Offshore underwater component device mooring cable and manufacturing method thereof

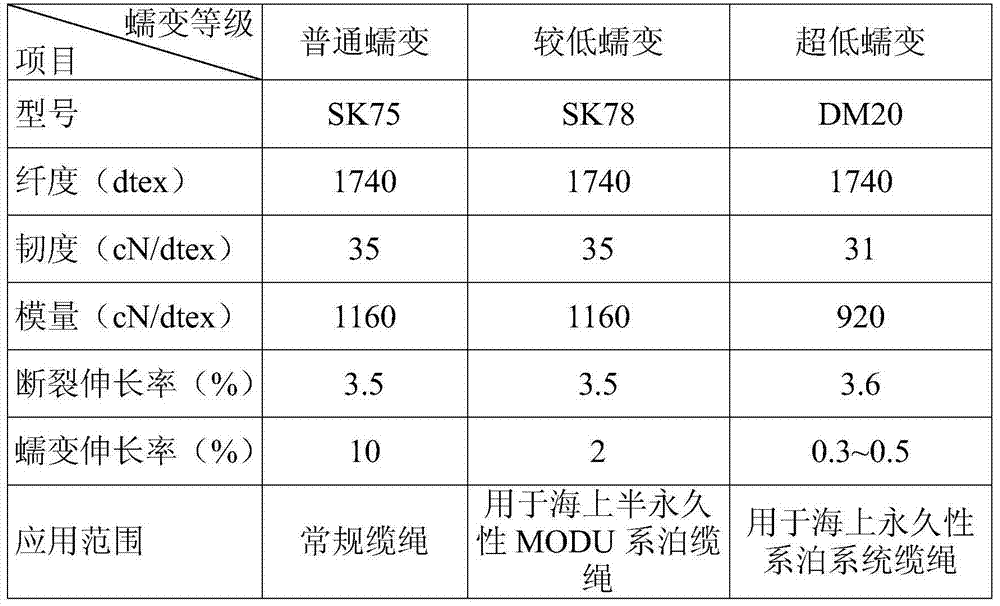

A component and cable technology, which is applied in the field of mooring cables for component devices in water, can solve problems such as poor creep performance, limited long-term application, and fiber material damage, and achieve the effects of light weight, low creep, and low elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

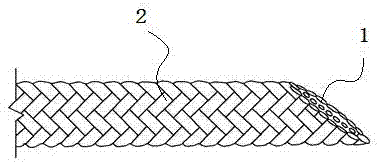

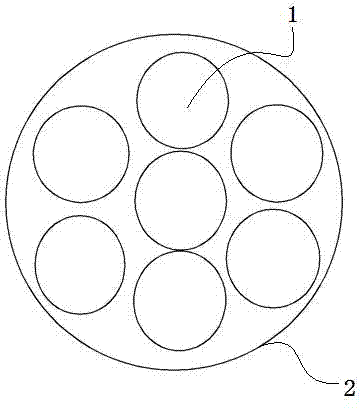

[0032] Such as figure 1 with figure 2 As shown, a mooring cable for underwater component devices in the sea is a skin-core composite double-layer structure; the inner cable core 1 is an 8-strand structure made of DM20 ultra-high molecular weight polyethylene, and the outer layer is wear-resistant high-strength polyester Fiber braided fixed sheath2.

[0033] The present invention is a method for manufacturing a mooring cable for a component device in sea water, the manufacturing process of which is as follows:

[0034] Step 1: The preparation method of the cable core with 8-strand structure is as follows:

[0035] a, make roving, choose 3 fineness DM20 ultra-high molecular weight polyethylene fibers and twist into roving by splicing machine;

[0036] B, system rope yarn, 7 synthetic rovings are twisted into rope yarn by twisting machine;

[0037] C, making rope strands, 3 synthetic rope yarns are twisted into rope strands by a strand making machine;

[0038] d, braiding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com