Method for preparing hot-melt adhesive net film

A technology of adhesive omentum and hot melt adhesive, applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of high cost, development restrictions, high grammage, etc., and achieve the goal of improving production efficiency, reducing production cost, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

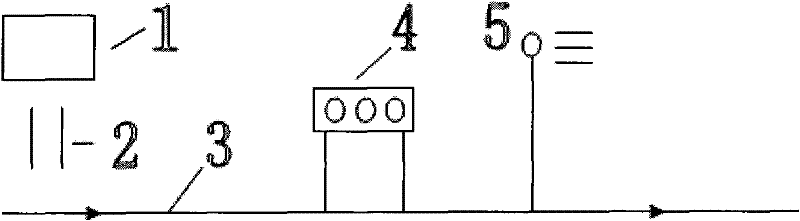

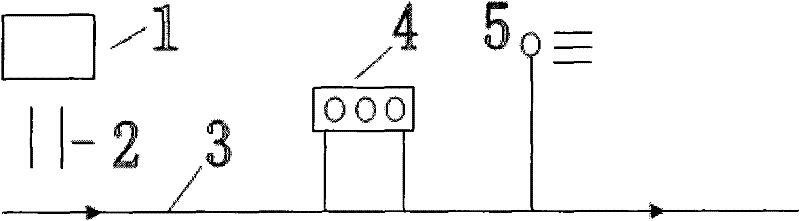

Image

Examples

Embodiment 1

[0016] Weigh a total of 10kg of copolyamide hot-melt adhesive with a model of 7200 (melting index is 30g / 10min), put it into the twin-screw after drying, melt it at 225°C, and then pressurize it to 0.8MPa in the melt pump. The diameter of the nozzle is 0.9mm, and the pressure of the compressed air is controlled to make the air flow rate 90m / min, the speed of the spinneret line is 13m / min, the diameter of the sprayed hot melt adhesive thread is 60μm, and the moving speed is 15m / min The conveyor belt was heated to 100 ℃ by infrared irradiation, and then sprayed by a sprayer with a water spray rate of 2Kg / h for 1.5 minutes, the crystallization was solidified, and the total duration was 10 minutes, and finally a hot-melt adhesive mesh was made. mesh, the average gram weight is 61g / m 2 .

Embodiment 2

[0018] Weigh a total of 10kg of polyester hot-melt adhesive with a model of 3150 (melting index is 40g / 10min), put it into the twin-screw after drying, melt it at 200℃, and then put it into the melt pump and pressurize it to 0.8MPa. It is sprayed from a 0.3mm nozzle, and the pressure of the compressed air is controlled so that the airflow speed is 90m / min, the speed of the spinneret is 15m / min, and the diameter of the sprayed hot melt adhesive wire is 50μm, and the moving speed is 10m / min. The conveyor belt was heated to 90°C by infrared irradiation, and then sprayed by a sprayer with a water spray rate of 1Kg / h for 2 minutes, the crystallization was solidified, and the total duration was 12 minutes, and finally a hot-melt adhesive mesh was made. The average gram weight is 69g / m 2 .

Embodiment 3

[0020] Weigh 3142 polyester hot melt adhesive (melting index is 80g / 10min) for a total of 10kg, put it into the twin-screw after drying, melt it at 200℃, and then put it into the melt pump and pressurize it to 0.5MPa. It is sprayed from a 0.9mm nozzle, and the pressure of the compressed air is controlled so that the airflow speed is 60m / min, the linear speed of the spinneret is 10m / min, and the diameter of the sprayed hot melt glue wire is 60μm, and the moving speed is 10m / min. The conveyor belt was heated to 85°C by infrared irradiation, and then sprayed for 2 minutes by a sprayer with a water spray rate of 1Kg / h, and the crystallization was solidified. The average gram weight is 65g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com