Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

317 results about "Engine testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Autonomous Environmental Control System and Method For Post-Capture and Pre-Launch Management of an Unmanned Air Vehicle

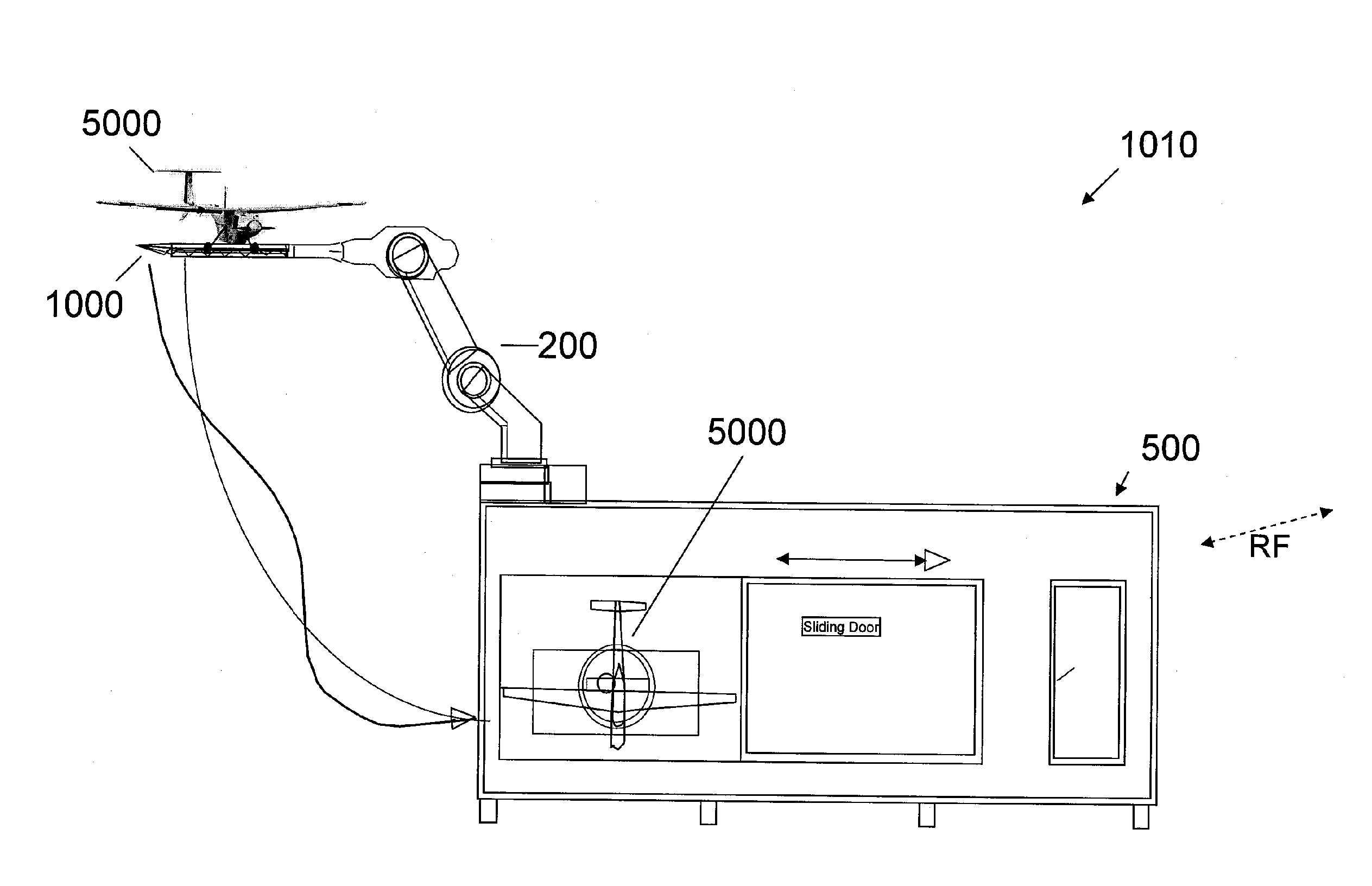

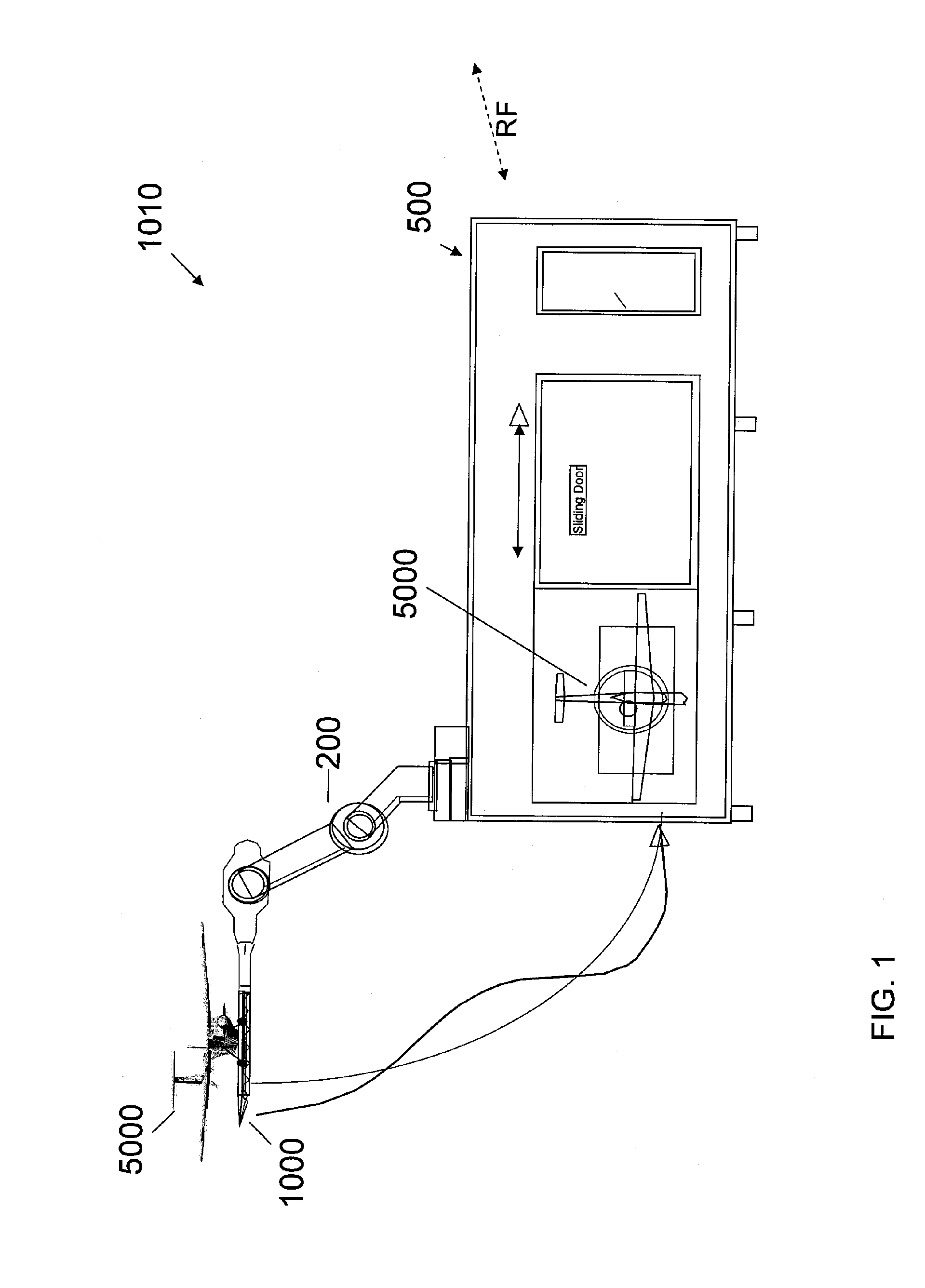

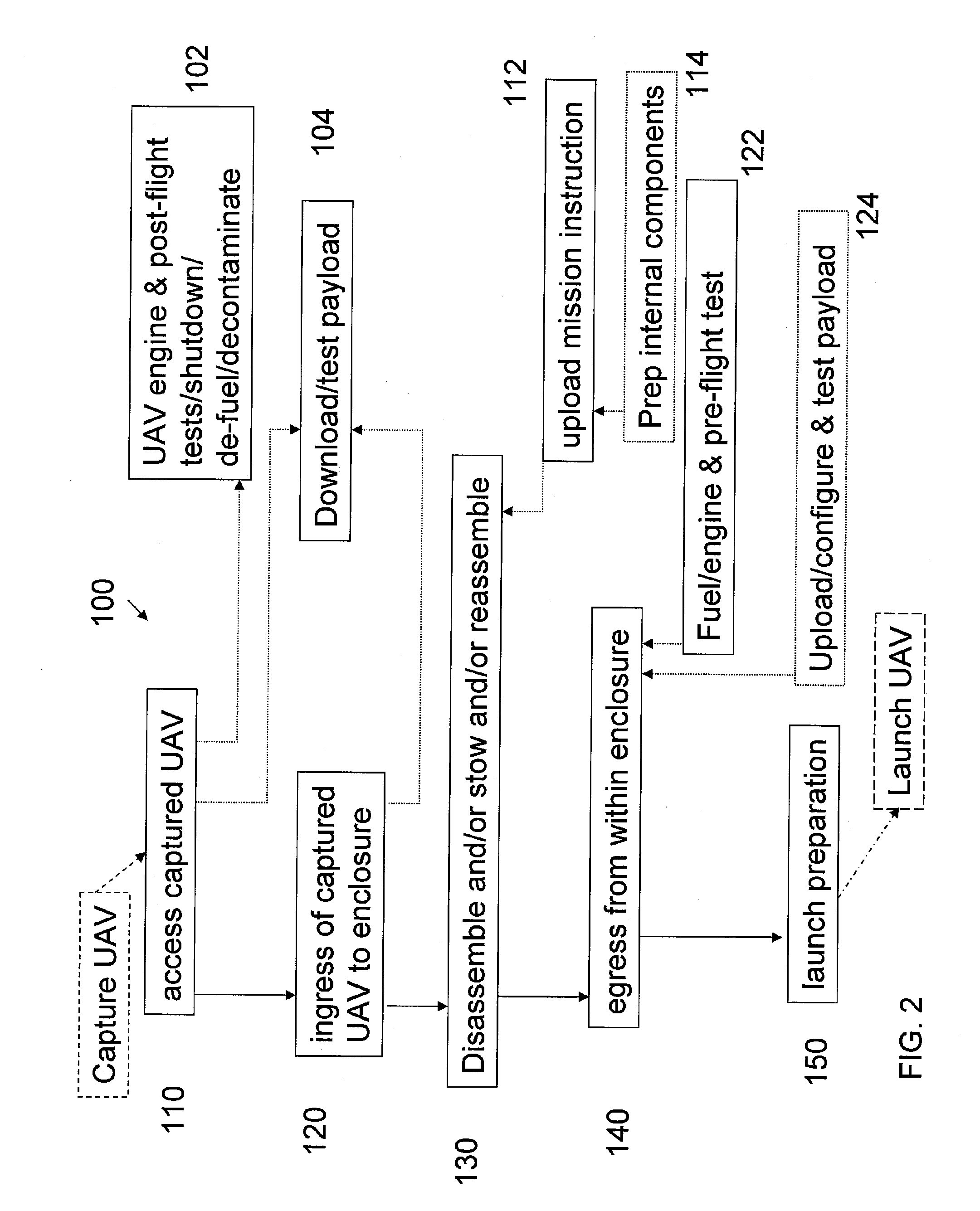

An embodiment of the invention is directed to a system for controlling and managing a small unmanned air vehicle (UAV) between capture and launch of the UAV. The system includes an enclosure that provides environmental protection and isolation for multiple small UAVs in assembled and / or partially disassembled states. Control and management of the UAVs includes reorientation of a captured UAV from a landing platform and secure hand-off to the enclosure, decontamination, de-fueling, ingress to the enclosure, downloading of mission payload, UAV disassembly, stowage, retrieval and reassembly of the UAV, mission uploading, egress of the UAV from the enclosure, fueling, engine testing and launch readiness. An exemplary system includes two or more robots controlled by a multiple robot controller for autonomously carrying out the functions described above. A modular, compact, portable and autonomous system of UAV control and management is described.

Owner:LOCKHEED MARTIN CORP

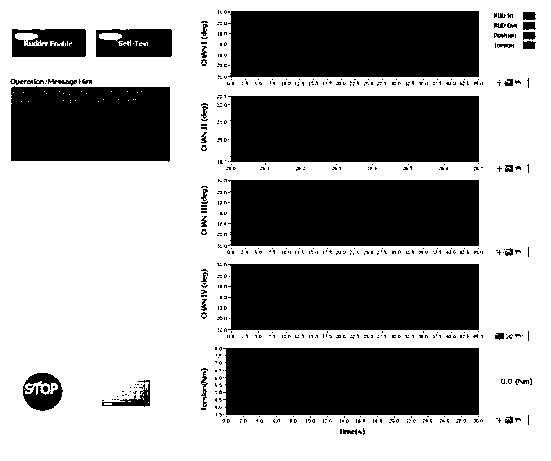

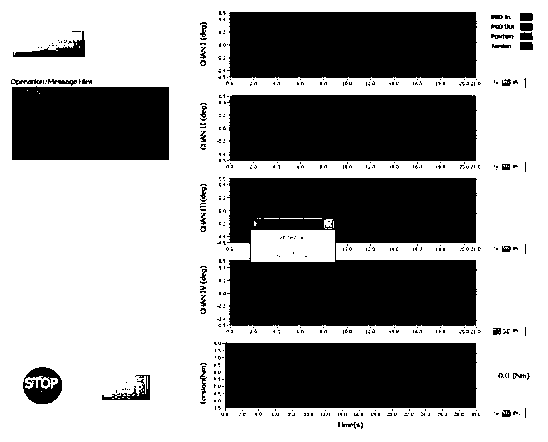

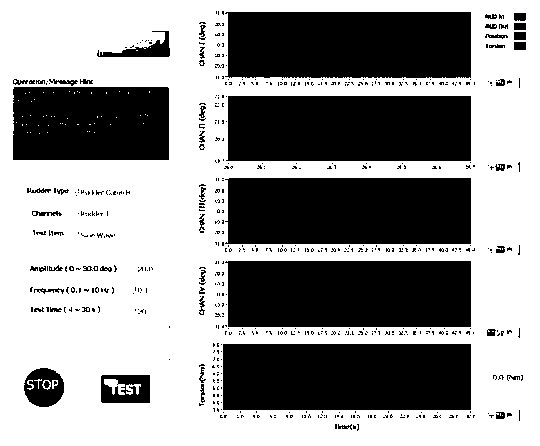

Steering engine tester and testing method thereof

ActiveCN103076195AEasy to observe test resultsAvoid lossStructural/machines measurementKey pressingEngine testing

The invention relates to a steering engine tester and a testing method thereof, which belong to the technical field of guided bombs. The tester comprises a control cabinet and a simulation load table, wherein the control cabinet comprises a steering engine controller, a regulated power supply, an industrial control computer, a display, a keyboard and a main power supply switch; the simulation load table comprises a photoelectric encoder, a torque sensor and a magnetic powder brake; a steering engine shaft of a steering engine to be tested is mechanically connected with a rotating shaft of the photoelectric encoder through a shaft coupling; the steering engine to be tested is in digital signal communication with the steering engine controller through a data line; and steering engine testing software is installed in the industrial control computer. The tester provided by the invention has the advantages of more plentiful testing contents, more complete testing equipment, more intelligent testing software, prompting of operating information on a software interface, shielding of keys which are required to be operated, change of parameter input items according to selected testing items, information prompt for improper operation, and great reduction in the probability of error operation.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

Engine testing system and testing method thereof

InactiveCN1884992AIncrease productivityReduce testing costsEngine testingProduction rateEngine testing

The invention relates to an engine testing system and relative testing method, wherein it uses direct-current servo motor to rotate the tested engine; it uses sensor to collect relative data to be analyzed, to be calculated and compared with preset limit value, to judge if the tested engine is qualified. The invention can shorten the testing time, improve the producing efficiency, reduce the test cost and avoid pollution.

Owner:SHANGHAI W IBEDA HIGH TECH DEV

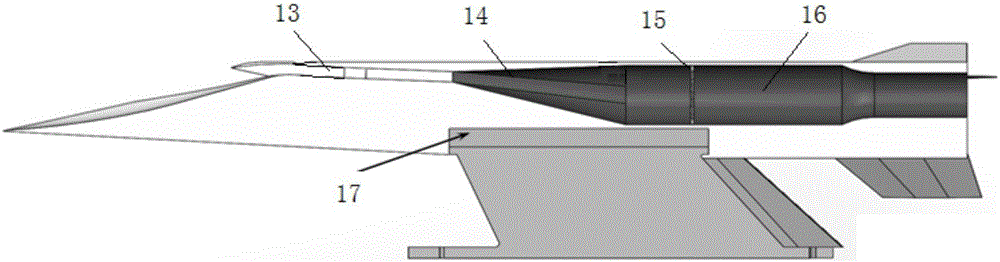

Air inlet system of ultrasonic engine testing platform

An air inlet system of an ultrasonic engine testing platform comprises a supply source, a temperature simulation unit, a simulation cabin and an ultrasonic jet pipe. The supply source comprises a fueloil supply source, an oxygen supply source an engine air inlet supply source, and an alcohol supply source; the temperature simulation unit comprises a tube and a casing, the tube is positioned in the casing, the internal of the tube serves as a first medium channel, and a space between the outer wall of the tube and the inner wall of the casing forms a second medium channel; a tested engine is positioned in the simulation cabin; and the ultrasonic jet pipe comprises an inlet unidiameter segment, a subsonic speed convergence segment, an initial ultrasonic expansion segment and an ultrasonic expansion segment which are fixedly connected in the same axis successively. According to the air inlet system of the ultrasonic engine testing platform, the Laval type ultrasonic jet pipe is arrangedbetween the temperature simulation unit and the engine air inlet, so that the ultrasonic air inlet state of the ultrasonic engine is simulated during ultrasonic engine and engine ground test.

Owner:BEIJING AEROSPACE SANFA HIGH TECH

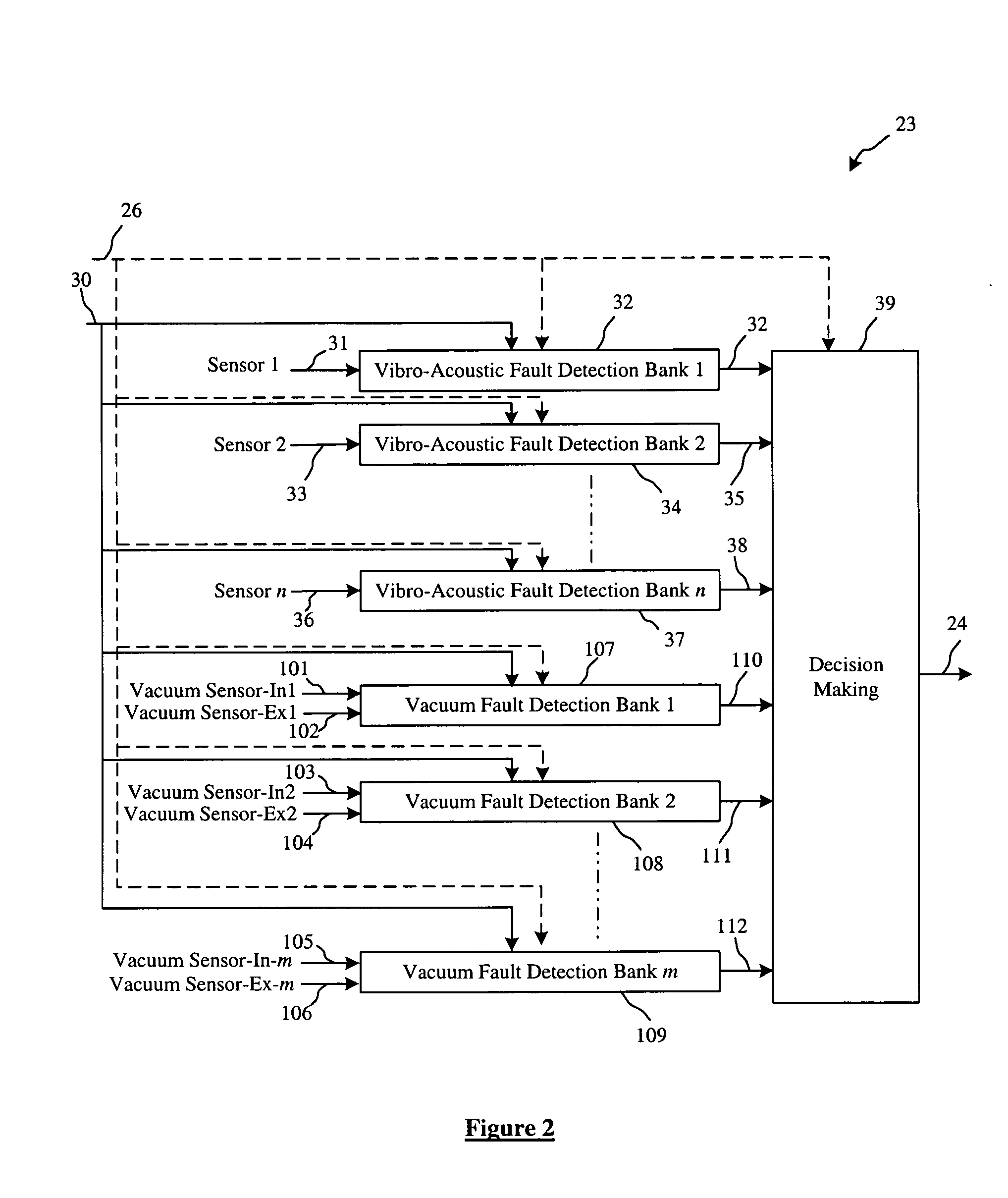

Vibro-acoustic engine diagnostic system

InactiveUS20040260454A1Analogue computers for vehiclesInternal-combustion engine testingDigital signal processingEngine testing

A diagnostic system is used for detecting the health condition of moving internal mechanical components in internal combustion engines. The system uses measurements of engine vibration and acoustic signals during cold or hot engine test. The system includes engine vibration and acoustic sensing, engine vacuum sensing, signal conditioning and pre-filtering, analog to digital conversion, advanced digital signal processing, and decision making. Engine vibration and acoustic signals are first amplified and then passed through a low-pass filter. The signals are then digitized and sent to a computer. An engine diagnostic software receives the digitized data and performs digital filtering to isolate signal parts that most influenced by each engine moving mechanical component of interest. Features are then extracted using statistical analysis and passed to a decision making inferences. The decision making inferences utilize fuzzy logic engines to fuse feature values and reach a conclusive decision about each component condition. The system is then summarizes all results and presents them to the operator.

Owner:INTELLIGENT MECHANTRONIC SYST INC

Large cryogenic liquid rocket engine test bed supply system

ActiveCN104729857ALow densityQuality impactGas-turbine engine testingJet-propulsion engine testingEngine test standPilot system

The invention discloses a large cryogenic liquid rocket engine test bed supply system. The system comprises a fuel pressurization system, an oxidizing agent pressurization system, a fuel transport system and an oxidizing agent transport system. According to the system, propellant is pressurized through a gas supercharging method, and the stability and reliability of liquid flow in the engine testing process are guaranteed; the domestic normally-used pump pressurization method is not adopted and has the defects that the output flow of liquid is in an impulse mode, vibration is strong and difficulty is caused in the testing process, so the gas supercharging method has high adaptability to the system; the function that liquid propellant is converted into gas propellant is expanded, the requirements of other testing systems for the gas propellant can be met in future, and the multifunctionality of the testing system is greatly expanded.

Owner:BEIHANG UNIV

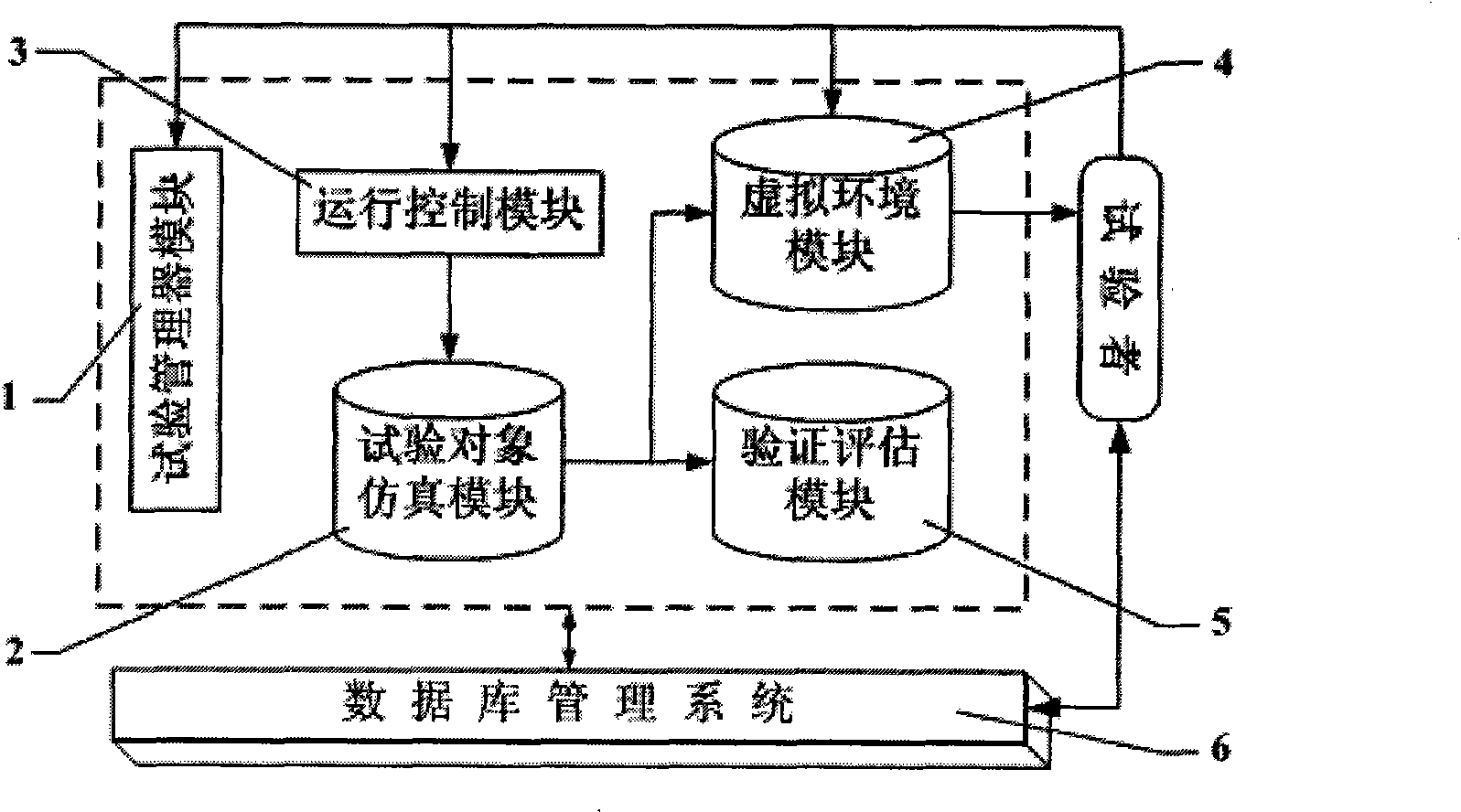

Virtual testing platform of liquid rock engine and testing method thereof

InactiveCN101576440AConvenient virtual expressionImprove versatilityEngine testingEngine testingTrue test

The invention discloses a virtual testing platform of a liquid rock engine and a testing method thereof, comprising a test manager module, a test object simulating module, an operation control module, a virtual environment module, a verification evaluating module and a database managing system. By determining a test object and a test proposal, the operation control module controls the simulation process of the test object simulating module, the virtual environment module performs three-dimensional display and entity mapping, the verification evaluating module evaluates a virtual test result, and the database managing system stores and manages data information, thus realizing the combination of the engine testing technology and the computer method, achieving the effect that the virtual testing platform serves as a seamless integrated system of a project, being led to be similar to true test operating practice, and being capable of having functions and performances similar to a true engine igniting test to a certain extent.

Owner:BEIHANG UNIV

Wind generating set monitoring system based on physical component model and real-time data

ActiveCN104018988AInnovative monitoring modelWind motor controlMachines/enginesElectricityEngine testing

The invention relates to the field of engine testing, and provides a wind generating set monitoring system based on a physical component model and real-time data. A wind condition input module receives real-time wind condition information obtained by a power plant, and the real-time wind condition information is respectively transmitted to a control system and a blade physical simulation module. The control system sends a yaw system control strategy to a yaw control module and sends a variable pitch system control strategy to a variable pitch control module, and information of a rotation angle, angular speed and angular acceleration of a cabin is generated by the yaw control module and transmitted to the blade physical simulation module. Information of a rotation angle, angular speed and angular acceleration of a blade is generated by the variable pitch control module and transmitted to the blade physical simulation module. After the blade physical simulation module integrates the obtained information with blade stress and stress toque information, information of target torque, target rotation speed and target angular acceleration of the blade is obtained and transmitted to a transmission module, and the transmission module outputs electric power information. The wind generating set monitoring system provides dual verification for prediction of performance failure of a wind generating set.

Owner:SHANGHAI JIAO TONG UNIV

Method for indirectly measuring effective thrust of engine

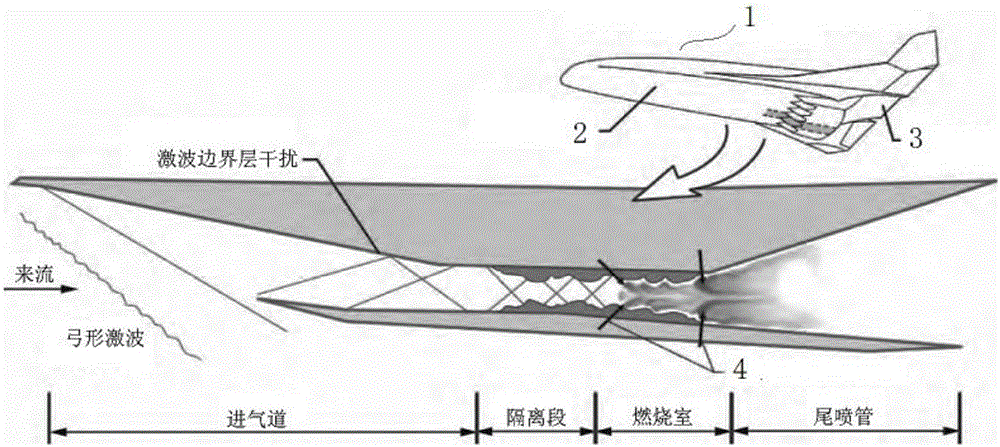

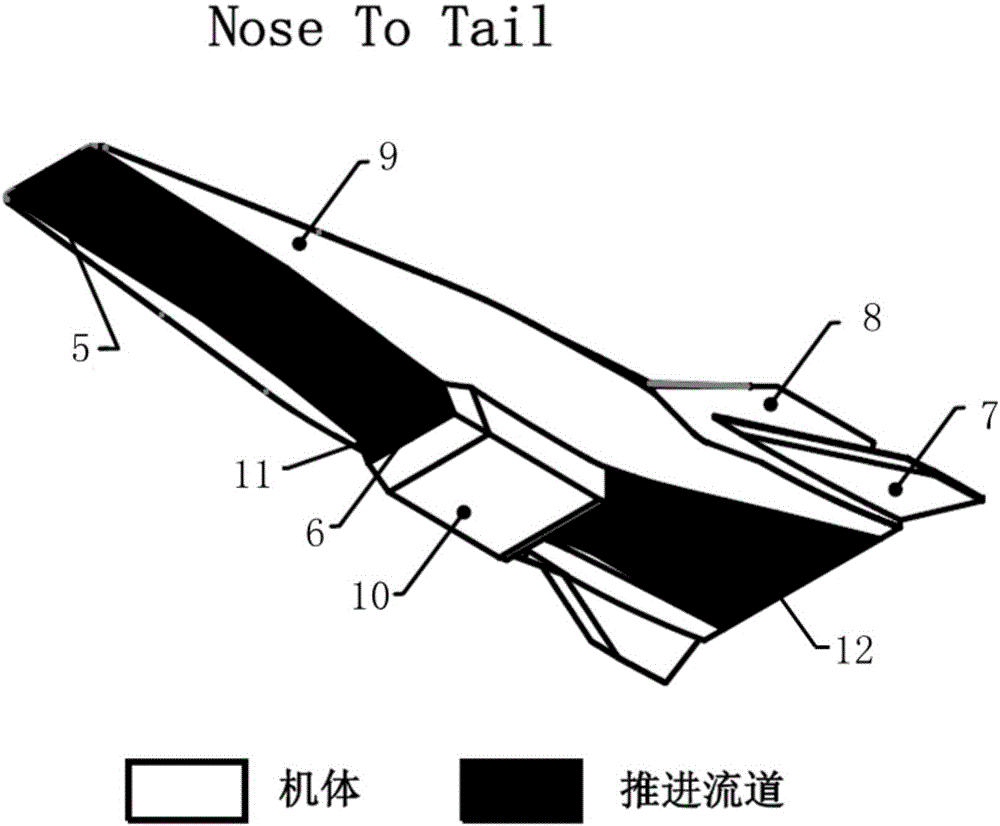

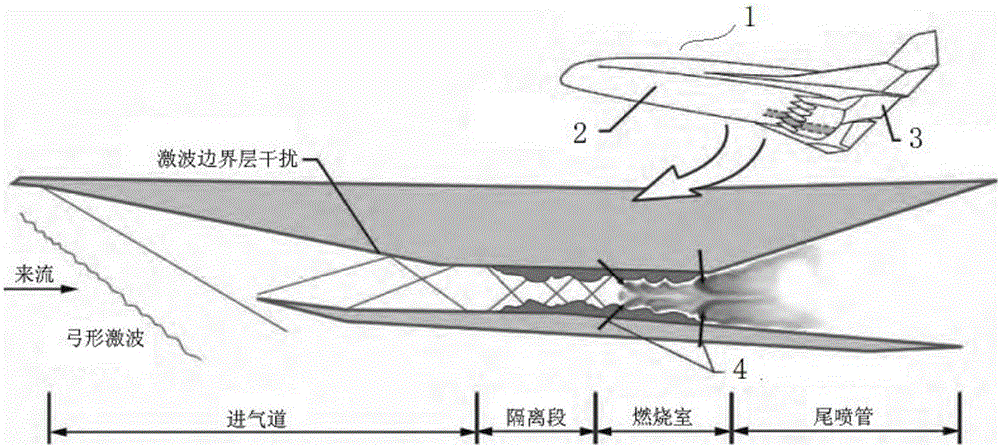

ActiveCN106092420ARemove uncertaintyAerodynamic testingMeasurement of vehicle's tractive/propulsive powerMeasurement testingEngine testing

The invention provides a method for indirectly measuring effective thrust of an engine. The method is used for measuring effective thrust of the engine of an aspiration-type integrated aircraft. The aircraft is a flow passage model. An engine-containing aircraft is subjected to thrust-to-drag feature measurement testing in a wind tunnel. Wind tunnel testing meets simulation rules of pneumatic and engine testing at the same time. In the test, an engine ignites to start combustion. A wind tunnel balance measures aircraft total thrust F balance total thrust, and the aircraft total thrust F(balance total thrust) is added with body drag D(external resistance) obtained by calculation or measurement so as to obtain effective thrust of the engine. Calculation of cold-state internal resistance is omitted, the effective thrust of the engine is obtained by adding the total thrust measured by thermal state testing with the body drag outside a flow channel, and the accuracy of measuring the effective thrust of the engine of the aspiration-type integrated aircraft is improved.

Owner:INHALE HYPERSONIC TECH RES CENT UNIT 63820 OF PLA

Flight-ground conversion method of push-resistance characteristic of motorized aircraft

The invention provides a flight-ground conversion method of the push-resistance characteristic of a motorized aircraft. A wind tunnel adopts total enthalpy h0, dynamic pressure q[indefinite] and Mach number M[indefinite] as simulation parameters. The content of oxygen in a test gas medium is maintained as same as that in pure air. A test model is an integrated aircraft motorized full size model, which means the size of a ground test model is identical to the size of an aircraft in a real flight condition. Meanwhile, the wind tunnel meets simulation rules of pneumatic and engine testing. The motor specific impulse is used as a correlation function of flight-ground conversion, and the correlation function is shown in the following formula which is described in the specification. An aircraft total thrust predicted value of the aircraft in flight is obtained using the abovementioned formula. The flight-ground conversion method of the push-resistance characteristic of the motorized aircraft provided by the invention can obtain the aircraft total thrust predicted value of the aircraft in flight and can provide data support for estimating push-resistance characteristics of an integrated aircraft.

Owner:INHALE HYPERSONIC TECH RES CENT UNIT 63820 OF PLA

Engine testing apparatus, and engine testing method

ActiveUS20140019081A1Easily and appropriately reproduceVehicle testingInternal-combustion engine testingEngine testingDynamometer

An engine testing apparatus is provided with a memory portion for storing a control command value obtained when the rotation speed of a dynamometer is changed by the control command value in accordance with the change of the engine rotation speed in a real vehicle in a period in which the engine behavior in a real vehicle is reproduced without connecting the dynamometer to an engine under test. The engine testing apparatus is provided with an output portion that supplies the control command value stored in the memory portion to the dynamometer with reference to an engine output signal showing the start of the reproducing period.

Owner:TOYOTA JIDOSHA KK +1

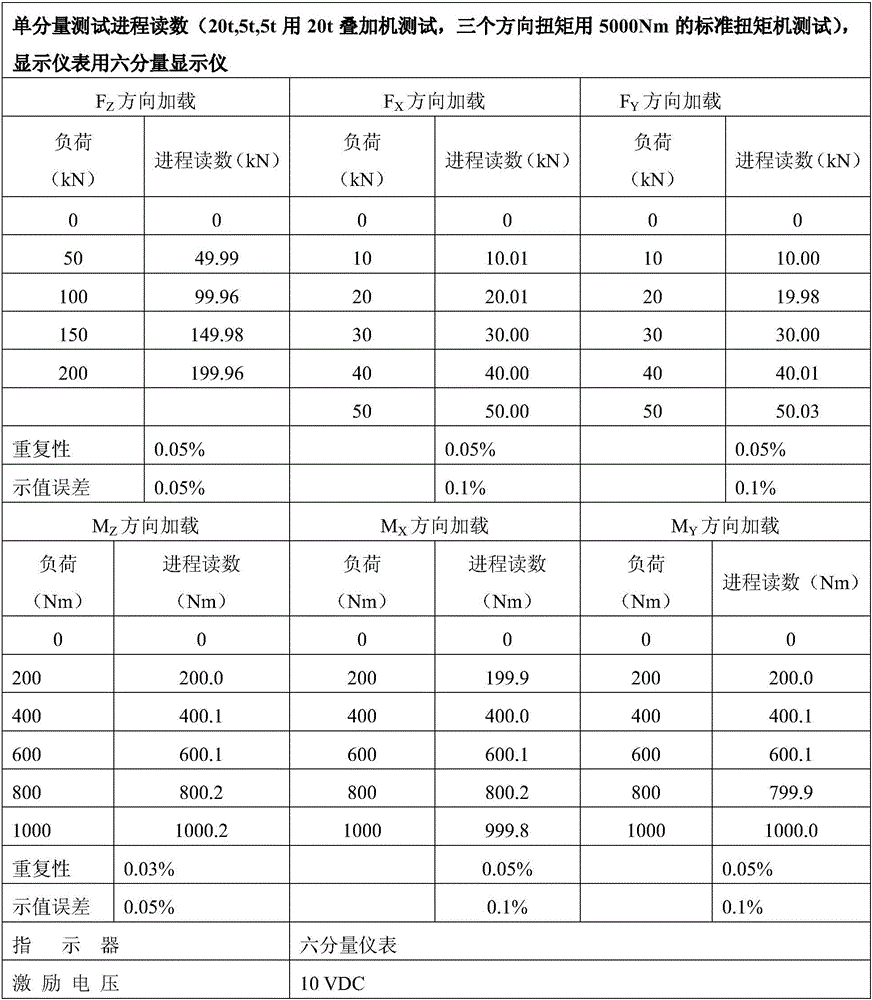

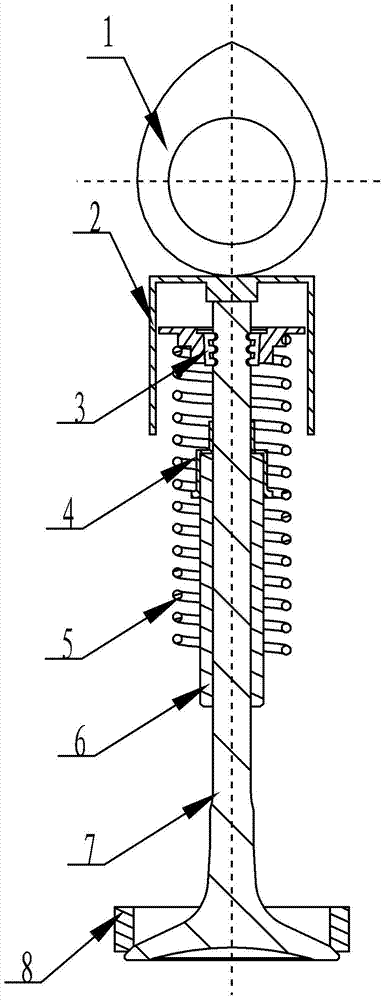

Strain type multidirectional force transducer with self-decoupling function

ActiveCN106500902AGood self-decoupling performanceReliable Thrust Measurement MethodsMeasurement of force componentsEngine testingSeparation technology

The invention relates to a strain type multidirectional force transducer with a self-decoupling function, wherein the strain type multidirectional force transducer belongs to the field of a load sensor. The strain type multidirectional force transducer comprises a four-column type structure, a strain gauge and a compensating gauge. The four-column type structure has a structure in which four columns are placed between an upper disc and a lower disc, and the four columns are arranged in a manner that two random columns are in symmetry with the other two columns. The strain gauge and the compensating gauge abut against the columns. The manufactured device is sealed in a sleeve, and air in the sleeve is replaced by insert gas, thereby ensuring no moisture absorption or moistening and preventing long-term stability reduction of the device. According to the strain type multidirectional force transducer, the four-column type symmetrical structure and bridging signal separation technology are utilized so that the sensor has high self-decoupling performance, thereby realizing simultaneous measurement for aeroengine thrust vectors, namely three force amplitude components and three moments, supplying more reliable and comprehensive technological data support for a vector thrust engine testing experiment, realizing higher reliability in an engine thrust measurement method, and obtaining higher accuracy of the measured data.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

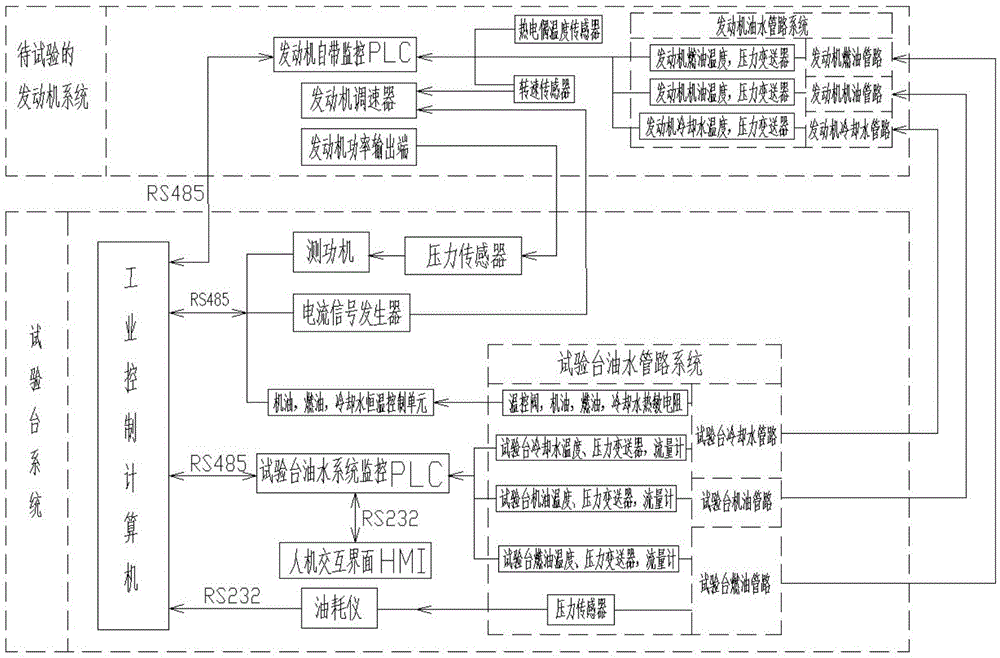

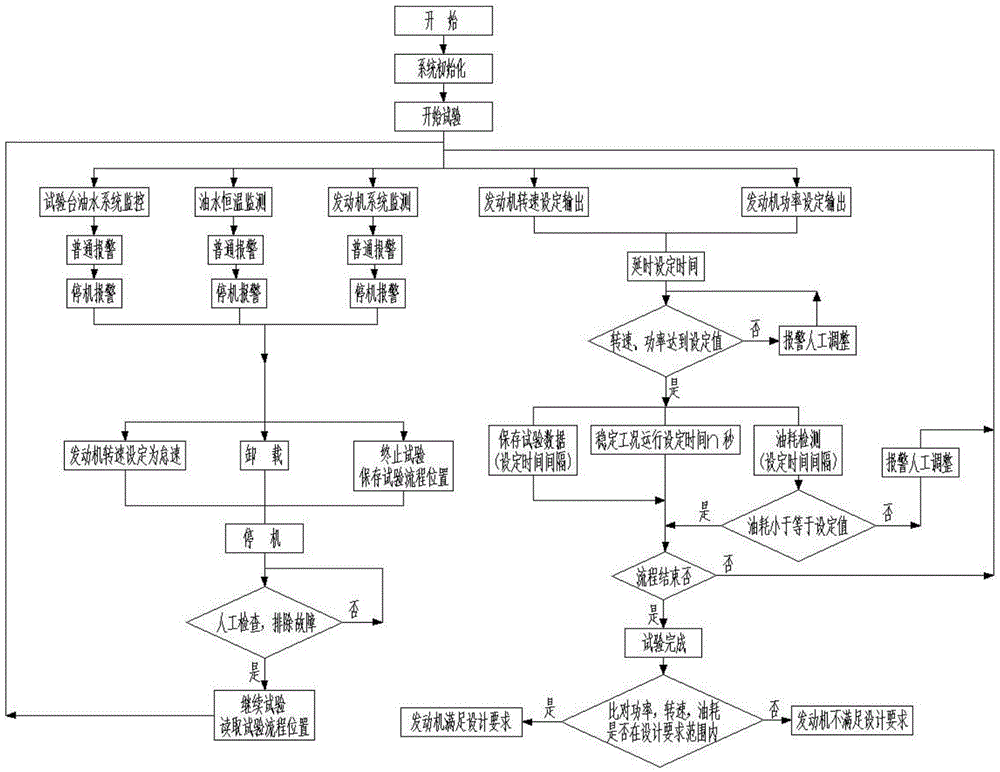

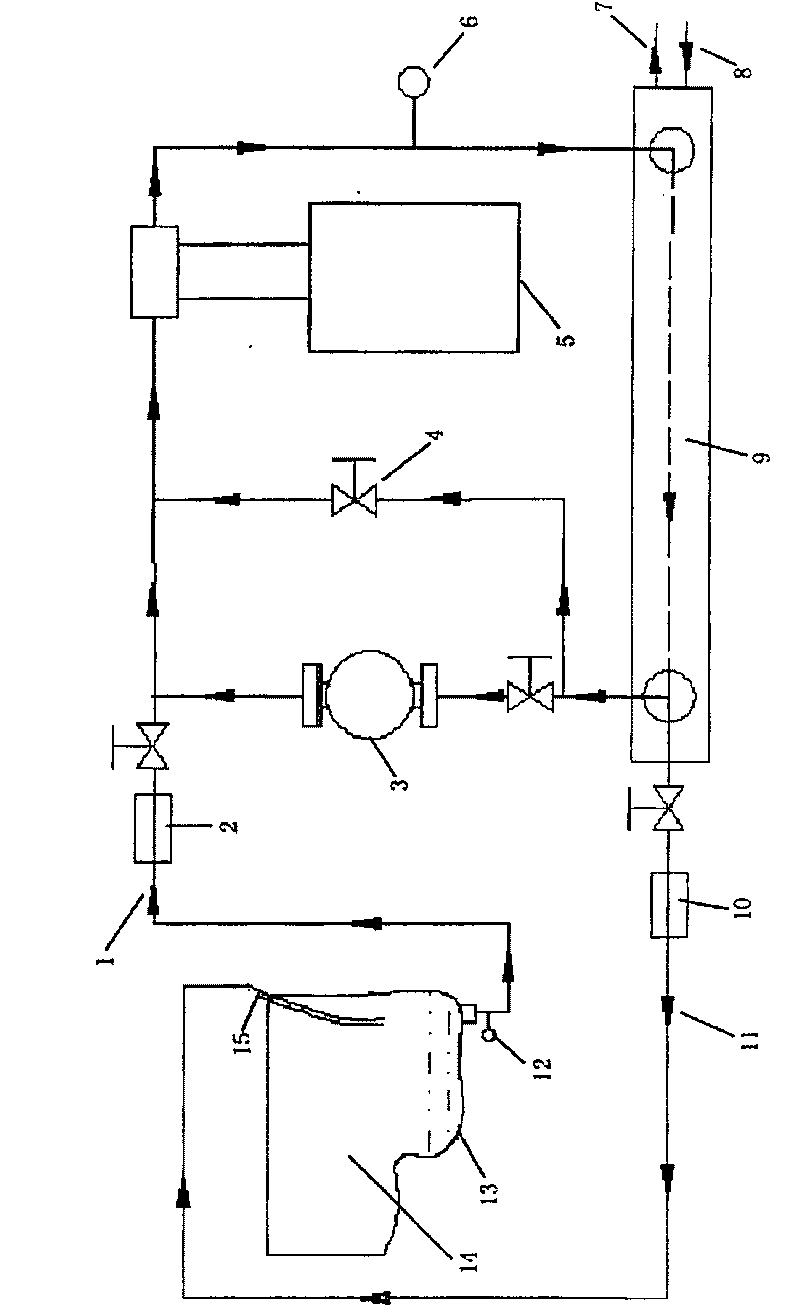

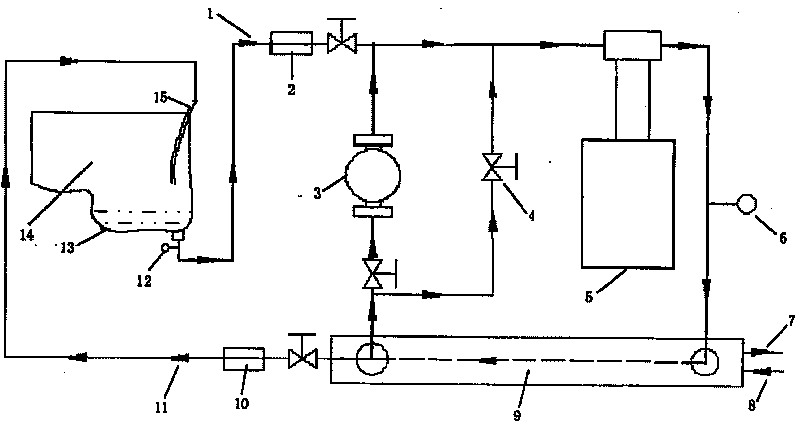

Engine test stand system and test method

InactiveCN105628386AHigh degree of automationSave labor costEngine testingTemperature controlEngine test stand

The invention provides an engine test stand system and test method. The engine test stand system comprises a test stand cooling water pipeline, a test stand engine oil pipeline, a test stand fuel oil pipeline, an industrial control computer, a dynamometer and a current signal generator. The test stand cooling water pipeline and the test stand engine oil pipeline are respectively provided with a constant temperature control unit. The test stand fuel oil pipeline is provided with a fuel consumption meter and a constant temperature control unit. The dynamometer, the current signal generator and the fuel consumption meter are electrically connected with the industrial control computer. The engine test method comprises the steps that power parameters, rotating speed parameters and the fuel consumption level of an engine are monitored in real time through the dynamometer, the current signal generator and the fuel consumption meter, and unified control and management are performed through the industrial control computer. System construction is easy and operation is simple, and the engine test result has high reliability so that test cost of engine testing can be greatly saved.

Owner:SICHUAN CRRC YUCHAI ENGINE CO LTD

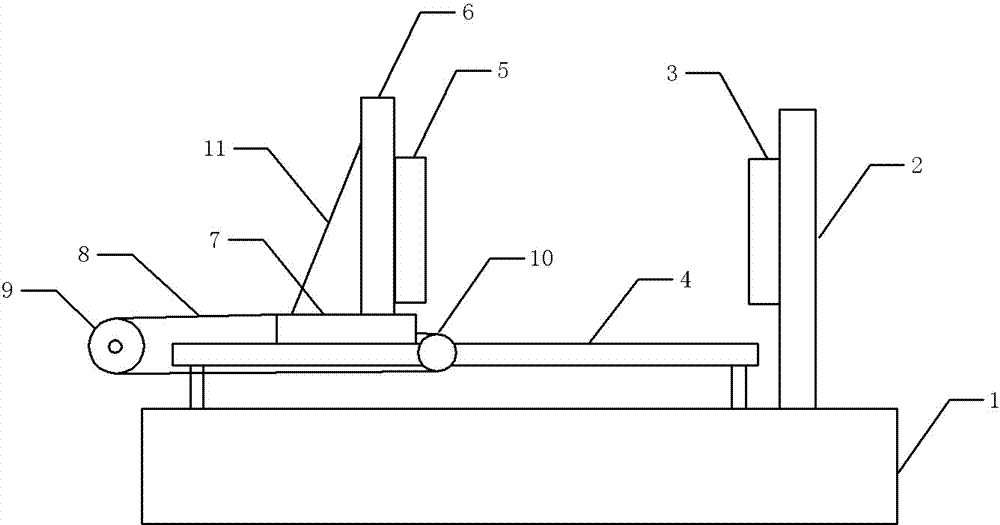

Engine air distribution mechanism abrasion testing device

ActiveCN103499451AEasy to adjustShort test cycleInternal-combustion engine testingEngine testingEngineering

The invention discloses an engine air distribution mechanism abrasion testing device, which belongs to engine testing equipment and particularly relates to a device used for the abrasion testing of an engine air distribution mechanism. The engine air distribution mechanism abrasion testing device is characterized in that two mutually parallel upright posts are arranged on a horizontal base, the tops of the upright posts are provided with a cam shaft with a driving device, an upper transverse support frame and a lower transverse support frame used for fixing an air valve air distribution mechanism are arranged between the two upright posts, a guide plate is arranged on the upper transverse support frame, a positioning plate is arranged on the lower transverse support frame, a seat ring seat sheathed on an air valve seat ring passes through a center hole of the positioning plate, a fastening screw nut fixedly arranged at the lower side of the positioning plate is connected with the seat ring seat through screw threads, and an air valve catheter is arranged in an inner hole of the seat ring seat. The testing device has the advantages that the abrasion condition of each part of the engine air distribution mechanism under the actual operation conditions can be completely simulated, and the support is provided for the final design of the engine air distribution mechanism.

Owner:济南沃德汽车零部件有限公司

Improved thermostatic control method and system for engine test-bed engine oil

ActiveCN1996198AMeet the maximum circulation flowDoes not affect oil pressureTemperature control with auxillary non-electric powerEngine testingTemperature controlEngine test stand

A modified engine testing bench oil constant temperature control method draws oil from the oil sump of the engine and injects the cooled oil back to the oil sump. It can allow the oil flow meeting the max circulation flow of the required oil of the oil sump, making timely monitoring of the oil temperature, controlling the oil temperature of the oil sump through adjusting the oil flow, filtering the oil at the input and output to ensure the quality of the oil. The modified engine testing bench oil temperature constant control system connects with the engine oil sump through the input and output composed of oil extraction and delivery device, cooling device, oil flow adjusting valve. The advantage is that it will not affect the major oil channel pressure of the engine, with high oil temperature control precision, low cost, better meeting the requirement for engine performance testing and the reliability testing of the engine for engine oil temperature control.

Owner:BYD CO LTD

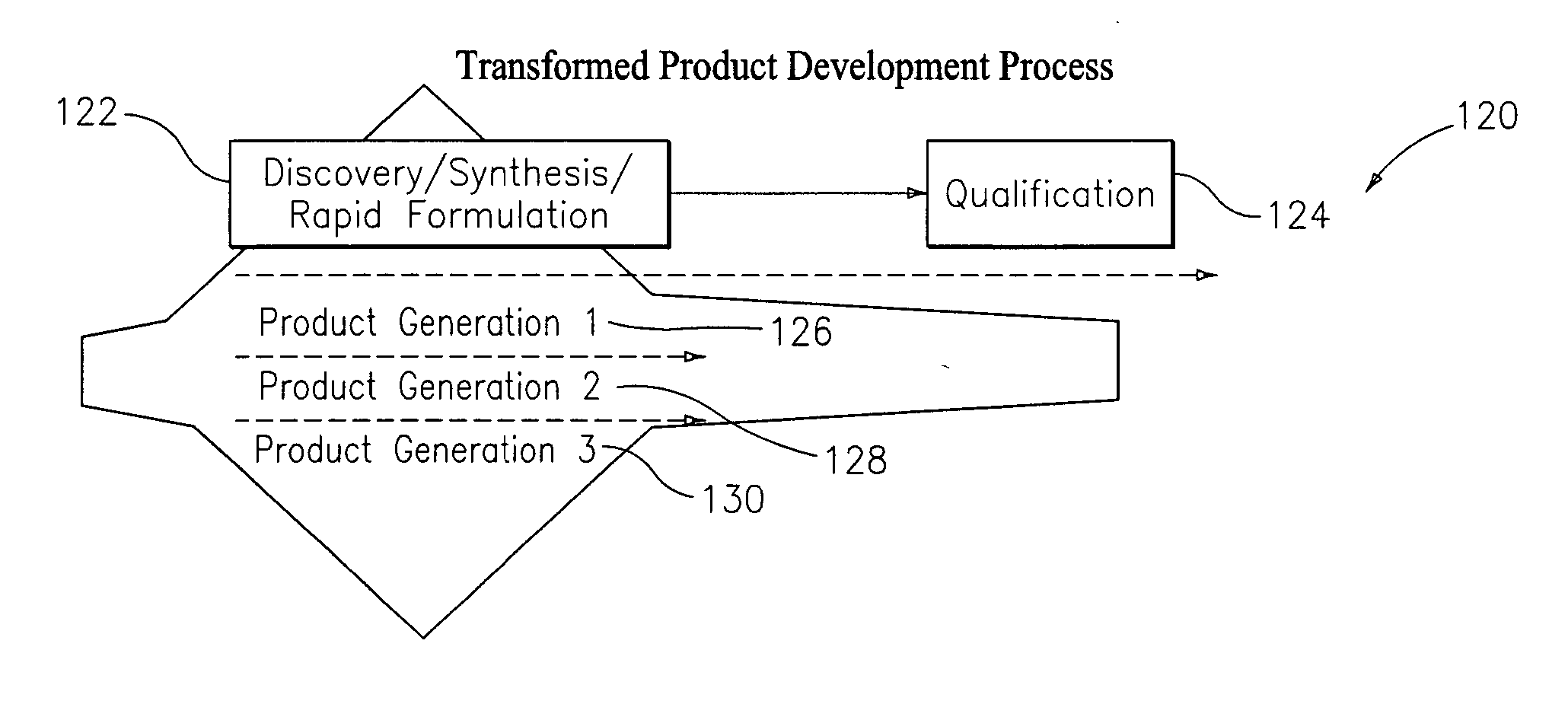

Method and system of product development process for chemical compositions using high volume modeling

InactiveUS20050096895A1Promote innovationAdd depthChemical property predictionLibrary screeningChemical compositionEngine testing

A method and system of transforming a product development process to reduce time in bringing a product to market through high throughput experimentation and advanced statistics and informatics, to transform the product development to a level of higher correlation with engine tests, and to develop better commercial products. This is achieved by modeling in Silico a plurality of component molecular models; deriving in Silico molecular characteristics (descriptors) for each of the plurality of compiled molecular models; creating at least one combinatorial library database record for each of the formulations, the at least one record having a plurality fields for storing information about compositional characteristics; receiving specification requirements for a lubricating oil composition; selecting from a database entries corresponding to compositions having specifications comparable to the received specification requirements; formulating a new lubricating oil composition to comply with received specification requirements; testing the new lubricant oil for compliance with received specification requirements; repeating the selecting, formulating, and testing steps until compliance with received specification requirements is achieved; and correlating the new lubricating oil composition to actual engine performance.

Owner:CHEVRON ORONITE CO LLC

Engine Fitting and Method of Assembling Vehicles

A dual-purpose engine fitting is provided that may be used both during engine testing and during engine use, for vehicles with vacuum assisted brakes and for those without. The fitting has a body portion configured to fit within an opening in the manifold and defining a passage having opposing first and second ends. The fitting has a seal portion enclosing the first end of the passage. The second end of the passage is open to the manifold when the body portion is fit within the manifold. A thinned wall joins the body portion and the seal portion, establishing a predetermined fracture region at which the seal portion will separate from the body portion when sufficient torque is applied to the seal portion to thereby open the first end of the passage. A method of assembling vehicles is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

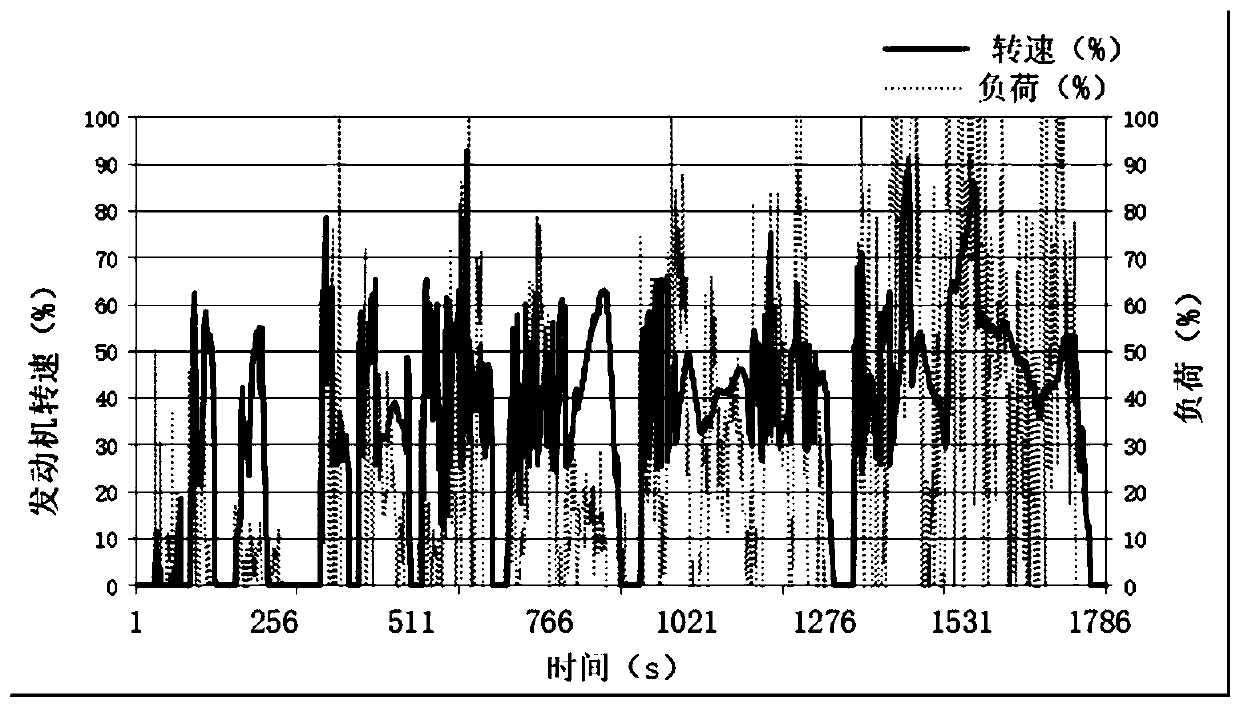

Construction method for engine testing working condition

InactiveCN109883710AReflect the operationMeet testing needsInternal-combustion engine testingTransient stateEngine testing

Various types of engines of heavy-duty commercial vehicles are in the presence, a finished vehicle is complex in configuration, in addition, since a production enterprise is committed to the improvement of vehicle fuel economic efficiency and handling performance, an engine and drive system technology changes and make a progress all the time, the direct collection of engine data for constructing atest loop is difficult to be suitable for the dynamic development of a technology, and the long-term applicability, the independence and the stability of a working condition are guaranteed. The invention puts forward a construction method for an engine testing working condition. The method comprises a transient state testing working condition and a steady state testing working condition. A CHTC (China heavy-duty commercial vehicle test cycle) working condition curve is taken as a basis to construct the transient state testing working condition; according to a transient state testing working condition curve, an engine speed-load percentage simultaneous distribution heat map is taken as a basis to construct the steady state testing working condition; and when the transient state testing working condition is established, through an engine transmission model, vehicle speed in the CHTC working condition curve is converted into the engine speed.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

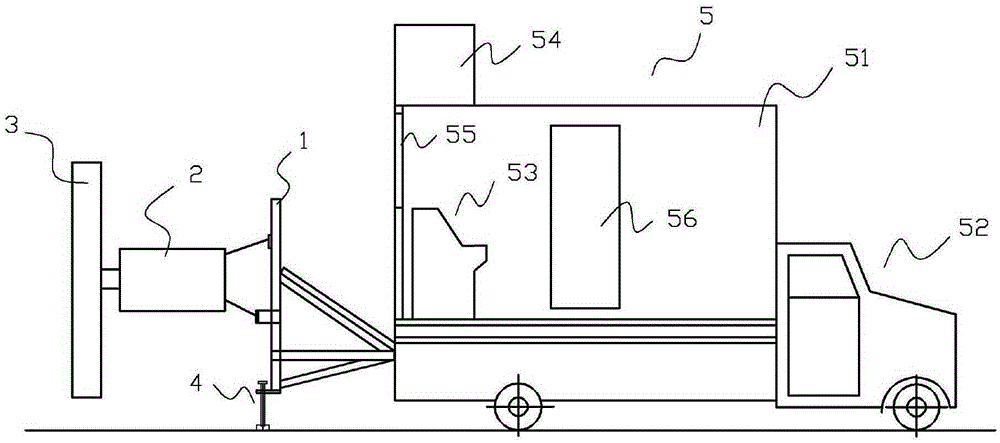

Piston type aero-engine test stand

The invention provides a piston type aero-engine test stand. The piston type aero-engine test stand comprises an engine installing rack, a testing engine installed on the engine installing rack and a propeller connected with the testing engine; a supporting rod is arranged on the engine installing rack and provided with a lifting device, the terrain clearance of the testing engine can be adjusted, the installing rack is connected with a test stand body, and the test stand body comprises a testing system, an engine testing room and a truck for placing the engine testing room. The truck is used as a chassis, and therefore the test stand is high in mobility, and convenient to transport and move; the lifting device is arranged on the supporting rod and can adjust the terrain clearance of the testing engine, and testing requirements of all kinds of piston type aero-engines can be met conveniently.

Owner:CHINA AIRCRAFT MAINTENANCE & ENG

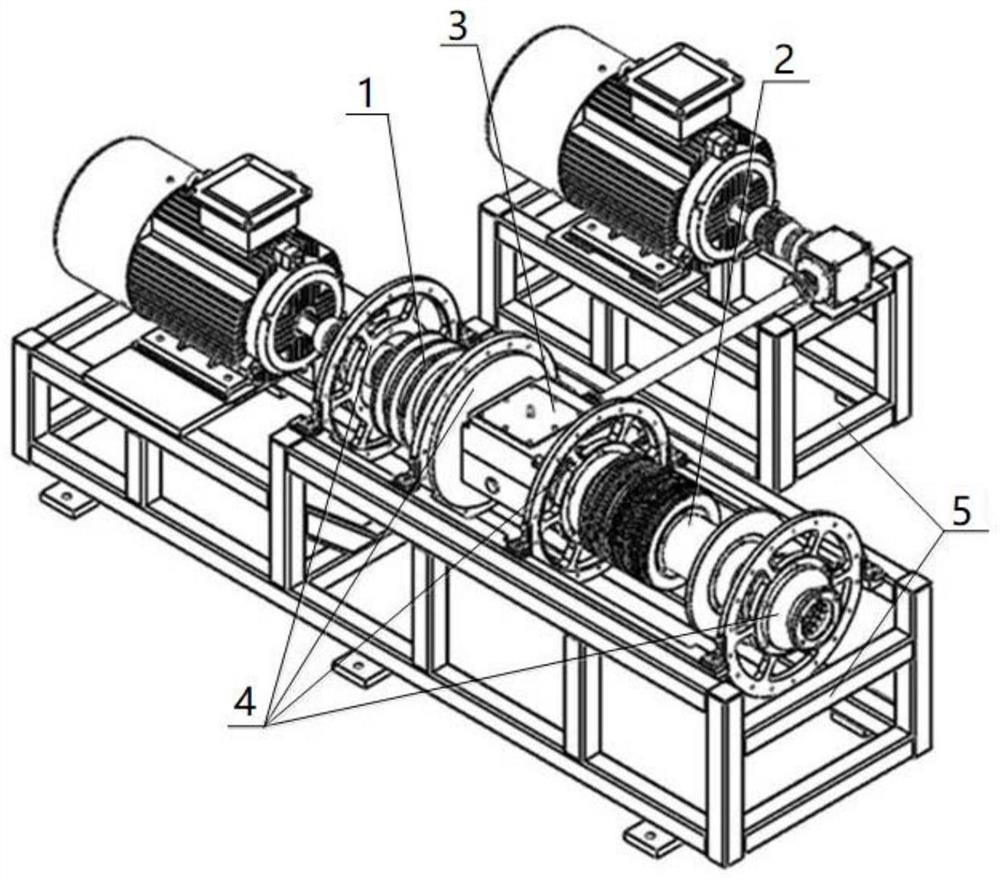

Dynamic simulation engine testing system and method

ActiveCN106053086ASimple structureNovel and reasonable designEngine testingProgramme control in sequence/logic controllersFreewheelFrequency changer

The invention discloses a dynamic simulation engine testing system, and the system comprises a dynamic simulation dynamometer, a sensing detection system, a control system, an engine rack, a throttle operating mechanism, a clutch operating mechanism, and a gear shift operating mechanism. The dynamic simulation dynamometer comprises a pedestal, a first inertia flywheel bearing support, a second inertia flywheel bearing support, a first motor bearing support, and a second motor bearing support. The first inertia flywheel bearing support and the second inertia flywheel bearing support are respectively provided with a flywheel shaft, and the flywheel shafts are connected with inertia flywheels. A dynamometer motor is disposed between the first motor bearing support and the second motor bearing support. End parts of the flywheel shafts are connected with a coder. The housing of the dynamometer motor is provided with a force sensor. The control system comprises a main control computer, a PLC module, and a frequency converter. The sensing detection system comprises a fuel consumption meter. The invention also discloses a dynamic simulation engine testing method. The system is convenient to install and use, is high in working reliability, and is high in practicality.

Owner:中检西部检测有限公司

Oscillating hydraulic steering engine testing table

InactiveCN103452957ALow costEasy maintenanceFluid-pressure actuator testingHydraulic cylinderTest efficiency

The invention discloses an oscillating hydraulic steering engine testing table, which relates to the technical field of marine steering engine manufacture and comprises an operation table and a base, wherein a loading oil cylinder, a transfer hydraulic cylinder and a steering handle are arranged on the base, the steering handle is arranged on a steering handle seat, two ends of the steering handle are respectively hinged to the transfer hydraulic cylinder, the steering handle is connected with the loading oil cylinder, the loading oil cylinder is respectively communicated with a loading pump group and a loading oil tank, and the transfer hydraulic cylinder is connected with a testing steering engine through an oil pipe. The oscillating hydraulic steering engine testing table can solve the problems that the occupied steering engine testing field is large, the testing efficiency is low, and the product detecting cost is high.

Owner:GUANGXI WUZHOU YUNLONG PORT & SHIP MACHINERY MFG

Device for testing low-temperature low-air-pressure starting and operating characteristics of engine

InactiveCN103048140AEasy dockingUniform temperatureInternal-combustion engine testingRefrigeration compressorTemperature control

The invention discloses a device for testing low-temperature low-air-pressure starting and operating characteristics of an engine and a testing method by utilizing the device. The device comprises a low-temperature low-air-pressure case, an engine testing case, a circulating system and an engine intake pipe, wherein the low-temperature low-air-pressure case and the engine testing case are respectively communicated with the engine intake pipe through the circulating system; the low-temperature low-air-pressure case comprises a refrigeration system and a low-air-pressure system inside; and the refrigeration system comprises a refrigeration compressor and a temperature controller, and the low-air-pressure system comprises a vacuum pump. According to the device for testing the low-temperature low-air-pressure starting and operating characteristics of the engine, disclosed by the invention, the low-temperature low-air-pressure case and the engine testing case can be assembled and disassembled according to different requirements of a user and can be applied to a test experiment of other devices under low temperature and low air pressure environment at the same time; the resource is saved; and under the conditions that the power of the refrigeration system is not enough and the air temperature is not reduced to be a temperature required by the experiment, liquid nitrogen and liquid oxygen can be placed in the low-temperature low-air-pressure case, and the device disclosed by the invention can also simulate a low-temperature environment of the south pole by matching with the refrigeration system.

Owner:SOUTHEAST UNIV

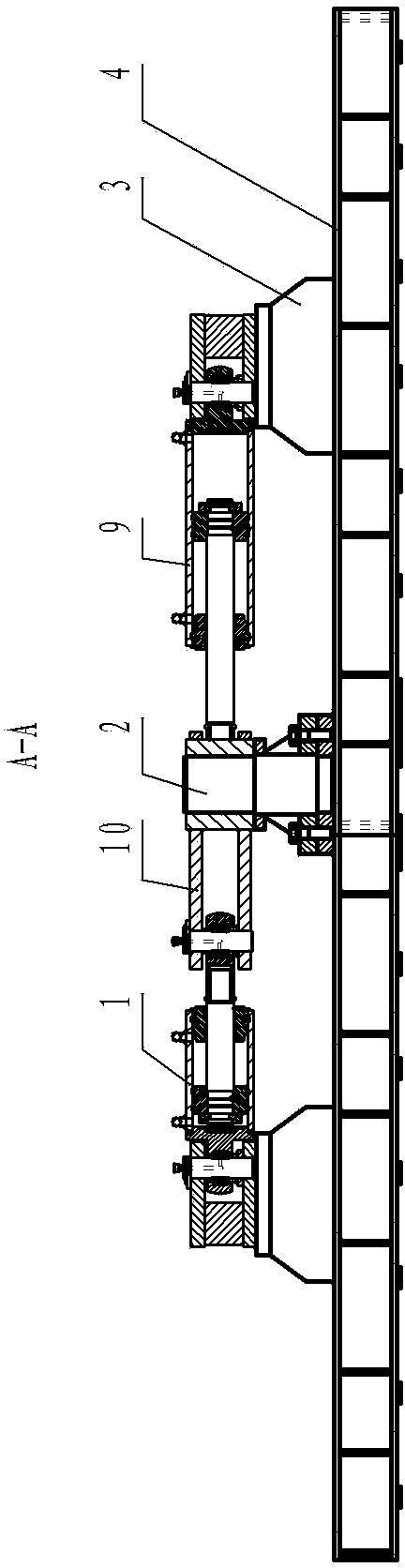

Aligning tool and method for engine testing

ActiveCN104849056AImprove operational efficiencyEasy to operateAngles/taper measurementsEngine testingEngine testingDynamometer

The invention discloses an aligning tool and method for engine testing. The aligning tool includes an engine aligning shaft (2), and a convex ridge aligning plate (3) and a concave ridge aligning plate (4) in ridge fit with each other. A fake shaft is connected to the output terminal of an engine (1) in a manner of being coaxial with an engine shaft. One of the two aligning plates is mounted in a manner of being coaxial with a shaft of a dynamometer (6) while the other one is mounted in a rotary sleeving manner of being coaxial with an aligning shaft of the engine. The aligning method includes aligning tool mounting steps, pre-aligning steps, alignment checking steps and fine alignment steps. Deviation between the two shafts is amplified by utilizing the diameters of the aligning plates and alignment precision can be guaranteed through fine processing of the ridges. During alignment operation, pre-alignment can be performed by utilizing a straight edge knife and through rotation and alignment between peripheral ridge faces and alignment between middle end faces are realized through adjusting the engine, so that the alignment process is implemented. The aligning tool and method is simple and direction in operation and high in alignment operation efficiency, and requires little manual experience.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

Internal combustion engine piston temperature remote-measuring system based on wireless charging and method

ActiveCN110350667AAddresses the need to frequently disassemble the engine to replace batteries mounted on internal combustion engine pistonsImprove energy efficiencyInternal-combustion engine testingBatteries circuit arrangementsEngine testingElectrical battery

The invention discloses an internal combustion engine piston temperature remote-measuring system based on wireless charging and a method, and belongs to the technical field of engine testing. The system comprises a wireless charging device, a temperature remote-measuring device, a first packaging box and a second packaging box, wherein the wireless charging device comprises a transmitting coil, atransmitting module, a receiving coil and a receiving module; and the temperature remote-measuring device comprises a rechargeable battery, a signal processing unit, a thermocouple and an upper computer. The invention also provides a corresponding working method. Power is supplied for the transmitting coil through an external power supply and the transmitting module, and then alternating current is generated in the receiving coil through electromagnetic induction, current is provided for the rechargeable battery after alternating current is converted into direct current through the receiving module, wireless charging and continuous power supply of electromagnetic induction for the remote-measuring system are realized, the energy efficiency is relatively high, and the structure is simple; and the temperature remote-measuring device is used for transmitting temperature information to the upper computer through a wireless communication technology, and the temperature measurement of an internal combustion engine piston is wireless.

Owner:HUAZHONG UNIV OF SCI & TECH

Clamping mechanism for general gasoline engine testing

InactiveCN103707219AAvoid shockGuaranteed uptimeEngine testingWork holdersEngine testingElectric machinery

The invention discloses a clamping mechanism for general gasoline engine testing. The clamping mechanism comprises a base, a positioning clamping cylinder which is fixed on the base with a first mounting plate and a guiding track which is arranged on the base. A driving clamping cylinder which corresponds to the positioning clamping cylinder is arranged on a second mounting plate. A horizontal mounting plate is perpendicularly fixed with the second mounting plate and is arranged on the guiding track of the base. One end of the horizontal mounting plate away from the positioning clamping cylinder is connected with one end of a chain and the chain wraps around a chain wheel. The other end of the chain is connected with one end of the horizontal mounting plate next to the positioning clamping cylinder and the chain wheel is connected with an output shaft of a stepping motor. The smooth running of the driving clamping cylinder at a constant speed can be achieved by setting specified parameters to the stepping motor, so that huge impact caused by clamping on general gasoline engines can be avoided. Additionally, the chain and the chain wheel can be driven by the stepping motor to achieve fine-tuned clamping after the driving clamping cylinder contacts to the general gasoline engines.

Owner:CHONGQING DAJIU SCI & TECH DEV

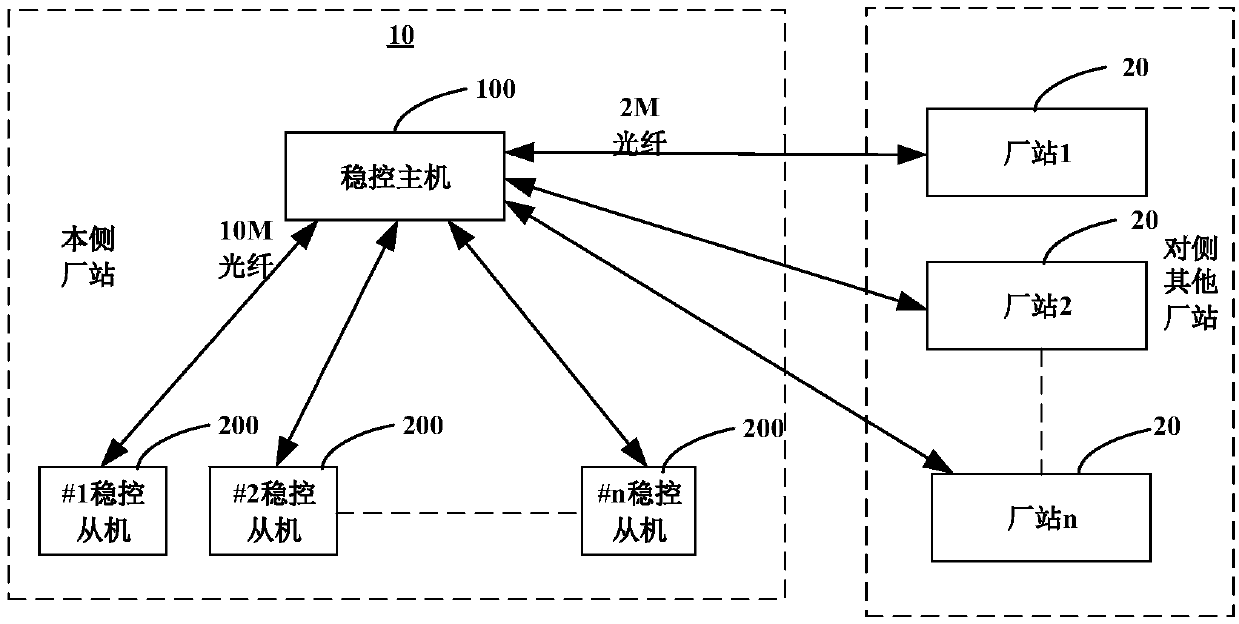

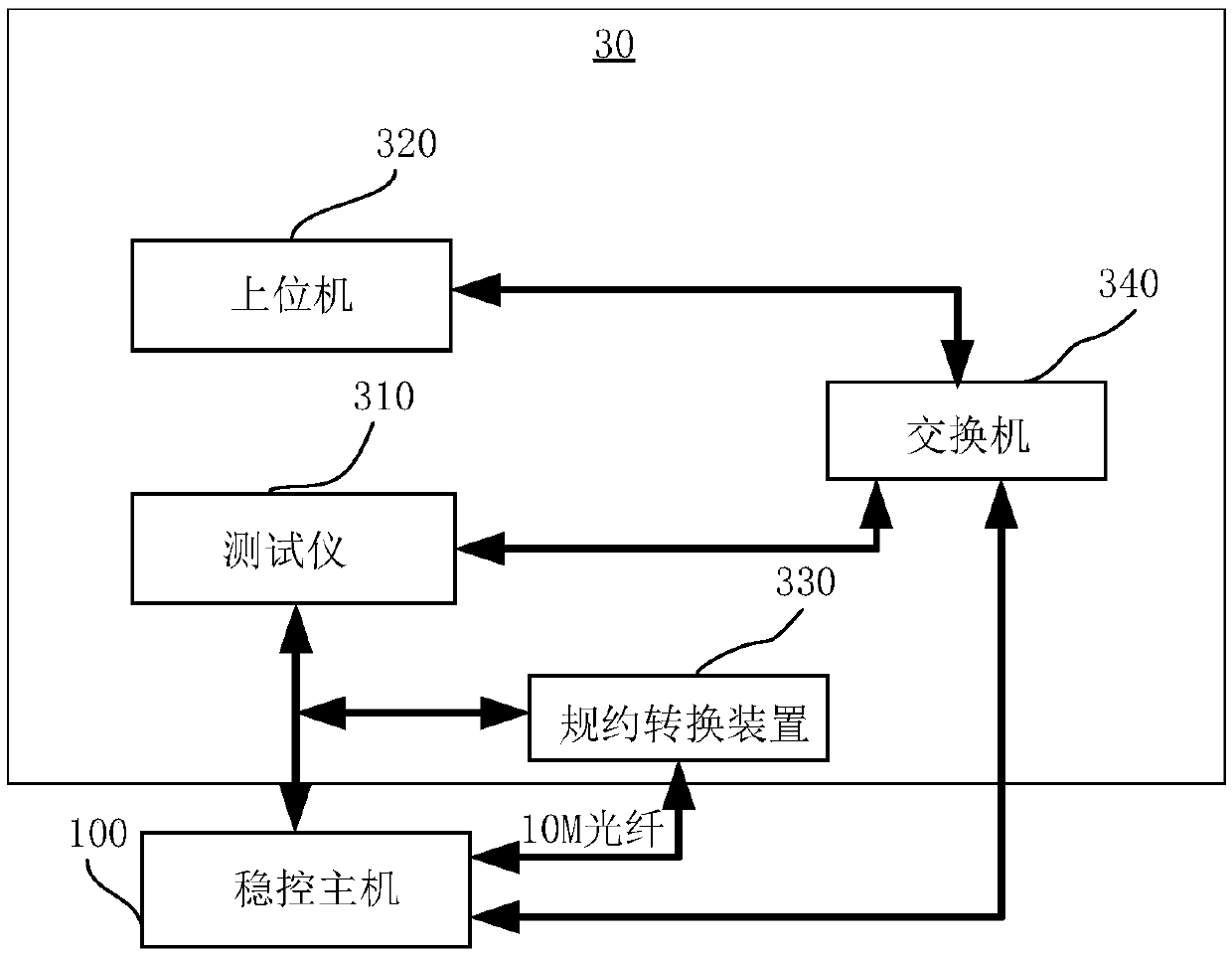

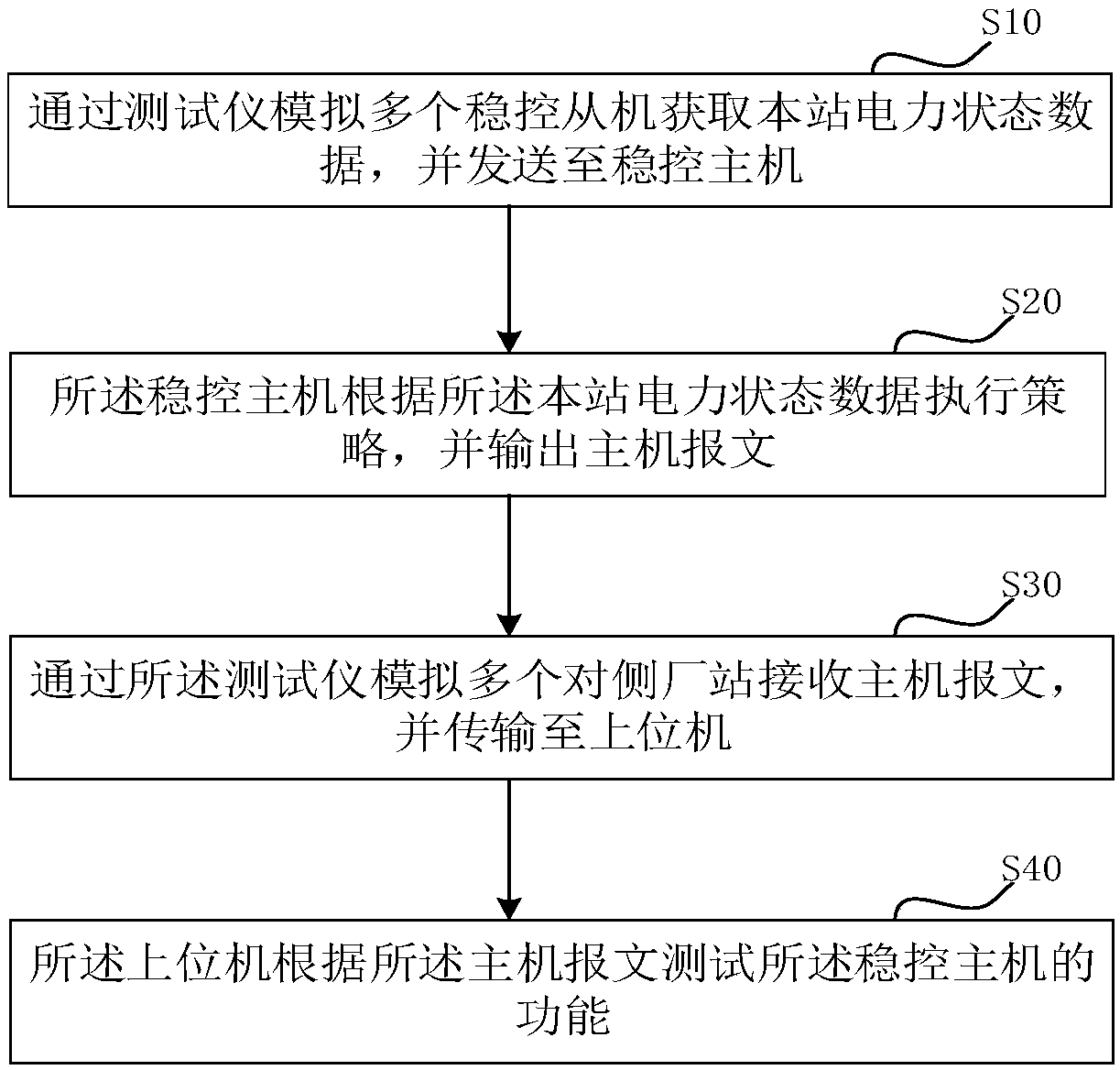

Stability control main engine testing method and system

ActiveCN109613909AReduce wiringImprove test efficiencyProgramme controlElectric testing/monitoringTest efficiencyEngine testing

The invention relates to a stability control main engine testing method and system. The stability control testing method comprises the steps of simulating a plurality of stability control slave engines through a tester to acquire power state data of the home station, and sending the power state data to a stability control main engine. The stability control main engine executes a strategy accordingto the power state data of the home station and outputs a main engine message. The tester simulates a plurality of opposite factory stations to receive the main engine message and transmits the messages to an upper computer. The upper computer tests the function of the stability control main engine according to the main engine message. The stability control main engine testing method improves testing efficiency and saves testing cost.

Owner:SHENZHEN POWER SUPPLY BUREAU

Improved thermostatic control method and system for engine test-bed engine oil

ActiveCN1996198BHigh temperature control accuracyHigh control precisionTemperature control with auxillary non-electric powerEngine testingTemperature controlEngine test stand

A modified engine testing bench oil constant temperature control method draws oil from the oil sump of the engine and injects the cooled oil back to the oil sump. It can allow the oil flow meeting themax circulation flow of the required oil of the oil sump, making timely monitoring of the oil temperature, controlling the oil temperature of the oil sump through adjusting the oil flow, filtering the oil at the input and output to ensure the quality of the oil. The modified engine testing bench oil temperature constant control system connects with the engine oil sump through the input and outputcomposed of oil extraction and delivery device, cooling device, oil flow adjusting valve. The advantage is that it will not affect the major oil channel pressure of the engine, with high oil temperature control precision, low cost, better meeting the requirement for engine performance testing and the reliability testing of the engine for engine oil temperature control.

Owner:BYD CO LTD

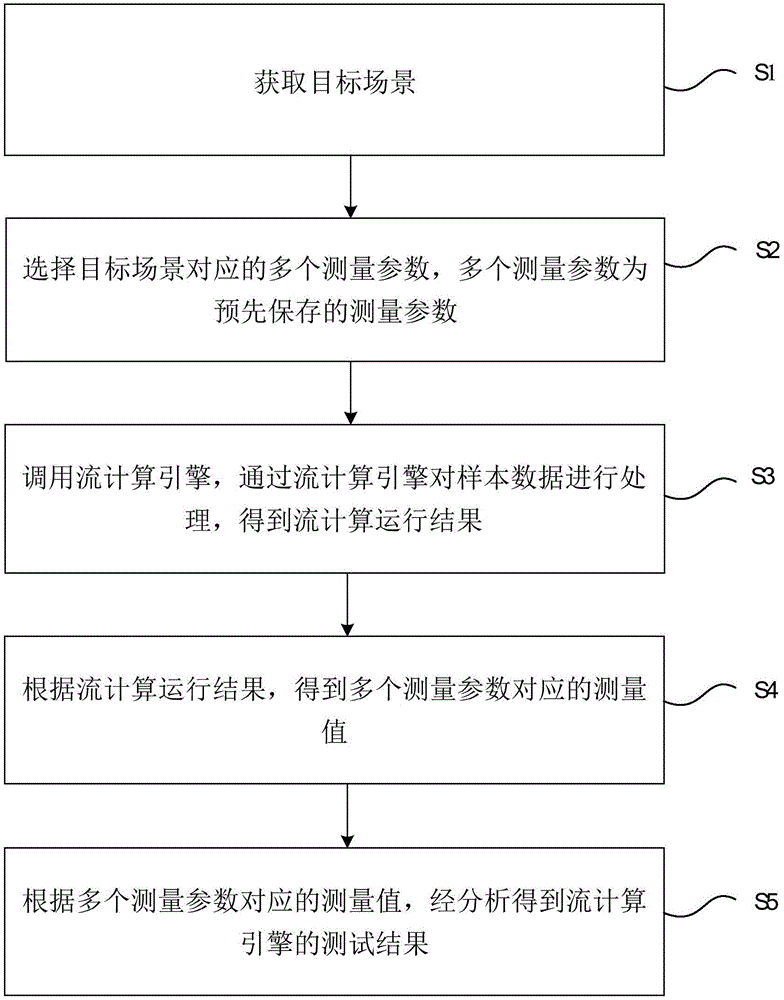

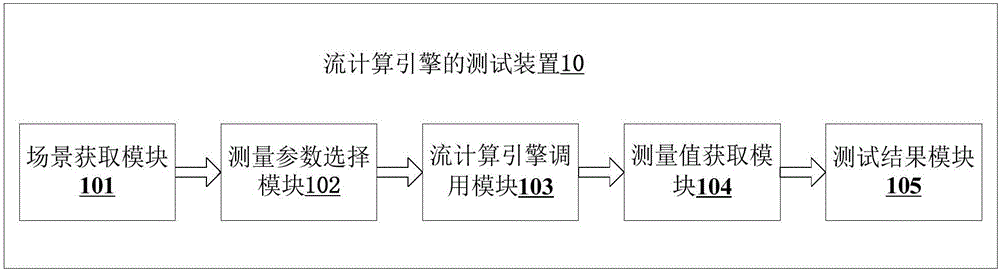

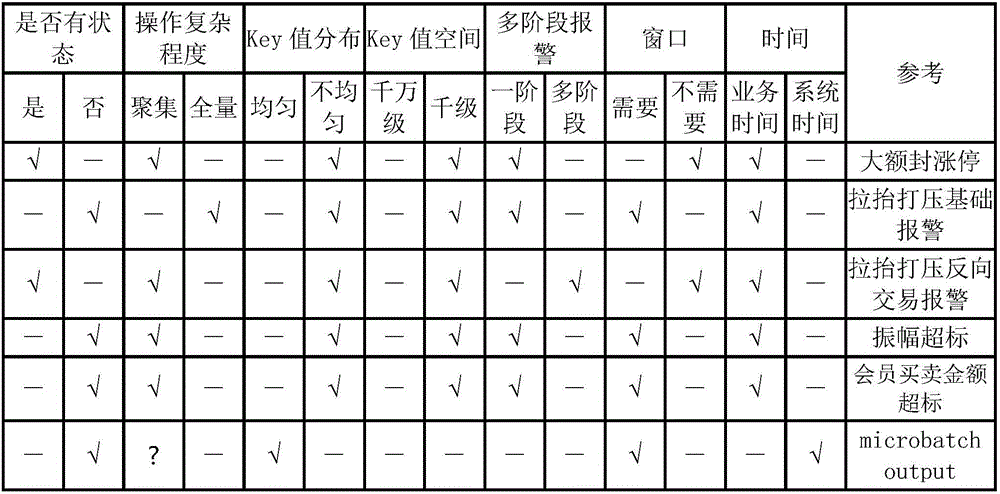

Stream computing engine testing method and device

ActiveCN106649119AObjectively reflect performanceImprove efficiencySoftware testing/debuggingEngine testingParallel computing

The invention provides a stream computing engine testing method and device. The method comprises the steps that a target scene is acquired, multiple measuring parameters corresponding to the target scene are selected, stream computing engines are called, and sample data is processed with the stream computing engines to obtain stream computing running results; measuring values corresponding to the measuring parameters are obtained according to the stream computing running results, and testing results of the stream computing engines are obtained through analyzing. According to the stream computing engine testing method and device, different stream computing engines are automatically called through programs, the running results of the stream computing engines are collected, and an appropriate stream computing engine is selected by analyzing the running result; evaluation on the stream computing engines is abstracted into a plurality of testing parameters, the running process of the stream computing engines is monitored by calling the stream computing engines, therefore, the measuring values of all the testing parameters are acquired, the performances of the stream computing engines are objectively reflected, and the efficiency is high.

Owner:SHENZHEN AUDAQUE DATA TECH

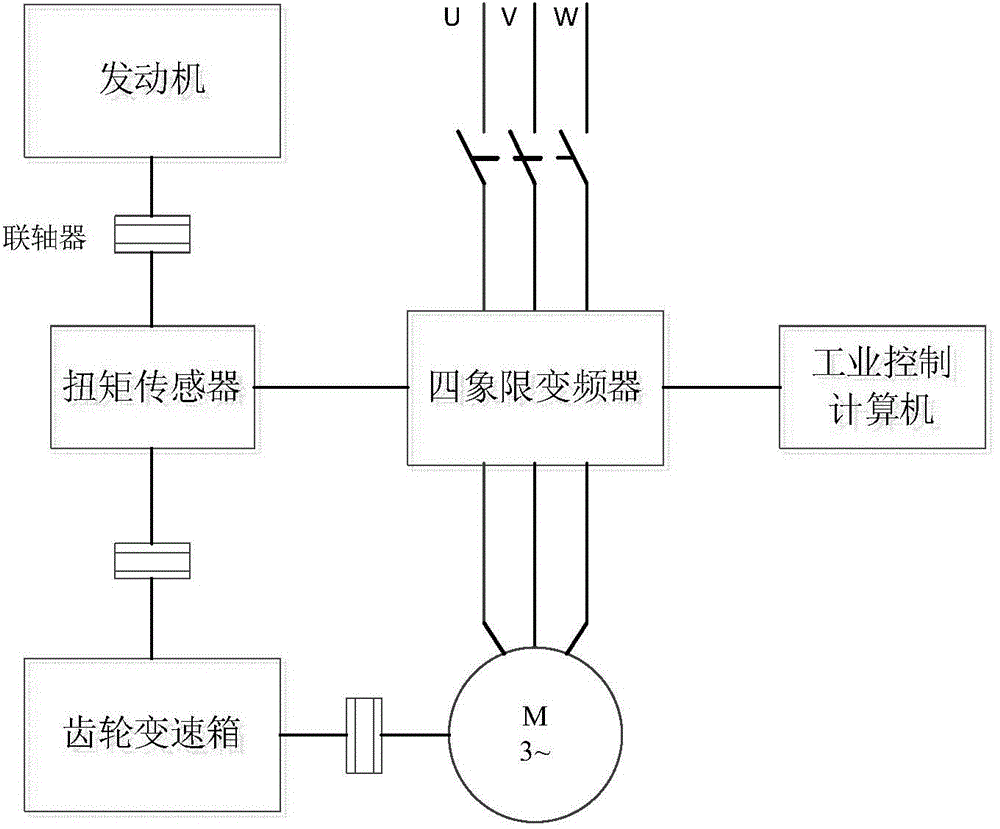

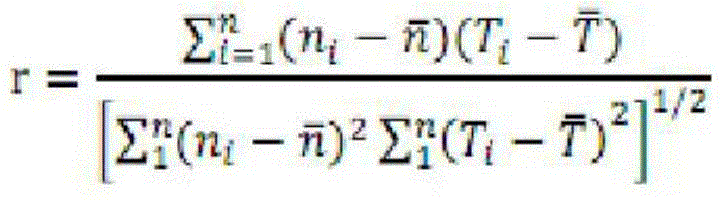

Automatic load increase testing system and testing method for engine

InactiveCN104697799AImprove test accuracyReduce running timeEngine testingFrequency changerEngine testing

The invention discloses an automatic load increase testing system and testing method for an engine. The automatic load increase testing system comprises the engine, a torque sensor, a gear transmission, a slave motor, an industrial control computer and a 4-quadrant frequency converter; the engine is connected with the torque sensor through a coupling, the other end of the torque sensor is connected with the gear transmission, the gear transmission is connected with the slave motor through a coupling, the slave motor is connected with the 4-quadrant frequency converter through a cable, and the industrial control computer is connected with the torque sensor and 4-quadrant frequency converter. The automatic load testing method for the engine includes that judging the similarity and difference between a theoretical load characteristic curve of the engine and an actual measured load characteristic testing curve to obtain an engine testing conclusion. The system and method are capable of realizing the automatic load increase testing, the testing precision of the system is improved, and the running time of the system is shortened.

Owner:无锡惠科电工高新技术有限公司

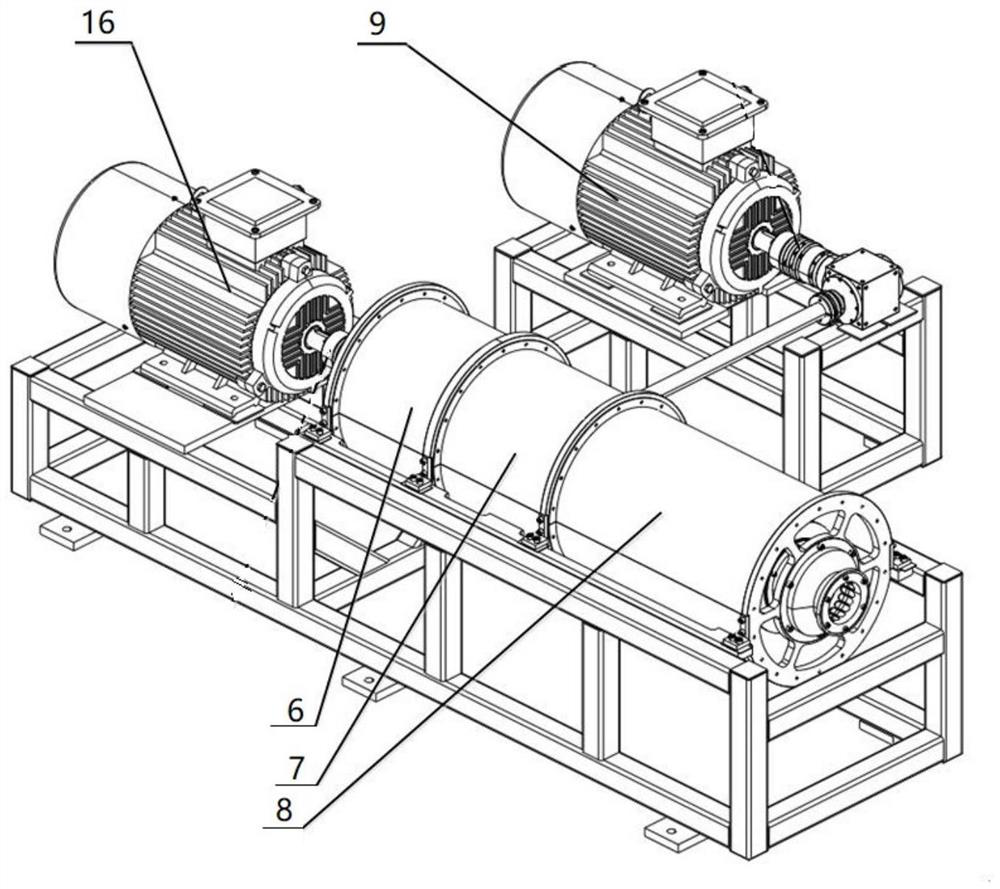

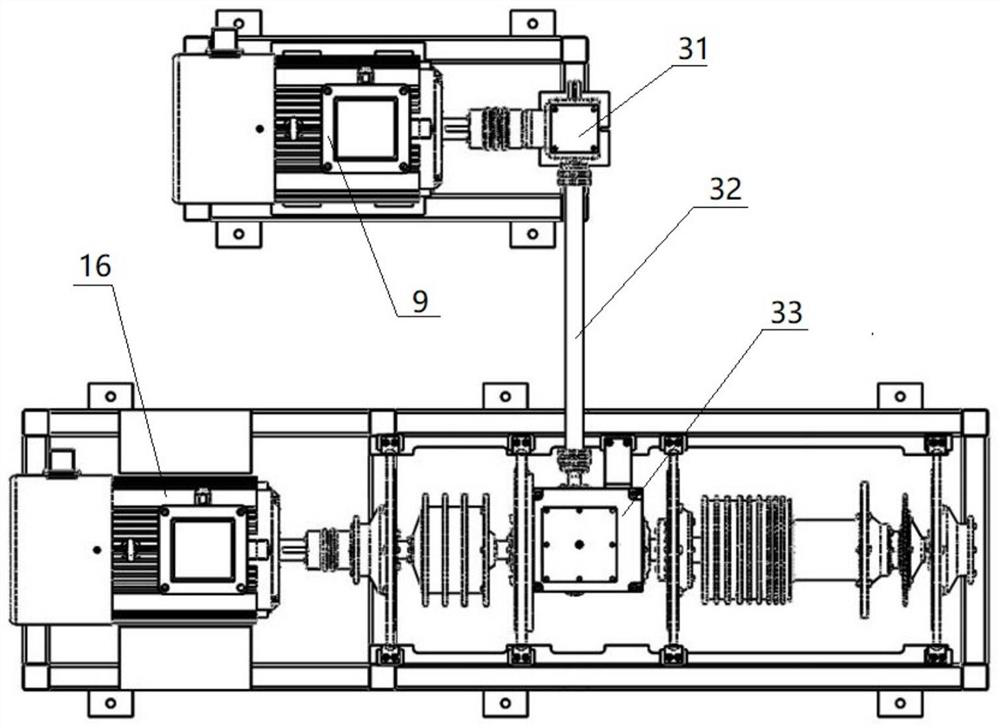

Aero-engine birotor-support-casing tester and testing method thereof

PendingCN112629840AReflect coupling characteristicsMeeting Vibration Research NeedsMachine part testingSubsonic/sonic/ultrasonic wave measurementEngine testingControl engineering

The invention belongs to the technical field of aero-engine testing and testing, and particularly relates to an aero-engine birotor-support-casing tester and a testing method thereof. The aero-engine birotor-support-casing tester comprises a low-pressure rotor, a central bevel gear system, a high-pressure rotor, a low-pressure casing, a middle casing and a high-pressure casing; the low-pressure rotor comprises a low-pressure turbine shaft, and the low-pressure turbine shaft penetrates through the central bevel gear system and is rotationally connected with the high-pressure rotor; and the low-pressure rotor is driven by a low-pressure driving motor, the central bevel gear system is connected with a high-pressure driving motor, and the high-pressure rotor is driven by the central bevel gear system. The structure is simplified and reasonable, the scale design with the fixed proportion (such as 2: 1) is adopted according to the real engine structure, and the four-stage fan disc and the nine-stage high-pressure disc are consistent with the real engine structure. Structures such as a squirrel cage, a conical shell, a bearing spoke plate and a flexible casing in a real machine are reserved, the structure and vibration of an engine rotor system can be truly simulated, and the whole machine vibration research requirement of an aero-engine is met.

Owner:韩清凯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com