Conductor wire core aluminum alloy for welding machine cable and making method thereof

A technology of conductive wire core and manufacturing method, applied in the direction of metal/alloy conductor, etc., to achieve the effects of good ductility, improved thermal stability of connection, and reduced creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

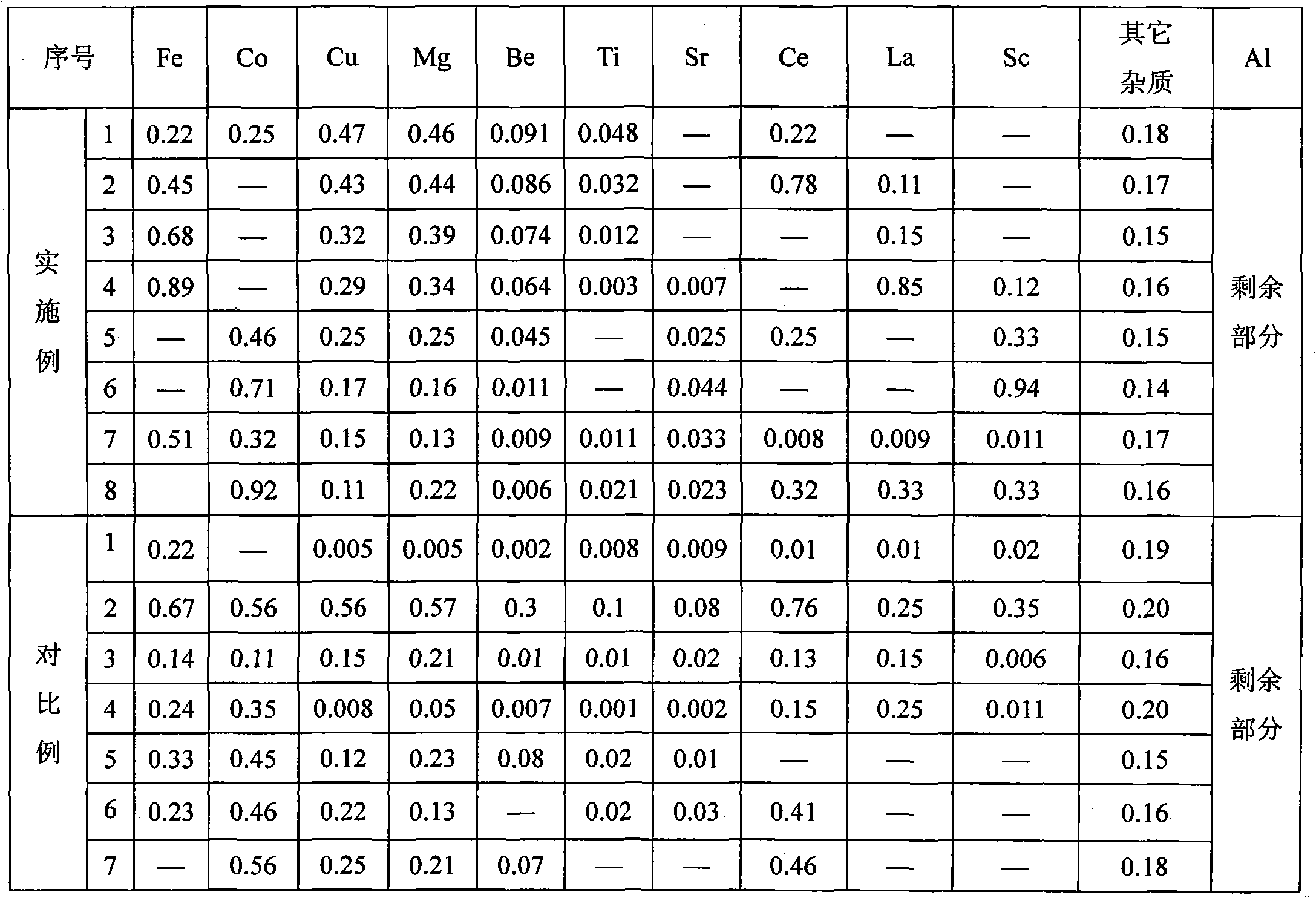

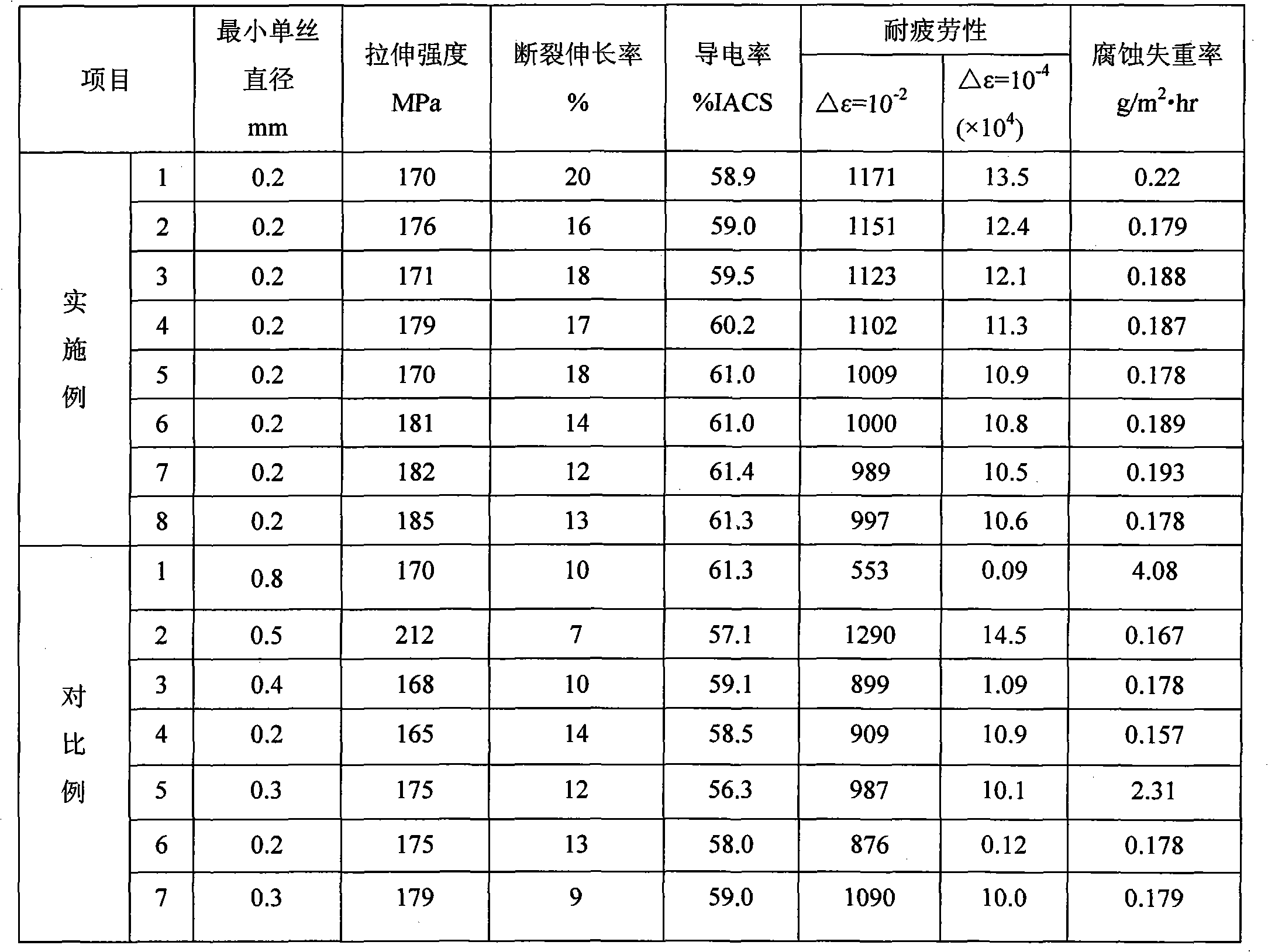

Embodiment 1

[0033]An aluminum alloy with a conductive wire core for an electric welding machine cable, the aluminum alloy material includes the following components: at least one of Fe and Co, the total mass fraction of which accounts for 0.4 to 1.0 wt% of the total mass of the aluminum alloy, for example, it can be selected as 0.5 %, 0.6%, 0.8%, 0.9%, Cu accounts for 0.1-0.5wt%, for example can be selected as: 0.2%, 0.3%, 0.4%, Mg accounts for 0.1-0.5wt%, for example can be selected as: 0.2% , 0.3%, 0.4%, Be accounted for 0.005 ~ 0.1wt%, for example can be selected as: 0.008%, 0.01%, 0.05%, 0.08%, rare earth accounted for 0.05 ~ 1wt%, for example can be selected as 0.09%, 0.2%, 0.5 %, 0.9%, and the rest are aluminum and unavoidable impurities.

[0034] In the above technical solution, the content of Fe and Co in mass percentage of the aluminum alloy is preferably 0.6-0.8 wt%. Rare earth elements are composed of one or more of cerium, lanthanum and scandium. The aluminum alloy material ...

Embodiment 2

[0037] The conductive core aluminum alloy material comprises the following components: 0.4-1.0wt% of Fe or Co, 0.1-0.5wt% of Cu, 0.1-0.5wt% of Mg, 0.005-0.1wt% of Be, 0.05-1wt% of Miscellaneous rare earth, the rest is aluminum and unavoidable impurities.

[0038] The aluminum alloy material also contains one or both of titanium and strontium, and the percentage content is not more than 0.05wt%.

[0039] The aluminum alloy material contains one or both of Fe and Co, the content of which is 0.4-1.0 wt%, and the optimal selection is 0.6-0.8 wt%.

[0040] Rare earth elements are composed of one or more of cerium, lanthanum and scandium.

[0041] Aluminum alloy conductive wire cores for electric welding machines are manufactured by the following methods:

[0042] 1) Proportioning according to the range set by the above alloy elements, adding aluminum ingots with a purity of 99.7wt% into the shaft furnace, raising the temperature to 710-760°C, for example, 750°C can be selected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com