Method and technique for preparing Nano type sol of polyaluminium chloride in high purity

A polyaluminum chloride, nano-type technology, applied in aluminum chloride, aluminum halide and other directions, can solve the problems of harsh reaction conditions, low content, increase production cost, etc., and achieve the effects of low cost and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

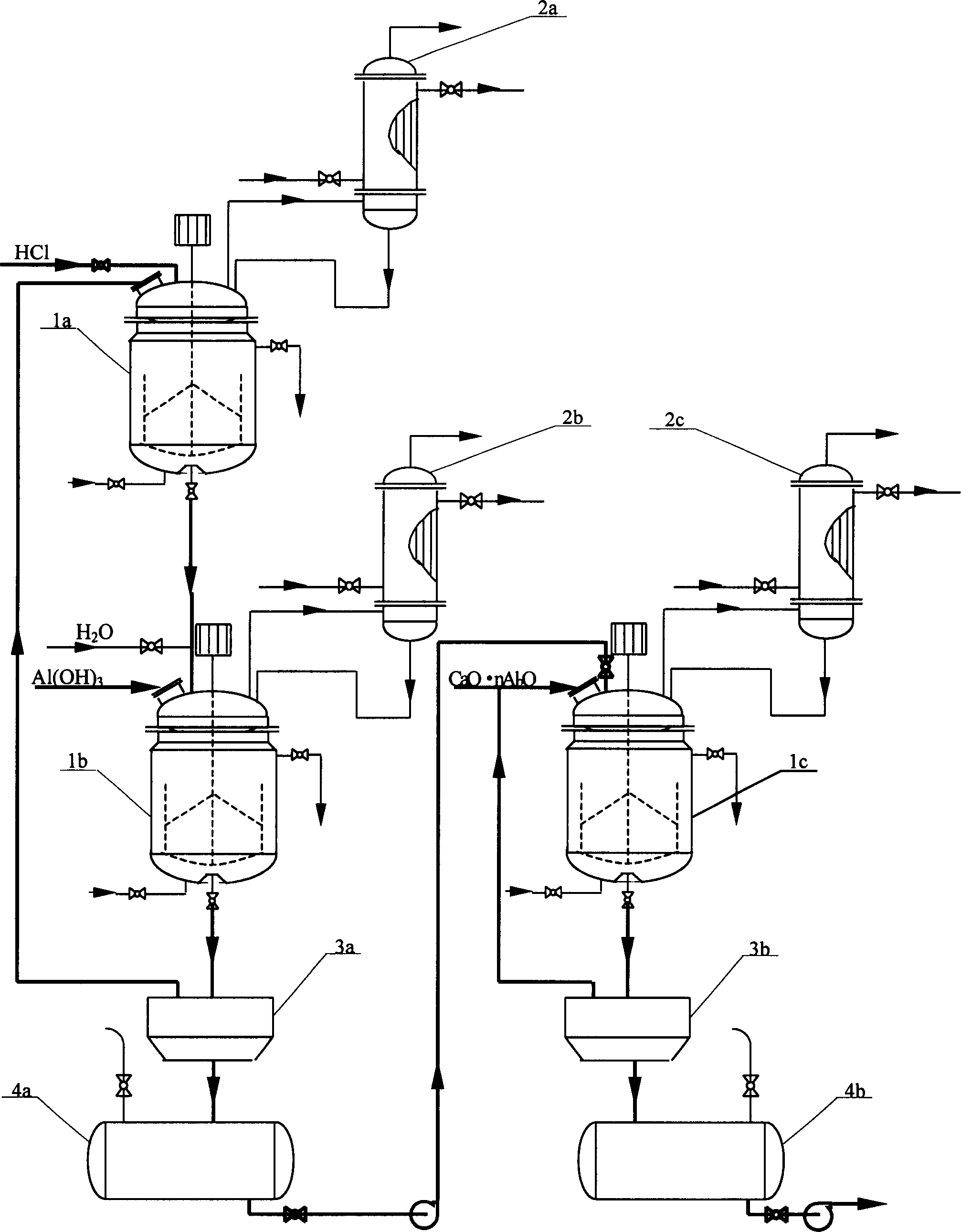

Method used

Image

Examples

example 1

[0030]Add 225L of hydrochloric acid with a concentration of 31% into the second-stage acid-dissolving kettle 1a, and at the same time add 78kg of aluminum hydroxide returned from the filter tank 3a, stir and heat up to 95°C, and react for 2 hours; after the reaction, put the reactants into the first-stage acid-dissolving kettle 1b Add 115kg of active aluminum hydroxide, stir and heat up to 95°C for 1hr, add 445kg of water to adjust the total aluminum concentration of the solution, continue stirring and reacting at 95°C for 1hr, cool down after the reaction, filter in the filter tank 3a, and return the filter residue to the second Section continues to carry out acid-dissolution reaction, makes filtrate 818kg, puts into low alkalization polyaluminum chloride storage tank 4a, and total aluminum concentration is 9.2%, and alkalization is 51.8%; 818kg low alkalization polyaluminum chloride Pump into the alkali adjustment kettle 1c, add 64kg of high-purity calcium aluminate, stir and...

example 2

[0032] Add 365L of hydrochloric acid with a concentration of 20% into the second-stage acid-dissolving kettle 1a, and at the same time add 78kg of aluminum hydroxide returned from the filter tank 3a, stir and heat up to 95°C, and react for 2.5hr; after the reaction is completed, put the reactants into the first-stage acid-dissolving kettle In 1b, add 115kg of active aluminum hydroxide, stir and heat up to 90°C for 1.5hr, add 330kg of water to adjust the solution to the required total aluminum concentration, continue stirring and reacting at 90°C for 1hr, cool down after the reaction, and filter in the filter tank 3a , the filter residue returns to the second section to continue the acid-dissolving reaction, and 843kg of filtrate is obtained, which is put into the low alkalization polyaluminum chloride storage tank 4a, the total aluminum concentration is 8.6%, and the alkalization is 52.6%; the 843kg low alkalization Pump the polyaluminum chloride into the alkali adjustment kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com