Twenty-four- heald composite fiber polyester three-layer papermaking net

A technology of composite fiber and papermaking mesh, which is applied in papermaking, papermaking machines, textiles and papermaking, etc. It can solve the problems of short service life of papermaking forming mesh, insufficient wear resistance of contact surface, uneven sheet forming, etc., and achieve fiber and Improvement of filler retention rate, improvement of fiber support index, and firm combination of upper and lower layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

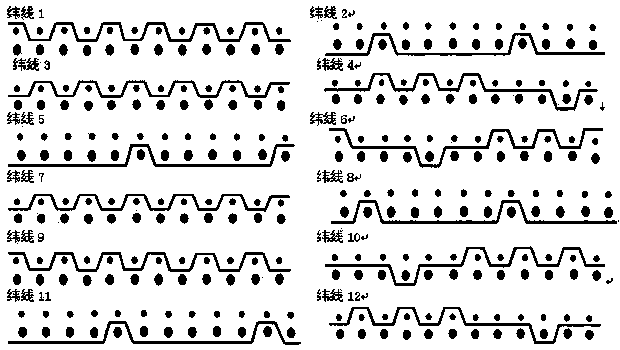

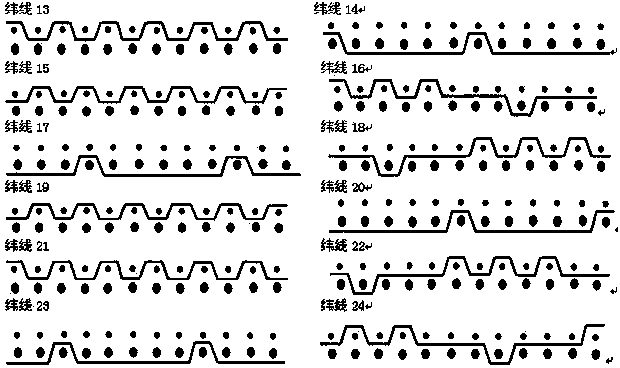

[0021] see Figure 1-7 , the 24-shed composite fiber polyester three-layer paper-making wire is a coarse-mesh paper-making wire, which uses 24 heald frames to interweave polyester or nylon monofilaments into a paper layer, an intermediate connection layer and a machine layer. Three layers of different weaving structures are connected into a whole. Composite interwoven fabric, the smallest organizational unit of which is composed of 24 polyester monofilaments as warp threads and 72 polyester or nylon monofilaments as weft threads, wherein the ratio of the warp threads of the paper-forming layer to the machine layer is 1:1; the number of weft threads The ratio is 3:2; the number of weft threads in the middle connection layer accounts for 2 / 6 of the total number of weft threads; in the paper layer, the warp thread is made of polyester monofilament, and the diameter of the warp thread is 0.18mm; the weft thread is made of polyester monofilament, and the diameter of the weft thread ...

Embodiment 2

[0026] see Figure 1-7 , the 24-shed composite fiber polyester three-layer paper-making wire is a coarse-mesh paper-making wire, which uses 24 heald frames to interweave polyester or nylon monofilaments into a paper layer, an intermediate connection layer and a machine layer. Three layers of different weaving structures are connected into a whole. Composite interwoven fabric, the smallest organizational unit of which is composed of 24 polyester monofilaments as warp threads and 72 polyester or nylon monofilaments as weft threads, wherein the ratio of the warp threads of the paper-forming layer to the machine layer is 1:1; the number of weft threads The ratio is 3:2; the number of weft threads in the middle connection layer accounts for 2 / 6 of the total number of weft threads; in the paper layer, the warp thread is made of polyester monofilament, and the diameter of the warp thread is 0.24mm; the weft thread is made of polyester monofilament, and the weft thread diameter is 0.2...

Embodiment 3

[0030] see Figure 1-7 , the 24-shed composite fiber polyester three-layer paper-making wire is a coarse-mesh paper-making wire, which uses 24 heald frames to interweave polyester or nylon monofilaments into a paper layer, an intermediate connection layer and a machine layer. Three layers of different weaving structures are connected into a whole. Composite interwoven fabric, the smallest organizational unit of which is composed of 24 polyester monofilaments as warp threads and 72 polyester or nylon monofilaments as weft threads, wherein the ratio of the warp threads of the paper-forming layer to the machine layer is 1:1; the number of weft threads The ratio is 3:2; the number of weft threads in the middle connection layer accounts for 2 / 6 of the total number of weft threads; in the paper layer, the warp thread is made of polyester monofilament, and the diameter of the warp thread is 0.21mm; the weft thread is made of polyester monofilament, and the diameter of the weft thread ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warp diameter | aaaaa | aaaaa |

| Warp diameter | aaaaa | aaaaa |

| Weft diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com