Swollen starch-latex compositions for use in papermaking

a technology of starch-latex compositions and compositions, which is applied in the field of filler treatment with starch-latex compositions, can solve the problems of reducing paper strength, limiting the amount of filler that can be added, and cost saving, and achieves the effects of enhancing filler retention, tensile properties and air resistance, and reducing the amount of filler added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0074] PCC retention results were obtained in the Britt jar at 750 rpm, using PCC treated with different polymeric combinations. Furnishes at 0.5% solids were prepared by mixing PCC treated with swollen cationic starch (Cato 232), made in the absence and presence of CMC and latex, with BTMP suspensions at 50° C. and under shear. The amount of treated PCC in the furnish was 40%. At the same dosage levels the retention of PCC was low (i.e., less than 30%) when the PCC was treated with swollen starch, anionic latex (Acronal S866) or cationic latex (Latex 8675). The PCC retention ranged between 75 and 80% when the PCC was treated with swollen starch-latex compositions made with or without co-additive CMC. It was over 90% when the filler treated with swollen starch-latex compositions, prepared in the presence or absence of CMC, was added to pulp suspension then followed by addition of anionic silica (0.1 to 0.2% based on furnish). Similar retention results were obtained with kaolin clay....

example 2

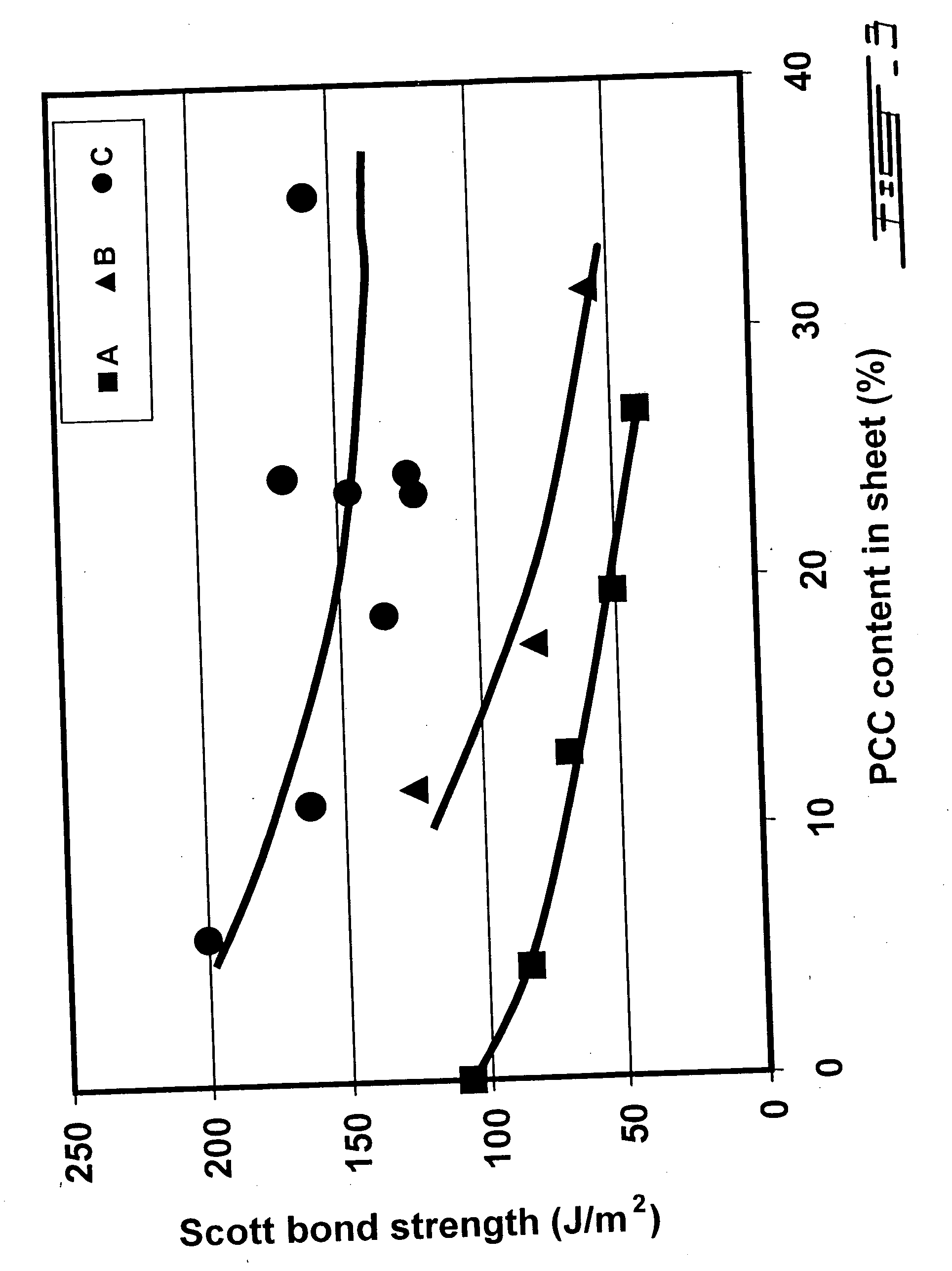

[0075] Table 1 presents the properties of 60 g / m2 BTMP sheets made with and without PCC (treated and untreated) at pH 7.0. The sheet were all calendered under the same conditions (80 kN / m and 50° C.). The treatment of PCC had no detrimental effect on sheet opacity. The content of PCC in the 60 g / m2 sheets varied between 23 and 39%. The sheets made with the addition of untreated PCC (27% in sheet) have higher air permeability (more open sheet) and have lower internal bond strength (Scott bond) and burst strength. The treatment of PCC with swollen cationic starch-latex compositions, in the presence or absence of CMC, reduced the air permeability of the sheet and substantially improved the Scott bond strength and burst strength. The treatment of PCC with the swollen cationic starch starch-anionic latex compositions increased the bond strength of the filled sheet even at high filler content. A less permeable sheet is more desirable because of reduced absorbency of liquids in ink, coatin...

example 3

[0076] Table 2 presents the properties of wood-free sheets made with and without addition of 25% PCC (treated and untreated) to a pulp furnish #1 (collected from a mixed stock of a paper machine producing fine paper) at pH 8.3. The treatment of PCC with the swollen cationic starch followed by anionic latex substantially improved the bonding strength and tensile properties. The sheets having 20% PCC have greater bonding strength then the sheets made without PCC (control sample). The treatment of PCC with the blend has small negative effect on the gain in brightness and opacity due to a small reduction in the light scattering coefficient of the filler.

TABLE 2Fine paper sheets - mill pulp furnish #15% CS / 5% CS / NoNon5% Cs1% A5% APropertiesPCCtreatmenton PCCL on PCCL on PCCPCC content020.919.120.024.3in sheet, %Internal bond22591145203243strength, J / m2Breaking4.712.082.643.173.37length, kmStretch, %3.371.422.092.432.76Opacity, %74.585.085.584.881.4Brightness, %89.392.090.189.989.7

PCC: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com