Adjustable plastic netting material transversal stretching device

A technology of transverse stretching and plastic mesh, which is applied in the field of adjustable plastic mesh transverse stretching device, which can solve the problems of product specificity, wide adaptability, high cost, etc., and achieve the effect of preventing falling off and falling off under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

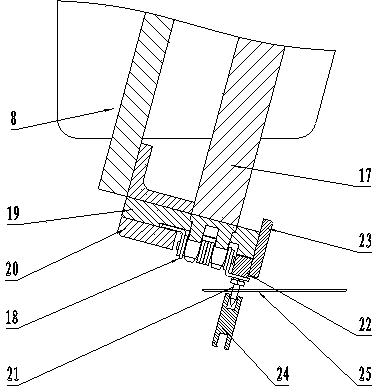

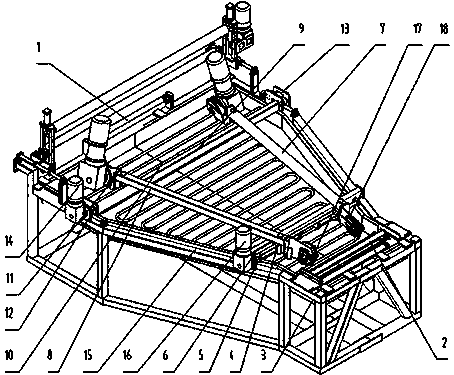

[0012] refer to figure 1 , the heat oven 3 is set on the frame 15, the rear guide roller 1 and the pull-out roller are arranged at the rear of the frame 15, the front guide roller 2 is arranged at the front of the frame 15, and the front beam is fixed horizontally at the front of the frame 15 6. The left trolley 12 and the right trolley 13 are supported floatingly on both sides of the rear of the frame 15, and the left trolley 12 and the right trolley 13 support the rear beam 9, and the front part of the right expansion bracket 7 and the left expansion bracket 8 are supported in the front On the crossbeam 6 and the rear part is supported on the rear crossbeam 9, the front distance between the right expanding support 7 and the left expanding support 8 which are adjustable in position relative to the front crossbeam 6 and the rear crossbeam 9 is less than the rear distance, and the right expanding Sprocket 17 is set at the front and rear ends of support 7 and left expansion supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com