Manufacturing method for flexible preprinted carton

A production method and carton technology, which is applied in box production operations, rigid/semi-rigid container production, papermaking, etc., can solve the problem of difficulty in meeting customer cost and increasingly higher requirements for printing and packaging quality, aggravating environmental pollution and recycling Difficulties, human body, packaged goods, environmental pollution and other problems, to achieve the effect of bright colors, stable and reliable printing quality, and rich layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

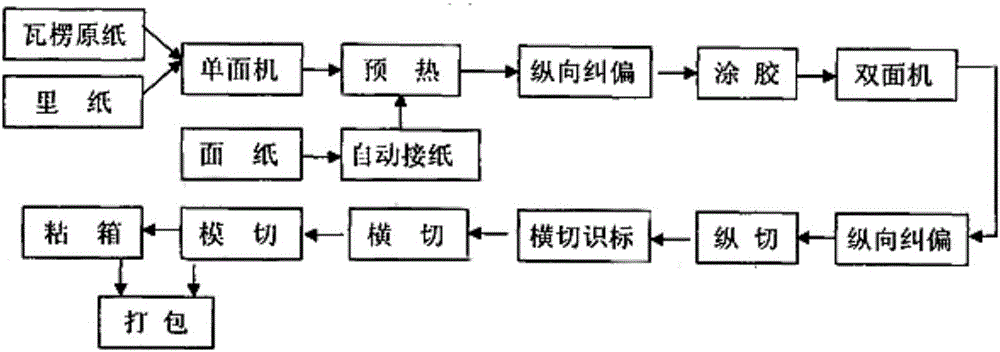

[0036] refer to figure 1 and figure 2 , a method for making a flexo pre-printed carton, comprising the following steps:

[0037] 1) Making flexographic facial paper: Use a flexo printing machine to print patterns on the roll facial paper to be pre-printed to form a flexographic facial paper with a good flexographic pattern.

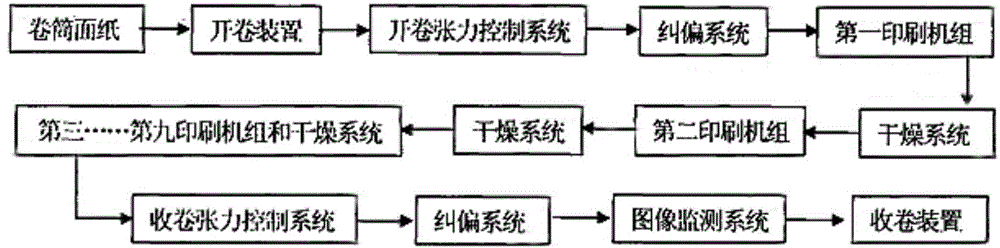

[0038] Such as figure 1 As shown, the flexo printing process is as follows: place the roll of facial paper to be pre-printed on the paper release shaft of the unwinding device of the flexo printing machine, and the beginning of the roll of facial paper passes through various printing and drying systems, and then is placed on the flexo printing machine. On the shaft tube, the shaft tube is placed on the winding shaft of the flexo printing machine winding device:

[0039] The roll surface pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com