Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

170results about How to "Low extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

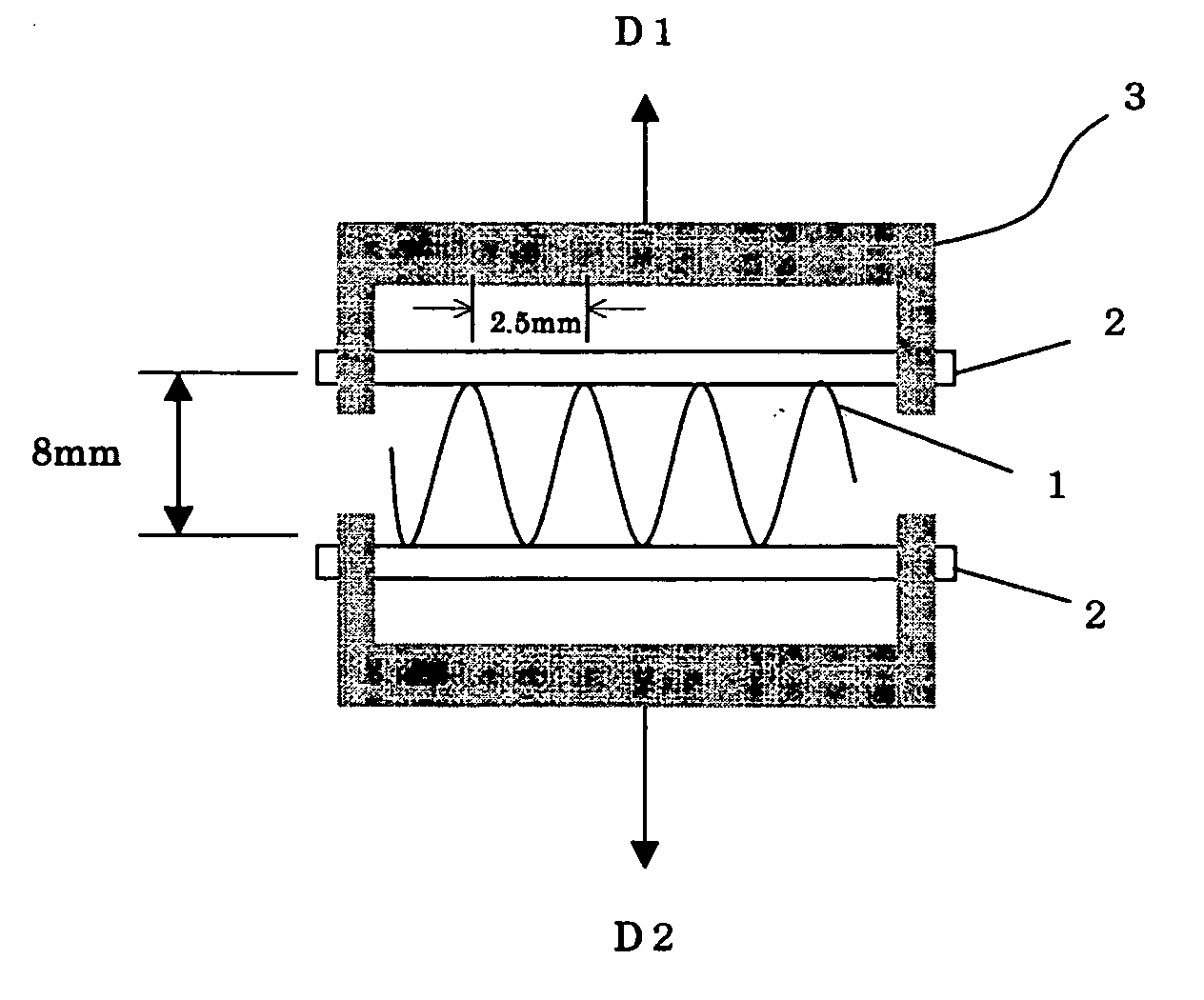

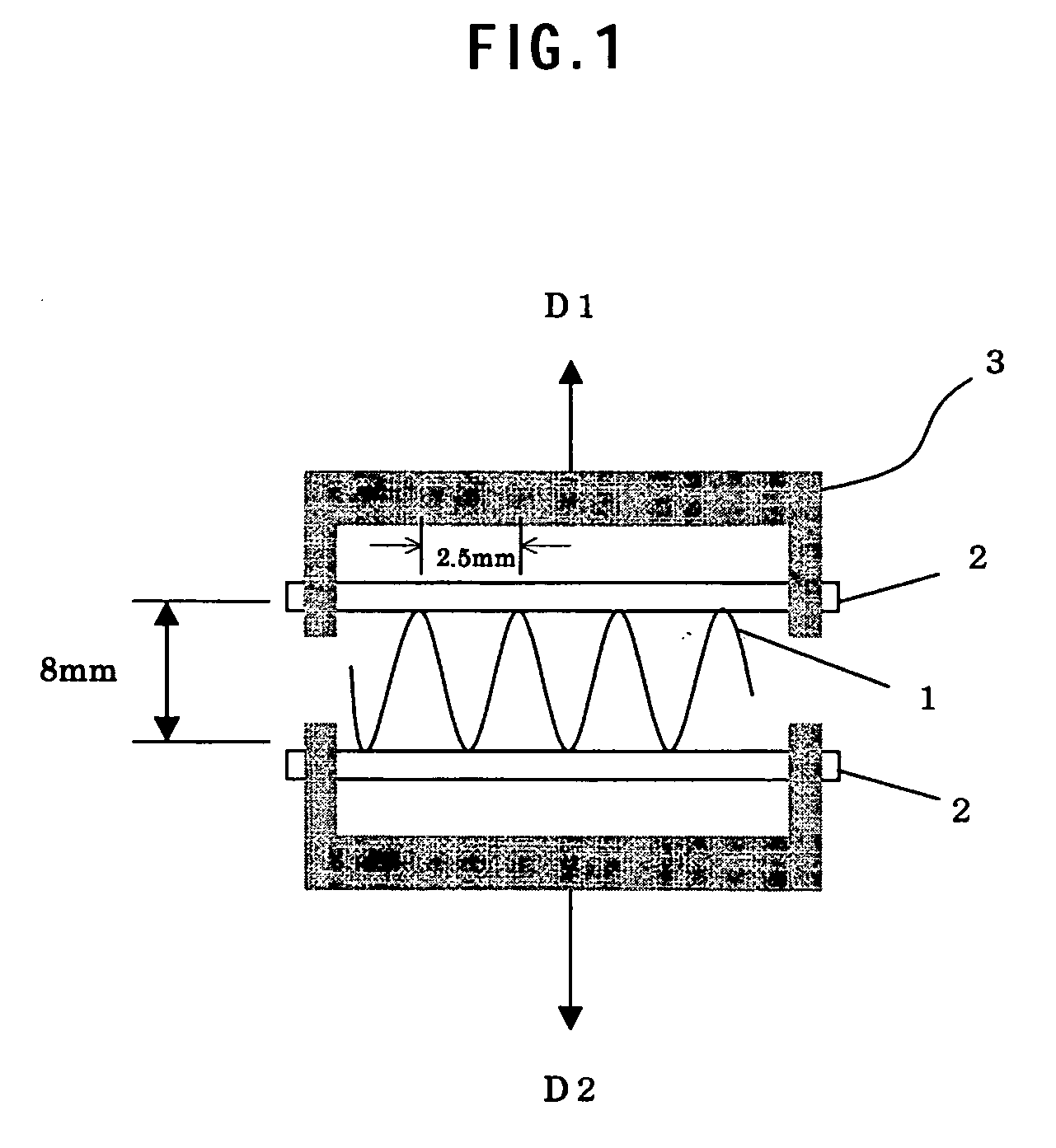

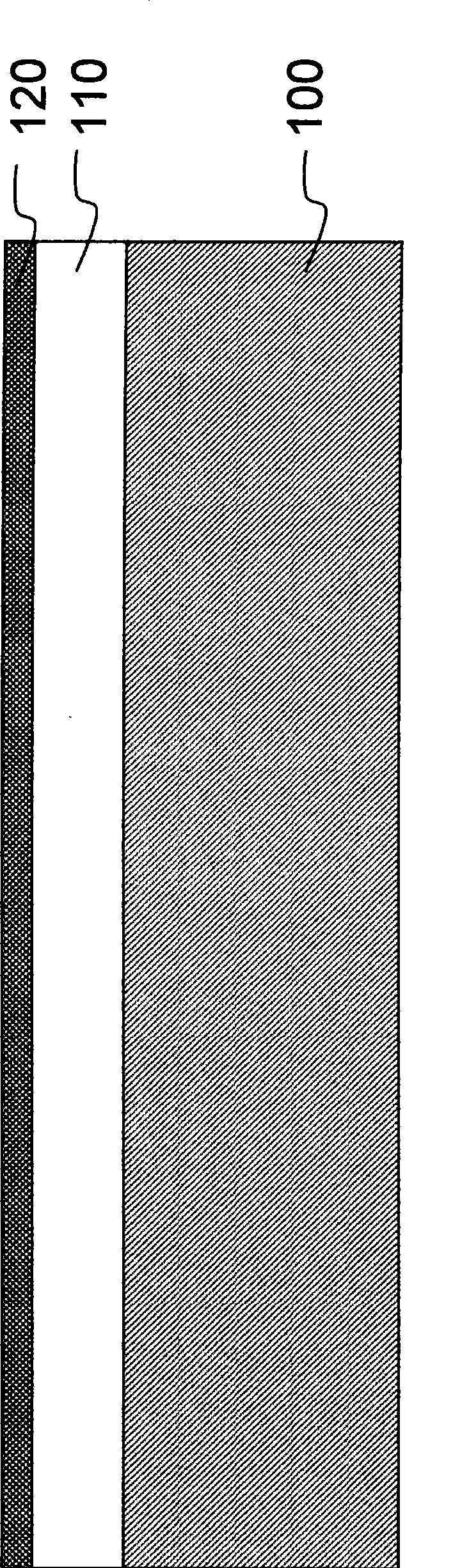

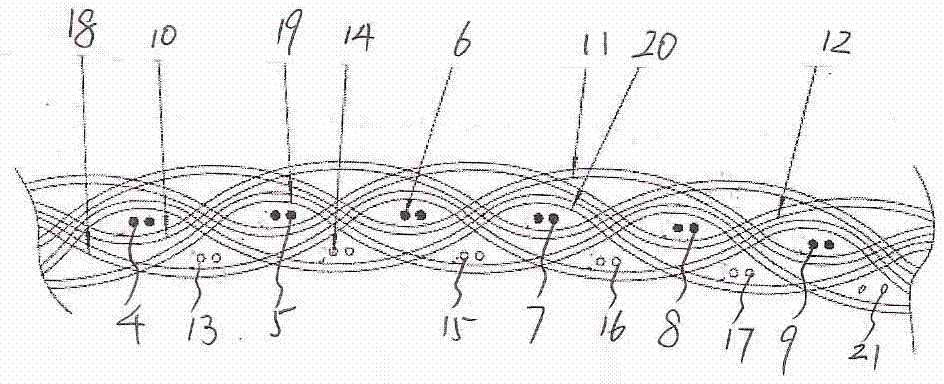

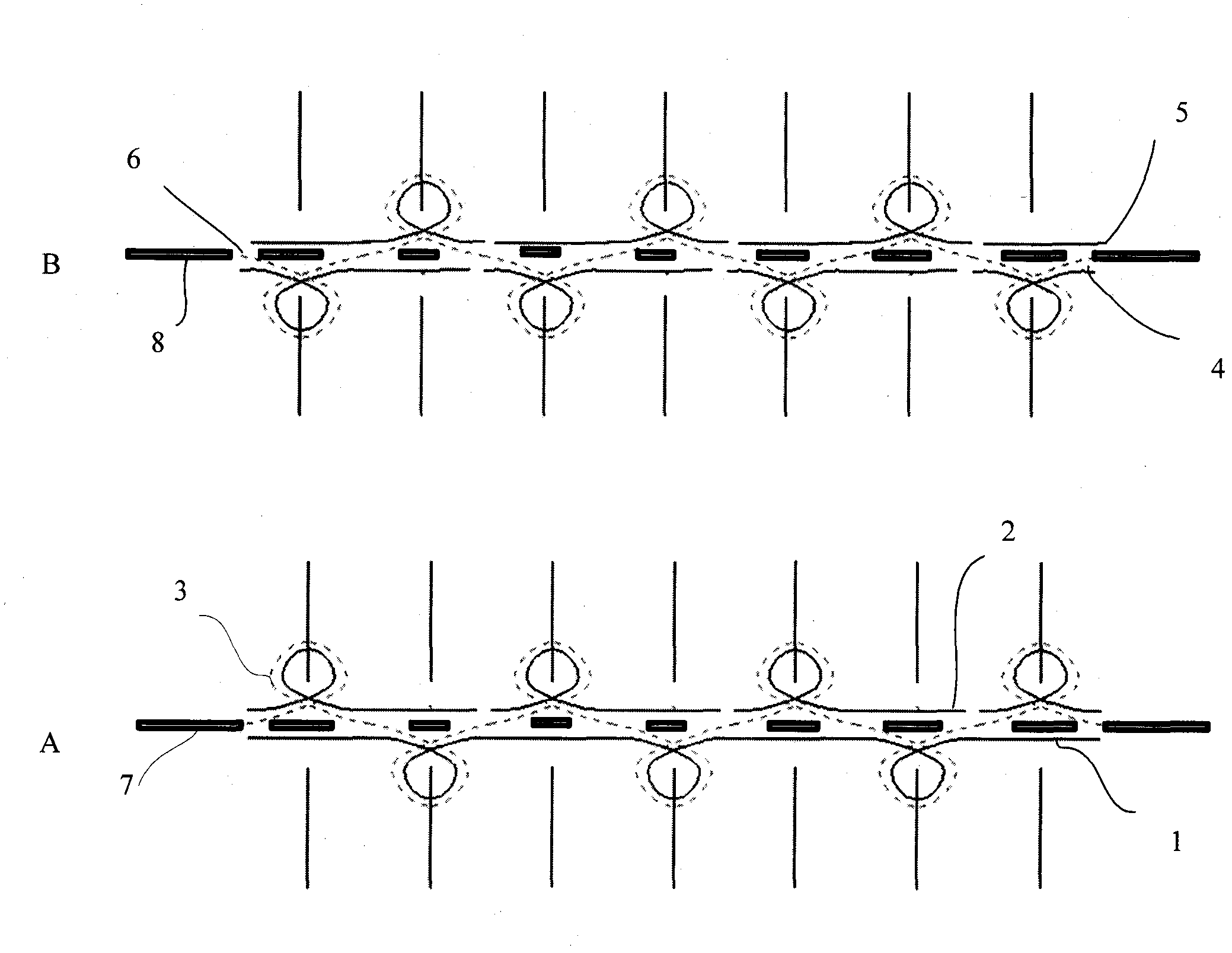

Differentially-stretched elastic laminate

InactiveUS20070141311A1Low extensionImprove hysteresisLaminationLamination apparatusEngineeringStress relaxation

An elastic material that lowers extension tension over a given range without a significant impact on the retractive tension or stress relaxation. The elastic laminate includes a first set of elastic members attached to one or more substrates while the elastic members are stretched, and a second set of elastic members or an elastic film attached to the one or more substrates while the elastic members or film are stretched to a different extent than the first set of elastic members. Both the substrate(s) and one of the sets of elastic members or film are gathered when the other set of elastic members or film is relaxed. Also included is a method of making the differentially-stretched elastic laminate.

Owner:KIMBERLY-CLARK WORLDWIDE INC

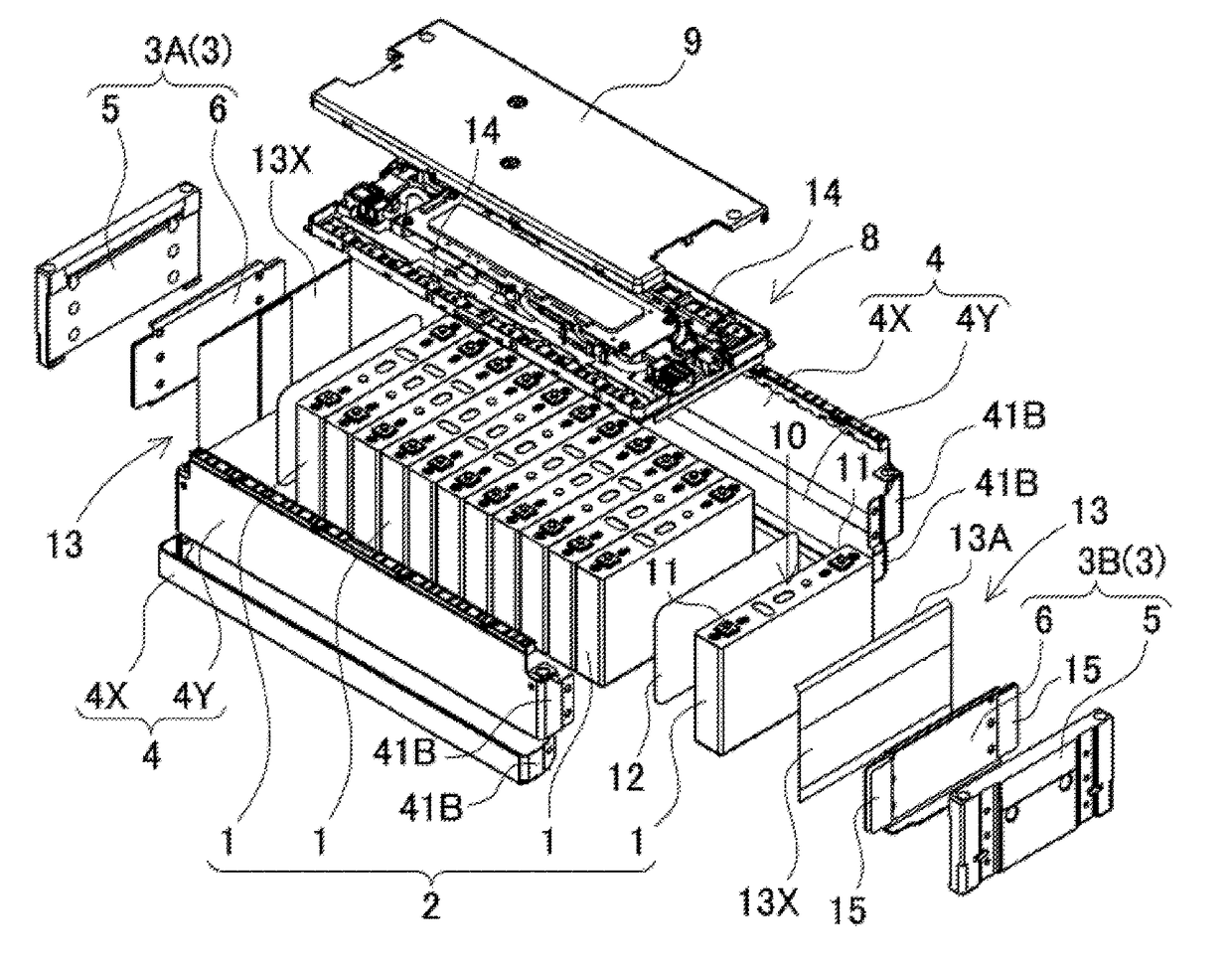

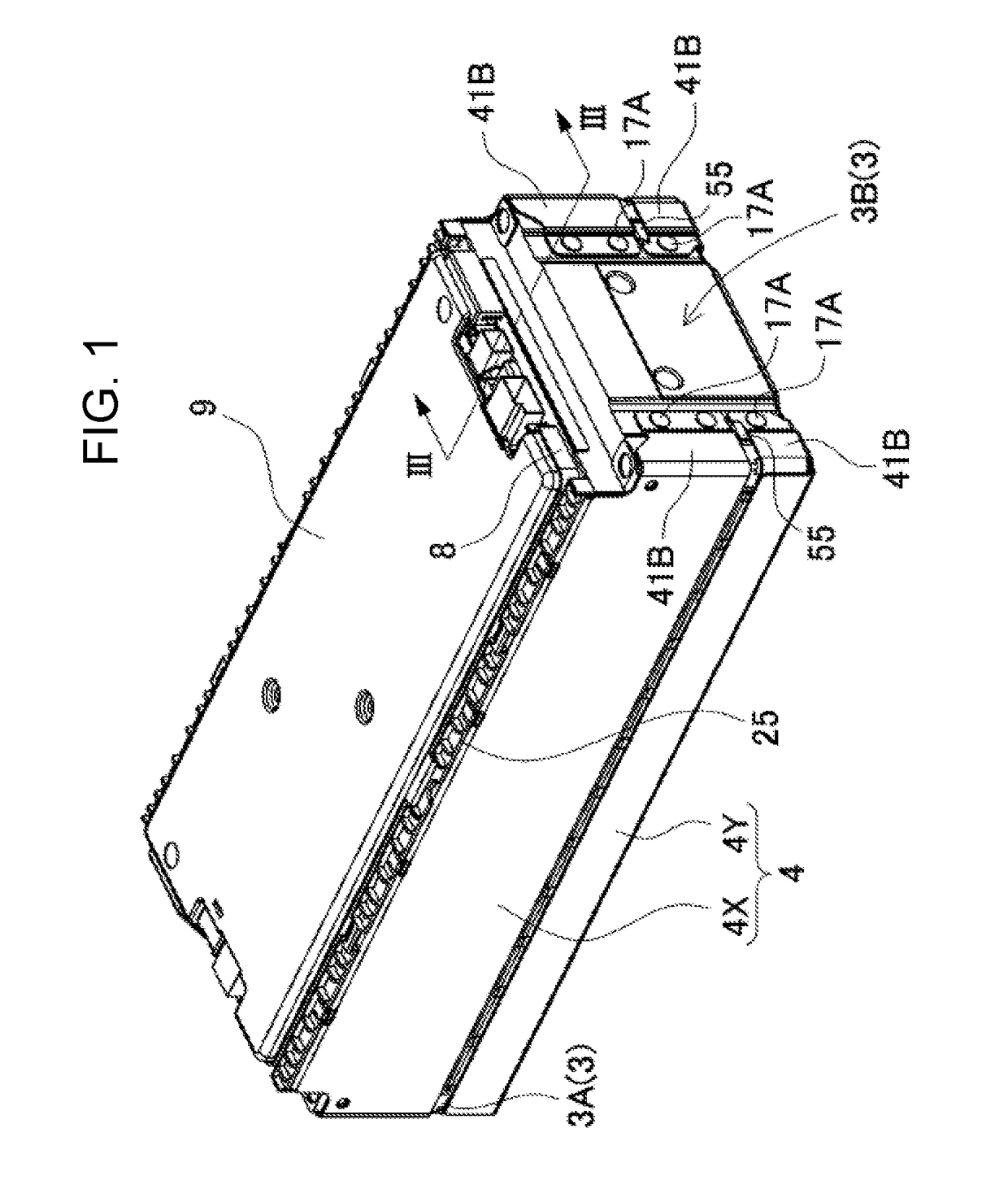

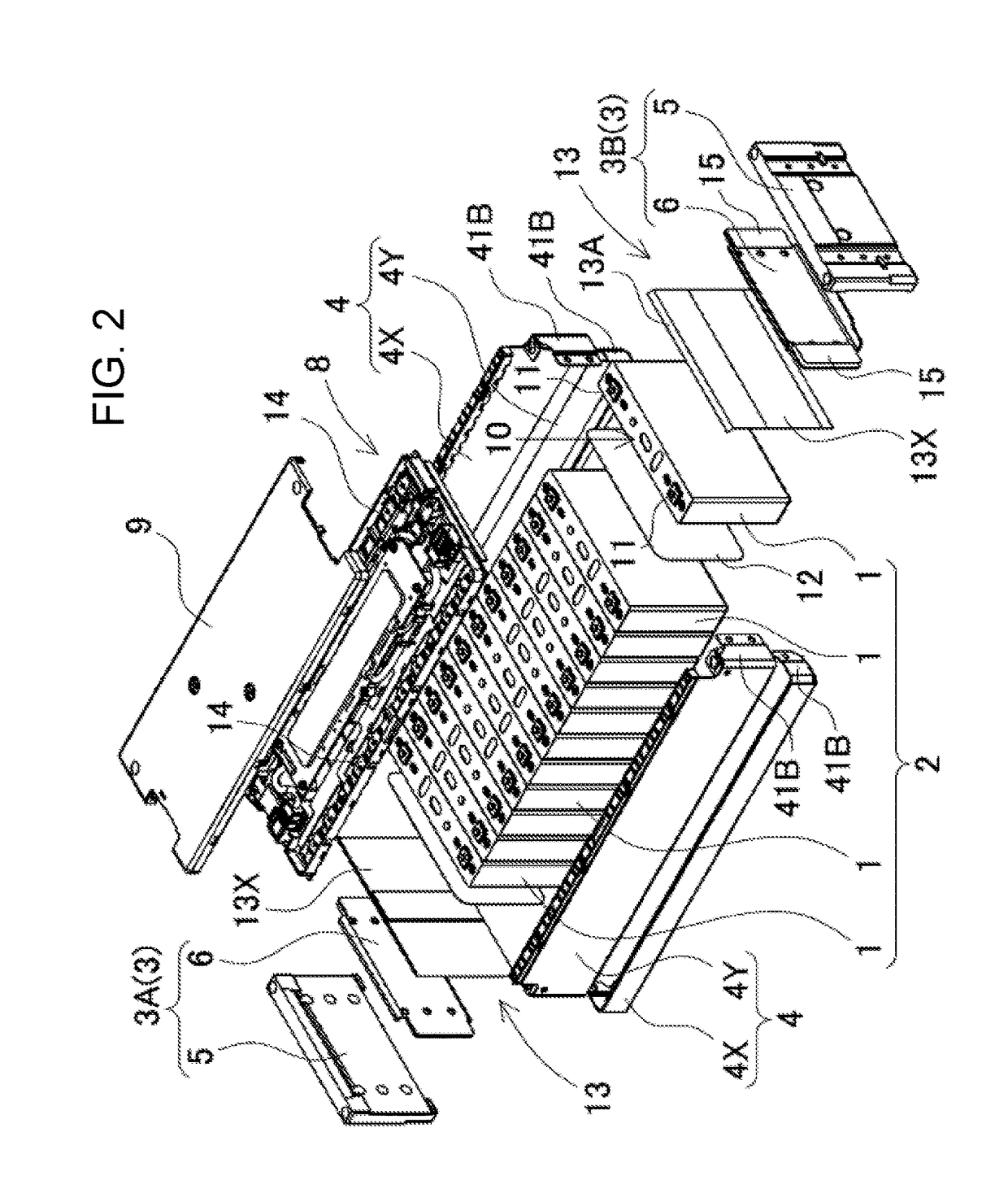

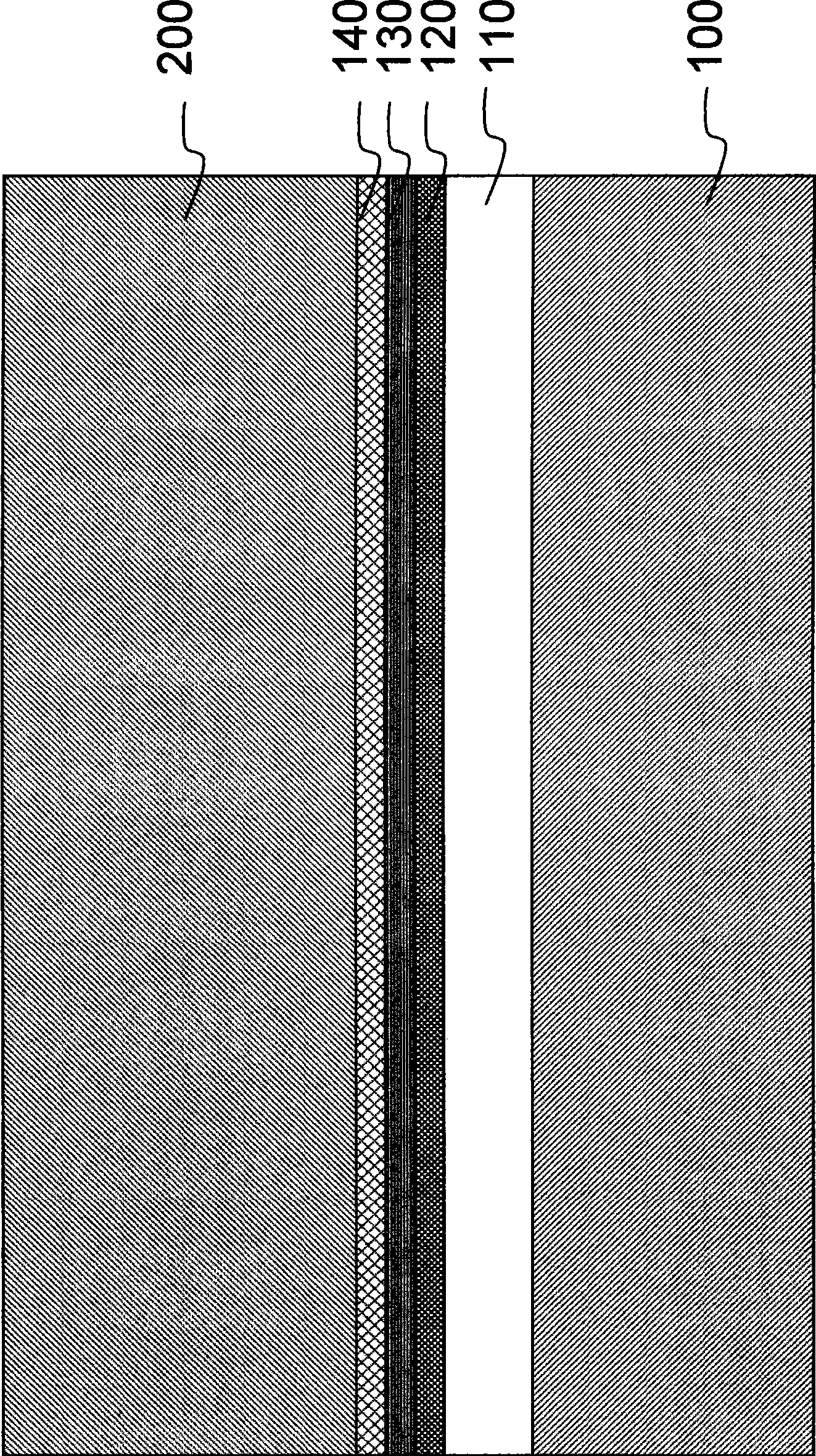

Battery pack and vehicle equipped with same

ActiveUS20170352850A1Improve rigidityImprove bending strengthCell component detailsBatteriesSpecific gravityMetallic materials

A battery pack including a lightweight and high-rigidity end plate is provided. The battery pack includes: cell stacked body including a plurality of stacked rectangular cells; first end plate disposed at one end of cell stacked body in the stacking direction of rectangular cells; second end plate disposed at the other end of cell stacked body; and connection member connected to first end plate and second end plate. At least one of first end plate and second end plate includes first member made of a first metal material and second member made of a second metal material different from the first metal material. First member and second member are stacked in the stacking direction of rectangular cells. The rigidity of the second metal material is higher than that of the first metal material. The specific gravity of the first metal material is lower than that of the second metal material.

Owner:SANYO ELECTRIC CO LTD

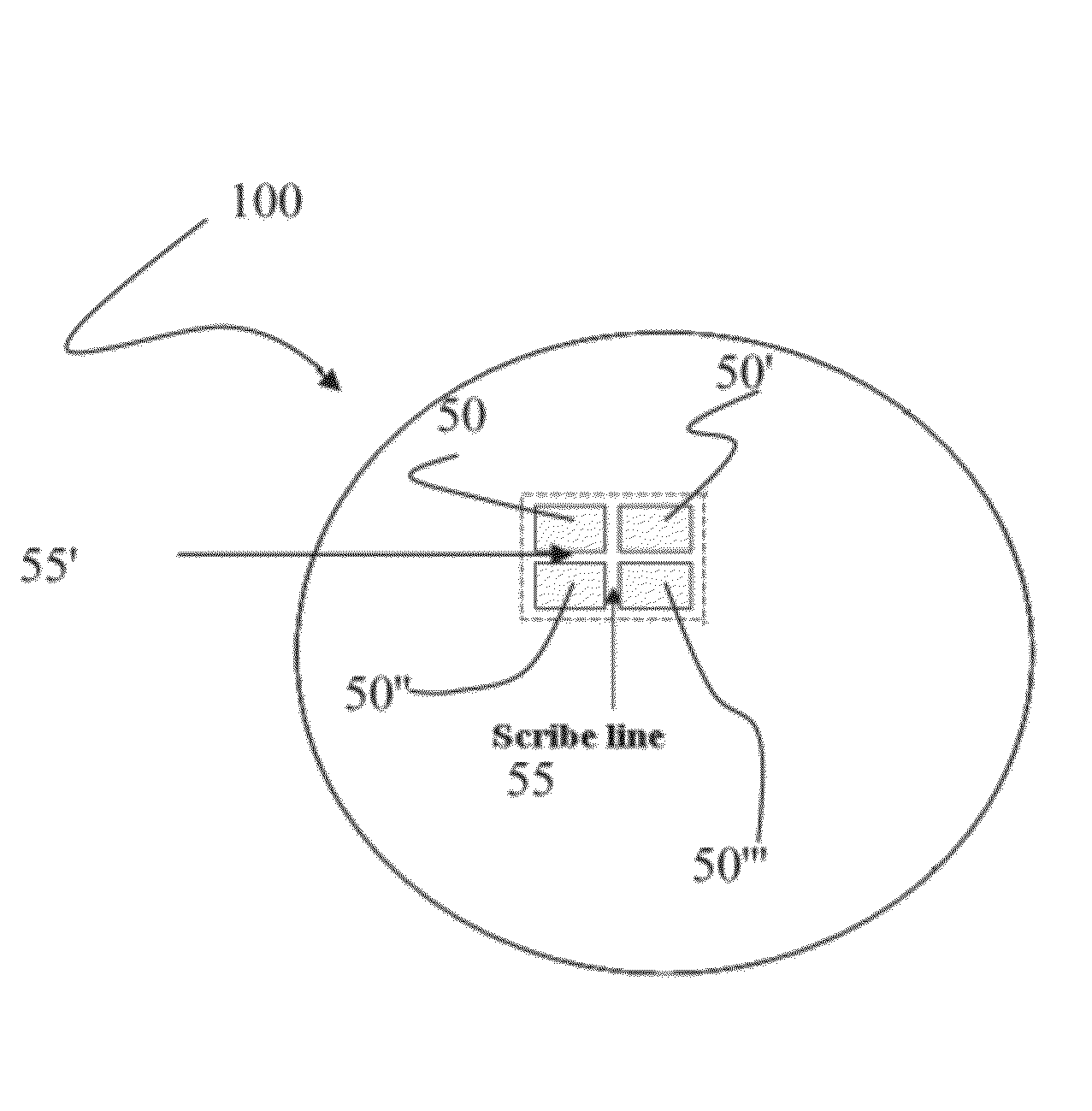

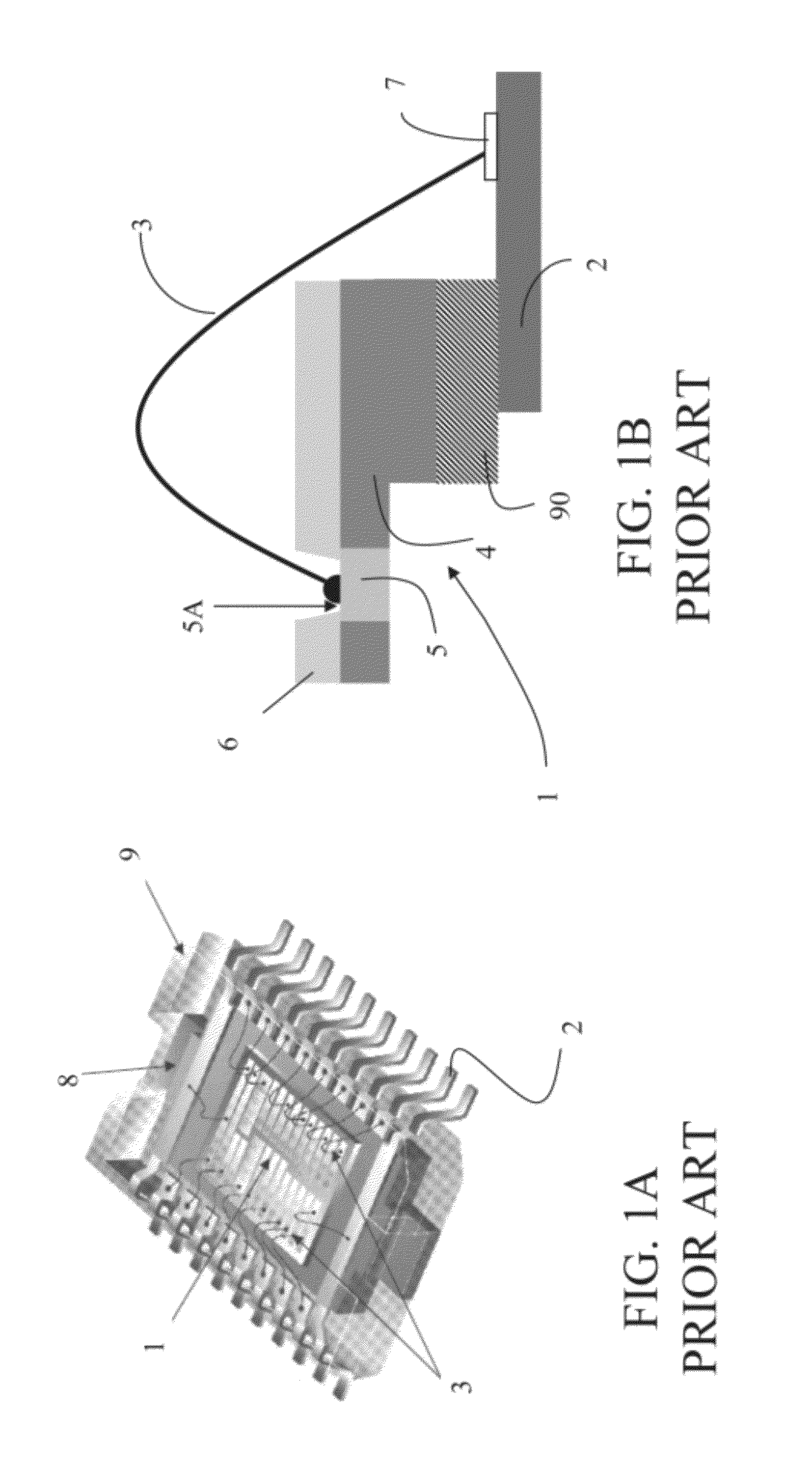

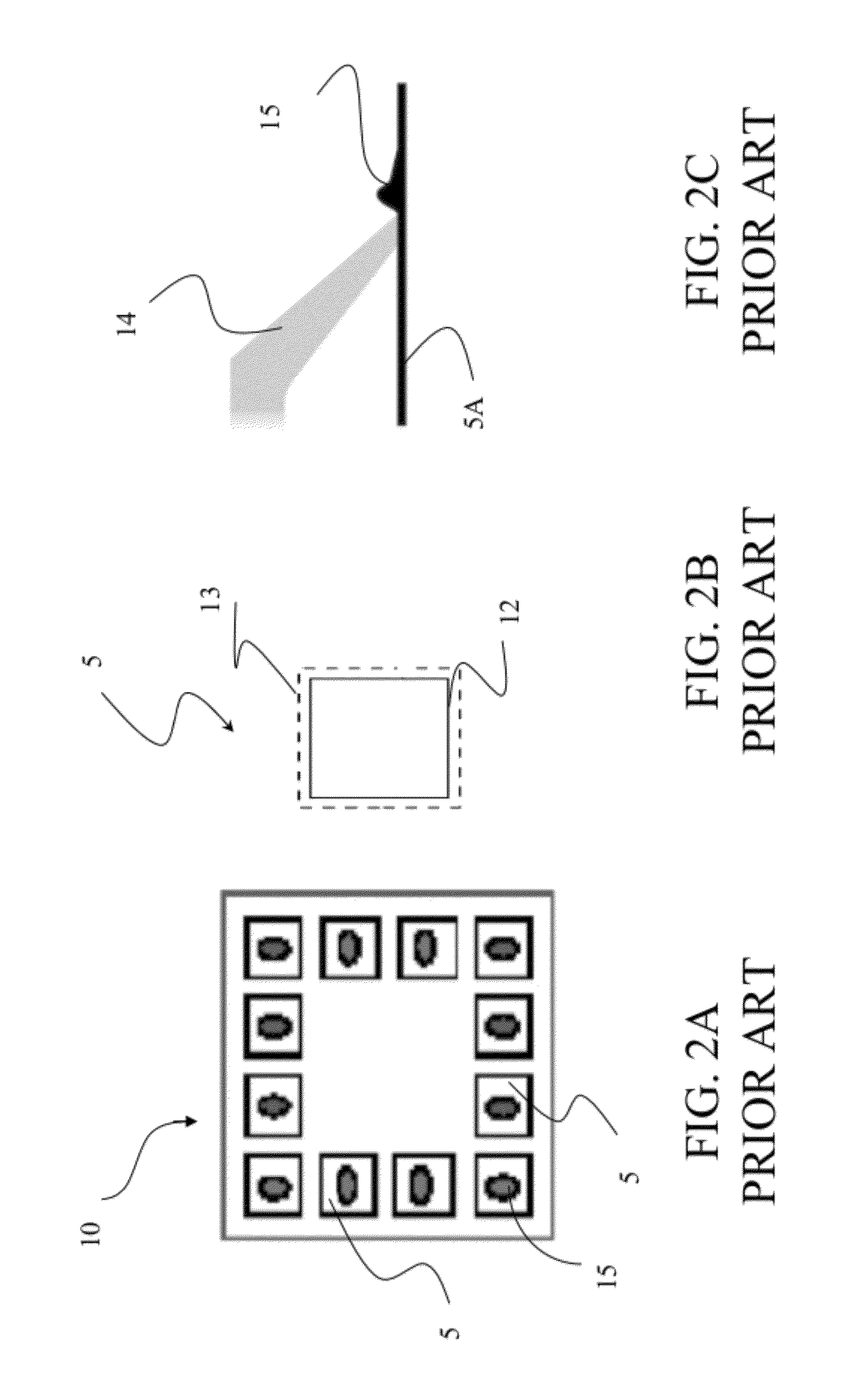

Electronic devices with extended metallization layer on a passivation layer

ActiveUS8362620B2Reduce harmSimple and low-cost processSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectricityElectrical testing

A method performs electrical testing and assembly of an electronic device on a wafer and comprising a pad made in an oxide layer covered by a passivation layer. The method includes connecting the electronic device to a testing apparatus; providing said electronic device with a metallization layer extending on the passivation layer from the pad to a non-active area of said wafer. The method comprises-performing the electrical testing on wafer of the electronic device by placing a probe of on a portion of the extended metallization layer; performing the cut of said wafer, reducing the extension of the metallization layer to the edge of the electronic device; embedding the device inside a package, forming on the metallization layer an electrical connection configured to connect the metallization layer to a circuit in said package.

Owner:STMICROELECTRONICS SRL

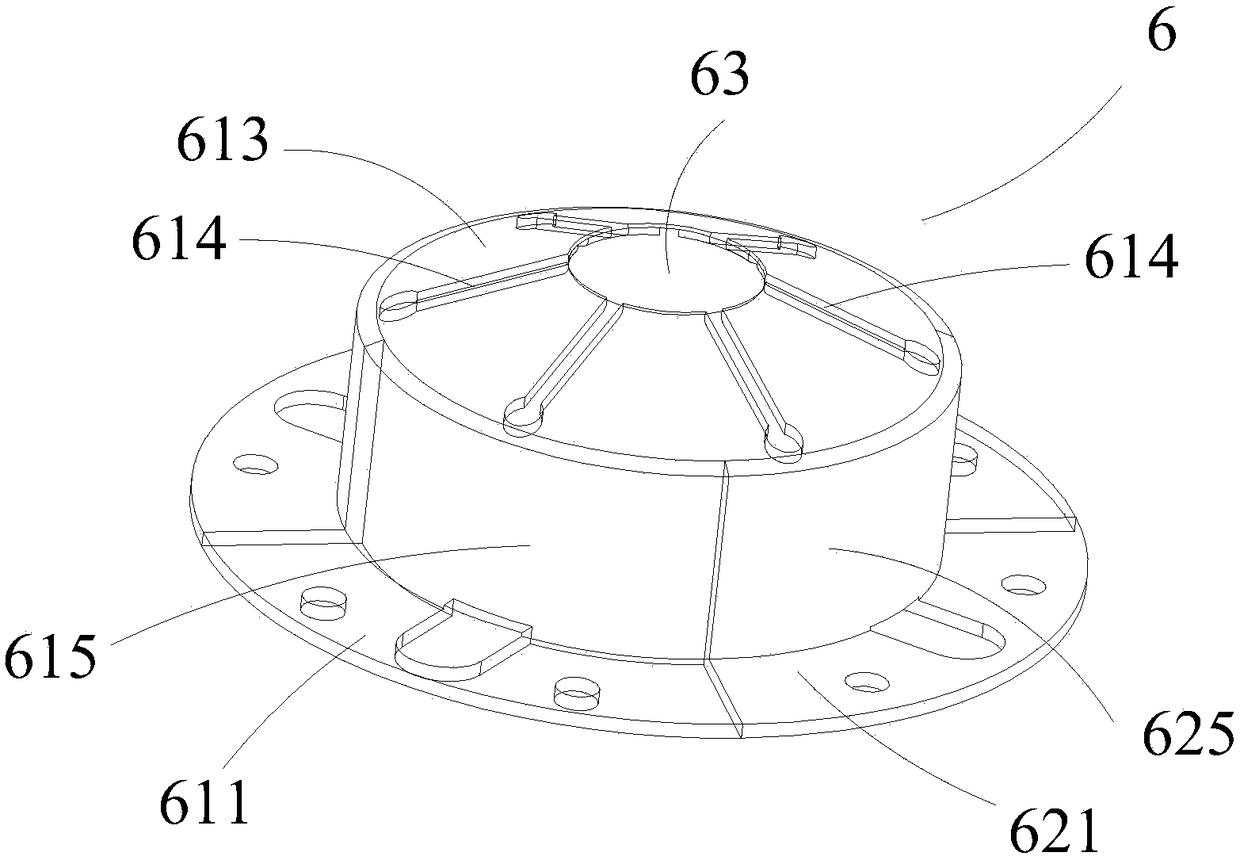

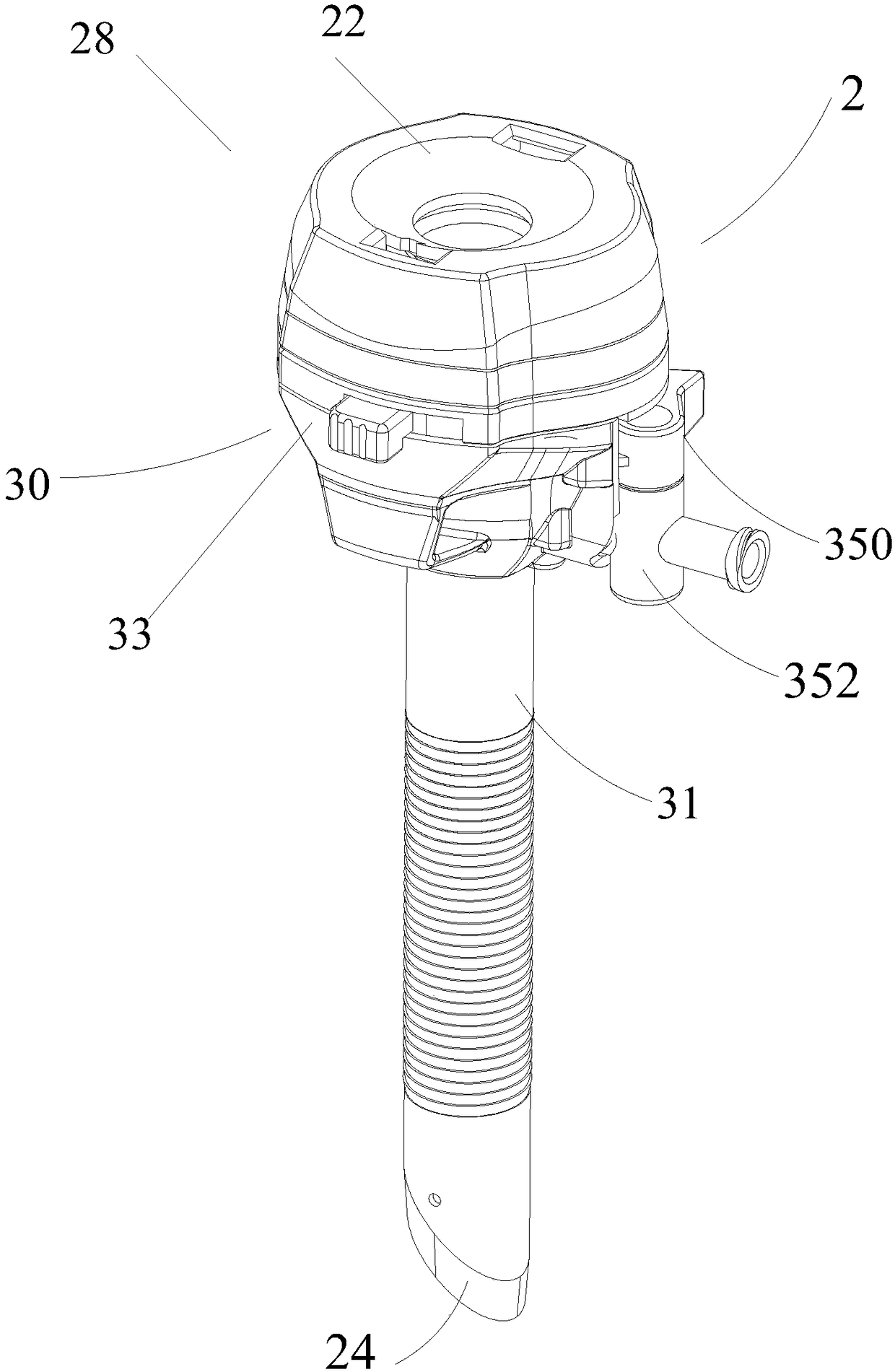

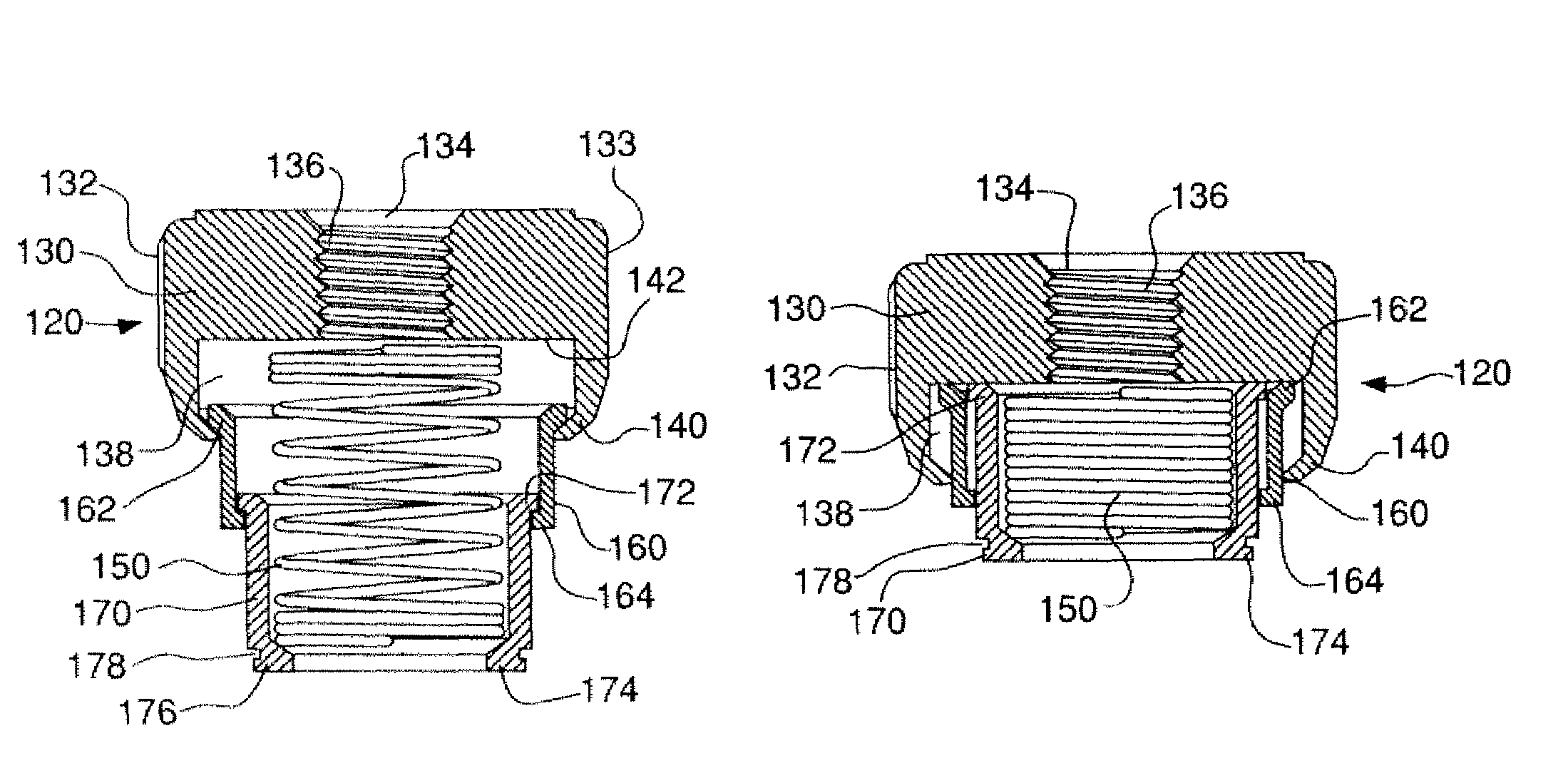

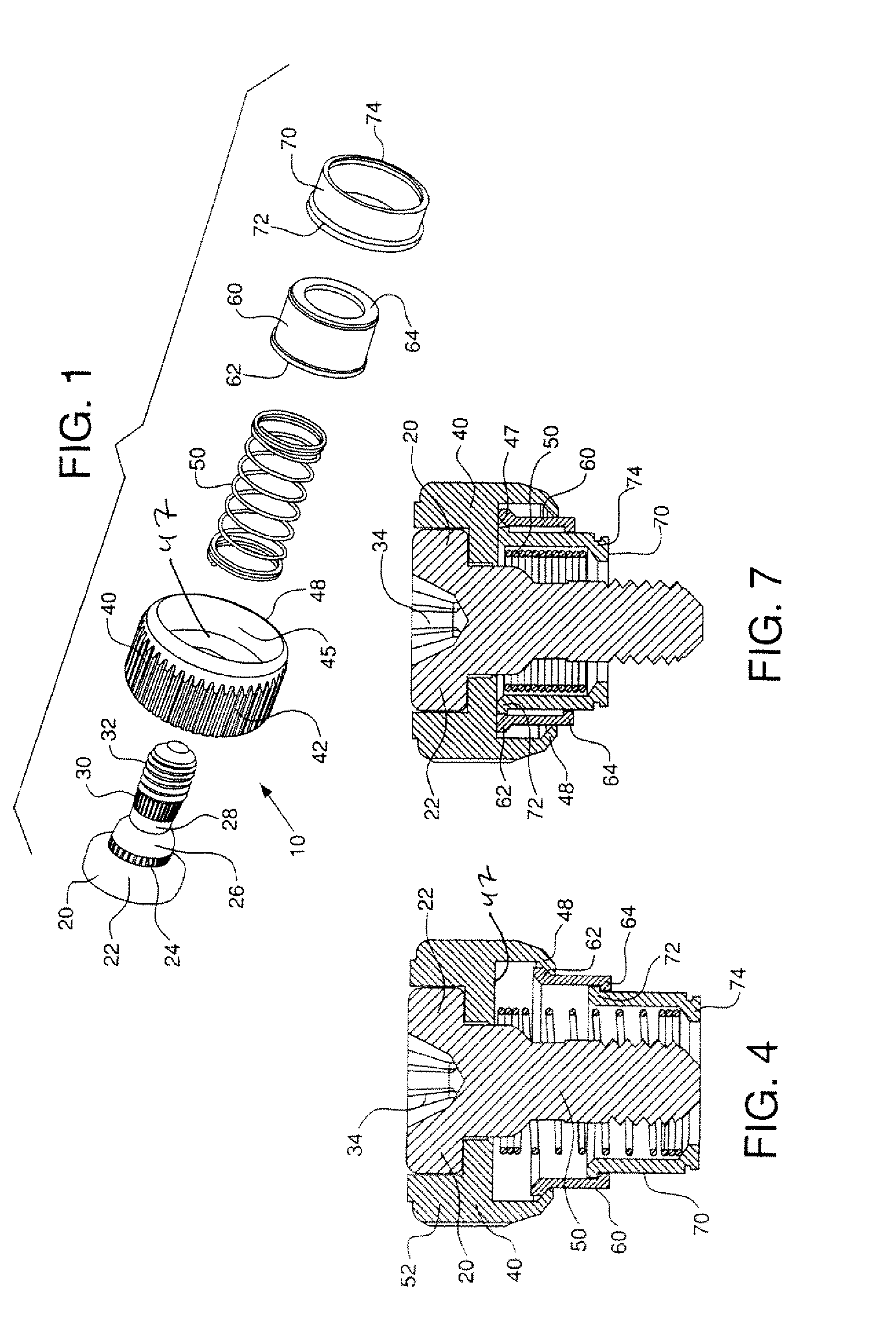

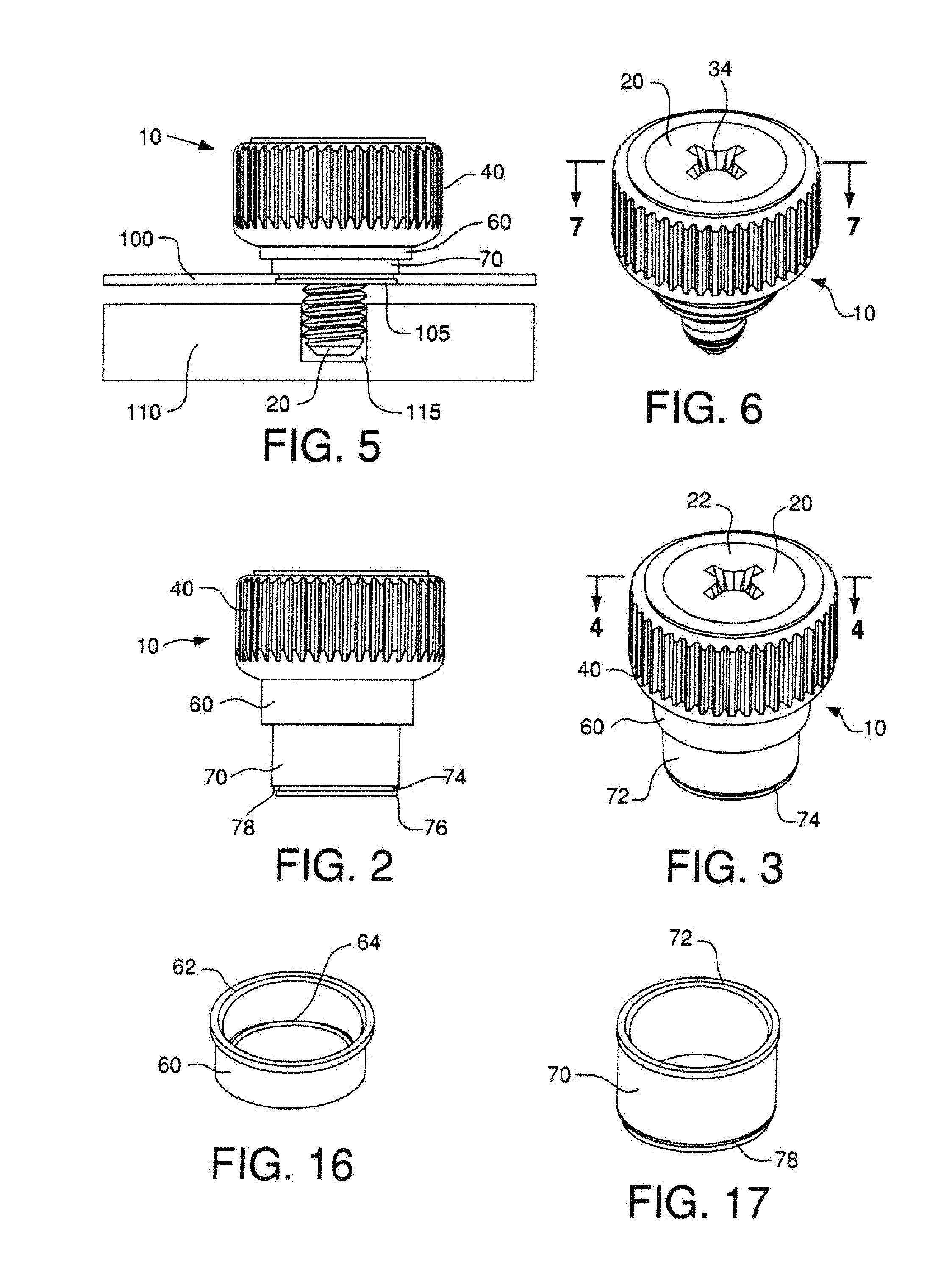

Seal assembly and puncture outfit with seal assembly

The invention discloses a seal assembly for a puncture outfit. The seal assembly comprises a seal film and a seal protection part. The seal film comprises a seal hole, and an instrument inserted in the seal hole is sealed by the seal film; the seal protection part is close to the seal film and used for protecting the seal film from being damaged by the instrument and comprises one or more press fit plates; each press fit plate comprises a near-end opening, a far-end hole and a protection wall which extends from the near-end opening to the far-end hole; each protection wall comprises two or more slits which extend horizontally from the corresponding far-end hole, the slits can allow the protection walls to deform so that the far-end holes can expand, and the instrument penetrates through the far-end holes conveniently. According to the seal assembly for the puncture outfit, the seal film can be effectively protected and prevented from being scratched or torn by the sharp edge of the instrument, the protection walls of the seal protection part are simple in structure, the number of the protection walls is small, and accordingly assembly is easy.

Owner:FENGH MEDICAL CO LTD

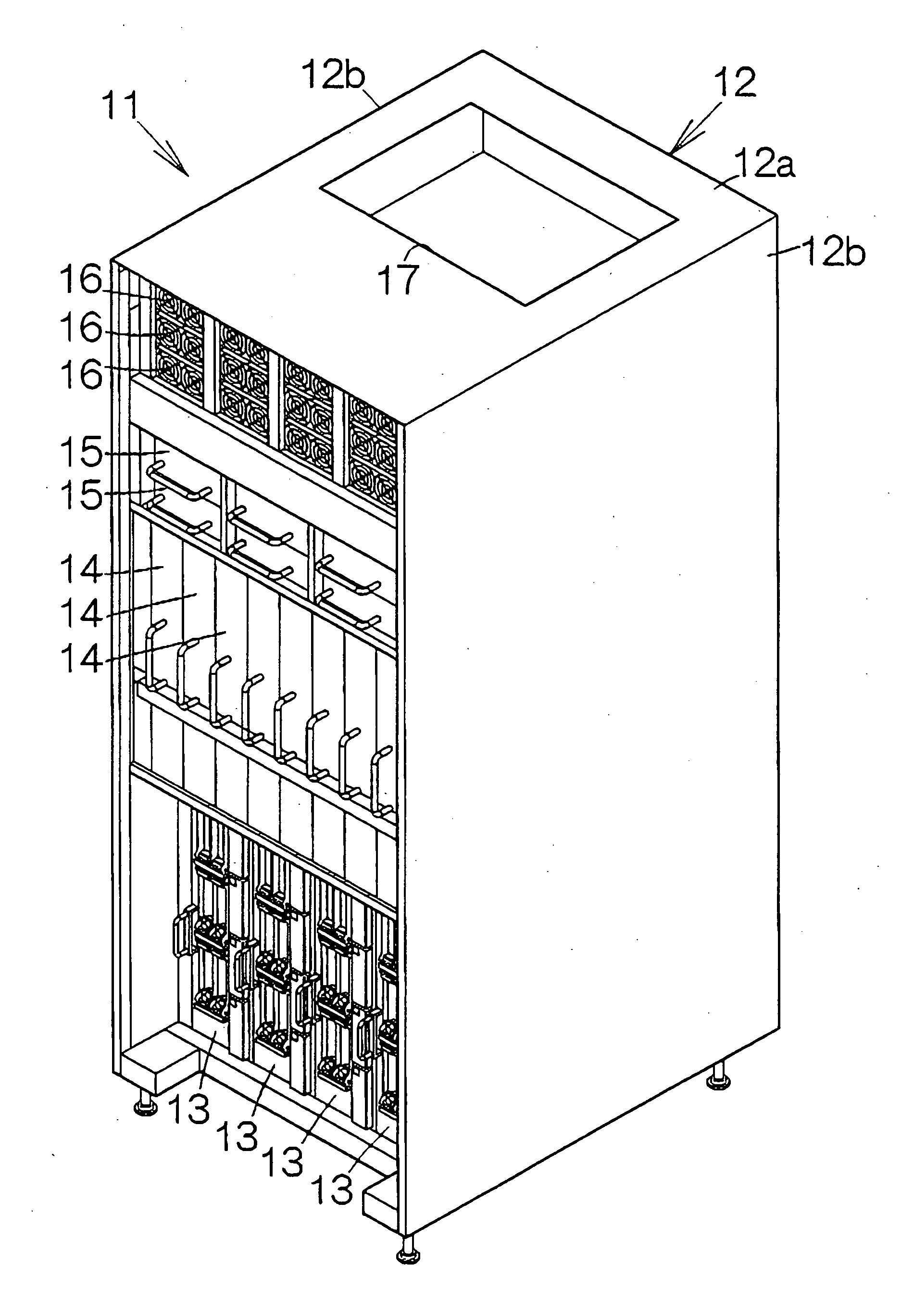

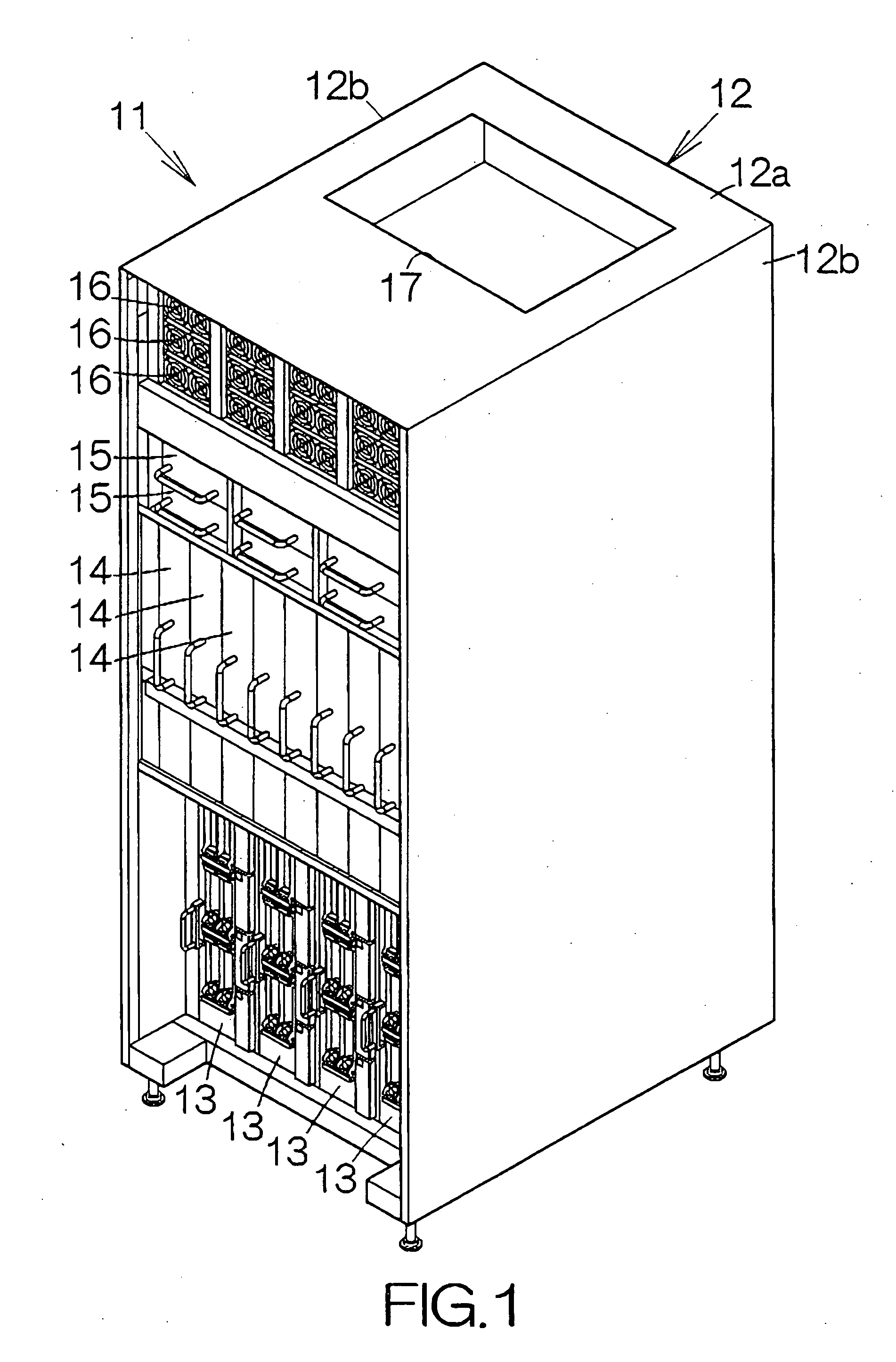

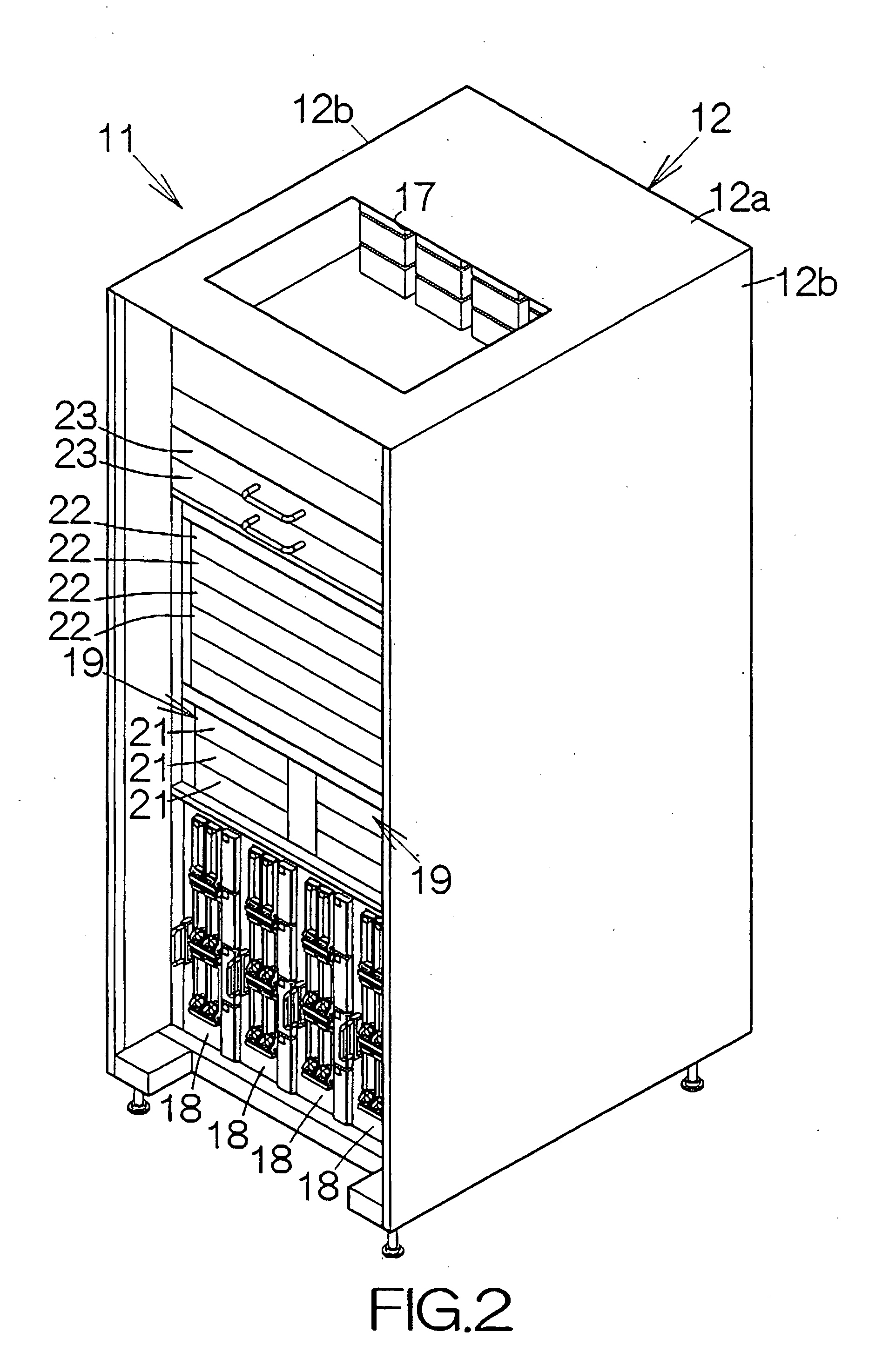

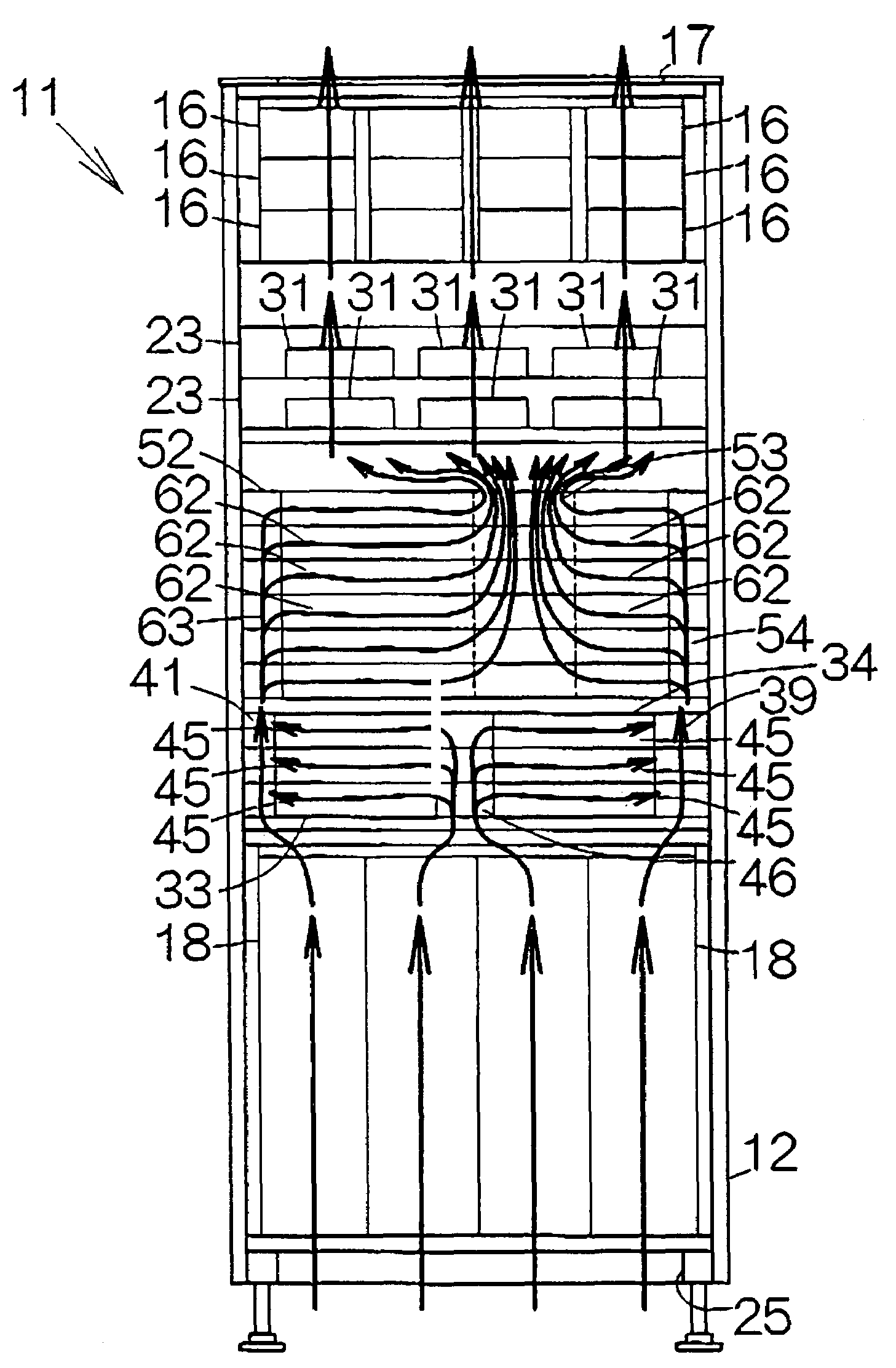

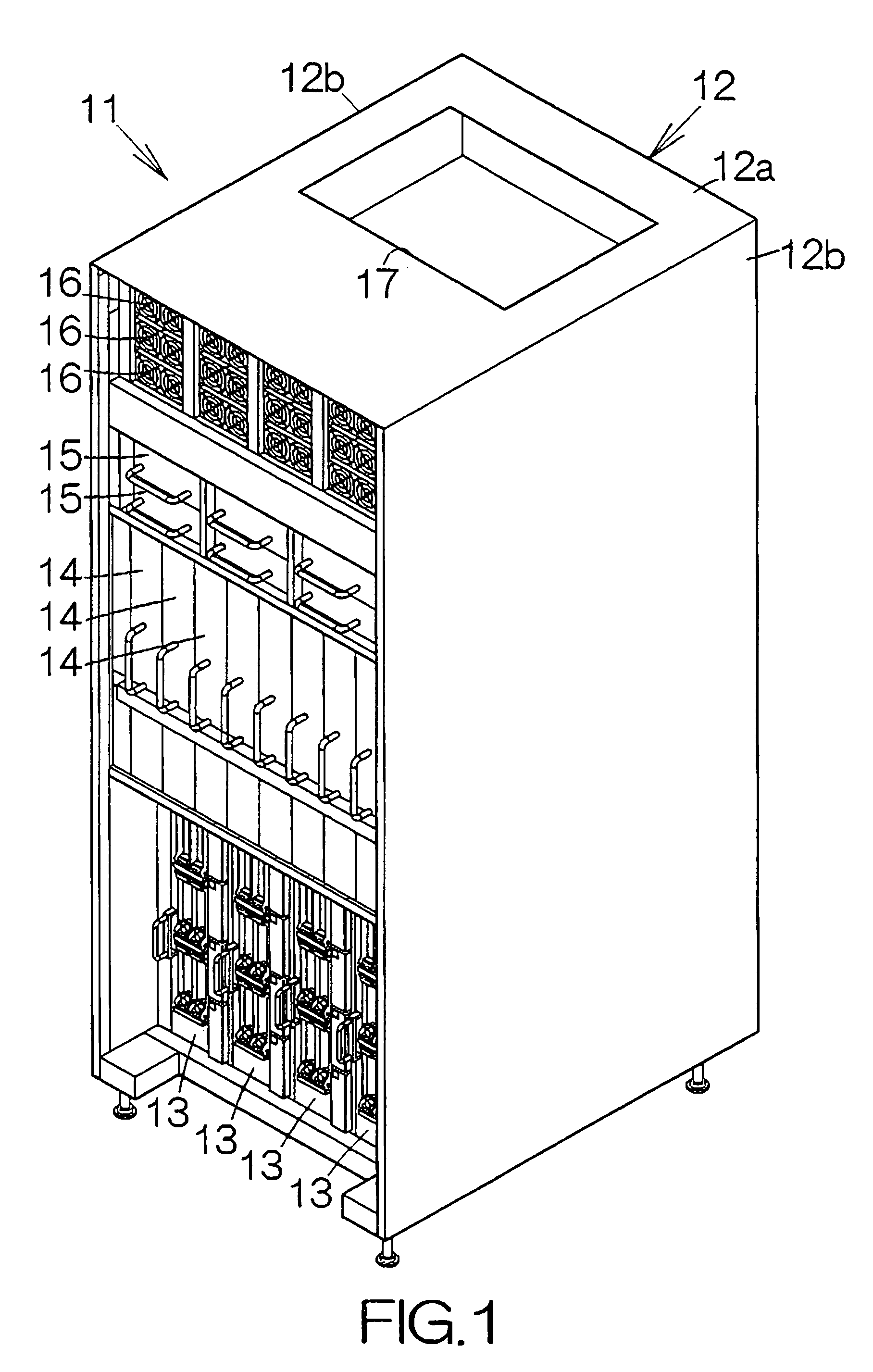

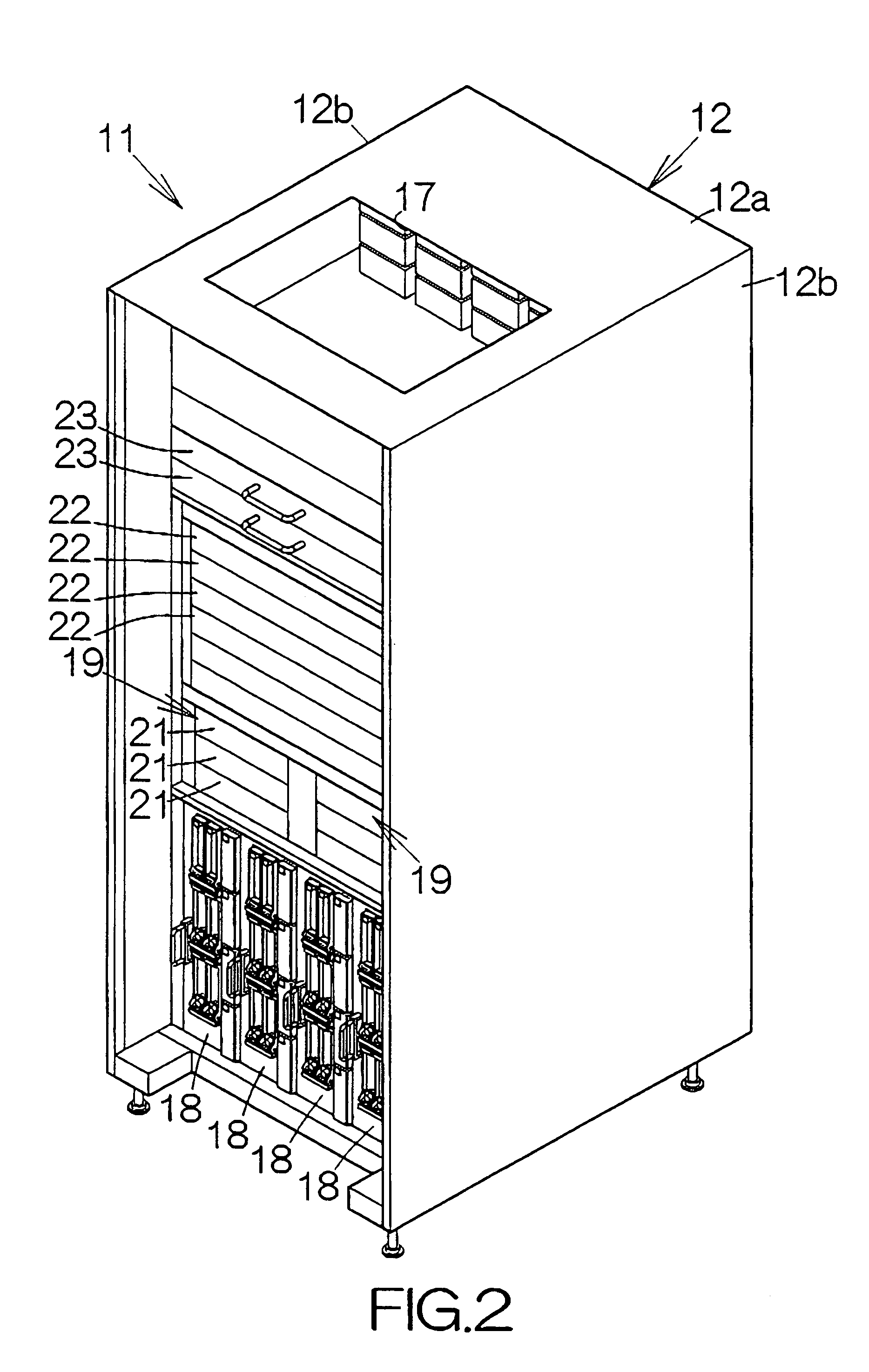

Electronic apparatus

InactiveUS20070223199A1Small sizePreventing an efficient airflowDigital data processing detailsCooling/ventilation/heating modificationsElectrical and Electronics engineeringElectronic equipment

A first printed wiring board extends in the vertical direction within a first duct that extends in the vertical direction. A first axial flow fan generates airflow which absorbs heat from the first printed wiring board. Second and third ducts extends in parallel with the first duct. A fourth duct extends between the second and third ducts. A second printed wiring board extends in the horizontal direction within the fourth duct. A second axial flow fan is connected to the third duct. The second axial flow fan generates airflow which absorbs heat from the second printed wiring board. The electronic apparatus can be reduced in size.

Owner:FUJITSU LTD

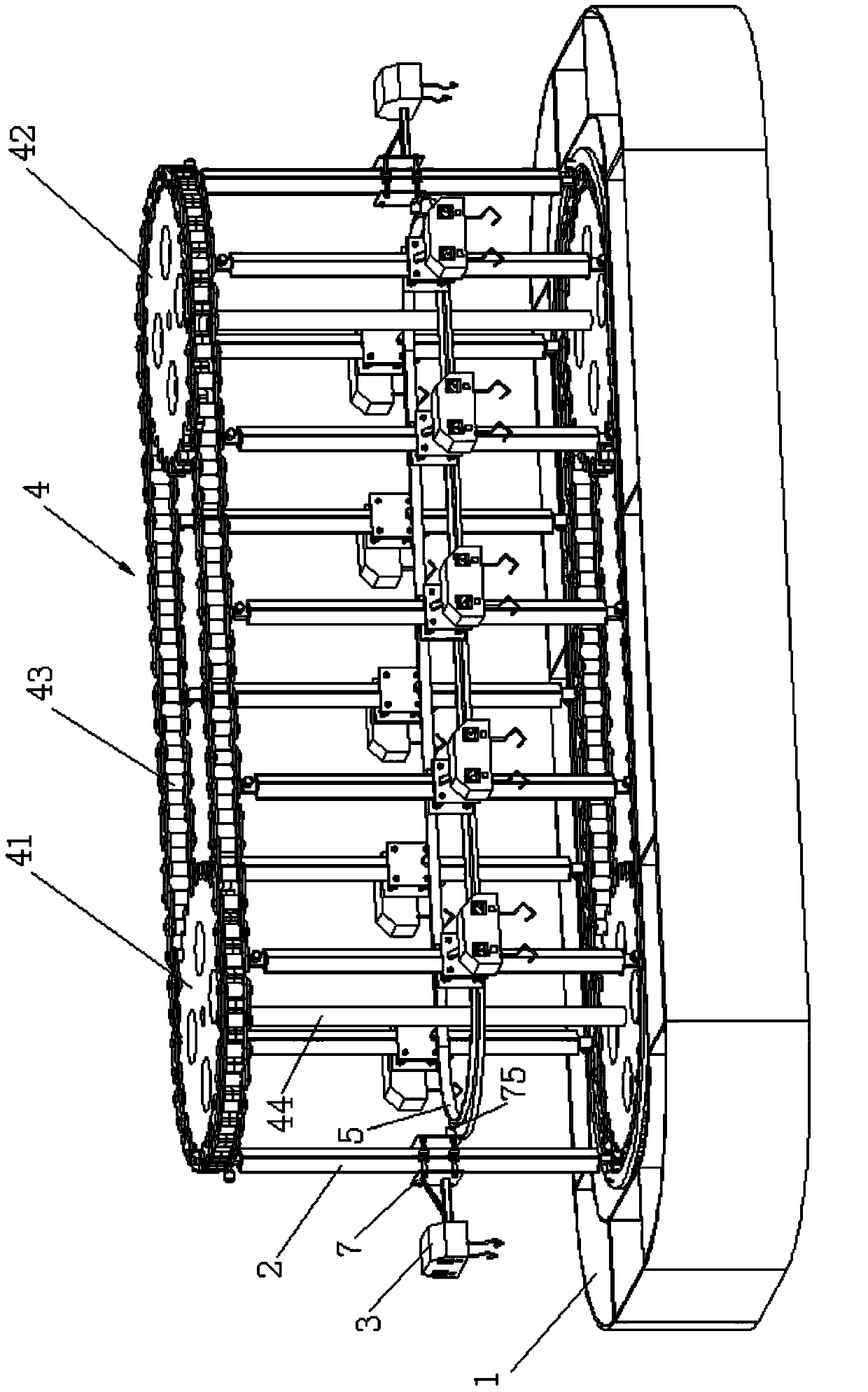

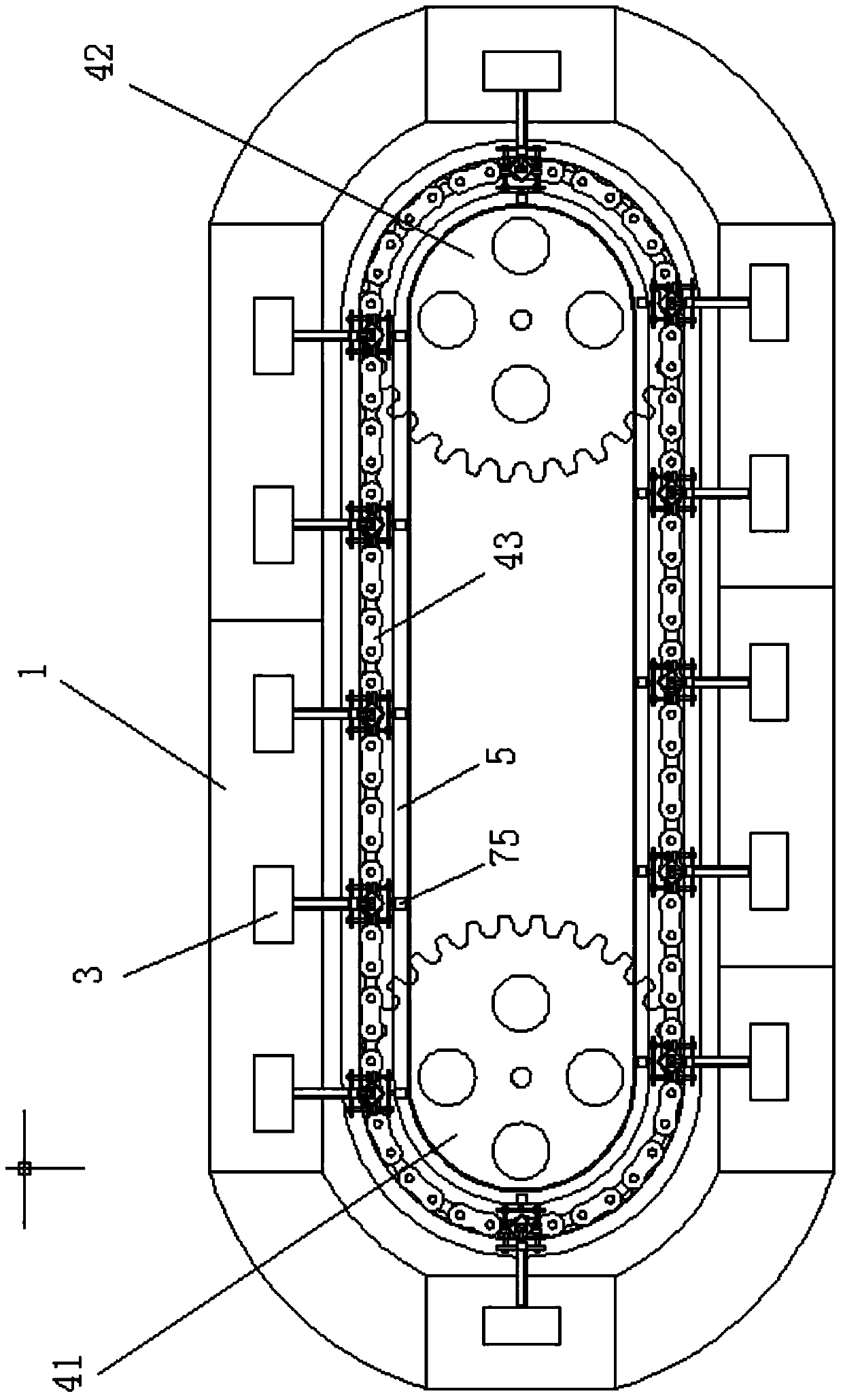

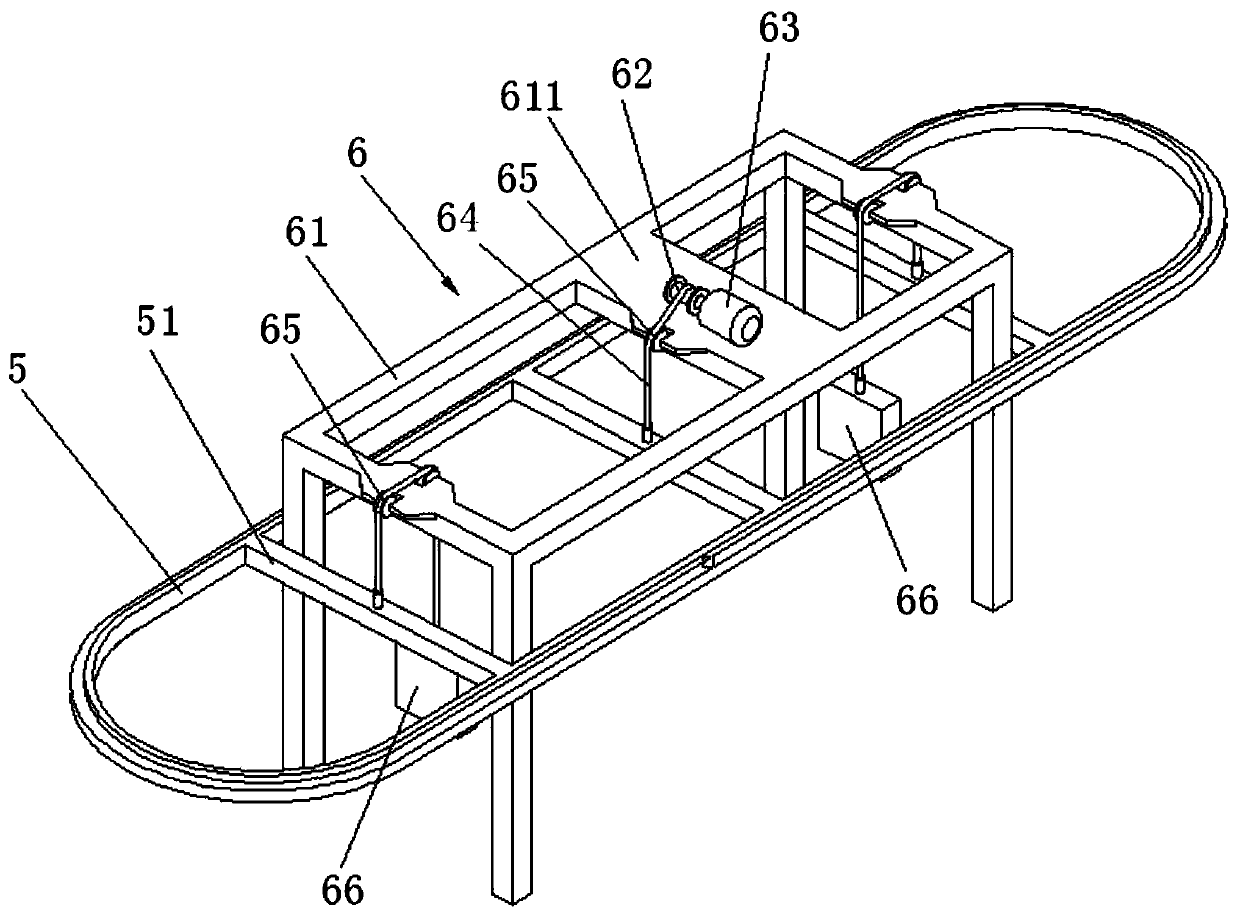

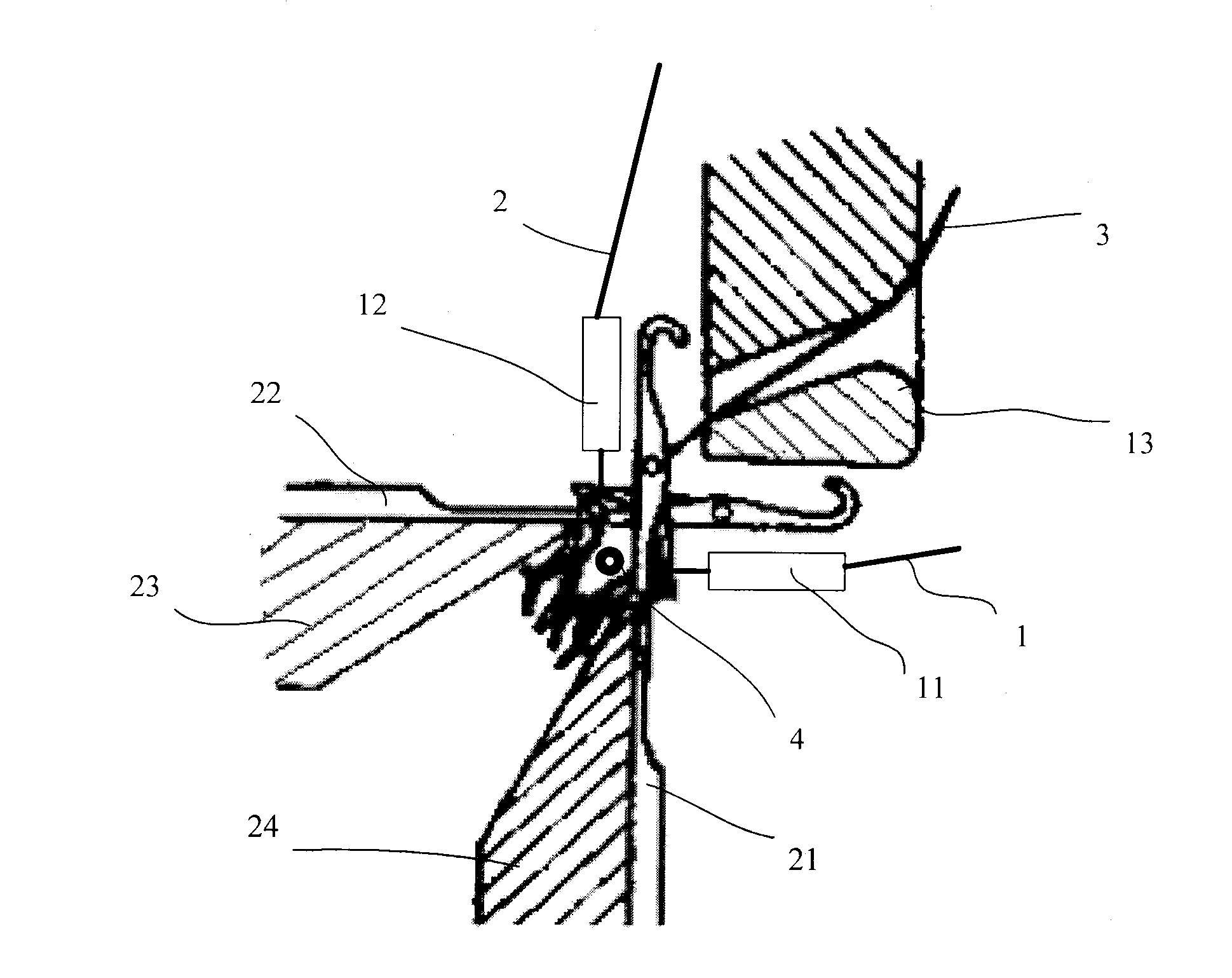

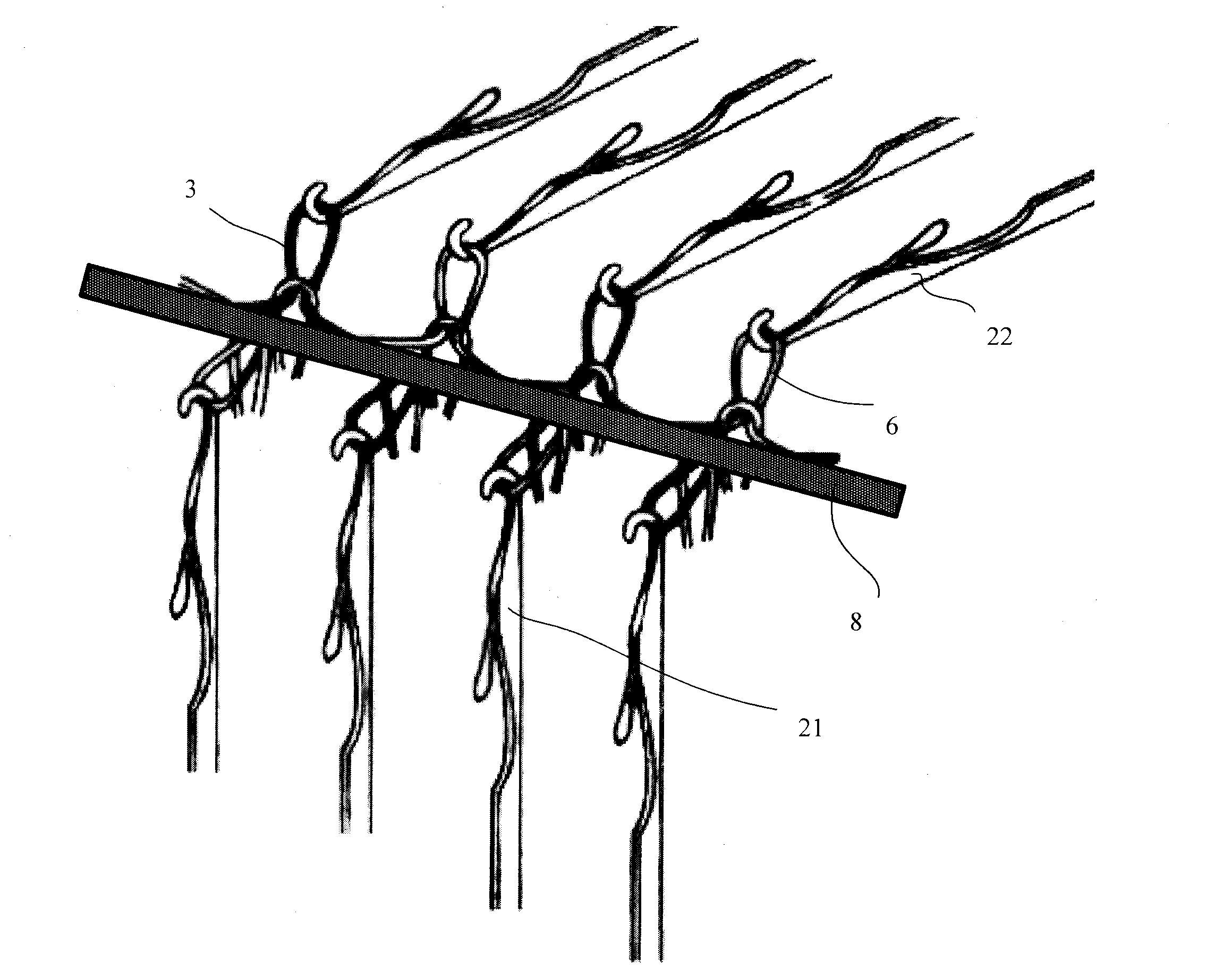

Automatic electroplating equipment for zipper head

ActiveCN103469270AImprove the quality of electroplatingImprove plating qualityCellsSlide fastenersControl systemEngineering

The invention provides automatic electroplating equipment of a zipper head. The equipment consists of electroplating grooves which are formed by a pre-electroplating treatment groove, an electroplating treatment groove and a post-electroplating treatment groove and are connected head-to-tail to form a closed ring, wherein an anode generator is installed on a vertical guide rail which is connected with a chain of a traveling device, the anode generator is further provided with an idler wheel which is placed on a horizontal circular track, and the circular track driven by a lifting device can ascend and descend. Under the effects of a control system, the traveling device and the lifting device, the anode generator intermittently travels on the circular track and circulates according to a sequence of ascending, traveling, descending and stopping. According to the invention, the zipper head is continuously electroplated through the automatic equipment, so that the electroplating production efficiency is greatly improved. Times of the steps are controlled through intelligent programs, so that the electroplating quality is high and the electroplating quality of the zipper head is enhanced. Meanwhile, the labor intensity of the workers is further reduced, and the field environment is improved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

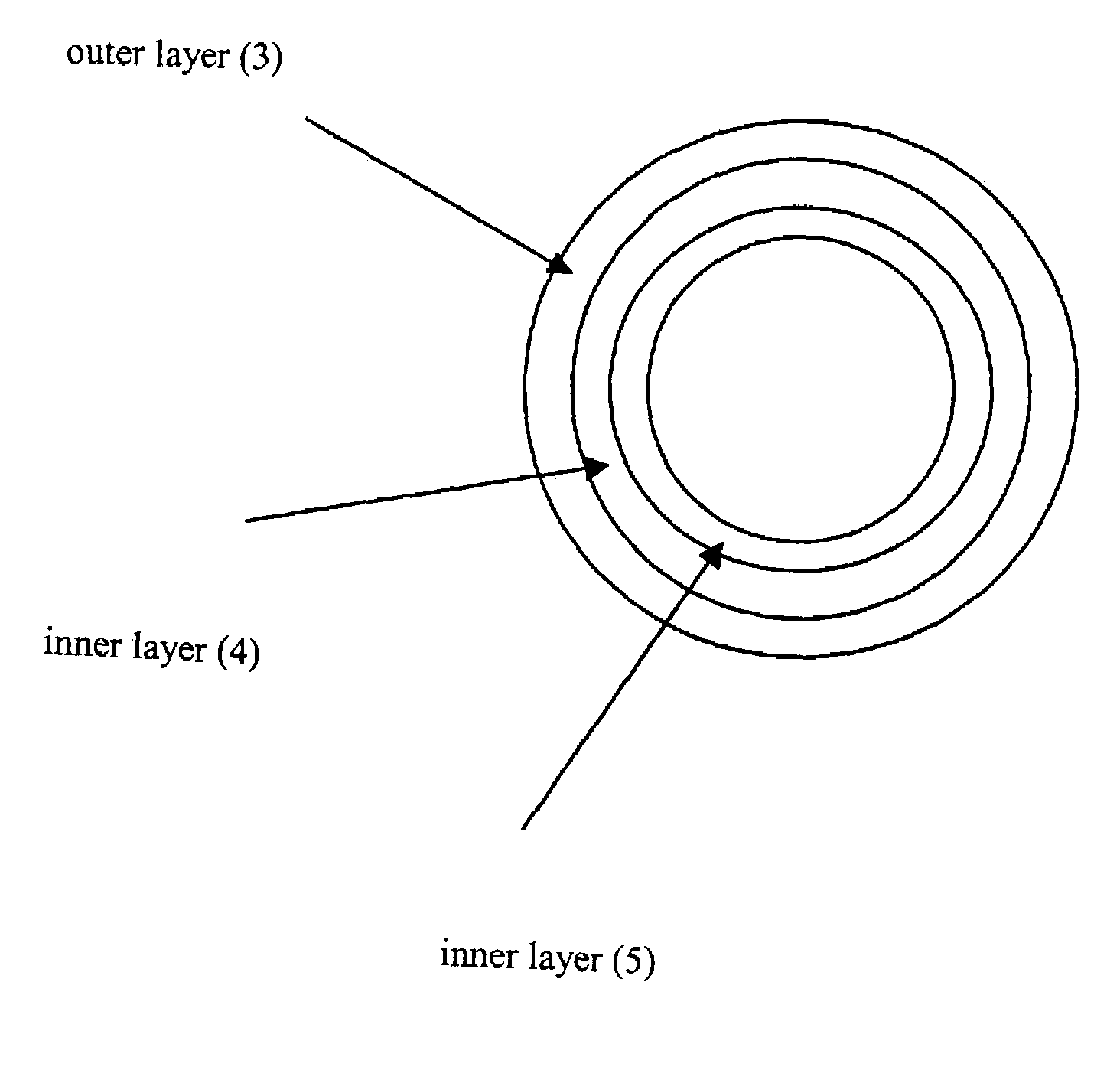

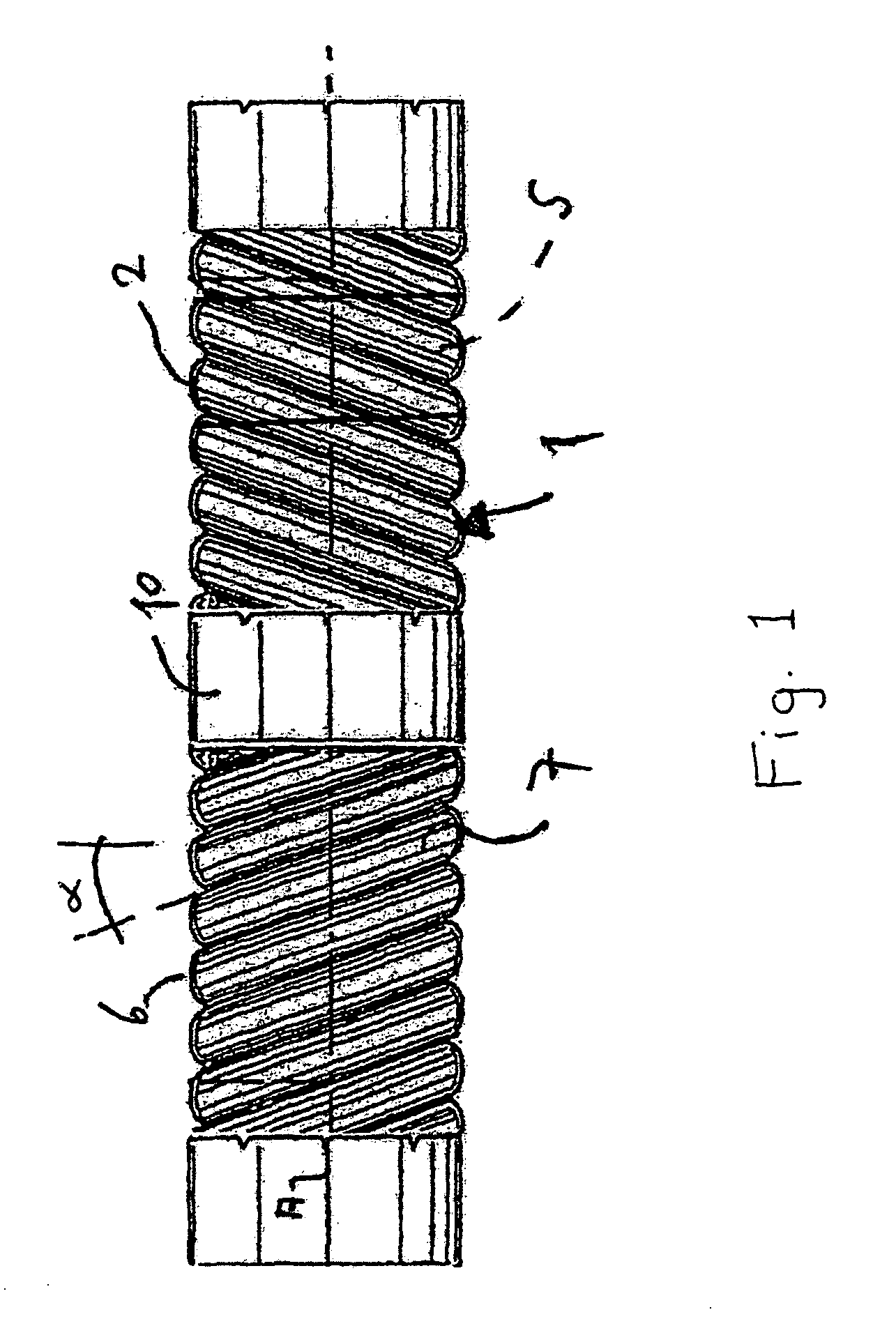

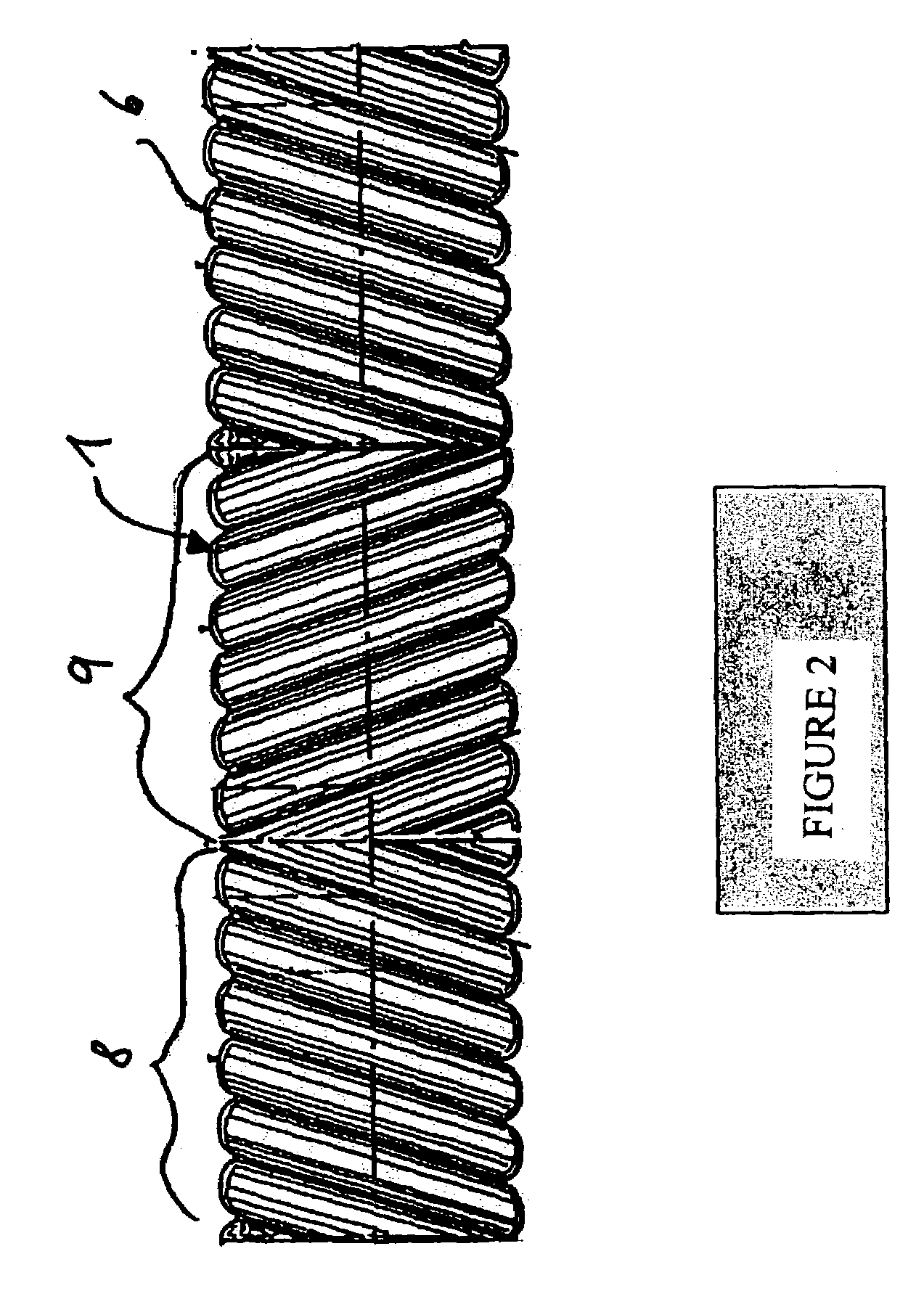

Multilayer polymer hose line or tubing having reduced length variations

Two-layered or three-layered polymer tubing for use as a pressurized fluid conduit in automobiles can be either walled or have walls continuously or partially corrugated. The tubing has an outer layer of a hard polymer molding material and an inner layer of a soft rubber-like polymer or a polymer mixture. The inner layer can be provided on the innerside with a layer of a thermoplastic adhesion-modified elastomer composition. The a materials are selected for the layers to provide a so-called “hard-soft-combination”. The rubber-like polymer composition has a hardness in the range of 30 Shore A to 60 Shore D, especially of about 30 Shore A to 90 Shore A, the compositions being selected so that they are processable by coextrusion or the so-called conex method and adhere directly to each other non-positively or positively fitted, i. e. without additional bonding agent, without delaminating.

Owner:EMS CHEM AG

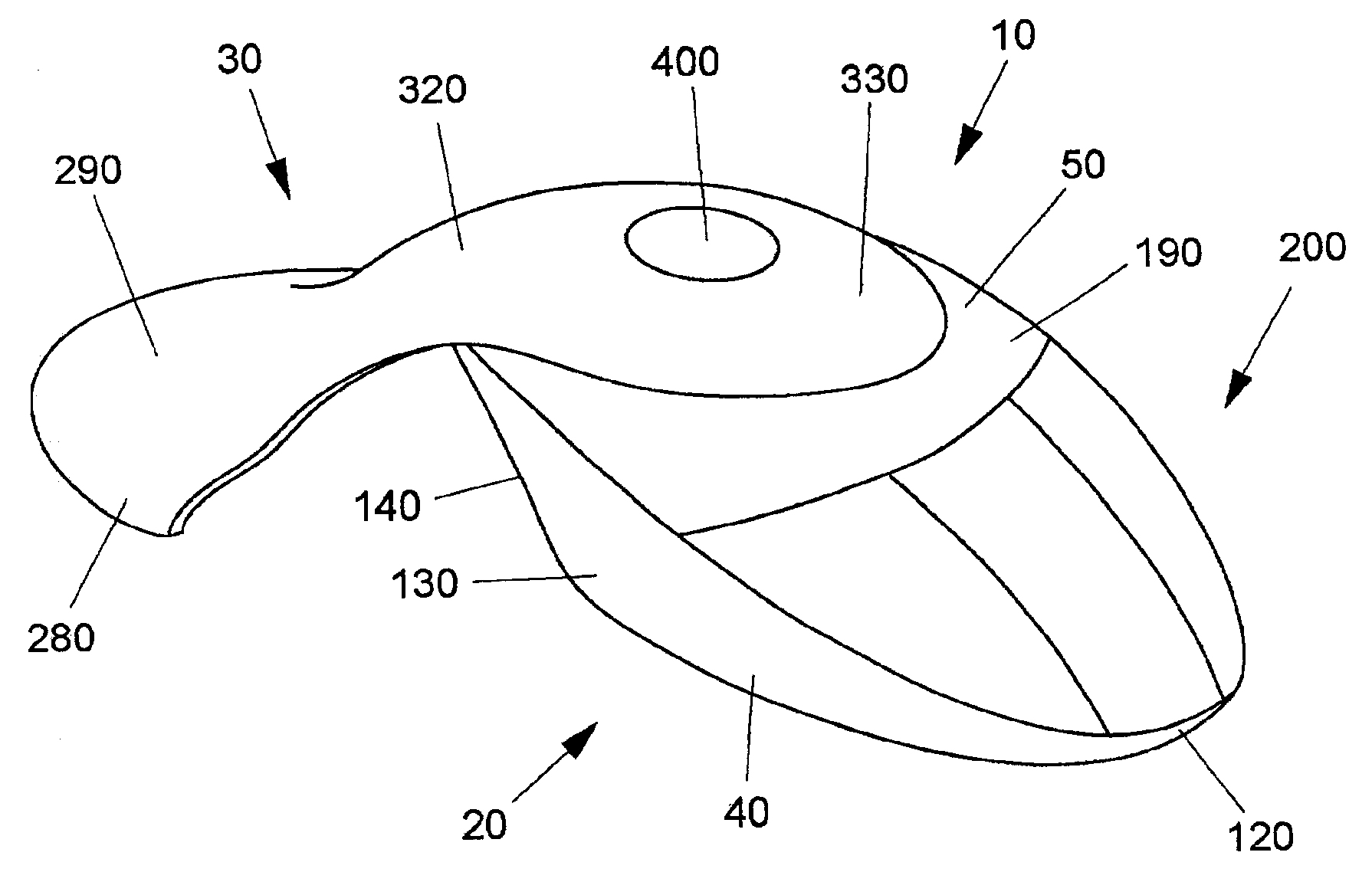

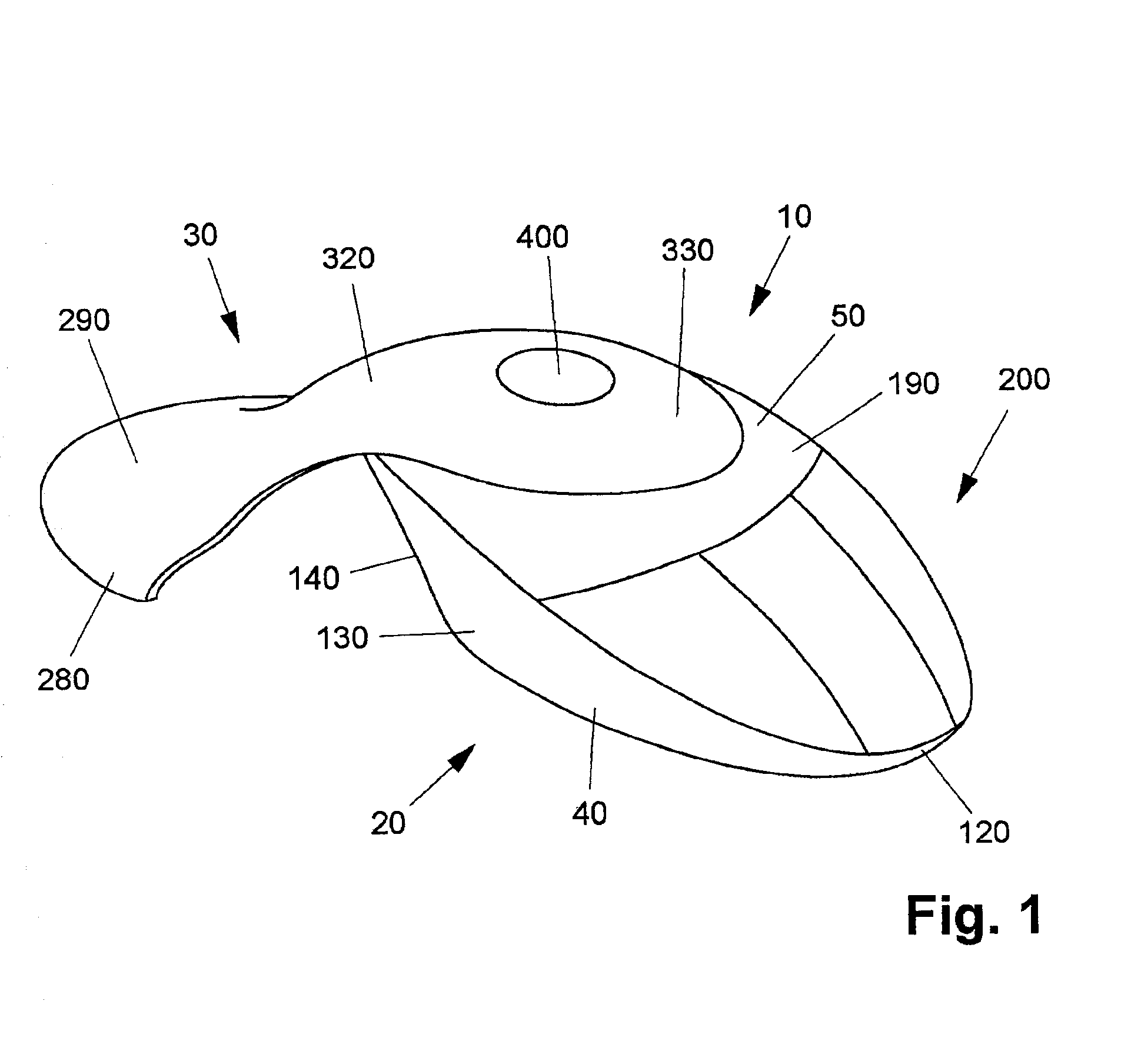

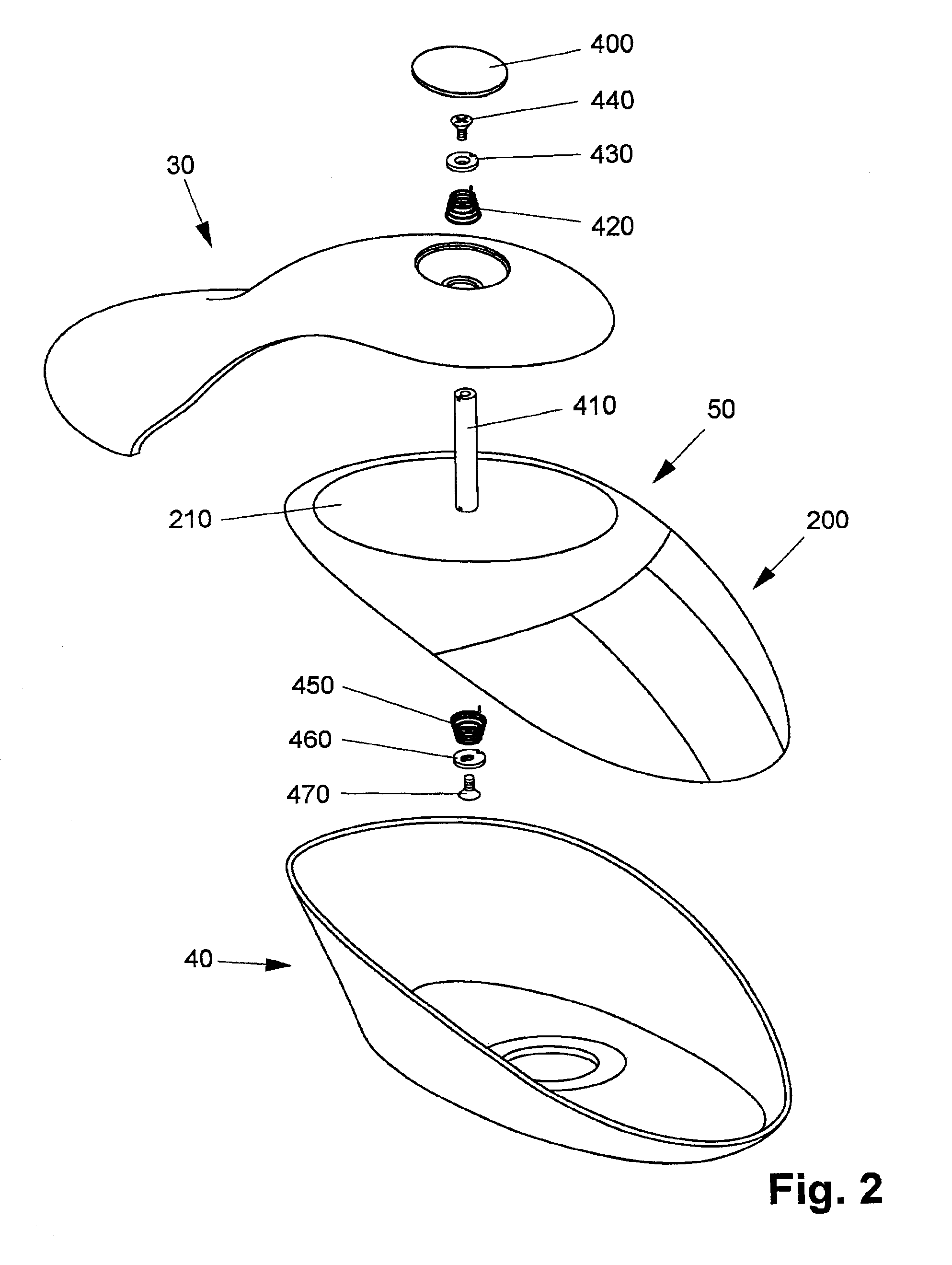

Ergonomic mouse

A computer mouse having a separately movable hand rest. The mouse comprises a housing having a conically shaped depression within a top wall of the housing tapering to an aperture through the top wall. A connecting pin extends through the aperture with an interior end secured within the mouse housing. A hand rest providing support to the heel and palm of the hand is orbitally connected to the connecting pin by an aperture through the hand rest located within a concave portion sized to fit within the depression of the mouse housing. The hand rest has an arcuate shaped bottom portion and a base end moving about the mouse housing during use to maintain alignment of the hand rest with the hand. The housing moves free of interference from the hand rest adjacent the arcuate shaped bottom portion. A tensioning means tensions movement of the hand rest about the housing.

Owner:DOAN JIMMY QUANG V

Wear-resisting high-strength cable and preparation method thereof

ActiveCN104762748AImprove performanceImprove breaking strengthRope making machinesCoatingsYarnPolyester

The invention discloses a wear-resisting high-strength cable produced by a non-single material and a preparation method of the wear-resisting high-strength cable. A cable body is an 8-strand structure core body which is prepared from ultra-high molecular weight polyethylene (UHMWPE) and high-strength polyester according to the amount ratio of 3 to 1; a high-toughness wear-resistant coating woven by adopting vectran fibers is arranged outside the core body; and a wear-resistant coating which is especially made of a wear-resistant material PTFE as a matrix coats the outer surface of the sleeve; the preparation method comprises the following steps: fabricating a cable body by the procedures of preparing roving, preparing rope yarns, infiltrating resin, preparing rope strands, braiding ropes, prestretching and drying; weaving a high-strength wear-resisting sleeve on the surface of the core body; and dipping and coating a wear-resisting coating which is especially prepared from PTFE as a matrix on the outer layer of the sleeve.

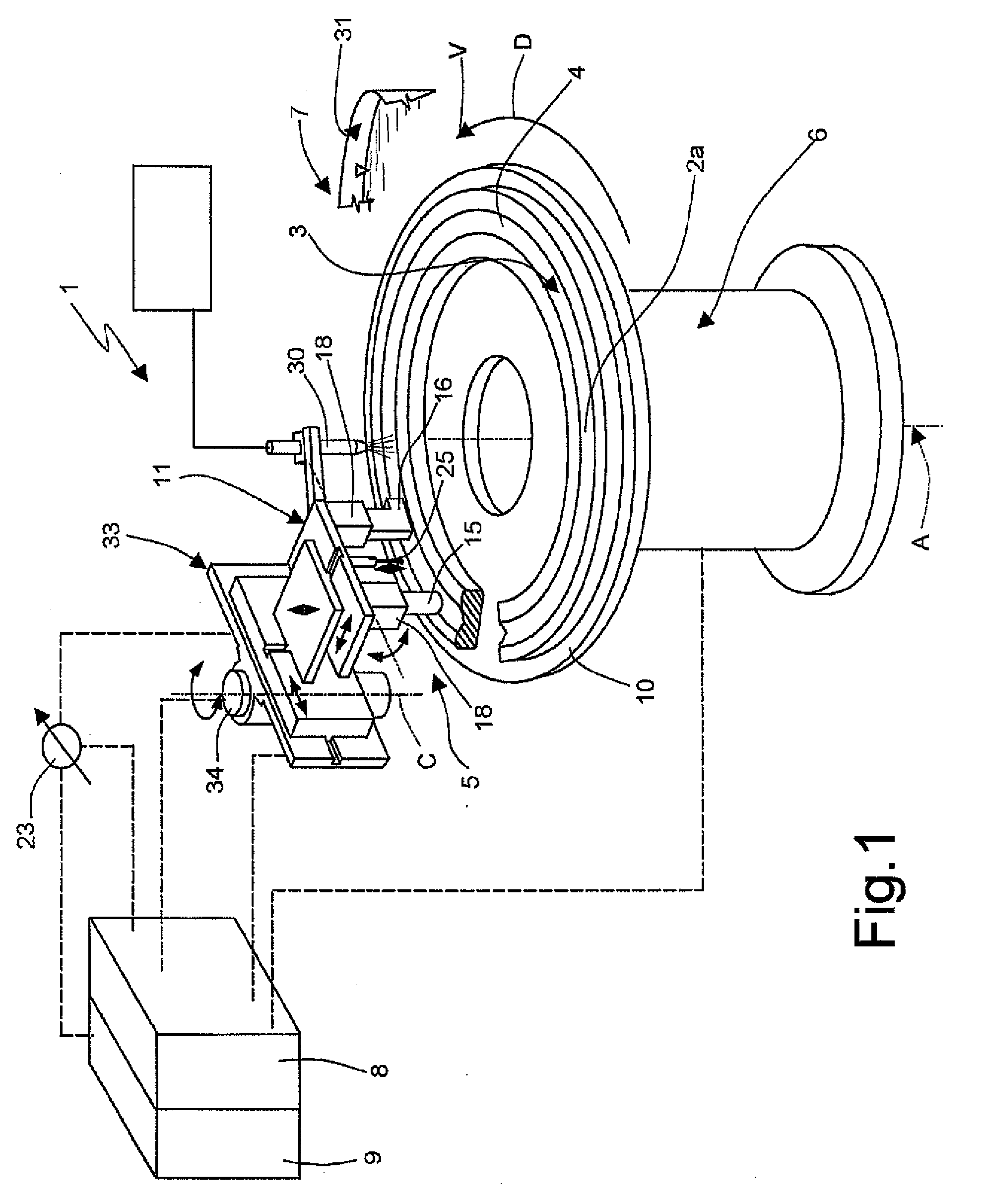

Device and method for performing a localized induction hardening treatment on mechanical components, specifically thrust blocks for large-sized rolling bearings

InactiveUS20100243643A1Increase chanceIncrease heatCoil arrangementsIncreasing energy efficiencyMechanical componentsRolling-element bearing

A device and method for induction hardening rolling tracks of thrust blocks of bearings, according to a required hardening profile. At least two inductors arranged in tandem are used within a track to be hardened, at a predetermined distance from a surface of the track and the thrust block is rotated with respect to the inductors, so as to make them cover the entire track, with a complete 360° turn; the inductors, at least one first pre-heating inductor and one at least heating inductor, are shaped so as to generate a first and a second magnetic fields, respectively, both having flux lines which are perpendicular to each other, and one of the two inductors is mounted on an orientable head so as to be able to arrange the two inductors oriented according to the curvature of the track. The mentioned predetermined distance of the inductors from the track is obtained by using a feeler to accurately detect the geometry of the track and which is introduced between the two inductors and then moved away during the heating steps which are performed sequentially in synchronism with the rotation of the thrust block, and by varying, in a final step, the electric power fed to at least one inductor.

Owner:SAET

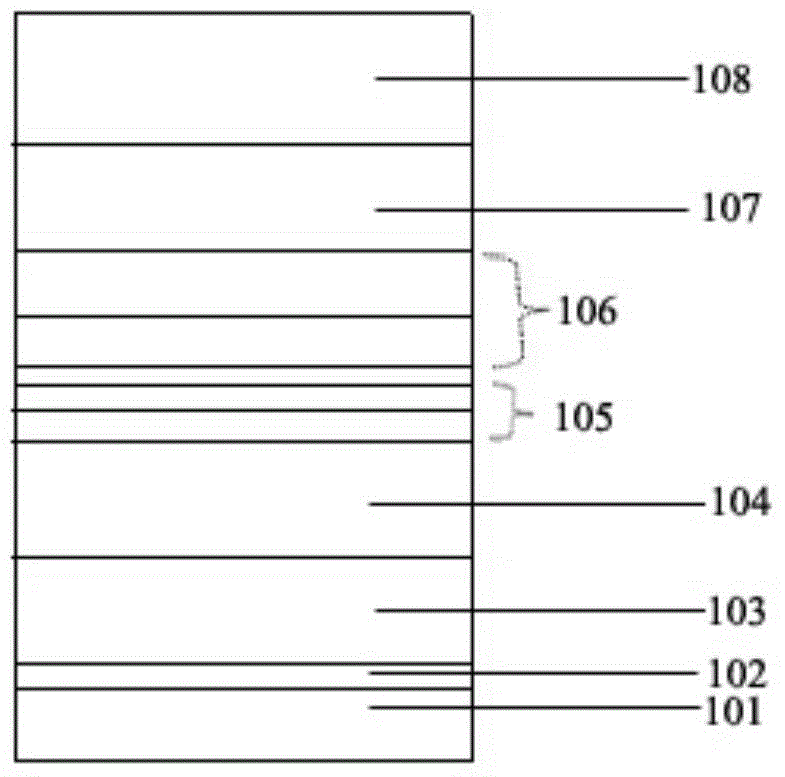

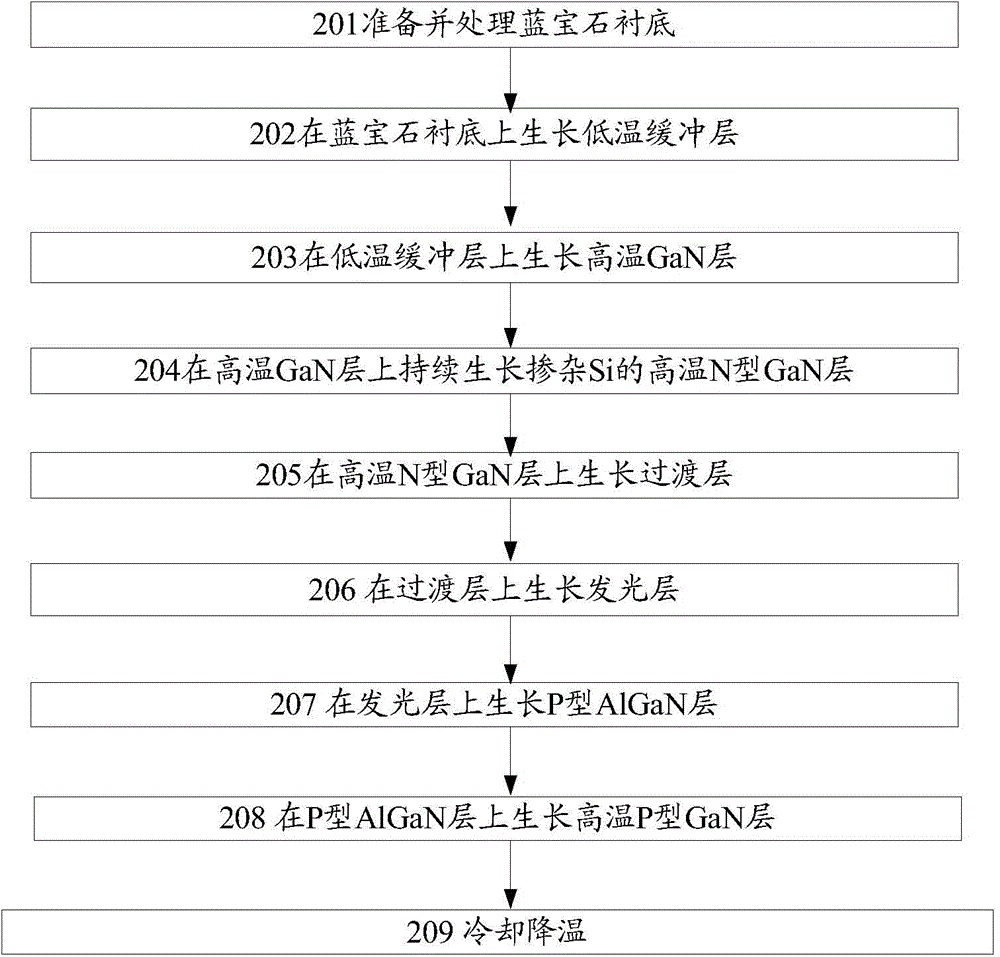

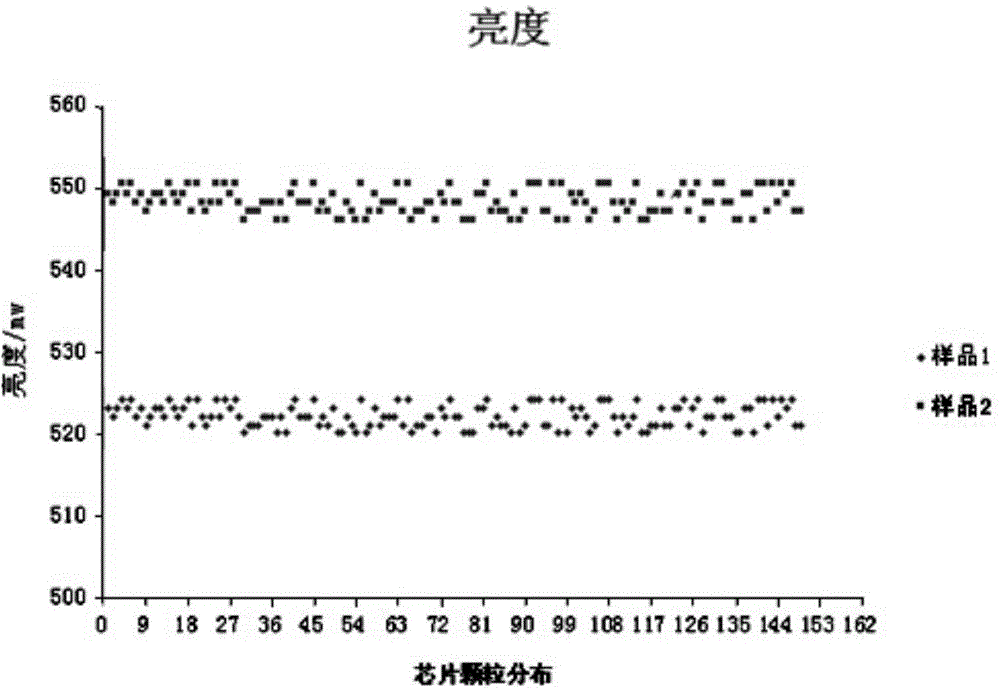

LED (light emitting diode) epitaxial layer structure and growth method thereof

The invention discloses an LED (light emitting diode) epitaxial layer structure. The LED epitaxial layer structure comprises a sapphire substrate, a low temperature buffer layer located on the sapphire substrate, a high temperature GaN layer located above the low temperature buffer layer, a high temperature N type GaN layer located above the high temperature GaN layer, a transition layer located above the high temperature N type GaN layer, a luminous layer arranged above the transition layer, a P type AlGaN layer located above the luminous layer and a high temperature P type GaN layer located above the P type AlGaN layer, wherein the transition layer is formed by alternately arranging Si3N4 / GaN superlattice layers and non-doped GaN layers, the thickness of the transition layer ranges from 30nm to 120nm, and the luminous layer comprises InxGa(1-x)N layers doped with In and non-dopted GaN layers, which are alternately arranged. The invention further discloses a growth method of the LED epitaxial layer structure. The LED epitaxial layer structure reduces stress between the high temperature N type GaN layer and the luminous layer.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

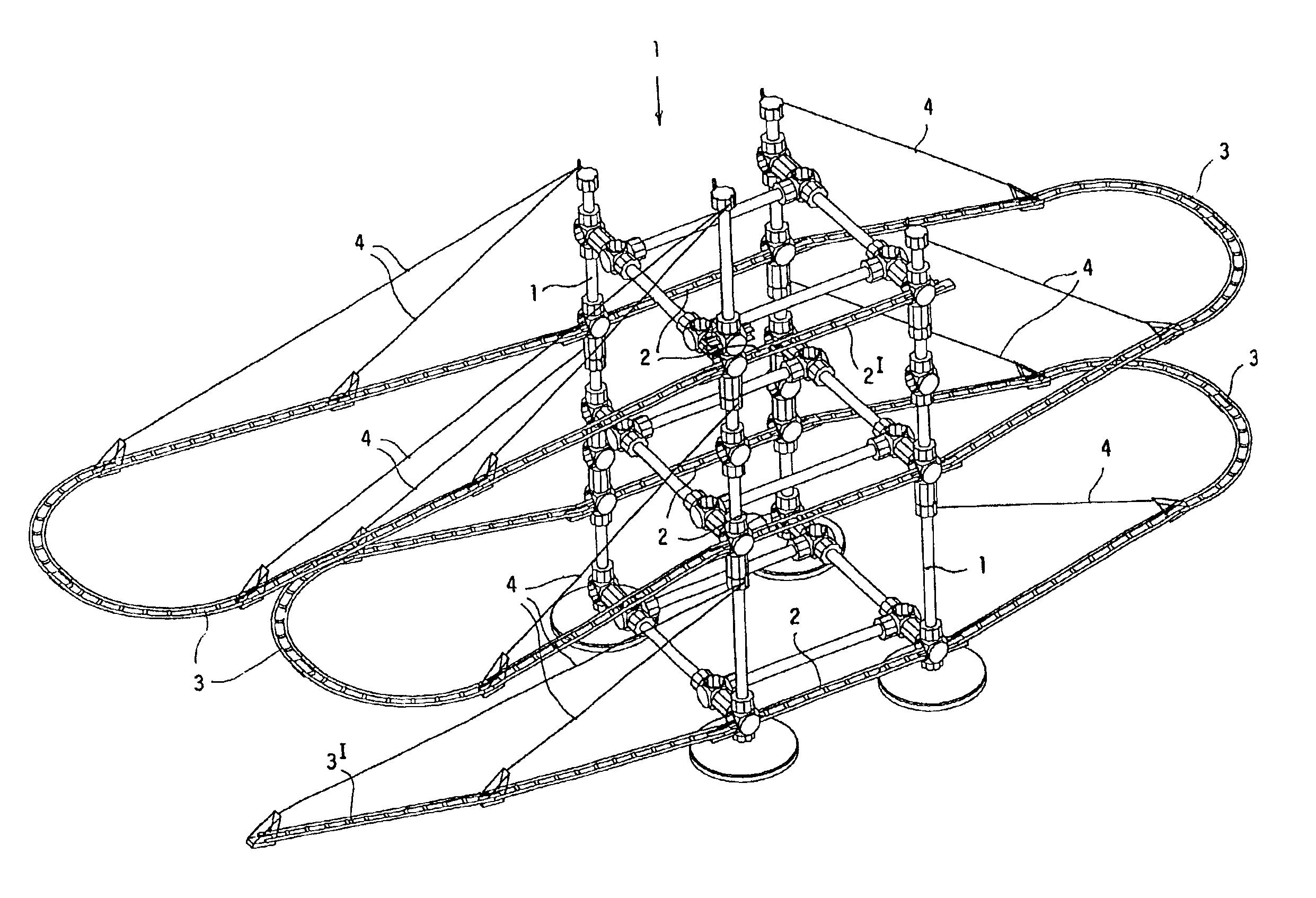

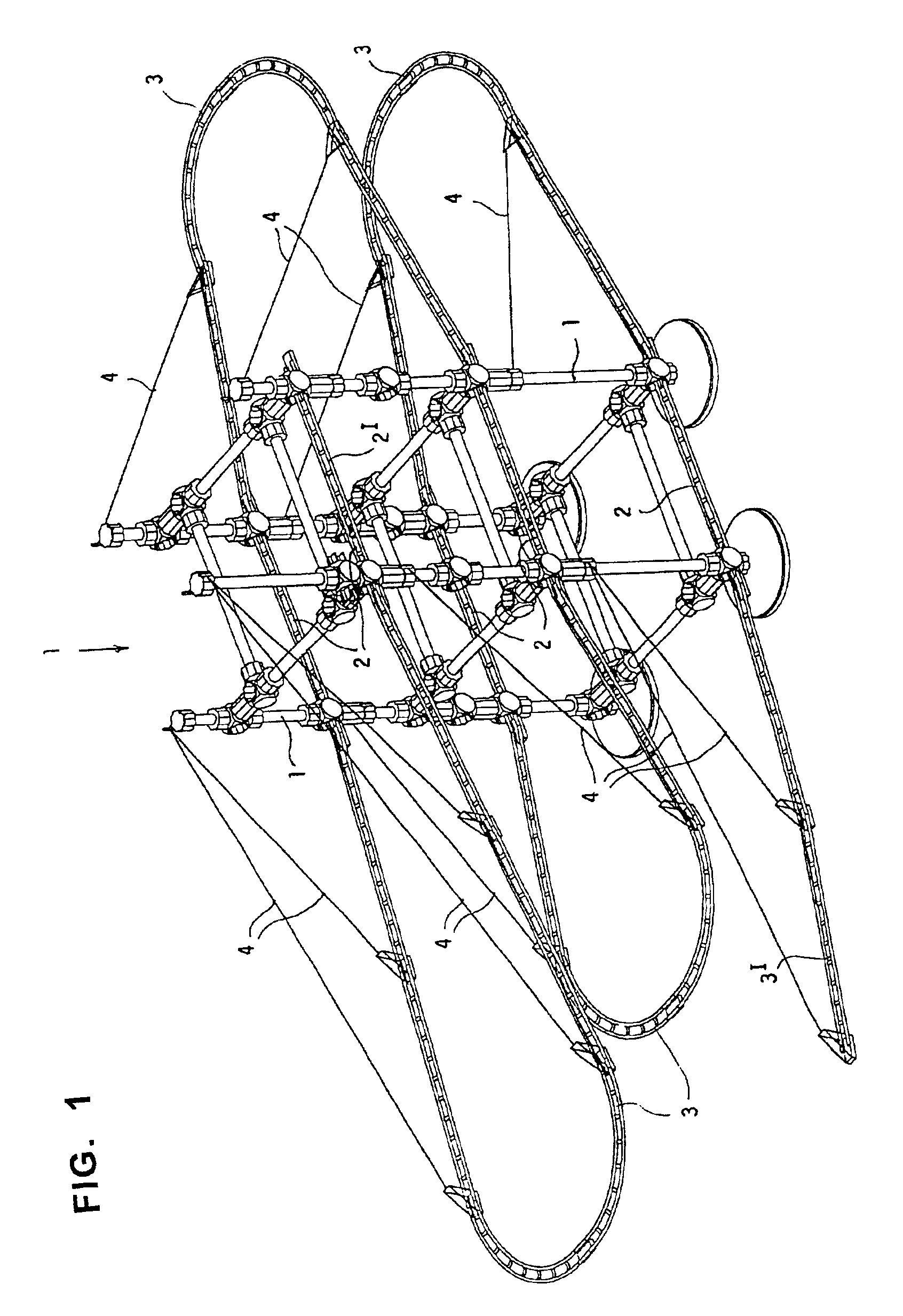

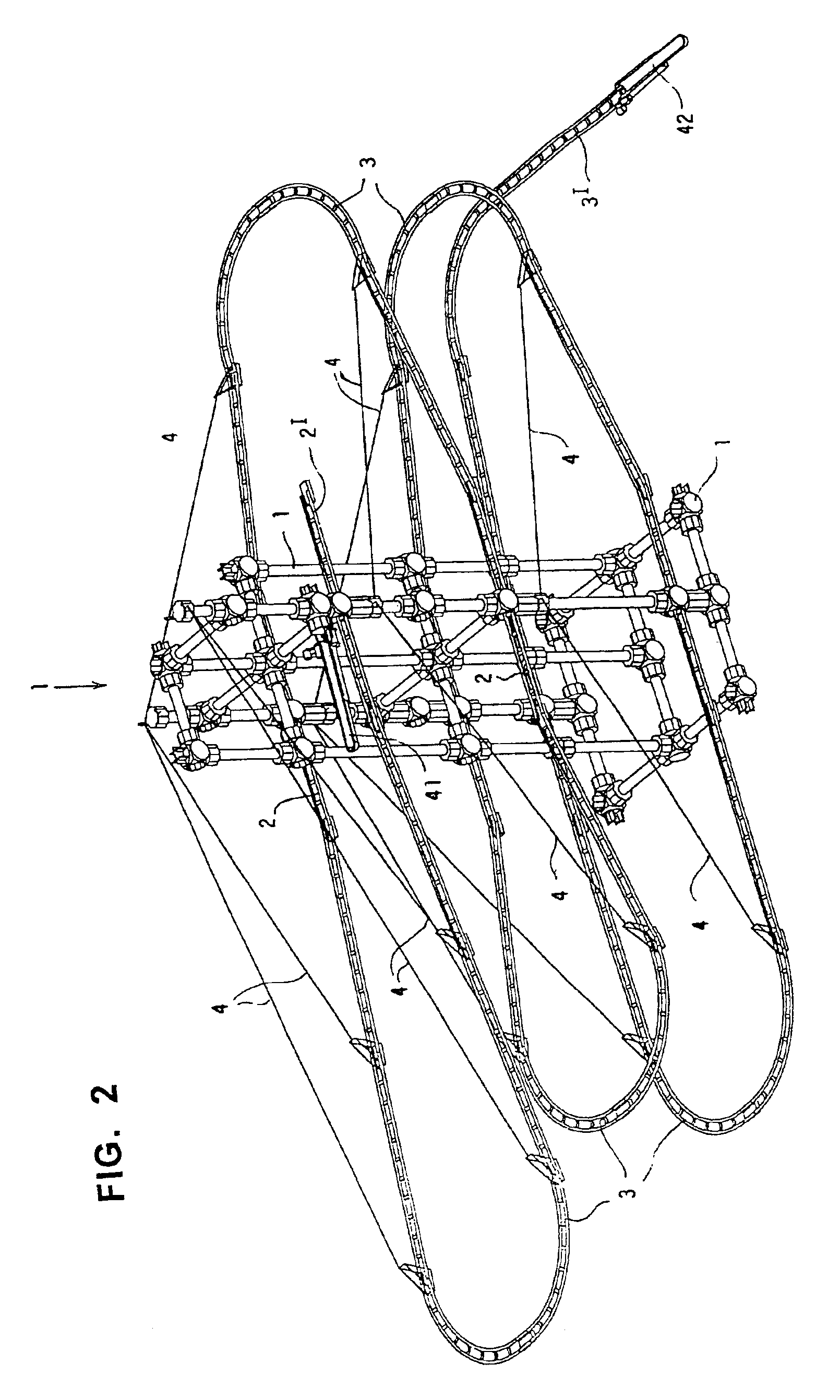

Suspended runway

InactiveUS6945839B2Increase attractivenessAdd supportDollsSelf-moving toy figuresTrackwayEngineering

A runway over which can travel vehicles driven by gravity, comprising a supporting structure and a track line structure sustained by the supporting structure and extending from a upper start region to a lower arrival region, wherein the supporting structure is limited to a central region of the runway by forming a pillar, and the track line structure includes some track line sections directly connected to the supporting structure and several overhanging track line sections of large extent, which project out of the supporting structure and are sustained by the same by means of rigging systems whose extension can be regulated; these rigging systems establish the geometrical location of the overhanging track line sections. In the embodiments intended to be used as games, the structures are embodied by the composition of systems of composable modular elements, which moreover allow to realize non-suspended runway structures, and which are compatible and integrated with a general system of composable elements, preferably the system of composable elements according to the U.S. Pat. No. 6,315,628.

Owner:ALESSANDRO QUERCETTI & C FAB GIOCATTOLI FORMATIVI

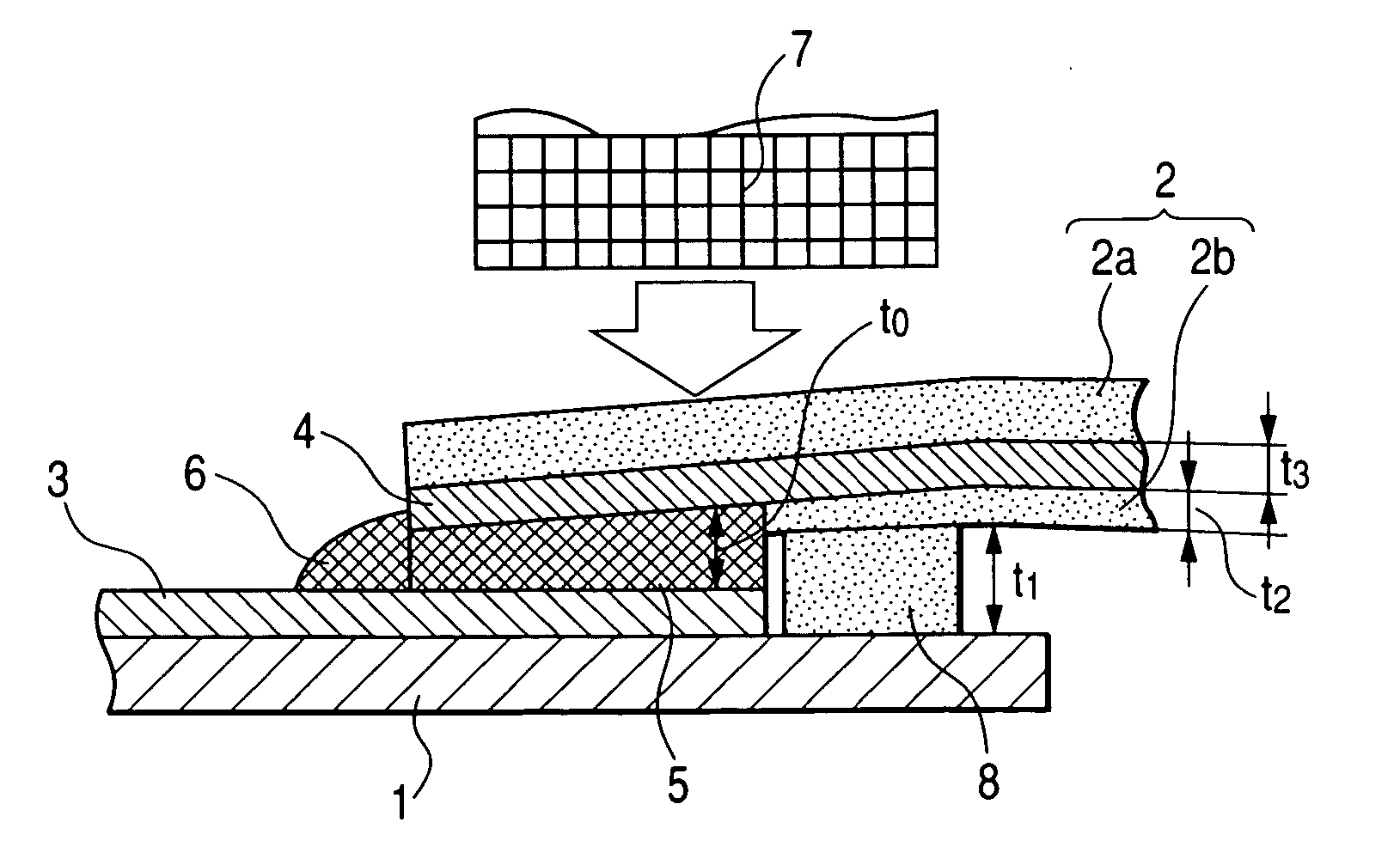

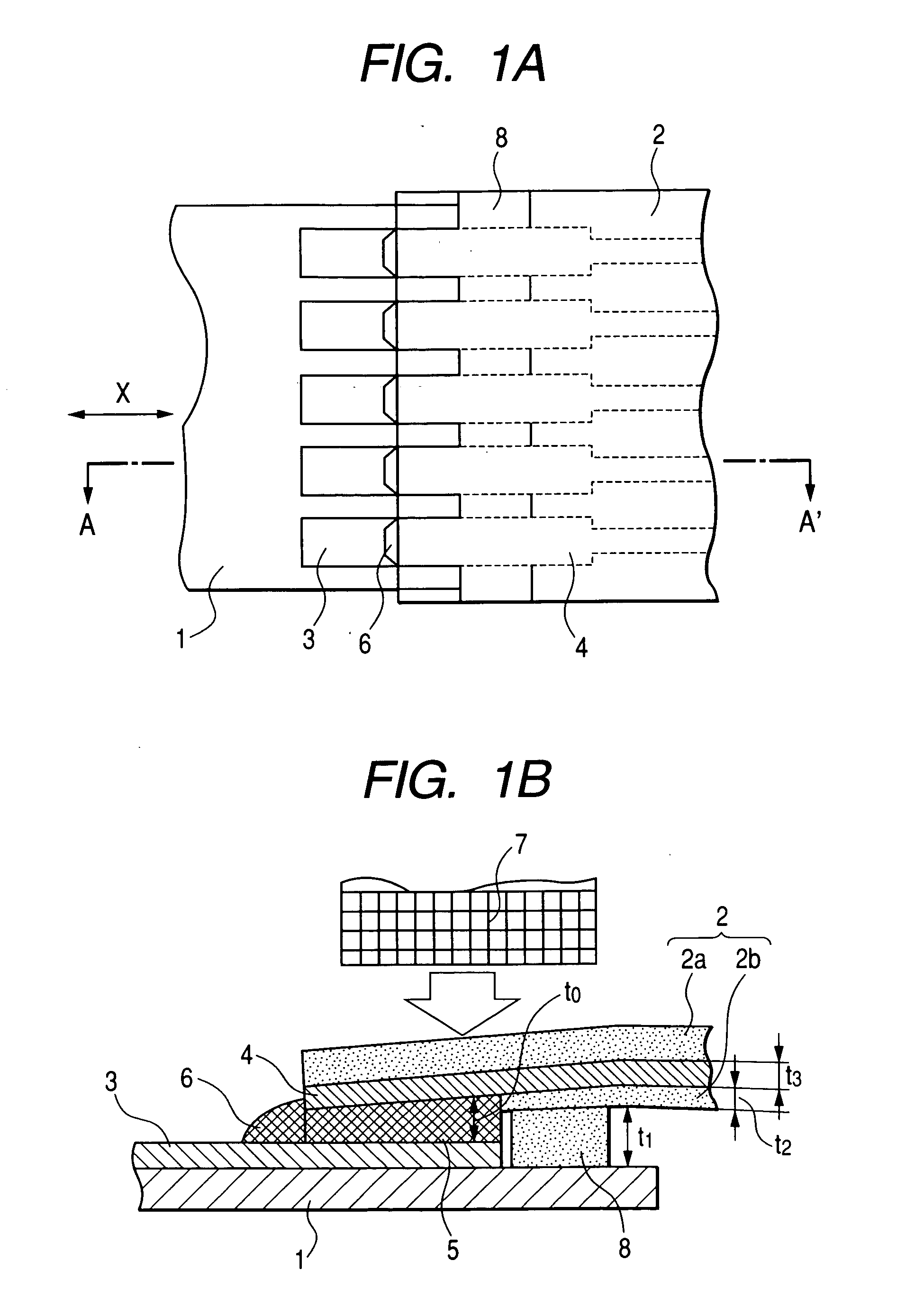

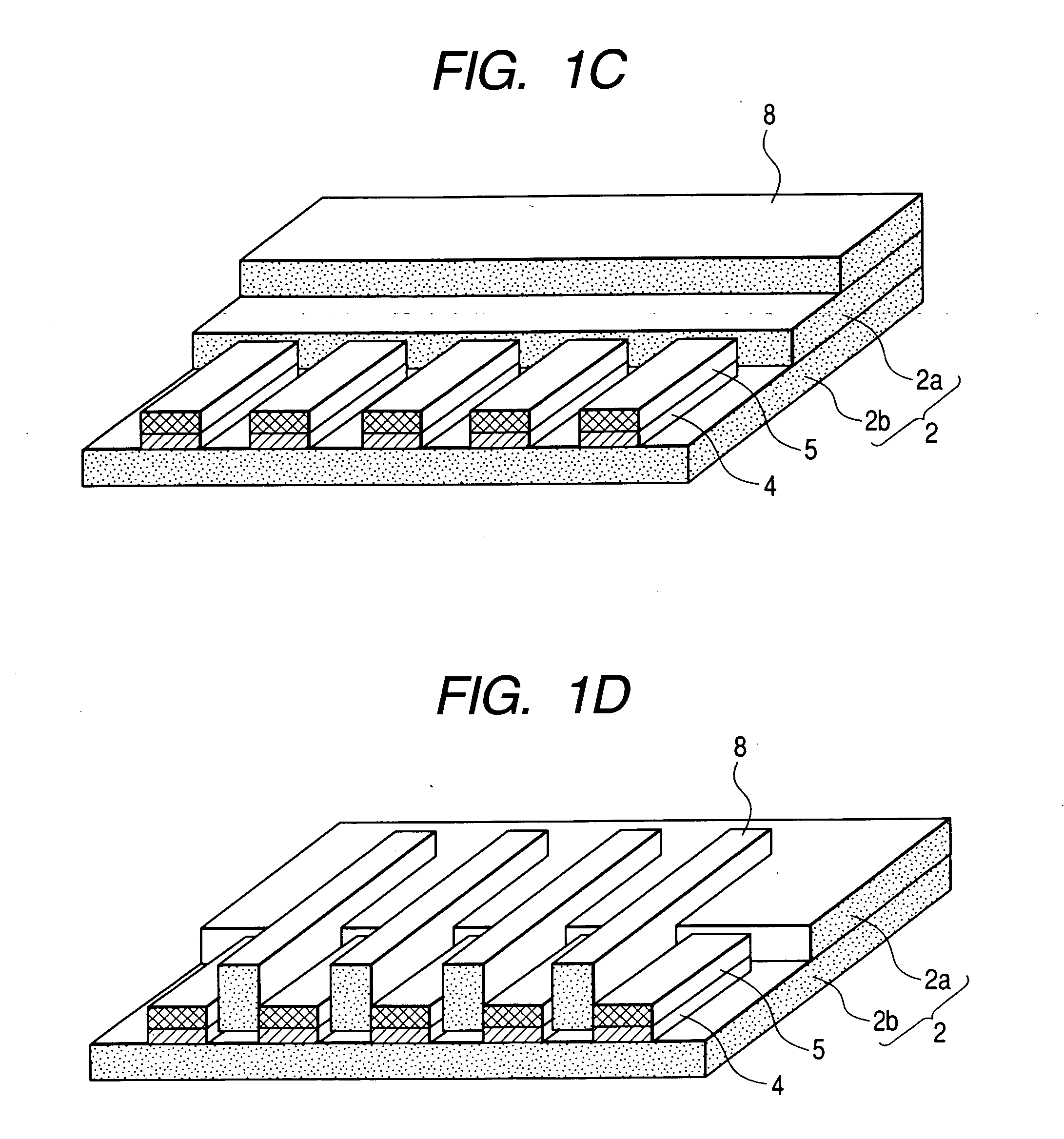

Connection structure of rigid printed circuit board and flexible circuit, the connection process and the circuit module using it

InactiveUS20050176310A1Improve reliabilityLow costPrinted circuit assemblingLine/current collector detailsResistFlexible circuits

In a connection structure of a rigid printed circuit board and a flexible circuit each having a plurality of connection terminals, there are provided a connection structure that can obtain a necessary connection strength and prevent short-circuiting between adjacent connection terminals, and a connection process thereof. A rigid printed circuit board having a plurality of connection terminals is superimposed on a flexible circuit that puts a conductive pattern having connection terminals having the same configuration as that of the connection terminals of the rigid printed circuit board at an end thereof by flexible insulating resin, and connected to the flexible circuit with a solder due to thermo compression. A solder resist is disposed on the flexible insulating resin on the flexible circuit, and the solder connection can be realized by using a solder plating formed on one or both electrodes of the rigid printed circuit board and the flexible circuit while an amount of occlusion gas is controlled.

Owner:OPNEXT JAPAN INC

Electronic apparatus

InactiveUS7365976B2Small sizePreventing an efficient airflowDigital data processing detailsCooling/ventilation/heating modificationsElectronic equipmentElectrical and Electronics engineering

A first printed wiring board extends in the vertical direction within a first duct that extends in the vertical direction. A first axial flow fan generates airflow which absorbs heat from the first printed wiring board. Second and third ducts extends in parallel with the first duct. A fourth duct extends between the second and third ducts. A second printed wiring board extends in the horizontal direction within the fourth duct. A second axial flow fan is connected to the third duct. The second axial flow fan generates airflow which absorbs heat from the second printed wiring board. The electronic apparatus can be reduced in size.

Owner:FUJITSU LTD

Heat exchanger and fin material for the heat exchanger

ActiveUS20060166030A1Securing durabilityStable characteristicsCurling devicesWelding/cutting media/materialsFilling materialsTriple layer

A heat exchanger which has i) a fin material comprising a triple-layer clad material constituted of a core material composed of an aluminum alloy containing from 0.5 to 1.8% by weight of Mn and from 0.5 to 3.0% by weight of Zn and, provided on both sides of the core material, a brazing filler material composed of an Al—Si alloy containing from 6.5 to 13.0% by weight of Si and from 0.15 to 0.60% by weight of Cu and ii) an aluminum alloy tube having a Zn concentrated surface; the both having been brazed with each other; wherein, after brazing, recrystallized grains of the core material have an average length of from 100 to 1,000 μm in the lengthwise section of a fin and the recrystallized grains of the core material are 4 or less in average number in the thickness direction of that lengthwise section. This heat exchanger is improved in the durability of fin joints and fins themselves and their strength after corrosion.

Owner:FURUKAWA SKY ALUMINUM CORP

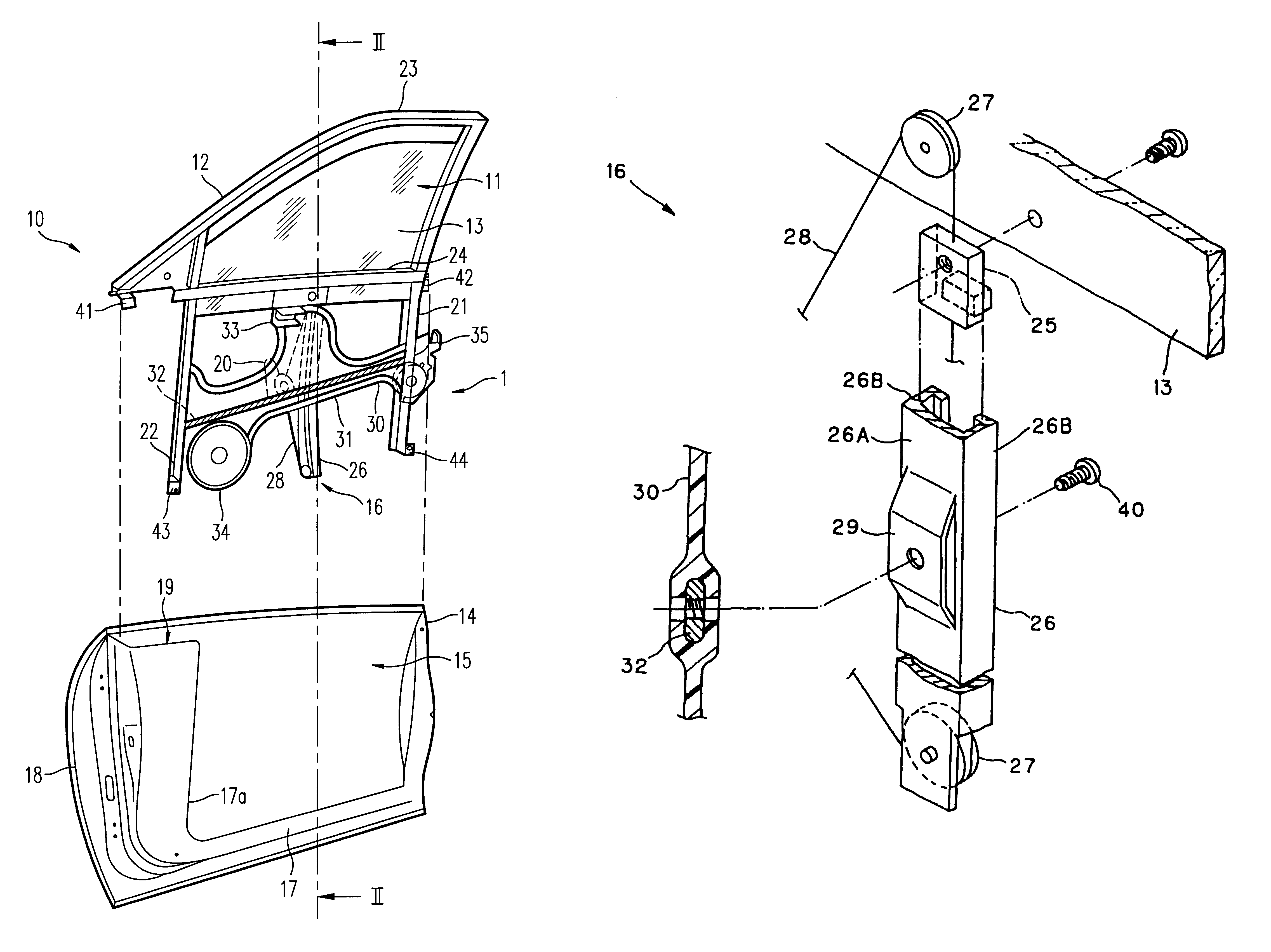

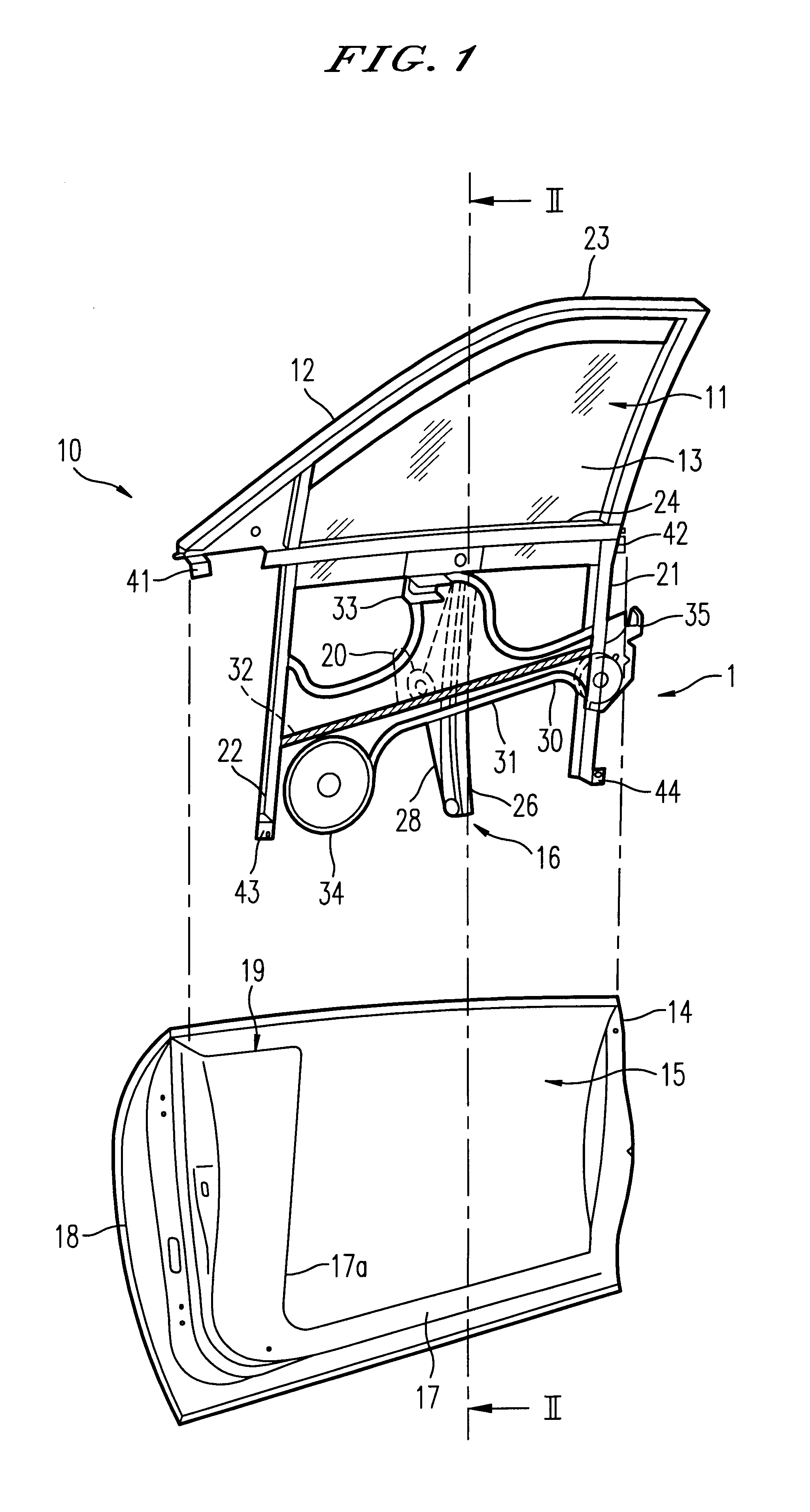

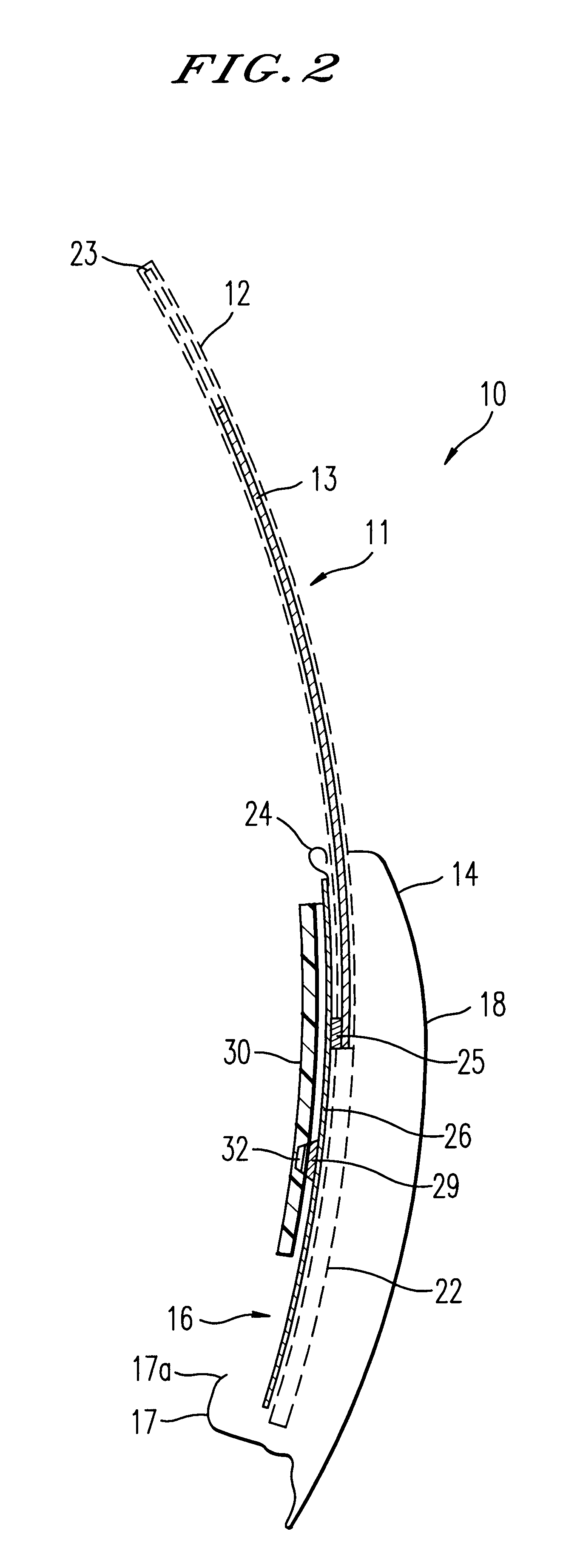

Vehicle door module including metallic elongated member incorporated within resin base plate

InactiveUS6223472B1Reduce vehicle weightEnsure required strengthMan-operated mechanismMonocoque constructionsWindow openingCar door

A vehicle door including a window regulator, a first sash, a second sash, and a metallic elongated member which are incorporated with a base plate as a module which is to be mounted to a door main body. The main body is provided under the window opening of the door and has a housing space configured to house a windowpane. The window regulator is configured to move the windowpane between the window opening and the housing space. Each of the first and second sashes are configured to guide a respective one of the sides of the windowpane when the windowpane is moved by the window regulator. The first and second sashes are provided in parallel with each other. The base plate extends between the first sash and the second sash and is made of a resin material in a plate-shaped form. The metallic elongated member extends between the first sash and the second sash. The window regulator is provided on the elongated member.

Owner:ASAHI GLASS CO LTD

Method for preparing film GaN LED based on plane bonding and temporality substrate transfer technology

ActiveCN101465401AAchieve absolute separationReduce generationSemiconductor devicesOptoelectronicsLead preparation

The invention discloses a film GaN LED preparation method based on the plane bonding and temporary substrate transfer technology. In the method, a plane is firstly bonded on a support substrate and then unit devices are separated, so that the gapless seaming between the GaN LED and the support substrate can be realized; then the absolute separation among all the GaN LED devices is achieved so as to reduce the production and extension of the cracks in the laser stripping process; through the temporary substrate, chip manufacturing is carried out after the laser stripping to ensure high yield rate of GaN LED film production when the sapphire substrate is removed after large-area laser stripping.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

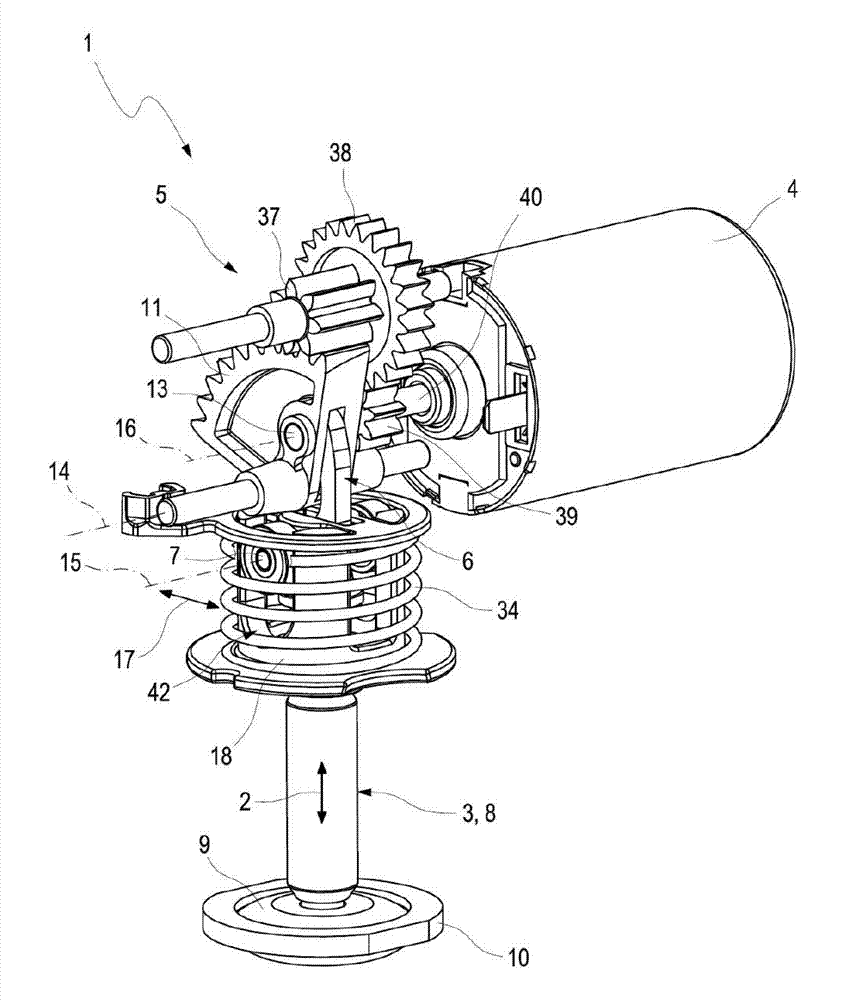

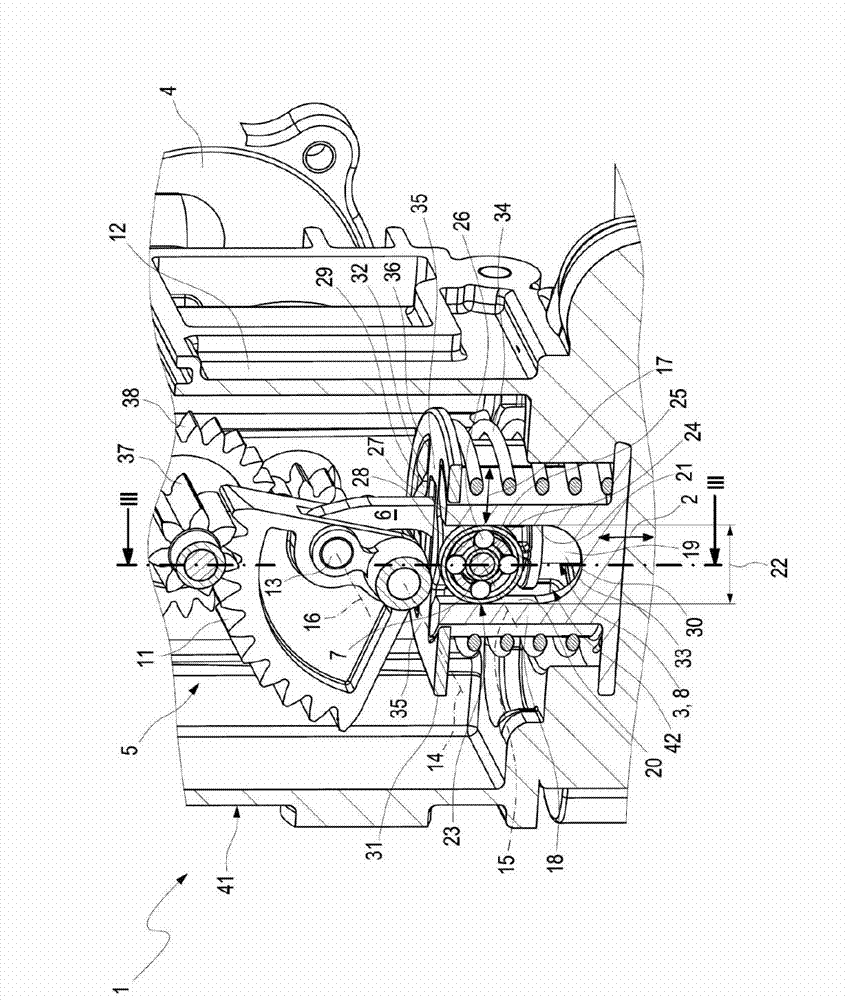

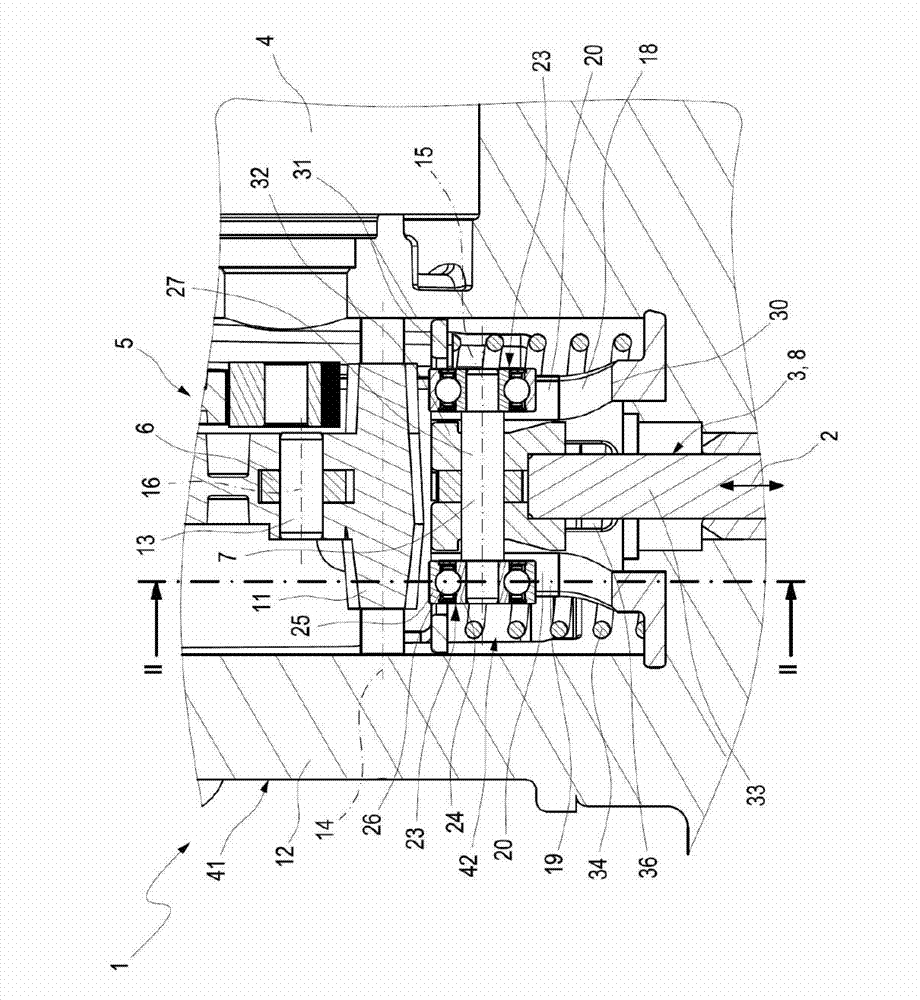

Actuating drive, exhaust gas recirculating valve, turbocharger

ActiveCN102971520AStable supportLow extensionOperating means/releasing devices for valvesNon-fuel substance addition to fuelTurbochargerActuator

The invention relates to an actuating drive (1) for a bidirectionally adjustable actuating element (3), in particular for an exhaust gas recirculating device or for a turbocharger, comprising an actuator (4) for generating driving forces, comprising a toggle lever (6) that is connected to the actuating element (3) in an articulated manner via a first toggle lever joint (7), and comprising a force transmitting arrangement (5) that connects the actuator (4) to the toggle lever (6) in order to transmit forces. An output-side output element (11) of the force transmitting arrangement (5) is pivotably mounted on a support housing section (12) of the actuating drive (1), and the toggle lever (6) is connected to the output element (11) in an articulated manner via a second toggle lever joint (13). Wear reduction can be achieved using a transverse support (42) that supports the toggle lever (6) and / or the actuating element (3) on a guiding housing section (18) of the actuating drive (1) in a direction of support (17) that is oriented transversally to the direction of movement (2) of the actuating element (3).

Owner:MAHLE INT GMBH

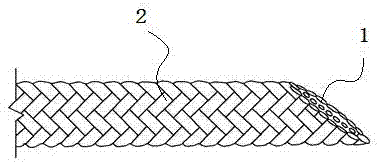

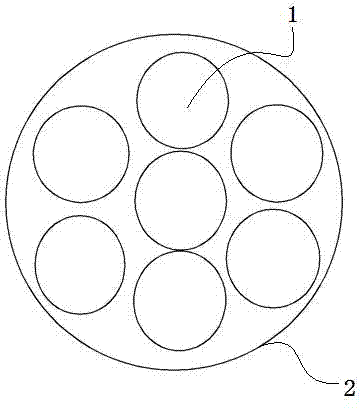

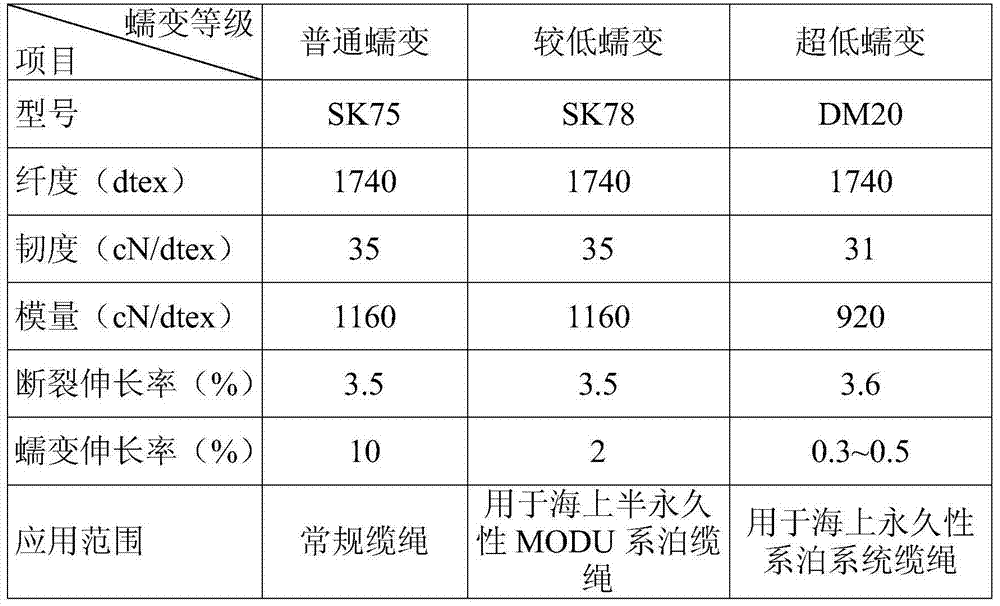

Offshore underwater component device mooring cable and manufacturing method thereof

The invention relates to an offshore underwater component device mooring cable. The offshore underwater component device mooring cable is characterized by being of a sheath-core composite double-layer structure, an inner core is of a eight-strand structure made of DM20 ultra-high molecular weight polyethylene, an outer layer is a fixing sheath formed by weaving wear-proof high-strength polyester fibers, the inner core is formed according to the steps of manufacturing rough yarn, manufacturing rope yarn, manufacturing strands, weaving ropes, soaking the inner core in resin, prestretching the inner core and drying the inner core, and the fixing sheath is formed according to the steps of splicing threads, twisting the threads, manufacturing strands and weaving the 32 strands around the inner core into the fixing sheath in a one-off mode through a double-layer weaving machine.

Owner:TAIZHOU HONG DA ROPE & NET

High-strength fiber double-layer interweaved composite hose and production method thereof

InactiveCN103879036AGood flexibilityImprove pressure resistanceLayered productsMulti-ply fabricsRubber materialWhole body

The invention discloses a high-strength fiber double-layer interweaved composite hose and a production method of the composite hose. The high-strength fiber double-layer interweaved composite hose comprises a hose blank, wherein in an inner surface and an outer surface of the hose blank, a rubber material layer is composited on at least the inner surface of the hose blank; the hose blank is a double-layer fabric with a double-layer section, and six paths of warps form a circulative weaving tissue; the double-layer fabric comprises an inner layer and an outer layer, the outer layer comprises an outer-layer warp and an outer-layer weft, the inner layer comprises an inner-layer warp and an inner-layer weft, and the inner-layer weft is interweaved with the inner-layer warp and is also interweaved with the outer-layer warp, so that the inner layer and the outer layer are interweaved into a whole body. According to the high-strength fiber double-layer interweaved composite hose disclosed by the invention, the woven hose blank has good flexibility, high pressure resistance, a few interweaving points, small yarn strength loss and small torsion degree; superlarge-aperture and high-pressure-resistance hoses meeting the market demand can be produced without special modification on the original device; the production process is simple; the practical value is high, and the production generalization performance is excellent.

Owner:蔡宝祥

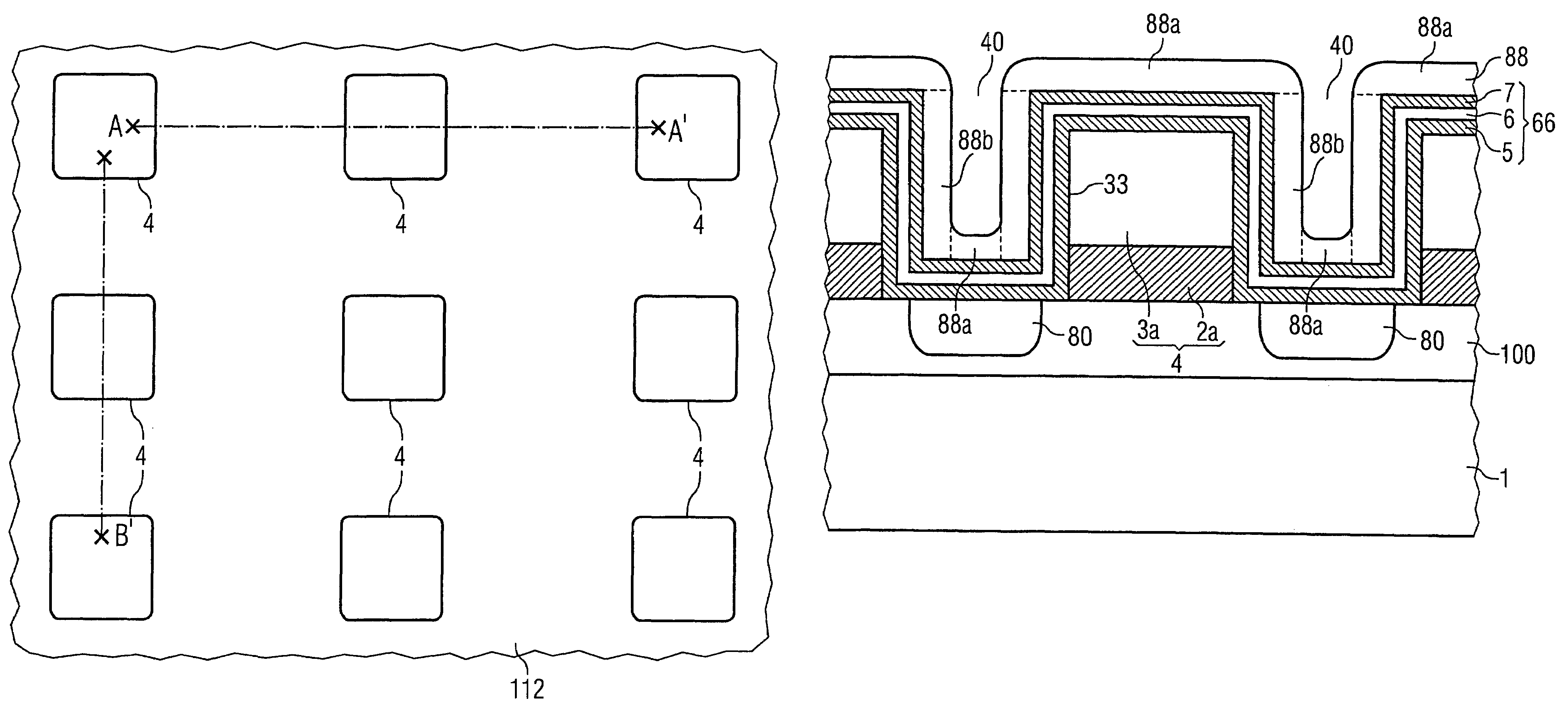

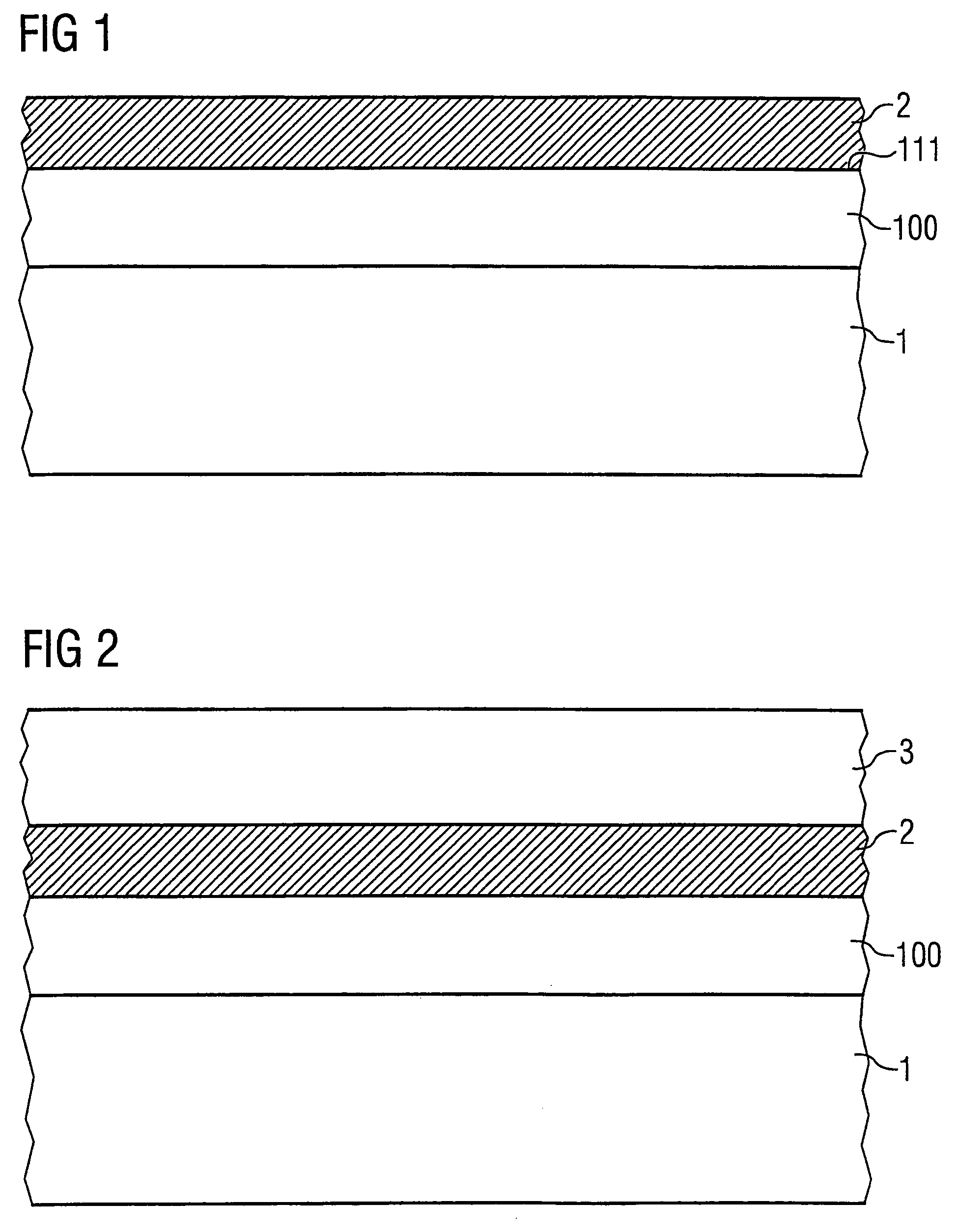

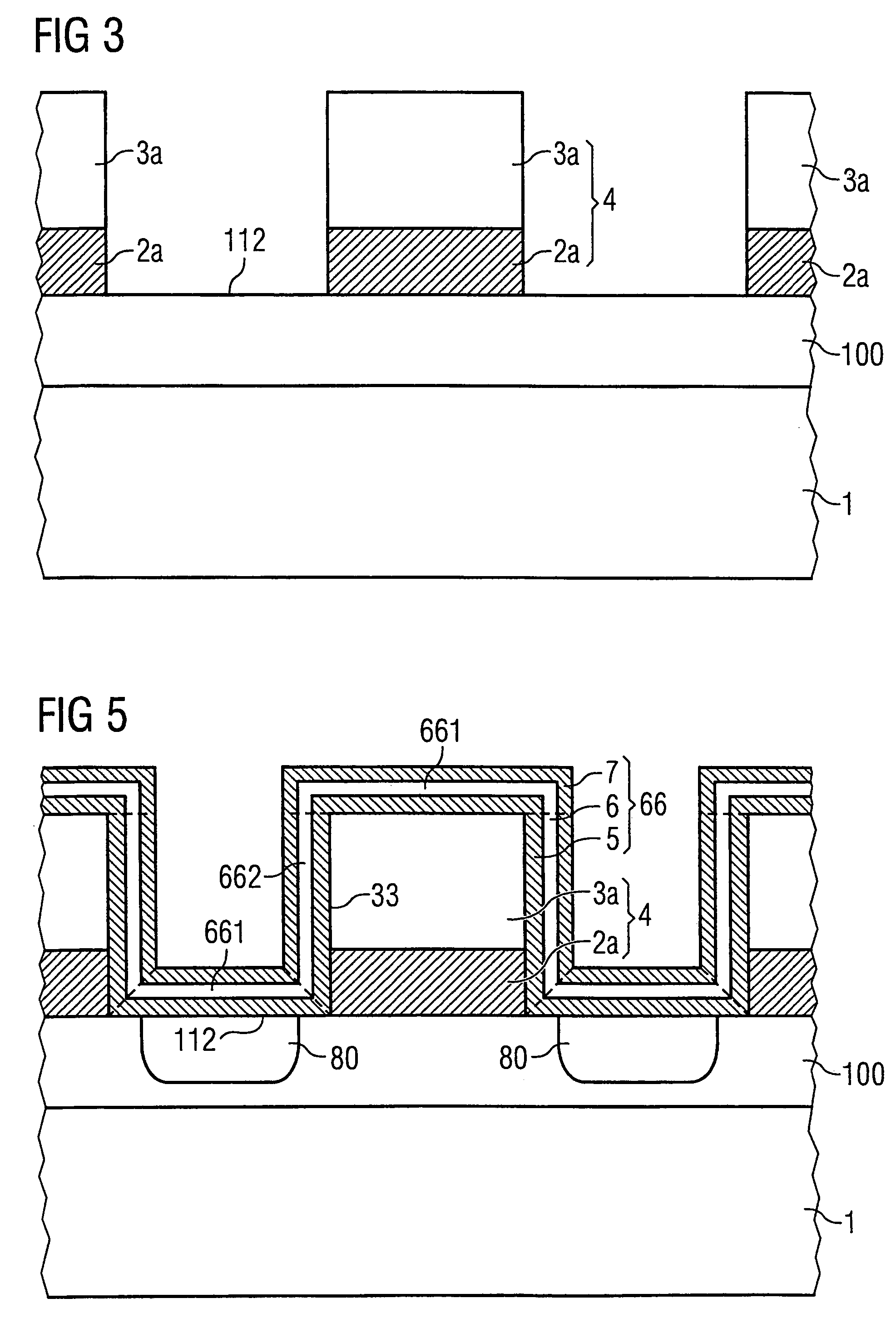

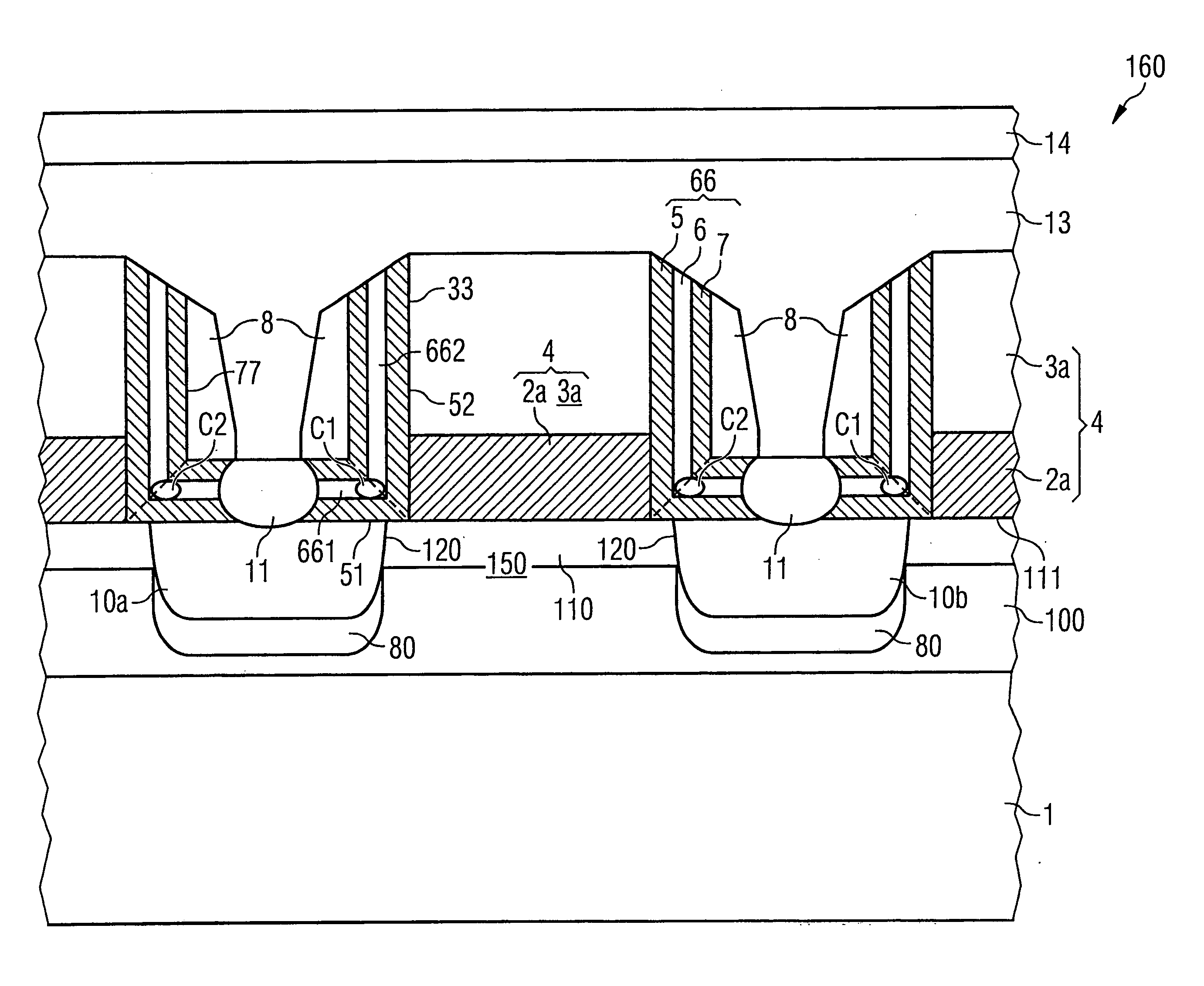

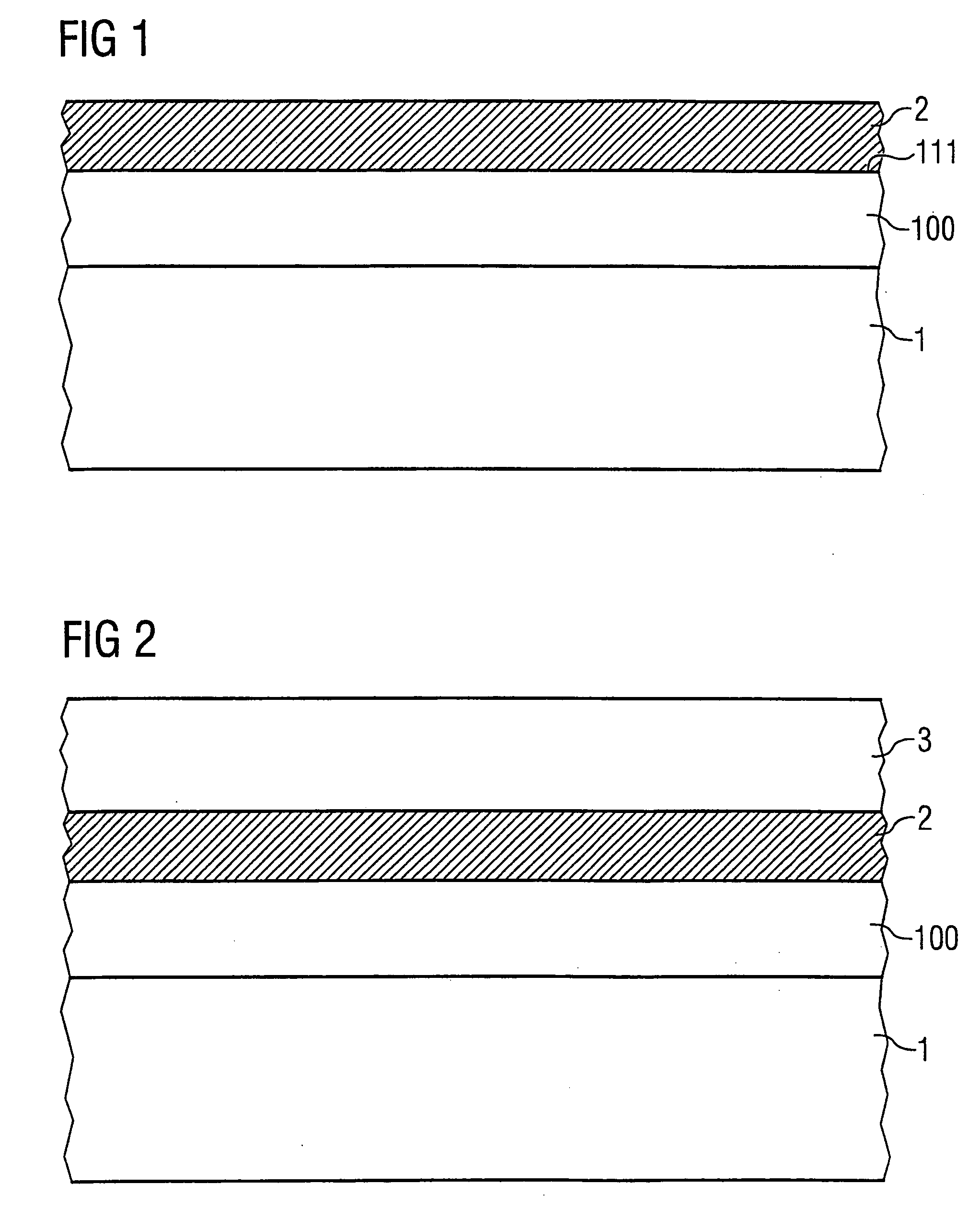

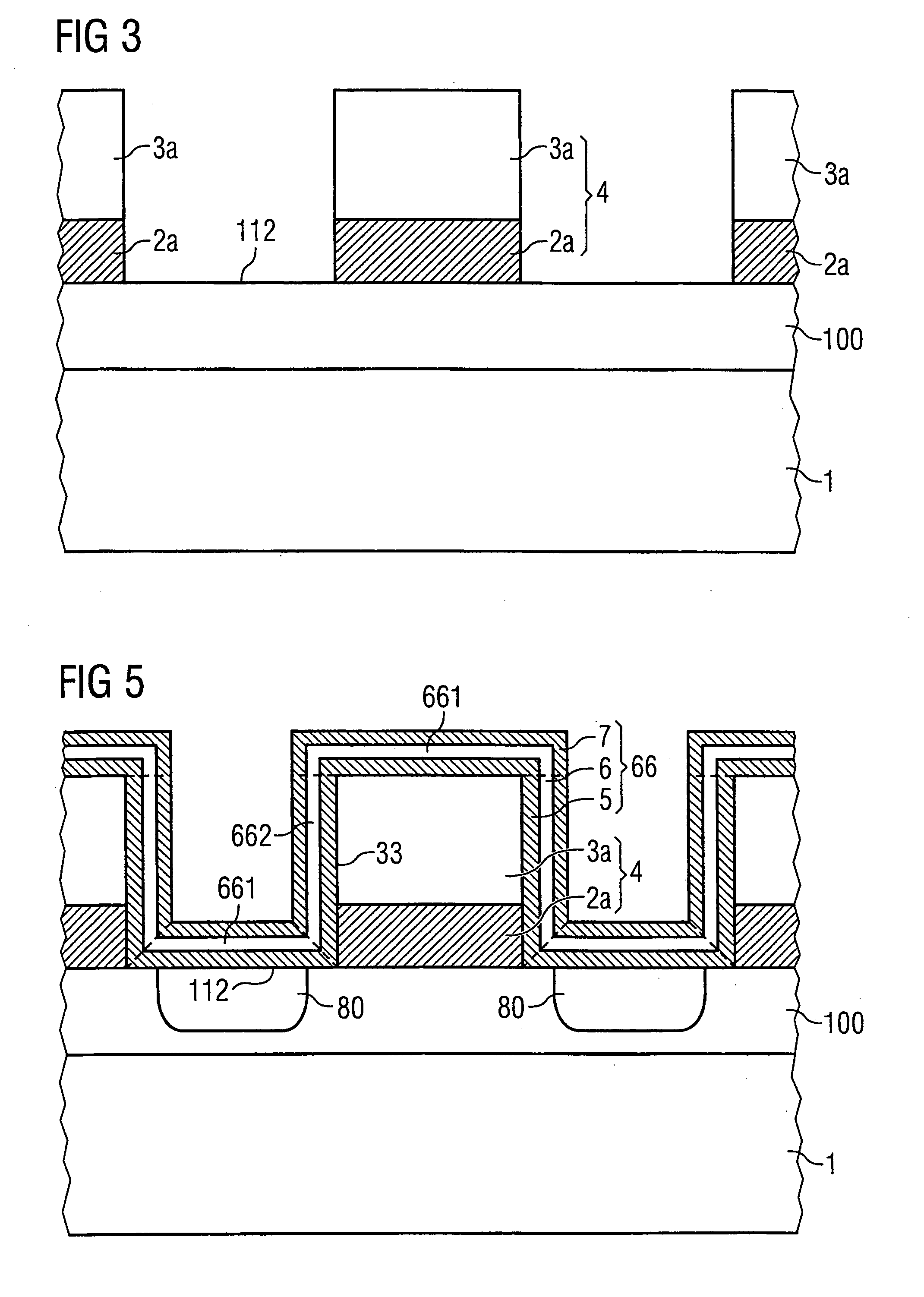

Semiconductor device and method of producing a semiconductor device

InactiveUS7238974B2Good two-bit segregationEasy alignmentTransistorSemiconductor/solid-state device detailsDielectric layerNitride

A semiconductor device comprises a memory cell (160) including a transistor body (150) having a top surface (111) and including a first doping area (10a) and a second doping area (10b) with a channel region (110) in between. The memory cell (160) further includes a gate electrode (3a) arranged above the channel region (110) and separated therefrom by a dielectric layer (2a). An oxide-nitride-oxide layer (66) has first portions (661) and second portions (662). The first portions (661) of the oxide-nitride-oxide layer (66) are arranged above at least parts of the first and second doping areas (10a, 10b) and are substantially parallel to the top surface (111) of the transistor body (150). The second portions (662) of the oxide-nitride-oxide layer (66) are adjacent to the gate electrode (3a) and extend in a direction not substantially parallel to the top surface (111) of the transistor body (150).

Owner:QIMONDA

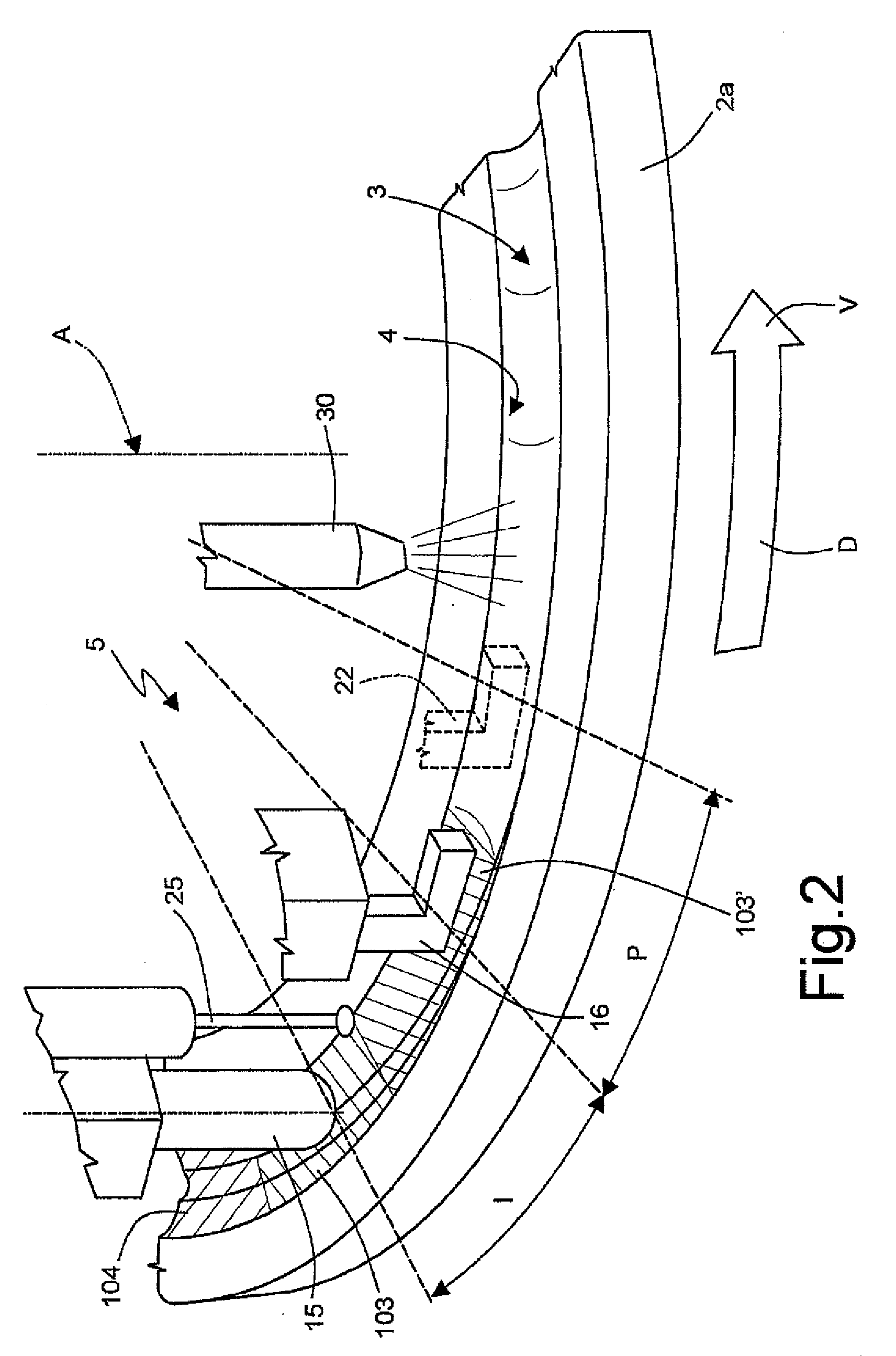

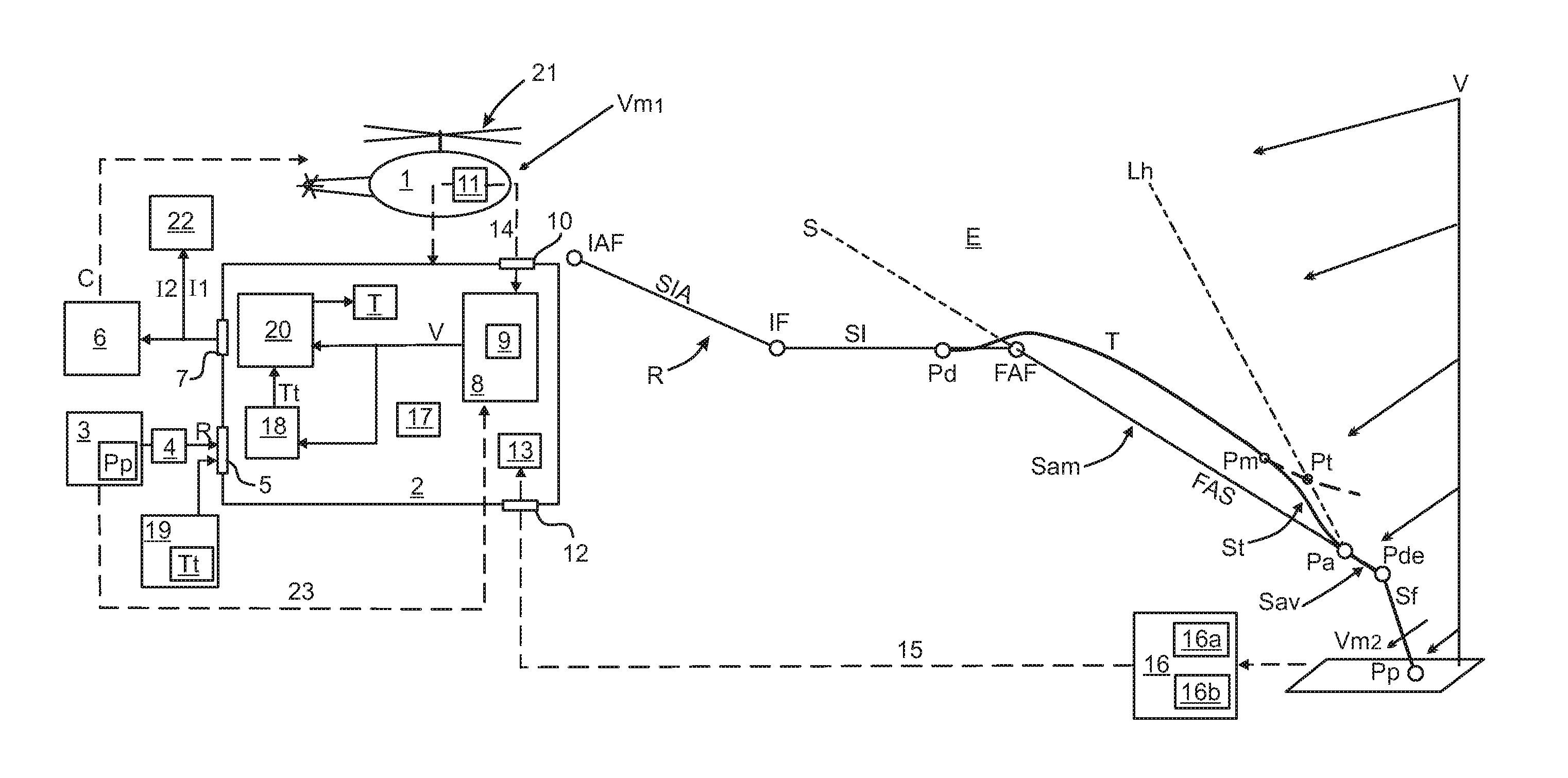

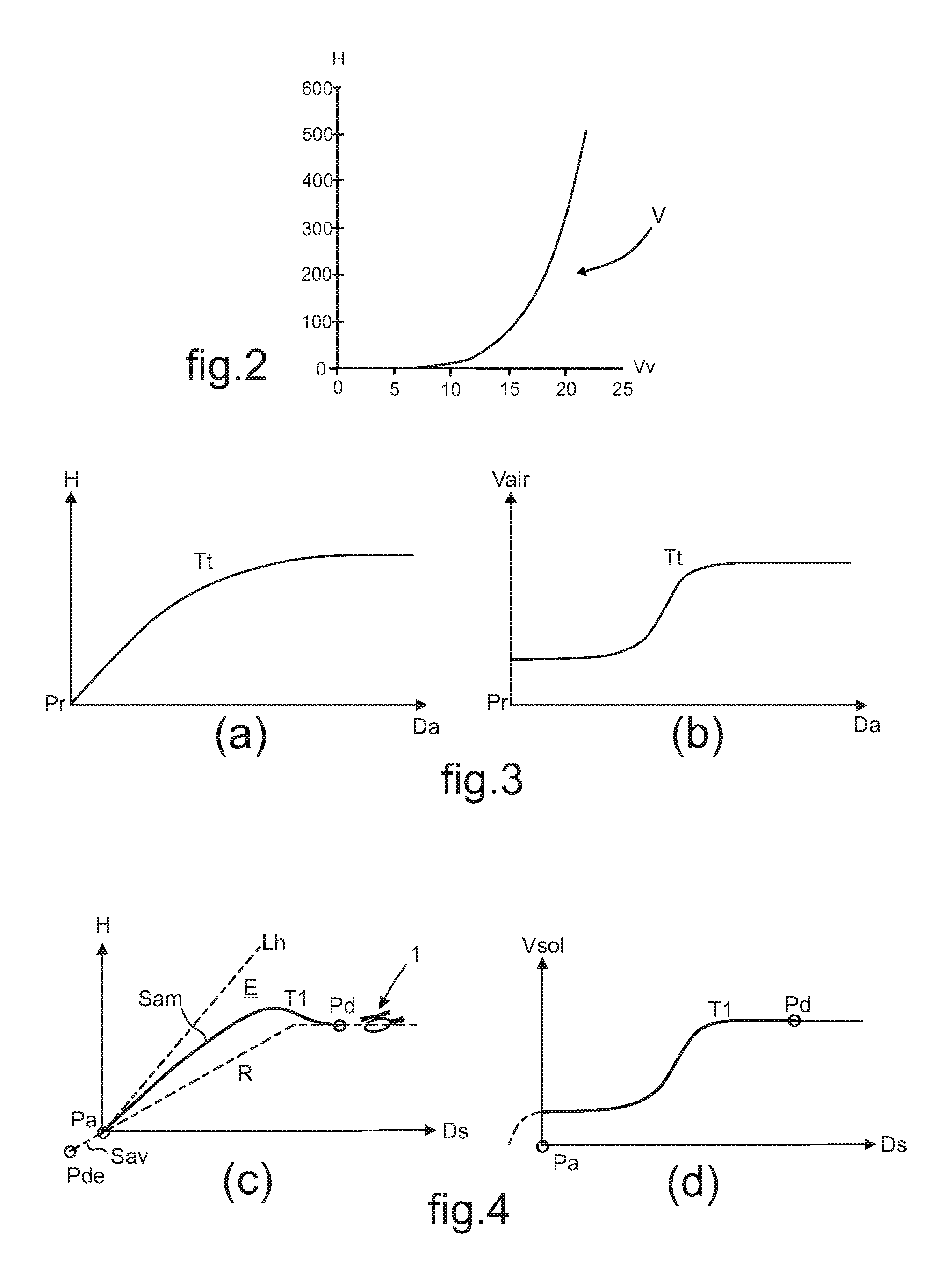

Method for the guidance of a rotorcraft, which method limits noise discomfort in a procedure for the approach to a landing point

ActiveUS20140246541A1Optimized reduction of noise discomfortLow extensionFuselage insulationVehicle position/course/altitude controlLow noiseWind model

A method for the guidance of a rotorcraft (1) in relation to a landing point (Pp) in accordance with a landing procedure. An approach route (R) is identified and an approach trajectory (T) is calculated in accordance with a ground slope (S) imposed by the approach route (R). An upstream segment (Sam) of the approach trajectory (T) is calculated through the application of a typical trajectory, as defined in accordance with the ground slope (S), the current mass of the rotorcraft (1), and a low-noise or noise-abatement criterion relating to the noise discomfort generated by the rotorcraft (1), taking into consideration a wind model (V) that represents the change in the wind between a current position of the rotorcraft (1) and the landing point (Pp). The position of the rotorcraft (1) is adjusted in proximity to the landing point (Pp) along the length of a transitional segment (St) of the approach trajectory (T), excluding, from the extension of the transitional segment (St), an application of the typical trajectory, and taking into consideration the ability of the rotorcraft (1) to perform a rapid maneuver toward a downstream segment (Sav) of the approach trajectory (T), as predefined in accordance with the ability of the rotorcraft (1) to reach the landing point (Pp) during stable flight.

Owner:EUROCOPTER

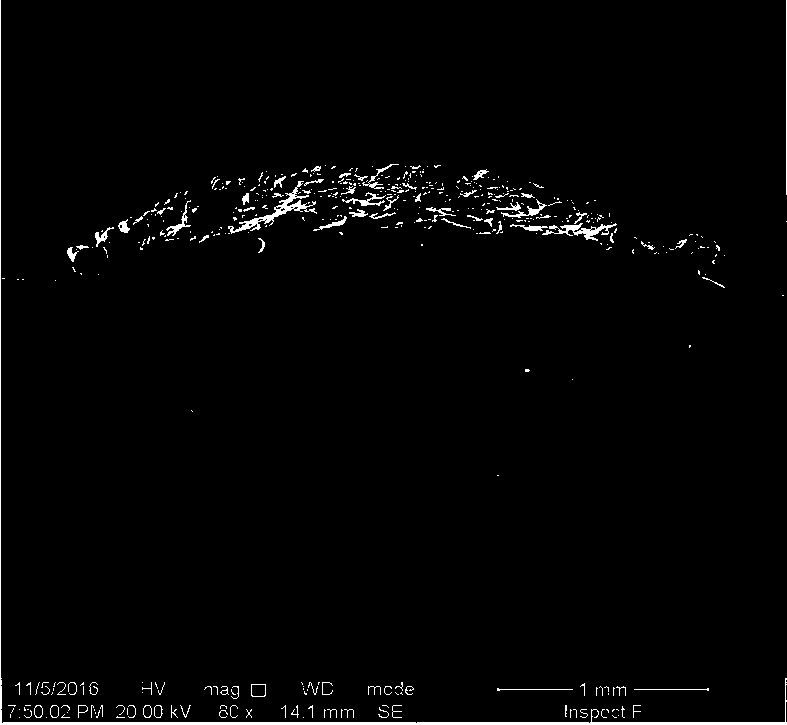

Laser cladding metal-ceramic coating material based on ZrO2 doping

ActiveCN108707893AReduce generationLow extensionMetallic material coating processesStress concentrationAlloy substrate

The invention discloses a laser cladding metal-ceramic coating material based on ZrO2 doping. The laser cladding metal-ceramic coating material based on ZrO2 doping is prepared by mixing 5-20 wt% of Ti powder, 70-92 wt% of TiBCN ceramic powder and 3-10 wt% of ZrO2 powder. The coating material is clad on the surface of a titanium alloy substrate by a laser cladding technology. The coating materialcan absorb strain energy of residual thermal stress of laser cladding, reduce crack generation and extension caused by stress concentration, improve fracture toughness of the cladding coating, and increase strength and corrosion resistance of the cladding coating to form a toughened metal-ceramic cladding coating.

Owner:ZHONGBEI UNIV

Manufacture method of secondary-seaming ternary-papermaking forming net

The invention discloses a manufacture method of a secondary-seaming ternary-papermaking forming net. Sixteen heald frames are adopted to interweave polyester or nylon monofilaments into three layers of different weaving structures into a whole, the three layers of different weaving structures comprise a paper-forming layer, an intermediate connecting layer and a machine layer, the minimum tissue unit comprising sixteen polyester monofilaments as warps and thirty-two polyester or nylon monofilaments as wefts, the warp number ratio of the paper-forming layer to the machine layer is 1:1, the weft number ratio of the paper-forming layer to the machine layer is 2:1, and the intermediate connecting layer comprises one half of total wefts and is characterized by being formed by the secondarily seaming of the self warp seaming and the self weft seaming of the paper-forming layer. The invention has the advantages of smooth papermaking surface, firm interlayer binding force, no internal abrasion or net elongation and compact and even net structure, and the machine layer has wear resistance, small thickness, long service life and strong dewatering performance.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Semiconductor device and method of producing a semiconductor device

InactiveUS20060091424A1Easy alignmentGood two-bit segregationTransistorSemiconductor/solid-state device detailsDevice materialDielectric layer

Semiconductor Device And Method Of Producing A Semiconductor Device A semiconductor device comprises a memory cell (160) including a transistor body (150) having a top surface (111) and including a first doping area (10a) and a second doping area (10b) with a channel region (110) in between. The memory cell (160) further includes a gate electrode (3a) arranged above the channel region (110) and separated therefrom by a dielectric layer (2a). An oxide-nitride-oxide layer (66) has first portions (661) and second portions (662). The first portions (661) of the oxide-nitride-oxide layer (66) are arranged above at least parts of the first and second doping areas (10a, 10b) and are substantially parallel to the top surface (111) of the transistor body (150). The second portions (662) of the oxide-nitride-oxide layer (66) are adjacent to the gate electrode (3a) and extend in a direction not substantially parallel to the top surface (111) of the transistor body (150).

Owner:QIMONDA

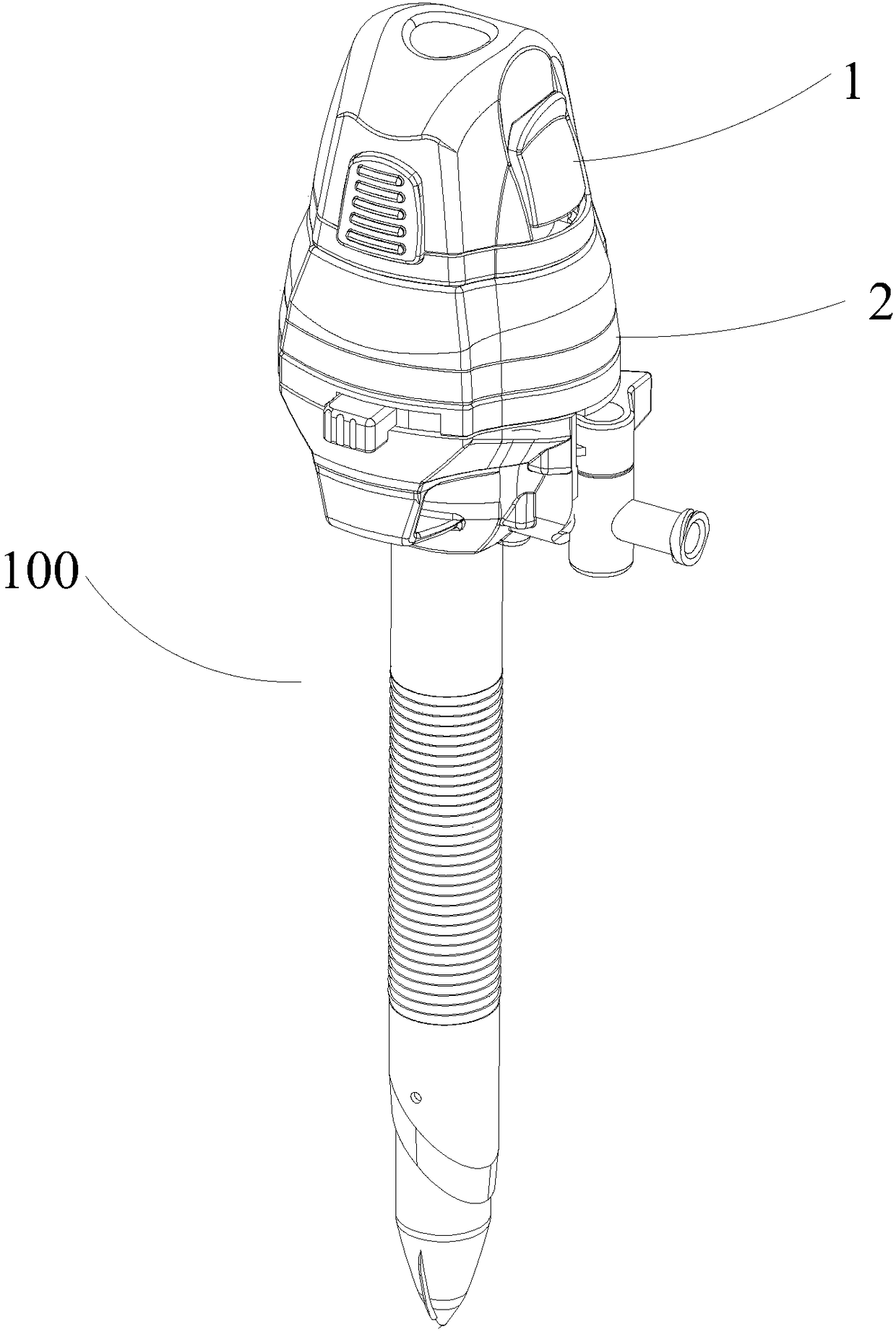

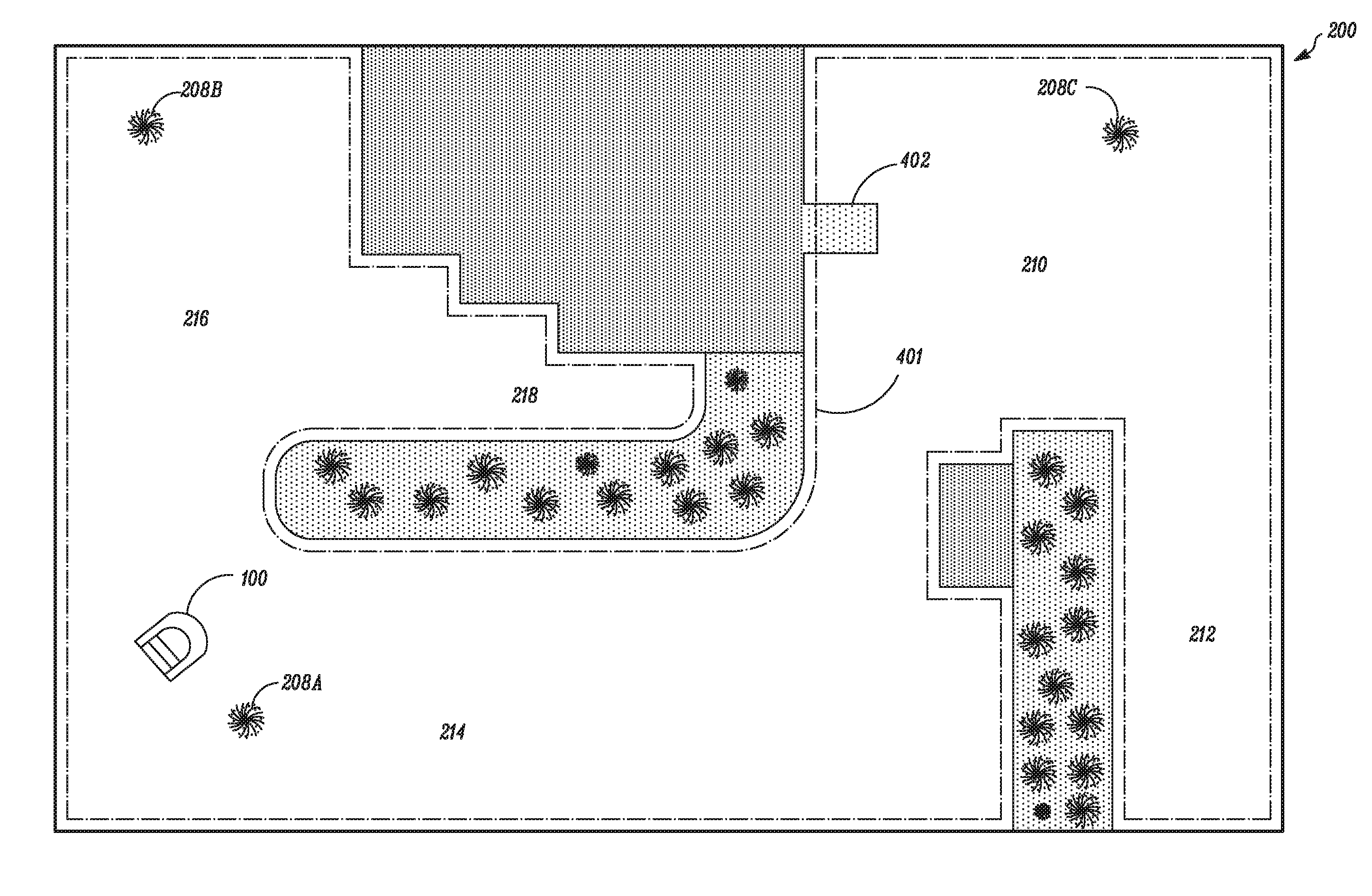

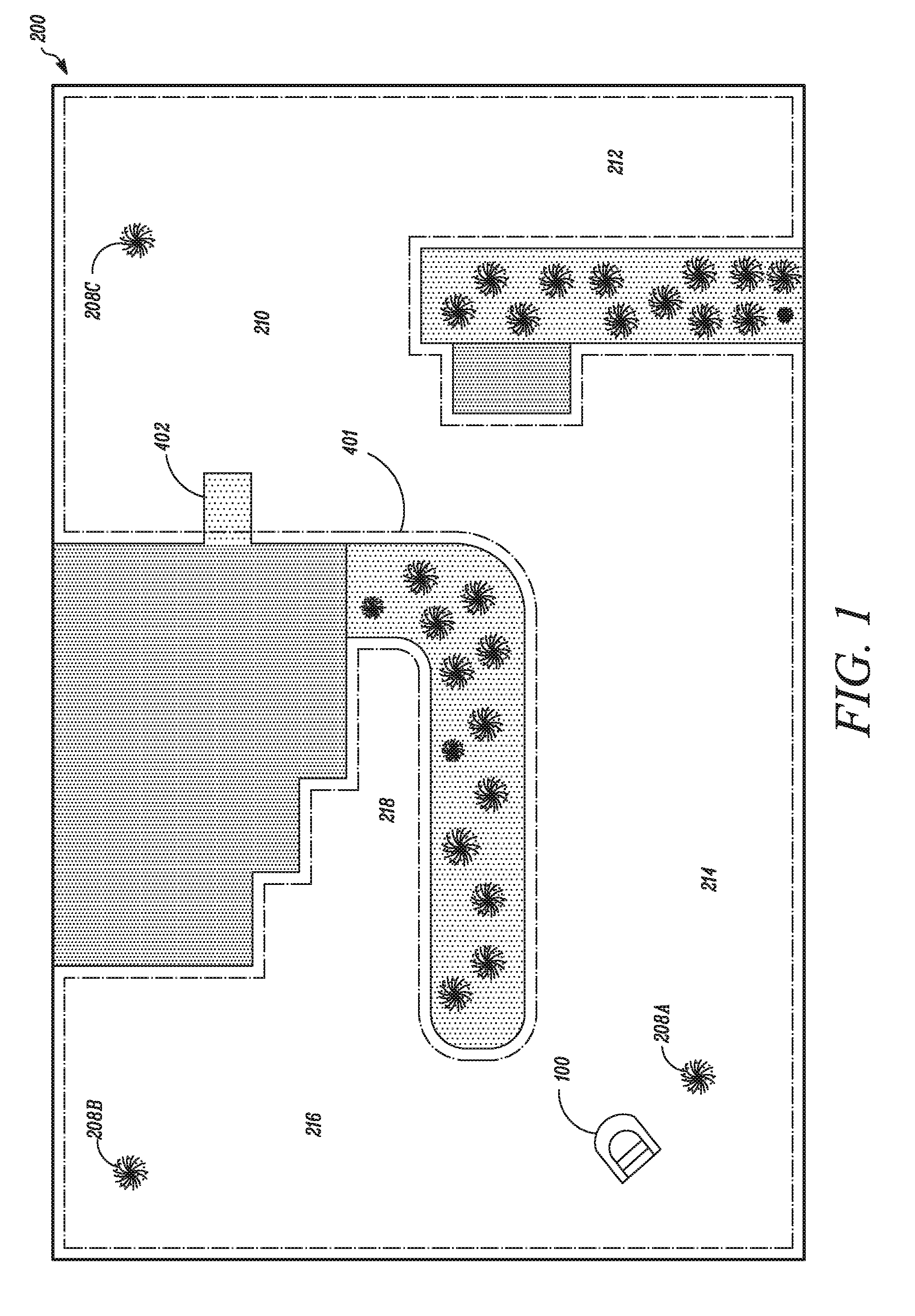

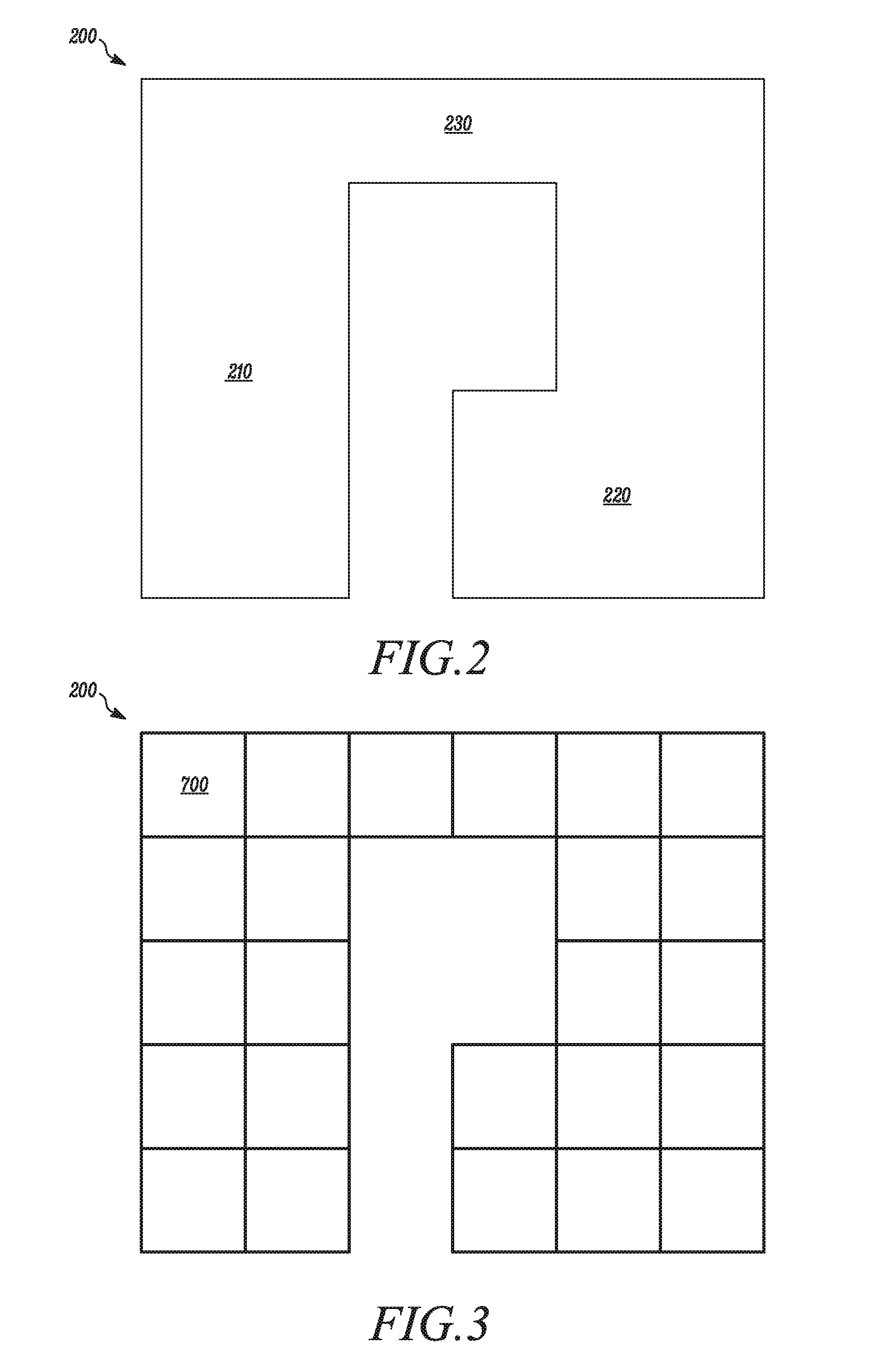

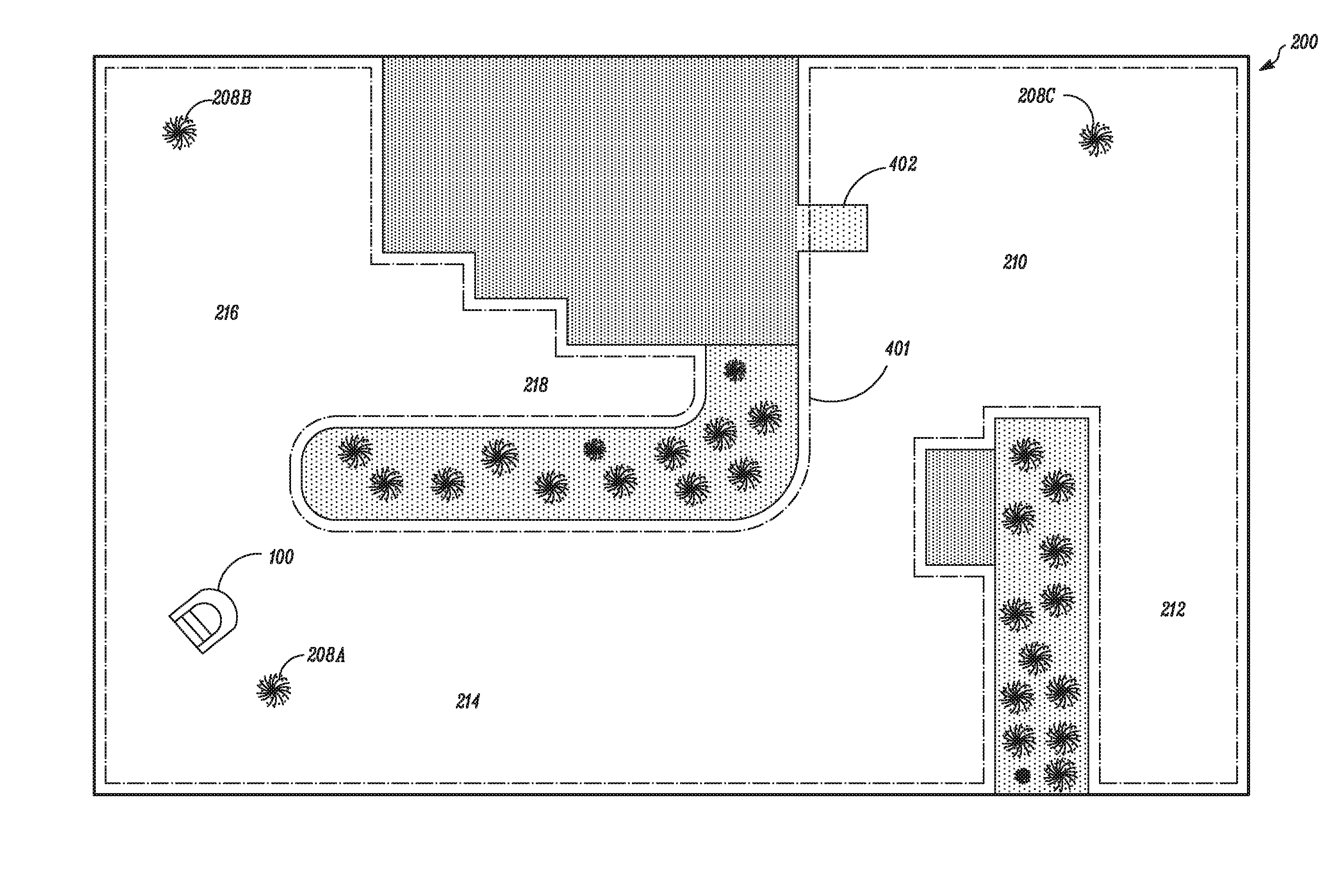

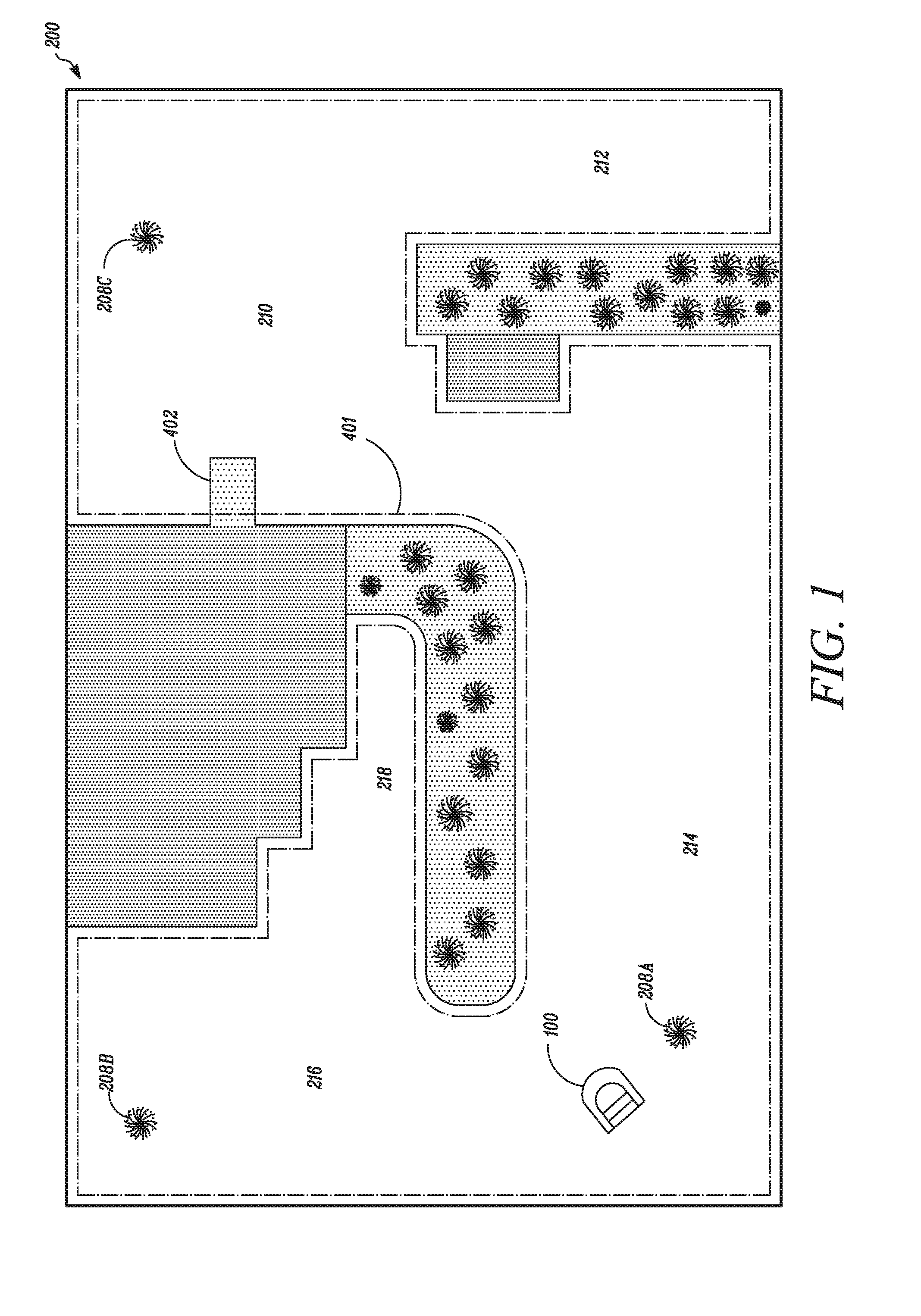

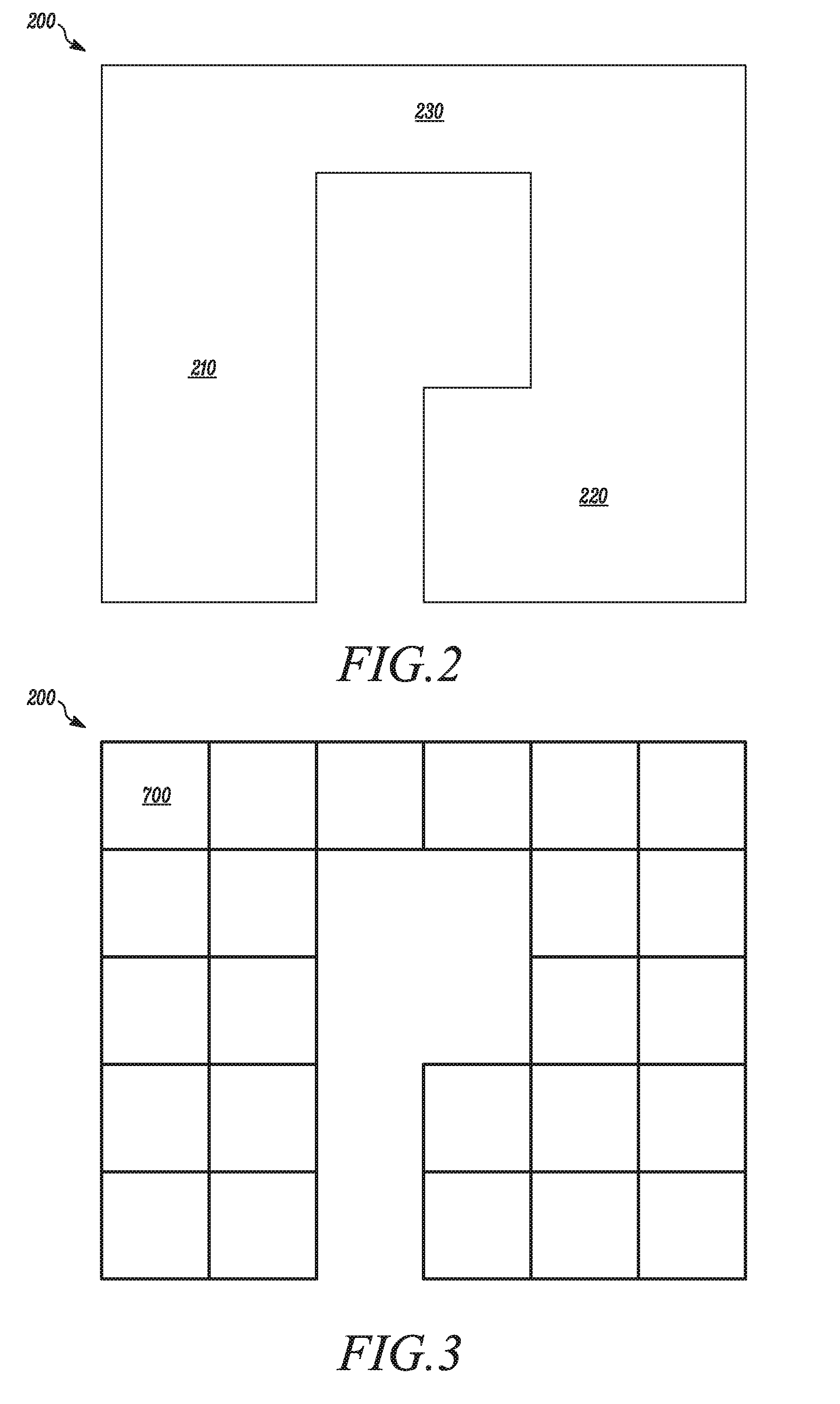

Method and System for Enhancing a Coverage Distribution of a Robotic Garden Tool

ActiveUS20150250097A1Enhancing coverage distributionExpand coverageMowersDistance measurementWorkspaceSteering control

A method for enhancing a coverage distribution of a robotic garden tool (100) operating within a predetermined working area (200), wherein the robotic garden tool (100) is provided with steering control means operable to change a movement direction of the robotic garden tool (100), and a positioning device (120). The method comprises the steps of providing (301) working area related data, defining (302) a temporary working area (500), based on the working area related data, which temporary working area (500) at least partly extends within the working area (200), estimating (303) a current position (600) of the robotic garden tool (100), evaluating (304) the estimated current position (600), selectively adapting (305) the temporary working area (500), in response to the step of evaluating (304) the estimated current position, selectively adapting (306) a movement direction of the robotic garden tool (100), in response to the step of evaluating (304) the estimated current position. The steps of selectively adapting (305) the extension of the temporary working area (500) and selectively adapting (306) a movement direction of the robotic garden tool are performed so as to push the robotic garden tool towards the temporary working area or so as to keep the robotic garden tool within the temporary working area (500).

Owner:HUSQVARNA AB

Knitting method for anti-stretch and anti-laddering dense and thick weft-knitted fabric

The invention discloses a knitting method for anti-stretch and anti-laddering dense and thick weft-knitted fabric. According to the method, the number of pieces of participant yarn in each coil height can reach up to 8, rectilinear yarn section arrangement of floating threads and weft insertion for limiting fabric stretch is achieved, and loose and curve yarn section arrangement of linter coil structures for increasing fabric thicknesses is also achieved. The fabric knitted through the method is dense and thick, little in fabric stretch, good in dimensional stability and anti-laddering.

Owner:JIANGNAN UNIV

Method and system for enhancing a coverage distribution of a robotic garden tool

ActiveUS9363945B2Expand coverageImprove accuracyMowersPosition/course control in two dimensionsSteering controlWork zone

A method for enhancing a coverage distribution of a robotic garden tool (100) operating within a predetermined working area (200), wherein the robotic garden tool (100) is provided with steering control means operable to change a movement direction of the robotic garden tool (100), and a positioning device (120). The method comprises the steps of providing (301) working area related data, defining (302) a temporary working area (500), based on the working area related data, which temporary working area (500) at least partly extends within the working area (200), estimating (303) a current position (600) of the robotic garden tool (100), evaluating (304) the estimated current position (600), selectively adapting (305) the temporary working area (500), in response to the step of evaluating (304) the estimated current position, selectively adapting (306) a movement direction of the robotic garden tool (100), in response to the step of evaluating (304) the estimated current position. The steps of selectively adapting (305) the extension of the temporary working area (500) and selectively adapting (306) a movement direction of the robotic garden tool are performed so as to push the robotic garden tool towards the temporary working area or so as to keep the robotic garden tool within the temporary working area (500).

Owner:HUSQVARNA AB

Synthetic method of glycerol carbonate

InactiveCN102383142AEfficient conversionReduce pollutionElectrolysis componentsElectrolytic organic productionN dimethylformamideGlycerol

The invention discloses a synthetic method of glycerol carbonate. The synthetic method is characterized in that: N,N-dimethylformamide is mixed with tetraethyl ammonium iodide and glycerol to obtain an electrolyte, the electrolyte is saturated with CO2 at normal pressure and is electrolyzed under conditions of a constant current, and the electrolyte is esterified and distillated to prepare glycerol carbonate. Compared with the prior art, the synthetic method of the invention, which has the advantages of simple technology, convenient operation, safety, cheap and easily available raw material, effective utilization of a greenhouse effect gas carbon dioxide, substantial reduction of atmospheric pollution, realization of the high efficiency conversion of glycerol, and alleviation of the increasingly exhausted energy problem and has a very significant meaning to the environment protection, is a technical route with a good industrial synthetic value.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com