Preparation method and application of polyacrylamide/keramite nanotube composite papermaking filler

A technology of halloysite nanotubes and polyacrylamide, which is applied in the field of papermaking, can solve the problems of complicated industrial production steps and increased costs, and achieve the effects of reducing adverse effects and increasing mechanical retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

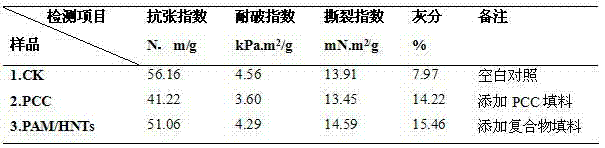

Examples

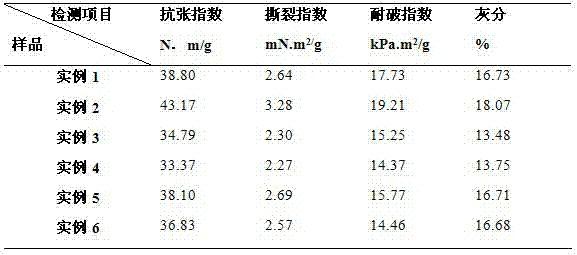

Embodiment 1

[0034] Weigh 40g of halloysite nanotubes, 4g of acrylamide monomer, and 100g of water into a suction filter bottle, stir and mix them evenly with a magnetic stirrer, connect the filter bottle to a vacuum pump, and keep the whole system sealed. Start the vacuum pump, vacuum for 10 minutes, then turn off the vacuum pump, and close the vacuum valve to seal for 20 minutes. Then open the vacuum valve to restore the air pressure in the system to normal atmospheric pressure. Repeat the above steps for a duration of 6 hours. The halloysite nanotube-acrylamide composite monomer is prepared. Weigh 30g halloysite nanotube / acrylamide composite monomer, add 100g water into a three-necked flask, stir and mix well, and then blow nitrogen gas for 30 minutes. Add 0.8g initiator (ammonium persulfate: sodium bisulfite = 1:1, mass ratio) and 0.5g cationic monomer dimethyl diallyl ammonium chloride, the polymerization reaction starts timing, and the reaction temperature is 60°C. After 3 hours o...

Embodiment 2

[0036] Weigh 40g of halloysite nanotubes, 4g of acrylamide monomer, 90g of water, and 10g of ethanol into a suction filter flask, and stir and mix them evenly with a magnetic stirrer. Start the vacuum pump, vacuum for 10 minutes, then turn off the vacuum pump, and close the vacuum valve to seal for 20 minutes. Then open the vacuum valve to restore the air pressure in the system to normal atmospheric pressure. Repeat the above steps for 6 hours to prepare halloysite nanotube / acrylamide composite monomer. Weigh 30g halloysite nanotube / acrylamide composite monomer, add 100g water into a three-necked flask, stir and mix well, and then blow nitrogen gas for 30 minutes. Add 0.3g initiator (ammonium persulfate: sodium bisulfite = 1:1, mass ratio) and 0.5g cationic monomer dimethyl diallyl ammonium chloride, the polymerization reaction starts timing, and the reaction temperature is 50°C. After 4 hours of reaction, stop the polymerization reaction to prepare polyacrylamide / haloysite ...

Embodiment 3

[0038]Weigh 10 g of halloysite nanotubes, 1 g of acrylamide monomer, and 100 g of water into a suction filter flask, and stir and mix them evenly with a magnetic stirrer. Start the vacuum pump, vacuum for 5 minutes, then turn off the vacuum pump, and close the vacuum valve to seal for 5 minutes. Then open the vacuum valve to restore the air pressure in the system to normal atmospheric pressure. Repeat the above steps for 1 hour to prepare halloysite nanotube / acrylamide composite monomer. Weigh 20g halloysite nanotube / acrylamide composite monomer, add 100g water into a three-necked flask, stir and mix well, and then blow nitrogen gas for 15 minutes. Add 0.1g initiator (ammonium persulfate: sodium bisulfite = 1:1, mass ratio) and 0.5g cationic monomer dimethyl diallyl ammonium chloride, the polymerization reaction starts timing, and the reaction temperature is 40°C. After 3 hours of reaction, stop the polymerization reaction to prepare polyacrylamide / haloysite nanotube composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com