Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "High yield limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

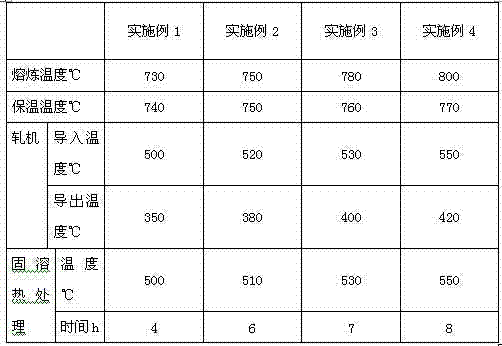

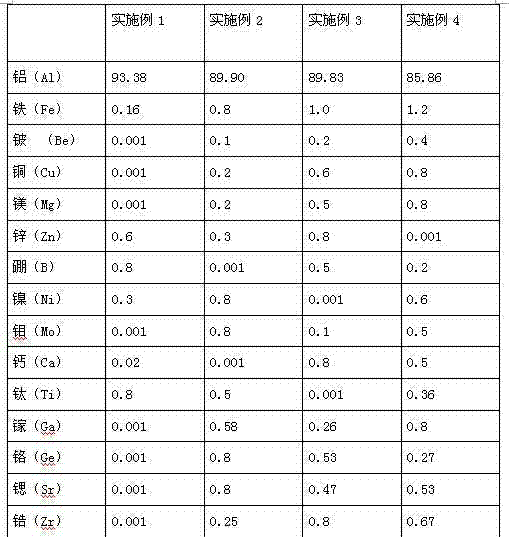

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

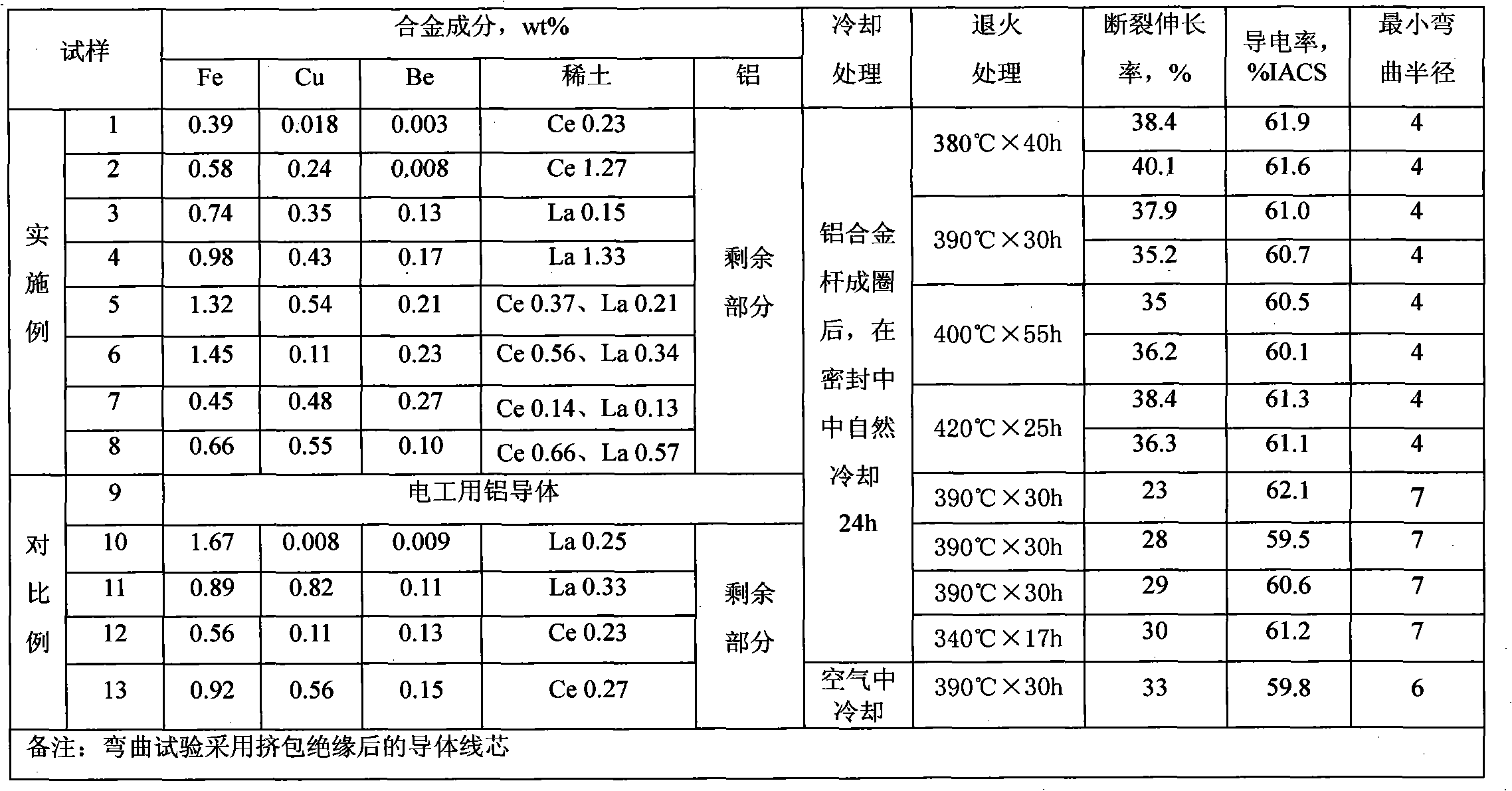

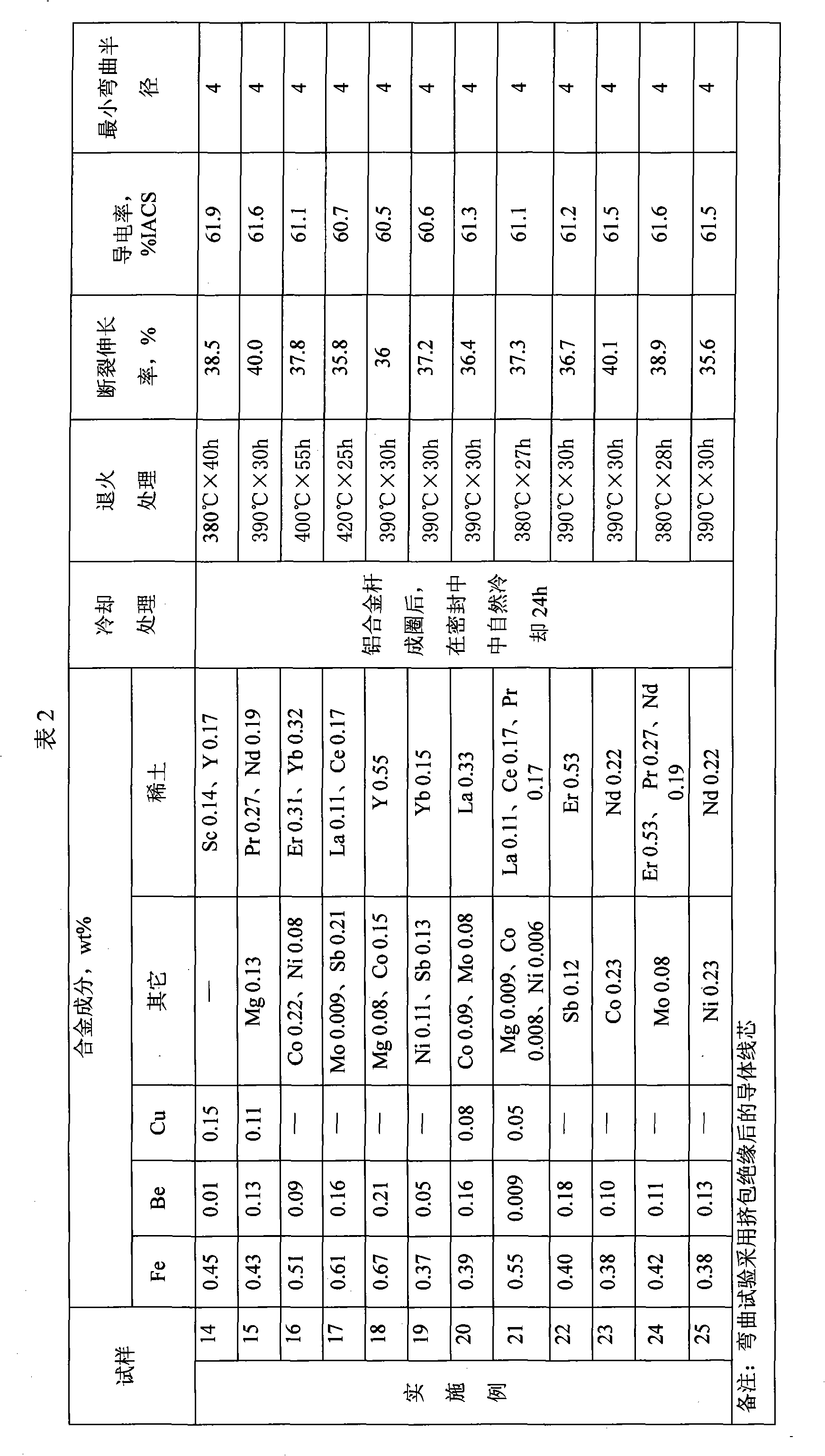

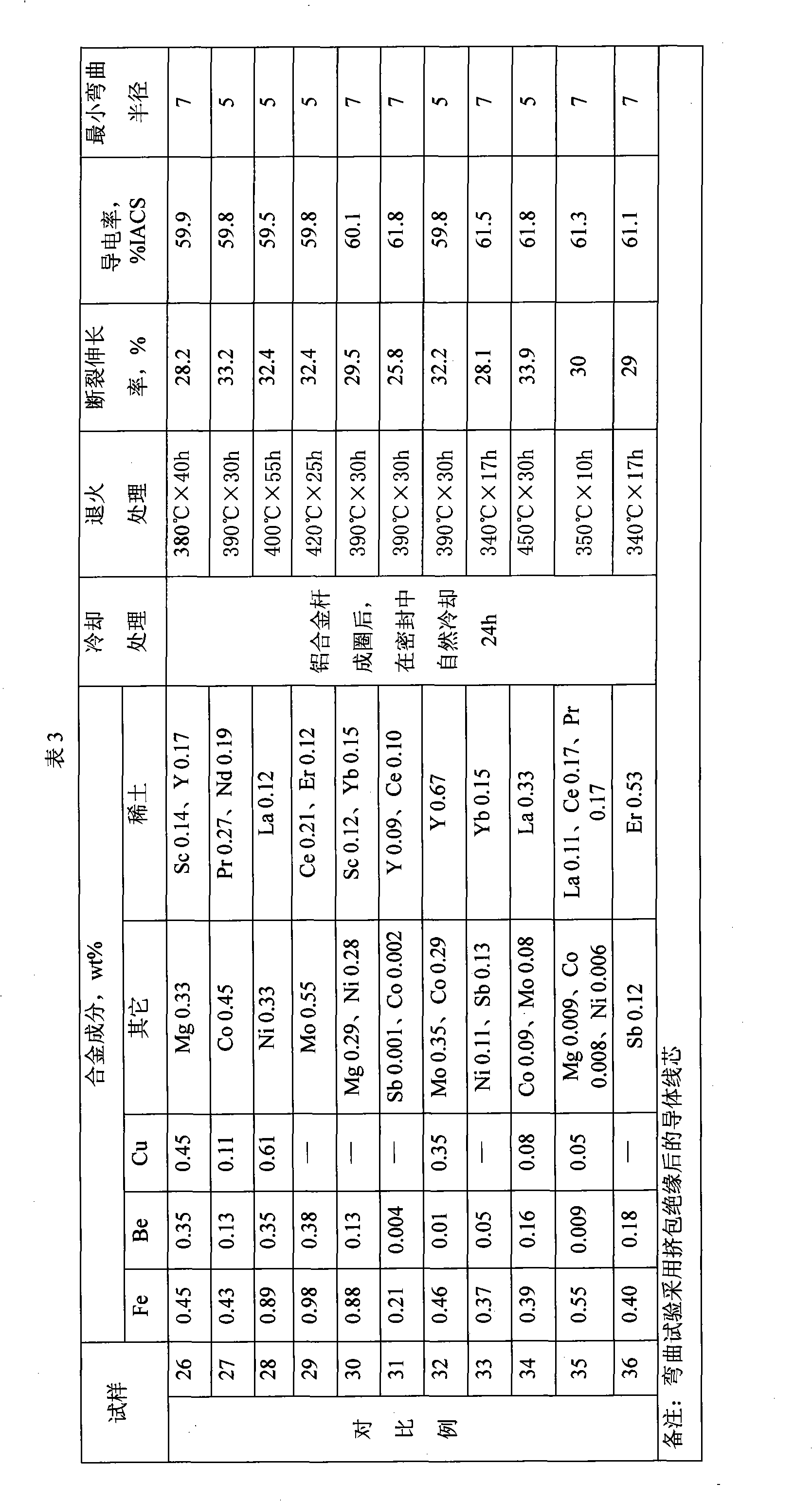

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

Conductor wire core aluminum alloy for welding machine cable and making method thereof

ActiveCN101921932AConductivity has little effectHigh tensile strengthMetal/alloy conductorsRare earthMaterials science

The invention discloses a conductor wire core aluminum alloy for a welding machine cable and a making method thereof. A conductor wire core is made of aluminum alloy materials. The aluminum alloy comprises the following compositions: 0.4-1.0wt percent of Fe or Co, 0.1-0.5wt percent of Cu, 0.1-0.5wt percent of Mg, 0.05-0.1wt percent of Be and 0.05-0.1wt percent of rare earth. An aluminum alloy wire harness is obtained by carrying out smelting, linecasting, rolling, intermediate annealing, drawing, bunch stranding and annealing on the alloy. The aluminum alloy wire core has the advantages of better conductivity, anti-fatigue performance, flexibility, bending performance and corrosion resistance and is suitable for the conductor wire core of the welding machine cable.

Owner:ANHUI JOY SENSE CABLE

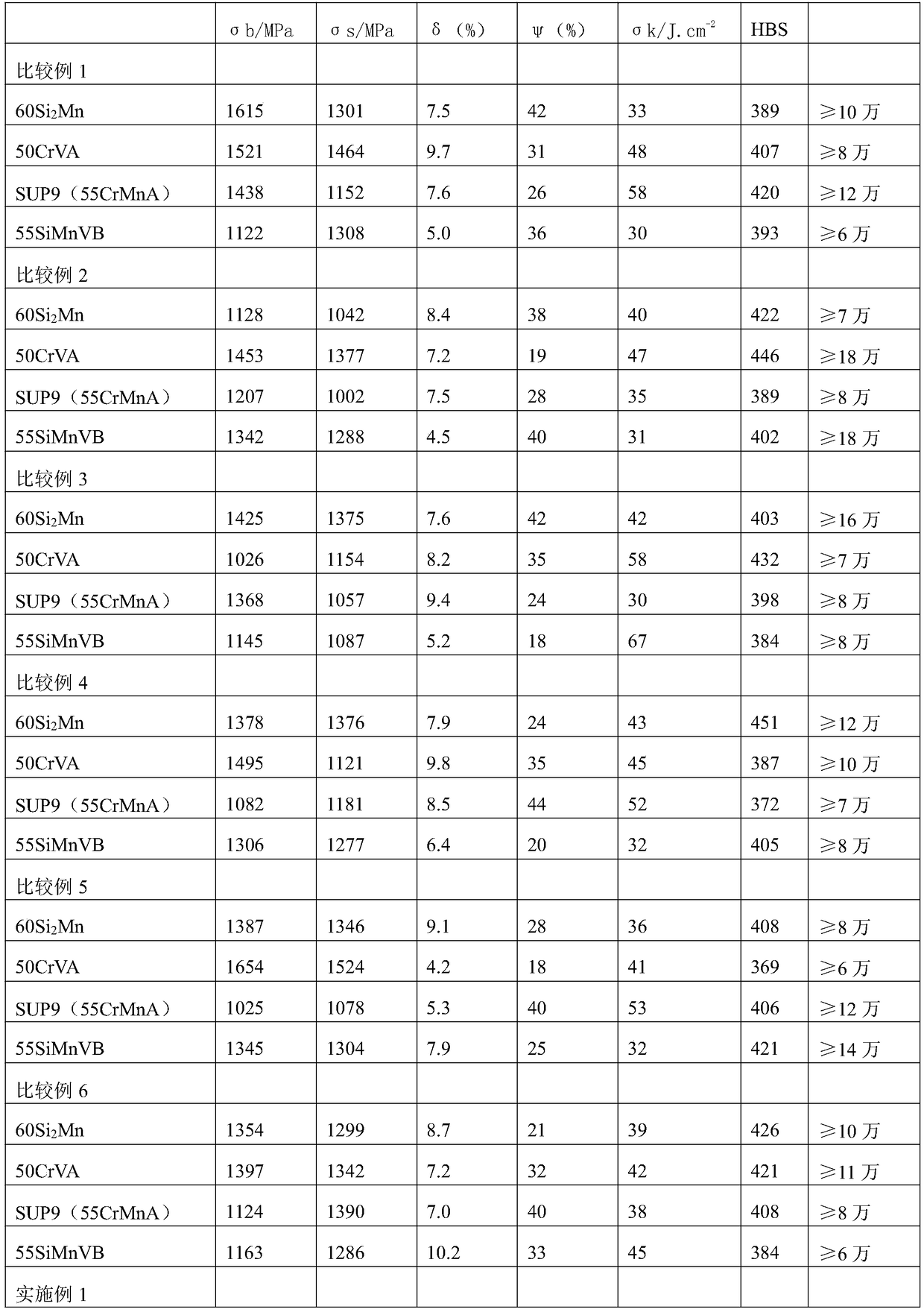

Process for quenching-distribution heat treatment on 60Si2CrVA steel spring for trains

InactiveCN101597680AHigh yield limitImprove fatigue strengthIncreasing energy efficiencyFurnace typesYield ratioRound bar

The invention discloses a process for quenching-distribution heat treatment on 60Si2CrVA steel spring for trains. The process comprises the following steps: polishing a 60Si2CrVA steel round bar with diameter less than or equal to 50mm, and heating the steel round bar to a temperature of between 960 and 1,060 DEG C through an inductive heating mode; then, wrapping the 60Si2CrVA steel round bar into a spring in the temperature state; cooling the wrapped spring to a temperature of between 810 and 900 DEG C, quenching the spring at a temperature of between 130 and 210 DEG C, and keeping constant temperature for 10 to 60 seconds; quickly placing the spring in a medium at a temperature of between 280 and 350 DEG C, maintaining for 50 to 800 seconds, and placing the spring into water or oil for cooling; and tempering the spring at a temperature of between 250 and 470 DEG C for 60 to 120 minutes. The 60Si2CrVA steel spring product has the advantages of high yield limit and fatigue strength, good quenching harden ability, high tensile strength and yield ratio, high toughness and the like.

Owner:GUIZHOU UNIV

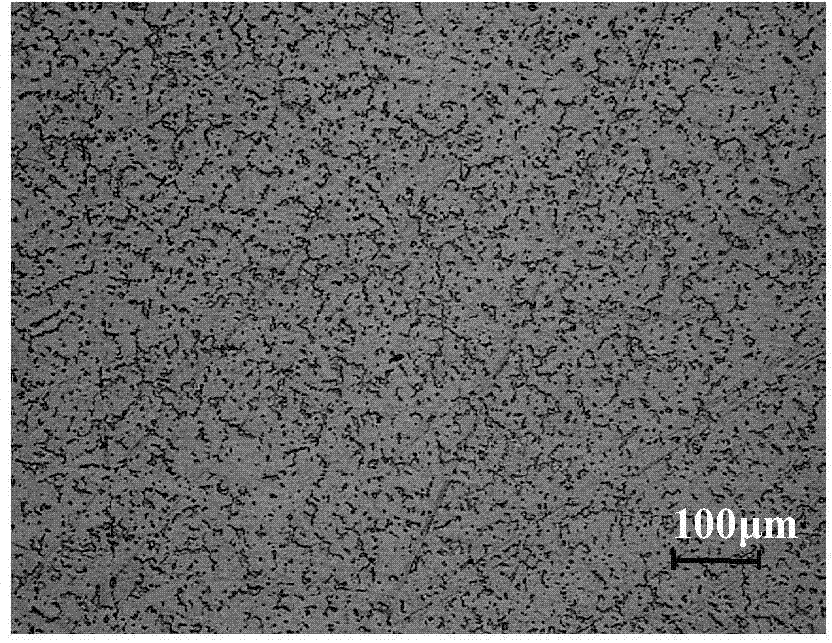

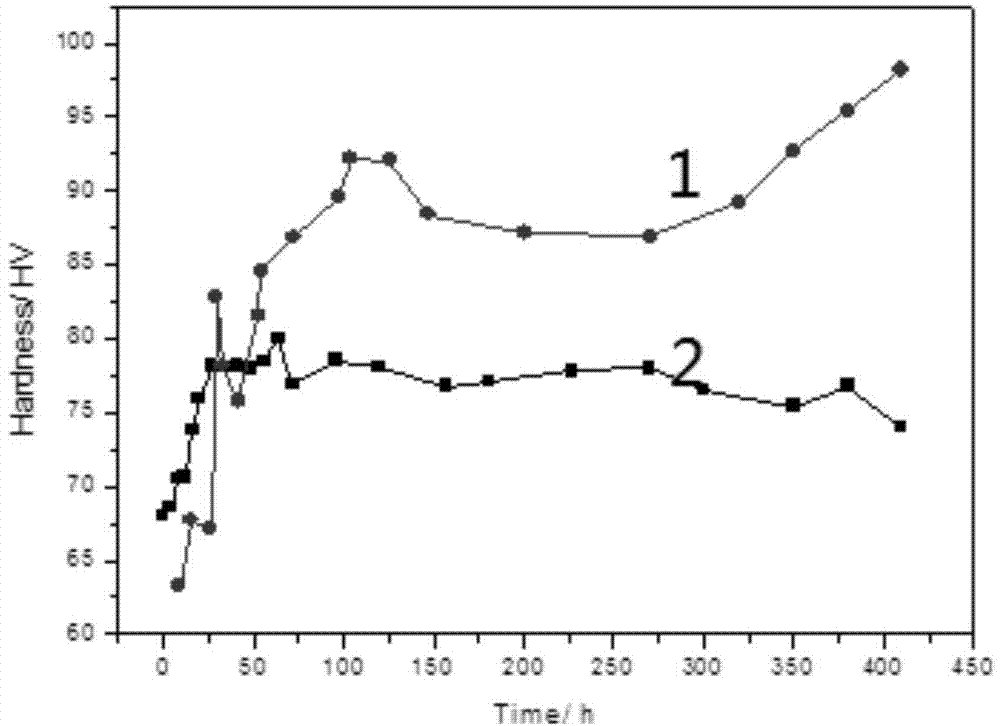

Magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and preparation method thereof

The invention discloses a magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and a preparation method thereof. Mass percent of components of the alloy is that 4 to 10% of zinc, 2 to 4% of aluminum, 0.1 to 0.5% of chromium, 0.1 to 1.0% of bismuth, 0.5 to 2.0% of calcium, the remaining is magnesium, and the total mass is 100%. The preparation method of the alloy comprises the following steps of preheating prepared alloy furnace materials, communicating a carbon dioxide and sulfur hexafluoride mixed gas to be served as a protection gas to perform smelting, performing diffusion annealing on obtained magnesium, zinc, aluminum, chromium, bismuth and calcium as-cast-condition alloy materials for 48 hours under 380 degrees, performing linear cutting to obtain aging thermal treatment samples and plate-shaped tensile samples, preserving heat of the above samples, performing water quenching and manual aging to obtain the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening. The preparation method can obtain preparation the magnesium, zinc, aluminum, chromium, bismuth and calcium alloy allowing age hardening and relatively thin in as-cast structure and high in thermal stability and mechanical property.

Owner:NORTHEASTERN UNIV LIAONING

Alloy for producing cold rolled working roll and method for producing same

The invention relates to an alloy for cold-rolling worker rollers and its preparing process, wherein the alloy comprises the main chemical constituents of: C 0.9-1.2%, Si 0.85-1.25%, Mn 0.40-0.60%, Cr 2.50-5.50%, Ni 0.25-0.45%, Mo 0.25-0.45%, V 0.05-0.155 and balancing Fe.

Owner:BAOSTEEL ROLL SCI & TECH

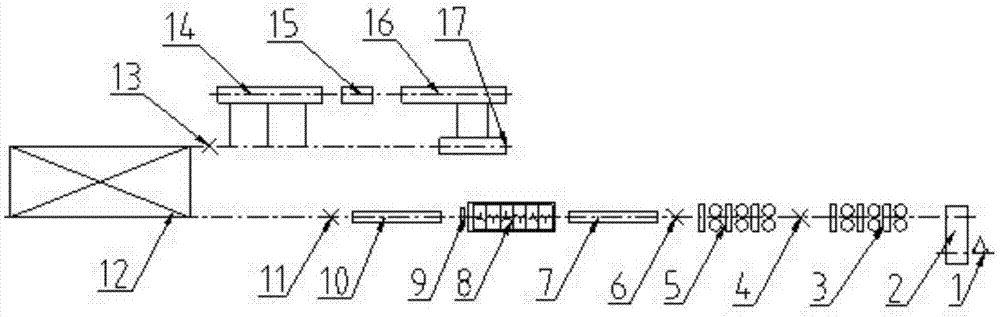

Method for rolling high-precision alloy steel wire rod

InactiveCN104841695AReal-time monitoring diameterEffective closed-loop controlWork cooling devicesWork heating devicesWire rodProduction line

The invention discloses a method for rolling a high-precision alloy steel wire rod. The rolling method is characterized in that a six-shelf precise rolling rack is removed on the basis of a traditional rolling technology, a six-shelf three-roller reducing sizing mill and an online diameter measurement device are adopted to freely adjust the rolling size, so that the surface quality of the final product is relatively good, and the tolerance precision of the size is relatively high, meanwhile one group of water penetration cooling devices are respectively arranged at front and rear sides of the six-shelf three-roller reducing sizing mill to realize low temperature rolling and controlled rolling and controlled cooling, so that the mechanical performance of a rolling line product can be greatly increased; the rolling method is slightly changed based on an original production line, temperature and rolling control and precision rolling of the finished size can be realized, the improvement cost is simultaneously greatly reduced, the additional value of the product is increased, and the finished product is high in precision, and thus the change from plain carbon steel to special steel can be quickly realized in a steel plant.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

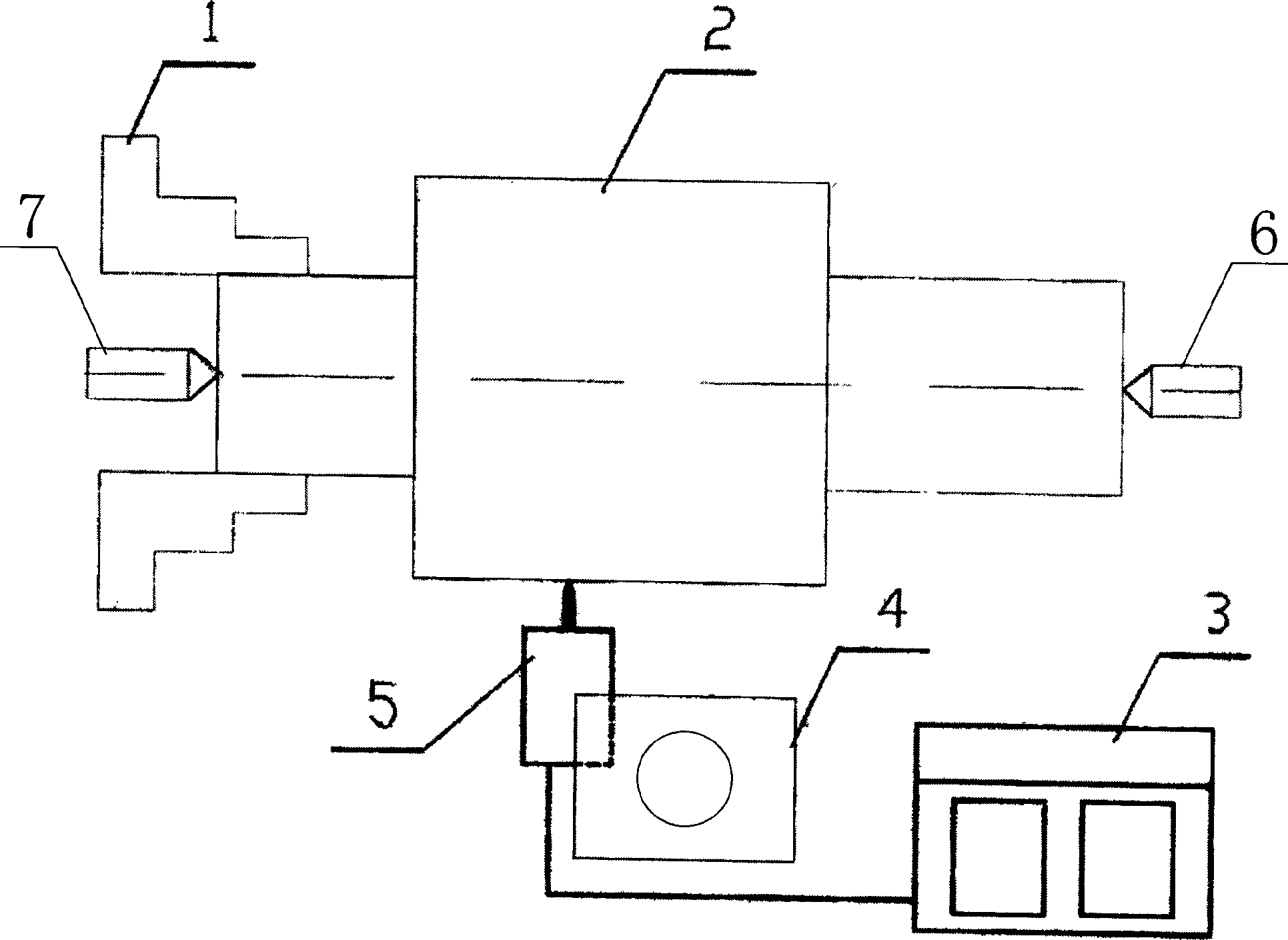

High small ultrasonic polishing, collating equipment in use for parts of axes, and processing method

InactiveCN1915592AChange performanceHigh strengthSuperfinishing machinesBiomedical engineeringUltrasonic generator

An efficient ultrasonic polishing apparatus for the axle-type parts is composed of a HF (200000-300000 H2) ultrasonic generator and a grinding head, and is installed to the cutting-tool carrier. Its polishing method features that the part to be polished is fixed to a lathe.

Owner:CITIC HEAVY INDUSTRIES CO LTD

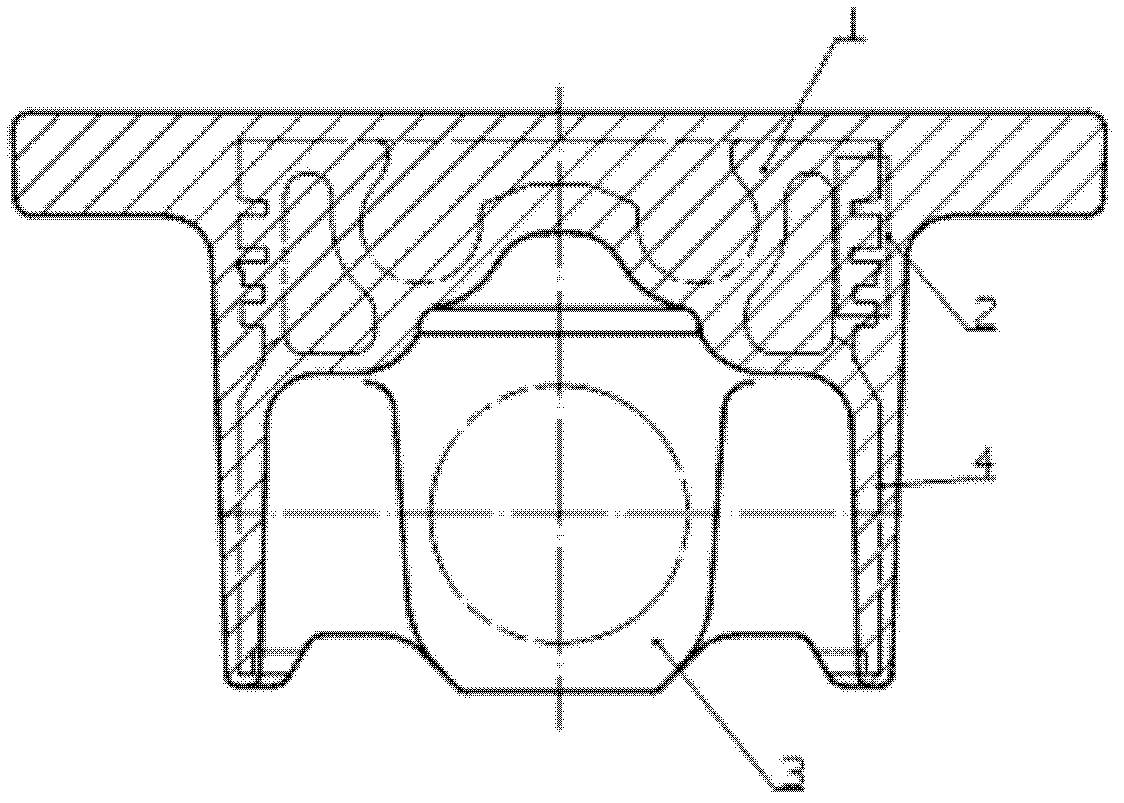

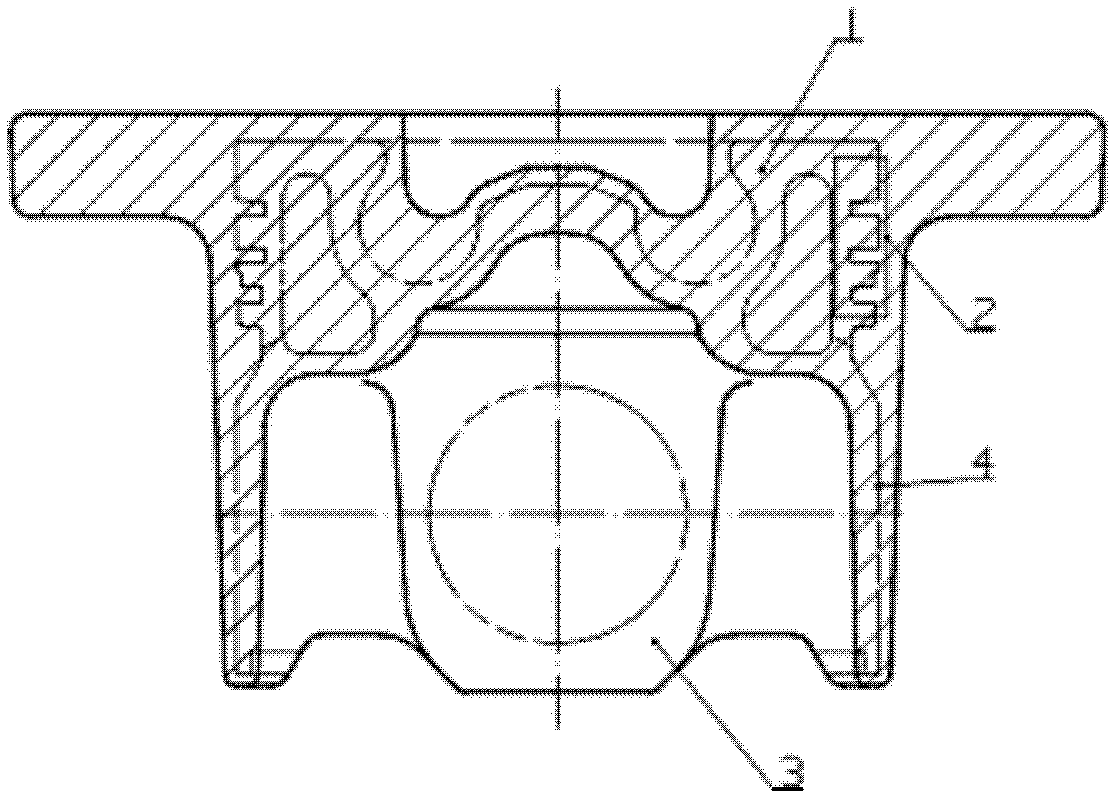

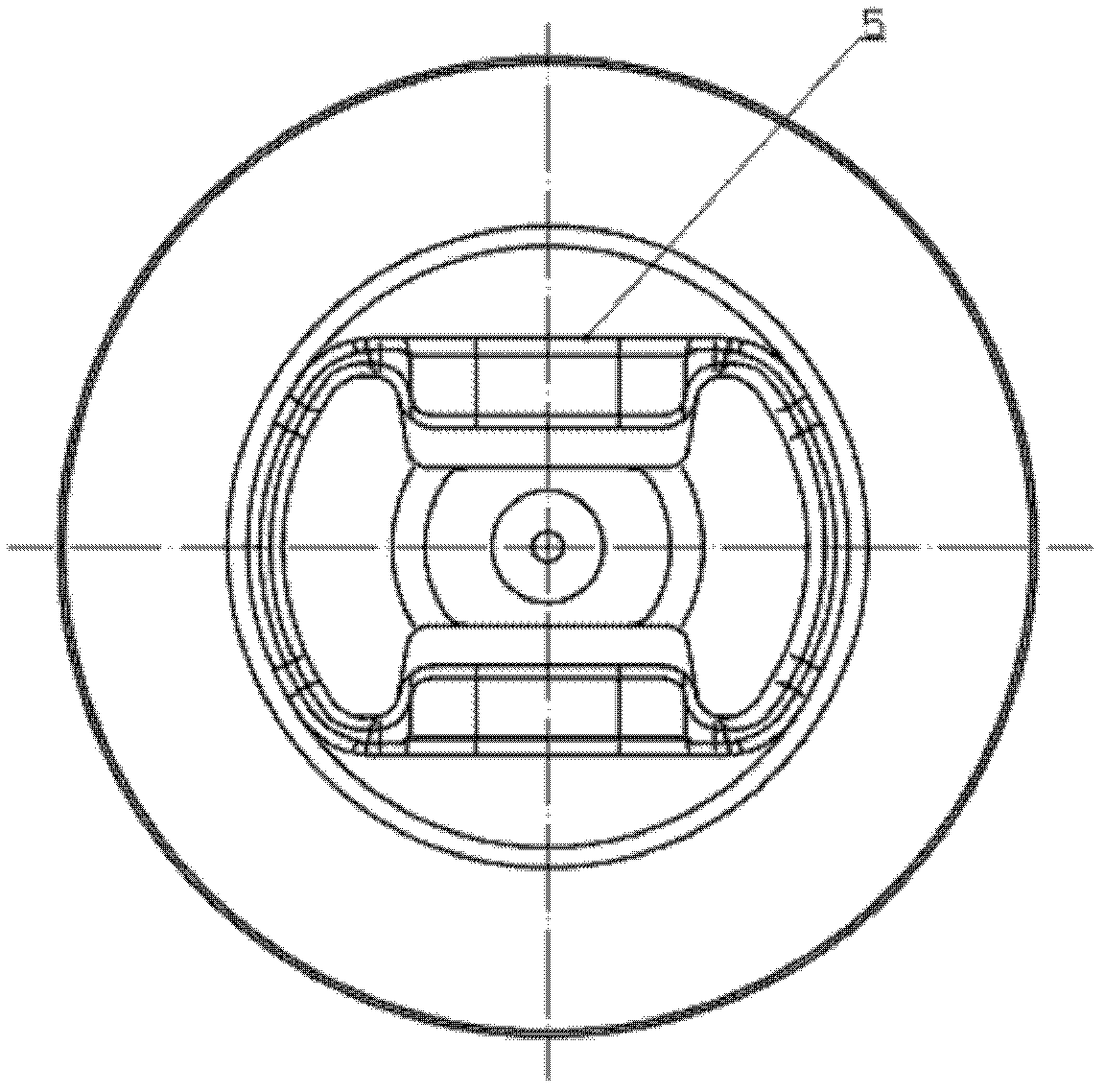

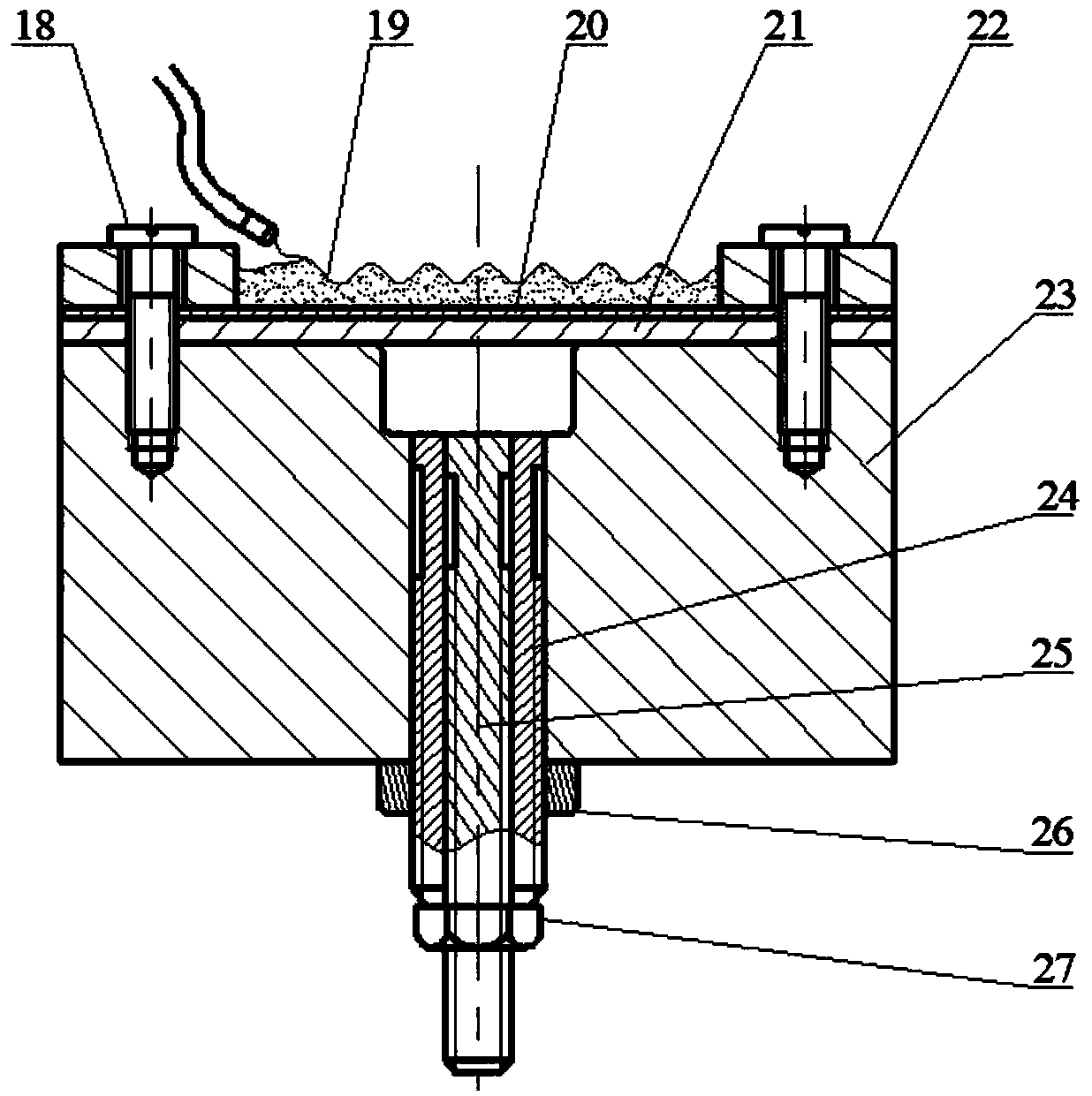

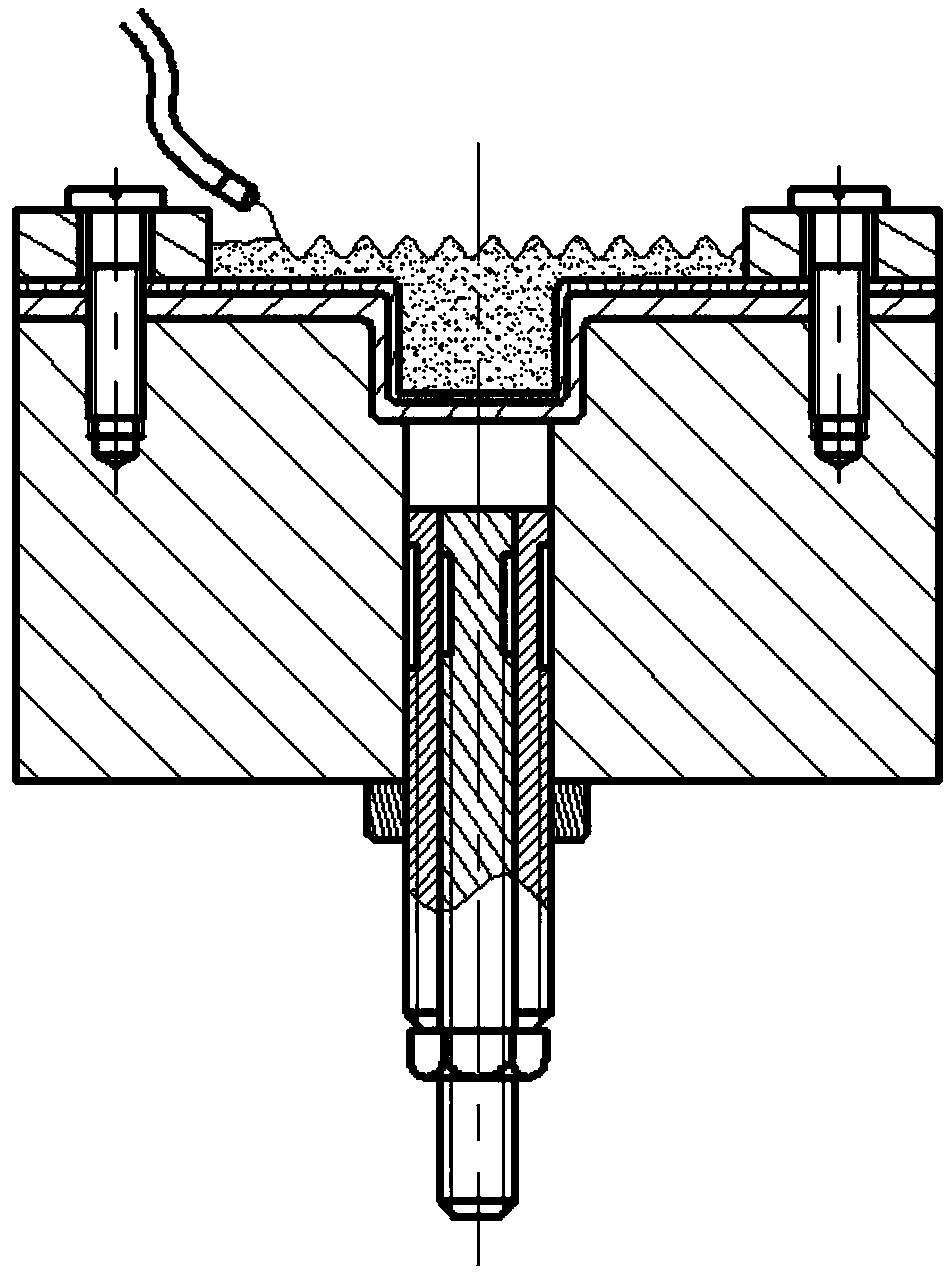

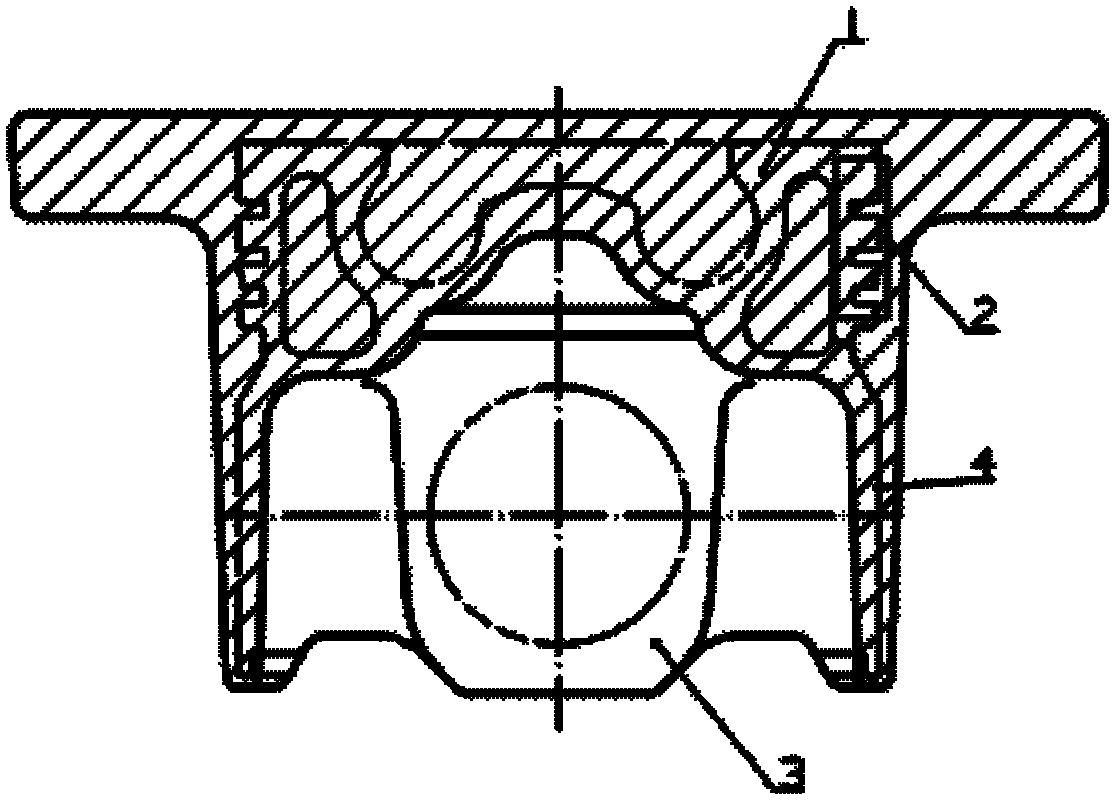

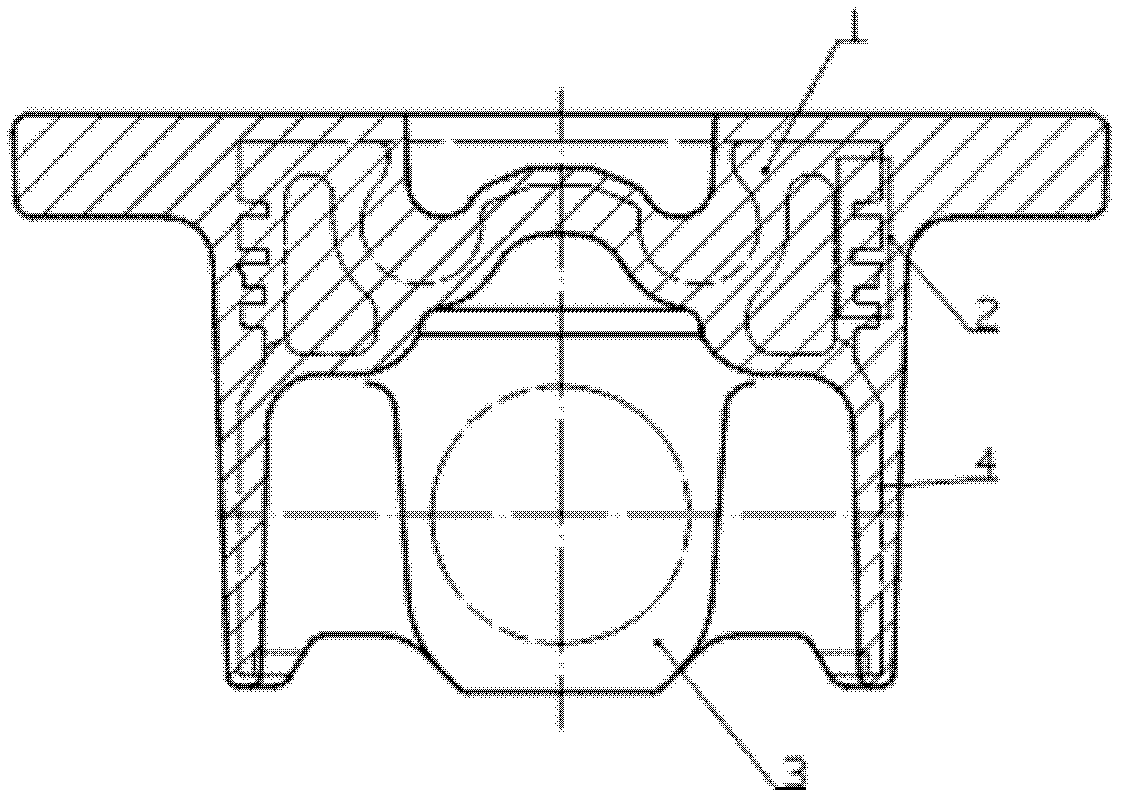

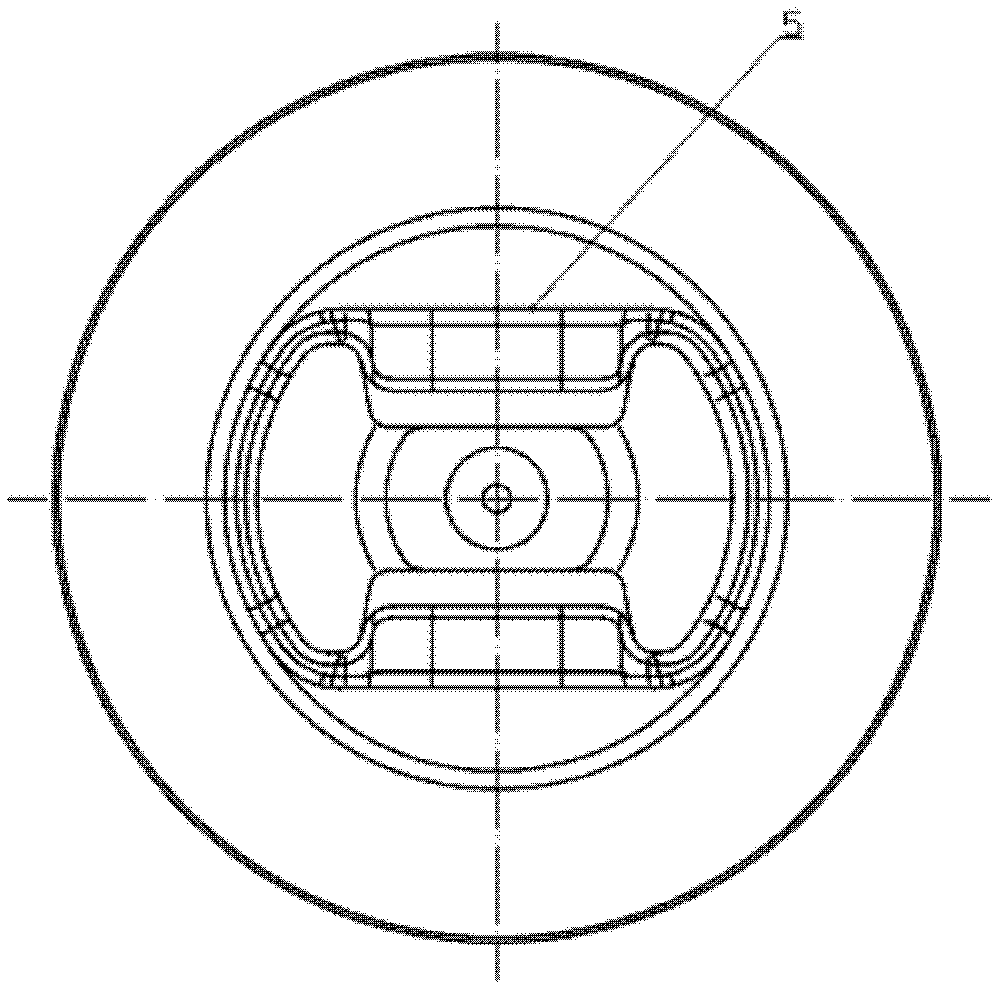

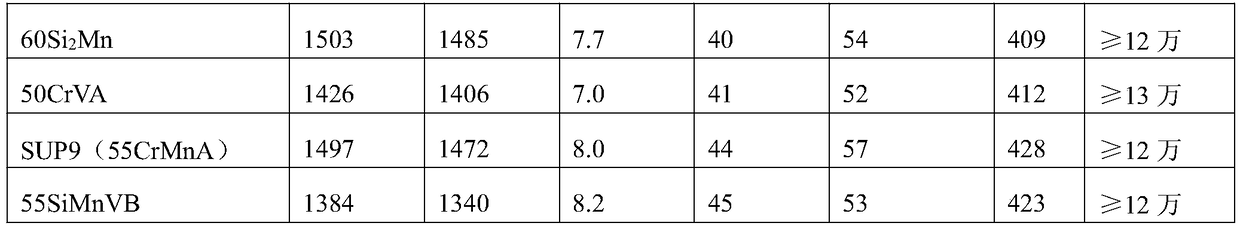

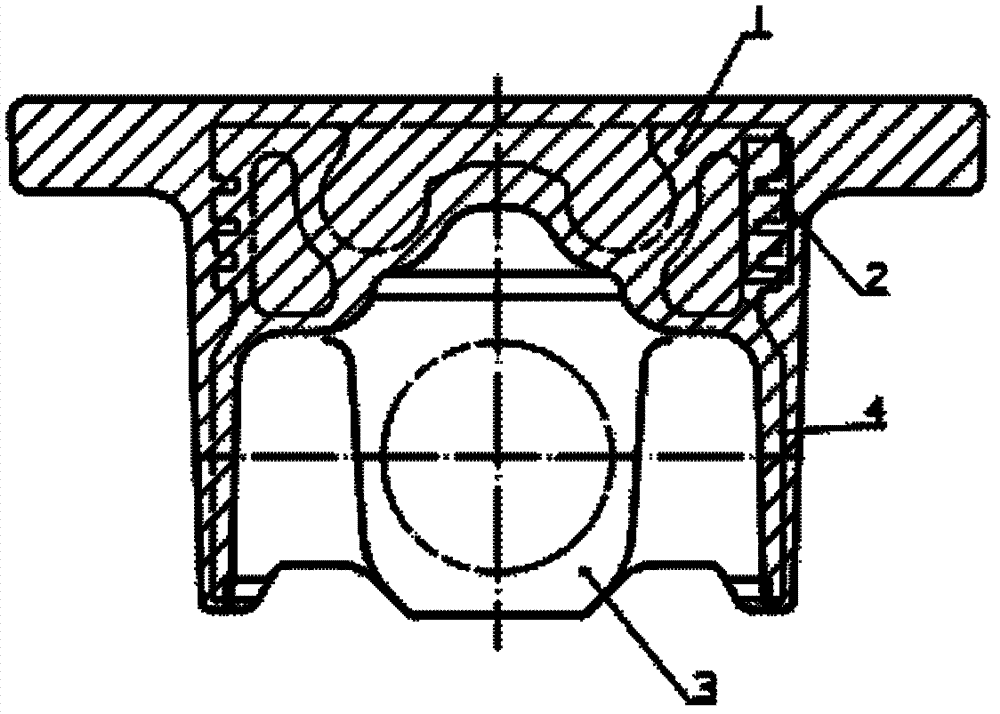

Manufacturing process of solid cold-spun forged steel piston with internal cooling oil chamber

The invention discloses a manufacturing process of a solid cold-spun forged steel piston with an internal cooling oil chamber. The manufacturing process comprises the following steps: performing solid forging to obtain a piston blank; machining a semi-finished piston product with an inside part of the internal cooling oil chamber and a shielding part for blocking off the internal cooling oil chamber; then heating the shielding part, and spinning downwards the shielding part of the internal cooling oil chamber of the piston by adopting the hot spinning process so that the shielding part contacts with the inside part of the internal cooling oil chamber so as to form the complete internal cooling oil chamber; and reserving the gap between the inside part and the shielding part of the internal cooling oil chamber and the shielding part without disposal or simply closing the gap by argon-arc welding and other common welding processes, and then performing precision machining to finally obtain the finished piston. The manufacturing process has the advantages of simple structure, more simple and convenient manufacturing procedures, high production efficiency, low manufacturing cost and the like, and can meet the requirements of an engine on high power, high strength and low emission.

Owner:BINZHOU BOHAI PISTON CO LTD

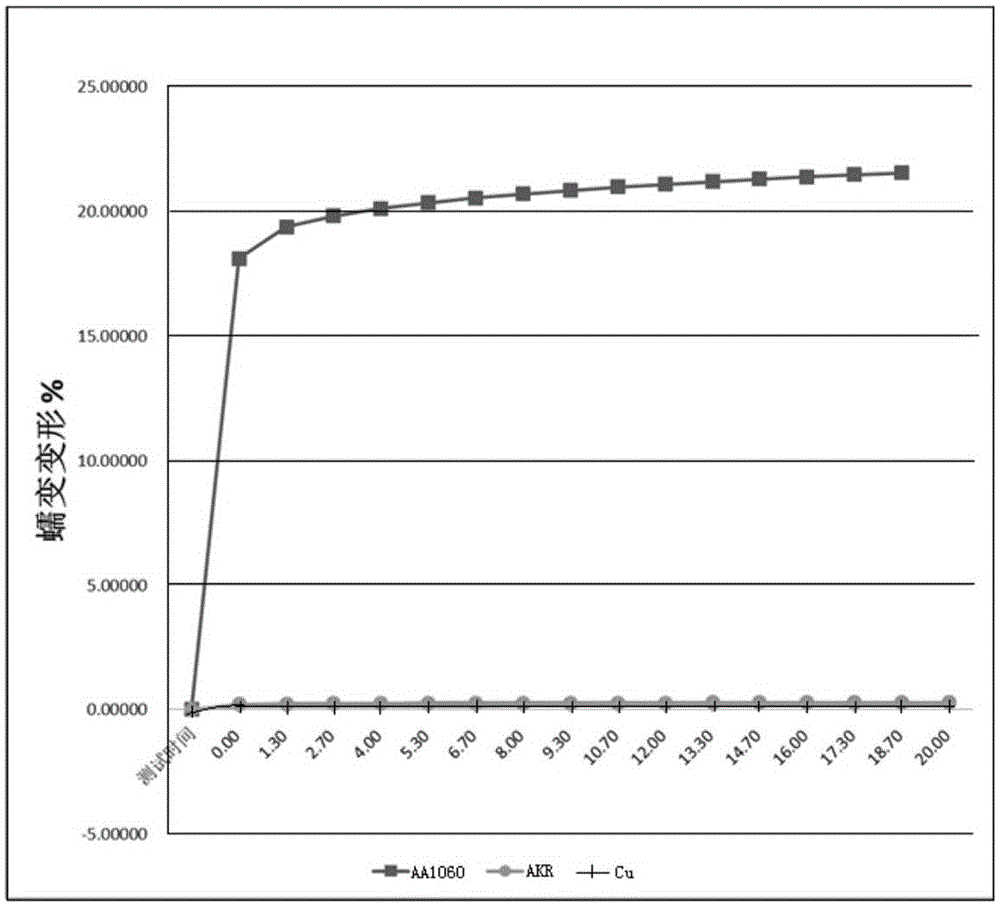

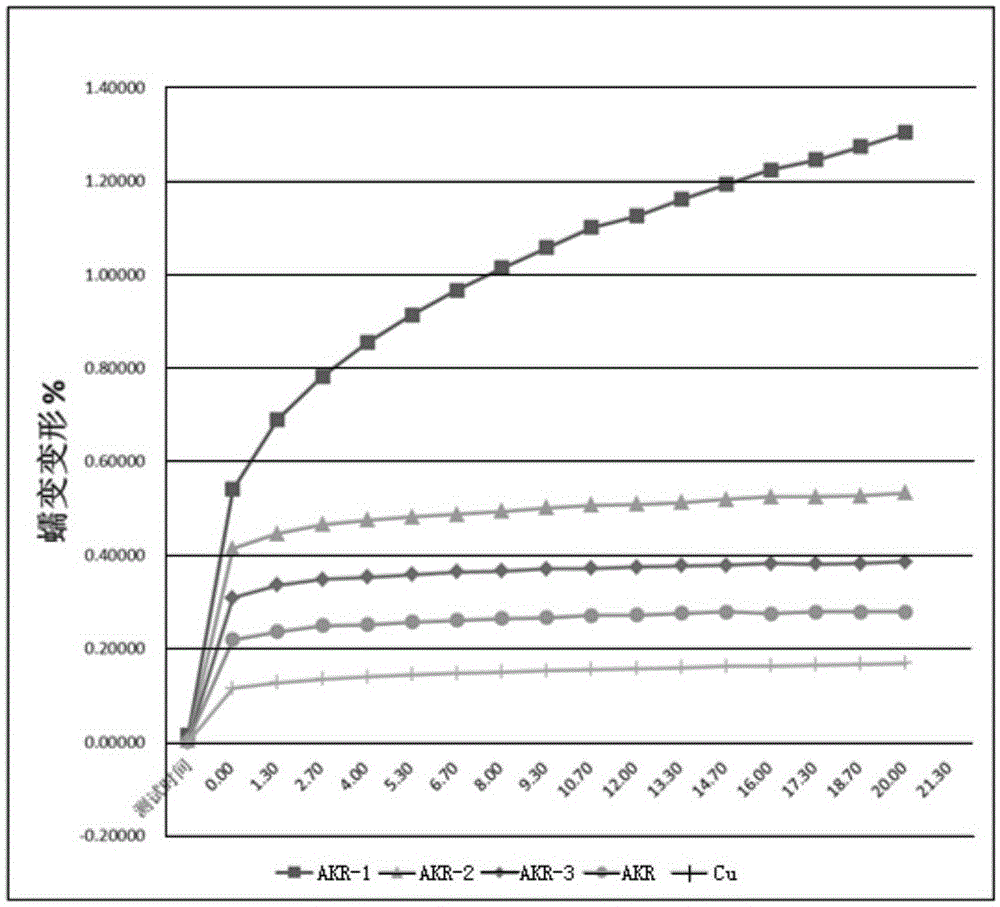

High-conductivity compressive-creep-resistant aluminum alloy and manufacturing method thereof

ActiveCN105132767AHigh tensile strengthHigh yield limitMetal/alloy conductorsCompressive creepRare earth

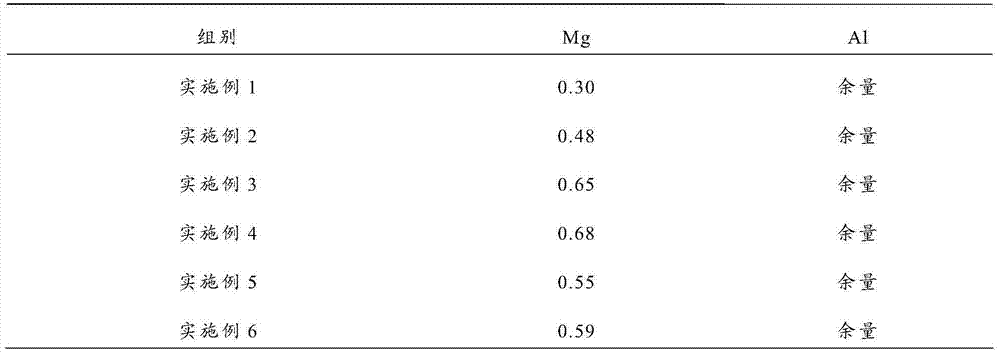

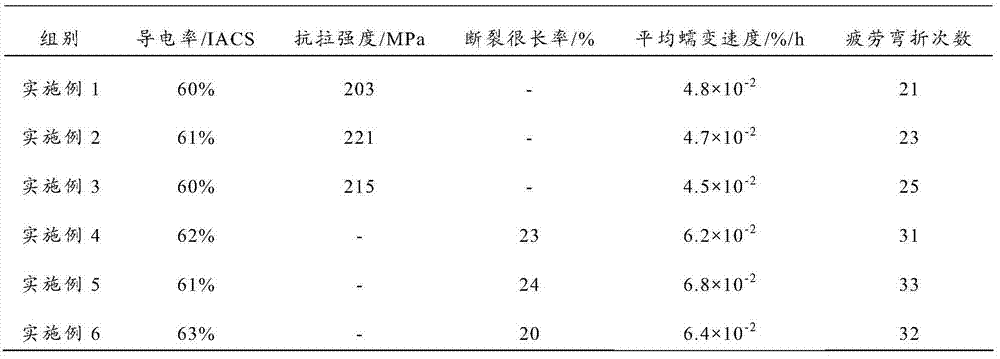

The invention discloses a high-conductivity compressive-creep-resistant aluminum alloy. The high-conductivity compressive-creep-resistant aluminum alloy comprises the following components in percentage by mass: 0.25%-2.5% of copper, 0.3%-2.8% of magnesium, 0.03%-0.5% of rare earth, 0.3%-1.2% of iron and the balance of aluminum. The invention further discloses a manufacturing method for the high-conductivity compressive-creep-resistant aluminum alloy. The manufacturing method comprises the following steps: (1) pre-treating an alloy raw material; (2) carrying out batching, melting and in-furnace treatment on the alloy raw material; (3) carrying out online refining treatment on a molten aluminum alloy; and (4) casting and forming the alloy. The obtained aluminum alloy material not only has high tensile strength and yield limit, but also has excellent electrical conductivity, and good thermal stability of a resistor at a high temperature; more importantly, at the high temperature, the aluminum alloy material has very excellent compressive creep resistance, is a major breakthrough of replacing copper with aluminum in the electrotechnical industry, greatly solves the defect caused by creep property difference in an aluminum alloy conductor material application process, and meets performance requirements of the aluminum alloy material while applied in the electrotechnical industry.

Owner:深圳阿尔泰克轻合金技术有限公司

Positive pole current collector of lithium ion battery

InactiveCN104282917AImprove heat resistanceDoes not reduce conductivityElectrode carriers/collectorsElectrical batteryLithium-ion battery

The invention relates to a positive pole current collector of a lithium ion battery. The current collector is of a three-layer structure, wherein the first layer and the third layer are made of aluminum and have the thickness of 2.5-3 microns; the second layer arranged between the first layer and the third layer is an aluminum alloy layer and has the thickness of 8-10 microns; and the aluminum alloy comprises the following components in percentage by mass: 0.4-0.45 percent of Si, 0.4-0.45 percent of Fe, 0.06-0.08 percent of Cu, 0.5-0.6 percent of Mn, 0.05-0.08 percent of Ca, 0.01-0.015 percent of Sb, 0.1-0.15 percent of Ti-B alloy, 0.45-0.6 percent of RE, 15-20 percent of La, 55-60 percent of Ce, 10-15 percent of Er, 10-15 percent of Sm and the balance of aluminum and inevitable impurities, wherein RE refers to mixture rare earths. The preparation method comprises the following steps: smelting, performing homogenizing treatment, cold rolling and performing two-stage aging. According to the positive pole current collector disclosed by the invention, the tensile strength can be 260-275MPa, a corrosive pitting phenomenon is avoided, and compared with an aluminum foil in the prior art, the positive pole current collector has the advantage that problems of wrinkle and breakage can be effectively solved on the basis that a certain aluminum foil thickness is guaranteed.

Owner:襄阳锦翔光电科技股份有限公司 +1

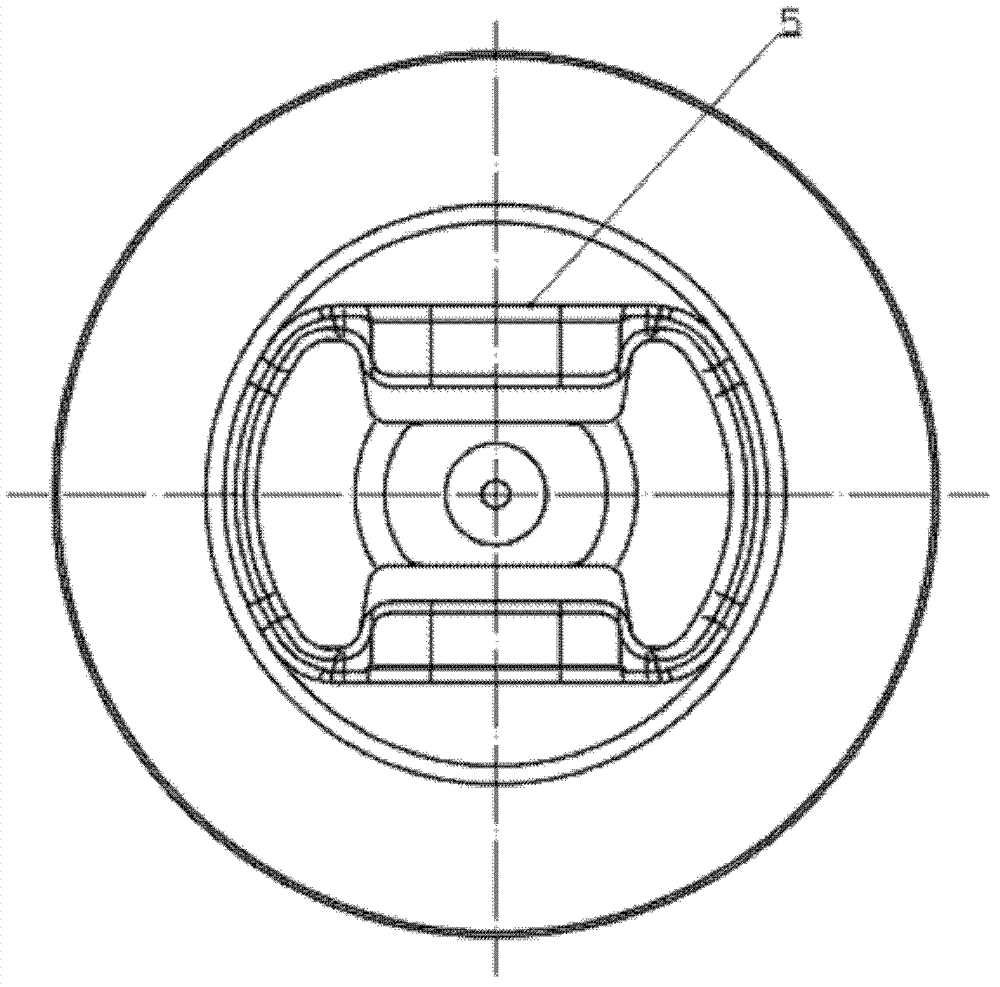

Spin-forming mould for kettle body of sliver kettle

InactiveCN105057461AReduce consumptionIncrease production capacityShaping toolsMaterial consumptionEngineering

The invention provides a spin-forming mould for a kettle body of a sliver kettle. The spin-forming mould comprises a mould rack, a kettle body internal supporting module arranged on the mould rack, a kettle body external forming module and a kettle body closing-in and rolling module, wherein the kettle body is arranged between the kettle body internal supporting module and the kettle body external forming module; and in a rotary process of the kettle body, the kettle body closing-in and rolling module can apply pressure to the kettle body, so that the kettle body completes closing-in. According to the spin-forming mould for the kettle body of the sliver kettle, the material consumption is reduced, the labor amount of an operator is reduced and the manufacturing cost can be effectively saved, and a manufactured product is light, uniform in thickness and high in yield.

Owner:宜兴瑞鑫贵金属艺术品有限公司

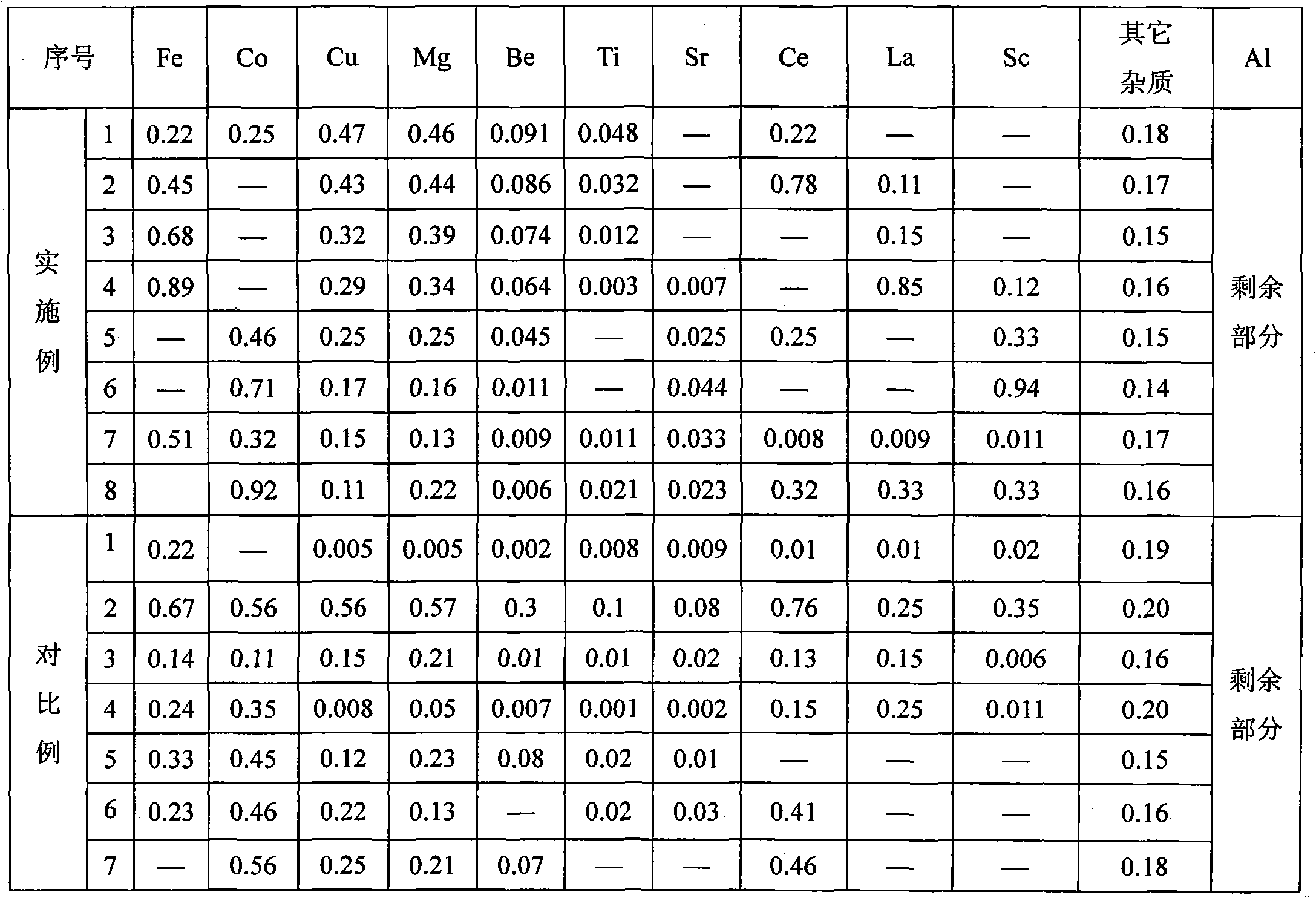

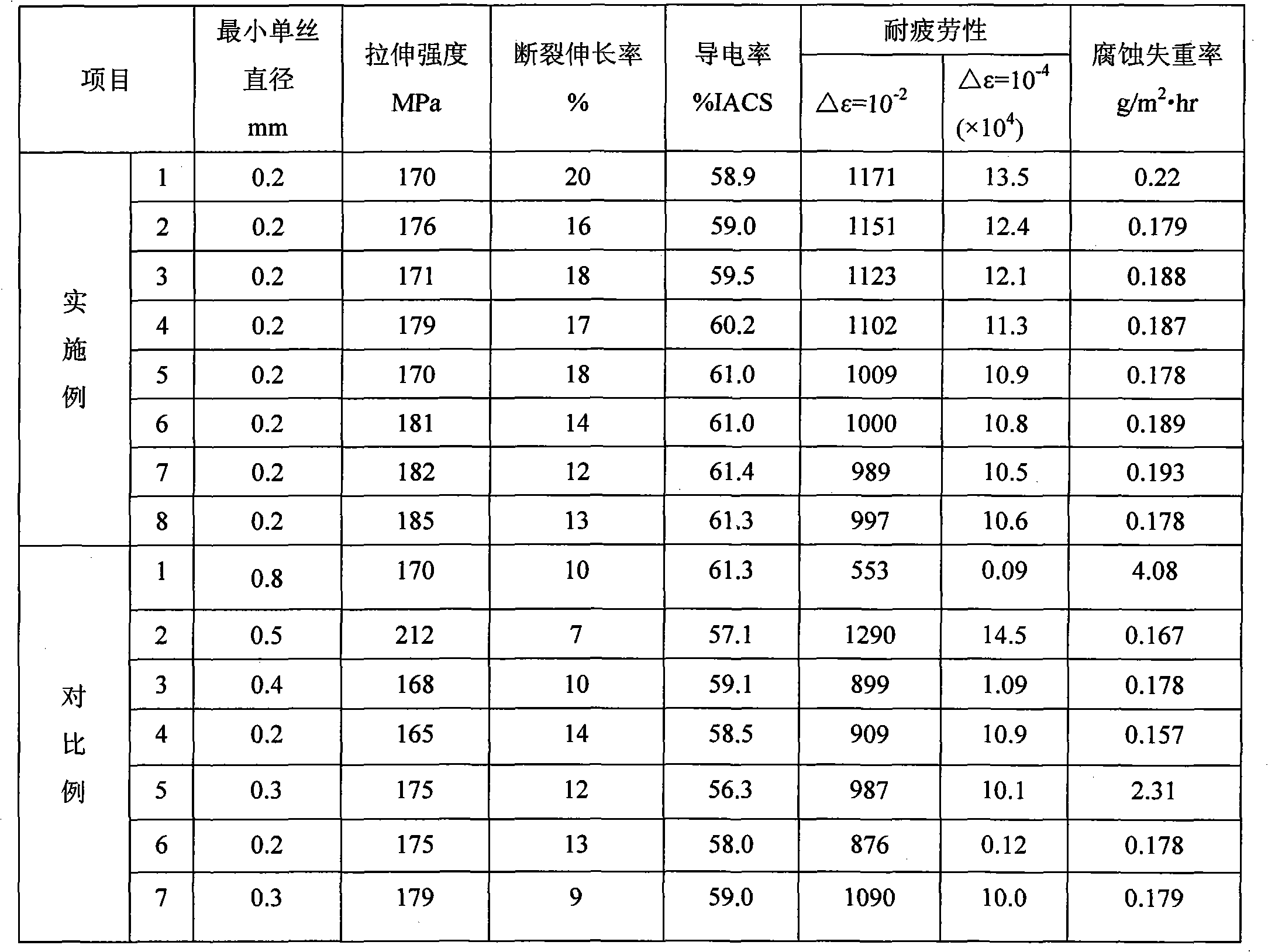

Aluminum, ferrum and cobalt rare earth alloy conductor material for cable and manufacturing method thereof

InactiveCN101923909AConductivity has little effectPlay a reinforcing roleInsulated cablesMetal/alloy conductorsElectrical conductorRare earth

The invention discloses an aluminum, ferrum and cobalt rare earth alloy conductor material for a cable and a manufacturing method thereof. The contents of the alloy components are Fe, Co, lanthanum-enriched rare earth, Si, less than 0.01% by weight of other single impurity, wherein the total amount is less than 0.15% by weight, and the balance of aluminum and inevitable impurities. The manufacturing method comprises the following steps of: adding an aluminum ingot with the purity greater than 99.70% by weight into a vertical furnace; adding an aluminum and ferrum intermediate alloy, an aluminum and cobalt intermediate alloy and an aluminum rear earth intermediate alloy at different temperature stages for smelting; and after purifying the melt, rolling the casting pieces into an alloy. The electric conductivity of the aluminum alloy conductor is greater than or equal to 60% IACS, the tensile strength of a hard alloy wire reaches 240MPa, the tensile strength and the coefficient of elongation of a soft alloy wire reach 120MPa and 30% respectively, the limit of yielding is 100-115MPa, and the aluminum alloy conductor can be pulled to an aluminum alloy wire with the thickness of 0.3mm or less.

Owner:欣意(通辽)特种电缆有限公司

Aluminum alloy mobile telephone shell

InactiveCN107974594AHigh strengthImprove plasticityVacuum evaporation coatingSputtering coatingComposite filmMobile phone

The invention discloses an aluminum alloy mobile telephone shell comprising a shell body; the surface of the shell body is coated with a nanoscale composite film layer in a vacuum mode. The thicknessof the shell body is 0.1-0.3 mm. The thickness of the nanoscale composite film layer is 200-300 nm. The thickness of shell body is 0.2 mm, and the thickness of the nanoscale composite film layer is 250 nm. The nanoscale composite film layer is a nano-sliver layer. The shell body is aluminum alloy sections. The aluminum alloy sections using in the shell body has good high tensile strength, high yield strength, high extending rate, anti-corrosion property, and high-temperature stability, and the performance of the aluminum alloy sections is higher than iron pipe.

Owner:JIANGSU SAIBO YUHUA TECH CO LTD

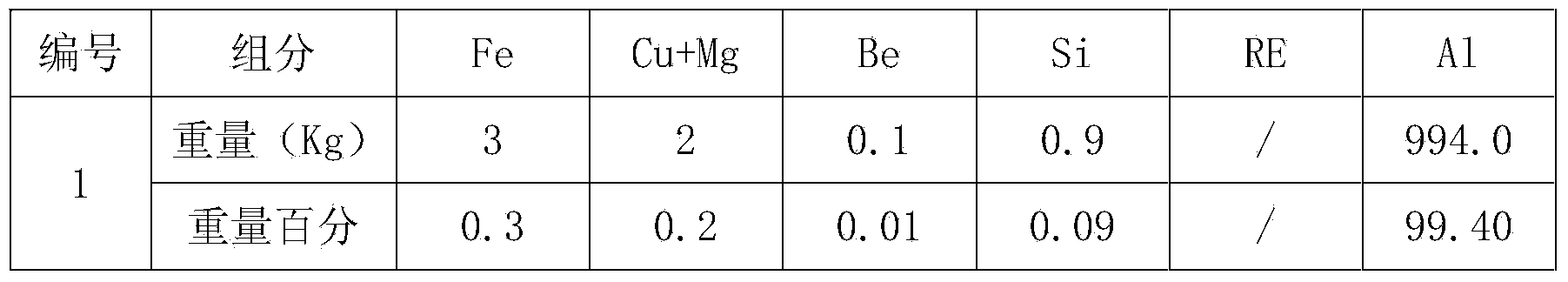

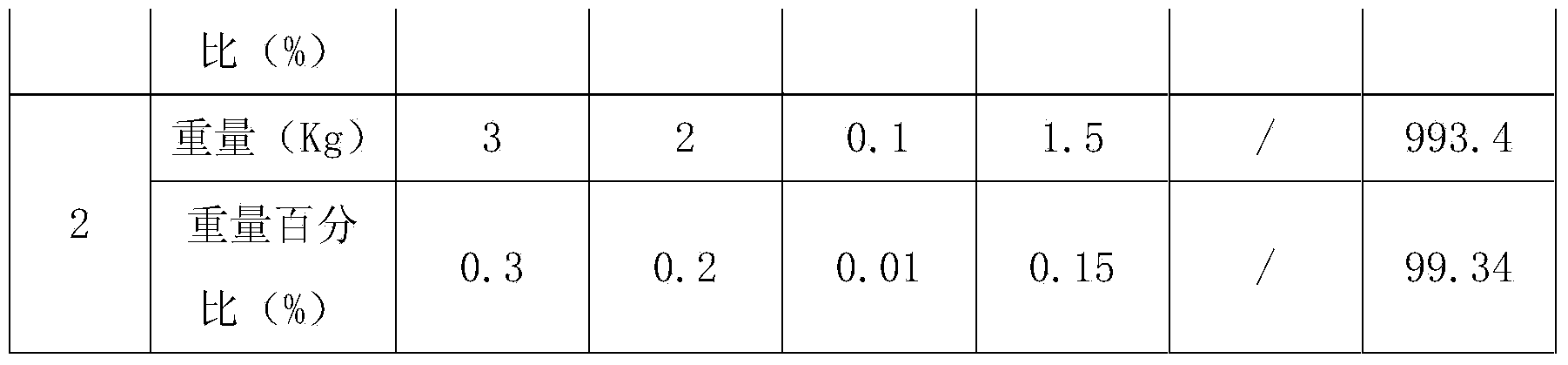

Al-Fe-Cu-Mg-Be alumium alloy for automobile wire and wiring harness therefore

PendingCN103725930AHigh mechanical strengthImprove tensile propertiesNon-insulated conductorsMetal/alloy conductorsSurface finishUltimate tensile strength

The invention discloses an Al-Fe-Cu-Mg-Be alumium alloy for an automobile wire and a preparation method thereof, and an automobile wiring harness prepared by the preparation method. The Al-Fe-Cu-Mg-Be alumium alloy for the automobile wire comprises the following components: 0.2-1.4wt% of Fe, 0.01-0.5wt% of Cu+Mg, 0.001-0.2wt% of Be, and the balance of Al and inevitable impurities. According to the invention, Fe element is added so that the mechanical strength and the tensile property of the alloy can be improved; Fe is also capable of obviously improving the high-temperature creep resistance and the fatigue resistance of the alloy; the addition of Cu+Mg is capable of improving the strength and the high-temperature creep property and the fatigue resistance of the alloy; Be is capable of improving the smelting quality of the alloy and the compactness of the surface oxide film, so that good-quality castings good in surface smoothness, high in strength and improved in ductility can be obtained; Be is also capable of improving the fluidity of the alloy so that the fluidity of the melt is improved, and can further improve the tensile strength and the limit of yielding of the alloy.

Owner:ANHUI JOY SENSE CABLE

Preparing process of aluminum alloy for mobile phone shell

The invention discloses a preparing process of an aluminum alloy for a mobile phone shell. The aluminum alloy comprises, by weight percent, 3 to 6% of Zn, 1 to 2% of Mg, 0.5 to 2% of Cu, 0.5 to 1.5% of Si, 0.01 to 0.1% of B, 0.5 to 1% of Fe, 0.1 to 2% of Ni, 0.1 to 2% of Mo, not larger than 0.02% of Cr, not larger than 0.025% of Ti, not larger than 0.1% of Zr, 0.2 to 1% of rare earth, not larger than 0.01% of other single impurities and the balance aluminum. The aluminum alloy prepared through the process improves the preparing process of an existing aluminum alloy, on the basis of ensuring strength and machining performance of the aluminum alloy, the friction resistance properties and excellent heat conduction properties are considered, and the aluminum alloy is suitable for being used inthe mobile phone shell.

Owner:山东创新精密科技有限公司

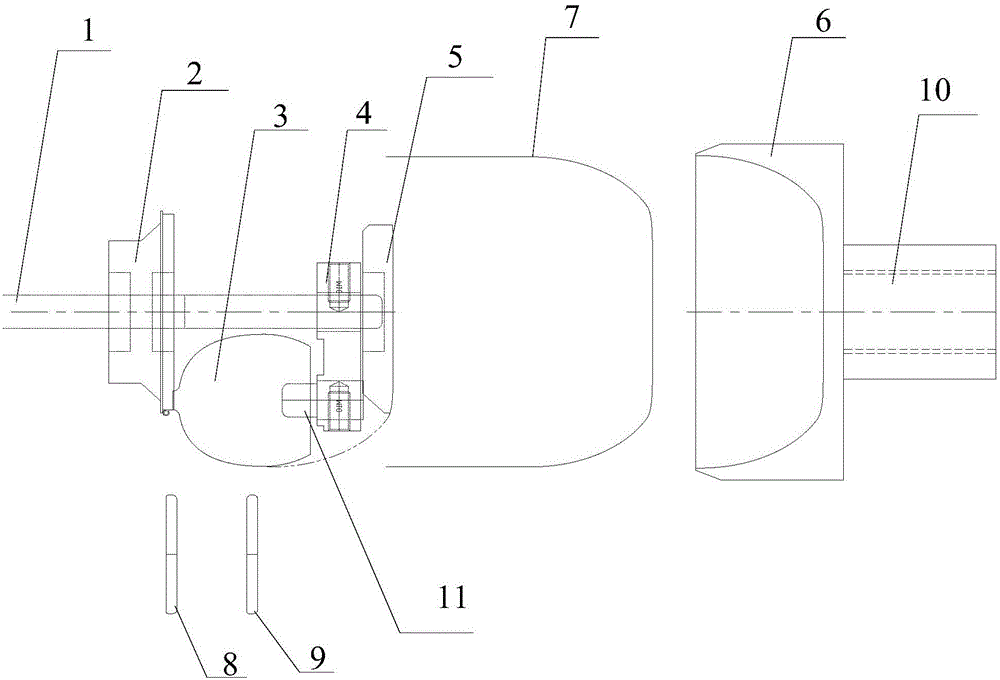

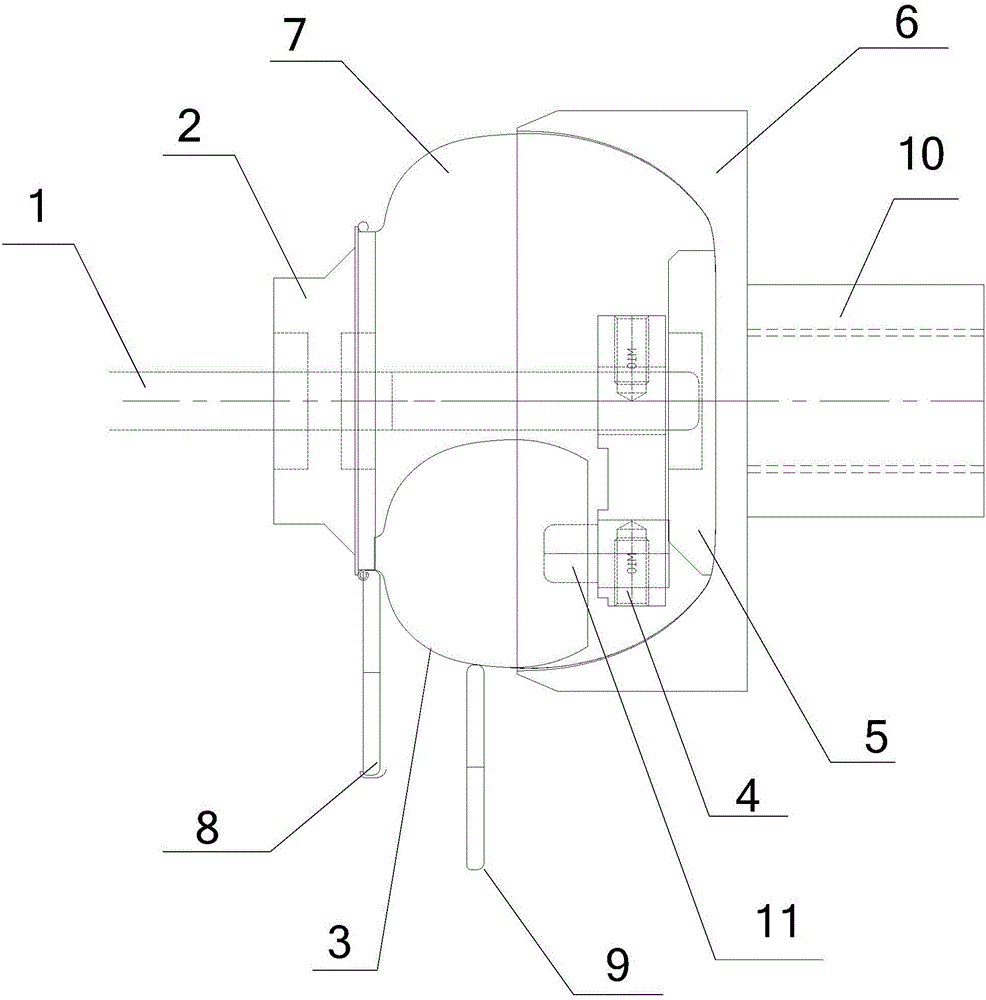

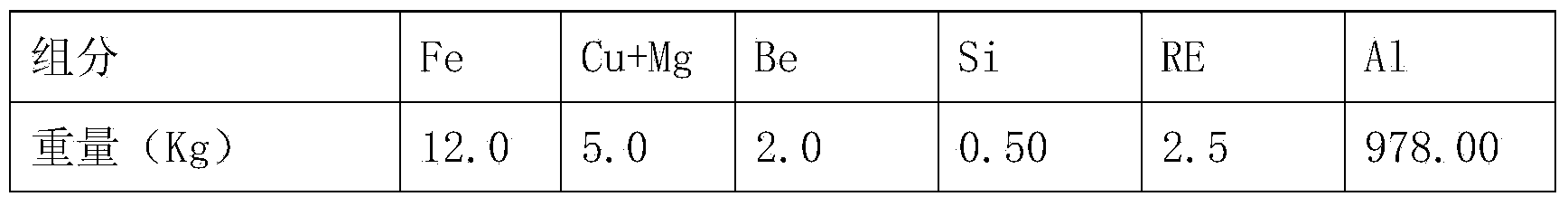

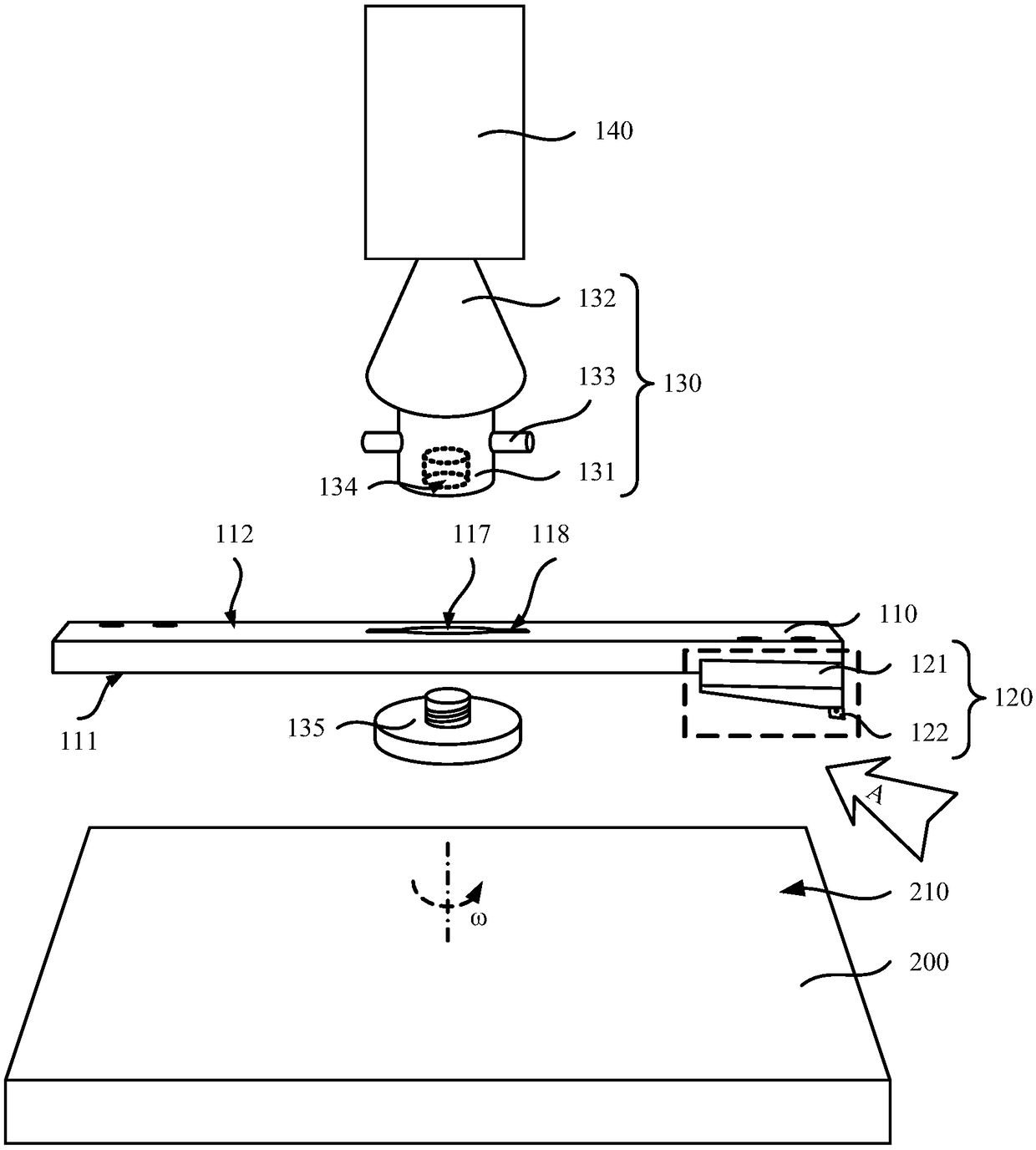

Method and device for forming stepped cylindrical member through laser impact

The invention discloses a method and device for forming a stepped cylindrical member through laser impact, and belongs to the technical field of sheet metal forming. Nano-sized carbon particles are uniformly mixed with deionized water, then the mixture is sprayed on an absorption layer as a constraining layer, when a laser beam is irradiated to the suspended carbon particles and the absorption layer, an axial shock wave with direction of the acting force parallel to an optical axis is formed, while the suspended carbon particles absorb the laser energy, a lateral shock wave propagating to theperiphery is formed, so that a thin metal plate is plastically deformed, and the thin metal plate is bonded to an cavity of a concave mold. A combined die with adjustable depth is adopted, the pulsedlaser beam with small energy is adopted to impact the thin metal plate in multiple steps, and finally the complicated stepped cylindrical member with large forming depth and good forming quality is formed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Technology for manufacturing hotly-spun pressed forged steel single-piece piston with inner cooling oil cavity

The invention discloses a technology for manufacturing a hotly-spun pressed forged steel single-piece piston with an inner cooling oil cavity, which comprises the following steps of: forging piston blanks; mechanically processing the piston blanks to obtain the piston as a semi-finished product with an inside part of the inner cooling oil cavity and a covering part for blocking the inner cooling oil cavity, heating the covering part and downwardly spinning the covering part of the inner cooling oil cavity in the piston by the hot spinning technology to contact the inside part of the inner cooling oil cavity to form a complete inner cooling oil cavity; and not processing gaps of the inside part and the covering part of the inner cooling oil cavity, remaining the gaps or simply sealing by the general welding technology, such as argon arc welding and the like, and precisely processing into the piston as a finished product. The hotly-spun pressed forged steel single-piece piston with the inner cooling oil cavity manufactured by the technology disclosed by the invention is simple in structure, relatively easy and convenient to manufacture, high in production efficiency and low in manufacturing cost, and can meet the requirements of an engine on high power, high strength, and low emission, and the like.

Owner:BINZHOU BOHAI PISTON CO LTD

Sleeve suitable for evaporite bed of oil well

InactiveCN102383040AHigh yield strengthHigh yield limitDrilling rodsDrilling casingsTrace elementMechanical property

The present invention provides a sleeve which is suitable for an evaporate bed of an oil well, which is composed of the following components by weight: 0.26%-0.31% of C; 0.25-0.35% of Si; 0.80-1.00% of Mn; less than or equal with 0.015% of P; less than or equal with 0.010% of S; 0.90-1.00% of Cr; 0.40-0.50% of Mo; 0.07-0.10% of V; and the balance of Fe and inevitable trace elements. The mechanical property is characterized in that: the yield strength is between 896MPa and 1034MPa; the tensile strength is larger than or equal with 1000MPa; an impact toughness index is characterized in that a Charpy impact energy is larger than or equal with 42J (0 DEG C+ / -3, 10*10*55mm, transverse sample); the elongation percentage is larger than or equal with 16%; the wall thickness precision reaches + / -10%; a ratio between an external diameter and the wall thickness reaches 9-14; the collapse resistance strength index exceeds an API 5C3 theoretical value for more than 40%; and the steel pipe is a seamless polished pipe structurally. The sleeve which is suitable for the evaporate bed of the oil well is advantageous in that: the ratio between the external diameter and the wall thickness is 9-14 under a non-uniform load environment when the non-uniform load Pu is larger than PO, an obvious advantage is obtained; and the sleeve can bear larger non-uniform load.

Owner:TIANJIN PIPE (GROUP) CORP

Heat-resistant aluminum-alloy conductor material for cables and manufacture method thereof

InactiveCN101948971BImprove creep resistanceHigh tensile strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare-earth elementElectrical conductor

Owner:绩溪欣意圣厚源电缆有限公司

High-strength low-temperature lead-free welding flux and tin soldering paste thereof

InactiveCN110125571AImproved tensile and shear strengthIncreased shear strengthWelding/cutting media/materialsSoldering mediaAlloy elementSoldering

The invention discloses high-strength low-temperature lead-free welding flux and tin soldering paste thereof. According to the high-strength low-temperature lead-free welding flux and tin soldering paste thereof disclosed by the invention, an alloy element In is added into an existing Sn-Bi brazing filler metal system, and In accounts for 15%-45% in percentage by mass. In the high-strength low-temperature lead-free welding flux and tin soldering paste thereof, components are as follows in percentage by weight: 34%-36% of Sn, 38%-40% of Bi, 24%-27% of In or the balance of In, based on 100% in total. With the adoption of the technical scheme, the high-strength low-temperature lead-free welding flux and tin soldering paste thereof have the advantages of being good in bonding pad adhesion, high in welding strength, low in melting point and moderate in cost.

Owner:深圳市唯特偶新材料股份有限公司

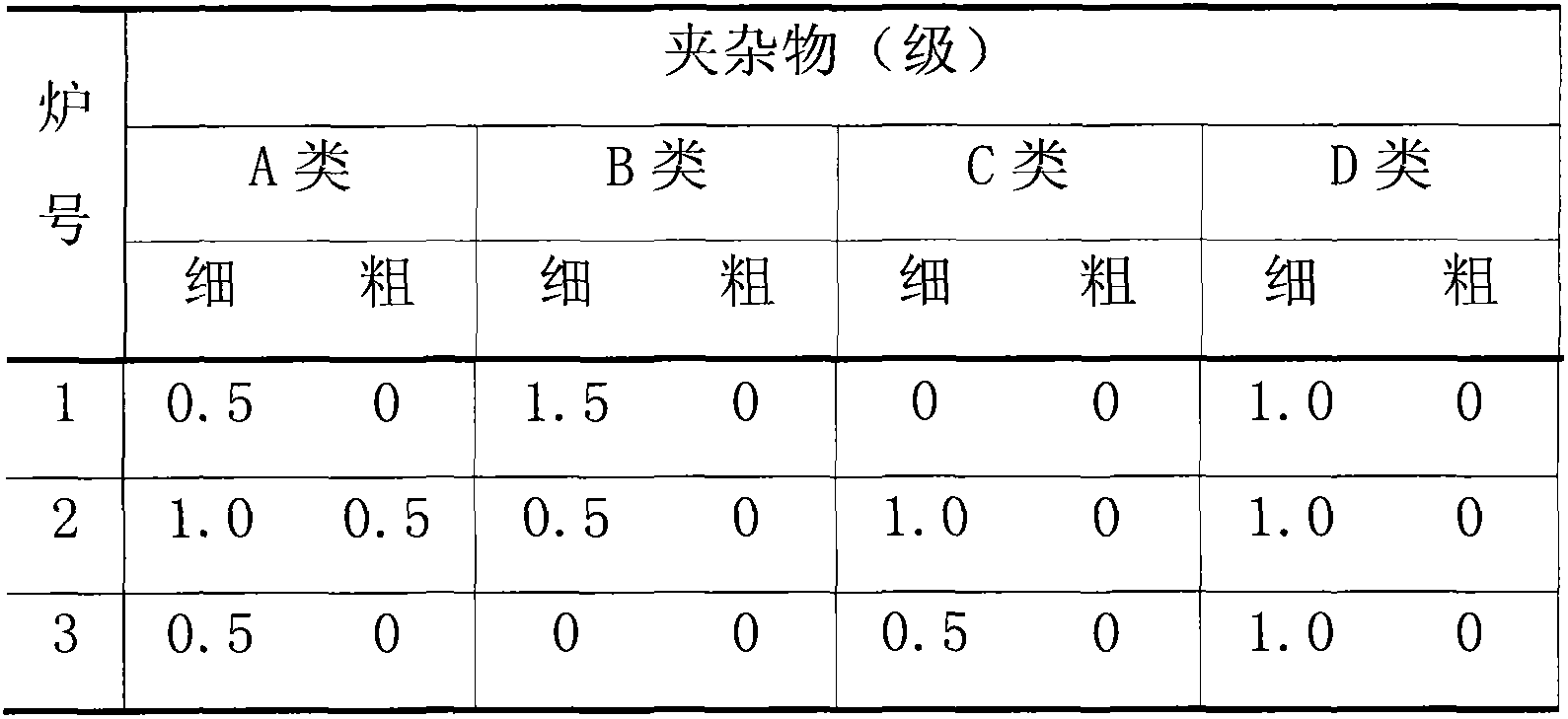

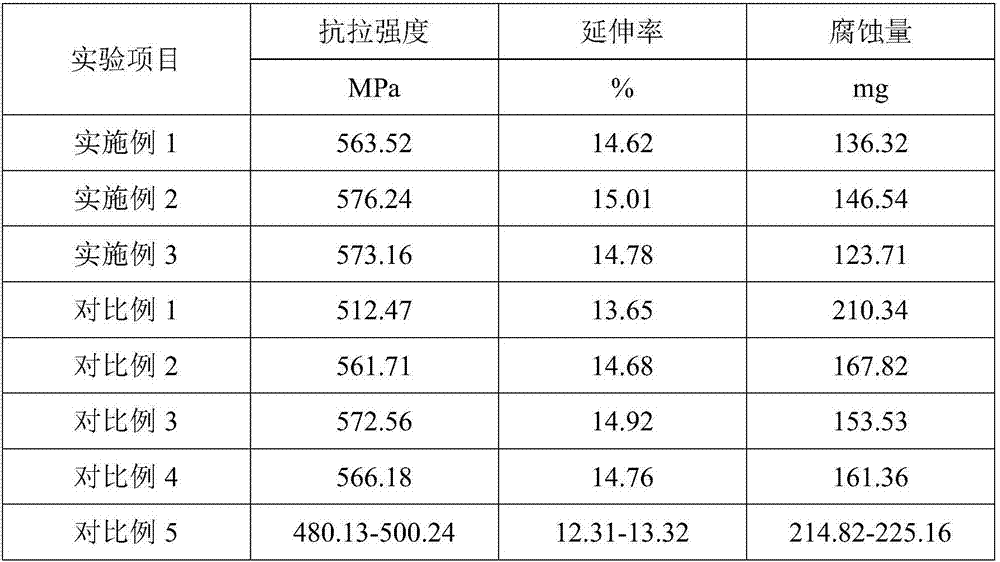

Automobile body plate aluminum alloy containing rare earths and preparation method of automobile body plate aluminum alloy

The invention discloses an automobile body plate aluminum alloy containing rare earths and a preparation method of the automobile body plate aluminum alloy, and belongs to the technical field of aluminum alloy preparation. The automobile body plate aluminum alloy containing rare earths comprises titanium, zinc, iron, silicon, manganese, copper, carbon, chromium, boron, magnesium, molybdenum, tungsten, vanadium, rare earth, refining agents, sodium alcohol ether sulphate, grain refinement agents and aluminum. The automobile body plate aluminum alloy containing rare earths is formed by the stepsof melting, refining, slagging, casting and the like. By means of the automobile body plate aluminum alloy containing rare earths, the tensile strength, elongation and corrosion resistance of the aluminum alloy can be improved obviously.

Owner:湖南恒佳新材料科技有限公司

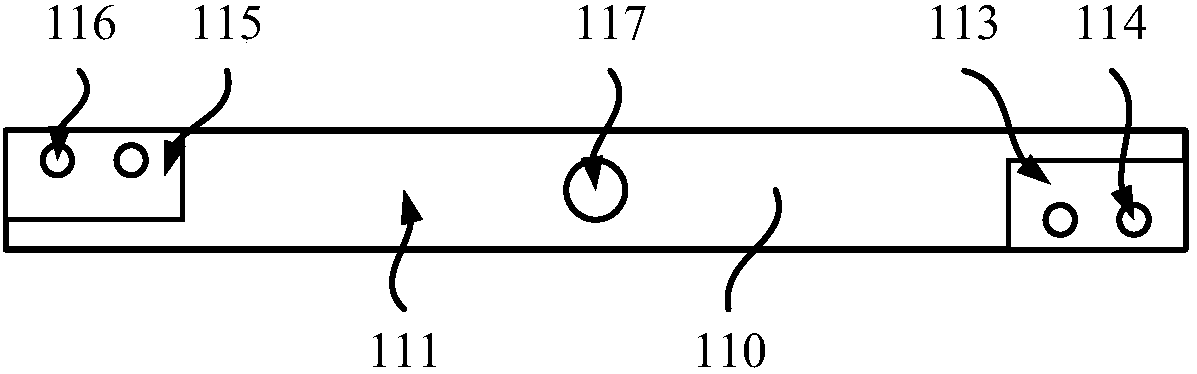

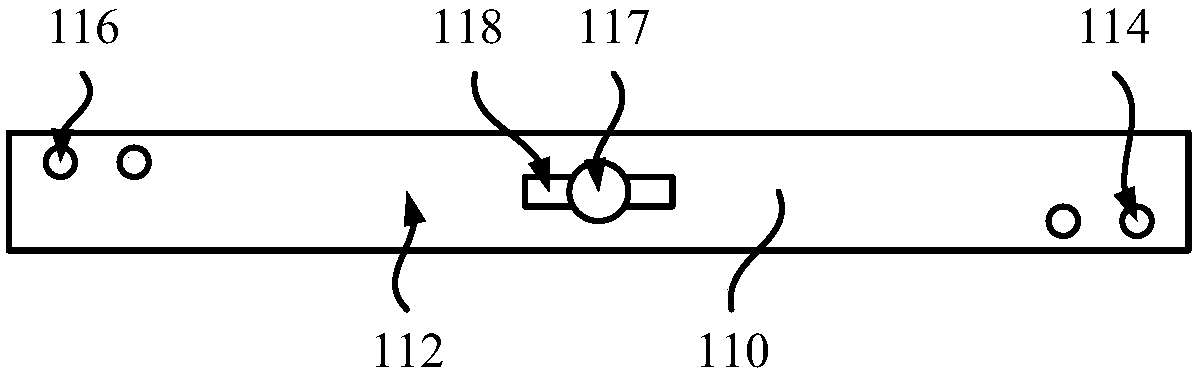

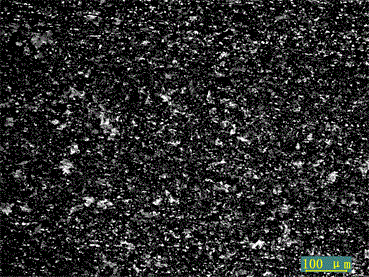

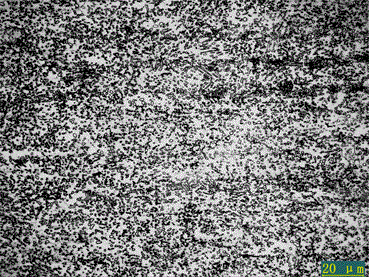

Cutter for processing sputtering face of target material and processing method

ActiveCN109261998AIncrease roughnessImprove uniformityBoring barsTurning toolsSputteringCivil engineering

The invention relates to a cutter for processing a sputtering face of a target material and a processing method. The cutter comprises a cutter rod and a cutter head. The cutter rod is provided with afirst face and a second face which are oppositely arranged; the cutter head is located on the first face and fixed to one end of the cutter rod in the extension direction and comprises a fixing base and a blade, the fixing base is fixedly connected with the cutter rod, the blade is connected with the fixing base, and an edge of the blade protrudes out of the surface of the fixing base. When the cutter is used for processing a to-be-processed surface, a continuous grain can only be formed on the to-be-processed surface, and the formed grain cannot cross; through formation of the continuous anduncrossed grain, the evenness of the sputtering grain of the target material can be effectively improved, the quality of the grain of the sputtering face of the target material is conveniently improved, the roughness of the sputtering face of the target material is improved, and accordingly the formed product meets the quality demand.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Aluminum alloy wire harness for light automobile and preparation method thereof

InactiveCN110157958AHigh strengthImprove high temperature creep performanceConductive materialManufacturing wire harnessesElectrical conductorPotassium

The invention discloses an aluminum alloy wire harness for a light automobile. The aluminum alloy wire harness for the light automobile comprises a conductor wire core and an outer layer insulating layer, wherein the conductor wire core comprises the following components of 0.2wt%-0.4wt% of V, 0.01wt%-0.3wt% of Cu+Mg, 0.001wt%-0.01wt% of Sb, 0.01wt%-0.05wt% of Ti, 0.001wt%-0.002wt% of Ag+F, 0.001wt%-0.003wt% of Zr, 0.1wt%-0.3wt% of RE, and the balance is Al; the alloy does not contain Si and Fe; Ce and La are 50% of the total amount of the RE or more; and in a wire drawing process, the conductor wire core is firstly subject to dipping in a mixed solution of potassium fluoborate and polydimethylsiloxane, intermediate annealing in a nitrogen atmosphere containing 5% oxygen concentration is carried out, and then wire drawing is carried out. According to the aluminum alloy wire harness and the preparation method, V, Ti, Ag, F and Zr are adopted as reinforcing systems and secondary smeltingis adopted, so that the elongation at break and the tensile strength of the aluminum alloy wire harness for the light automobile are improved.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

A kind of high-carbon cold-rolled automobile diaphragm spring steel and production method thereof

The invention discloses high-carbon cold-rolled automobile diaphragm spring steel. The high-carbon cold-rolled automobile diaphragm spring steel is prepared from the following constituents in percentage by weight: 0.70-0.90% of C, 0.15-0.35% of Si, 0.50-1.00% of Mn, P smaller than or equal to 0.008%, S smaller than or equal to 0.002%, 0.010-0.030% of Alt, 0.10-0.30% of V, 1.20-2.00% of Cr, 1.20-2.00% of Ni, 0.002-0.006% of Ca, and N smaller than or equal to 0.004%, and is prepared by the following production steps: molten iron desulphurization, smelting in a converter, refining in an LF (Ladle Furnace) furnace, processing in a RH vacuum furnace, continuous casting to form blanks, pit type slow cooling after cutting of cast blanks, cast blank heating, segmented hot rolling, reeling, slow cooling, annealing after cutting, cold rolling, quenching, tempering, and inspection for standby. The steel disclosed by the invention is rolled and thermally treated to achieve high strength, high elasticity, high limit of yielding, high fatigue limit resistance, low-temperature toughness and longer service life, and can be used for manufacturing various vehicle clutch assemblies, especially the large engineering machinery at the low temperature environment.

Owner:武汉钢铁有限公司

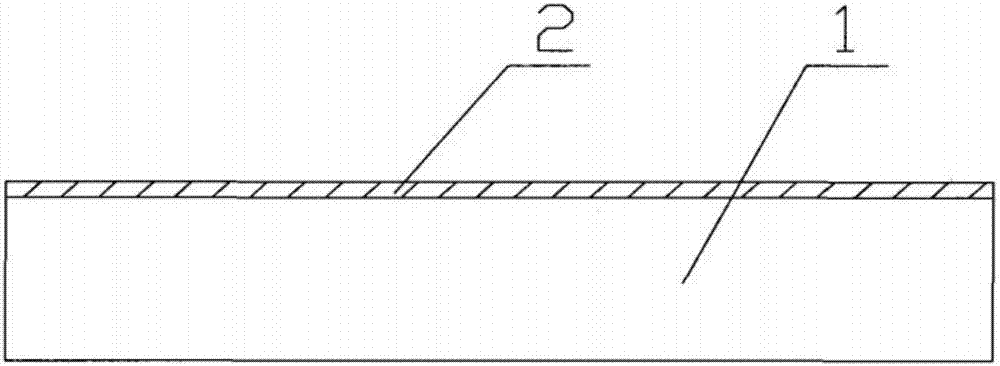

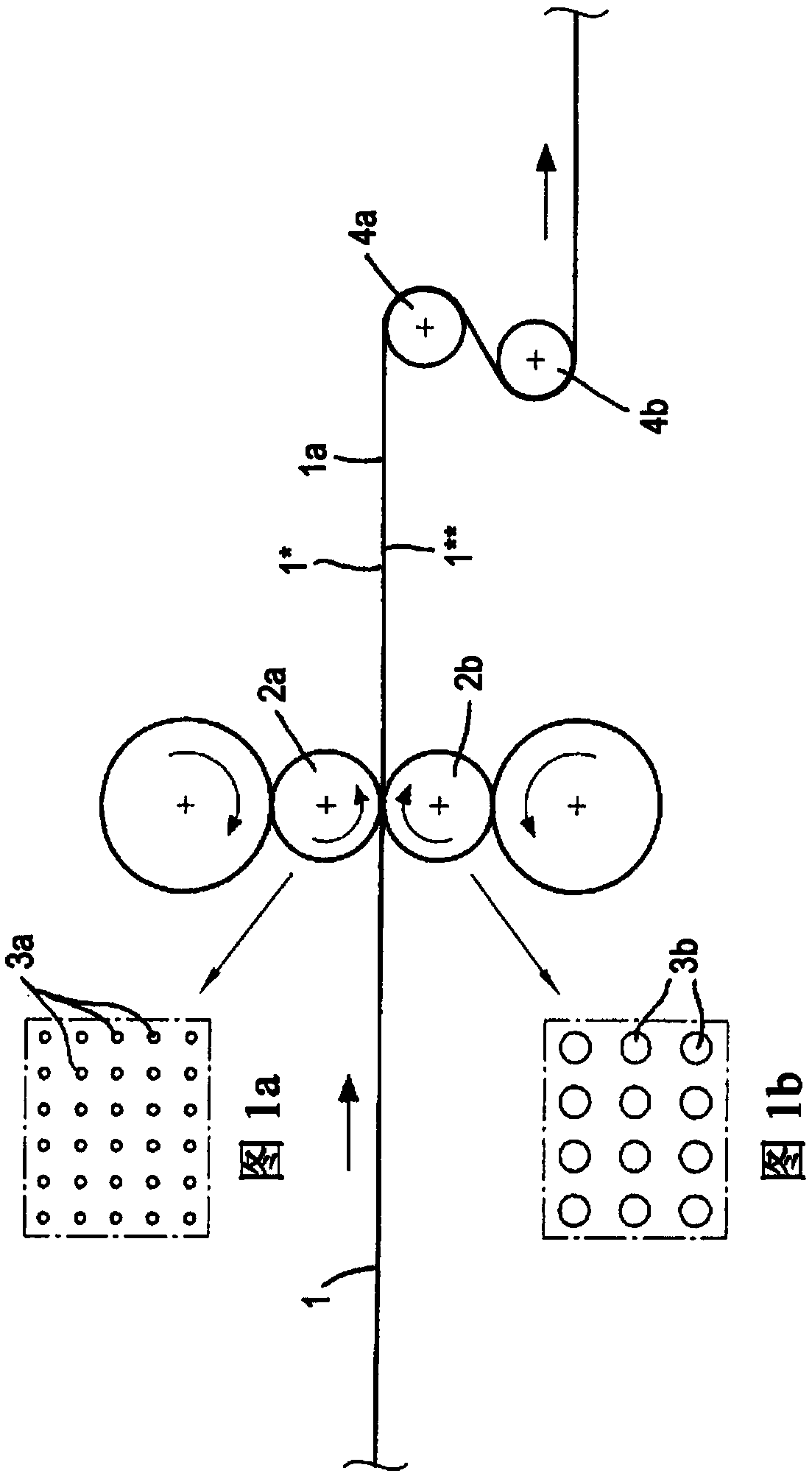

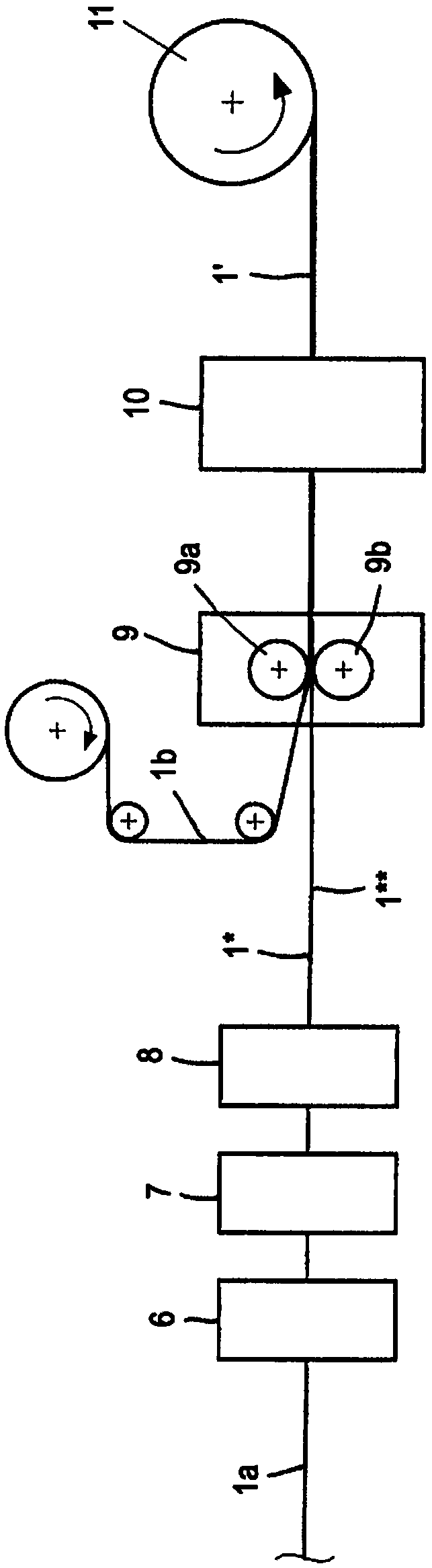

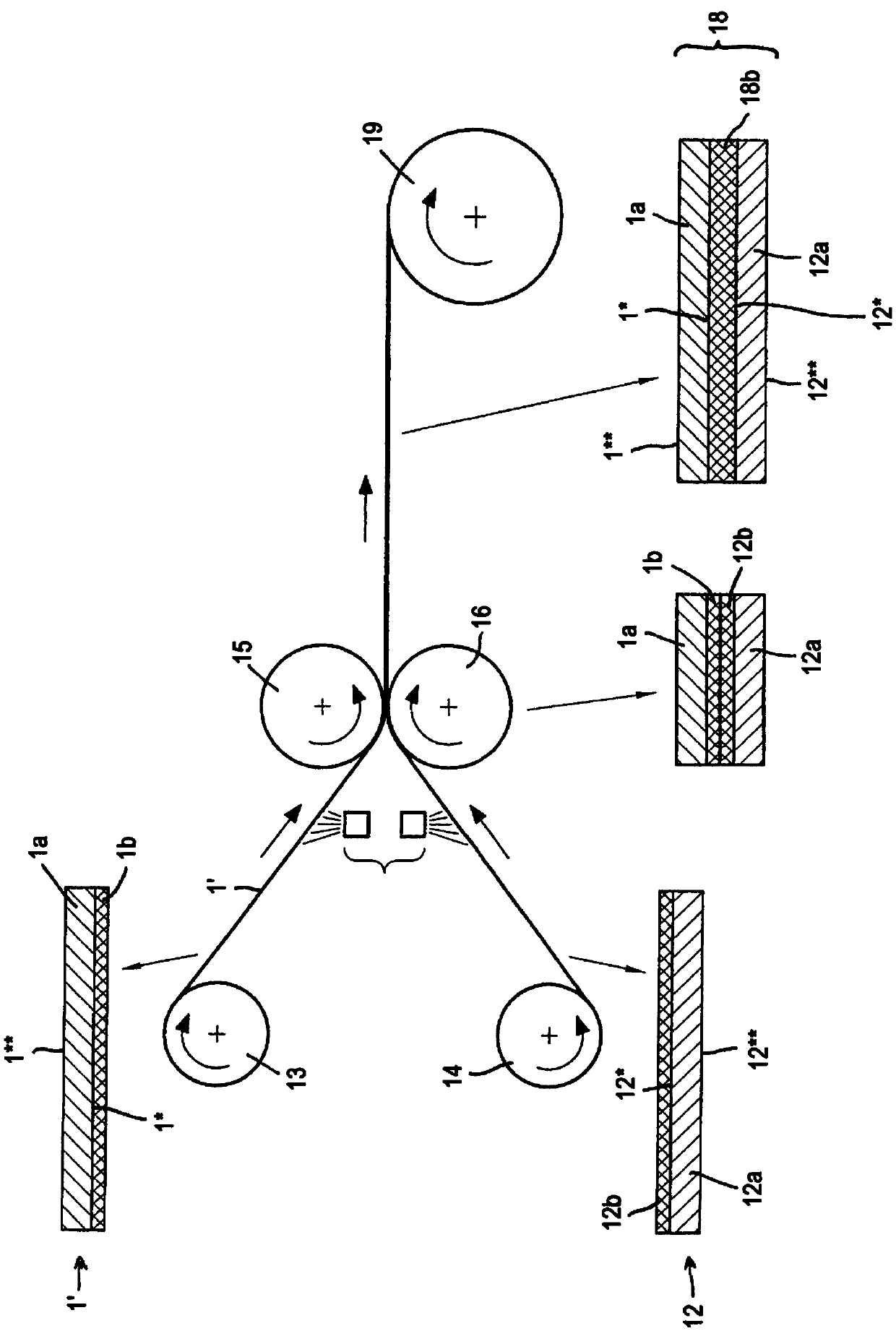

Metal-plastic sandwich sheet and method for the production thereof

InactiveCN105555526AHigh yield limitReduced risk of partial shrinkageLaminationLamination apparatusSurface roughnessEngineering

The present invention provides a metal-plastic sandwich sheet and a method for the production thereof. The invention relates to a metal-plastic sandwich sheet (18) having metallic outer sheets (1a, 12a) and at least one plastic layer (1b, 12b; 18b) which is arranged between the outer sheets and is bonded integrally to the outer sheets (1a, 12a). In order to improve a sandwich sheet of this type in respect of the further-processing properties thereof, the invention proposes that at least one of the two outer sheets (1a, 12a) is formed from a metal sheet having surfaces (1*, 1**, 12*, 12**) of differing roughnesses, wherein the difference in the roughness averages is at least 0.4 [micro]m, preferably at least 0.5 [micro]m. The invention is based on the concept of manufacturing the outer sheets (1a, 12a) with a differing roughness on the top and bottom side (outer and inner face) thereof, such that it is possible to freely satisfy the respective optimum in respect of the roughness desired by the customer for the outer faces of the sandwich material and also the optimum in respect of the bond between the outer sheet (1a, 12a) and the plastic layer (1b, 12b; 18b). A method for producing such a sandwich sheet (18) is also described and claimed.

Owner:THYSSENKRUPP STEEL EURO AG

Al-Mg aluminum alloy, preparation method thereof and aluminum alloy cable

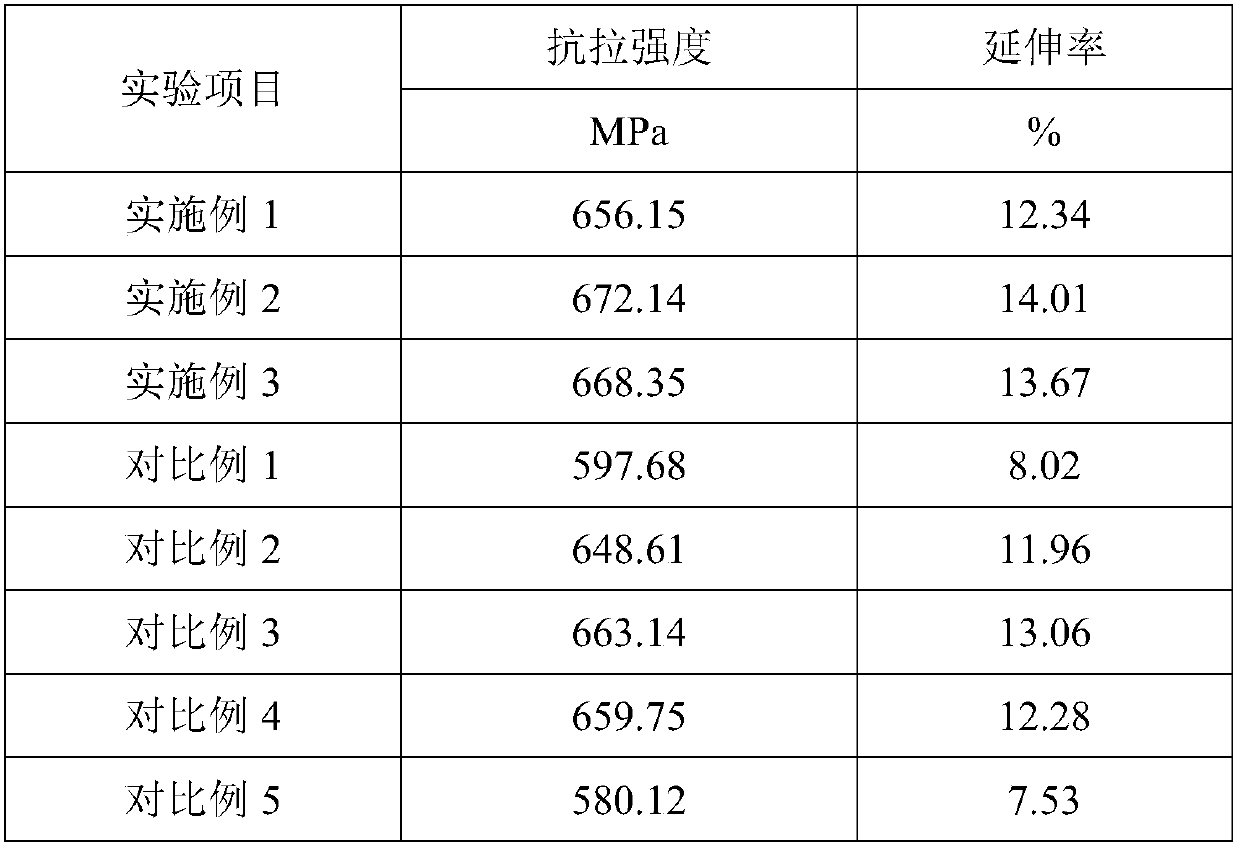

PendingCN103667817AHigh mechanical strengthImprove tensile propertiesMetal/alloy conductorsIngotSolid solution

The invention provides Al-Mg aluminum alloy. The invention additionally provides a preparation method of the Al-Mg aluminum alloy. The preparation method of the Al-Mg aluminum alloy comprises the steps of a) casting aluminum alloy ingots; b) sequentially performing solid solution treatment and aging treatment on the aluminum alloy ingots, and rolling the aluminum alloy ingots after the aging treatment to obtain the aluminum alloy. The invention additionally provides an aluminum alloy cable. By selecting and controlling added elements and by adopting a proper preparation process, the aluminum alloy is enabled to have better comprehensive performance.

Owner:ANHUI JOY SENSE CABLE

Grain refiner and application to preparation of rare earth aluminum alloy materials

The invention discloses a grain refiner and application to preparation of rare earth aluminum alloy materials, and belongs to the technical field of aluminum alloy preparation. The grain refiner comprises the following raw materials in parts by weight: 10-18 parts of aluminum-nickel-manganese-copper-lanthanum alloy intermediate, and 4-9 parts of aluminum-titanium-zirconium-cerium alloy intermediates. The grain refiner is adopted to prepare the rare earth aluminum alloy materials, so that the tensile strength and the ductility of the aluminum alloy materials can be improved.

Owner:广西胜荣科技集团有限公司

Automatable steel plate spring production process

InactiveCN109136513ASafe to useImprove performanceFurnace typesQuenching agentsSteel platesAqueous solution

The invention discloses an automatable steel plate spring production process which comprises steps of material discharge, straightening, mechanical processing, lug coiling, thermal treatment, shot blasting, undercoating, total assembling, pre-pressing and finish coating. The process is characterized in that the step of thermal treatment comprises the following steps: a, heating a steel plate spring to Ac3 or greater at 40-50 DEG C in a heating furnace, and keeping the temperature; b, soaking the steel plate spring into a solution with 3-8% of sodium chloride and 0.1-0.3% of polyvinyl alcohol at 40-75 DEG C, introducing helium into the solution, and carrying out quenching cooling; c, carrying out spraying washing on the quenched steel plate spring, putting into an annealing furnace, heatingtill a critical temperature, keeping the temperature, and cooling to the room temperature. A special quenching medium is used in the process, and tests show that for most common steel in the market,such as 55Si2Mn, 60Si2Mn and 5SiMnVB, the process has very good hardenability, is free of pollution, free of fire, and safe to use.

Owner:四川宏术汽车钢板弹簧有限公司

Manufacturing process of solid cold-spun forged steel piston with internal cooling oil chamber

The invention discloses a manufacturing process of a solid cold-spun forged steel piston with an internal cooling oil chamber. The manufacturing process comprises the following steps: performing solid forging to obtain a piston blank; machining a semi-finished piston product with an inside part of the internal cooling oil chamber and a shielding part for blocking off the internal cooling oil chamber; then heating the shielding part, and spinning downwards the shielding part of the internal cooling oil chamber of the piston by adopting the hot spinning process so that the shielding part contacts with the inside part of the internal cooling oil chamber so as to form the complete internal cooling oil chamber; and reserving the gap between the inside part and the shielding part of the internal cooling oil chamber and the shielding part without disposal or simply closing the gap by argon-arc welding and other common welding processes, and then performing precision machining to finally obtain the finished piston. The manufacturing process has the advantages of simple structure, more simple and convenient manufacturing procedures, high production efficiency, low manufacturing cost and the like, and can meet the requirements of an engine on high power, high strength and low emission.

Owner:BINZHOU BOHAI PISTON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com