A kind of aluminum alloy conductive wire core with high scandium content for cables and preparation method thereof

A conductive wire core, aluminum alloy technology, applied in the direction of metal/alloy conductors, rods/rods/wires/strip conductors, etc., can solve the problems of few insulated wire cores, the strength and elongation of aluminum cannot meet the requirements, difficulties, etc. , to reduce creep, improve ductility and improve tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

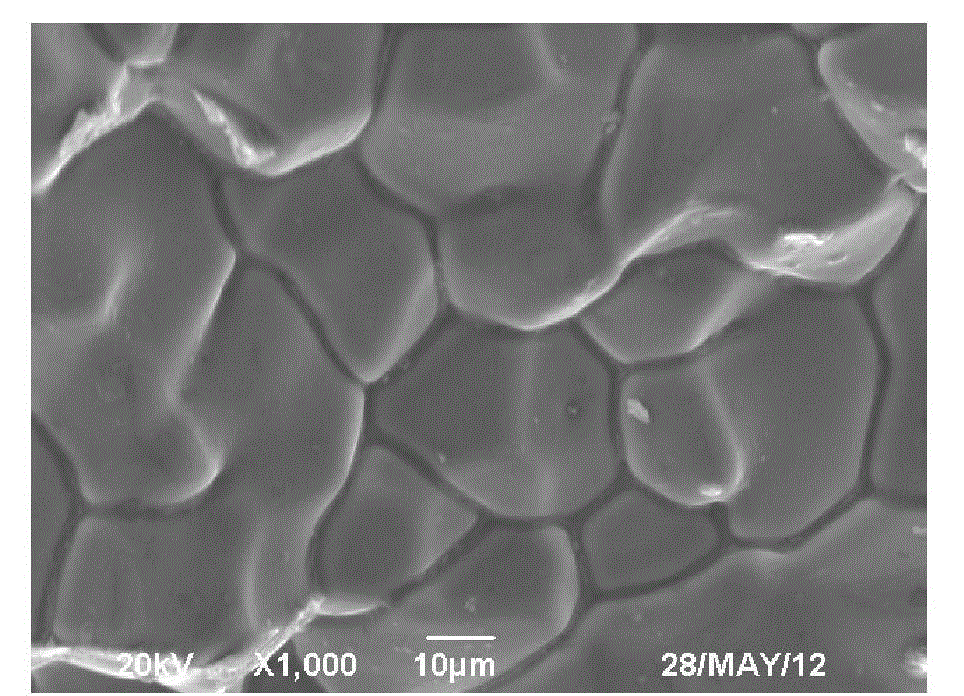

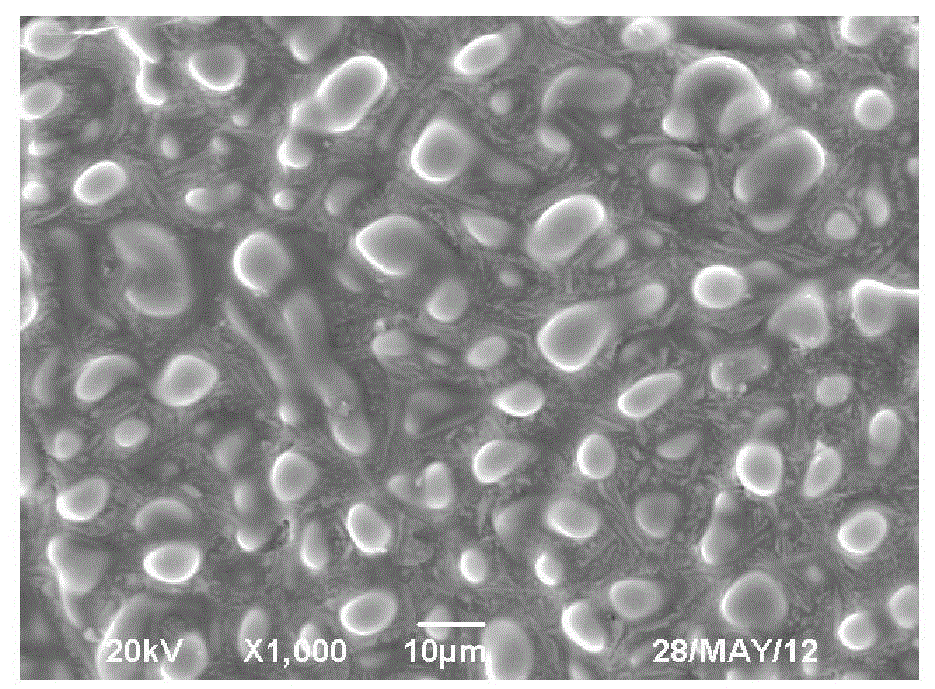

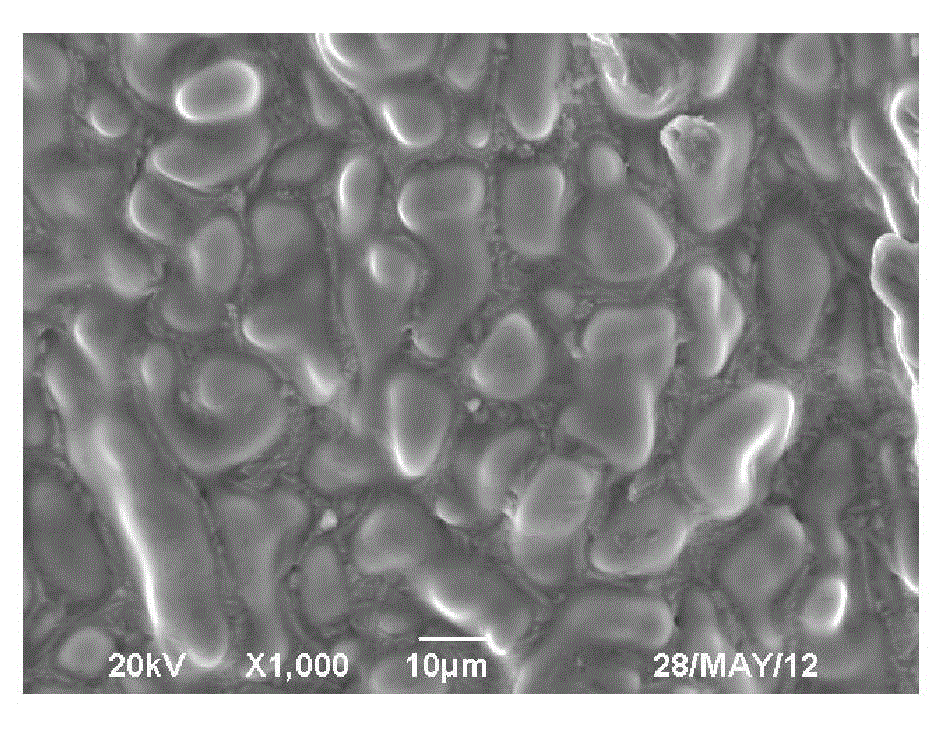

Image

Examples

Embodiment 1

[0025] The composition of the aluminum alloy conductive wire core with high scandium content for the cable of this embodiment is constituted by mass percentage as follows:

[0026] Sc0.6wt%, Fe0.01wt%, cerium-rich rare earth 0.04wt% (lanthanum 0.01wt%, cerium 0.03wt%), aluminum 99.35%.

[0027] The preparation method of the aluminum alloy conductive wire core with high scandium content for the cable of this embodiment is as follows:

[0028] According to the ratio, industrial pure aluminum with a purity of 99.80%, iron-aluminum master alloy (20%Fe+80%Al), cerium-rich rare earth master alloy (20% cerium-rich rare earth+80%Al) and scandium-aluminum master alloy (20% %Sc+80%Al) into the shaft furnace and heated up to 750-770°C, after melting, the alloy melt is obtained, the alloy melt flows into the holding furnace (or refining furnace), and the alloy is added to the holding furnace in a nitrogen atmosphere The refining agent with 0.05% of the melt mass is refined at 740-760°C f...

Embodiment 2

[0031] The composition of the aluminum alloy conductive wire core with high scandium content for the cable of this embodiment is constituted by mass percentage as follows:

[0032] Sc0.5wt%, Fe0.01wt%, cerium-rich rare earth 0.04wt% (lanthanum 0.01wt%, cerium 0.03wt%), aluminum 99.45%.

[0033] The preparation method of the aluminum alloy conductive wire core with high scandium content for the cable of this embodiment is as follows:

[0034] According to the ratio, industrial pure aluminum with a purity of 99.80%, iron-aluminum master alloy (20%Fe+80%Al), cerium-rich rare earth master alloy (20% cerium-rich rare earth+80%Al) and scandium-aluminum master alloy (20% %Sc+80%Al) into the shaft furnace and heated up to 750-770°C, after melting, the alloy melt is obtained, the alloy melt flows into the holding furnace (or refining furnace), and the alloy is added to the holding furnace in a nitrogen atmosphere The refining agent with 0.08% of the melt mass is refined at 740-760°C f...

Embodiment 3

[0037] The composition of the aluminum alloy conductive wire core with high scandium content for the cable of this embodiment is constituted by mass percentage as follows:

[0038] Sc0.4wt%, Fe0.01wt%, cerium-rich rare earth 0.04wt% (lanthanum 0.01wt%, cerium 0.03wt%), aluminum 99.55%.

[0039] The preparation method of the aluminum alloy conductive wire core with high scandium content for the cable of this embodiment is as follows:

[0040] According to the ratio, industrial pure aluminum with a purity of 99.80%, iron-aluminum master alloy (20%Fe+80%Al), cerium-rich rare earth master alloy (20% cerium-rich rare earth+80%Al) and scandium-aluminum master alloy (20% %Sc+80%Al) into the shaft furnace and heated up to 750-770°C, after melting, the alloy melt is obtained, the alloy melt flows into the holding furnace (or refining furnace), and the alloy is added to the holding furnace in a nitrogen atmosphere The refining agent with 0.1% of the melt mass is refined at 740-760°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com