Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

483 results about "Paper manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The paper manufacturing industry creates paper most commonly for writing and printing on; however, it is also widely used as a packaging material, in many cleaning products, in a number of industrial and construction processes. Plastics have long been aiding the production of paper.

Paper manufacturing process

ActiveUS7419569B2High strengthNon-fibrous pulp additionNatural cellulose pulp/paperPre-conditionPre conditioning

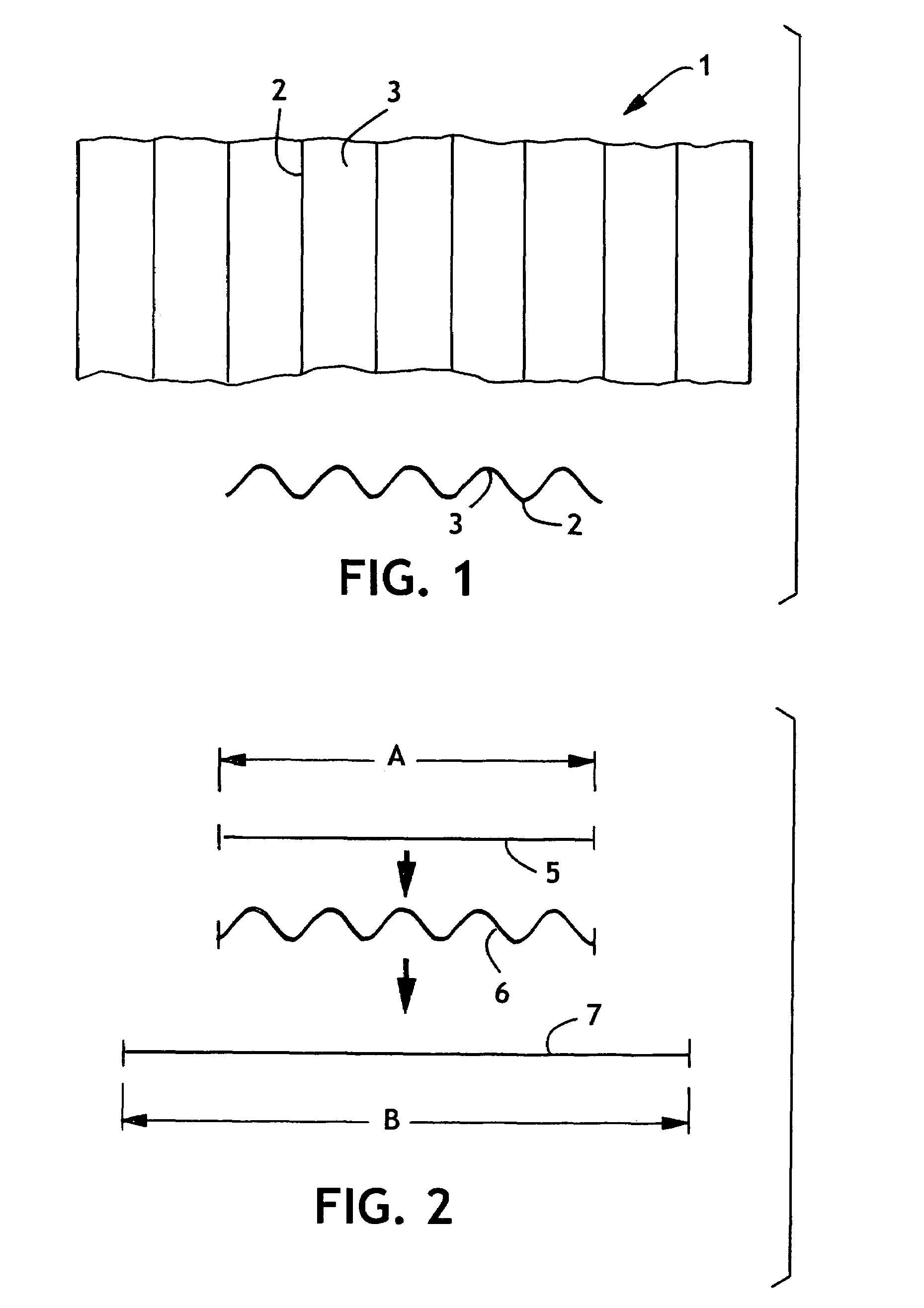

A method of making soft, strong, high bulk tissue is disclosed. The method includes pre-conditioning a wet web by straining the wet web in the cross-machine direction prior to transferring the wet web to a throughdrying fabric. The pre-conditioned web provides improved sheet softness and conforms more readily to the surface contour of the throughdrying fabric, thereby creating greater caliper (bulk) in the resulting dried sheet. The bulk is maintained during a subsequent creping step by maintaining the dried sheet in registration with the throughdrying fabric when the dried sheet is applied to the surface of the creping cylinder.

Owner:KIMBERLY-CLARK WORLDWIDE INC

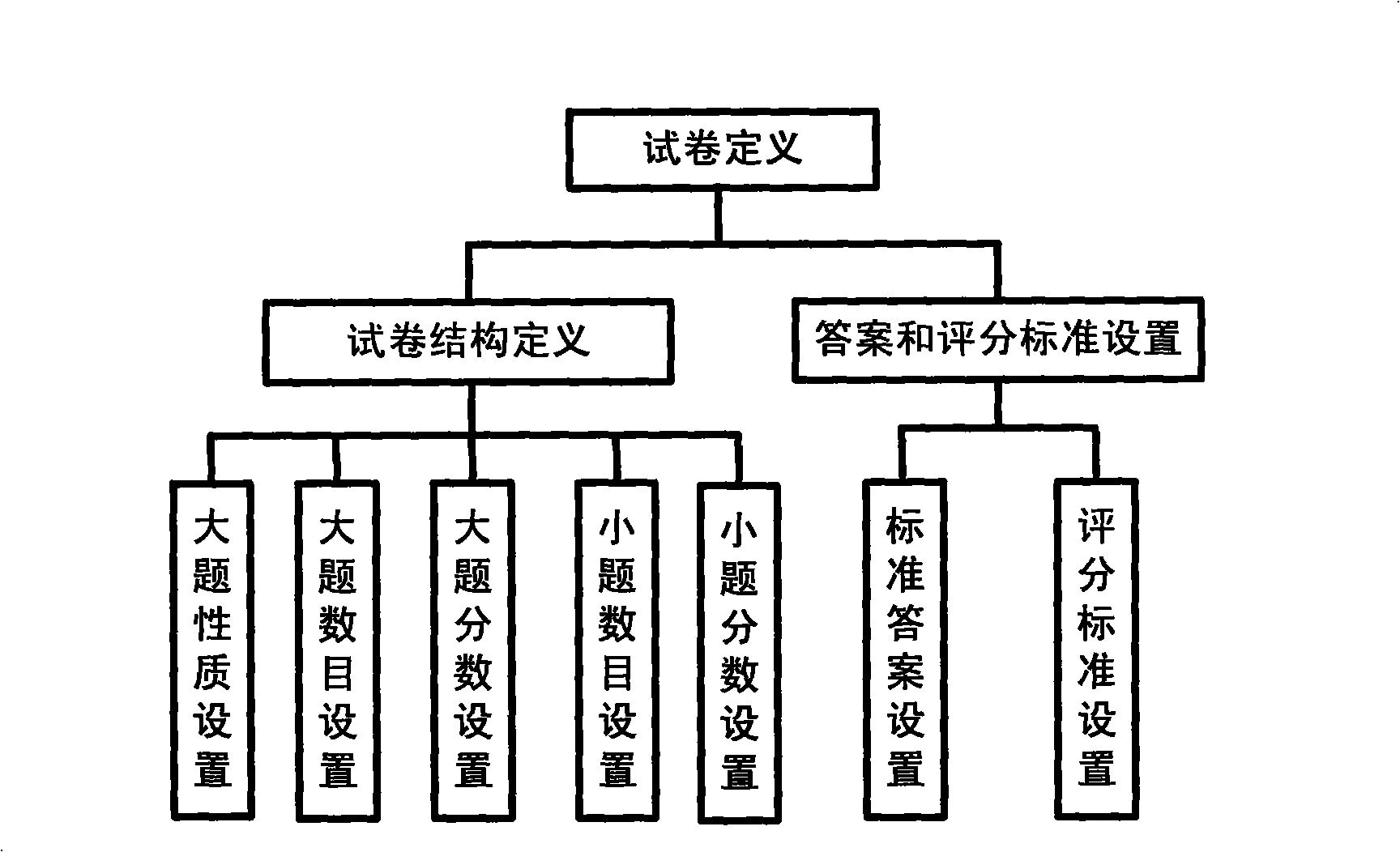

Automatic scanning and reading system and reading method

InactiveCN101334814ARealize identificationEasy to makeCharacter and pattern recognitionElectrical appliancesImaging processingInformation transmission

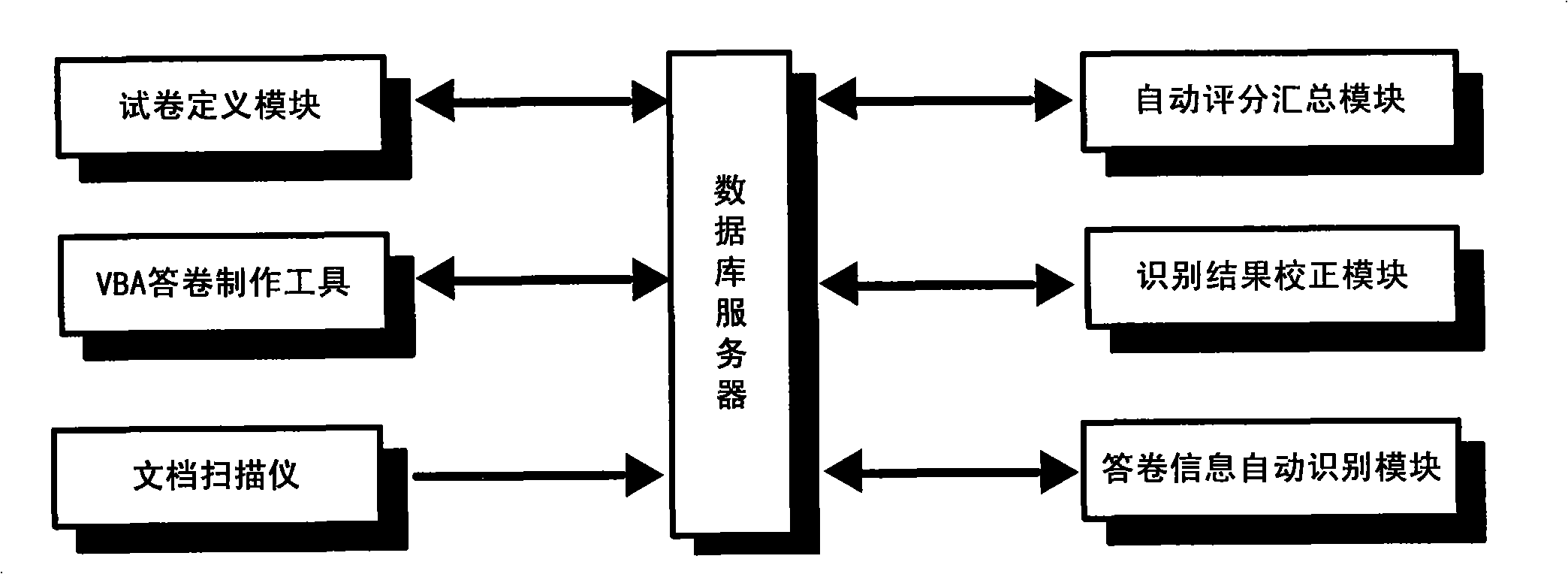

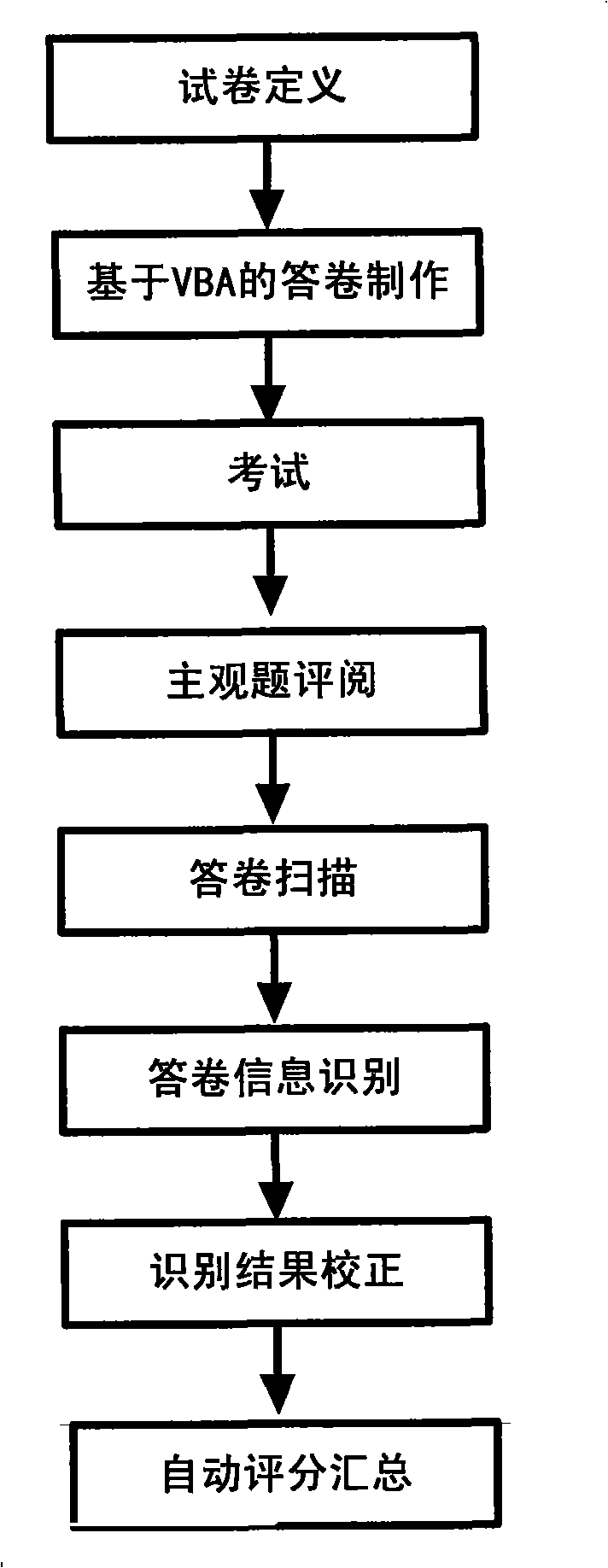

The invention discloses an automatic scanning examination paper marking system and a corresponding method, belonging to the image processing and mode identifying technique field. The system comprises a paper defining module, an answer sheet manufacturing tool based on VBA, a file scanner, a database server, an answer sheet information automatic identifying module, an answer sheet identified-result revising module and an automatic marking summarizing module. The whole structure of the automatic paper marking system appears as a star and the database server is the center of the system and other modules and apparatuses are respectively connected with the database server by network means and used for information transmission and network sharing. One automatic scanning examination paper marking method includes the following steps: paper defining, paper manufacturing based on VBA, examination, subjective question marking, answer sheet scanning, answer sheet information identifying, identified-result revising and automatic marking and summarizing. The advantage is that the invention can mark the paper including both subjective questions and objective questions; the requirements to the operation technique and apparatus are low; the requirements to the paper-quality of the answer sheet, pens and printing are low and the checking is convenient.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

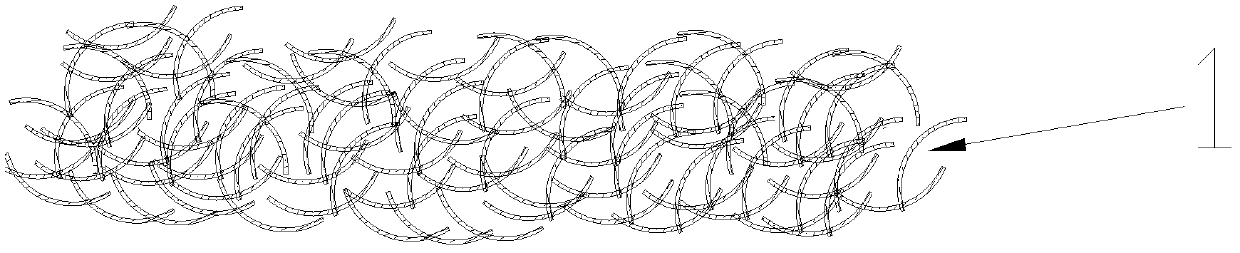

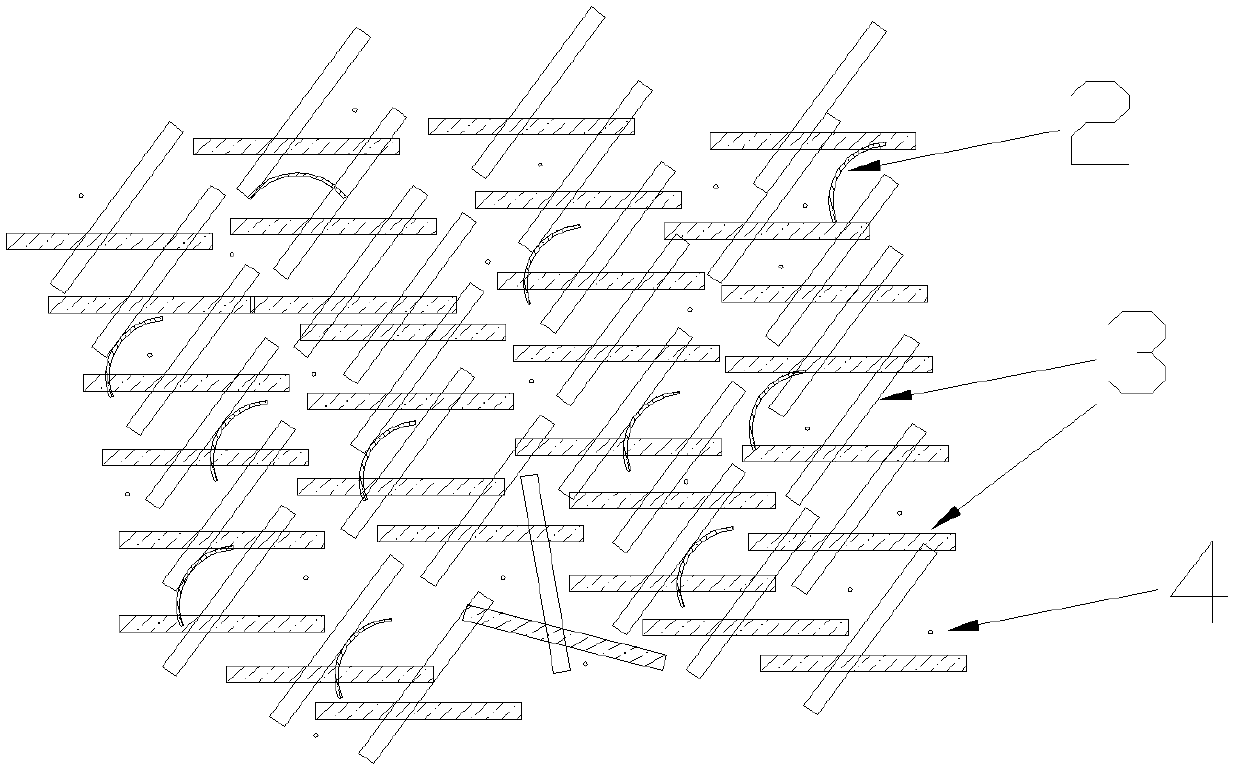

Fiber mat, preparation method and core material for vacuum thermal insulation plate

InactiveCN103306048ALow thermal conductivityHigh strengthFibreboardGlass/slag layered productsGlass fiberPunching

The invention discloses a fiber mat, comprising 50-100 (weight ratio accounting for the dried fiber mat and the same below) glass fiber and chopped strands, and one or more of 0.1-30 inorganic fibers, 0.1-30 natural fibers, 0.1-30 synthetic fibers, 0.1-30 manmade fibers and an anti-radiation material besides the glass fibers and the chopped strands. The fiber mat is prepared by a needle punching method, a spun lacing method, a thermal rolling method, a wet type paper-manufacturing acid process, a wet type paper-manufacturing thickener method, a wet type paper-manufacturing gel method and the like. According to the preparation method for the fiber mat disclosed by the invention, the conductive thermal coefficient of a vacuum thermal insulation plate made of the fiber mat achieves 25-65% under the premise of adopting the same production mode, and a more superexcellent thermal insulation effect is obtained.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

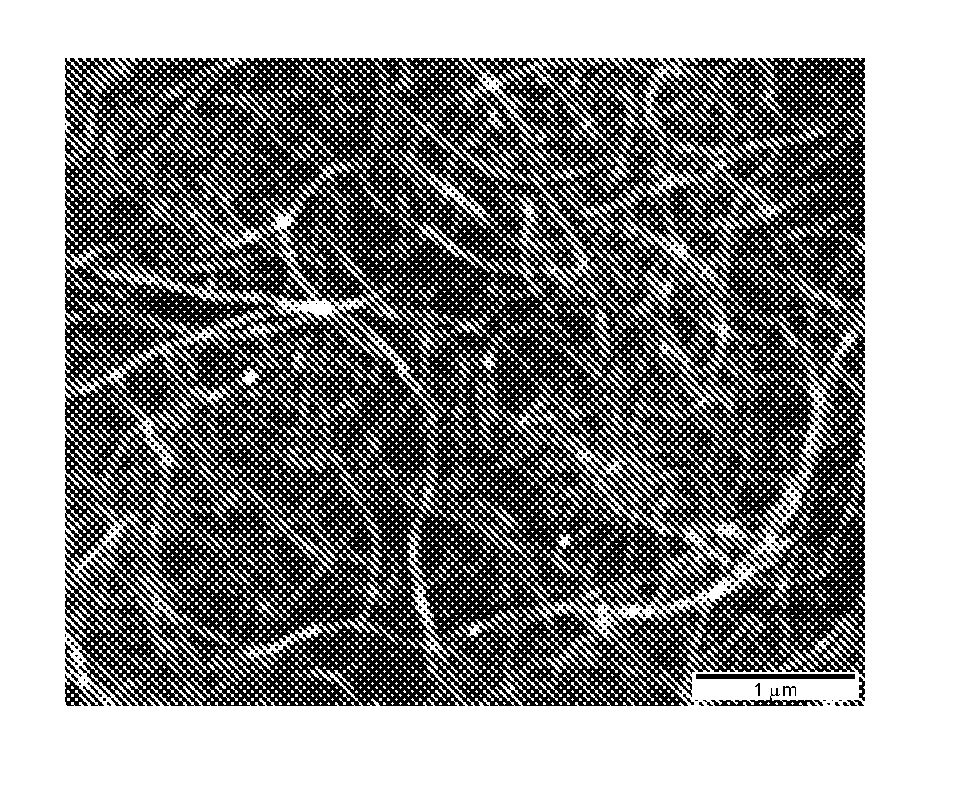

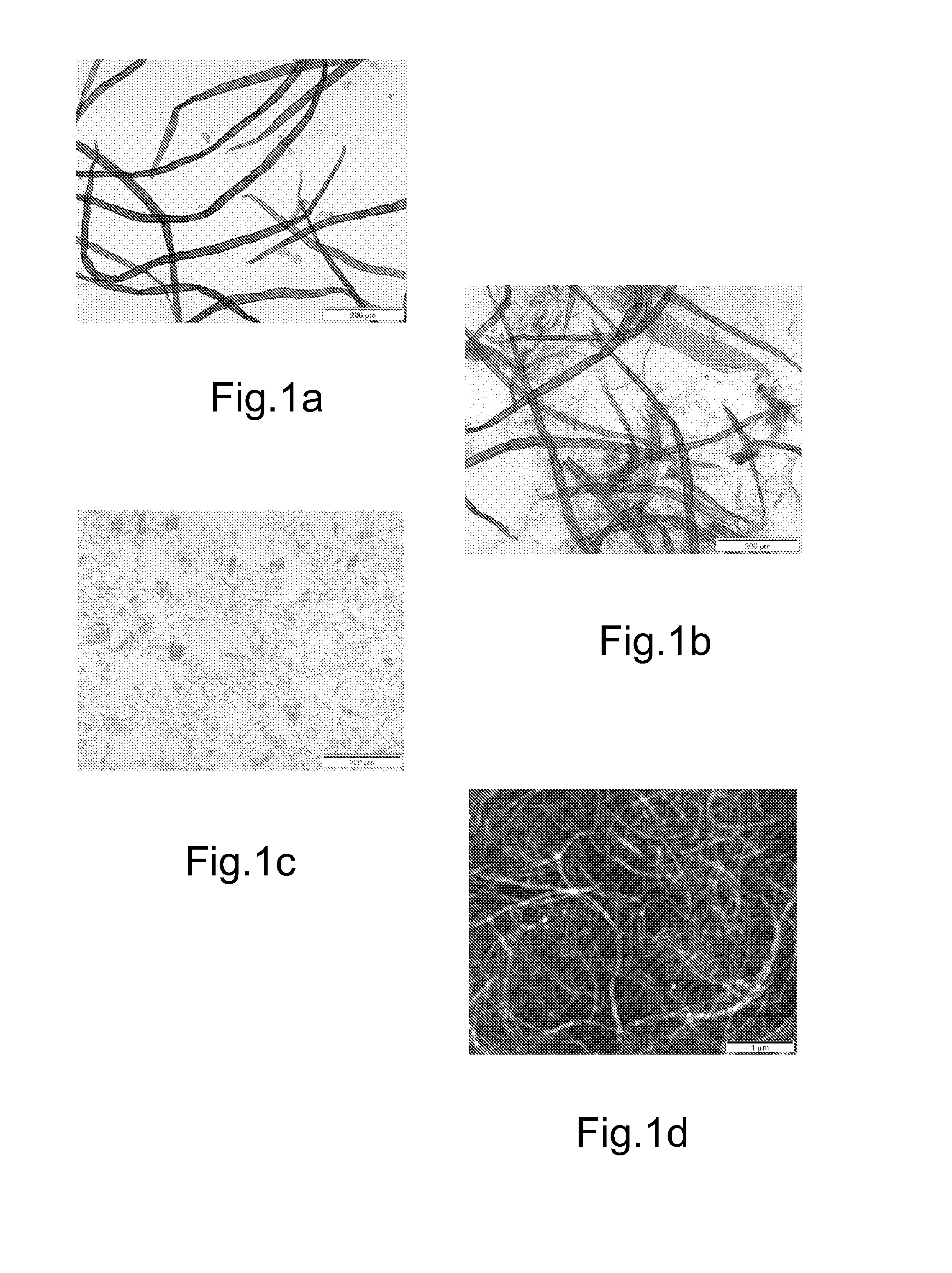

Method for manufacturing nanofibrillated cellulose pulp and use of the pulp in paper manufacturing or in nanofibrillated cellulose composites

InactiveUS20130000855A1Increase productivityPrevents hydrogen bondPulp properties modificationLuminescent/fluorescent substance additionPaper manufacturingPulp and paper industry

Owner:UPM-KYMMENE OYJ

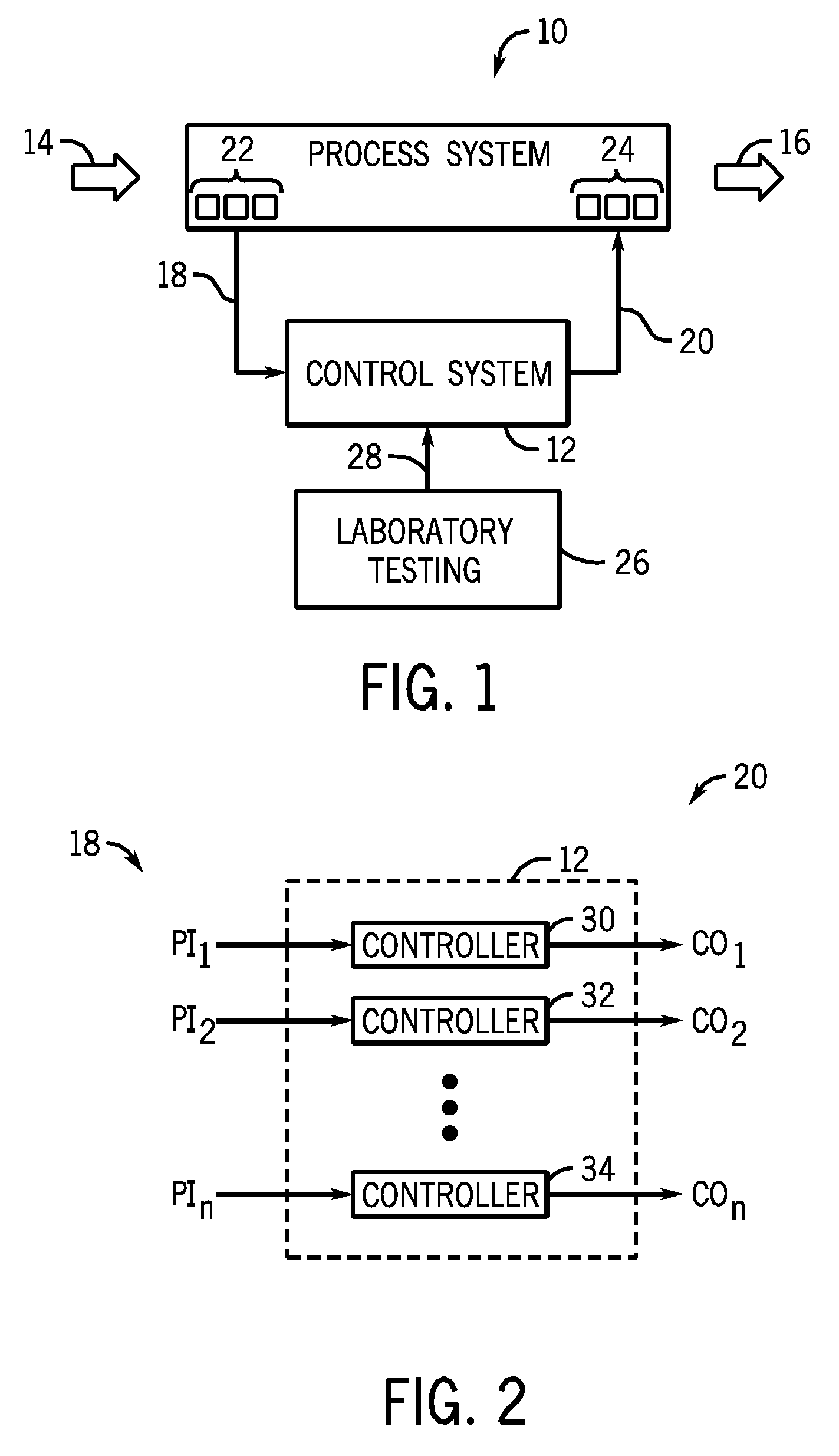

System and method for optimizing a paper manufacturing process

InactiveUS20100082120A1Mining valueReduce the amount requiredSimulator controlDigital differential analysersMeasurement devicePaper manufacturing

A technique is disclosed for optimizing a quality parameter in a process that is not directly measurable online using conventional measurement devices. The technique includes the use of a first inferential model to predict a value for the parameter based upon other process variables. A second inferential model predicts a residual component of the process parameter based off non-controllable residual variables of the process. The inferential model outputs are combined to produce a composite predicted value which may be further adjusted by an actual prediction error determined via comparison with an offline measurement. The adjusted predicted value is provided to a dynamic predictive model which may be adapted to implement control actions to drive or maintain the quality parameter at a target set point. The technique may further consider cost optimization factors and production reliability factors in order to produce a product meeting the target quality set point or range while considering production requirements and minimizing overall costs.

Owner:ROCKWELL AUTOMATION TECH

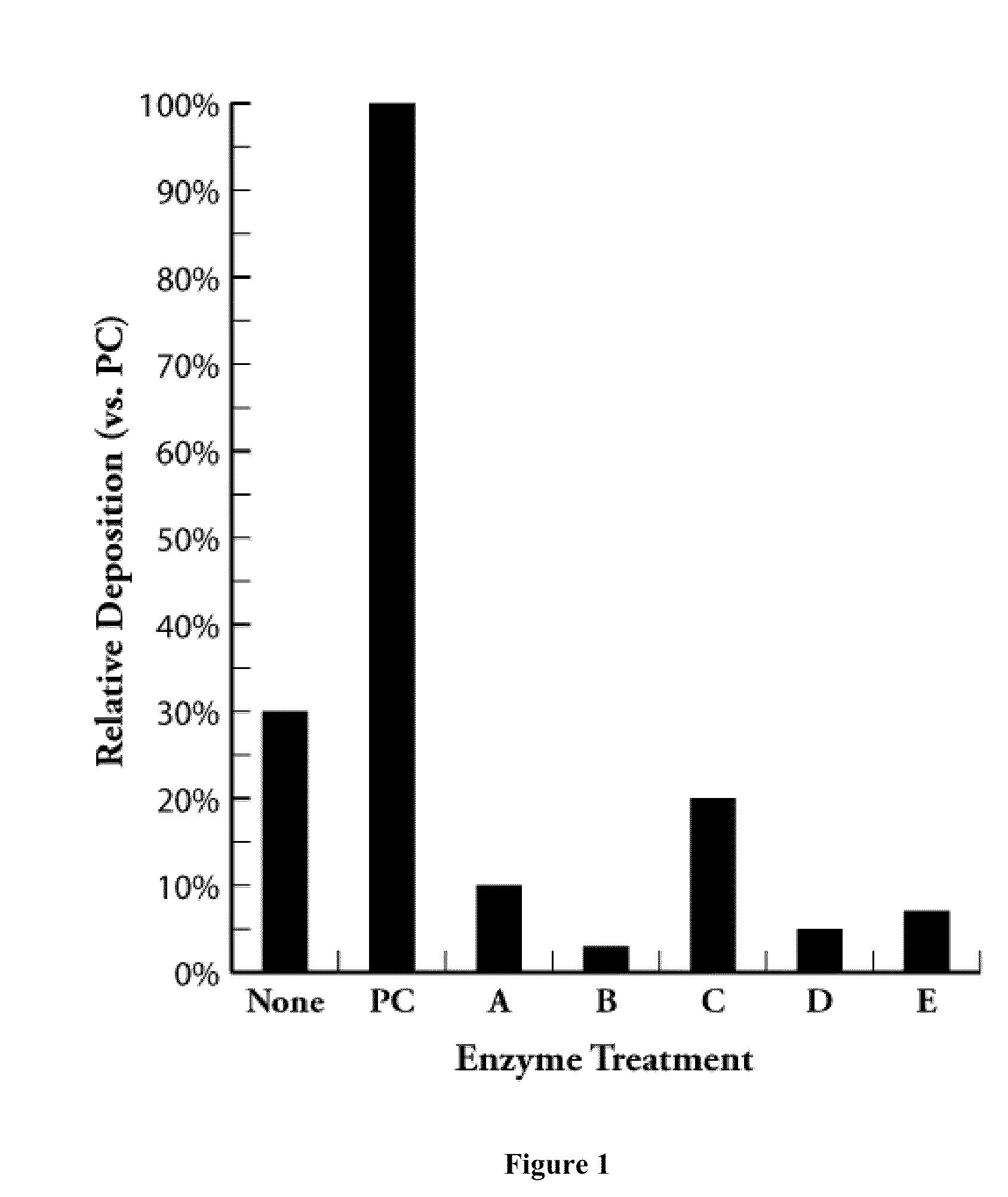

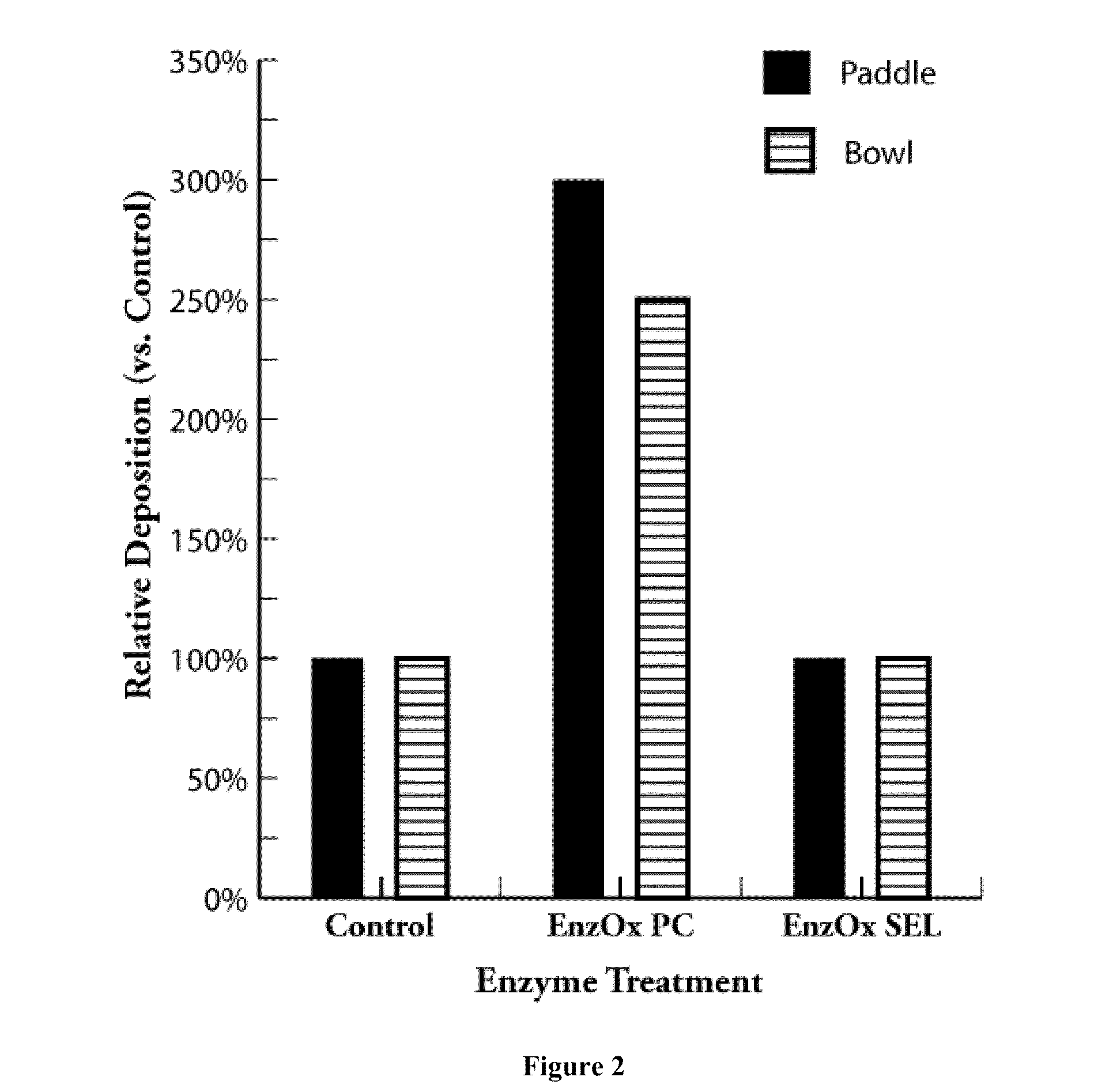

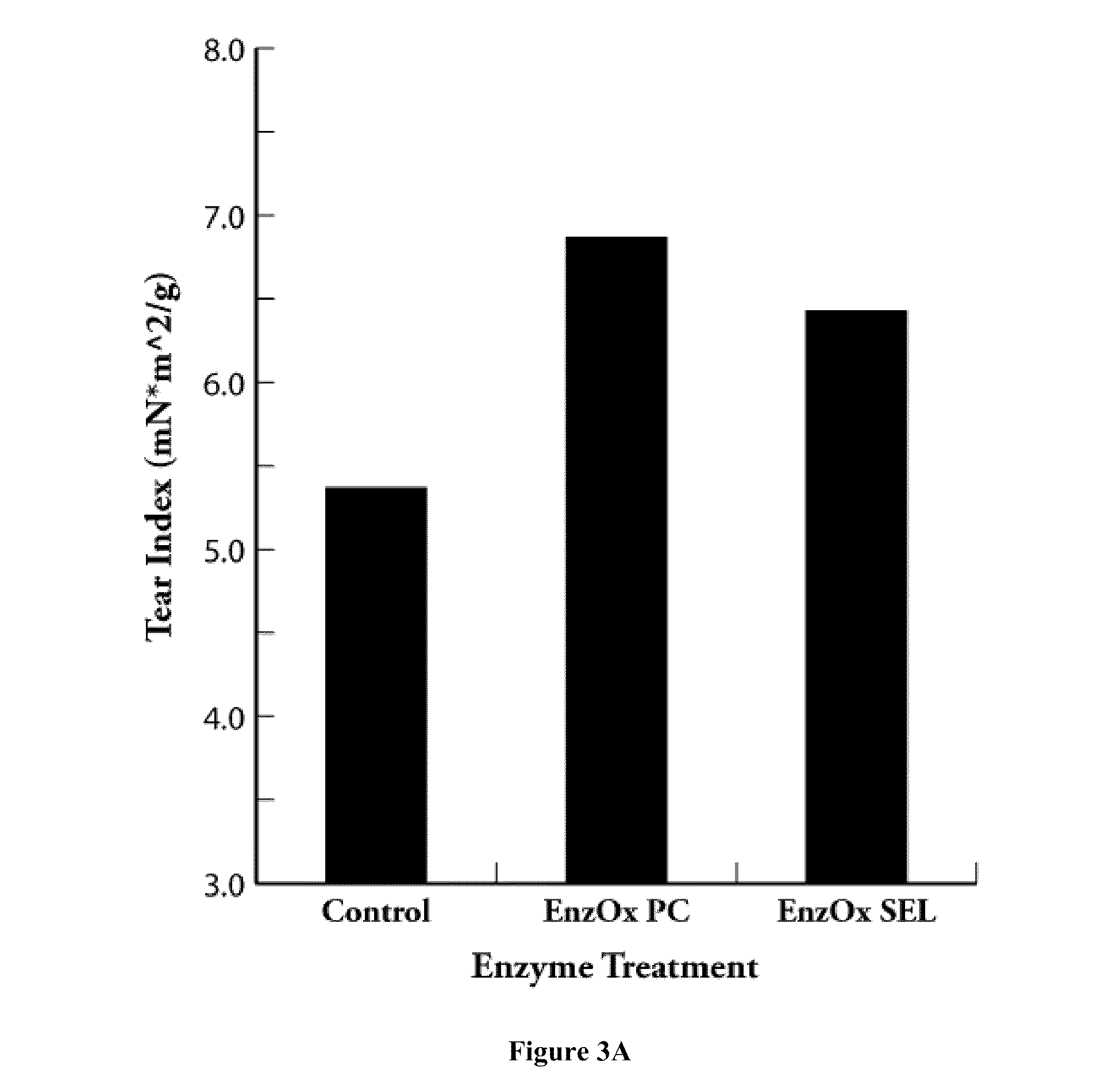

Use of 1,3-selective lipases for pitch control in pulp and paper processes

InactiveUS20100269989A1Reduce the amount requiredReduce concentrationNon-fibrous pulp additionFats/resins/pitch/waxes removal in pulpMonoglycerideSorbent

Formulations for pitch control, and methods of making and using thereof, are described herein. The formulations contains one or more 1,3-selective lipases. 1,3-selective lipases catalyze the hydrolysis of the terminal ester groups in triglycerides leaving the internal ester group intact. The enzyme formulations can contain one or more additives, such as dispersants, metal ions, absorbents, adsorbents, cationic polymers, and combinations thereof. The enzyme formulation is typically applied as a solution to the pulp stock. The enzyme formulations can be applied at any of one or more various points during the pulping and paper manufacturing processes. The use of selective lipase(s) decreases the total concentration of fatty acids in the system, and catalyzes the formation of monoglycerides, which are more effective at dispersing fatty acids than glycerol, the product of non-selective lipases, thereby improving pulp and paper machine runnability and pulp and paper quality.

Owner:ENZYMATIC DEINKING TECH LLC

Ionic liquid based method for extracting lignin by two-liquid-phase system

ActiveCN101712698AImprove solubilityHigh extraction rateLignin derivativesBulk chemical productionPaper manufacturingEthyl acetate

The invention relates to an ionic liquid based method for extracting lignin by a two-liquid-phase system, comprising the following steps of: 1, preparing a mixed solution of 40%-80% of imidazole salt ionic liquid and 20%-60% of organic solvents, and adding 0.5%-2% of deionized watert; 2, adding the mixed solution, a lignin-containing solid plant material or a plant material ramification into a reaction kettle, conducting oil bath for 0.5-3 hours under 403-443 K and 0.1-10 MPa, and then obtaining filter liquor and a filter cake; 3, adding 4-6 multiplied deionized water into the filter liquor, and separating rough lignin out; 4, purifying by a soxhlet extraction method, wherein the organic solvents are ethylacetate, dioxane and ethanol or methanol. The invention obtains lignin products, andreaction residuals can still be continuously used in slurrying process of the paper manufacturing industry; in addition, the invention has the advantages of high extraction rate of the lignin, solvent recycling, easy operation and low cost.

Owner:DALIAN ZHONGHUIDA SCI INSTR

Production technique of nano calcium carbonate by normal temperature method

ActiveCN102674425APassivation sensitivityLess investmentCalcium/strontium/barium carbonatesNanotechnologyPlastics industryFilling materials

The invention discloses a production technique of nano calcium carbonate by a normal temperature method, belonging to the technical field of fine chemical engineering. The production technique comprises the following steps: proportioning, carbonizing, treating, dehydrating, primary drying, secondary drying and depolymerizing. The invention has the characteristics of low equipment investment, low energy consumption, low production cost and the like, can implement production under normal temperature conditions, and can control the particle size and crystal form. The nano calcium carbonate produced by the technique disclosed by the invention can be used as a filling material in plastics industry, rubber industry, paint industry, paper manufacturing industry, ink industry, adhesive industry and other industries.

Owner:HUNAN JINJIAN NEW MATERIAL TECH

Coated paper for rotary machine printing and production method thereof

ActiveCN1546791AFar-reaching social benefitsImprove temperature resistanceNon-fibrous pulp additionCoated paper substrateRotary machinePrinting press

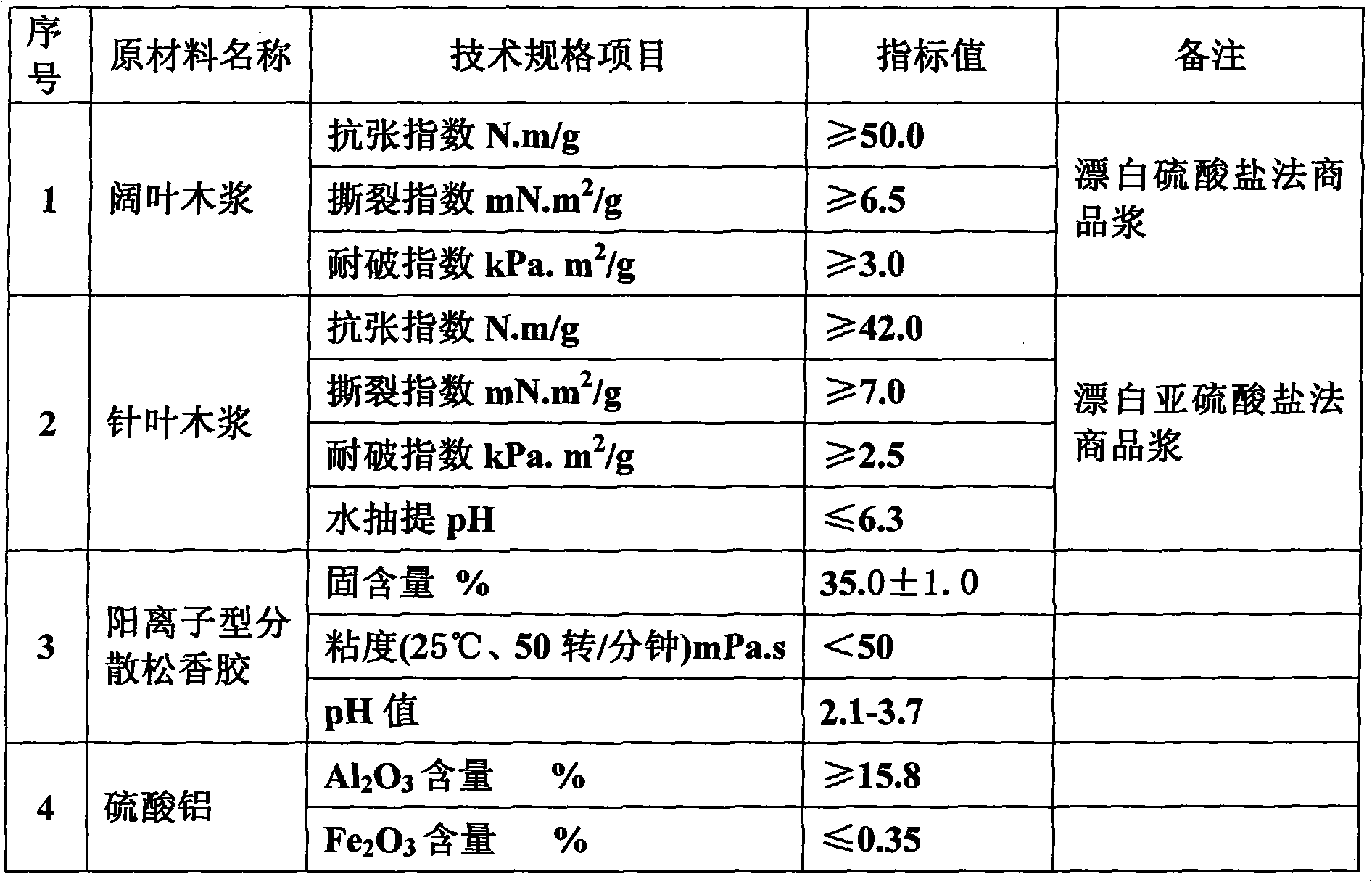

The invention is a kind of coating paper manufacturing method for rotary printer, which upgrades the temperature enduring is upgrades about 20-30 degrees. The coating paper includes paper pulp of broad-leaved wood pulp, needle-leaved wood pulp, the fillers and chemical additives, all of which are produced into base paper, in the base paper, needle-leaved wood pulp: broad-leaved wood pulp=15-55: 85-45; fillers: paper pulp= 6-12:100, chemical additives: paper pulp= 0.5-5:100; there has a coating layer out of the base paper. The manufacturing steps are: uses broad-leaved pulp and needle-leaved pulp to produce compound paper pulp, when adds in fillers and chemical additives, gets the base paper, then coats a layer of glue executing layer, precoating layer and surface coating layer on the surface of the base paper, thus the coating paper can be produced further through post pressing and polishing process. The coating paper can reach following standards: the glossiness is not less than 60 degrees, the coarse degree is not more than 1.2 micro meters, and the ink sorption rate is 25-35%, the temperature performance is not less than 180 degrees.

Owner:GOLD EAST PAPER JIANGSU

Method for preparing crystal whisker of gypsum

This invention describes a process for producing gypsum whiskers, which includes the the following processes: a)purification of chemical gypsum into dihydrate gypsum; b)levigation of the purified chemical gypsum, and then injection of the slurry thus obtained into an enamelled reactor; c)adding chloric acid or salts into the reactor, and boiling to the dissolution of the gypsum; d)stirring and cooling the solution to the recrystallization into dihydrate gypsum whiskers; e)swing-drying the recrystallization product; and f)neutralizing the swing-dried dihydrate gypsum to obtain a first product of wet dihydrate gypsum whiskers. In this invention the estimated production cost of the gypsum whiskers produced is 800-1900 RMB per ton, only 1 / 40-1 / 200 the price of the whiskers in the market. Besides, the overall process of this invention is easy to operate, and all the equipment utilized is common chemical equipment. The produced gypsum whiskers are mainly used for paper manufacturing and the corresponding paper products, while a minor part of them are used for reinforced materials of rubber and plastic products.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Apparatus for spraying of liquids and solutions containing solid particles such as paper manufacturing fibers and fillers

InactiveUS6866207B2Reduce energy consumptionShort time spanBurnersSpray nozzlesFiberChemical solution

Owner:KANGAS MARTTI Y O +1

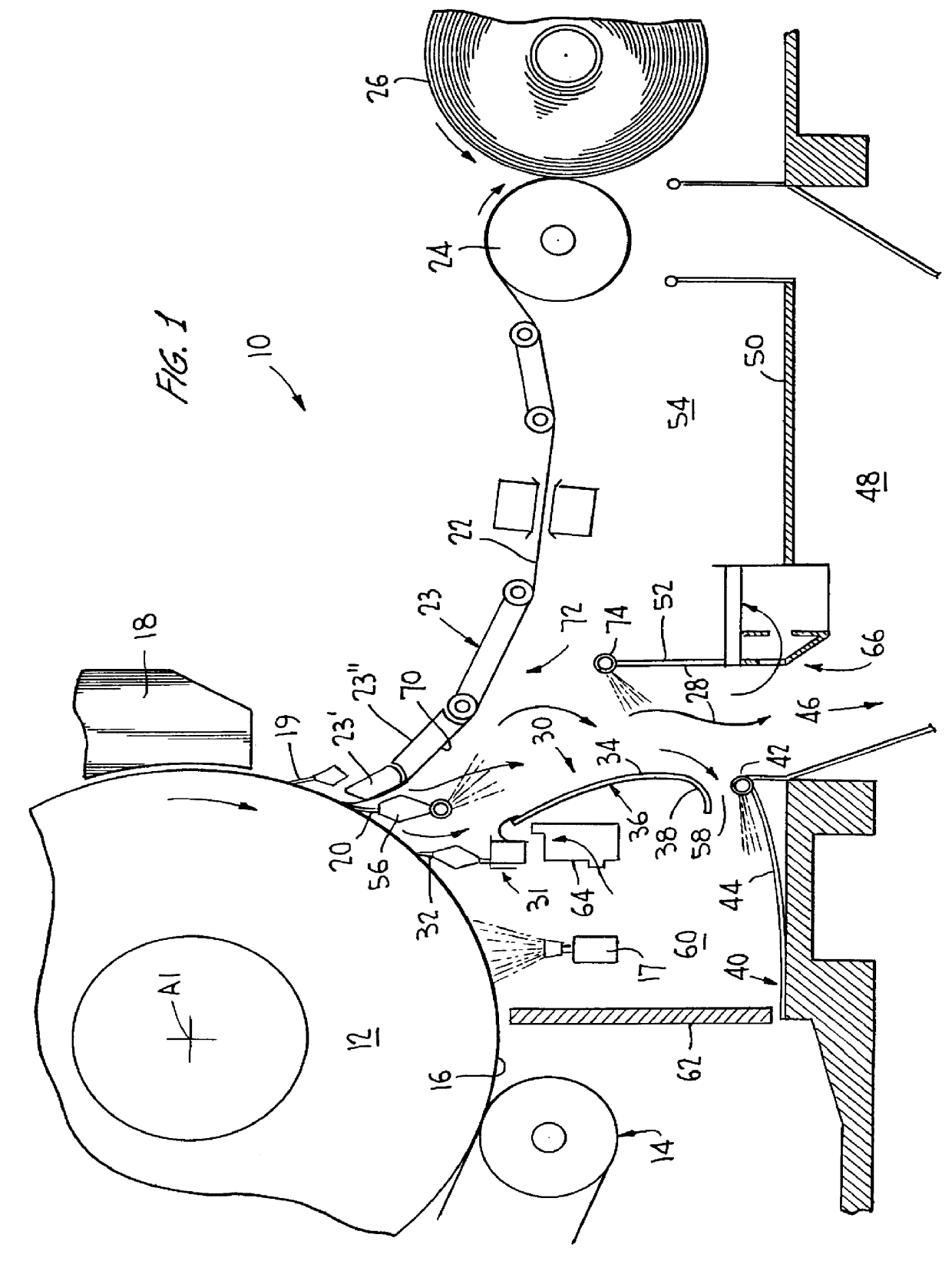

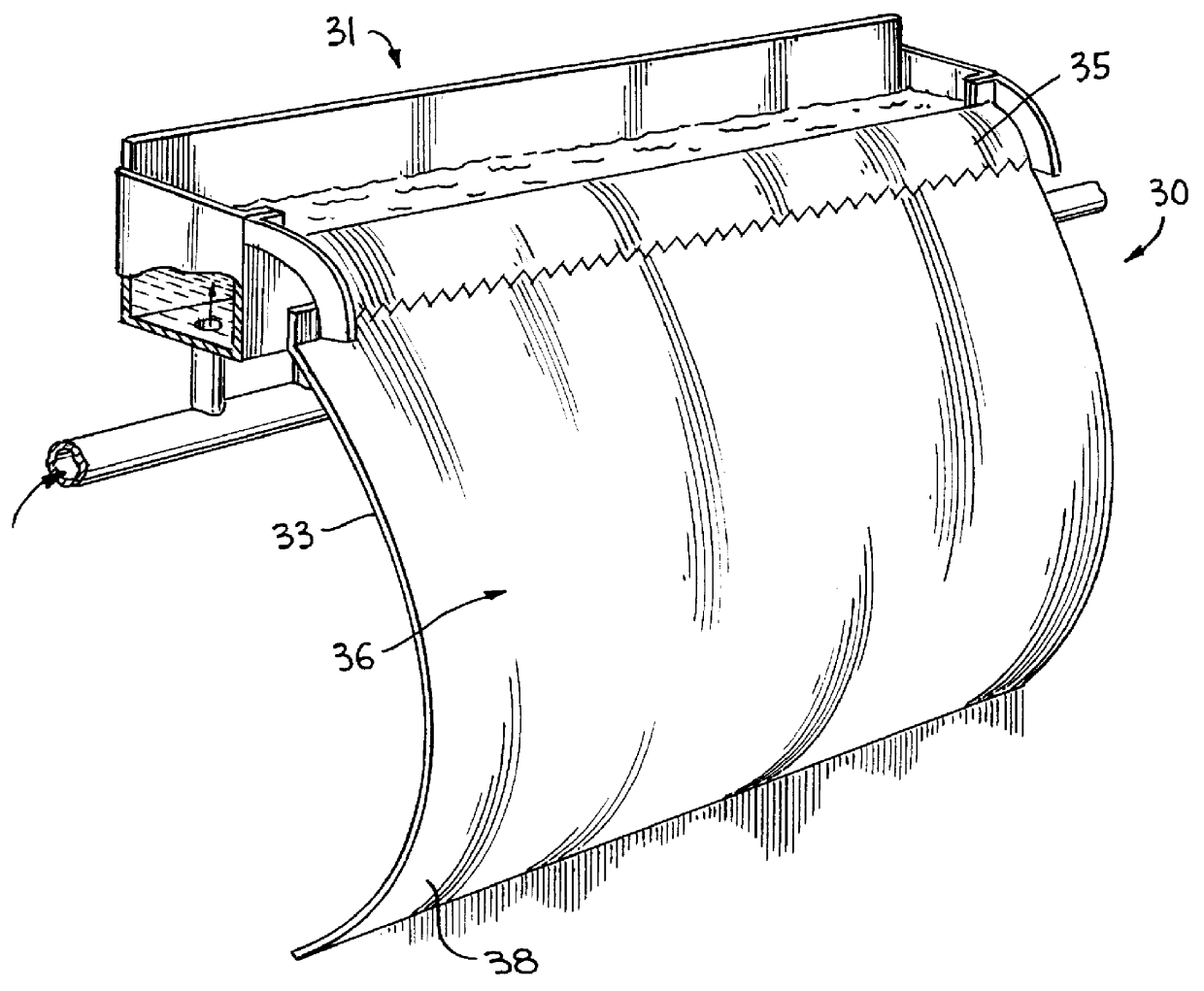

Dust-controlling apparatus, with a water curtain device, for a paper manufacturing machine

InactiveUS6068735AHighly efficient in removingEasy to captureMechanical working/deformationSpecial paperFiberDust control

A dust and fiber control device for paper making apparatus is described. The device includes a wall in conjunction with a feed spout for providing a water curtain. The water curtain serves to capture and remove air suspended dust and fiber particles from ambient air. The device is positioned transversely to the motion of a paper web underneath the web between a drying cylinder and a rewinder. The water curtain device is utilized in conjunction with air flow devices for assisting in controlling the collection of air suspended dust and fiber particles from the ambient air.

Owner:GEORGIA PACIFIC FRANCE SAS

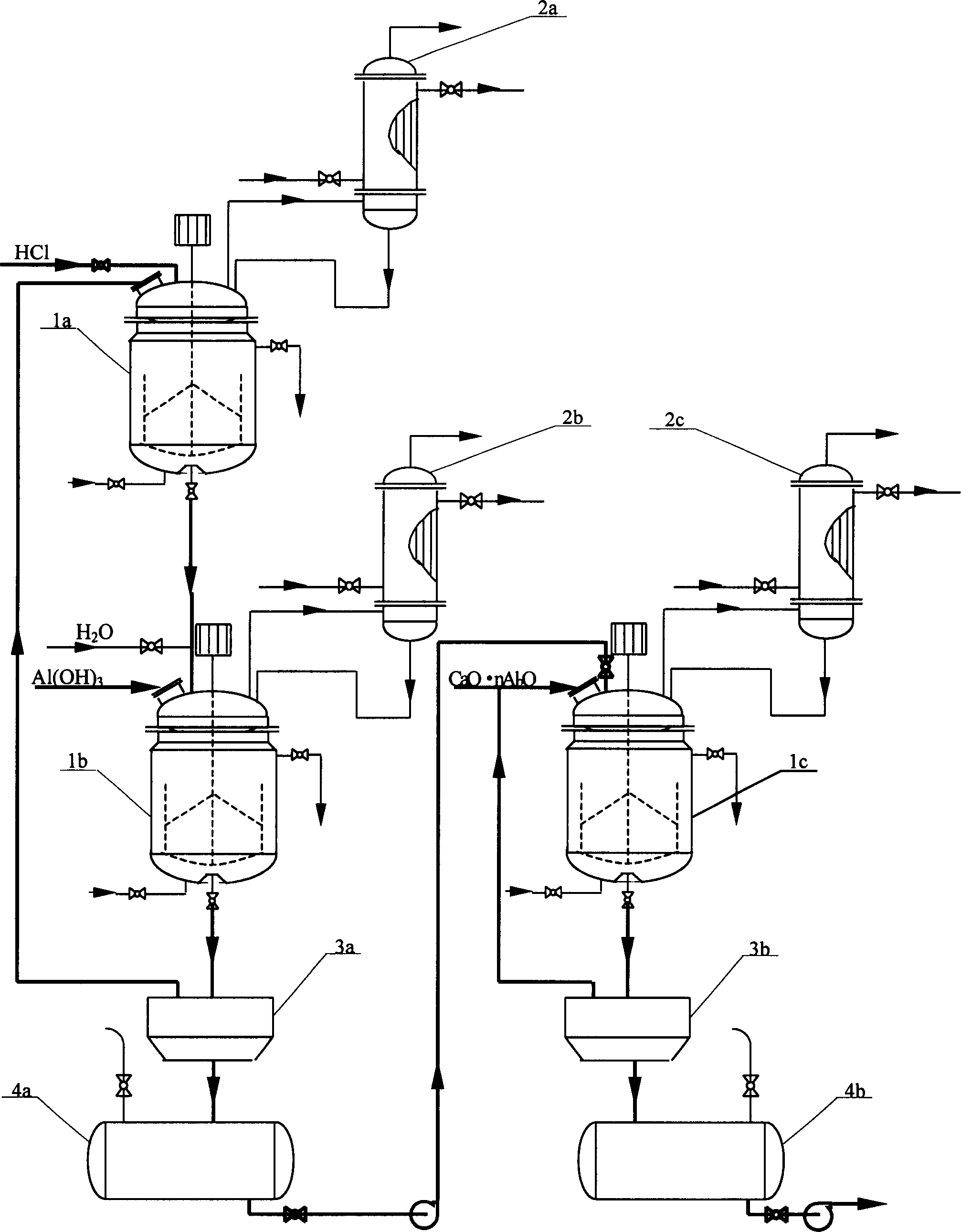

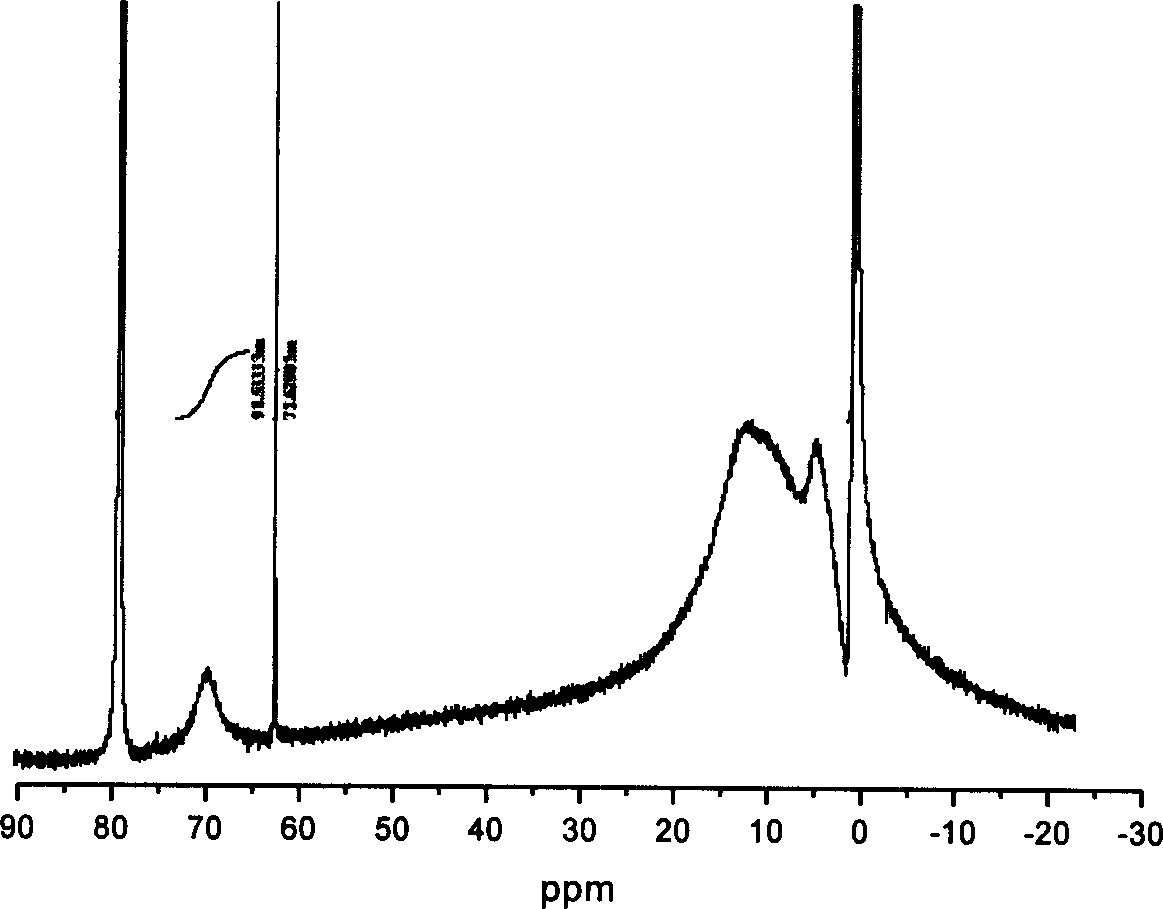

Method and technique for preparing Nano type sol of polyaluminium chloride in high purity

This invention describes a process for preparing high-purity nanoscale polyalumina sols. This invention uses active aluminum hydroxide and industrial hydrochloric acid as raw materials, and adopts a two-stage reverse stripping process to produce a solution of polyaluminum chloride with an alkalinity higher than 50%, which is then increased to 70% or higher using high-purity calcium aluminate as the alkalizer. The process ensures complete stripping of the aluminum hydroxide raw material at normal atmosphere and a low temperature, thus obtaining a high-purity product. In addition, in the produced polyaluminum chloride sols the total content of nanoscale Al13 and Al30 having Keggin structure is higher than 70%, the alkalinity is 70-85% and the aluminum concentration is 10-19% (measured as Al2O3). The product is widely used as raw material for modern fine chemical binders, gluing agent for neutral paper manufacturing, intermediate or additive for modern pharmaceutical technology, coupling agent and catalyst for chemical production and flocculant for water treatment, and has potential applications in such emerging fields as inorganic nanocomposites and inorganic membrane materials.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

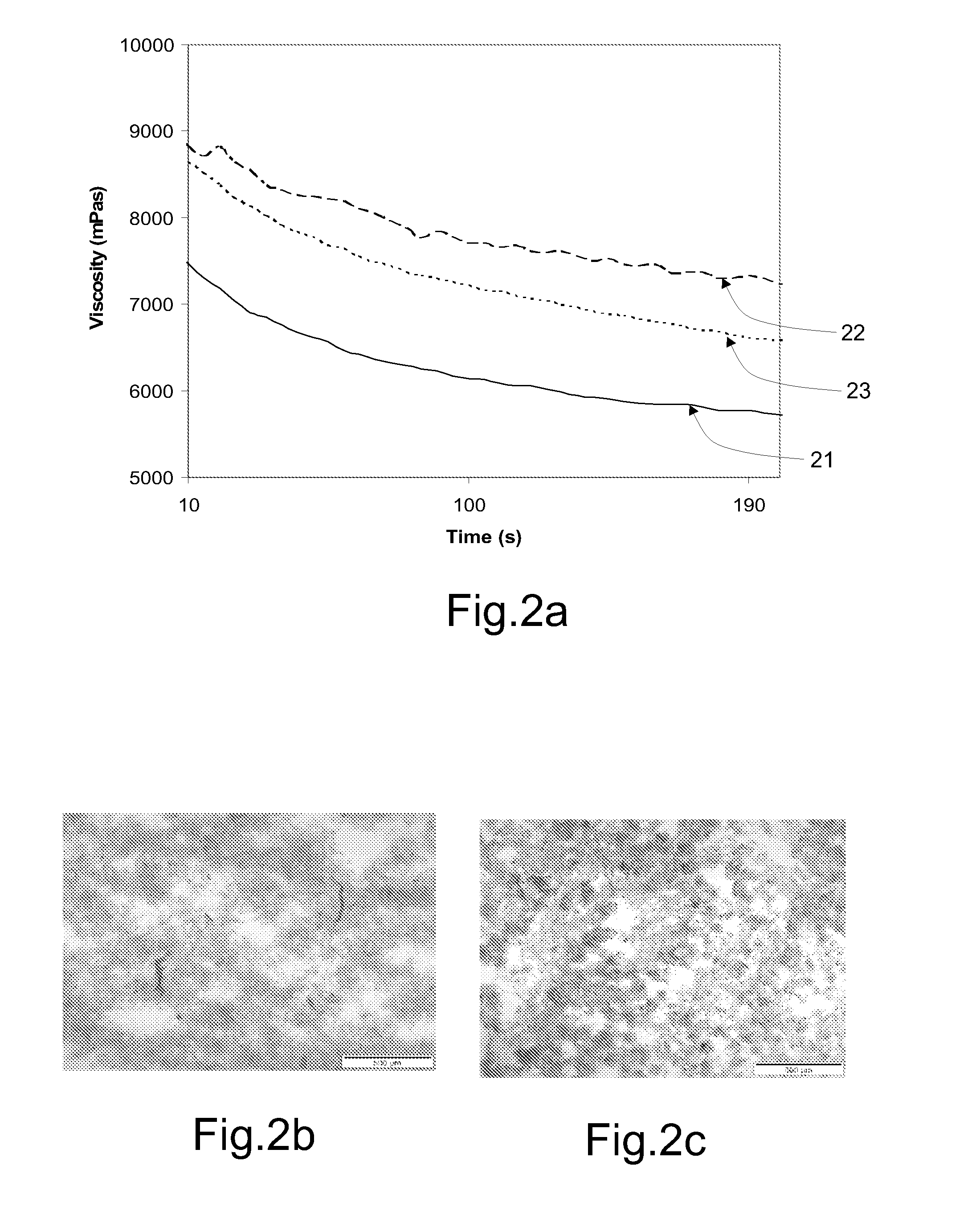

Polyacrylamide-based dry paper-strengthening agent, and paper manufacturing method

ActiveCN102808353AExcellent paper strengthening effectGood quality paperReinforcing agents additionPaper/cardboardPolymer sciencePaper manufacturing

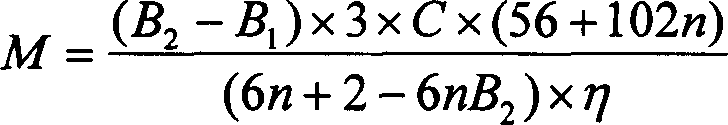

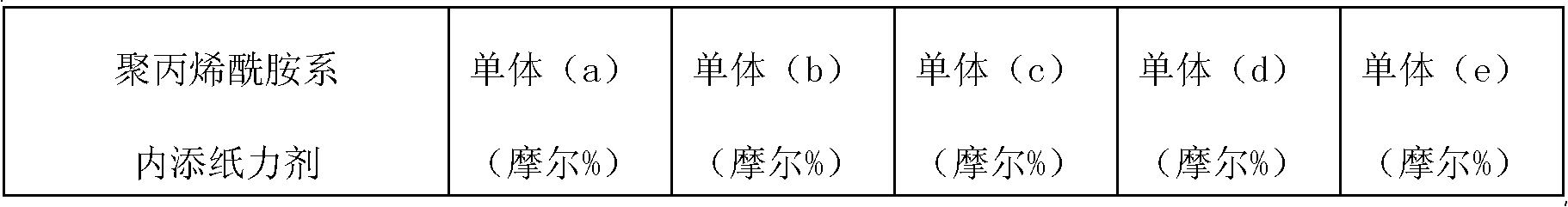

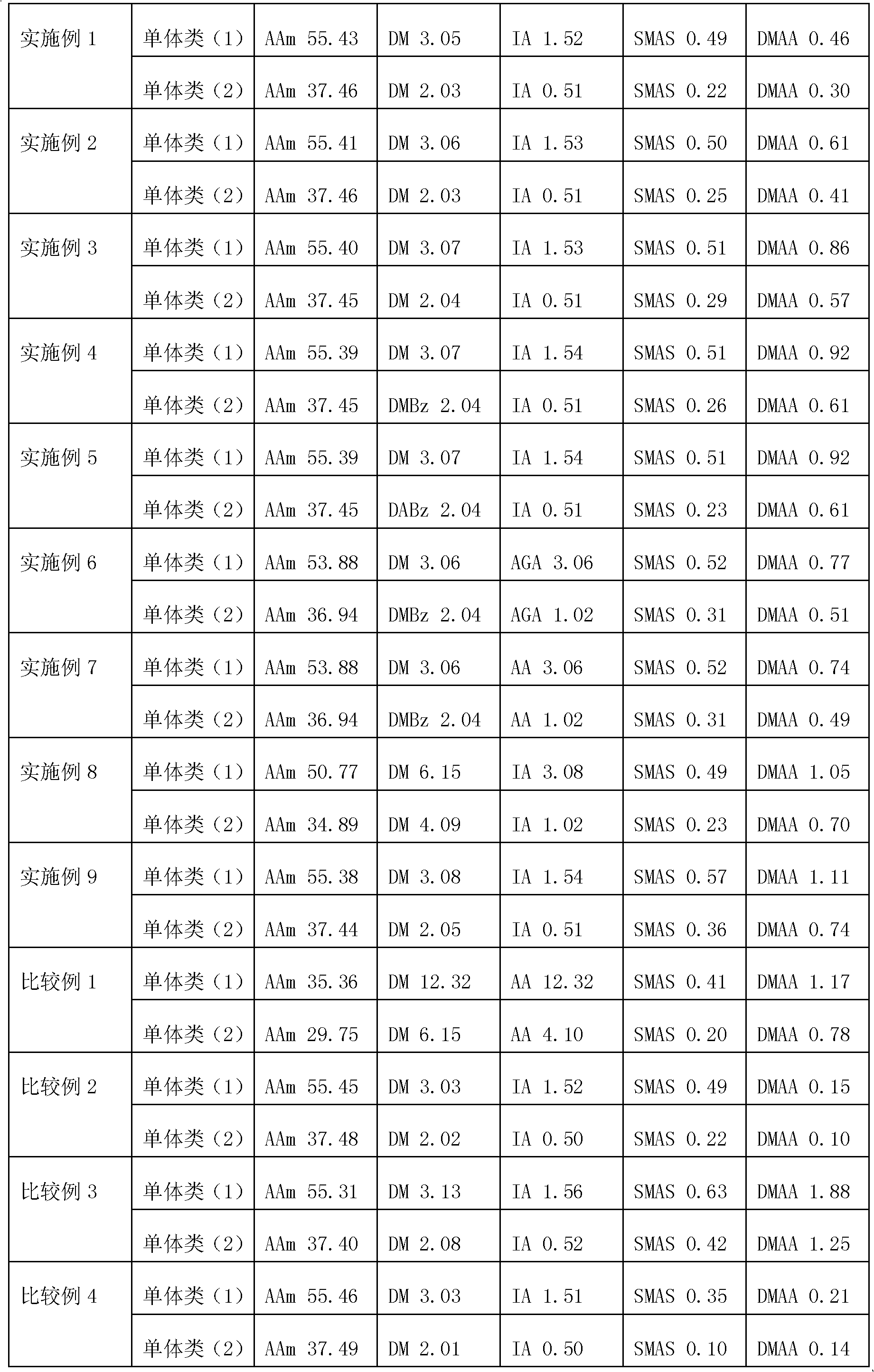

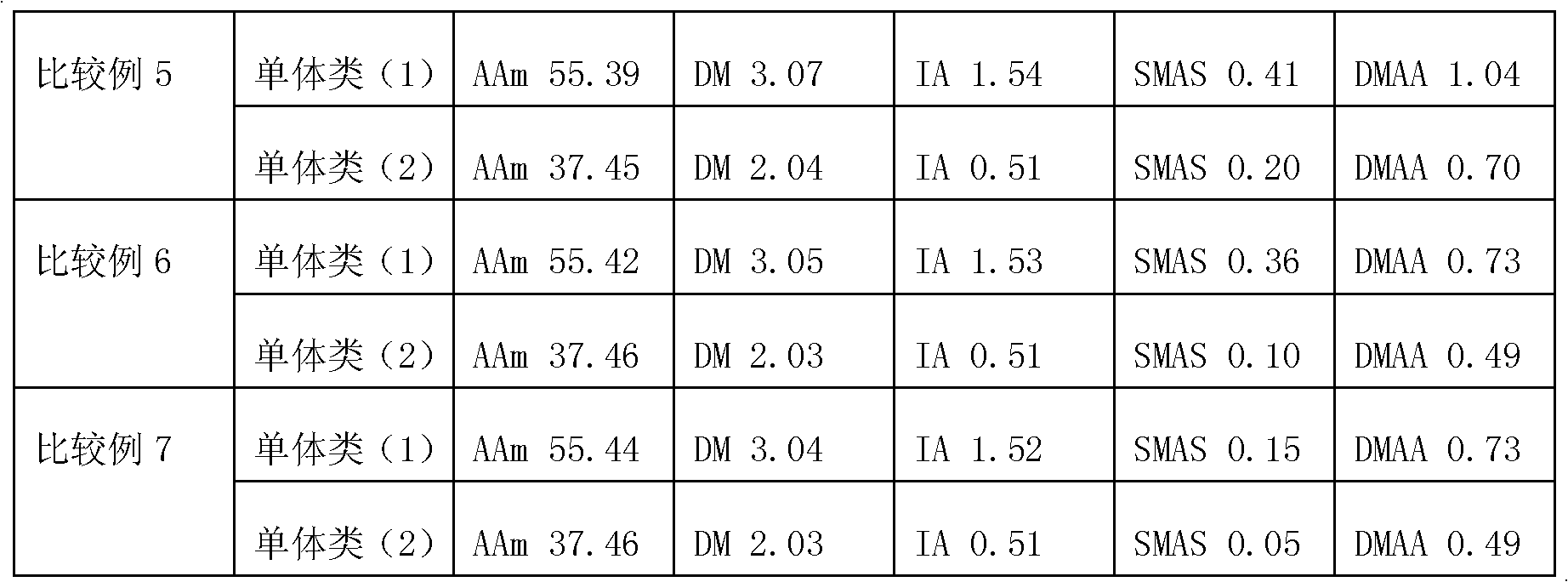

The present invention is: a polyacrylamide-based dry paper-strengthening agent containing amphoteric polyacrylamide, the polyacrylamide-based dry paper-strengthening agent being characterized in that the amphoteric polyacrylamide is obtained by polymerizing (a) 70-99.8 mol% of (meth)acrylamide, (b) 0.1-15 mol% of a cationic vinyl polymer, and (c) 0.1-15 mol% of an anionic vinyl polymer, the weight-average molecular mass (A) of the polyacrylamide-based dry paper-strengthening agent is 2,000,000-10,000,000, the ratio [(A) / (B)] between the weight-average molecular mass (A) and the B-type viscosity (B)(mPas) of a 20 mass% aqueous solution obtained by adjusting the polyacrylamide-based dry paper-strengthening agent so that the solids concentration in the polyacrylamide-based dry paper-strengthening agent is 20 mass% at 25 DEG C is equal to or greater than 500, and the thread length in a 20-mass% aqueous solution at 25 DEG C is 5-60 mm; and a method for manufacturing paper-in which the polyacrylamide-based dry paper-strengthening agent is used.

Owner:SEIKO PMC CORP

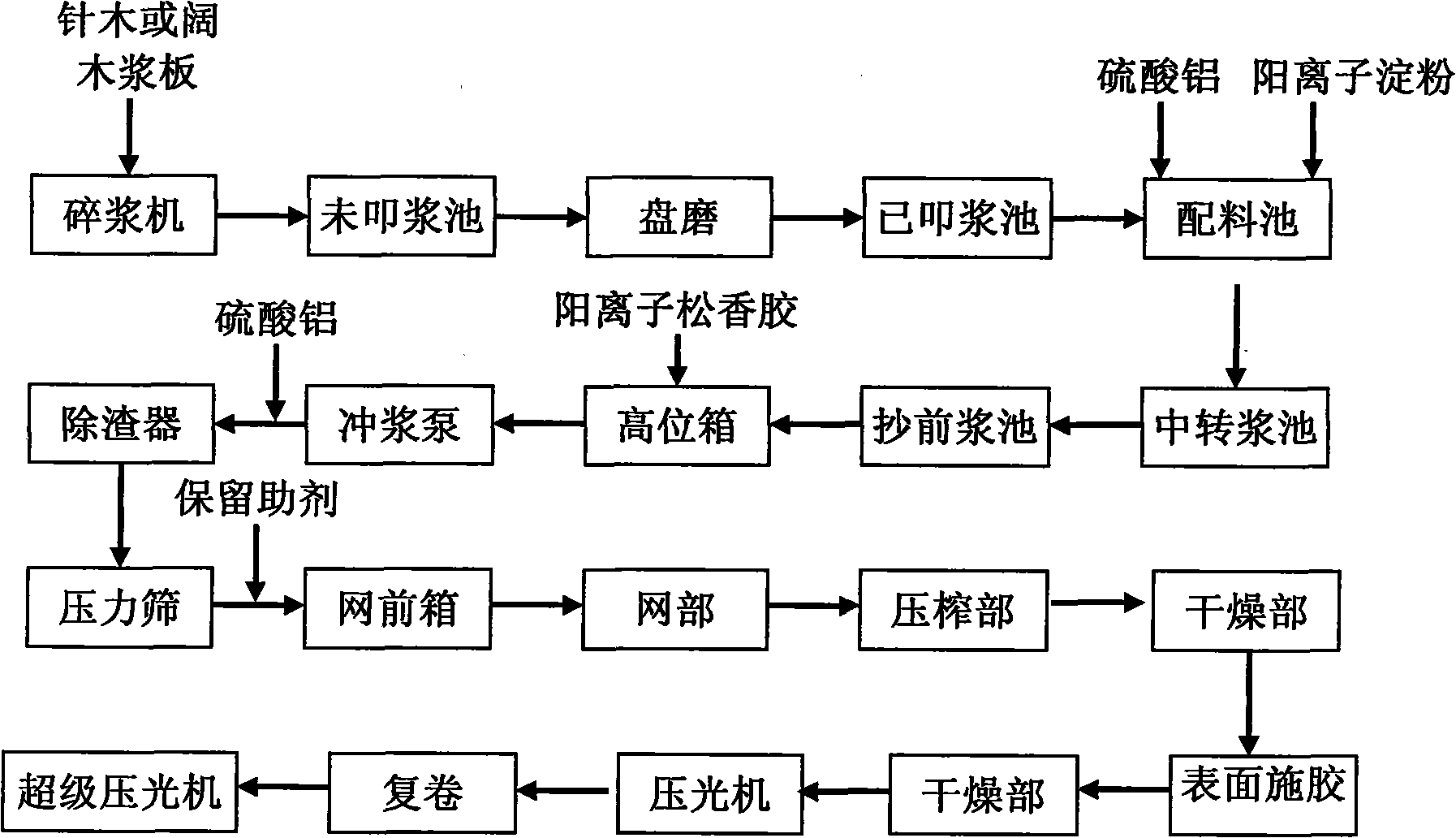

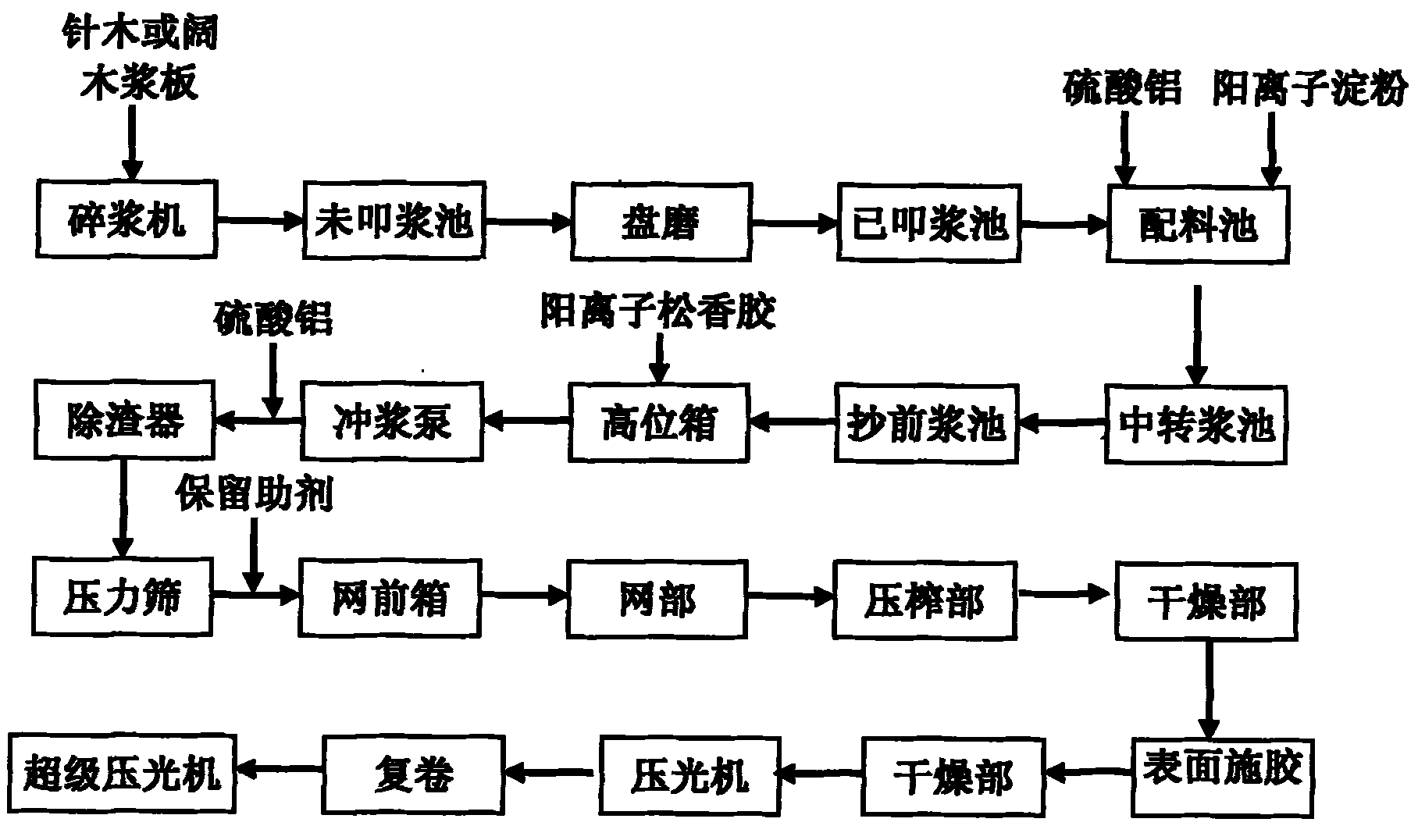

Method for producing computer-to-plate lining paper

ActiveCN101787662ASolve acidityStrong acidNatural cellulose pulp/paperWater-repelling agents additionAluminium sulfateComputer to plate

The invention provides a method for producing computer-to-plate (CTP) lining paper, which is characterized in that: the lining paper is produced by using a common multi-cylinder long mesh paper machine, and the production process comprises the following steps: pulp beating, pulp proportioning, paper manufacturing with pulps, surface sizing, press polish and rewinding to produce base paper, then carrying out subsequent press polish treatment on the base paper to produce finished paper; the CTP lining paper is produced from paper pulps which are made of hardwood pulps and softwood pulps, chemical additive cationic starch, cationic dispersed rosin size and auxiliary sizing agent aluminum sulfate serving as raw materials. In the method, the cationic dispersed rosin size is used and the auxiliary sizing agent aluminum sulfate is added for two times on a proportioning pool and at an outlet of a fan pump, so that the problem of producing the CTP lining paper by using cationic dispersed rosin acid sizing technology is successfully solved. The pH value of the water extract of the produced base paper is kept within a range of 5.2 to 5.8, so that the key indicator of the paper, namely, the pH value of the water extract of the paper, meets the quality requirement on the CTP lining paper.

Owner:ZHENJIANG DADONG PULP & PAPER

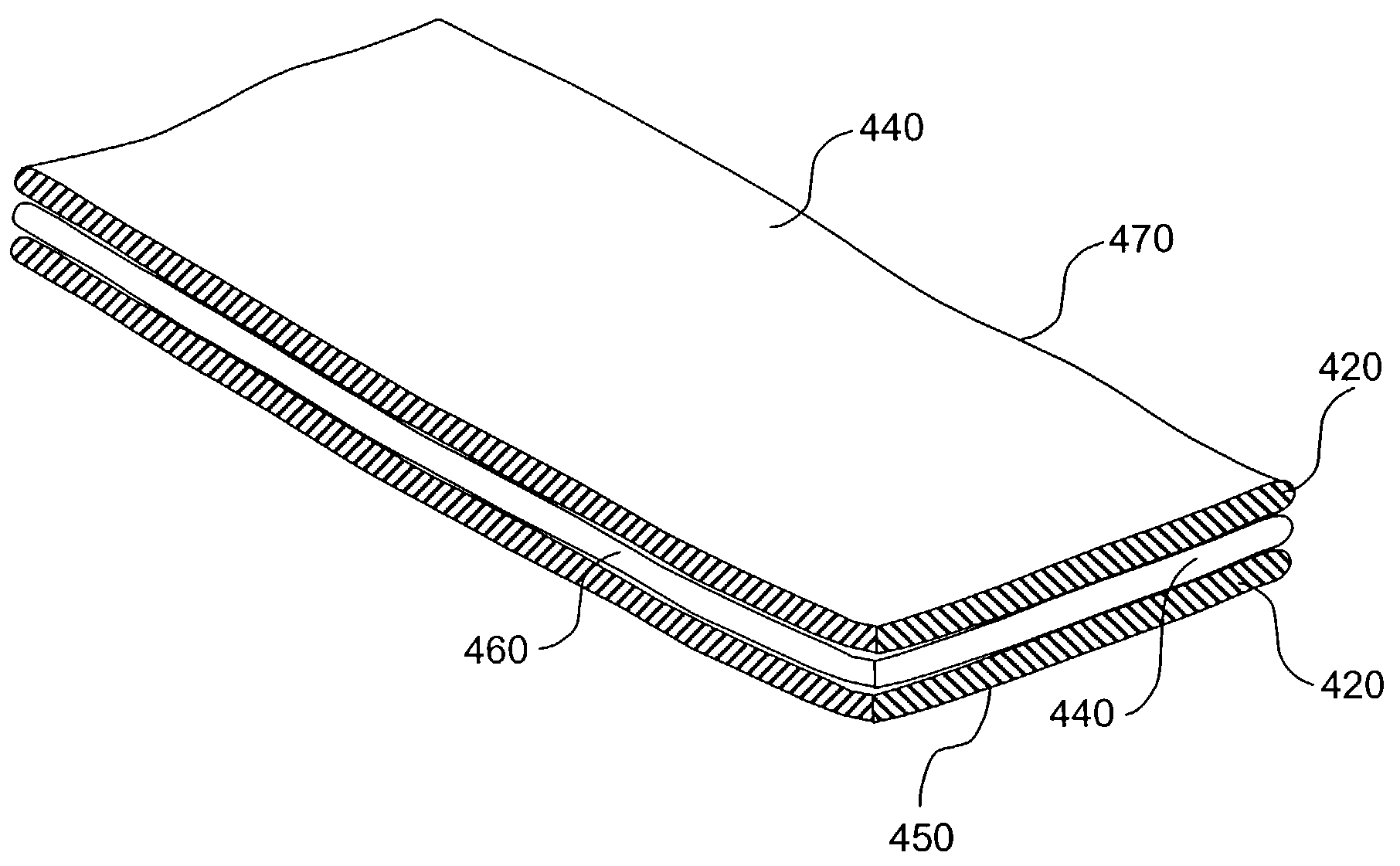

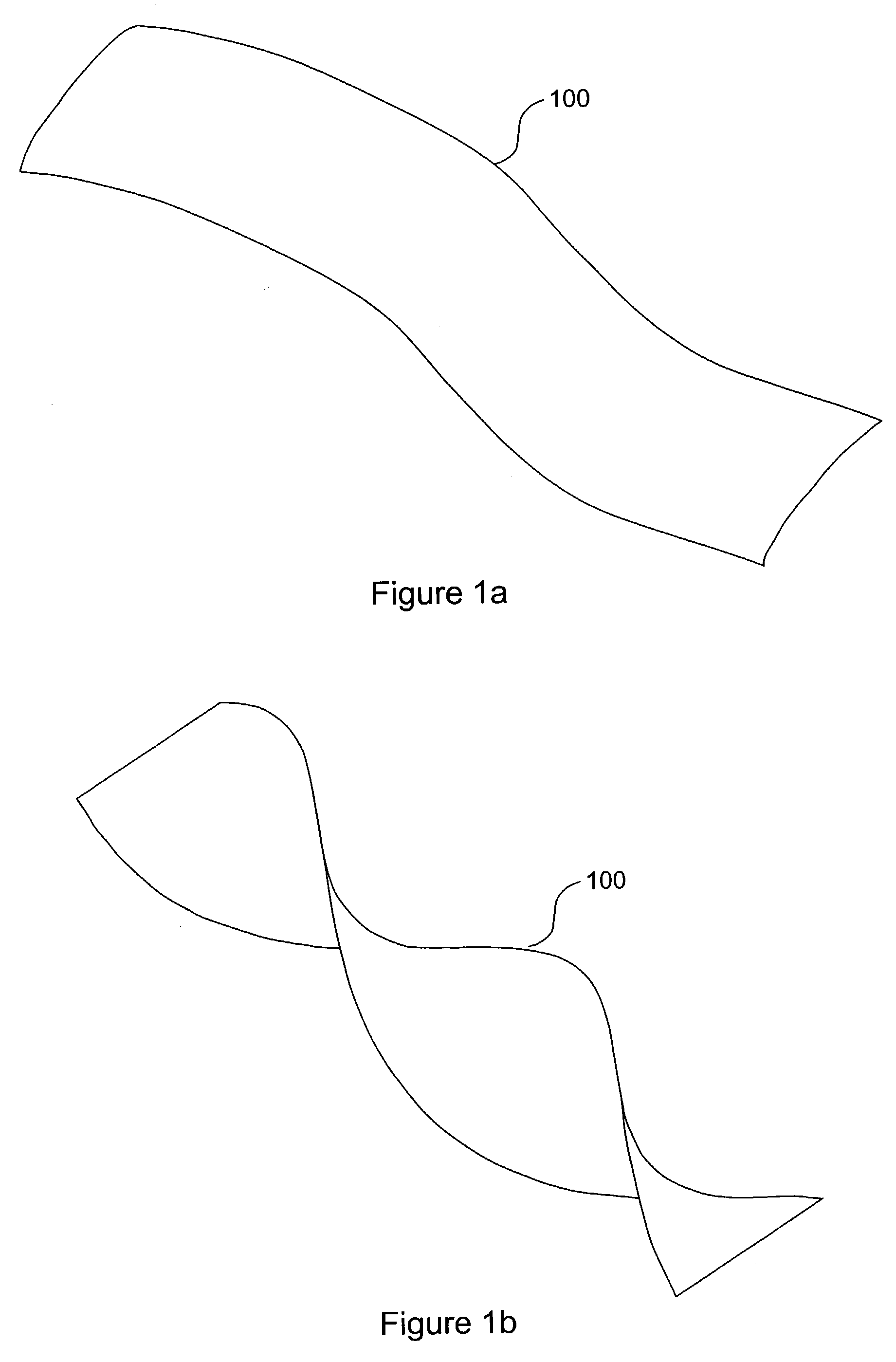

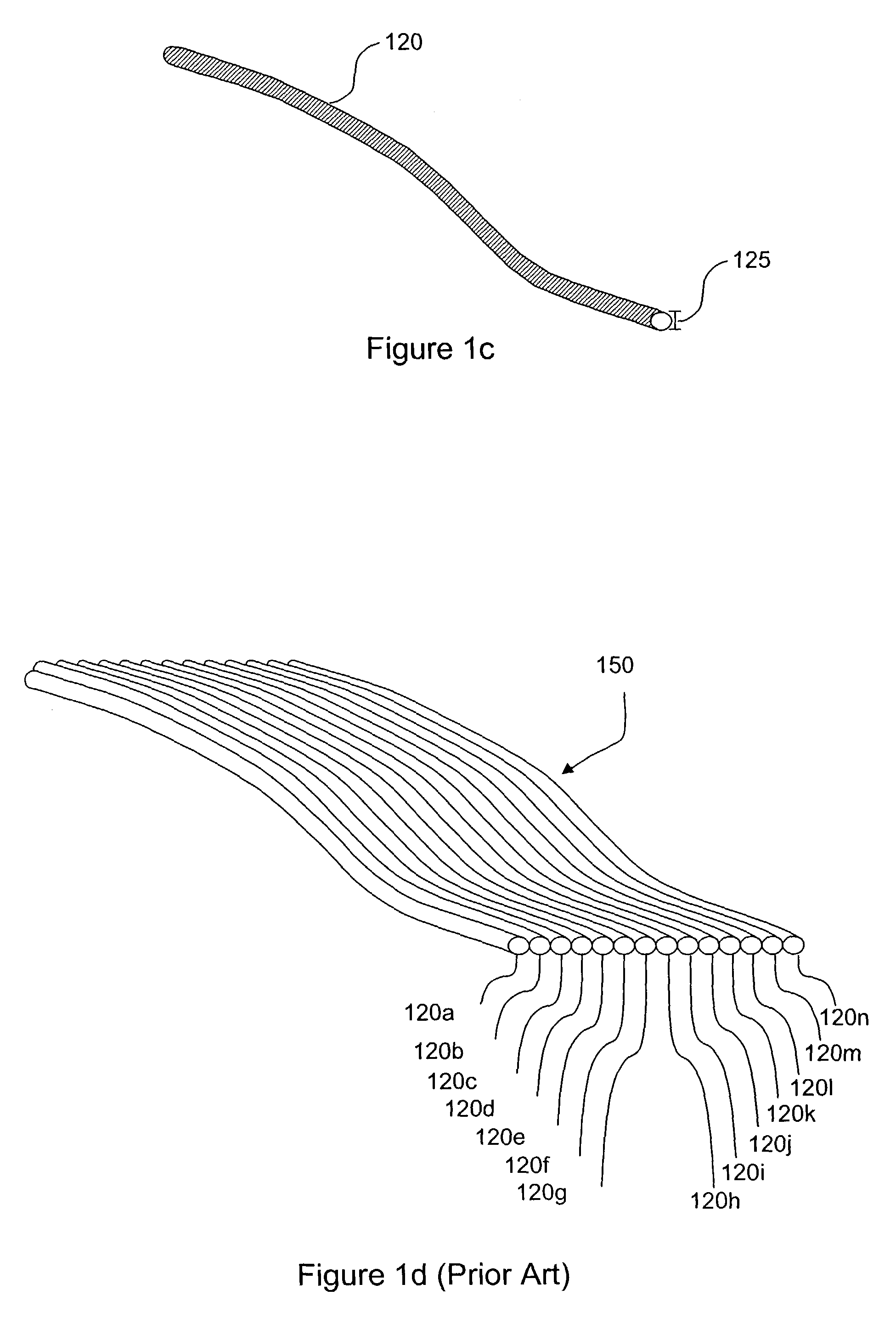

Paper Strap

InactiveUS7118648B2Shorten the timeEliminate needNon-fibrous pulp additionNatural cellulose pulp/paperCartonPaper manufacturing

Among other things, the present invention provides various apparatus useful in paper manufacturing and recycling. On such apparatus is a paper strap that includes a paper body that is formed of a compound structure. Such a paper strap further includes an adhesive material formed on at least a portion of the paper body. Methods for using the paper strap include methods related to recycling paper products, methods for sealing cartons, and methods for manufacturing paper products.

Owner:SDF GROUP

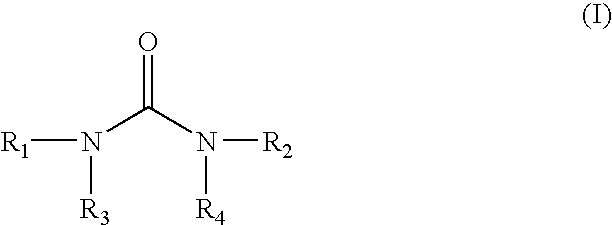

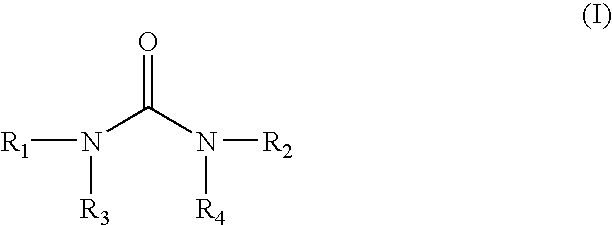

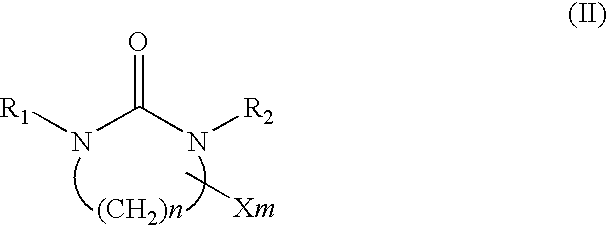

Ink composition

An ink composition is provided including an amide compound represented by formula 1, a coloring agent and a solvent. The amide compound and the polyhydric alcohol in the ink composition decrease the mobility of coloring agents and increase the adhesion to media, thereby minimizing the bleeding between colors of printed images, and improving the water fastness and dry and wet rub fastness to provide good color fastness on papers. The ink composition also improves the quality of the printed image, and also has good long-term storage stability. Thus, the ink composition can be widely used as ink-jet inks for ink-jet printers, printing inks, paints, textile printing, paper manufacturing, cosmetics manufacturing, ceramic industry, etc.

Owner:S PRINTING SOLUTION CO LTD

System and method to control press section dewatering on paper and pulp drying machines using chemical dewatering agents

InactiveUS20060162887A1Automatic controlEnhanced advantageChemical/biochemical paper treatmentDigital differential analysersAutomatic controlControl system

The present invention provides an automatic control system, method and paper manufacturing machine using such control system for automatically controlling the amount of press section dewatering via the metered application of chemical dewatering agents applied to a paper web in a paper manufacturing process. The control system includes a feedback controller for controlling the amount of chemical dewatering agent applied to a paper web, and a monitoring device for obtaining a measurement of the moisture of the paper web exiting the press section.

Owner:NALCO CO

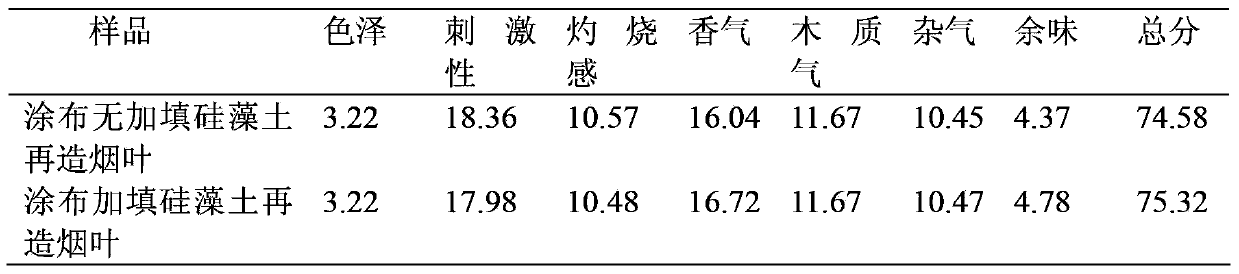

Method for improving ash content of paper-making process reconstituted tobaccos

InactiveCN103653233AHigh strengthIncrease ash contentTobacco preparationCell cavityPaper manufacturing

The invention discloses a method for improving the ash content of paper-making process reconstituted tobaccos. The method includes the steps that after tobacco raw materials are extracted, solid-liquid separation is carried out, tobacco liquid is partially refined, concentrated and charged and then is manufactured into coating liquid, pulping treatment is partially conducted on the tobacco solid part, so that tobacco slurry fibers are obtained, CaCO3 is added into the tobacco slurry fibers, and the CaCO3 is filled into cell cavities of the tobacco slurry fibers through pits of the tobacco slurry fibers; afterwards, the tobacco slurry fibers and additional fiber slurry are mixed according to the weight ratio of 4 to 1, and then paper manufacturing with pulp is carried out to manufacture reconstituted tobacco sheets; the coating liquid is made to coat the reconstituted tobacco sheets, so that the paper-making process reconstituted tobaccos are manufactured. According to the method, the technology that the CaCO3 is filled into the cell cavities of the tobacco slurry fibers is applied to the preparation technology of the paper-making process reconstituted tobaccos, any chemical agent such as a high-molecular polymer is not added, and the purposes that the ash content is improved and meanwhile the strength performance of the paper-making process reconstituted tobacco sheets is improved can be achieved.

Owner:HUBEI XINYE TOBACCO SLICE DEV

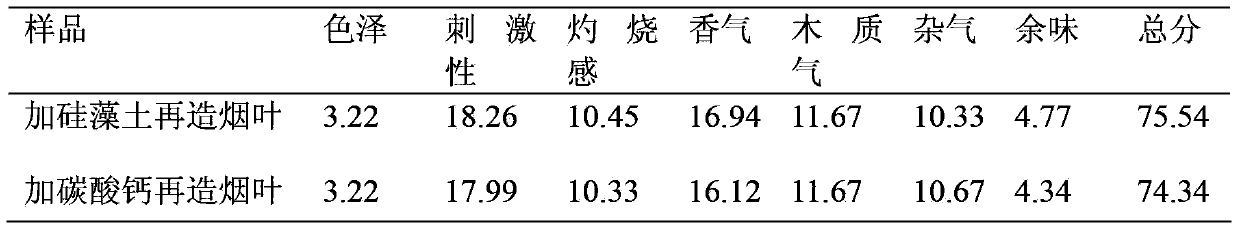

Method for improving paper-making reconstituted tobacco product performance

ActiveCN103416839AImprove performanceIncrease aromaTobacco preparationPaper manufacturingEngineering

The invention relates to the field of paper-making reconstituted tobaccos, in particular to a method for improving paper-making reconstituted tobacco product performance through filling of a novel filler of kieselguhr. The method for improving the paper-making reconstituted tobacco product performance includes the following steps that tobacco sheet raw materials are mixed, and water is added for extraction; after extraction, the materials are extruded by a machine to perform solid-liquid separation, a tobacco sheet base is obtained from the solid-phase materials through the processes of beating and paper manufacturing with pulp, and the aqueous-phase materials are concentrated to be made into coating liquid; the kieselguhr is filled into the coating liquid, and the amount of the filled kieselguhr occupies 5% to 15% of the mass of the coating liquid; the tobacco sheet base is coated with the coating liquid, and tobacco finished products are obtained through drying and slitting of the tobacco sheet base. Compared with a traditional reconstituted tobacco with calcium carbonate, tobacco sheets manufactured by the method for improving the paper-making reconstituted tobacco product performance are effectively improved in various performance, and certain improvement on aroma and remaining tastes of the products is achieved.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

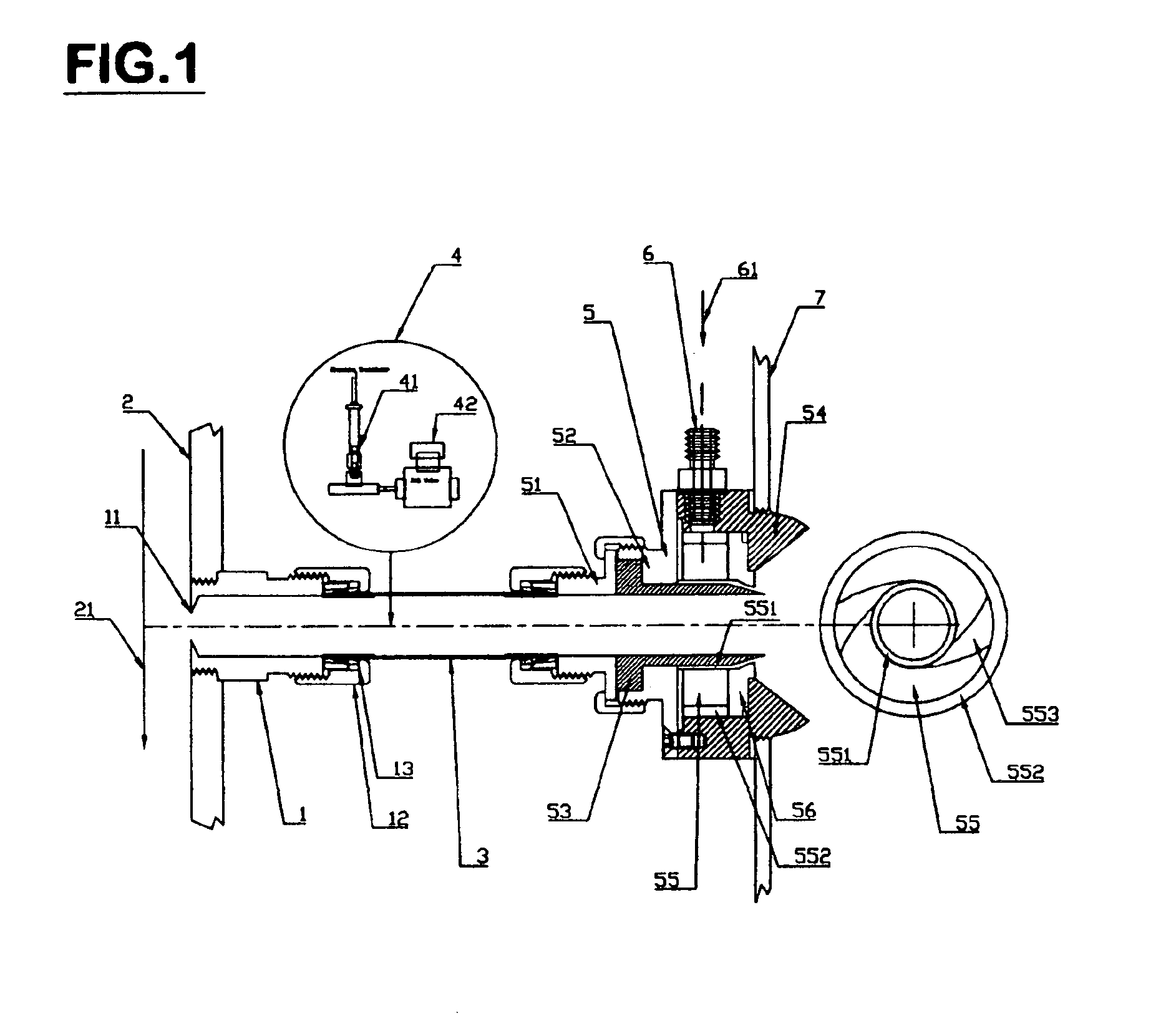

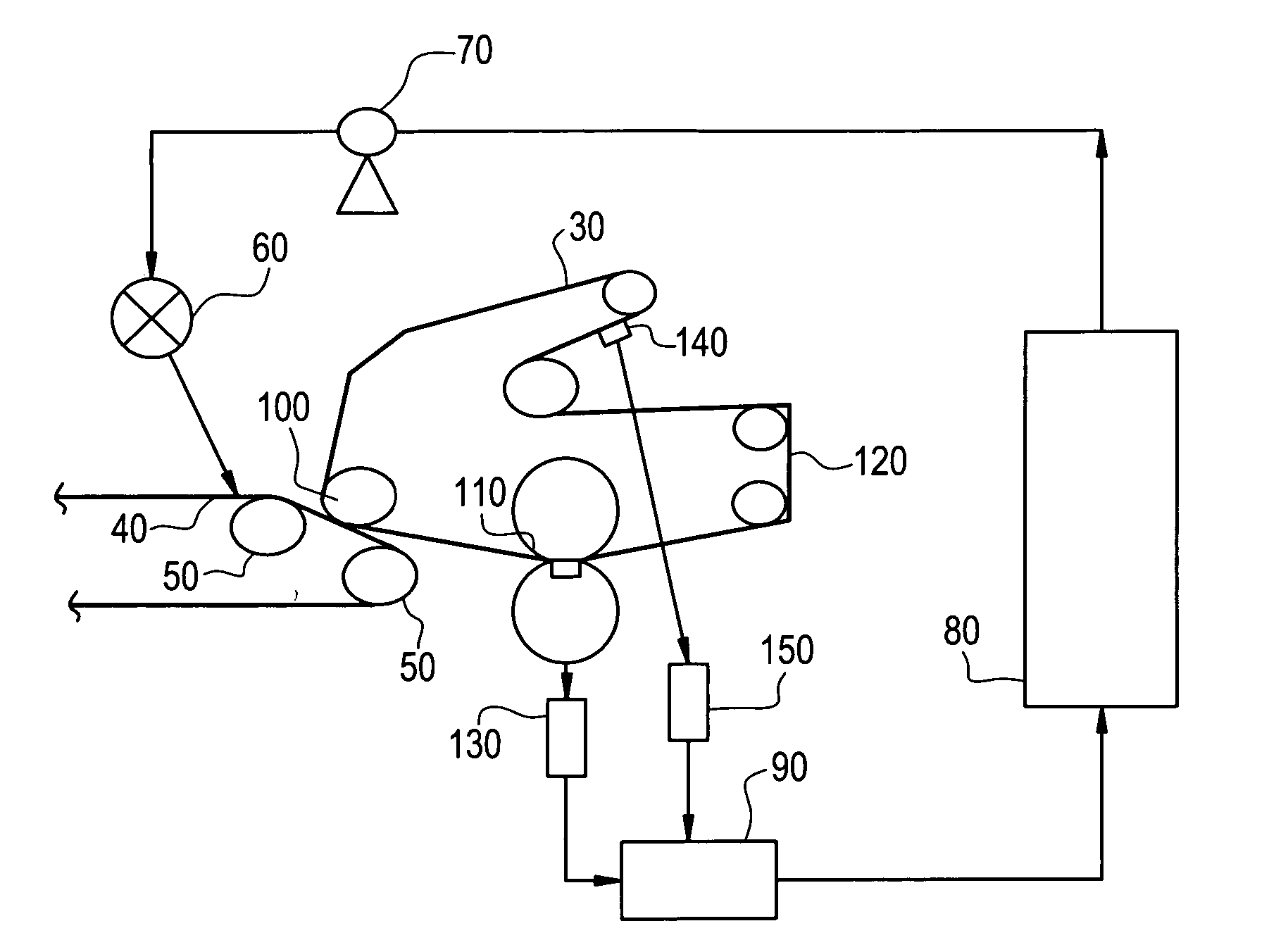

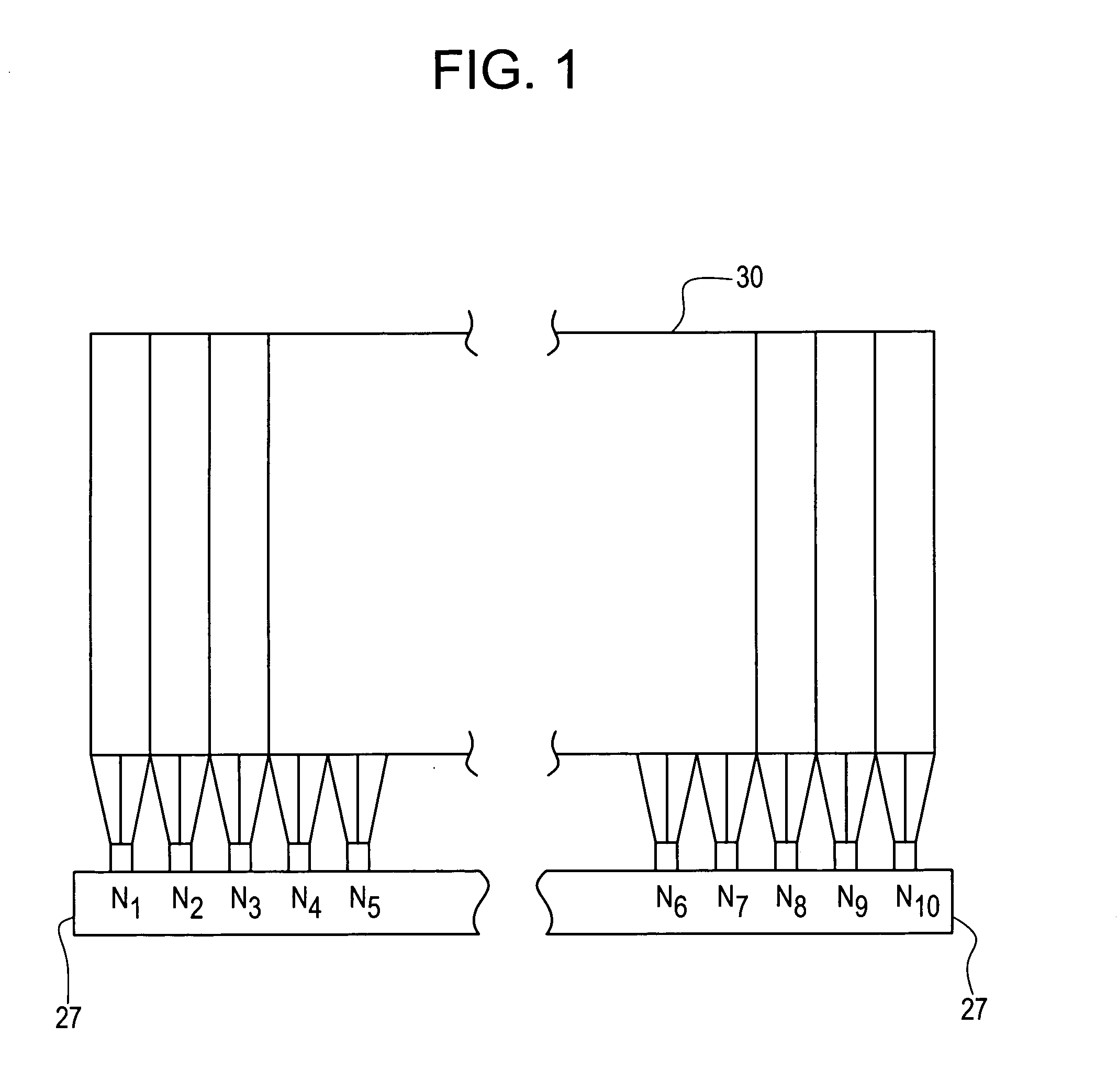

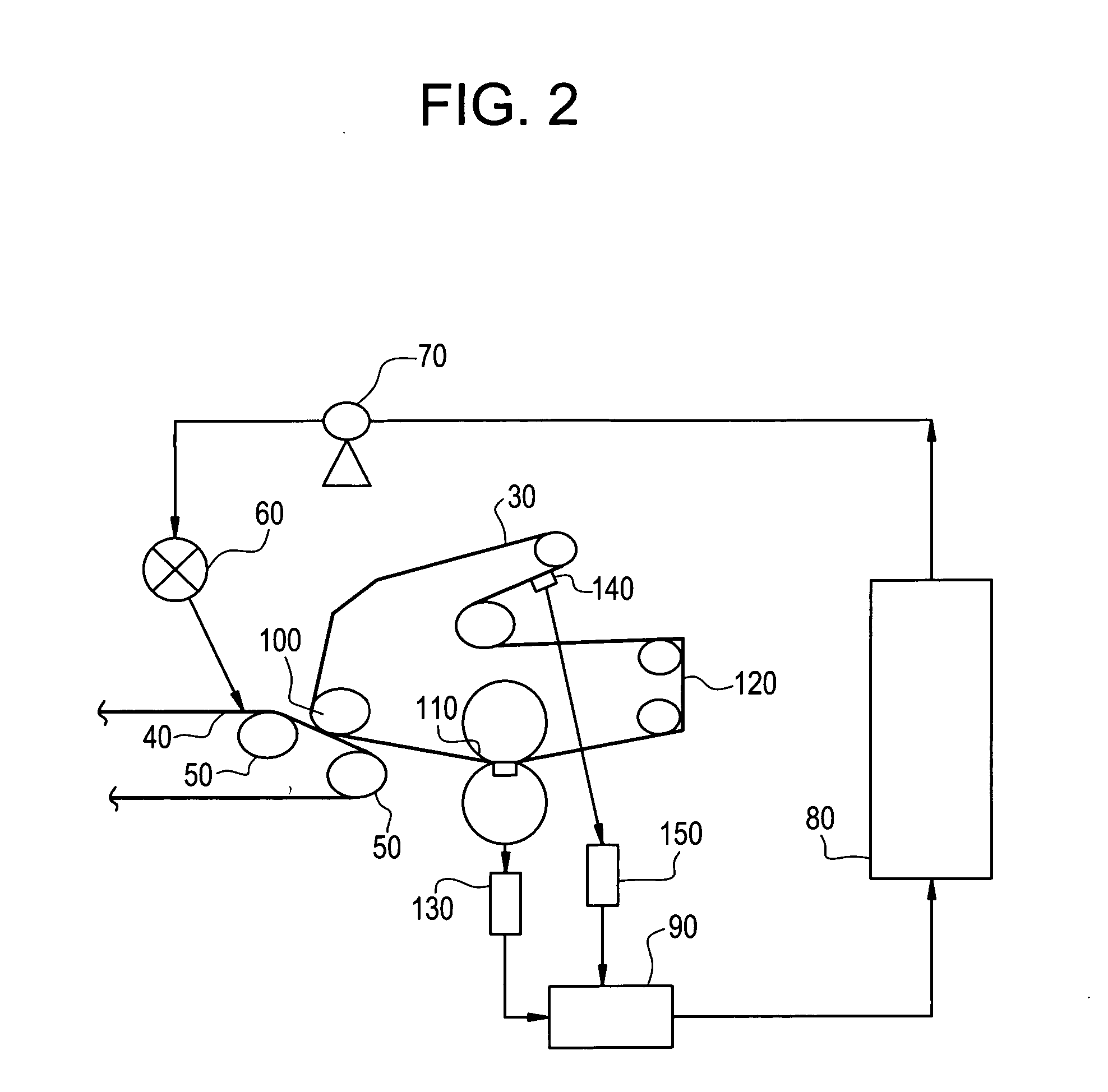

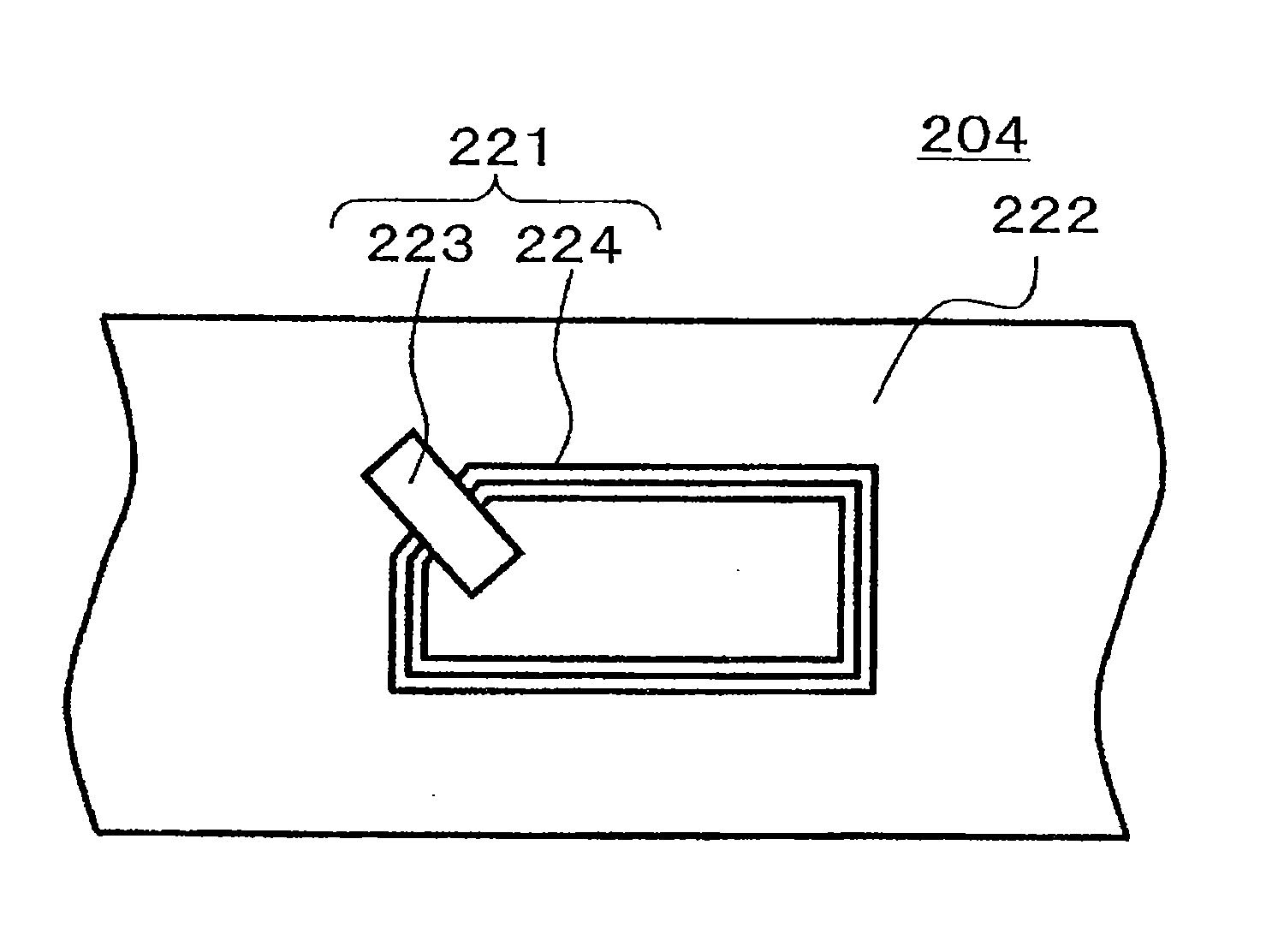

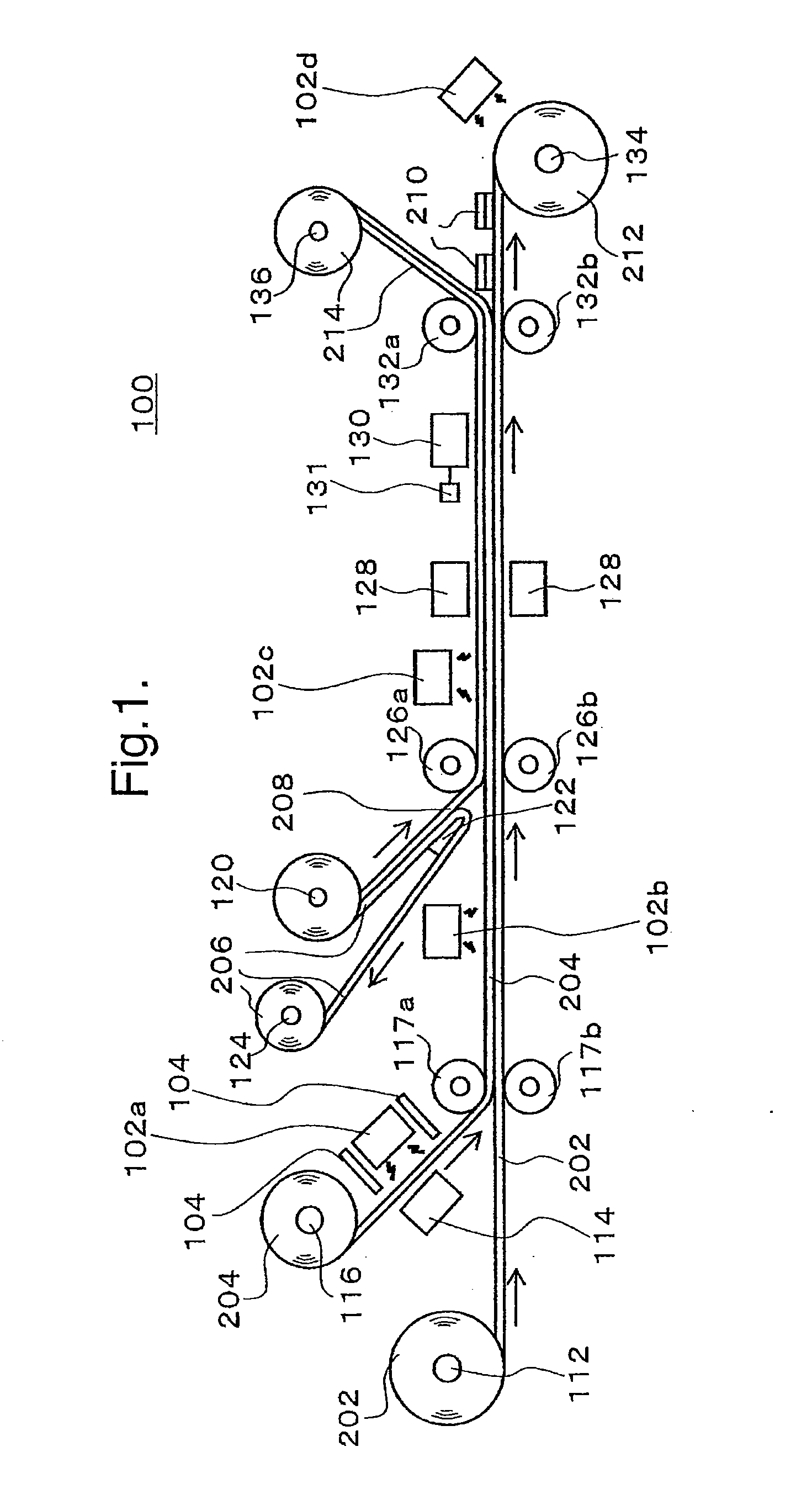

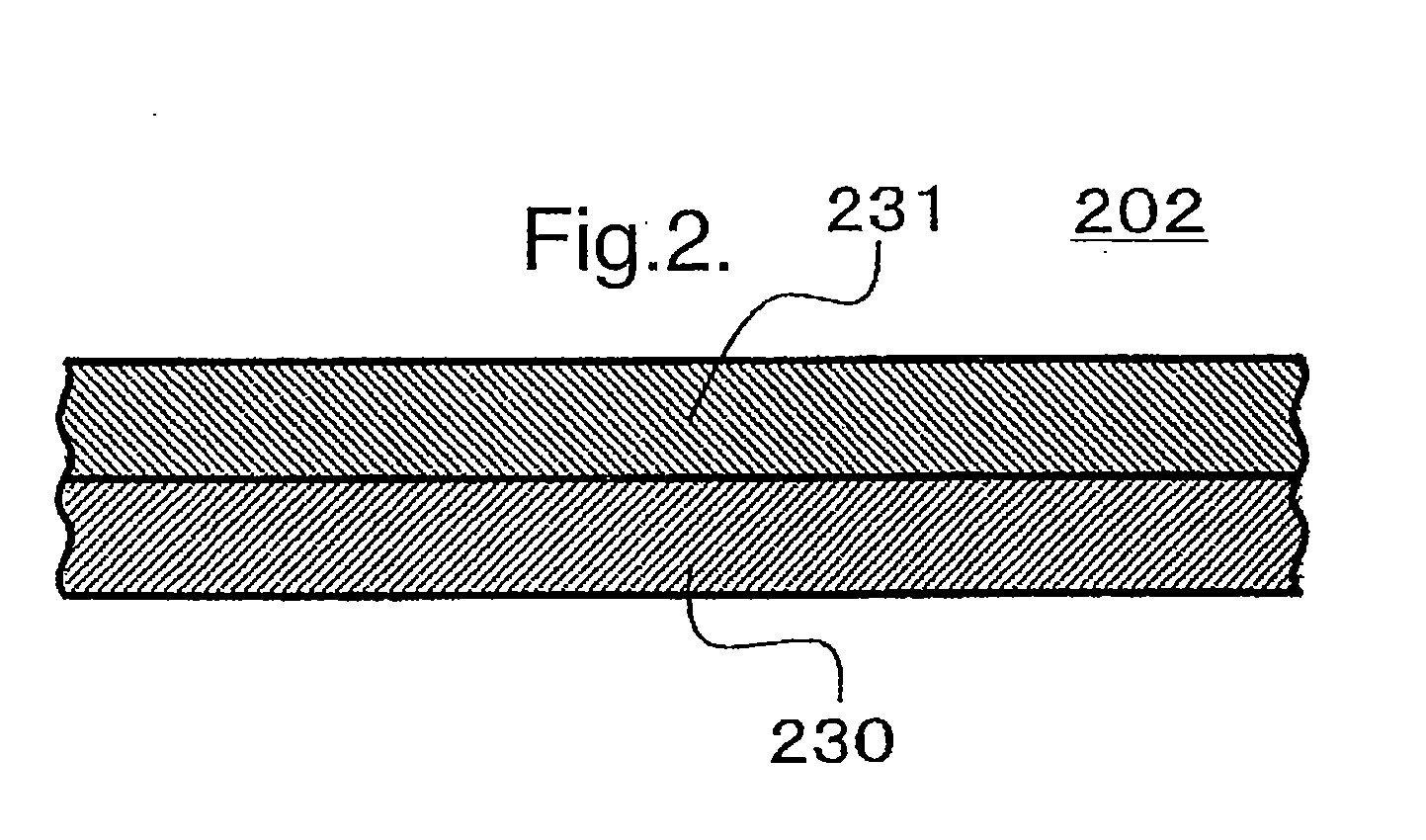

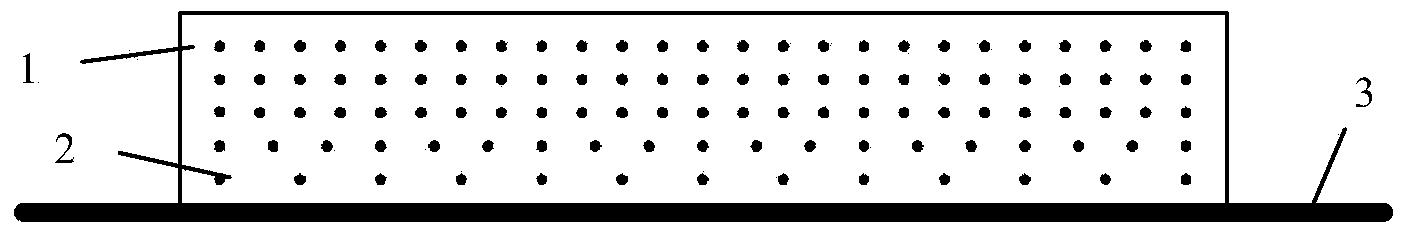

Rfid Paper Manufacturing Apparatus and Inspection Method of Rfid Paper Manufacturing Apparatus

InactiveUS20070216525A1Easy fault locationReduction in size and costCo-operative working arrangementsNear-field in RFIDManufactured apparatusPaper manufacturing

The present invention provides an RFID paper manufacturing apparatus and an inspection method of an RFID paper manufacturing apparatus with which the location of a fault in the apparatus causing a defect in an RFID tag can be specified easily. An RFID label manufacturing apparatus comprises: a reader / writer for performing at least one of reading the information stored in the RFID tag and writing information to the RFID tag; a plurality of antennas disposed in a plurality of predetermined positions on a path along which the RFID tag is conveyed, for transmitting and receiving information to / from the RFID tag; a switching circuit for switching the antenna that is connected to the reader / writer; and a CPU for detecting an error in at least one of the information writing and the information reading performed by the reader / writer via the antenna that is connected to the reader / writer by the switching operation of the switching circuit.

Owner:SATO CO LTD

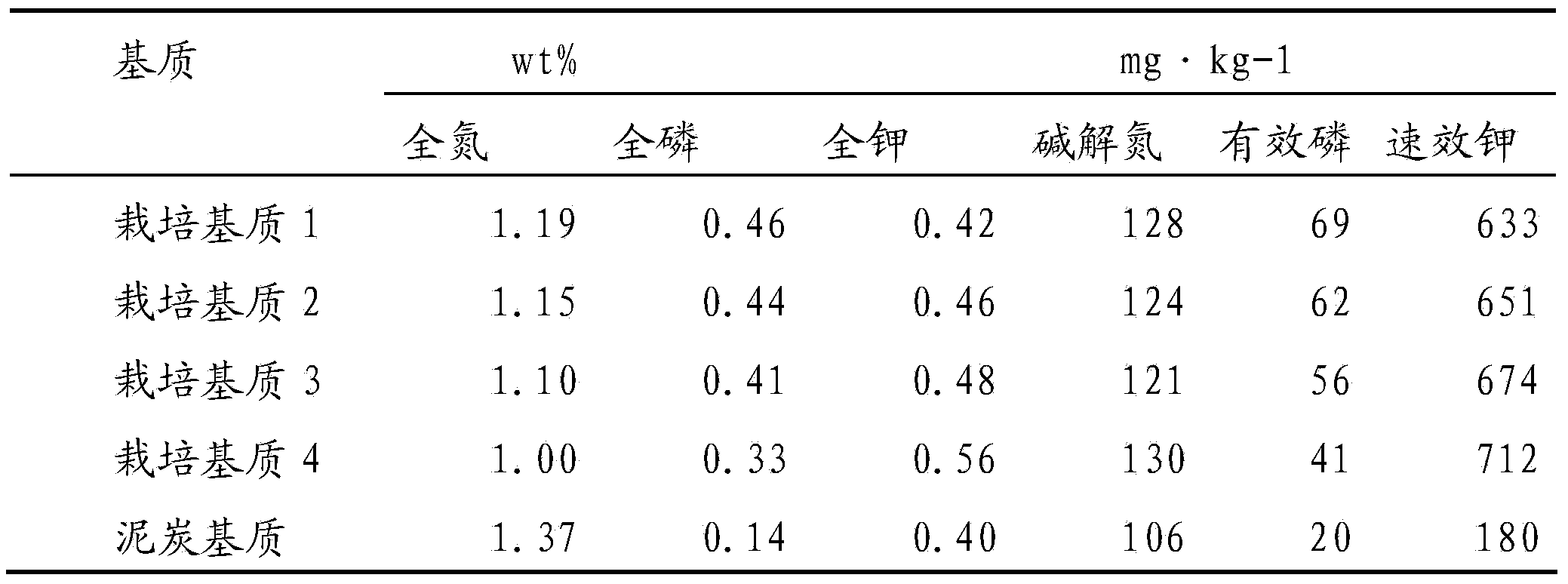

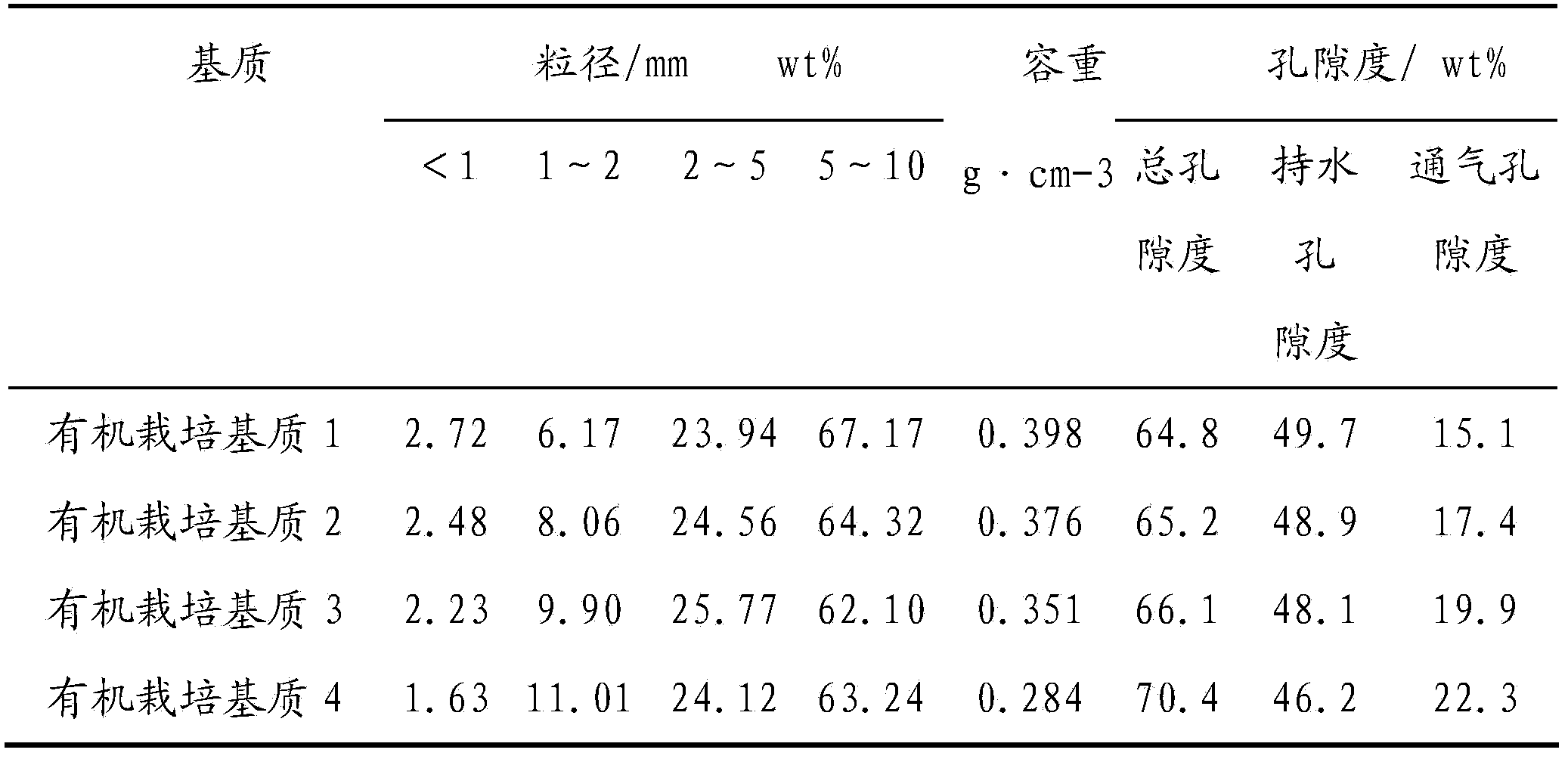

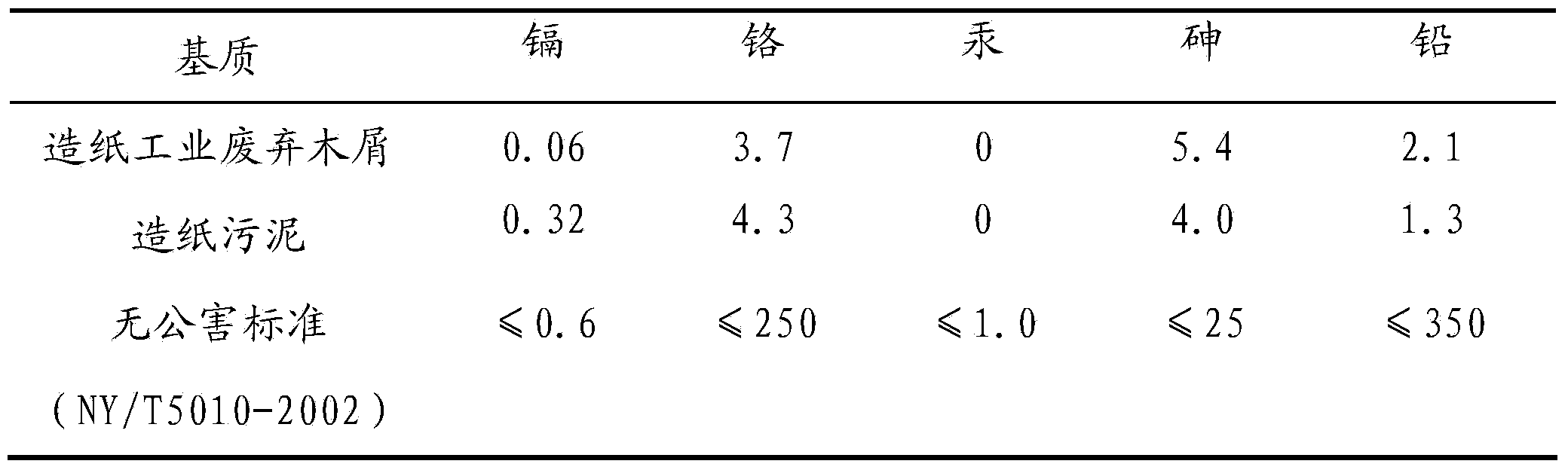

Culture medium and preparation method of culture medium

InactiveCN103392578ARealize resource utilizationWide variety of sourcesAgriculture gas emission reductionCultivating equipmentsResource utilizationPaper manufacturing

The invention discloses a culture medium which is used for cultivating flowers and plants and comprises waste saw dust of paper manufacturing industry, perlite, sand, and paper mill sludge, wherein the waste saw dust, the perlite and the sand are subjected to fermentation treatment; the paper mill sludge is subjected to compost treatment; the volume ratio of the waste saw dust, the perlite, the sand and the paper mill sludge is (1-3):(1-3):(0.5-2):(4-6). According to the invention, solid wastes of the paper manufacturing industry are taken as raw materials to prepare the culture medium, so that resource utilization of the solid wastes of the paper manufacturing industry is realized, the environmental problem of secondary pollution caused by the solid wastes is solved; in addition, the culture medium is excellent in physical and chemical properties, rich and comprehensive in nutrient elements; moreover, the nutrition in the culture medium can be continuously degraded and released for growth and development of crops, so the culture medium can be widely applied to the soilless culture technology of vegetables, flowers and plants.

Owner:郑全来

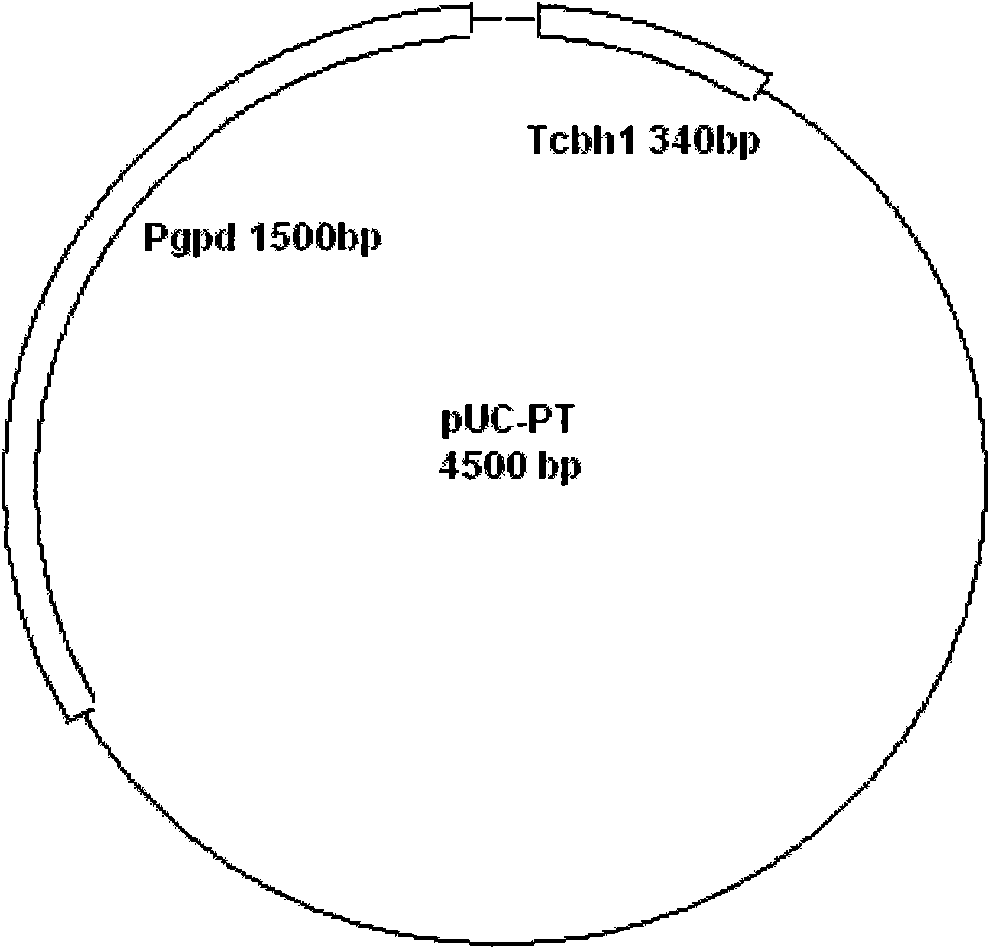

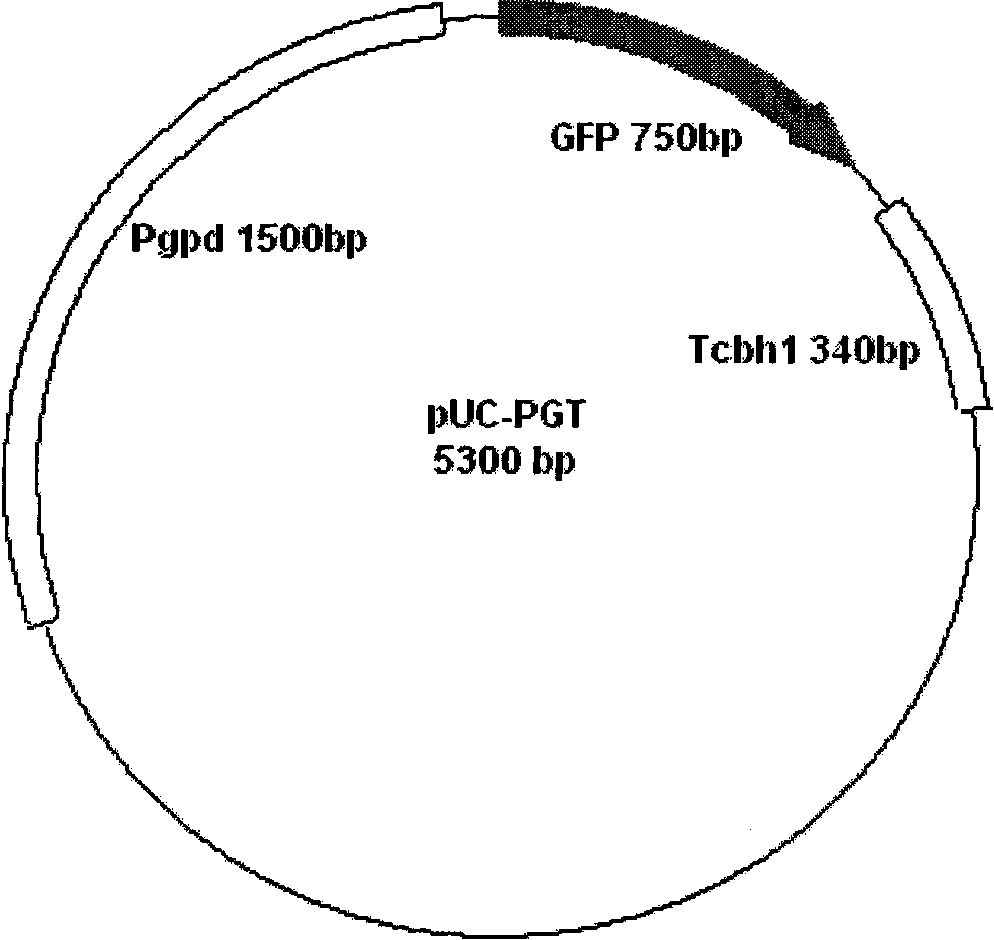

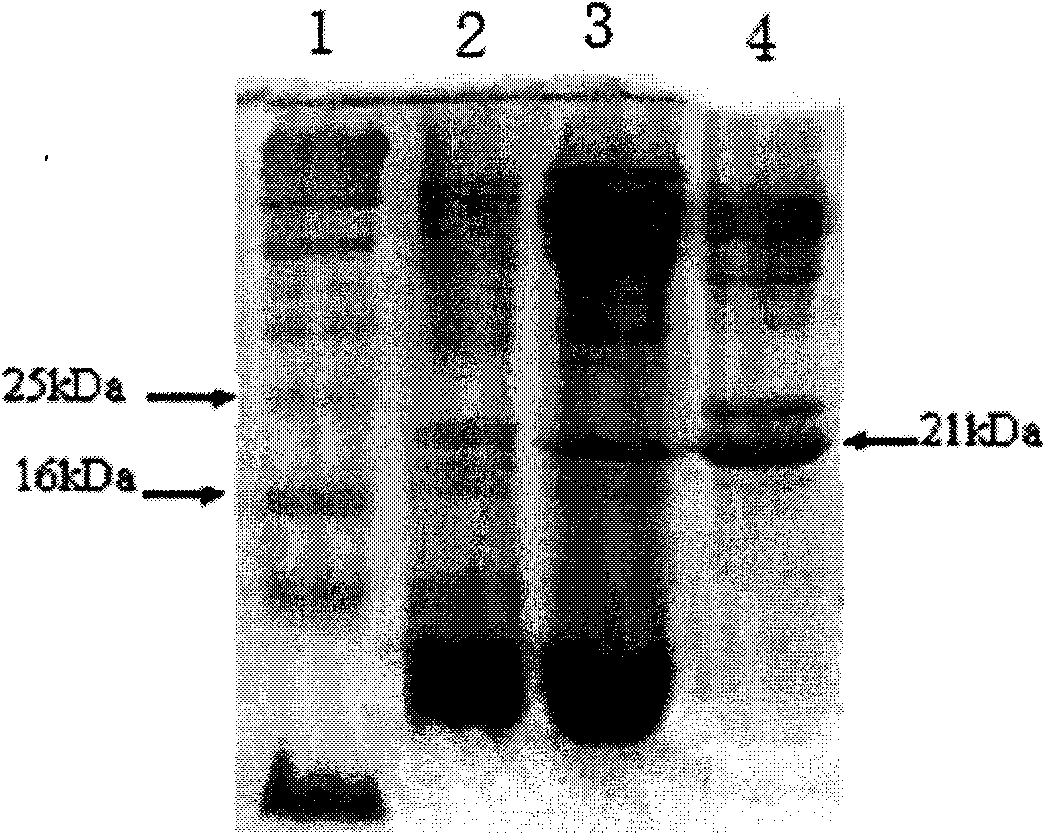

Trichoderma reesei expression cassette, recombinant strain and application thereof

InactiveCN101560513AHigh expressionAvoid it happening againFungiAnimal feeding stuffPaper manufacturingGlyceraldehyde

The invention discloses a Trichoderma reesei expression cassette, a recombinant strain and application thereof. The expression cassette includes Trichoderma reesei glyceraldehyde-3-phosphate dehydrogenase promoter, foreign target genes and Trichoderma reesei CBHI terminator. The expression cassette of the invention adopts the technical scheme that the sequence of the Trichoderma reesei glyceraldehyde-3-phosphate dehydrogenase gene promoter and the sequence of the Trichoderma reesei CBHI terminator form a constitutive promoter, genes of animals, vegetables or epiphyte can be expressed without induction, expression products can be properly modified, the efficient synthesis and exudation capability of the Trichoderma reesei can be utilized for high protein expression, and overmuch foreign proteins can be prevented from being generated in the expression products. The recombinant strain of the invention can efficiently express cellulose-free xylanase which has important using value in the paper manufacturing industry.

Owner:邢苗 +1

Medical crepe paper body paper

ActiveCN103161092AImprove the finishTissue is delicate and softReinforcing agents additionFiberWrinkly skin

The invention belongs to the technical field of special paper manufacturing, and particularly relates to medical crepe paper body paper which is used for protecting a sterilization instrument to carry out sterile storage or conveying in a sterile state. The medical crepe paper body paper is characterized in that cotton pulp and needle-point leaf wood pulp are used as fibrous materials, and a traditional papermaking technology is used for manufacturing the body paper, namely beating, rinsing, pulp rectifying, papermaking, slitting and packaging. The cotton pulp is used as the main raw material, the needle-point leaf wood pulp is used as the auxiliary raw material, the characteristics that cotton fibers are tough in property, fine and smooth and soft in texture, good in folding resistance and abrasion resistance and absorption performance are used, and therefore produced paper is fine and soft and good in smoothness. Polyphenylene oxide polyphenyl ether (PPE) wet strength agents are added in pulp, and the strength, the stiffness, the smoothness and the water resistance of the crepe paper body paper are further improved. The medical crepe paper body paper is soft in hand feel, good in air permeability, high in strength, high in tensile strength, good in smoothness and good in water resistance.

Owner:杭州特种纸业有限公司

Ink composition

An ink composition is provided including an amide compound represented by formula I, a coloring agent and a solvent. The amide compound and the polyhydric alcohol in the ink composition decrease the mobility of coloring agents and increase the adhesion to media, thereby minimizing the bleeding between colors of printed images, and improving the water fastness and dry and wet rub fastness to provide good color fastness on papers. The ink composition also improves the quality of the printed image, and also has good long-term storage stability. Thus, the ink composition can be widely used as ink-jet inks for ink-jet printers, printing inks, paints, textile printing, paper manufacturing, cosmetics manufacturing, ceramic industry, etc.

Owner:S PRINTING SOLUTION CO LTD

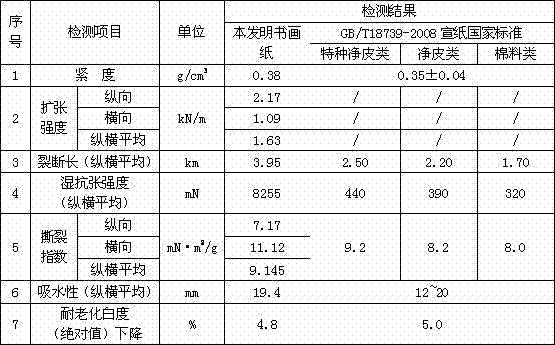

Water-resisting breaking-resisting oxidation-resisting calligraphy and painting paper

InactiveCN102454135AIncrease ink wettingReduce oxidative degradationNon-fibrous pulp additionSpecial paperFiberPaper manufacturing

The invention relates to the field of calligraphy and painting paper manufacturing, and specifically relates to a water-resisting breaking-resisting oxidation-resisting calligraphy and painting paper. The paper is prepared from raw materials and auxiliary materials through a pulping process and a paper making process. The raw materials comprise components of, by weight: 45-80 parts of bamboo pulp fiber, 10-30 parts of grass pulp fiber, 2-25 parts of wool pulp fiber, and 5-25 parts of viscose fiber. Each ton of the paper comprises auxiliary materials of, by weight: 0.5-2% of an antiseptic, and 3-15% of PVA. The calligraphy and painting paper provided by the invention has excellent water resistance, breaking resistance and oxidation resistance. The water-resisting and breaking-resisting functions are 10 times higher than a wet tensile strength index of a GB / T18739-2008 national standard of rice paper.

Owner:FUYANG JINYUAN PAPER

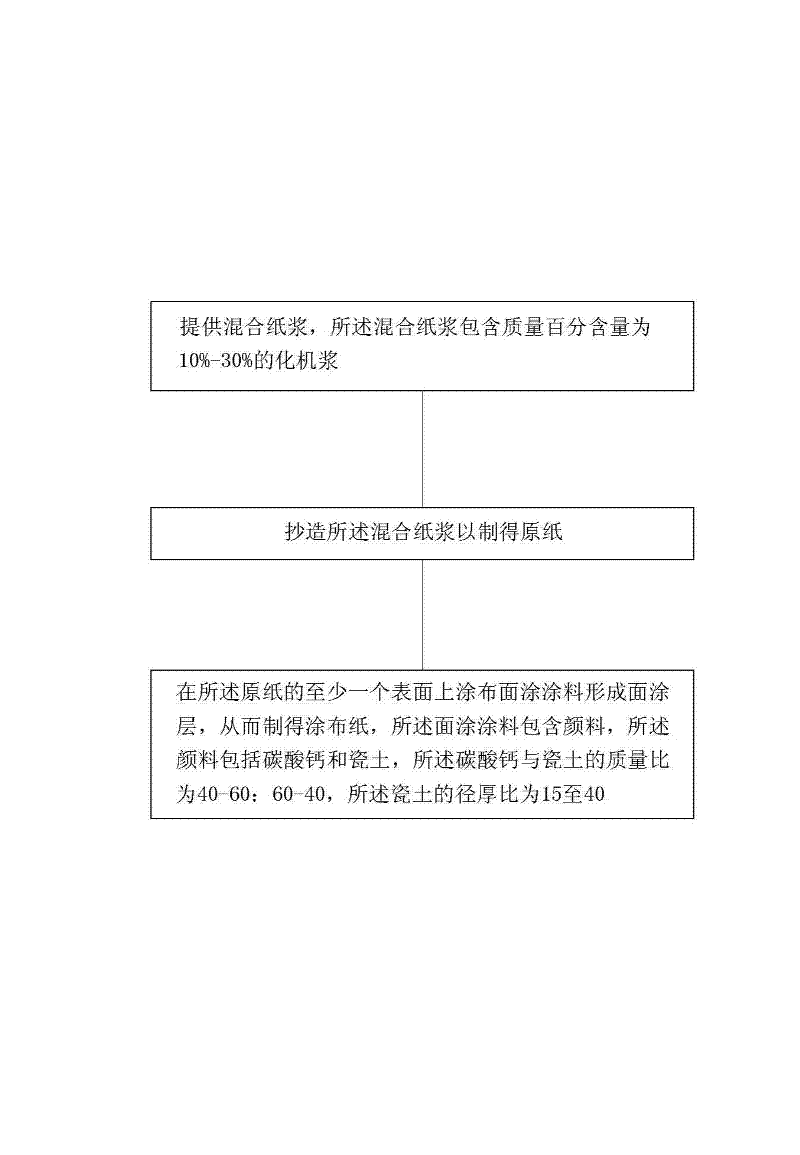

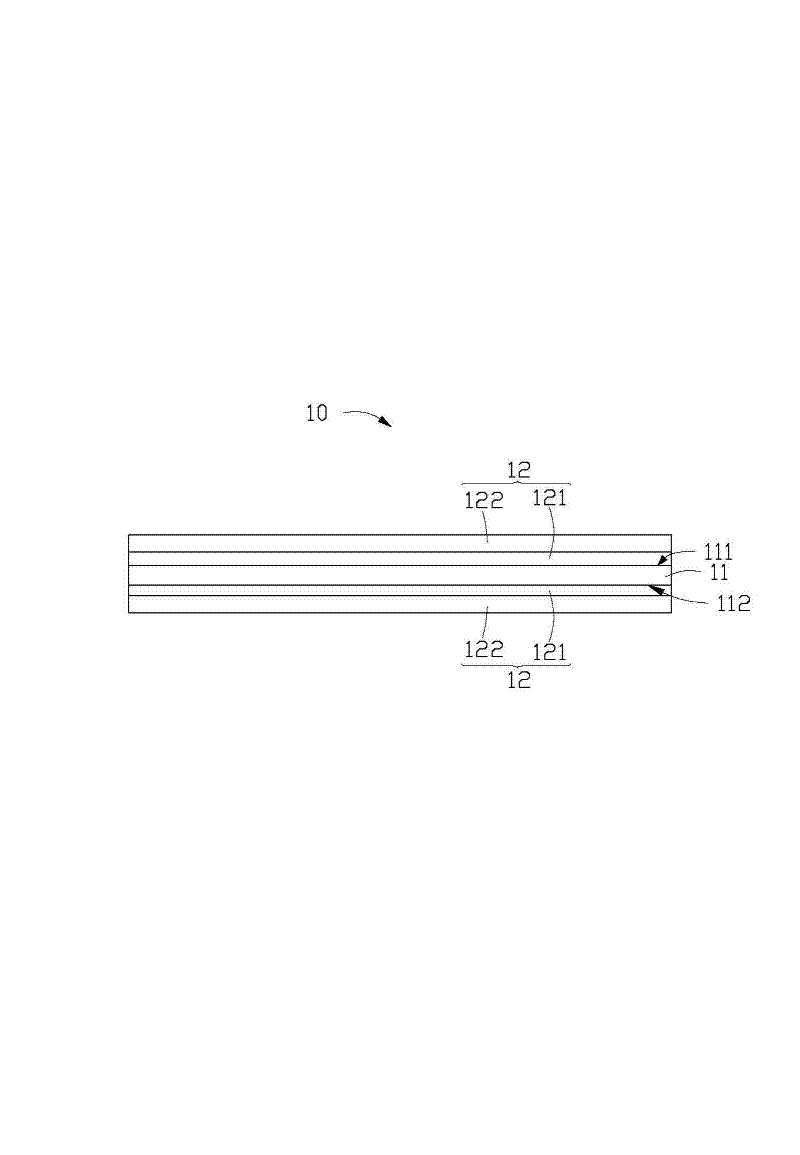

Coated paper and its manufacturing method

ActiveCN102268837AIncrease bulkReduce roughnessPaper coatingCoatingsPaper manufacturingMaterials science

The invention relates to a coating paper manufacturing method, which comprises the following steps of: providing mixed paper pulp which comprises 10 to 30 mass percent of chemical-mechanical pulp; manufacturing the mixed paper pulp to obtain body paper; and coating surface coating on at least one surface of the body paper to form a surface coating layer, and thus obtaining the coating paper, wherein the surface coating comprises paint; the paint comprises calcium carbonate and porcelain clay; the mass ratio of the calcium carbonate to the porcelain clay is (40-60):(60-40); and the radius-thickness ratio of the porcelain clay is 15 to 40. The invention also provides the coating paper manufactured by adopting the method.

Owner:GOLD EAST PAPER JIANGSU

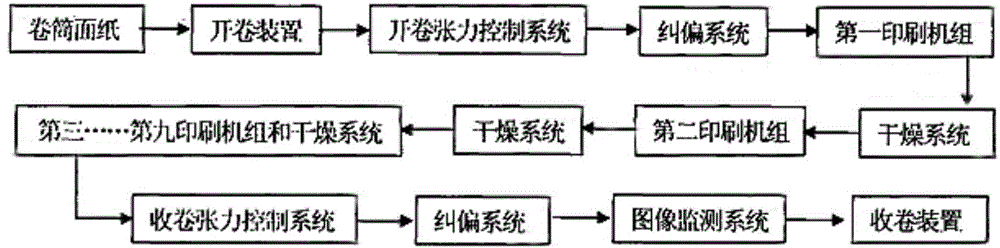

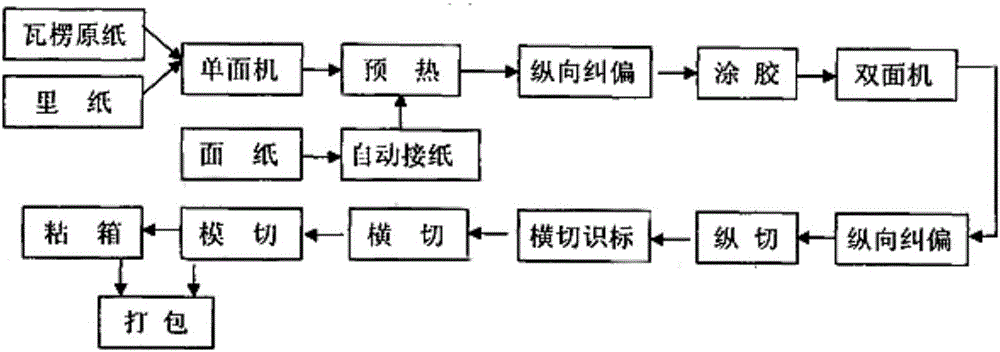

Manufacturing method for flexible preprinted carton

InactiveCN106363962AAdvantages of production methodRich layersMechanical working/deformationBox making operationsWater basedColor printing

The invention discloses a manufacturing method for a flexible preprinted carton. The manufacturing method comprises the flexible printed face paper manufacturing step, the corrugated paperboard manufacturing step, the cutting step, the carton body ground paper forming step and the carton forming step. A pattern layer on face paper on the flexible preprinted carton is formed through flexible printing, water-based ink is used during printing, and toxicity and pollution are avoided; a water-based gloss oil coating is used for replacing a plastic film, and pollution to the environment from the plastic film and film covering glue is eliminated. After the face paper is subjected to flexible printing, the face paper and single-face corrugated paper are combined to form a corrugated paperboard, damage to corrugations from printing is avoided, the edge pressing strength of the corrugated paperboard is improved, and accordingly the crushing resistance of the whole carton is improved; and the product has a high-level color printing effect, and it is ensured that the strength of the corrugated paperboard and the formed carton are not damaged.

Owner:杨茵

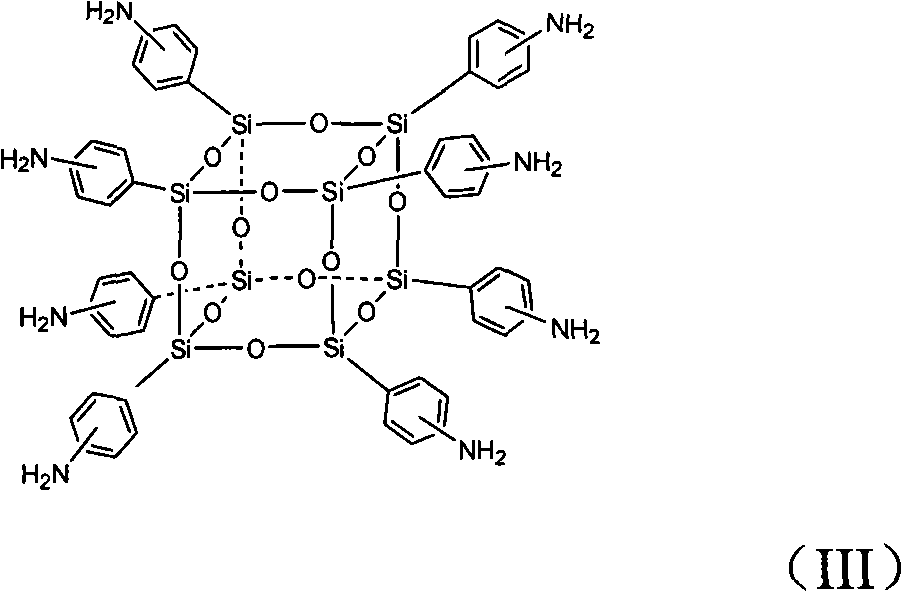

Polyamide/oligomeric silsesquioxane nano-hybrid material and preparation method thereof

The invention discloses a polyamide / oligomeric silsesquioxane nano-hybrid material and a preparation method thereof. The polyamide / oligomeric silsesquioxane nano-hybrid material is in a star-shaped molecular chain structure and has excellent flow properties and good comprehensive properties. In the invention, the problems of incompatibility of flow properties, thermal / mechanical properties and other properties of the existing polyamide are solved, the material and preparation method of the invention can be widely applied to automobiles, electrical equipment, mechanical parts, textile machinery, paper manufacturing machinery and the like, and especially can be applied to the manufacture of large complex thin-walled elements with higher requirements for surface gloss.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Method for reducing difference of two sides of paper, and prepared paper

ActiveCN103966887AReduce double-sidednessUniform compositionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperGlass fiberPaper manufacturing

The invention provides a method for reducing difference of the two sides of paper. The paper is designed to be of a multilayer fiber layer structure; the pulp preparing and beating of each fiber layer are realized independently; a pulp material enters a paper machine with multiple independent flow channels, and is formed in forming areas through simultaneous stacking and paper manufacturing with pulp, wherein the content of fine fibers of which diameters are smaller than 1 micron in the pulp material I entering a flow channel closely adjacent to a forming net is higher than that of fine fibers of pulp material in other layers, and preferably, the content of the fine fibers in the pulp material I is 5-10% higher than that of the fine fibers of the pulp material in other layers. The invention further provides the paper which has low two-side difference, and is prepared by the method, in particular to a glass fiber paper with low two-side difference as well as a coalescent filter element comprising the glass fiber paper with low two-side difference. According to the glass fiber paper with low two-side difference, provided by the invention, the density of fibers in the paper thickness direction is uniform, so that the efficiency and a separation capability of the coalescent filter element can be remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com