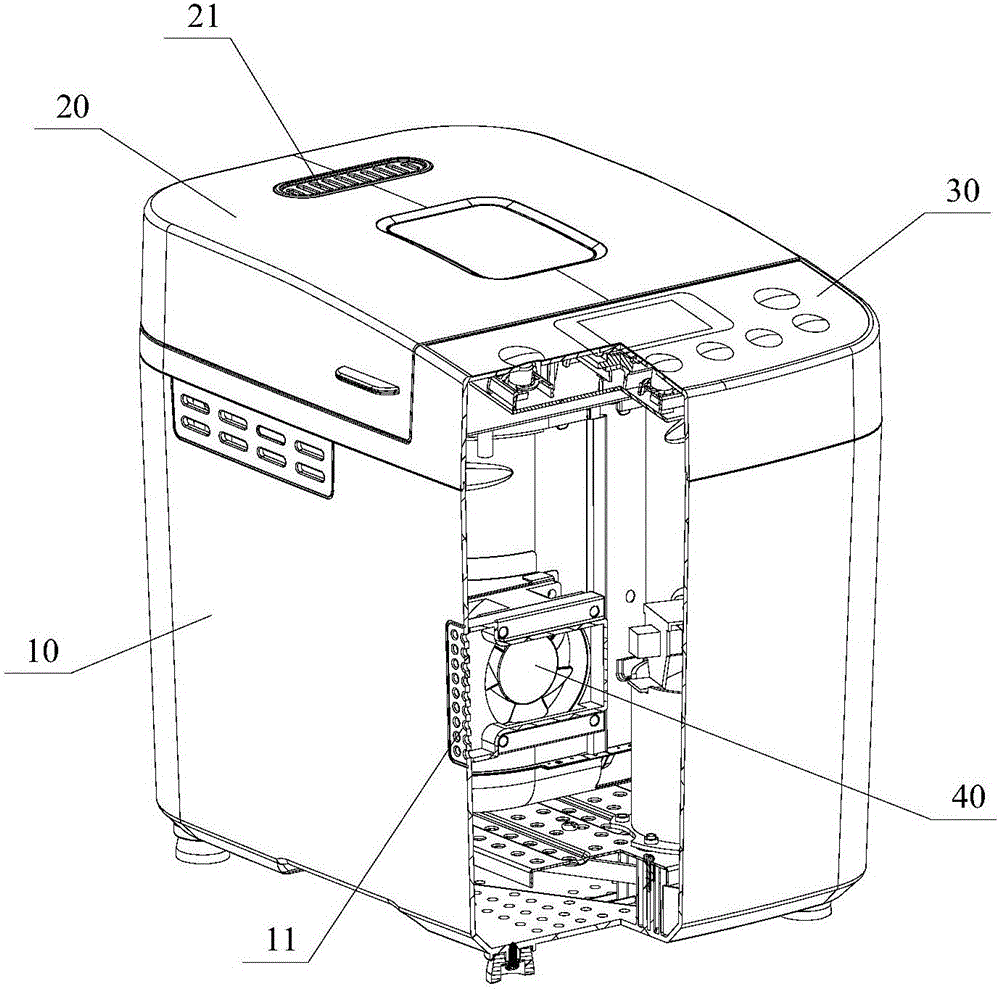

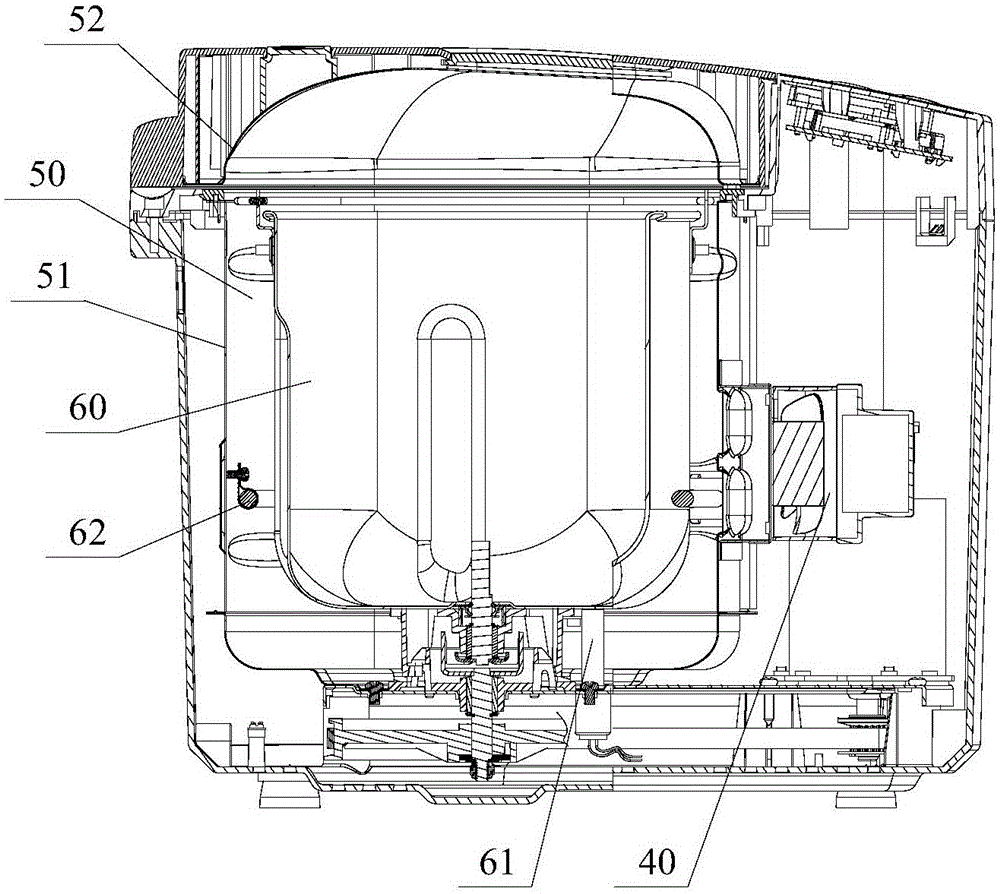

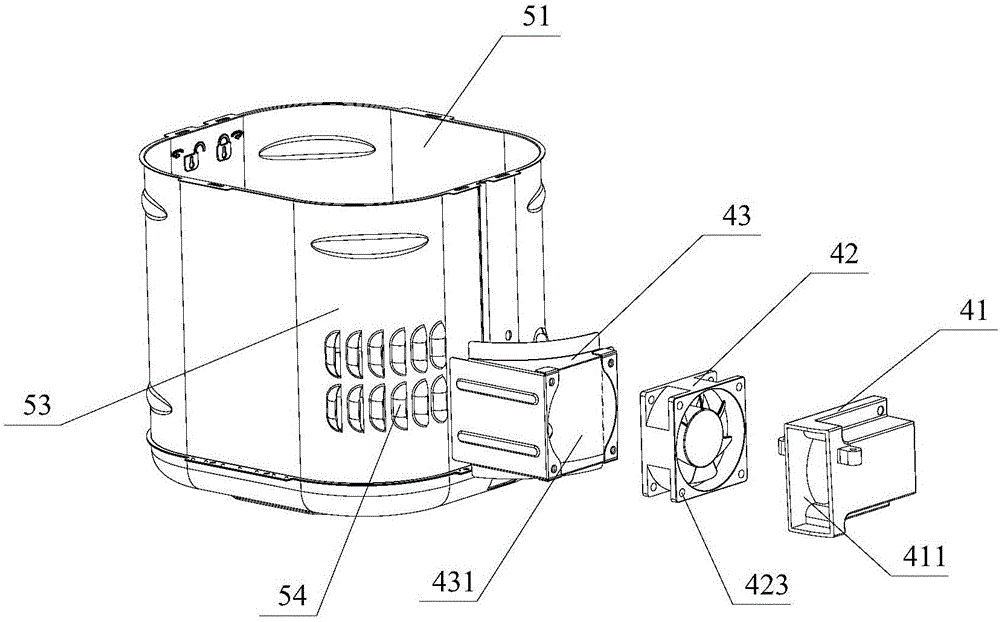

Full-automatic bread maker

The invention discloses a full-automatic bread maker which comprises a shell and an upper cover and a control panel which are arranged at the upper end of the shell. The control panel is provided with a control unit, an oven chamber is arranged between the shell and the upper cover, first air inlets are formed in the side wall of the oven chamber, an air duct device is arranged between the shell and the oven chamber, and the oven chamber is further internally provided with a temperature sensor used for detecting the temperature of a bread drum; the control unit starts the air duct device to make the cold air outside introduced into the oven chamber according to a detecting result of the temperature sensor. In the stirring or fermenting process, when the temperature sensor detects that the temperature of the surface of the bread drum or the temperature of dough is larger than a preset value, the control unit starts the air duct device automatically to make the cold air outside introduced into the oven chamber from the first air inlets, the temperature is controlled within the optimum stirring or fermenting temperature, automation control is achieved, the accuracy is very high, the flexibility and the convenience are achieved, and the bread made through the full-automatic bread maker is even in pores, exquisite in texture, pure in fragrance, good in taste and free of sour.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Batching method and batching device for preparing compound feed

PendingCN113262663AImprove production efficiencyImprove practicalityFeeding-stuffTransportation and packagingBiotechnologyNutrition supplementation

The invention discloses a batching method for preparing a compound feed and a batching device thereof, and relates to the technical field of compound feed methods. The batching method for preparing the compound feed comprises the five steps of standard selection, environment measurement, raw material processing, mixed sterilization and vacuum packaging. According to the batching method for preparing the compound feed, the condition of anorexia of animals is reduced, nutrients contained in the animals can be better eaten and absorbed by the animals, the growth speed of the animals is guaranteed, the selected raw materials are more targeted through the addition of the environment measurement step, and if the growth environment temperature is low, the raw materials with high calorie are selected, the condition of resistance reduction caused by insufficient heat supplement of animals can be avoided, the health state of animals is relatively ensured, and the condition of insufficient nutrition supplement caused by small food intake of hot animals can be solved when the small raw material in the same nutrition raw material volume is selected at the high growth temperature, and the practicability of the batching method is improved.

Owner:浙江金甲水产饲料有限公司

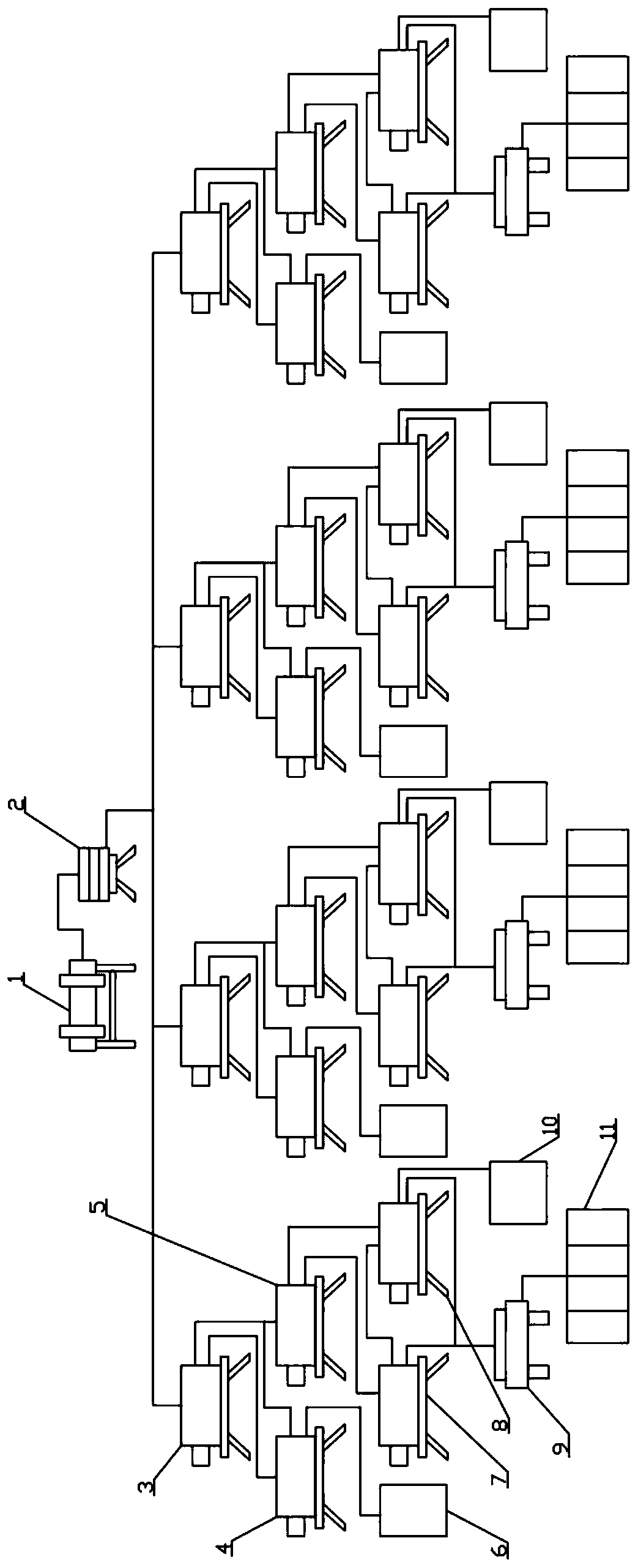

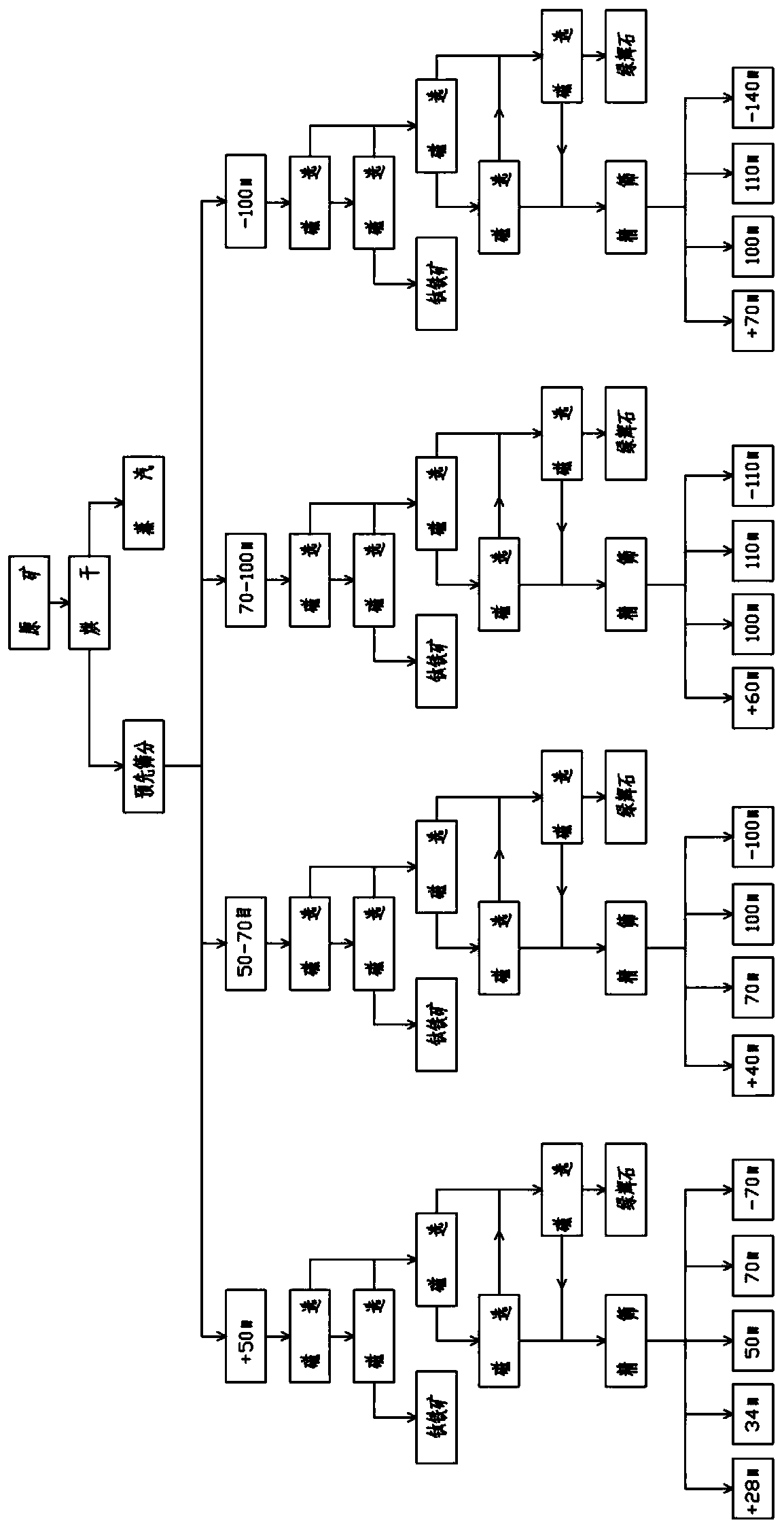

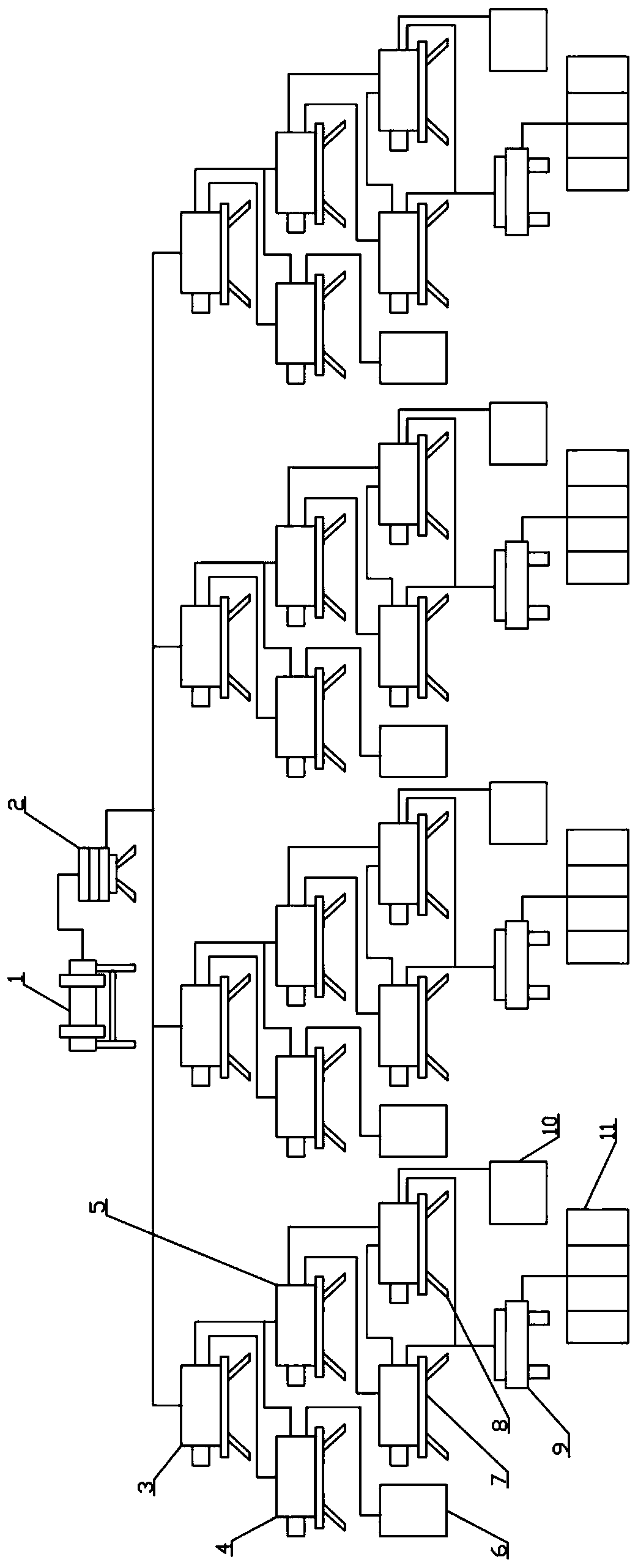

Efficient garnet combining and magnetic separation screening device and technology

PendingCN109909159AHigh purityRealize separate processingGas current separationMagnetic separationTitaniumEngineering

An efficient garnet combining and magnetic separation screening device comprises an assembly line for treating garnet containing crude sand. The assembly line is provided with a drying machine, a first screening machine, a second screening machine and a plurality of magnetic separation units. During magnetic separation screening, the garnet containing crude sand is dried, water in the crude sand is discharged, then, the dried crude sand is screened, the crude sand is screened into several parts according to the mesh number of the crude sand, then each part of crude sand is subjected to magnetic separation operation, iserite, rutile and omphacite in the crude sand are sorted out, finally, the left garnet sand is screened again, the crude sand is screened into several parts according to themesh number of the crude sand, and pure garnet sand different in mesh number is obtained. The device conducts operation of screening, magnetic separation and re-screening on the crude sand, separatedtreatment is conducted on the crude sand, the equipment treatment pressure is lowered, the treatment efficiency is improved, and the garnet higher in purity and more uniform in mesh number is obtained.

Owner:江苏金红新材料股份有限公司

Fabricated truss type light steel frame-punched thin steel plate-concrete composite wall

ActiveCN108277903AImprove carrying capacityImprove seismic performanceWallsCeramic shaping apparatusSheet steelSteel frame

The invention relates to a fabricated truss type light steel frame-punched thin steel plate-concrete composite wall and a manufacture method thereof. Concrete-filled steel tube frame columns, concrete-filled steel tube frame beams and wall concrete-filled steel tube truss ribs together form a wall plate concrete-filled steel tube truss stress system and then form a composite wall steel frame together with punched thin steel plates, so that the integrity of wall panels is improved, concrete is poured in a formwork, and after maintenance, the fabricated truss type light steel frame-punched thinsteel plate-concrete composite wall is formed and is fabricated to an external structure simply by connecting bolts. The fabricated truss type light steel frame-punched thin steel plate-concrete composite wall has good bending resistance, shear bearing capacity and stiffness out of panel, and good anti-seismic performance; and at the same time, wall panels are manufactured by a factory and fabricated on site to effectively solve the common quality problems caused by on-site construction, the efficiency of engineering construction is improved greatly, the amount of labor used in construction isreduced, and the fabricated truss type light steel frame-punched thin steel plate-concrete composite wall is suitable for wide popularization and application in low-storey agricultural house structures of villages and towns.

Owner:BEIJING UNIV OF TECH

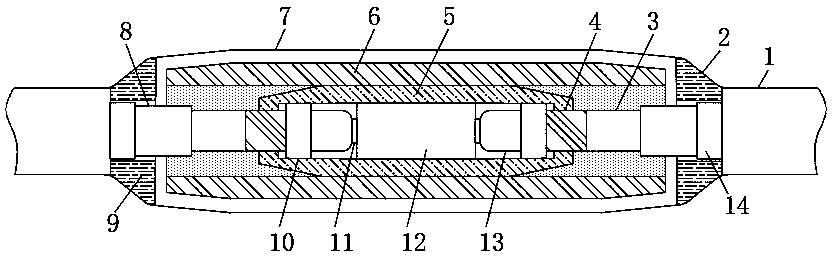

Temperature sensing optical fiber type power cable joint structure adopting guide cover

InactiveCN110635444ASo as not to damageHigh strengthInsulated cablesPower cables including optical transmission elementsPower cableCopper

The invention discloses a temperature sensing optical fiber type power cable joint structure adopting a guide cover, which comprises two cables. A plurality of filling tubes are arranged in the cable;an insulating sheath is arranged in the cable; a plurality of power lines are arranged in the insulating sheath; a loose tube is arranged in the cable; a temperature sensing optical fiber is arrangedin the loose tube; a sleeve filler is arranged between the loose tube and the temperature sensing optical fiber; the end of the cable is sleeved with a steel armor, an end protective layer, a coppershielding layer, an outer semiconducting layer and a wire core insulating layer; and the steel armor is located at the rear end of the end of the cable. The structure is reasonably designed, the situation in which the temperature sensing optical fiber is irregularly and randomly wound on the outer surface of a copper connecting pipe, and consequently the curvature radius of the local temperature sensing optical fiber is too small or the optical fiber is damaged can be effectively avoided, the protection safety performance of the cable joint is greatly improved, and the using effect of the cable joint is improved.

Owner:李新荷

Adjustable plastic netting material transversal stretching device

Owner:SHANDONG TONGJIA MACHINERY

Mechatronic fast flat screen printing equipment

ActiveCN108162575BThe operating range can be adjustedHigh degree of automationScreen printersPrinting press partsScreen printingWater vapor

Owner:台州同兴印染有限公司

Fabricatedsash type frame type light steel frame-punching thin steel plate-concretecomposite wall

InactiveCN108625507ASimple constructionGood bearing capacity and shock resistanceWallsProtective buildings/sheltersSteel platesSteel tube

The invention relates to a fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wall. A concrete-filled steel tube frame column, a concrete-filled steel tube frame beam and a concrete-filled steel tube frame rib together form a light steel frame sash of a wall board, and form a compositewall steel skeleton with a punching thin steel plate to improve integrity of the wall board. A framework is erected and the concrete is poured; after maintenance, the fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wallis formed, and only connection bolts are needed for assembling the composite wall onto an external structure. The fabricated composite wall has good bend-resisting and shear-resisting capacities, out-of-plane stiffness, and good anti-seismic performance; and meanwhile, the wall board is manufactured in a factory, and is assembled on-site, and therefore the common quality problem caused by site construction is effectively solved; construction efficiency of a project is greatly improved; and work amount of the project is lowered. The fabricated composite wall is suitable for being widely popularized and used in the structure of low and multi-storey rural house structures in villages and towns, and plays an important role in promoting improvement of the traditional rural house structure technology.

Owner:BEIJING UNIV OF TECH +1

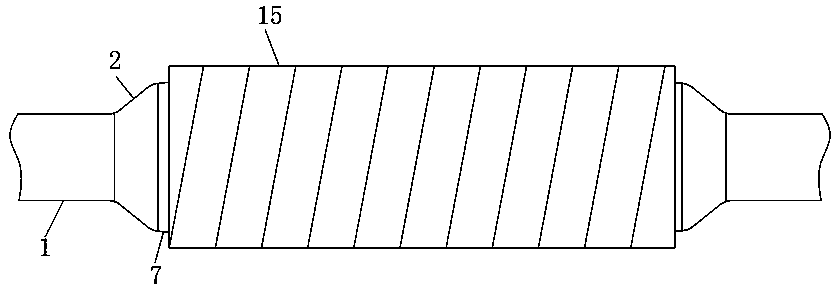

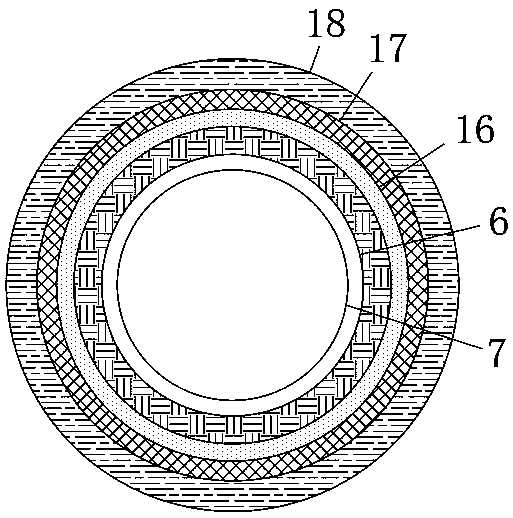

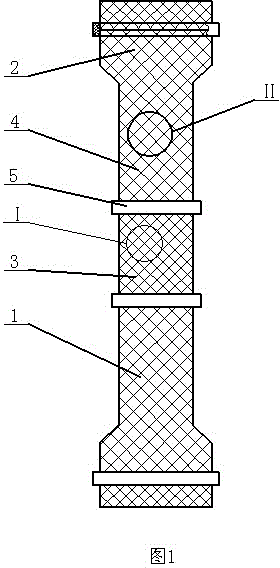

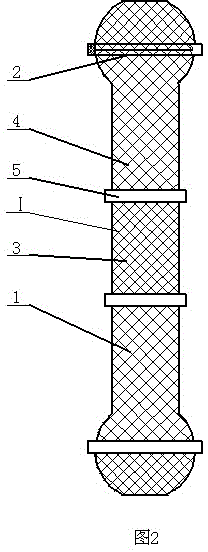

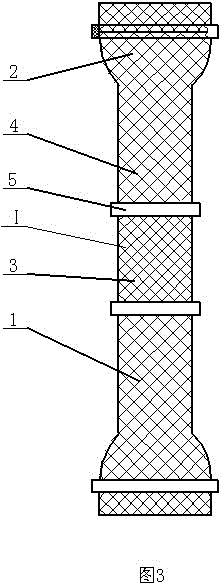

Digestive tract stent of soft section and hard section structure

The invention provides a digestive tract stent of a soft section and hard section structure. The digestive tract stent comprises a tubular support body and two heads. The wall of the support body and the walls of the two heads are all mesh bands. The two ends of the support body are connected with the two heads respectively. The support body is formed by connecting a plurality of soft supporting units and a plurality of hard supporting units in an alternate mode. Each head is composed of soft supporting units and hard supporting units. The outermost end of the each head is the soft supporting unit. According to the digestive tract stent, the soft supporting units can reduce the supporting force of the ends, the hard supporting units correspond to the stenosis or obstruction diseased part needing expanding treatment, in this way, the hard supporting units have large supporting force, the supporting effect is good, and restenosis can be reduced; due to the structure that the soft sections and the hard sections are connected in an alternate mode, the compliance of the support can be improved, the digestive tract stent can be better adaptive to curving and peristalsis of the digestive tract, untoward effects such as movement and stimulus are reduced, recycling of the digestive tract is convenient, and the clinical effect is better.

Owner:山东省医疗器械研究所

Prefabricated sash light steel frame-perforated thin steel plate-concrete composite wall

InactiveCN108625507BImprove carrying capacityImprove seismic performanceWallsProtective buildings/sheltersEarthquake resistanceSheet steel

The invention relates to a fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wall. A concrete-filled steel tube frame column, a concrete-filled steel tube frame beam and a concrete-filled steel tube frame rib together form a light steel frame sash of a wall board, and form a compositewall steel skeleton with a punching thin steel plate to improve integrity of the wall board. A framework is erected and the concrete is poured; after maintenance, the fabricated sash type frame type light steel frame-punching thin steel plate-concretecomposite wallis formed, and only connection bolts are needed for assembling the composite wall onto an external structure. The fabricated composite wall has good bend-resisting and shear-resisting capacities, out-of-plane stiffness, and good anti-seismic performance; and meanwhile, the wall board is manufactured in a factory, and is assembled on-site, and therefore the common quality problem caused by site construction is effectively solved; construction efficiency of a project is greatly improved; and work amount of the project is lowered. The fabricated composite wall is suitable for being widely popularized and used in the structure of low and multi-storey rural house structures in villages and towns, and plays an important role in promoting improvement of the traditional rural house structure technology.

Owner:BEIJING UNIV OF TECH +1

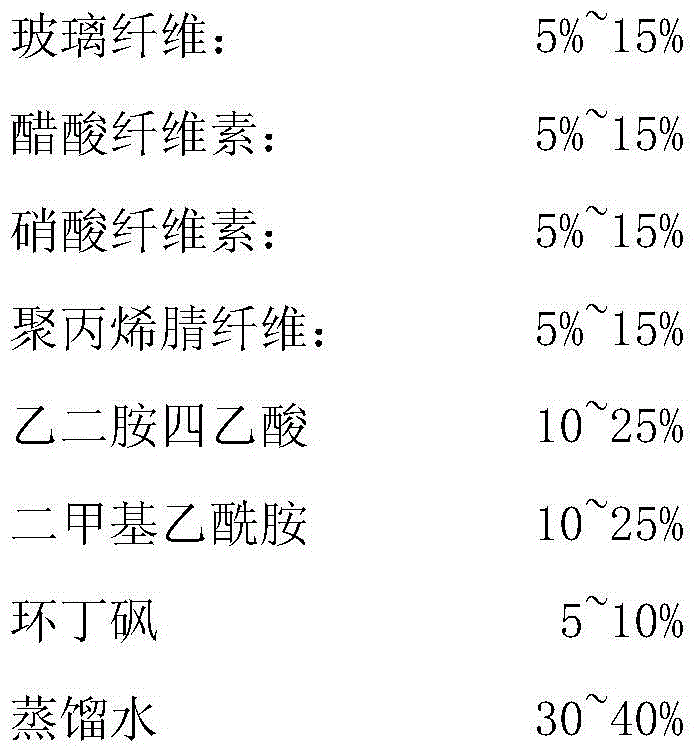

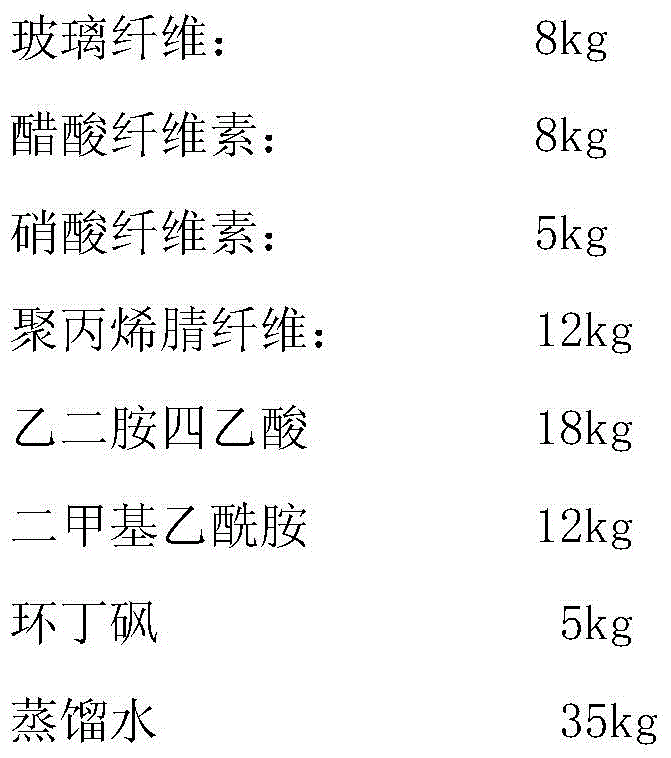

Biological filter paper and its preparation method and application

The invention discloses biological filter paper. A plurality of composite fibers, i.e. a glass fiber, a cellulose acetate, a nitrocellulose and a polyacrylonitrile fiber serve as the main materials of the filter paper. The filter paper is uniform in meshes and easy to clean, particles of the filter paper do not easily fall off; the filter paper can filter out particles with the partical size of less than 15 microns and pathogenic microorganisms; the biological filter paper is not reacted with the microorganisms, so that the biological filter paper can be applied in the fields of bioengineering and medical science.

Owner:杭州特种纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com