Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

299results about How to "Small creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

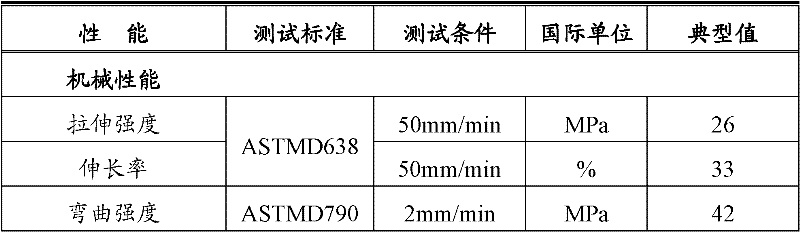

Carbon fiber reinforcement non-bittern flame-proof nylon 66 and preparation method thereof

The invention discloses a carbon-reinforced halogen-free fire-resistant nylon 66, which comprises by weight: nylon 66 resin 30-50 portions, long carbon fiber 10-50 portions, covering red phosphorus substrate 5-20 portions, fire resisting assistant 0-20 portions, flexibilizer 0-10 portions, antioxidant 0.1-1 portions, and processing assistant 0.1-15 portions. The carbon-reinforced halogen-free fire-resistant nylon 66 made by the invention is of high strength, high modulus, small creepage, and permanent anti-static performance, also good fire resistance, high mechanical strength, is resistant to high temperature, light, easy to process, with good fire resistance, and is also environmental friendly. The preparing method of the invention is simple to operate and applicable for industrialized production.

Owner:GUANGDONG HIGH & NEW ENG PLASTICS +1

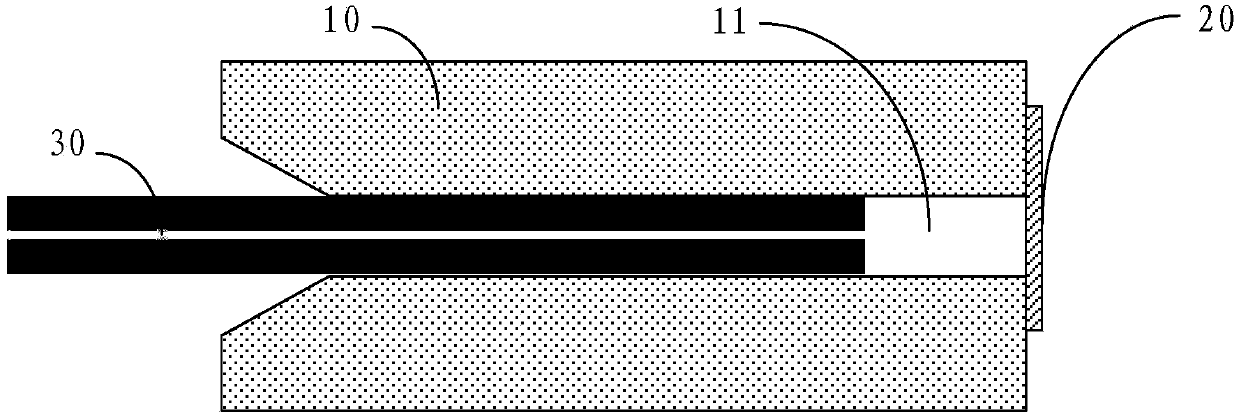

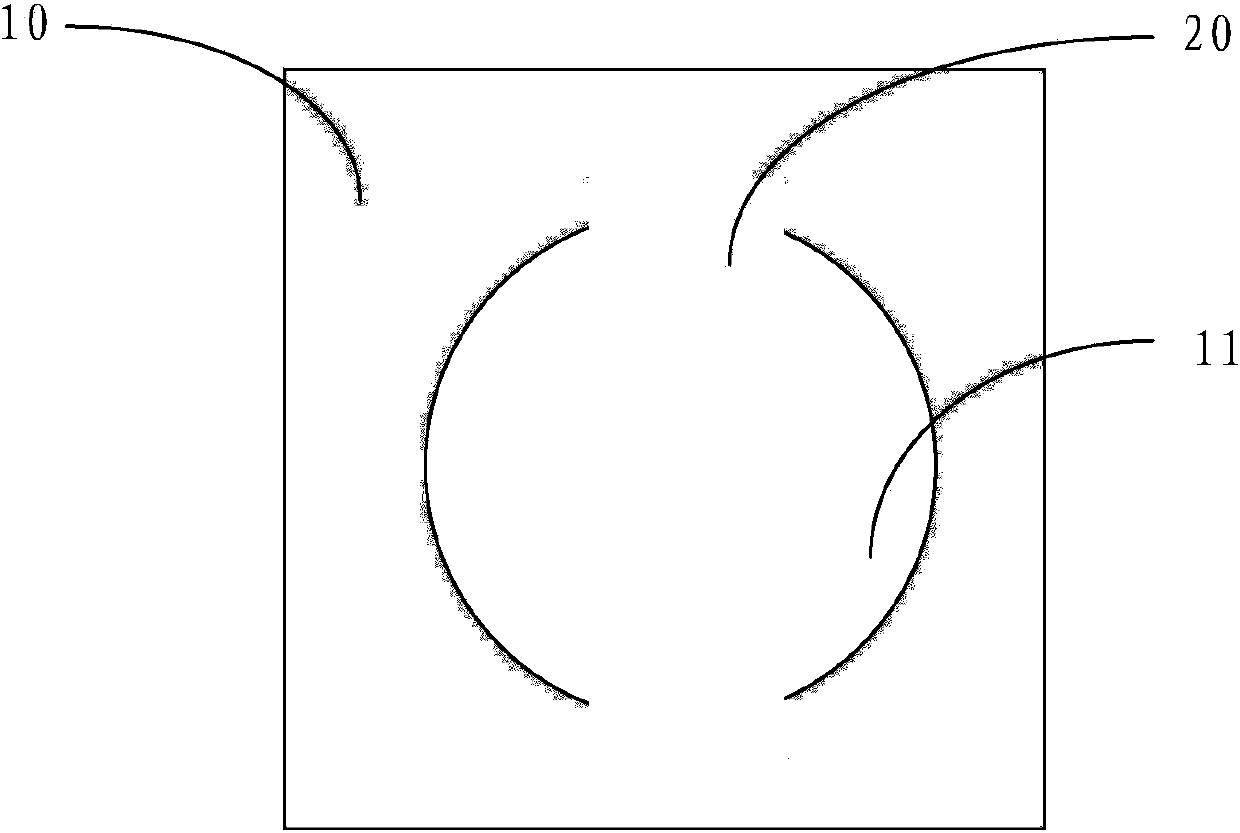

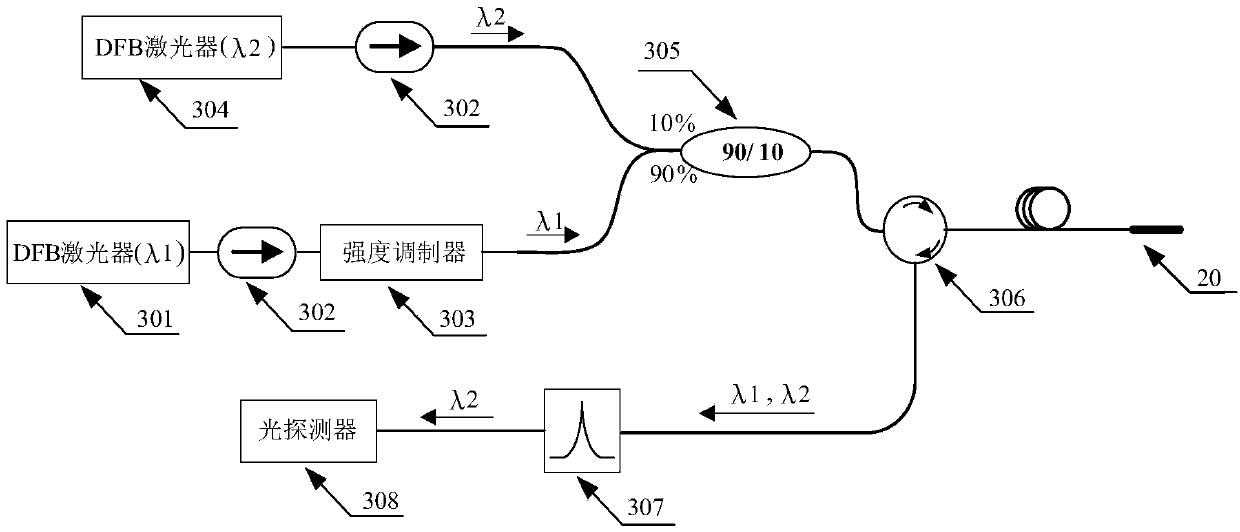

Resonant type Fabry-Perot optical fiber sensor, manufacturing method and air pressure detecting method

ActiveCN103994851AImprove applicabilitySmall creepFluid pressure measurement by optical meansResonanceEngineering

The invention provides a resonant type Fabry-Perot optical fiber sensor which comprises a sensor body and a through hole penetrating through the sensor body. One end of the through hole is provided with a graphene thin film for sensing the to-be-detected air pressure in an attached mode, and the other end of the through hole is provided with transmission optical fibers which penetrate through the through hole and are matched with the through hole. According to the resonant type Fabry-Perot optical fiber sensor, the air pressure of gas is calculated in the mode that graphene thin film resonant frequency changes are caused by damp of the gas to the graphene thin film, so that a closed Fabry-Perot cavity is not needed, and the manufacturing difficulty is reduced; the the original measurement thin film deformation quantity is replaced by resonance to further conduct air pressure measurement, and thin film material creeping caused by repeated film deformation is effectively reduced; digital frequency signals after probe laser detection are output after the sensor conducts detection, and result analysis can be conveniently carried out compared with light wave signals of an interferometric sensor. Stimulation and detection are carried out through the single transmission optical fibers, and long-distance air pressure measurement can be achieved, and the applicability of the sensor is greatly improved.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

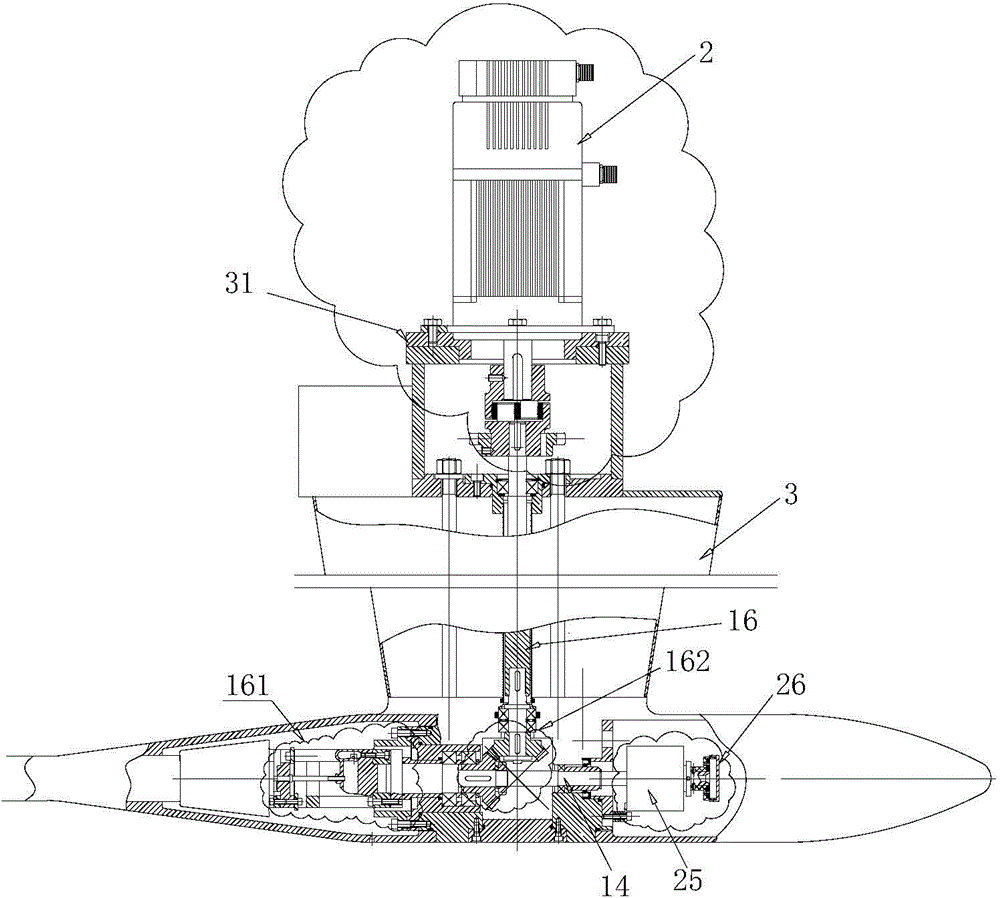

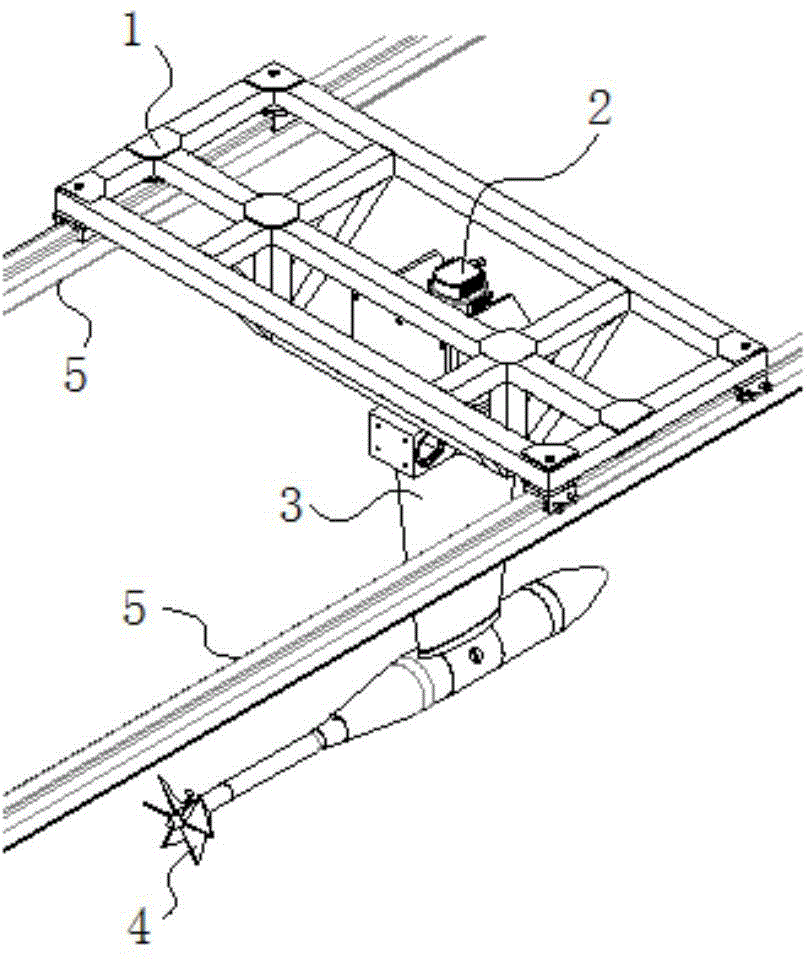

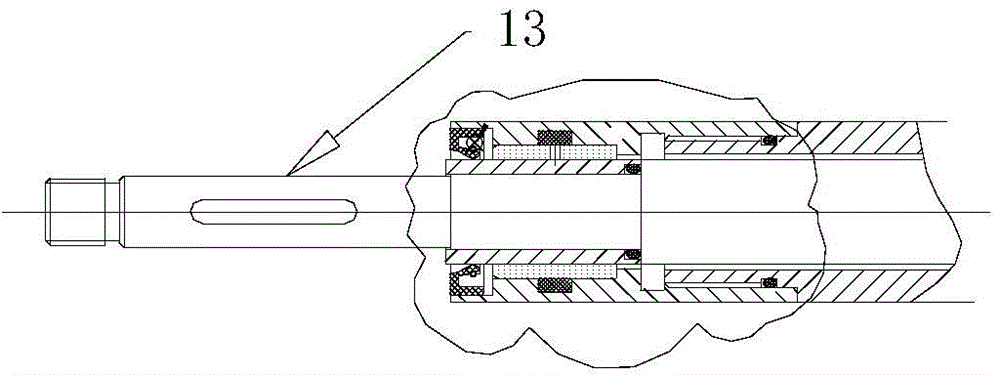

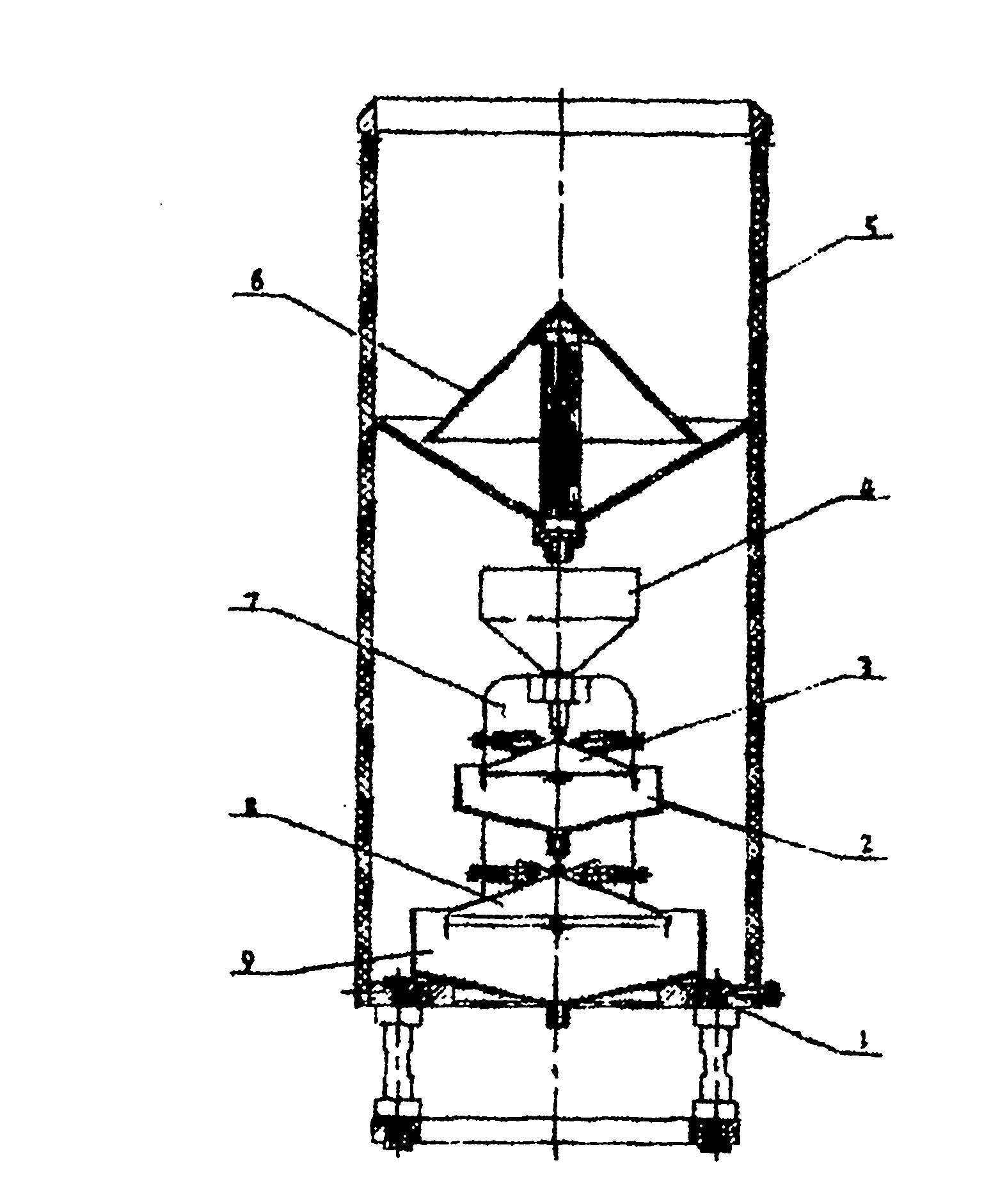

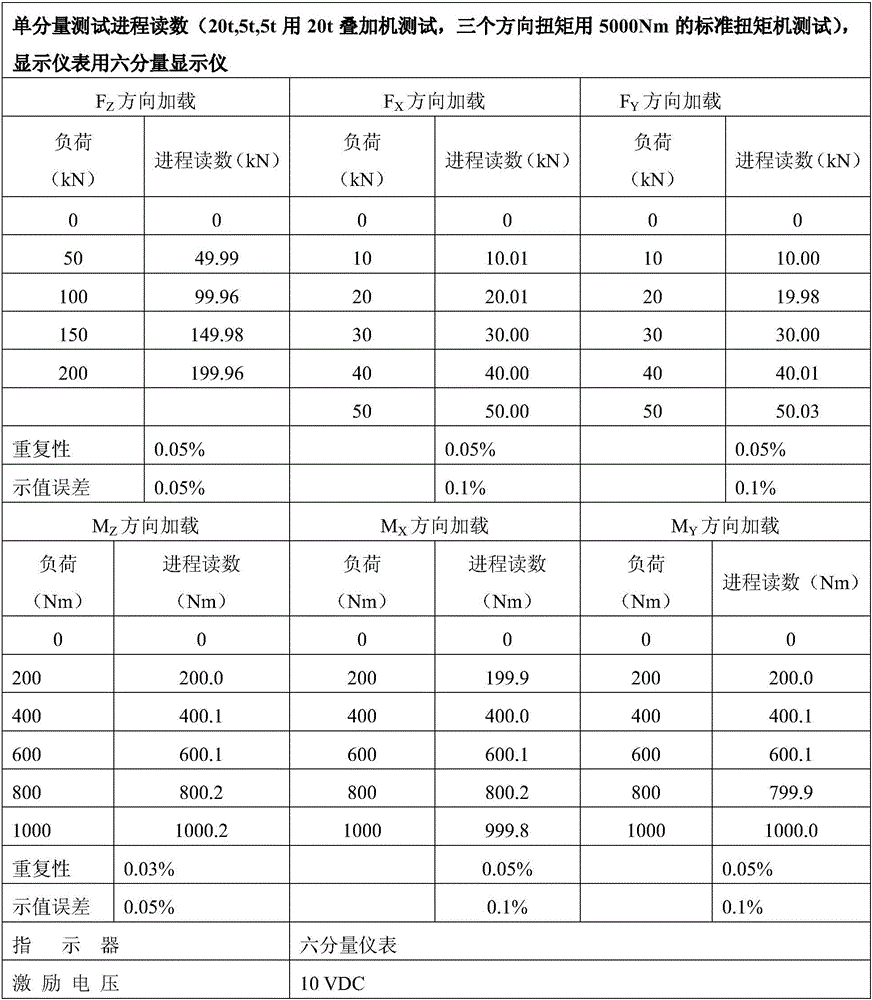

Strain propeller electric test dynamometer

ActiveCN103604600AEasy to assembleLow costMachine part testingForce measurementHorizontal transmissionStress conditions

The invention discloses a strain propeller electric test dynamometer which comprises a support, a servo motor arranged above the support, a vertical transmission shaft in transmission connection with the servo motor, and a horizontal transmission shaft in meshed transmission with the vertical transmission shaft through a gear set, wherein one end of the horizontal transmission shaft is connected with a thrust / torque sensing device; the thrust / torque sensing device is connected with a propeller through a horizontal spindle; a junction box is arranged at the other end of the horizontal transmission shaft through a sliding ring. The immersion depth tested by the dynamometer is 500mm, the dynamometer has high water tightness and normally operates at the temperature of 0-40 DEG C, the stress conditions of an underwater propeller in an operating state can be accurately measured, and the error is controlled to be 0.5 percent.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

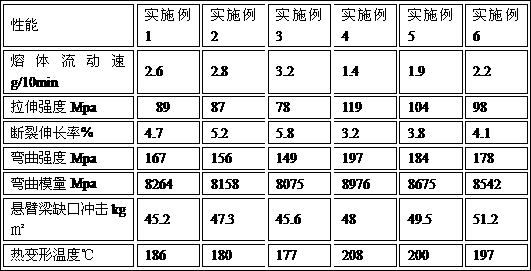

Wear-resistant enhanced PPO/HIPS material and preparation method therefor

The invention relates to the PPO / HIPS material technology field, and concretely relates to a wear-resistant enhanced PPO / HIPS material and a preparation method therefor. The wear-resistant enhanced PPO / HIPS material is composed of the following raw materials, by weight, 20-40 parts of HIPS resin, 5-30 parts of PPO resin, 3-8 parts of nitrile rubber, 3-8 parts of TPU resin, 10-30 parts of glass fibers, 10-15 parts of aramid fiber, 3-10 parts of molybdenum disulfide, 3-10 parts of calcium sulfate whiskers, 1-10 parts of polytetrafluoroethylene, 0.5-1.5 parts of coupling agent, 0.5-1 part of lubricant and 0.2-0.8 part of anti-oxidant. The PPO / HIPS material has advantages of PPO such as excellent mechanical properties, heat resistance and electrical insulating properties and little creep deformation at a high temperature and the characteristic of HIPS improving the material fluidity, has high mechanical strength and modulus, and has excellent wear resistance.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

Phosphate binder for casting

InactiveCN101417315AHigh heat intensityLow collapsibilityFoundry mouldsFoundry coresPhosphatePhosphoric acid

The invention relates to a phosphate binder used for casting, which comprises the components by weight ratio: 45 to 55 percent of phosphoric acid, 33 to 45 percent of aluminium dihydrogen phosphate, 5 to 15 percent of boric acid and 6 to 12 percent of citric acid. The binder can also be mixedly matched with 0.5 to 2 percent of magnesium oxide curing agent by weight ratio. The binder adopts the phosphoric acid and the aluminium dihydrogen phosphate as a binder main body, and is added with the boric acid and citric acid for improving the bonding property, thus being one phosphate binder with good property used for casting. The binder has the advantages of low cost, little environmental pollution, high hot strength, good collapsibility and the like, can improve working environment to the utmost extent, and reduce production cost.

Owner:大连核心铸造技术工程研究所

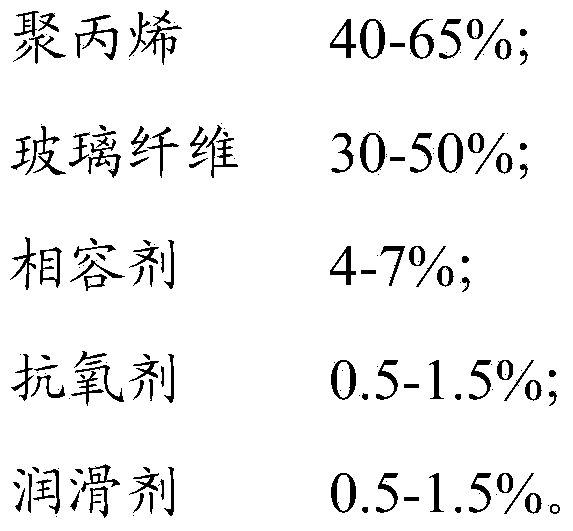

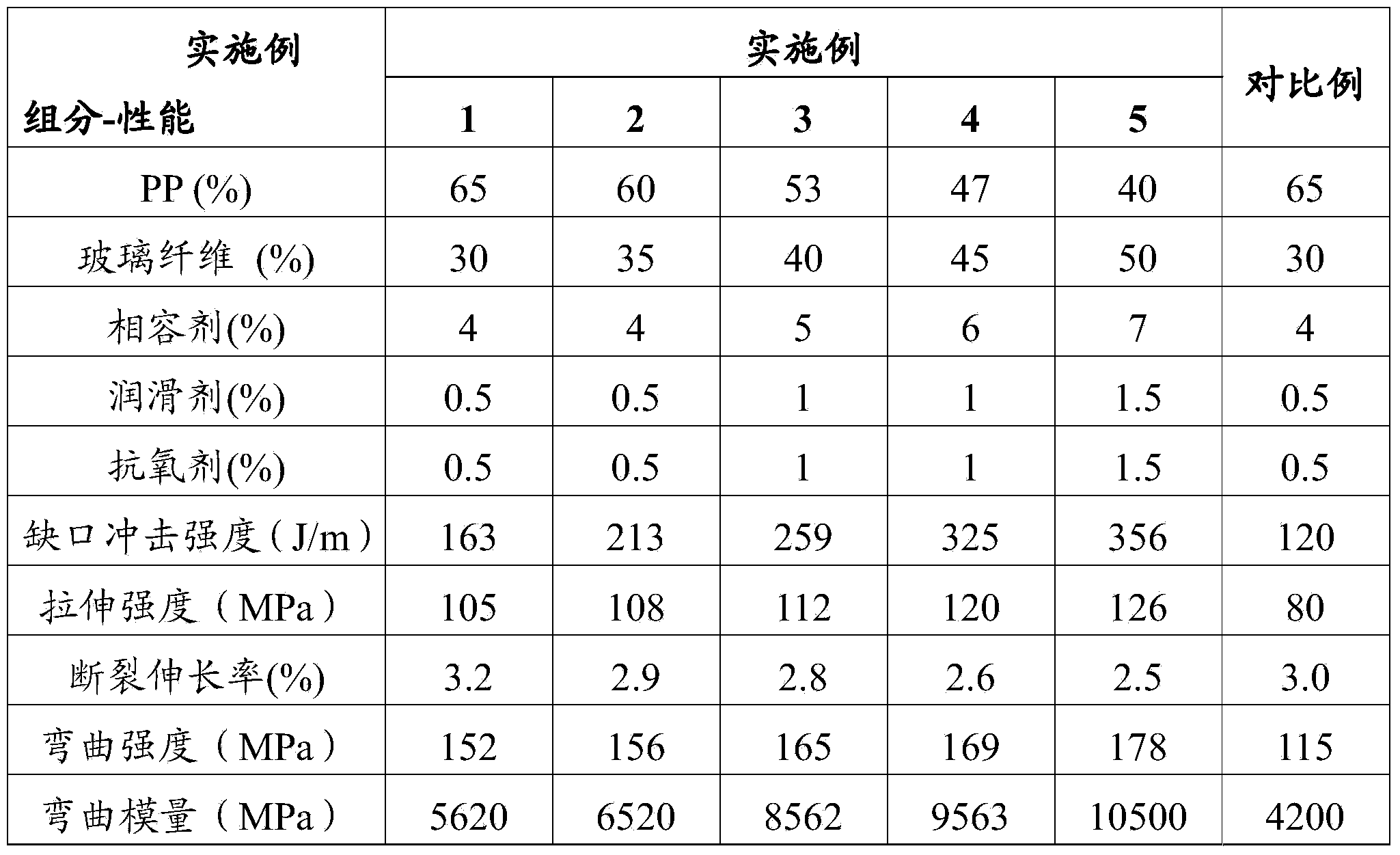

Long glass fiber enhanced polypropylene composite material and preparation method thereof

InactiveCN103772825AUniform mechanical propertiesHigh impact strengthGlass fiberPolypropylene composites

The invention discloses a long glass fiber enhanced polypropylene composite material and a preparation method of the long glass fiber enhanced polypropylene composite material. The long glass fiber enhanced polypropylene composite material comprises the following components in percent by weight: 40-65 percent of polypropylene, 30-50 percent of glass fiber, 4-7 percent of a compatilizer, 0.5-1.5 percent of an antioxidant and 0.5-1.5 percent of a lubricating agent. The preparation method comprises the following steps: correspondingly mixing the polypropylene, the compatilizer, the lubricating agent and the antioxidant, dispersing long glass fibers in the fused and mixed materials for performing impregnation treatment, and preparing the long glass fiber enhanced polypropylene composite material. The long glass fiber enhanced polypropylene composite material provided by the invention is balanced in mechanical property, is particularly high in impact strength and has low shrinkage, high dimensional stability, low warpage, small anisotropism, low creep and high dynamic fatigue resistance. According to the preparation method, the long glass fibers can be effectively dispersed, and the length of the long glass fibers is kept.

Owner:徐东

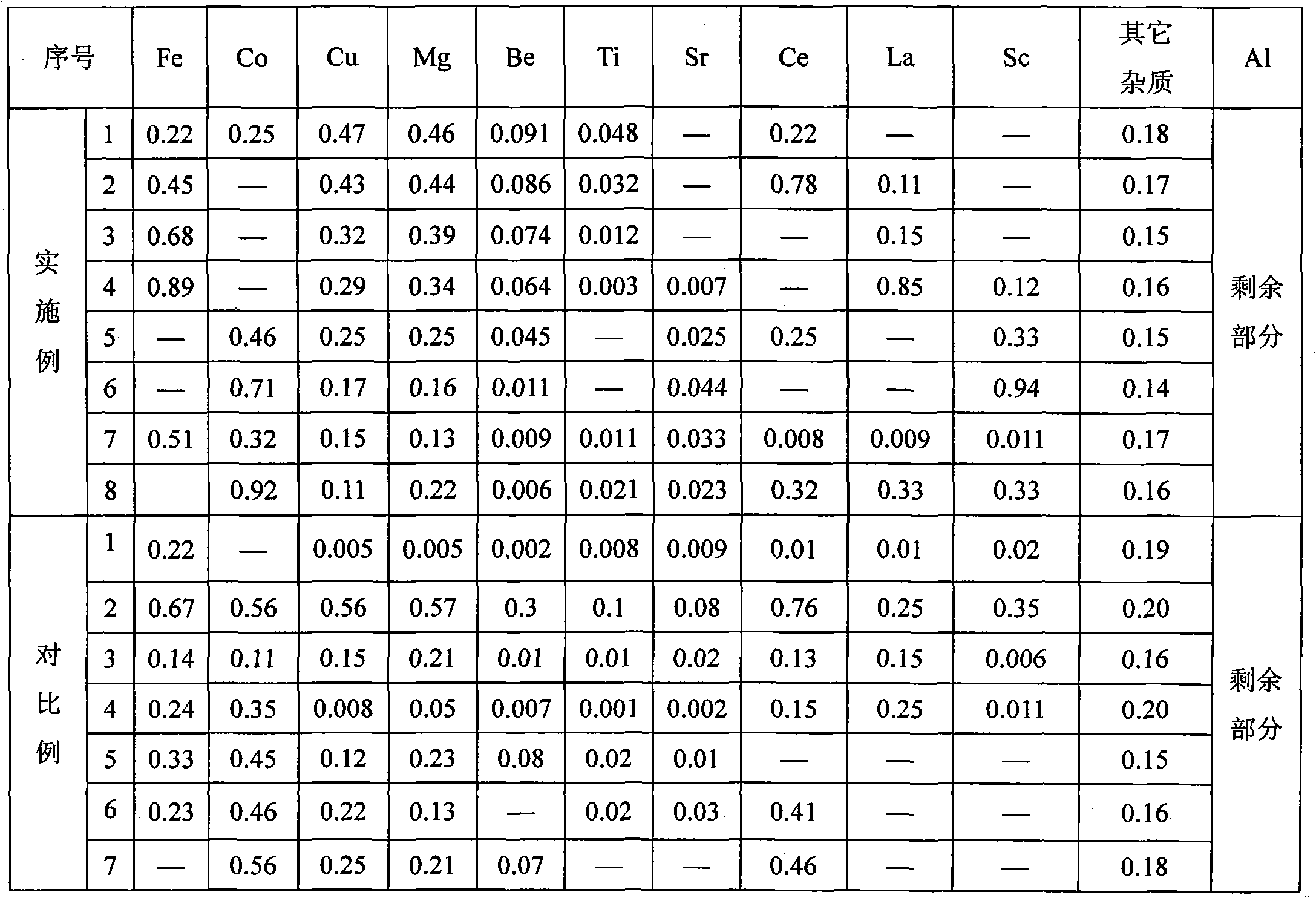

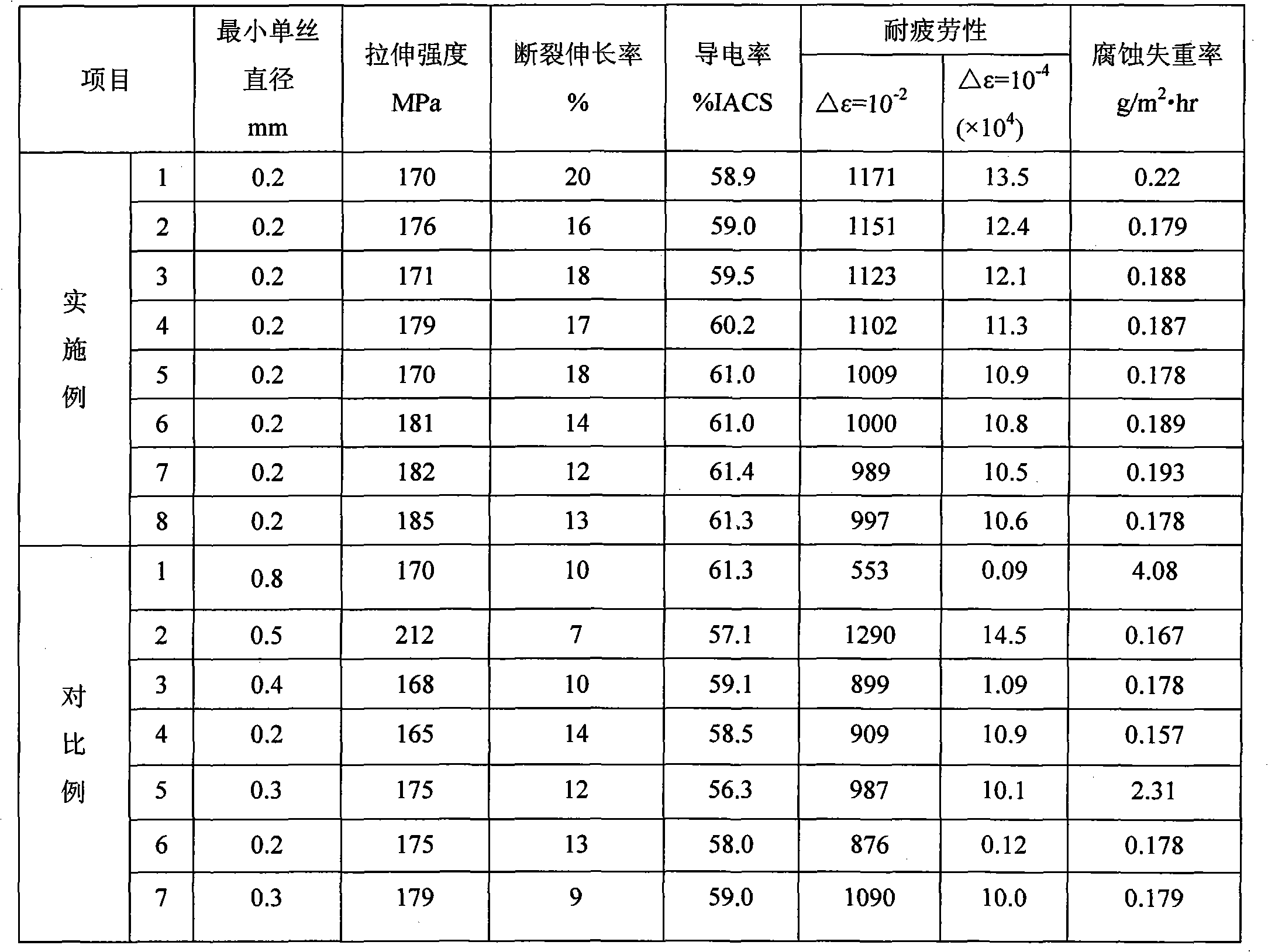

Conductor wire core aluminum alloy for welding machine cable and making method thereof

ActiveCN101921932AConductivity has little effectHigh tensile strengthMetal/alloy conductorsRare earthMaterials science

The invention discloses a conductor wire core aluminum alloy for a welding machine cable and a making method thereof. A conductor wire core is made of aluminum alloy materials. The aluminum alloy comprises the following compositions: 0.4-1.0wt percent of Fe or Co, 0.1-0.5wt percent of Cu, 0.1-0.5wt percent of Mg, 0.05-0.1wt percent of Be and 0.05-0.1wt percent of rare earth. An aluminum alloy wire harness is obtained by carrying out smelting, linecasting, rolling, intermediate annealing, drawing, bunch stranding and annealing on the alloy. The aluminum alloy wire core has the advantages of better conductivity, anti-fatigue performance, flexibility, bending performance and corrosion resistance and is suitable for the conductor wire core of the welding machine cable.

Owner:ANHUI JOY SENSE CABLE

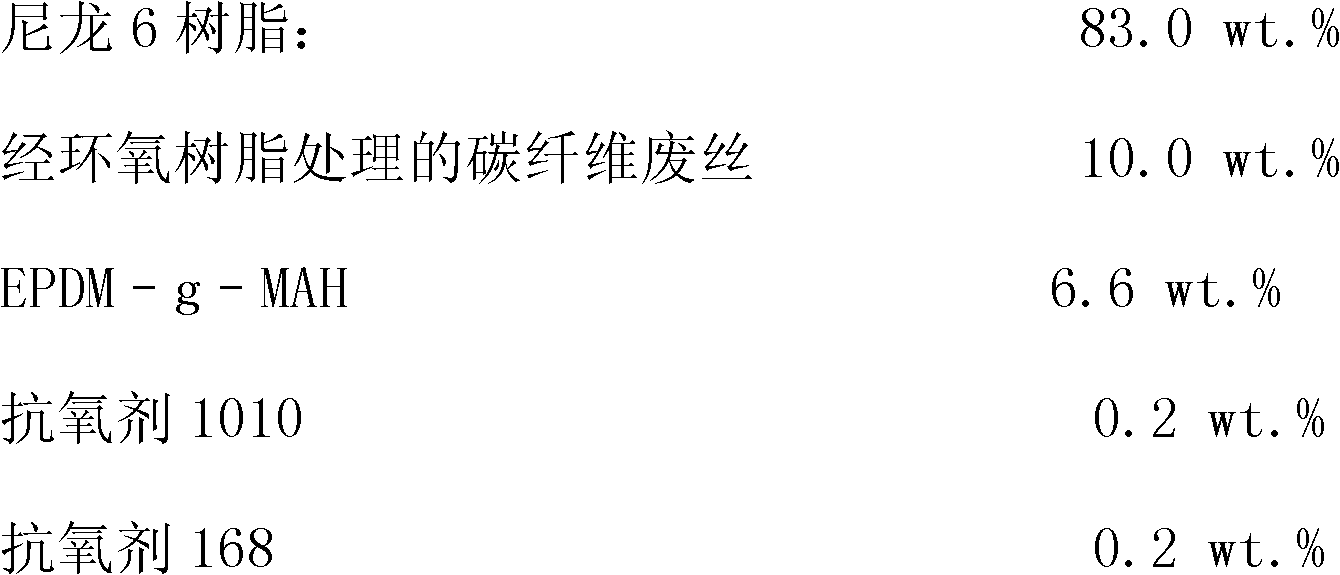

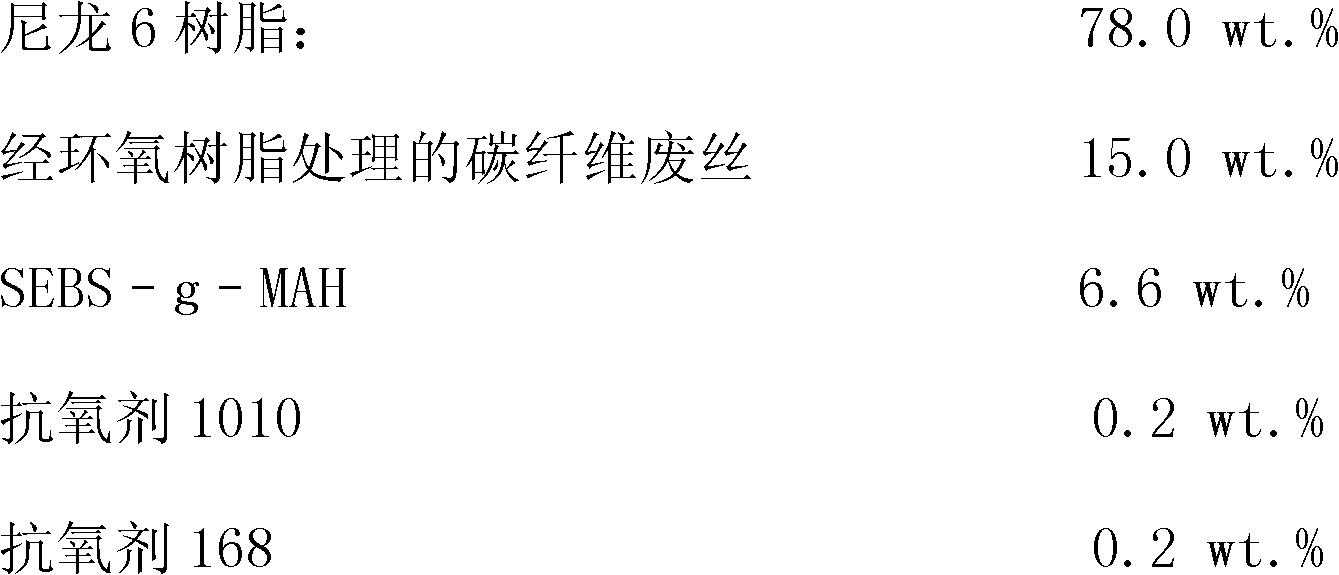

Waste carbon fiber reinforced nylon 6 composite material and preparation method thereof

The invention discloses a waste carbon fiber reinforced nylon 6 composite material and a preparation method thereof, and belongs to the technical field of macromolecular materials. The composite material comprises the following components in percentage by weight: 70 to 90 weight percent of nylon 6 resin, 5 to 20 weight percent of waste carbon fiber subjected to surface modification treatment of epoxy resin or concentrated nitric acid and silane coupling agent, 0 to 10 weight percent of toughening agent, and 0.2 to 0.5 weight percent of antioxidant. The preparation method comprises the following steps of: performing modification by using the bisphenol A epoxy resin or sequentially using the concentrated nitric acid and the silane coupling agent, and drying; adding the mixed materials into a double-screw extruder in a ratio, performing melt blending extrusion, controlling each section of a charging barrel to the temperature of between 240 and 260 DEG C, and controlling a head outlet to the temperature of between 250 and 260 DEG C; and staying the melt, performing water cooling, granulating, sieving and drying. The composite material prepared by the method has high strength, modulus and antistatic performance; and the impact resistance of the composite material is improved by adding the toughening agent.

Owner:BEIJING UNIV OF CHEM TECH

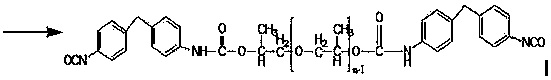

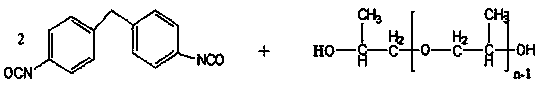

A preparation method of a polyurethane/epoxy resin composite material

ActiveCN103524703AImprove rigidity and comprehensive mechanical propertiesImprove bonding performancePolyureas/polyurethane adhesivesIsocyanateChemistry

A preparation method of a polyurethane / epoxy resin composite material comprises a step of adding a polyether polyol into a reactor to be treated, adding a diisocyanate and heating, controlling the mass content of free -NCO, and obtaining an A component after vacuum deaeration; a step of heating a binary aromatic amine, adding dropwise the liquid epoxy resin and heating again, and reacting to obtain a B component; and a step of stirring and mixing uniformly the A component and the B component stoichiometrically, and reacting and curing to obtain the polyurethane / epoxy resin composite material. When being used as an adhesive, the composite material has good bonding strength, high-temperature resistance, low-temperature resistance, impact resistance and flexibility. The composite material has a wide application scope, and can be prepared into a high-hardness polyurethane elastomer composite material to be applied.

Owner:太原英可奥笔墨科技有限公司

Piezoresistive strain gauge with ceramic substrate

ActiveCN103047927ASimple processLow costForce measurementElectrical/magnetic solid deformation measurementElectrical conductorStrain gauge

The invention provides a piezoresistive strain gauge with a ceramic substrate. The piezoresistive strain gauge comprises a ceramic substrate, a conductor layer, a resistive layer with a piezoresitive effect, an insulation protective layer and a seal glass layer, wherein the conductor layer and the resistive layer are manufactured on the upper surface of the ceramic substrate, the insulation protective layer covers on the upper parts of the conductor layer and the resistive layer, and the seal glass layer is manufactured on the lower surface of the ceramic substrate. The piezoresistive strain gauge disclosed by the invention can be used to manufacture high-temperature-resistant and corrosion-resistant force sensors for weighing, pressure and the like, and is high in precision, good in stability and long in service life.

Owner:ADVANCED PLATINUM TECH

Halogen-free flame-retardant anti-static glass fiber reinforced nylon 66 particle and preparation method thereof

The invention relates to the technical field of high-polymer materials and particularly relates to a halogen-free flame-retardant anti-static glass fiber reinforced nylon 66 particle and a preparation method thereof. The particle comprises the components by weight percent: 20-50% of nylon 66 resin, 10-40% of glass fiber, 15-25% of halogen-free flame retardant, 3-10% of antistatic agent, 2-8% of toughening agent, 0.1-0.8% of antioxidant and 0.2-1.5% of auxiliary processing aid. The halogen-free flame-retardant anti-static glass fiber reinforced nylon 66 particle is high in strength, modulus and mechanical strength, little in creep deformation, stable in size, good in flame retardant property, light in weight, easy to process and capable of resisting to statics and meeting the requirements of people for environment friendliness (composite ROHS (Restriction of Hazardous Substances Directive) and RECHA (Registration, Evaluation, Authorization and Restriction of Chemicals) laws and regulations). The preparation method provided by the invention is simple in operation and suitable for industrial production.

Owner:NINGBO EAGLE NEW MATERIAL

Superhigh molecular polyethylene compound pipe and method for manufacturing same

InactiveCN1963278AHigh strengthFor special requirements with heavy wearFlanged jointsLaminationSteel tubeMetal

The invention relates to a metal and nonmetal combined pipe and its processing method. It is made of inside and outside layers and a linkage flange, featuring on the steel pipe with flange as the outside of the reinforcement layer, coated with super high molecular weight-high density polyethylene pipe as the inside of the base pipe which extends to the outside edge of the flange end face to form an integral piece along the opening of the exterior layer. The steel pipe is firstly flange welded, lining the super high molecular weight-high density polyethylene pipe to the steel pipe with the material being heated, insulated, flanged, chilled and shaped, and put to stock passing quality inspection. With not too difficult techniques, simple process, quick plant construction, small investment and high using value of products. With straight angle ridge of the lining, it can safeguard the precision of the pipe engineering, having the ability of bearing pressure 6 Mpa.

Owner:山东东方管业有限公司

Polypropylene composition for outdoor communication cabinet

The invention discloses a polypropylene composition for an outdoor communication cabinet. The polypropylene composition comprises the following components in part by weight: 100 parts of polypropylene, 0.5 to 20 parts of compatilizer, 1 to 30 parts of toughening agent, 5 to 40 parts of flame retardant, 0.5 to 20 parts of flame retardant synergist, 0.1 to 2 parts of antifogging agent, 1 to 50 parts of dimensional stabilizer and 0.05 to 5 parts of ultraviolet absorber. The polypropylene composition for the outdoor communication cabinet has higher flame retardancy, mechanical properties and weather resistance.

Owner:SHENZHEN XINGSHENGDI NEW MATERIALS

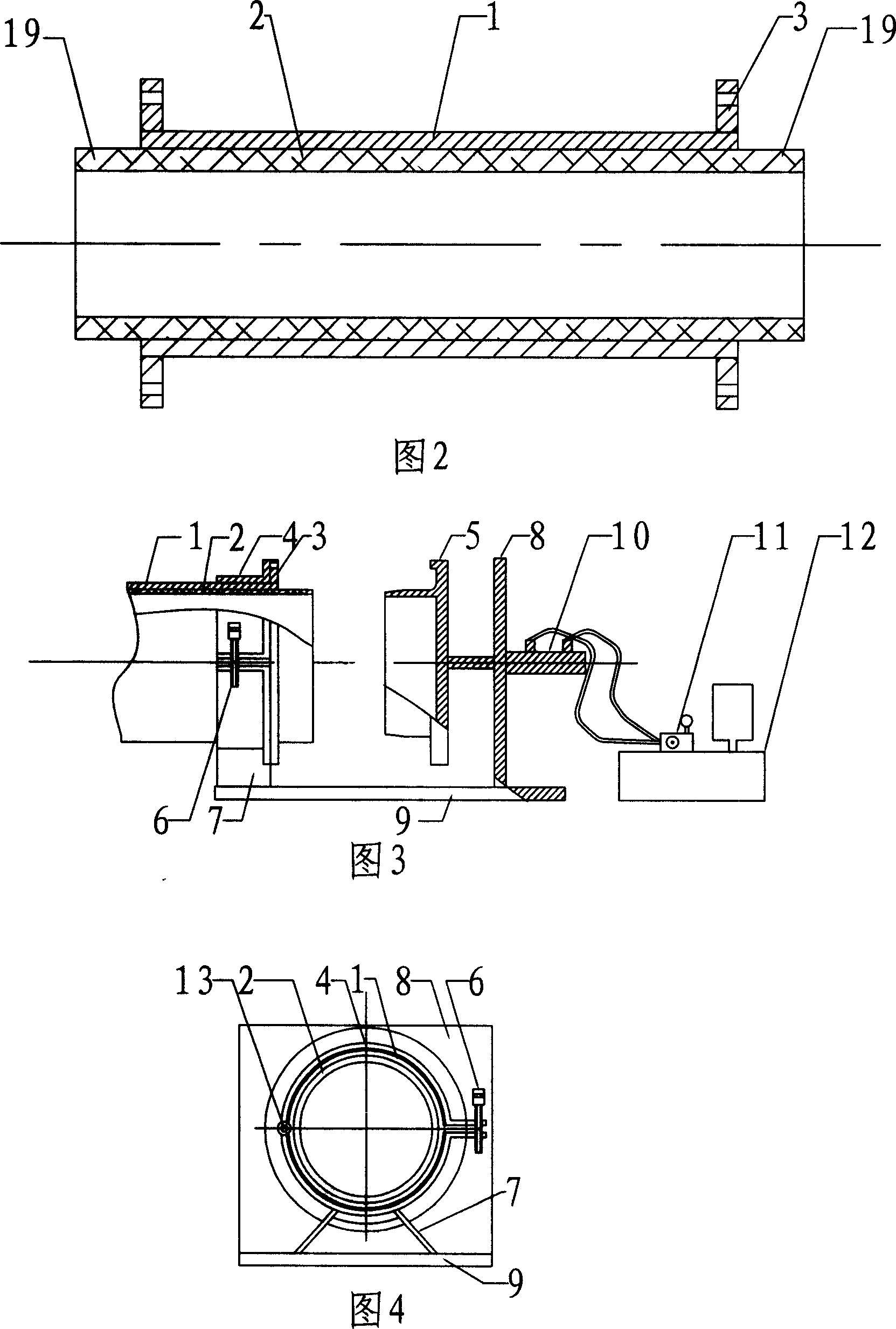

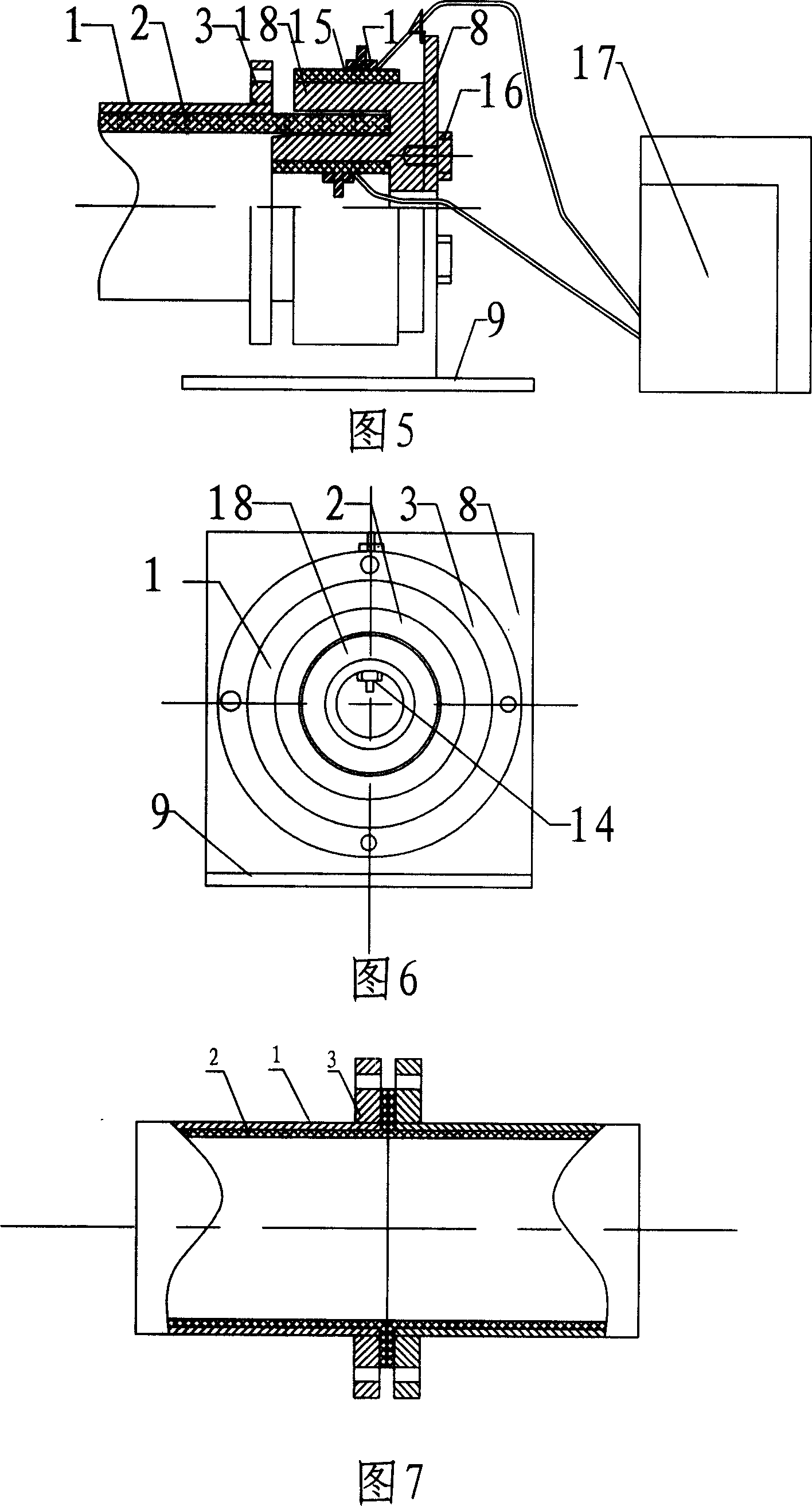

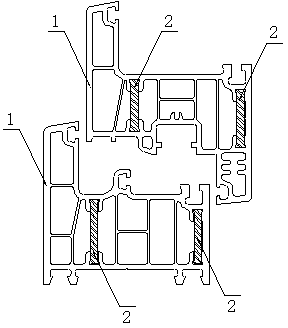

Preparation method for PVC (Polyvinyl Chloride)/modified PBT (Polybutylece Terephthalate) lining material composite section

ActiveCN103075071AMaintain fatigue resistanceSmall creepWindow/door framesWing framesGlass fiberPolymer science

The invention discloses a PVC (Polyvinyl Chloride) / modified PBT (Polybutylece Terephthalate) lining material composite section and a preparation method. The PVC / modified PBT lining material composite section is characterized in that PBT is reinforced and modified, is extruded with a PVC section in a cavity together and is compositely formed to substitute a reinforced section. Compounding with the PVC section can be realized through a co-extrusion process, so that mounting steps of a metal lining are simplified, the effect is improved, and the production cost is greatly reduced. A modified material comprises the following components in parts by weight: 75-84 parts of PBT resin, 15-30 parts of glass fiber reinforcing agent, 0.1-0.3 part of lubricating agent, 1.0-1.4 parts of dispersant, 0.5-1 part of processing flow modifier (AMS), 0.5-0.7 part of anti-aging agent and 1-3 parts of low-temperature modified toughening agent.

Owner:HARBIN ZHONGDA PROFILE TECH

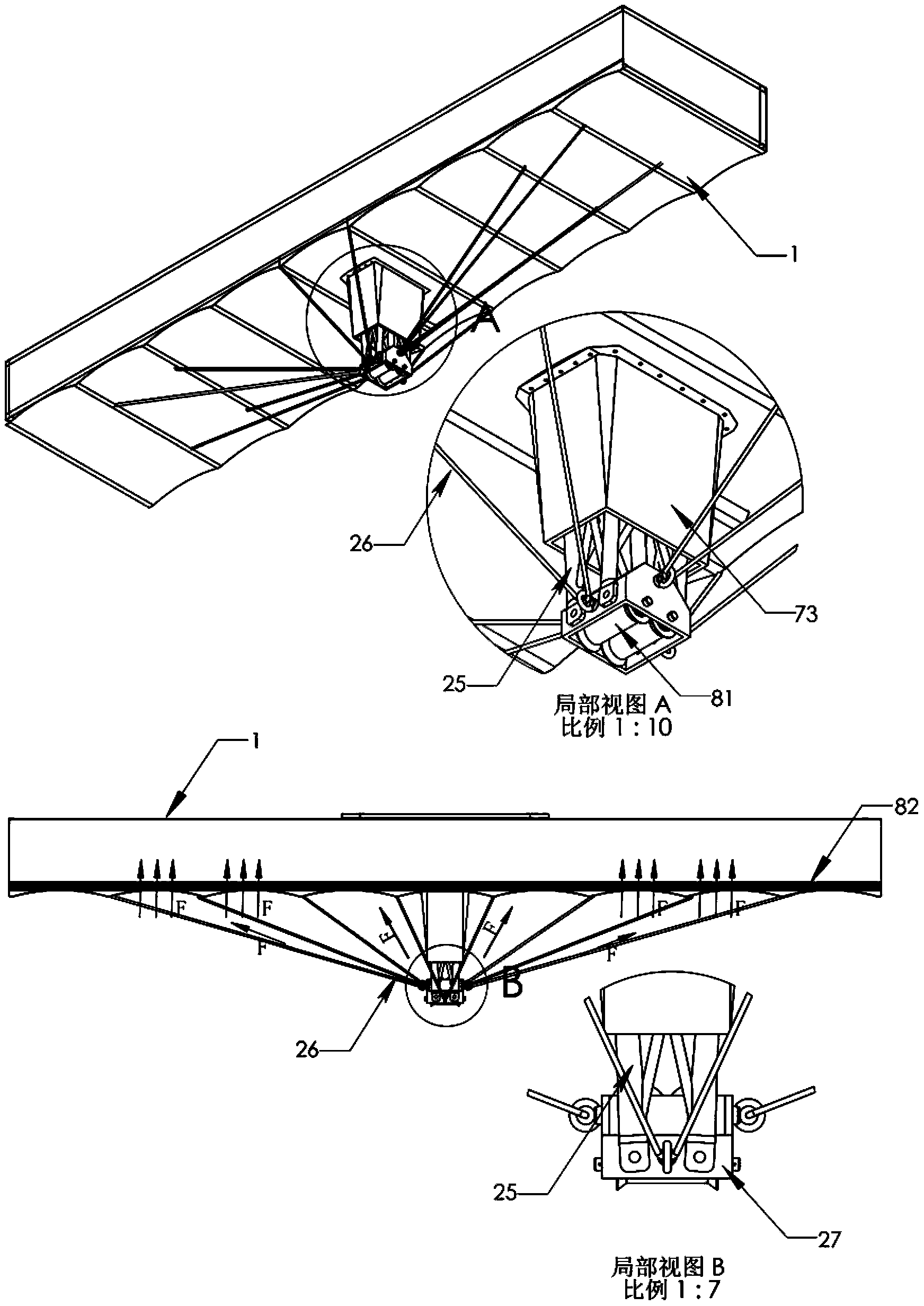

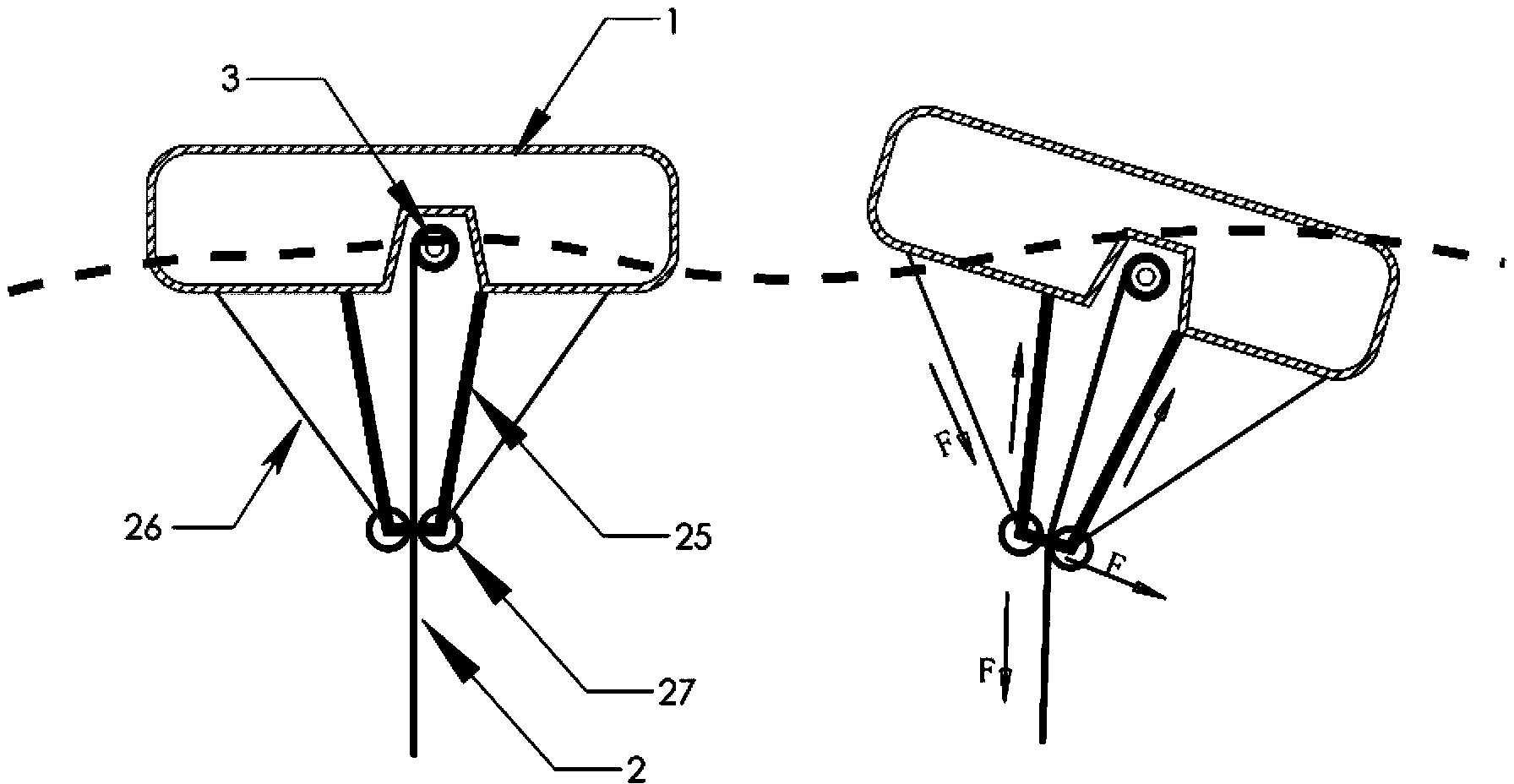

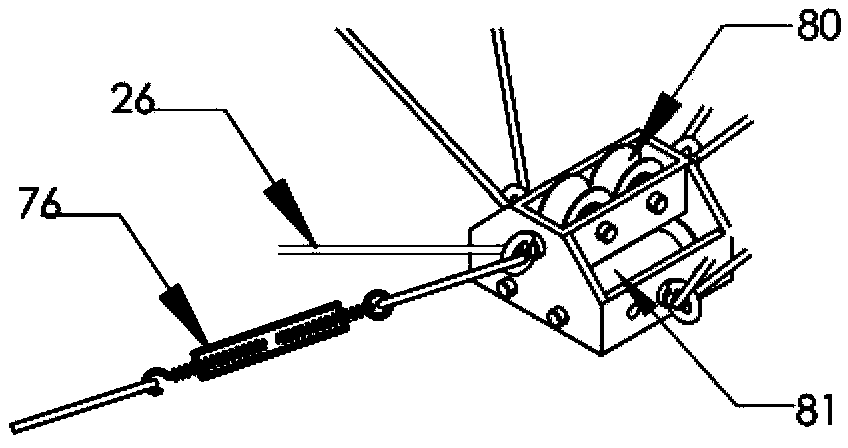

Weave power acquisition device adopting floating body and rope wheel

A return spring adjustment apparatus and method of a wave power system. The apparatus comprises return springs (5, 9), a stepper motor (6), transducers (7, 10, 27, 29), a single chip microcomputer control module (8) and a power source. The two ends of the return springs (5, 9), a chassis (12) of the stepper motor, a rotor (11), the two ends of the transducers (7, 10, 27, 29) can all be randomly arranged in series, and connected with a spindle (4) and a frame (22). When a single chip microcomputer detects that the transducers (7, 10, 27, 29) measure that the pulling force is too large or too small, it sends an instruction to the stepper motor (6) to perform adjustment. After the adjustment is completed, the stepper motor (6) stalls and brakes, so that the return springs (5, 9) can work in within a specified range.

Owner:安徽迪思自动化设备有限公司

0.5mm sensitivity double-skip-bucket type rainfall sensor

InactiveCN102116878AImprove wash resistanceHigh surface hardnessRainfall/precipitation gaugesICT adaptationHardnessEngineering

The invention discloses a 0.5mm sensitivity double-skip-bucket type rainfall sensor. The bottom of a cylindrical rain container is provided with a base; the base of the rain container is provided with a lower water collector, a large skip bucket, an upper water collector, a small skip bucket and a funnel from bottom to top in turn; each water collector is arranged on a vertical plate; and an anti-blocking device is arranged above the funnel. The upper small skip bucket is designed to be a symmetric slope container, the lower large skip bucket is designed to be a labyrinthic container, the centers of gravity of a left bucket chamber and a right bucket chamber of each skip bucket are symmetric, and the skip bucket swings in a balanced way, so that stable performance is guaranteed during impact of heavy rains, and the sensor has high measuring accuracy. A hydrophobic layer has high flushing resistance and high surface hardness, and is environment-friendly and safe. Error is not influenced by raininess, and instant rainfall can be measured. Stable work and accurate measuring data of the rainfall sensor are guaranteed. Failed components can be easily approached during maintenance, and the failed components are easy to disassemble and replace, so that the manufacturing cost and the field maintenance cost are reduced.

Owner:天津华云天仪特种气象探测技术有限公司

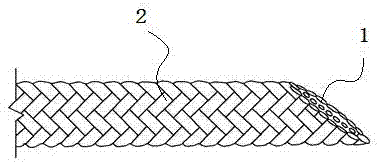

Offshore underwater component device mooring cable and manufacturing method thereof

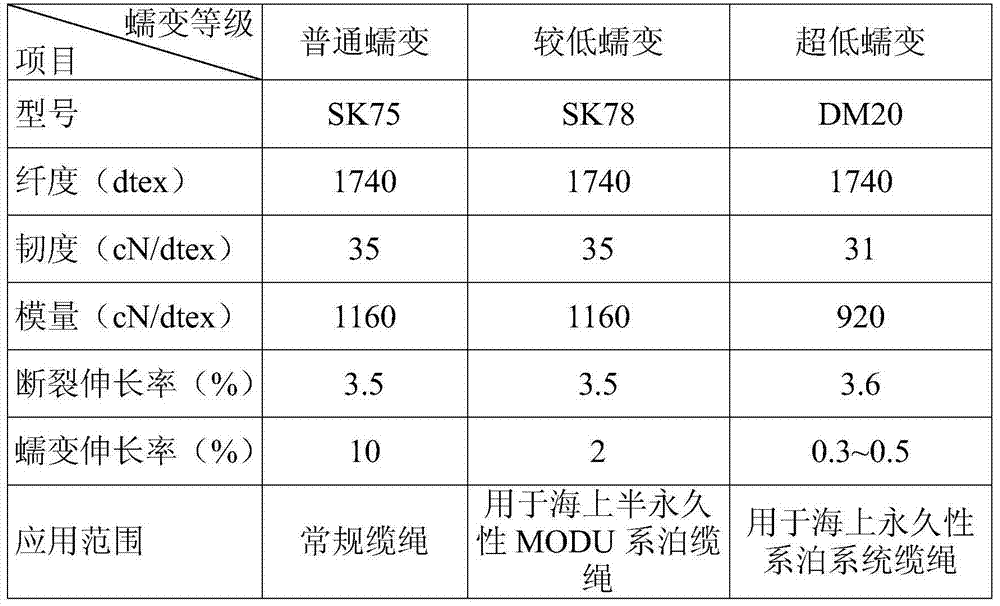

The invention relates to an offshore underwater component device mooring cable. The offshore underwater component device mooring cable is characterized by being of a sheath-core composite double-layer structure, an inner core is of a eight-strand structure made of DM20 ultra-high molecular weight polyethylene, an outer layer is a fixing sheath formed by weaving wear-proof high-strength polyester fibers, the inner core is formed according to the steps of manufacturing rough yarn, manufacturing rope yarn, manufacturing strands, weaving ropes, soaking the inner core in resin, prestretching the inner core and drying the inner core, and the fixing sheath is formed according to the steps of splicing threads, twisting the threads, manufacturing strands and weaving the 32 strands around the inner core into the fixing sheath in a one-off mode through a double-layer weaving machine.

Owner:TAIZHOU HONG DA ROPE & NET

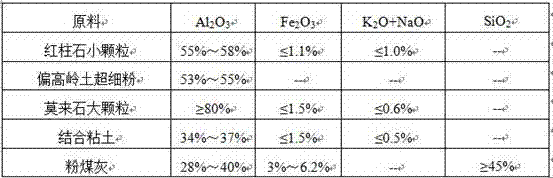

Corrosion-resistant microporous mullite lightweight refractory brick and preparation method thereof

The invention provides a corrosion-resistant microporous mullite light-weight refractory brick, which comprises a refractory brick base and a high-temperature resistant coating coated on the surface of the refractory brick base; wherein, the raw materials of the refractory brick base include: 20% to 30% of large tolite particles, 15% to 25% of small andalusite particles, 13% to 24% of metakaolin ultrafine powder, 5% to 10% of bound clay, 0.5% to 1.5% of expanded graphite, and fly ash 15% to 20%, hollow glass microspheres 3% to 6%, and the balance is pulp water; the raw materials of the high temperature resistant coating include: silica aerogel 65% to 70%, yttrium oxide gel 15% ~ 17%, nano silicon nitride 5% ~ 10%, potassium hexatitanate whisker 1% ~ 3%, and the balance of ethanol is ethanol. The invention also provides a preparation method of the corrosion-resistant microporous mullite light refractory brick, which has simple steps and is easy to produce automatically.

Owner:HENAN HAINADE NEW MATERIAL CO LTD

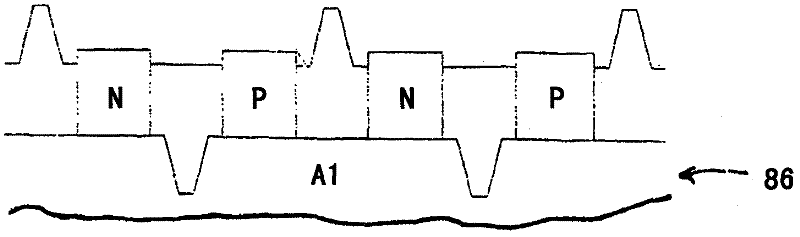

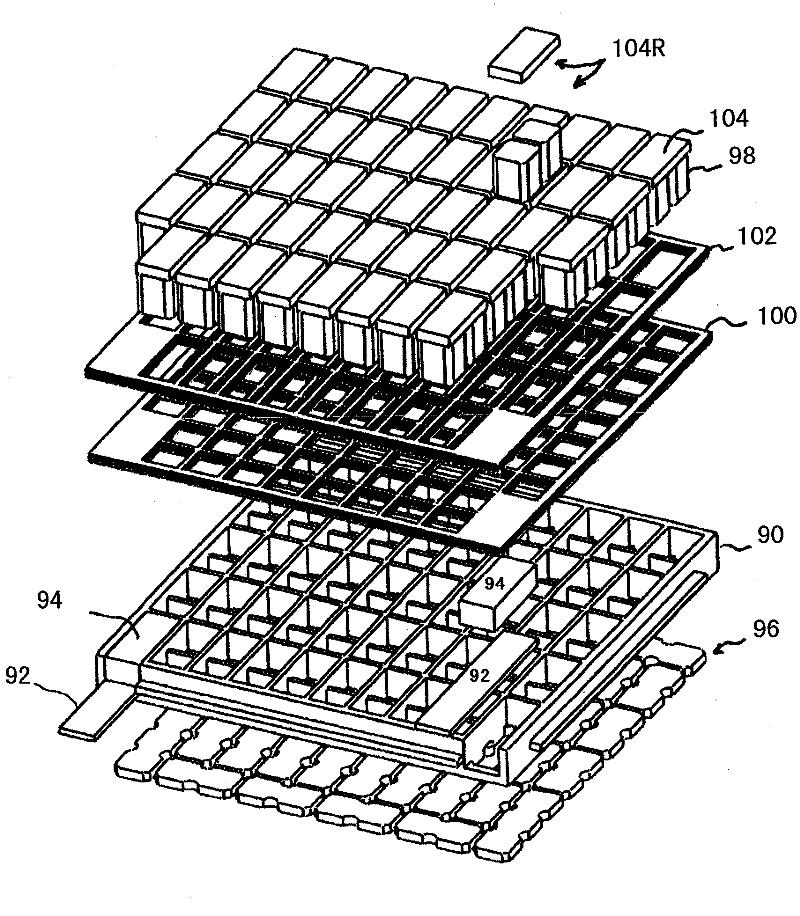

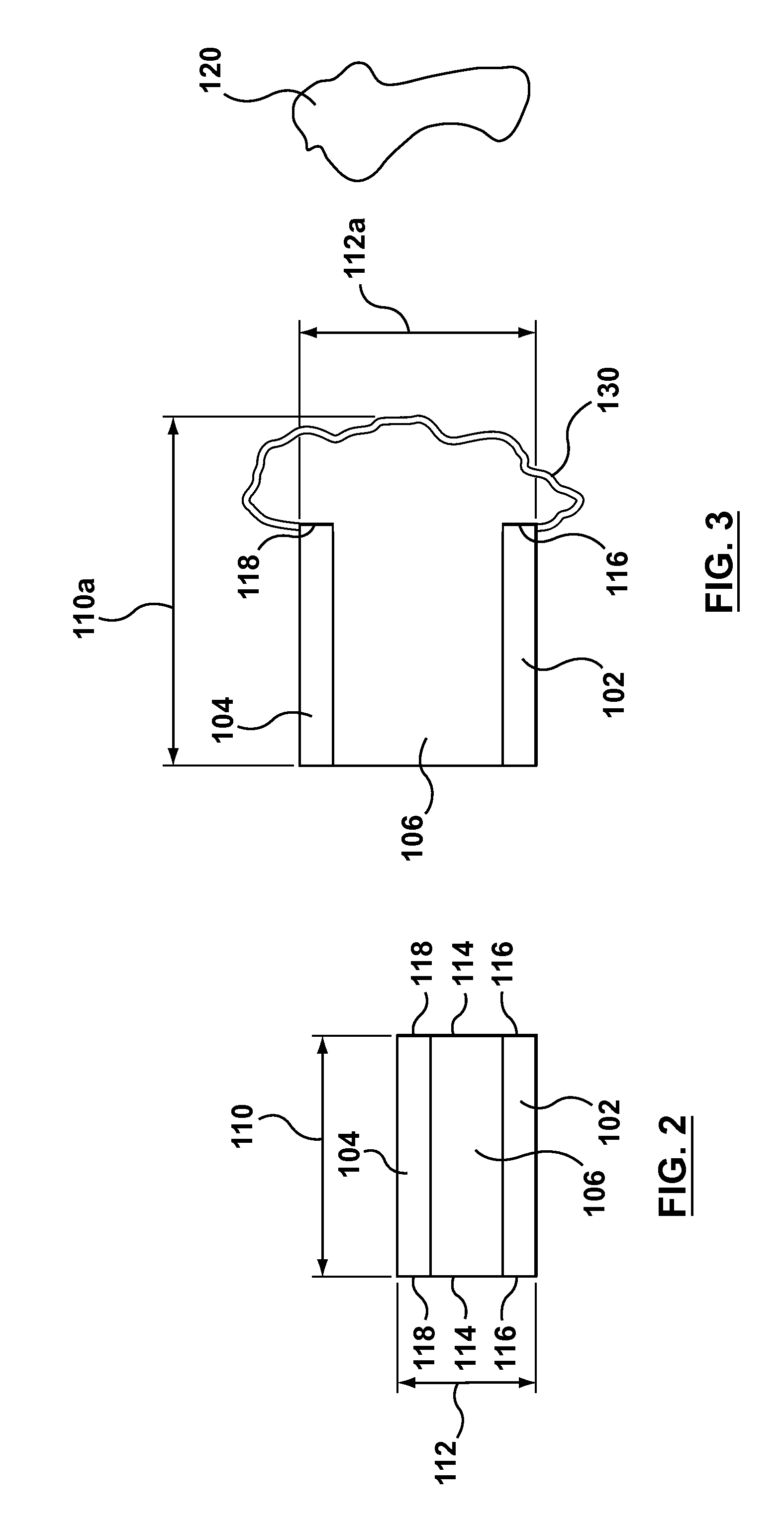

High temperature, high efficiency thermoelectric module

InactiveCN102308400AInhibit growthAvoid spreadingThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsThermoelectric cooling

A long life, low cost, high-temperature, high efficiency thermoelectric module. Preferred embodiments include a two-part (a high temperature part and a cold temperature part) egg-crate and segmented N legs and P legs, with the thermoelectric materials in the three segments chosen for their chemical compatibility or their figure of merit in the various temperature ranges between the hot side and the cold side of the module. The legs include metal meshes partially embedded in thermoelectric segments to help maintain electrical contacts notwithstanding substantial temperature variations. In preferred embodiments a two-part molded egg-crate holds in place and provides insulation and electrical connections for the thermoelectric N legs and P legs. The high temperature part of the egg-crate is comprised of a ceramic material capable of operation at temperatures in excess of 5000C and the cold temperature part is comprised of a thermoplastic material having very low thermal conductivity.

Owner:HI Z TECH

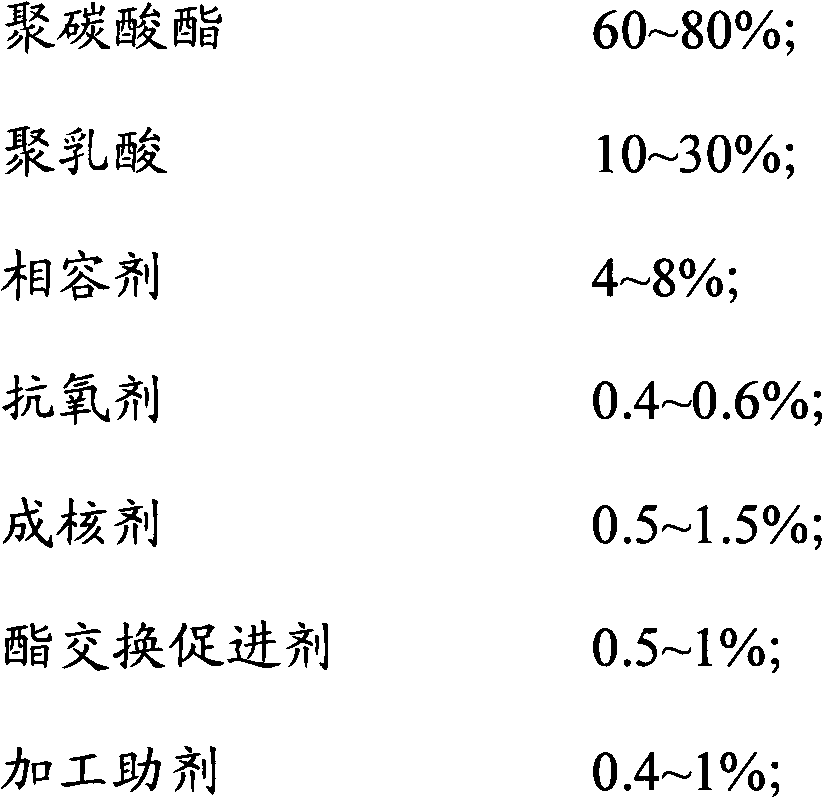

Degradable PC (Poly Carbonate)/PLA (Poly Lactic Acid) alloy and preparation method thereof

The invention relates to the technical field of modification of thermoplastic high molecular materials, and discloses a degradable PC (Poly Carbonate) / PLA (Poly Lactic Acid) alloy which is applied to the aspects of household appliances, living goods, electronic and electrical equipment and the like. The degradable PC / PLA alloy is prepared from the following materials: PC, PLA, compatilizer, antioxidant, nucleating agent, ester exchange accelerator and processing aid. The invention also discloses a preparation method of the degradable PC / PLA alloy. The invention aims to provide a degradable PC / PLA alloy which can be degraded on the basis of ensuring good comprehensive performance, thereby reducing the pollution to the environment. The invention also aims to provide a preparation method of the degradable PC / PLA alloy.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

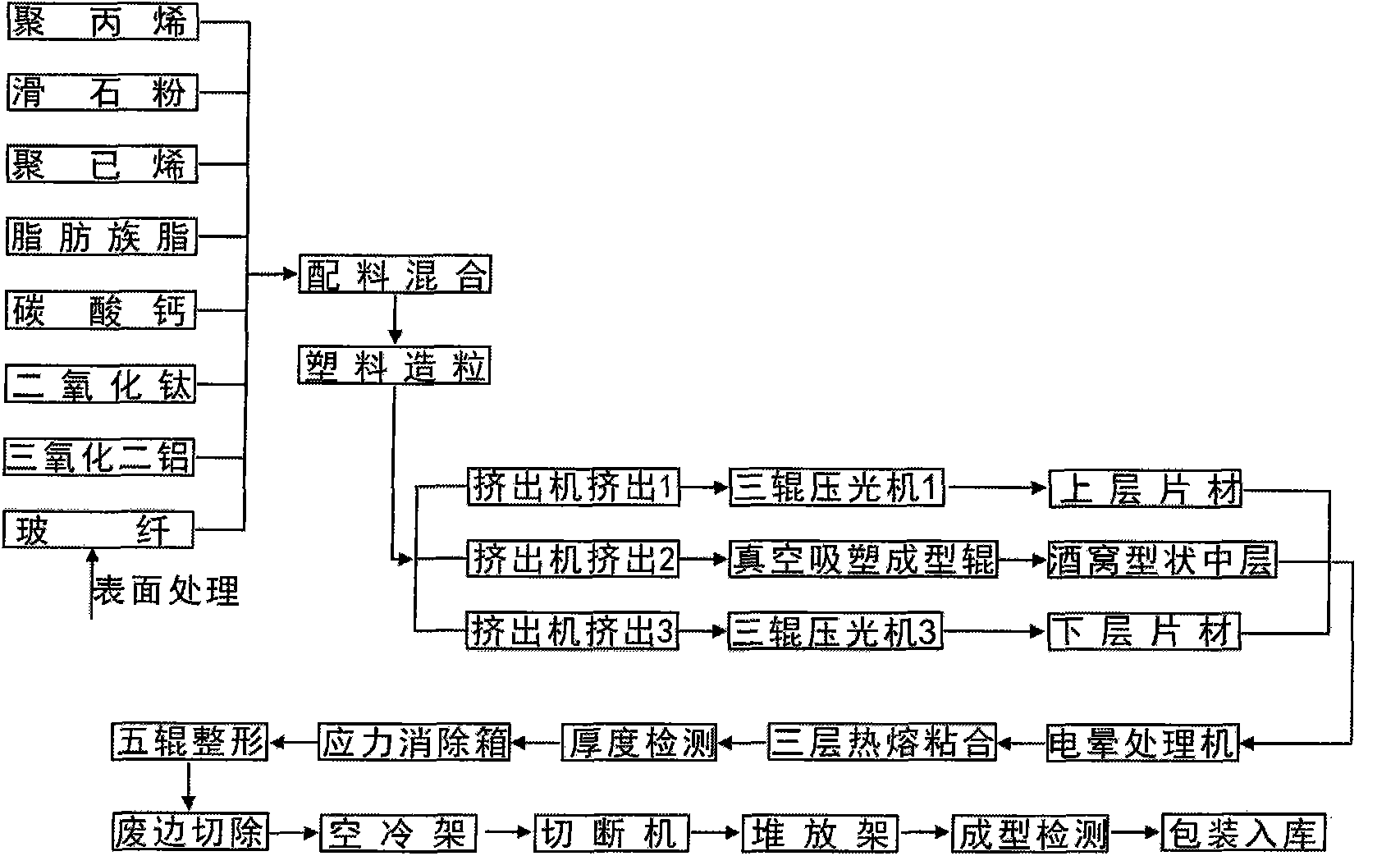

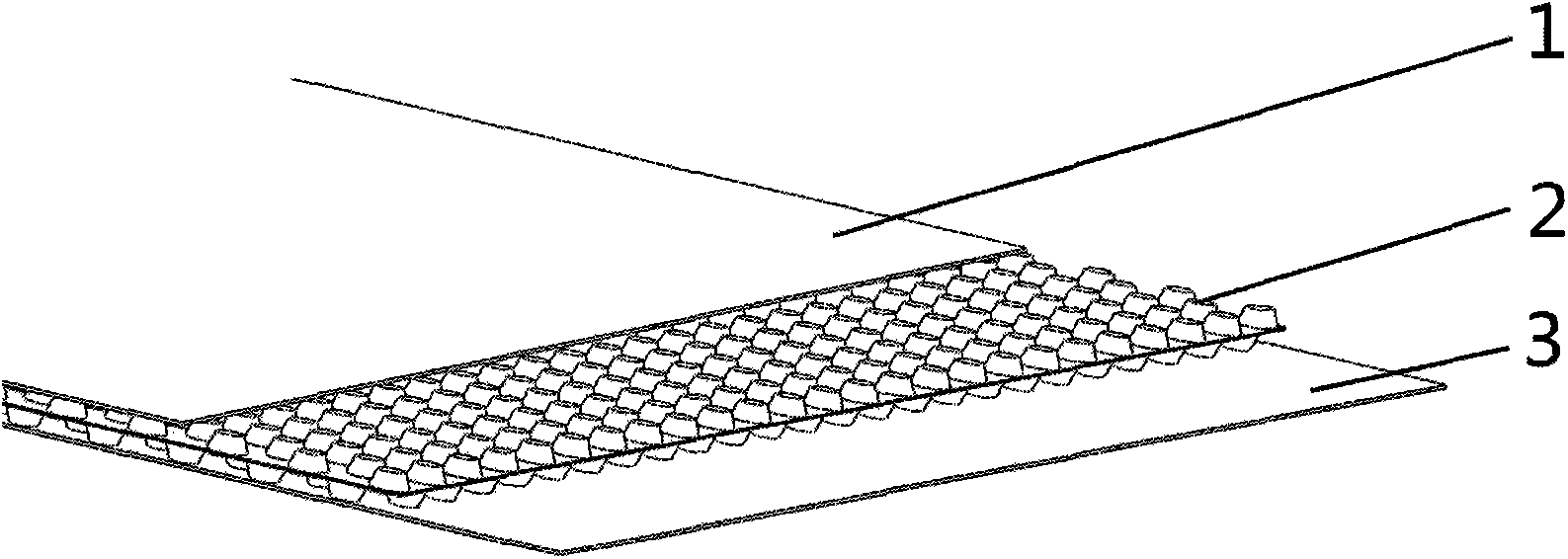

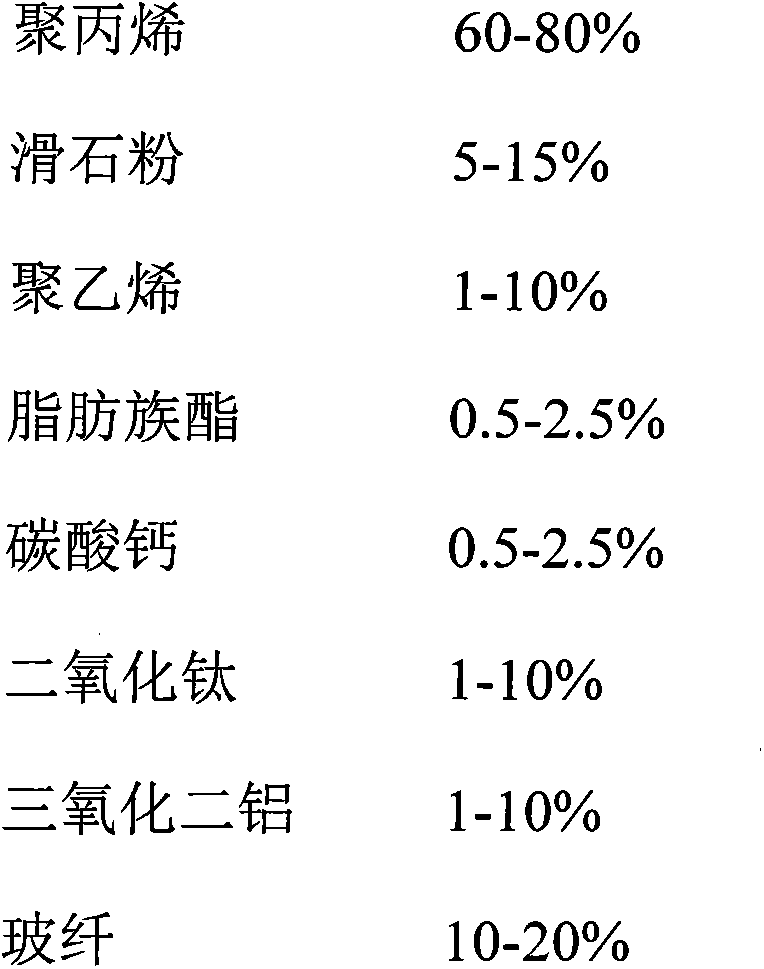

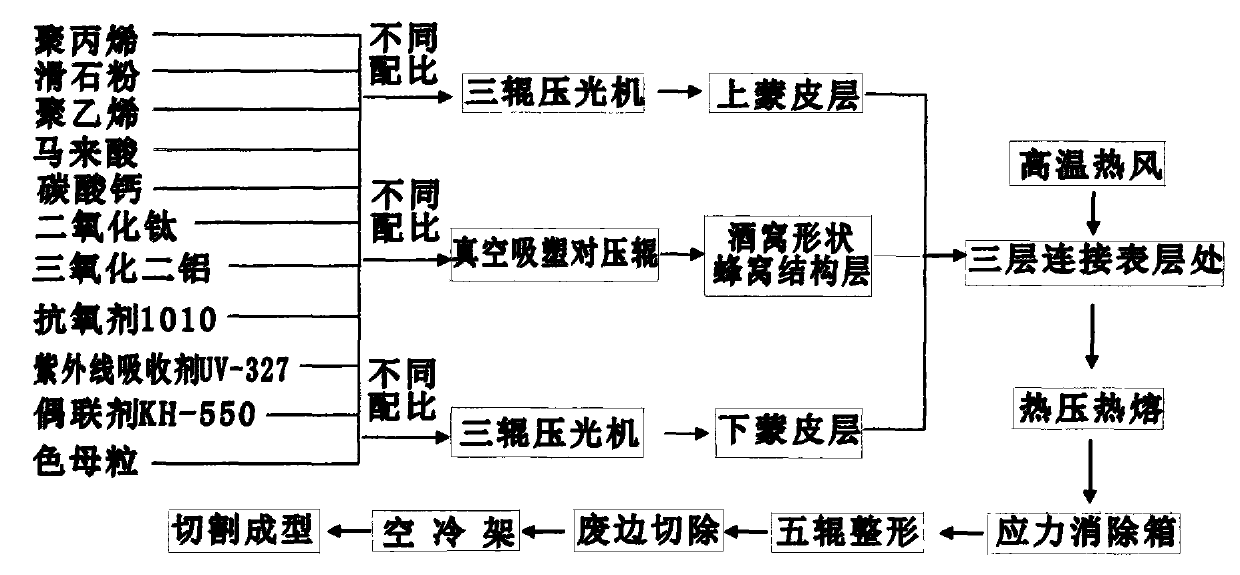

Dimple-shaped honeycomb hollow plate and manufacturing method thereof

InactiveCN104275836AImprove toughnessReduce crystallinityLamination ancillary operationsSynthetic resin layered productsPolypropyleneCHEEK DIMPLES

The invention discloses a dimple-shaped honeycomb hollow plate and a manufacturing method thereof, belonging to a manufacturing method of a multiplayer co-extruded molding hollow plate. The dimple-shaped honeycomb hollow plate is characterized in that an internal structure of the dimple-shaped honeycomb hollow plate comprises the following components in percentage by weight: 60-80 percent of polypropylene, 5-15 percent of talcum powder, 1-10 percent of polyethylene, 0.5-2.5 percent of aliphatic ester, 0.5-2.5 percent of calcium carbonate, 1-10 percent of titanium dioxide, 1-10 percent of aluminum oxide and 10-20 percent of glass fiber. The dimple-shaped honeycomb hollow plate is of a sandwich structure and structurally comprises an extrusion molding surface panel at the upper layer, a dimple-shaped honeycomb structure layer as a middle core layer and an extrusion molding surface panel at the lower layer. The manufacturing method of the dimple-shaped honeycomb hollow plate comprises the following steps: proportioning and mixing raw materials; plastifying and pelleting; extruding the extrusion molding surface panels at the upper layer and the lower layer by an extruder, and extruding a dimple-shaped honeycomb structure layer (formed by means of a vacuum plastic suction roller) by the extruder, performing corona treatment, performing hot-press and hot-melting splicing, annealing by a stress removing box, shaping and sizing by five rollers, cooling by an air cooling frame, forming and cutting to manufacture the dimple-shaped honeycomb hollow plate.

Owner:周挺

Strain type multidirectional force transducer with self-decoupling function

ActiveCN106500902AGood self-decoupling performanceReliable Thrust Measurement MethodsMeasurement of force componentsEngine testingSeparation technology

The invention relates to a strain type multidirectional force transducer with a self-decoupling function, wherein the strain type multidirectional force transducer belongs to the field of a load sensor. The strain type multidirectional force transducer comprises a four-column type structure, a strain gauge and a compensating gauge. The four-column type structure has a structure in which four columns are placed between an upper disc and a lower disc, and the four columns are arranged in a manner that two random columns are in symmetry with the other two columns. The strain gauge and the compensating gauge abut against the columns. The manufactured device is sealed in a sleeve, and air in the sleeve is replaced by insert gas, thereby ensuring no moisture absorption or moistening and preventing long-term stability reduction of the device. According to the strain type multidirectional force transducer, the four-column type symmetrical structure and bridging signal separation technology are utilized so that the sensor has high self-decoupling performance, thereby realizing simultaneous measurement for aeroengine thrust vectors, namely three force amplitude components and three moments, supplying more reliable and comprehensive technological data support for a vector thrust engine testing experiment, realizing higher reliability in an engine thrust measurement method, and obtaining higher accuracy of the measured data.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

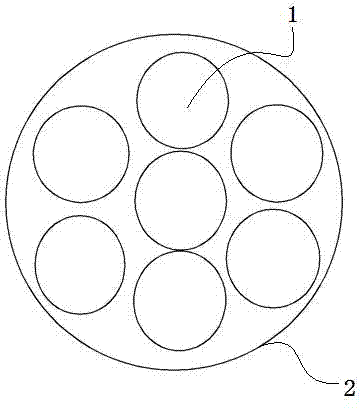

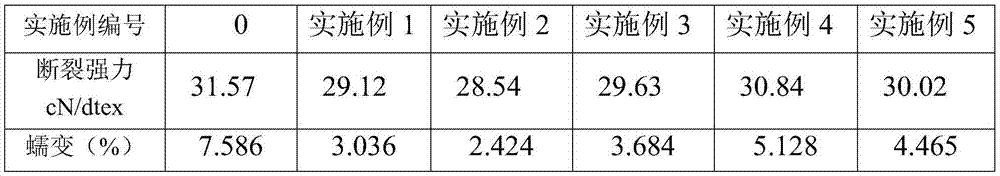

Ultra-high molecular weight polyethylene fiber and preparation method thereof

ActiveCN105442100AHigh strengthSmall creepSynthetic polymer filament chemical after-treatmentCross-linkFiber

The invention discloses an ultra-high molecular weight polyethylene fiber and a preparation method thereof. The preparation method comprises steps as follows: an ultra-high molecular weight polyethylene spun filament after solvent extraction is put in a modified solution containing a radiation-sensitive cross-linking agent for impregnation treatment; the spun filament after impregnation is dried and subjected to multi-stage hot air drafting; high-energy rays are adopted to radiate the fiber after drafting, and accordingly, the ultra-high molecular weight polyethylene fiber subjected to radiation-crosslinking is obtained. According to the preparation method of the ultra-high molecular weight polyethylene fiber, the radiation-sensitive cross-linking agent is introduced into the ultra-high molecular weight polyethylene spun filament after solvent extraction, the radiation-sensitive cross-linking agent enters the fiber easily and inlaid between fiber macromolecules in the drafting process, and ultra-high molecular weight polyethylene fiber cross-linking is triggered through radiation of the high-energy rays, so that the process is simple, the operation is convenient, and the prepared ultra-high molecular weight polyethylene fiber has performance of high strength and low creep.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP

Polytetrafluoroethylene alloy and preparation method thereof

The invention relates to a polymer alloy, which mainly comprises the following components in percentage by weight: 60 to 97 percent of polytetrafluoroethylene, 3 to 40 percent of main chain polyester liquid crystal polymer and the balance of auxiliary material. The auxiliary material is one or two of carbon fiber and glass fiber, wherein the carbon fiber is 0 to 15 weight percent of the auxiliary material; the glass fiber is 0 to 15 weight percent of the auxiliary material; and the auxiliary material comprises 0 to 5 weight percent of graphite. The wear-resistant polytetrafluoroethylene alloy has the advantages of high wear resistance, high hardness, low creep property, low friction coefficient and abrasion coefficient and the like.

Owner:浙江超维新材料有限公司

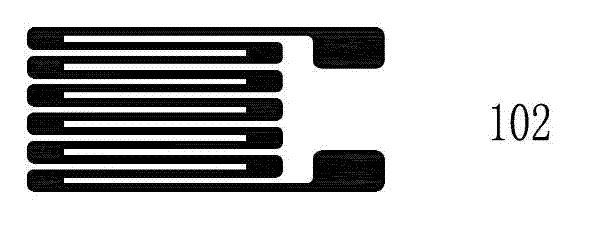

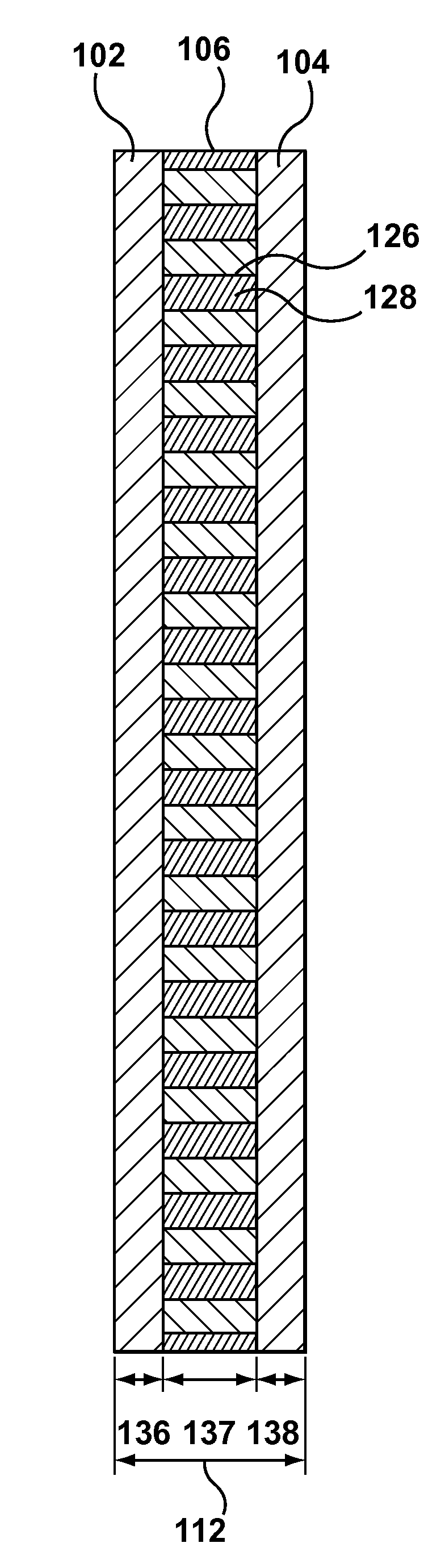

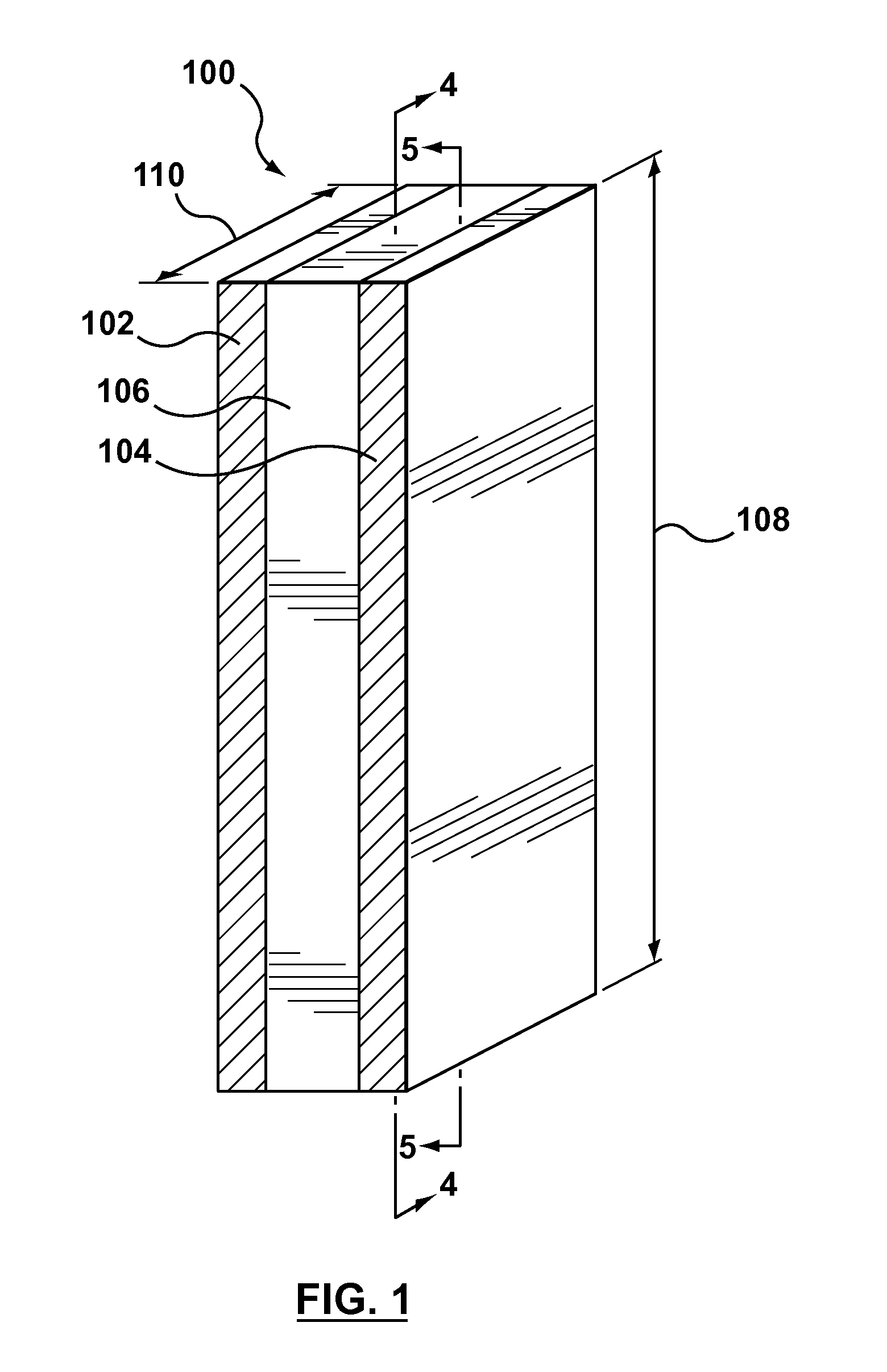

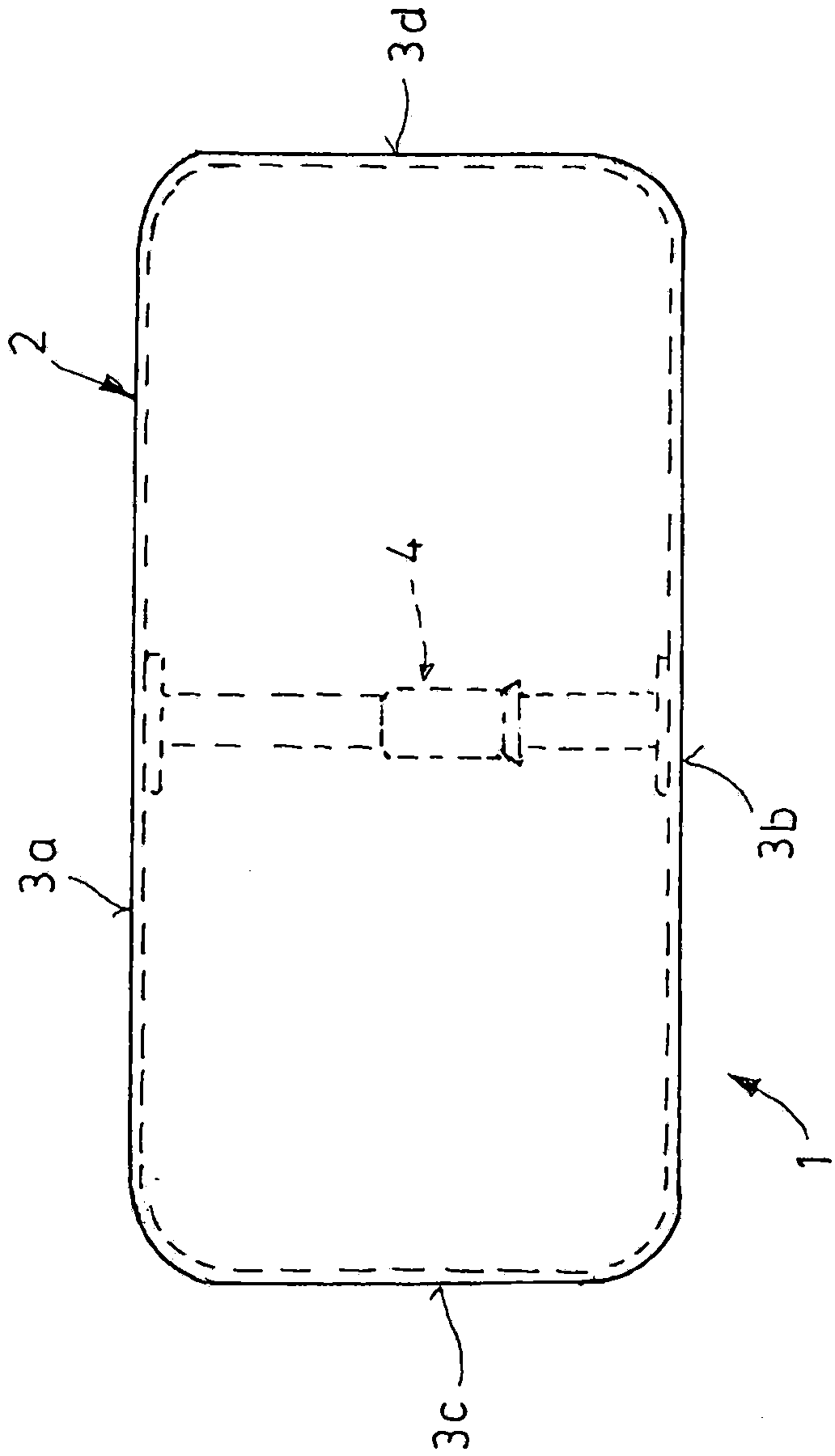

Intumescent fire door edge system

InactiveUS8230659B2Increase the gap sizeHigh trafficSynthetic resin layered productsBuilding repairsMelting temperatureActivation temperature

An intumescent strip includes a first material layer and an opposing second material layer. A third material layer, formed from an intumescent material, is positioned between the first and second layers. The intumescent material includes a combination of intumescent particles suspended within a thermoplastic material. The intumescent particles have an activation temperature and are expandable when exposed to temperatures above the activation temperature. The thermoplastic material has a melting temperature that is lower than the activation temperature.

Owner:LANCOTEK PROD

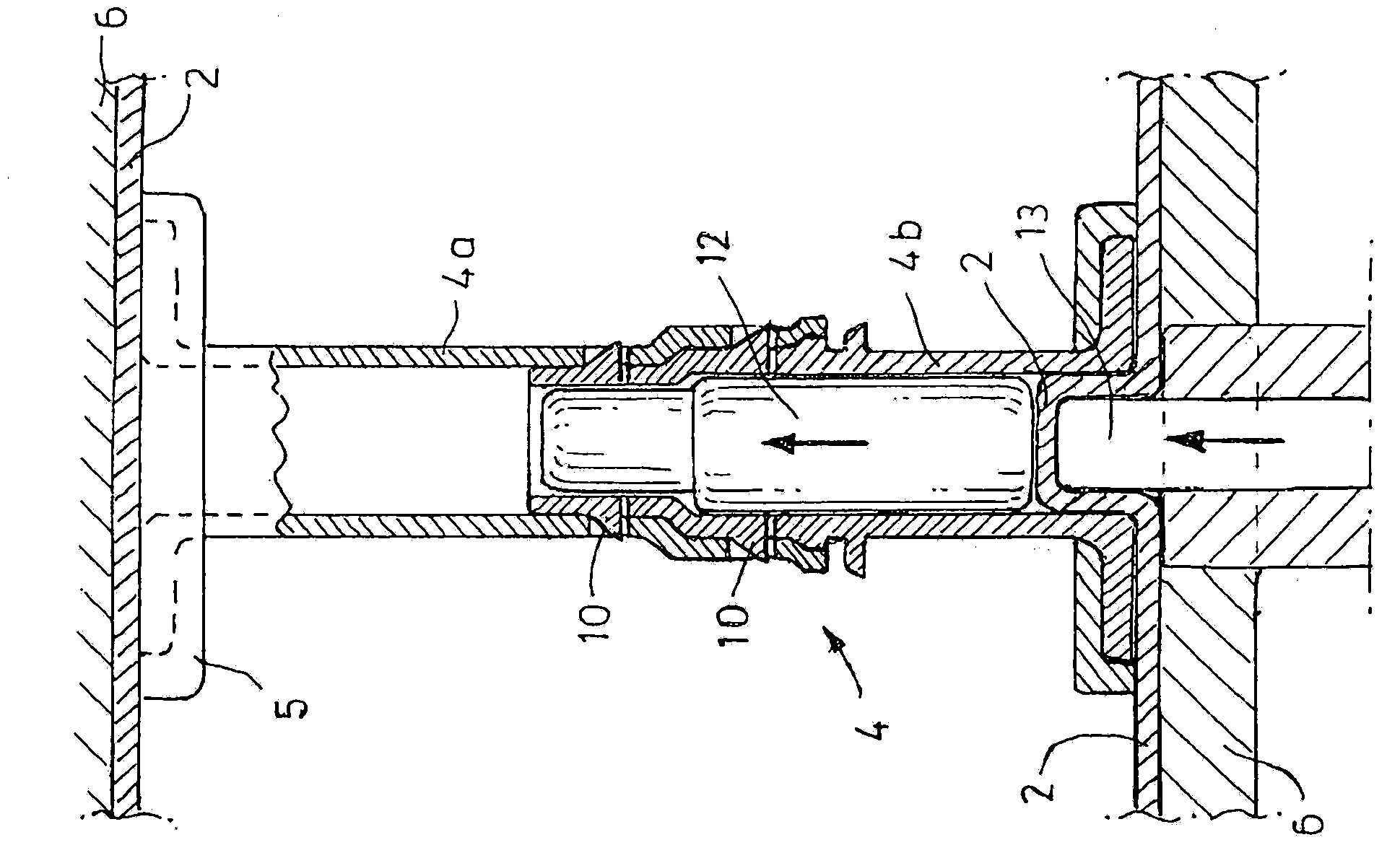

Tank for a motor vehicle, in particular fuel or auxiliary fluid tank for a motor vehicle, and method for producing such a tank

ActiveCN103930293AReduce lossesImprove mechanical stabilityUnderstructuresDomestic articlesFuel tankEngineering

The invention relates to a fuel tank for a motor vehicle, which is made up of two shells which are complementary to one another, wherein the shells are supported against one another by at least one strut penetrating the tank (1), connecting opposing wall regions of the tank. The strut is configured as a two- part hollow strut (4), wherein the parts of the hollow strut are latched together via a plug connection and the latching connection is secured by at least one closure body (12) at least partially filling up the cross section of the hollow strut (4) at least level with the latching connection.

Owner:KAUTEX TEXTRON

Dimple-shaped honeycomb hollow plate and manufacturing method thereof

InactiveCN104175613AImprove toughnessReduce crystallinitySynthetic resin layered productsLaminationHoneycomb structureEngineering

The invention relates to a dimple-shaped honeycomb hollow plate and a manufacturing method thereof, which belong to a manufacturing method of a multilayer co-extrusion molding hollow plate. The dimple-shaped honeycomb hollow plate is characterized in that an internal structure comprises an upper skin layer, a dimple-shaped honeycomb structure layer and a lower skin layer, wherein the dimple-shaped honeycomb structure layer is of an inlaid type sandwich structure in an up-and-down staggered mode. The dimple-shaped honeycomb hollow plate is provided, so as to overcome the defects of poor impact resistant performance, compressive deformation and infirmness of an existing plastic hollow plate, and the dimple-shaped honeycomb hollow plate has good performances of high strength, pressure resistance, wear resistance, heat insulation, impact resistance and breaking resistance, can simultaneously bear transverse section stress, longitudinal section stress and plate positive stress and has the advantages of uniform stress of each side surface, wide application range and good use effect.

Owner:NINGBO TIANQI HONEYCOMB MATERIALS

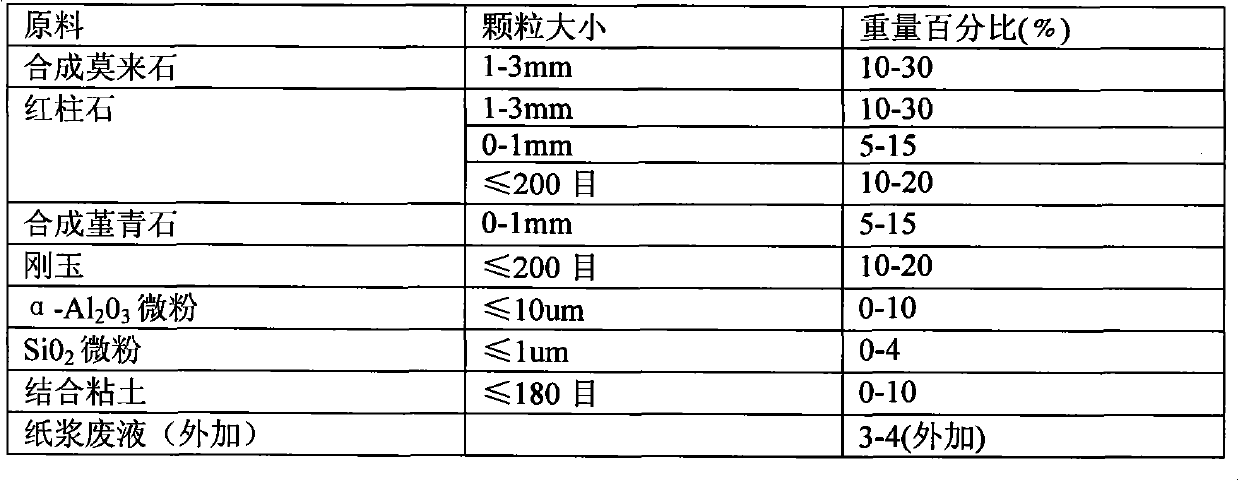

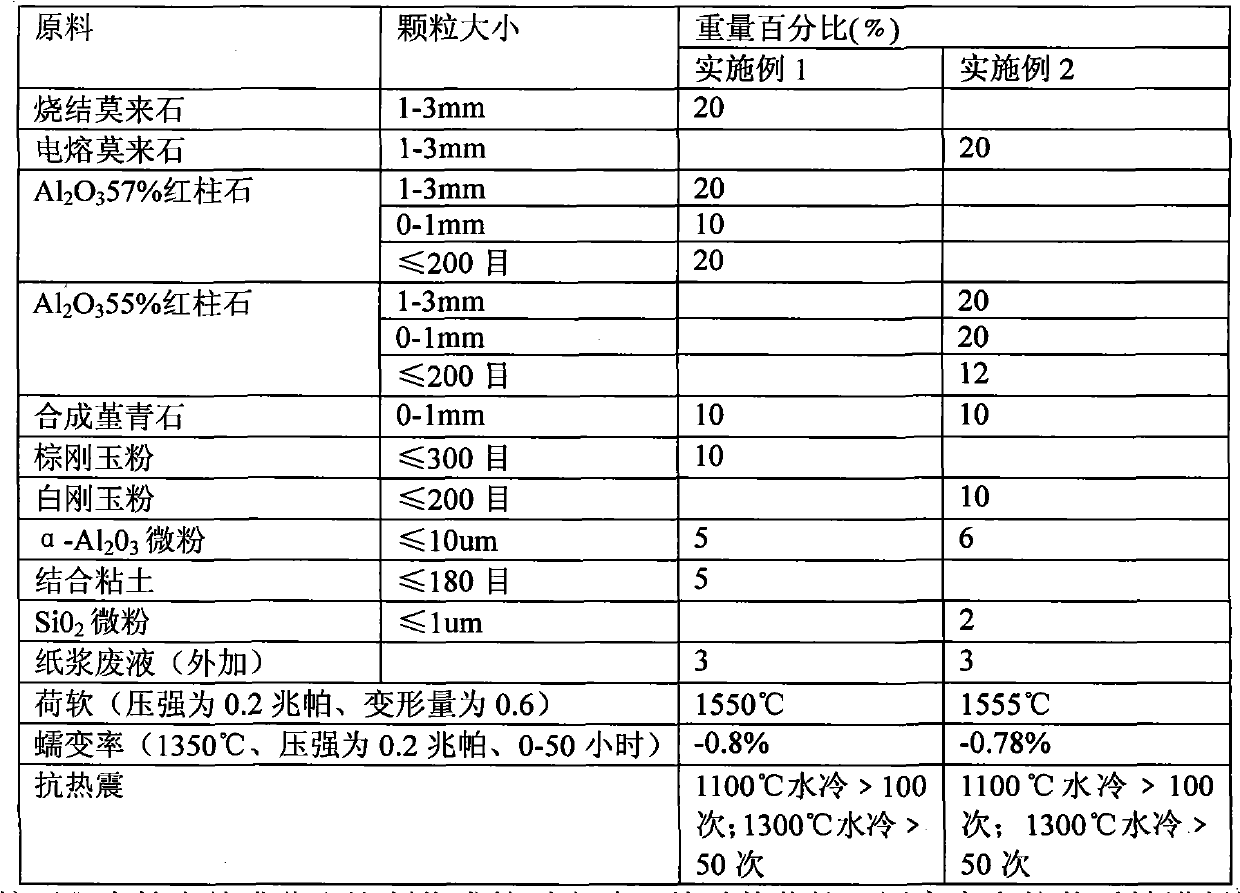

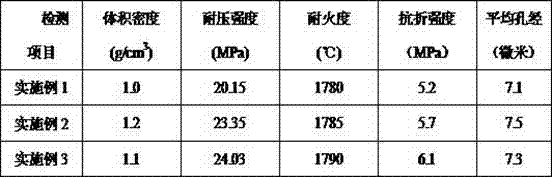

High-stress-strain low-creepage high-thermal-shock-resistance refractory brick and manufacturing method thereof

The invention discloses a manufacturing method of a refractory brick. According to the manufacturing method, low-and-medium-grade andalusite (the contents of Al2O3 are 53%, 55% and 57%) are used as main raw materials, large and intermediate andalusite particles are replaced with large mullite particles and intermediate cordierite particles, and corundum, alpha-Al2O3 micropowder and SiO2 micropowder and combining clay and waste paper pulp are added. The preparation method comprises the following steps of: mixing the ingredients in a wet pan mill evenly and then discharging out of the mill; forming by a frictional brick press; drying the formed green blanks in a dryer; calcining the dried blanks in a calcining kiln, wherein the highest calcining temperature ranges from 1370DEG C to 1400DEG C. The refractory brick obtained by adopting the method can effectively solve the problems of the conventional refractory brick, such as high manufacturing cost, low load softness, large creepage, poor anti-seismic property and short service life; the appearance defects of the refractory brick are fewer, and the refractory brick can be widely applied in a ceramic burner of an ironmaking blast-furnace hot blast stove.

Owner:ZHENGZHOU ANNEC IND

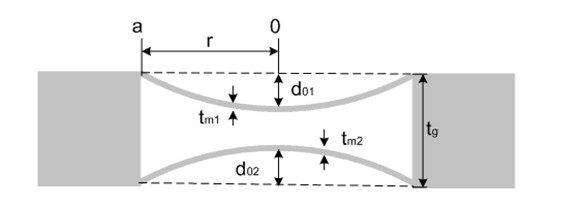

Capacitance pressure sensor with high Q value and large relative variable quantity

InactiveCN102052989ALittle effect of strainSmall short circuit with little effect of strainFluid pressure measurement using capacitance variationCapacitanceSurface acoustic wave

The invention discloses a capacitance pressure sensor which is used for wireless and passive measurement. A capacitor is composed of an elastic vibrating diaphragm of which the periphery is fixedly supported; by means of adjusting the ratio of the radium of a circular electrode to the radius of the vibrating diagram and arranging insulated salient points and the like, the vibrating diagram is in a large strain state; and the ratio of the maximum capacitance to the initial capacitance is as big as possible so as to obtain the capacitance with high Q value and large relative variable quantity. After being connected with a surface acoustic wave transmitter, the capacitance pressure sensor with high Q value and large relative variable quantity can realize wireless and passive high-precise measurement on pressure and can be used for the monitoring field of automobile tyre pressure.

Owner:HUAZHONG UNIV OF SCI & TECH

Microporous high-alumina bauxite clinker lightweight refractory brick and preparation method thereof

The invention provides a microporous high-alumina bauxite clinker lightweight refractory brick, which includes main ingredients and additives. The main ingredients include the following materials in mass percentages: 15% to 30% of high-alumina bauxite clinker large particles, Calcium aluminate fine powder 18% ~ 25%, kaolin superfine powder 8% ~ 12%, Al2O3 micropowder 15% ~ 25%, silicon micropowder 5% ~ 8%, pore forming agent 8% ~ 12%, fine silicon dioxide 1% to 3% of airgel; the mass of the additive is 4.5% to 5.5% of the mass of the main material. The composition of the microporous high-alumina bauxite clinker lightweight refractory brick is reasonably matched, and uniformly distributed micron-sized pores are formed inside the material, so that the product has good thermal shock resistance, good thermal stability and high load softening temperature. The present invention also provides a method for preparing the above-mentioned microporous high-alumina bauxite clinker lightweight refractory brick. The method has simple steps and is easy for automatic production.

Owner:HENAN HAINADE NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com