Hollow near-forming forging method of large MW wind power main shaft

A wind power spindle, near-molding technology, applied in mechanical equipment, engine components, metal processing equipment, etc., can solve the problems of low production cost and small inner hole at the small end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

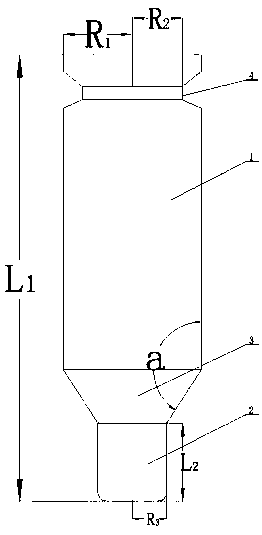

[0021] The forging method of the hollow near-forming of the large MW wind power main shaft includes the following specific steps:

[0022] Step 1: Heating the steel ingot to 1200-1250°C, keeping it warm, then chamfering, removing the spout, upsetting, drawing and cutting;

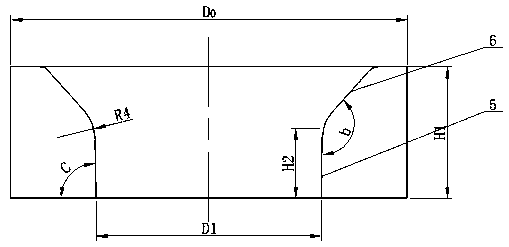

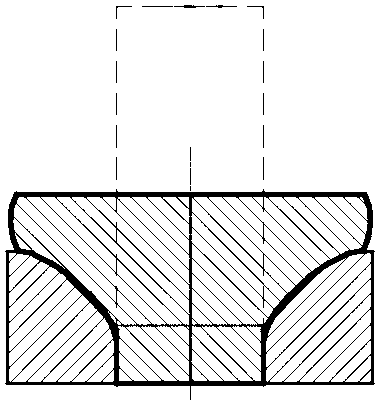

[0023] The second step: heat the steel ingot after the first step to 1200-1250°C and keep it warm, such as image 3 shown, and then upsetting with a special anti-extrusion leakage disc ( figure 2 ), after upsetting with a drain plate, such as Figure 4 As shown, then punch down to a certain height through a special punching mandrel, such as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com