Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

663results about "Boring bars" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boring bar

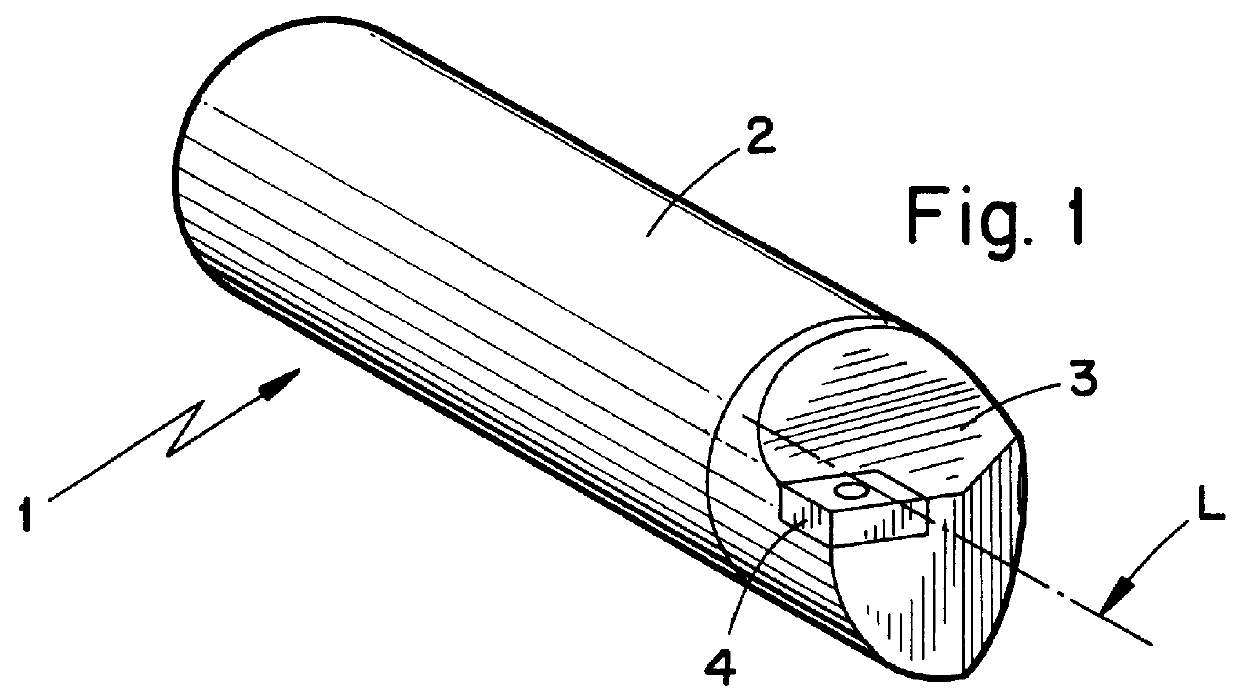

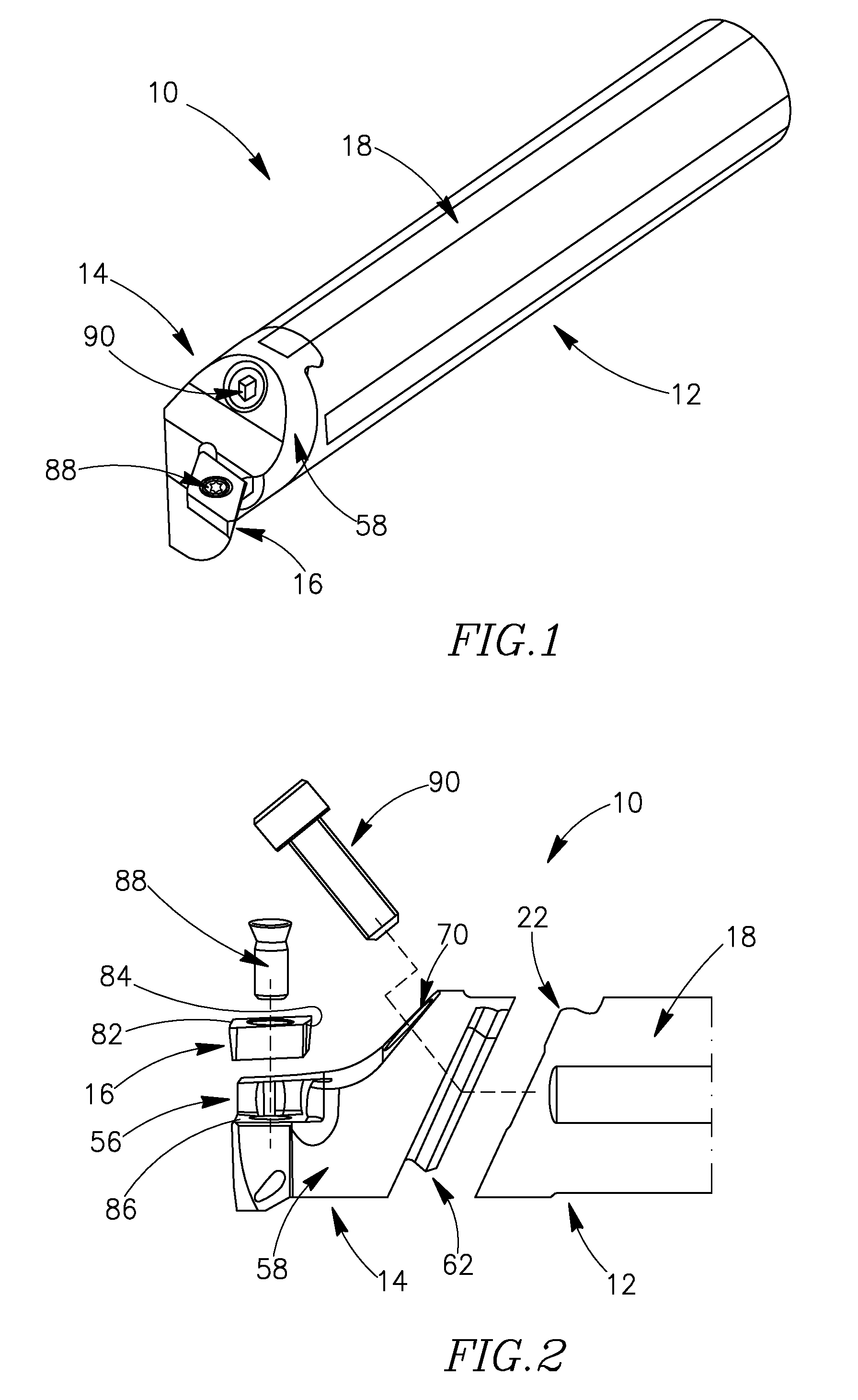

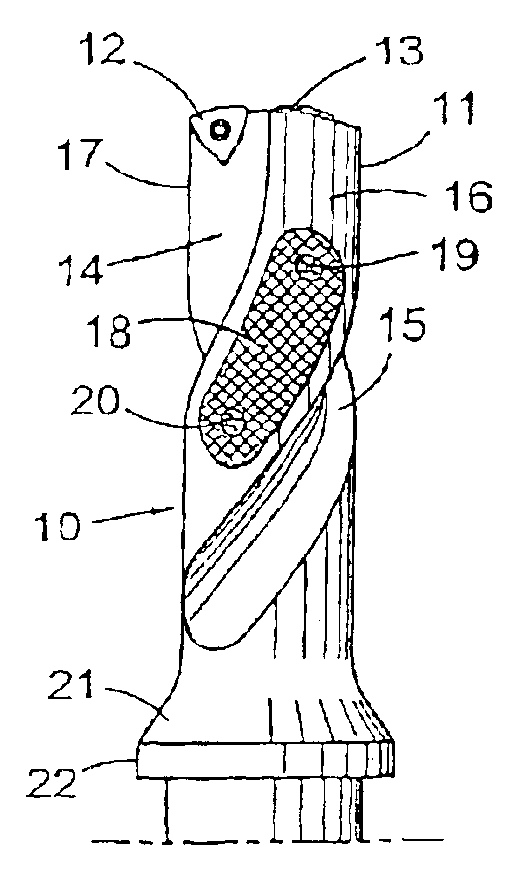

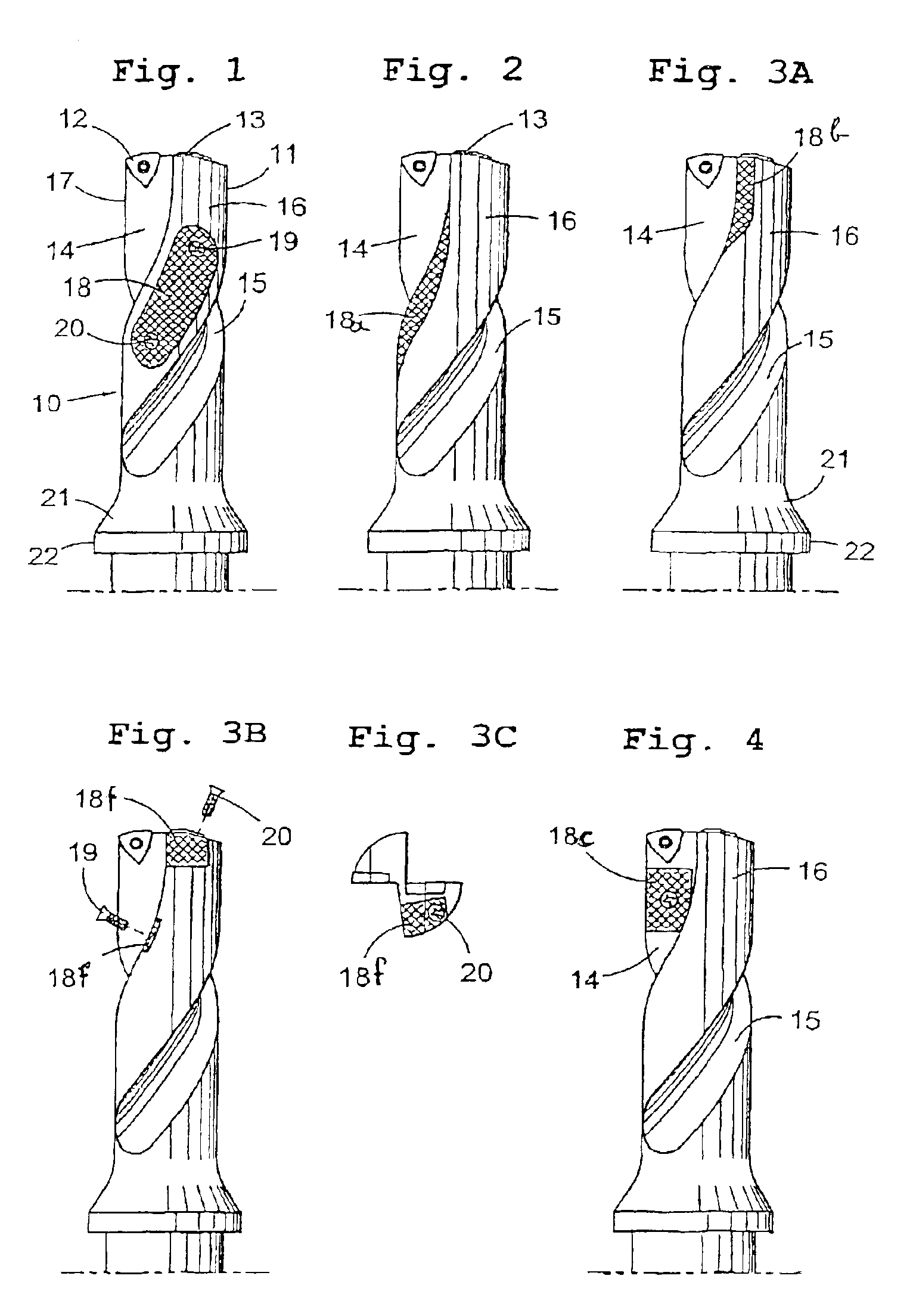

PCT No. PCT / SE97 / 01232 Sec. 371 Date May 14, 1999 Sec. 102(e) Date May 14, 1999 PCT Filed Jul. 7, 1997 PCT Pub. No. WO98 / 01250 PCT Pub. Date Jan. 15, 1998A boring bar includes a shaft and a head which carries a cutting insert. The head includes a conical protrusion which fits in a correspondingly shaped recess of the shaft and is secured therein by an adhesive joint in order to damp vibrations.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

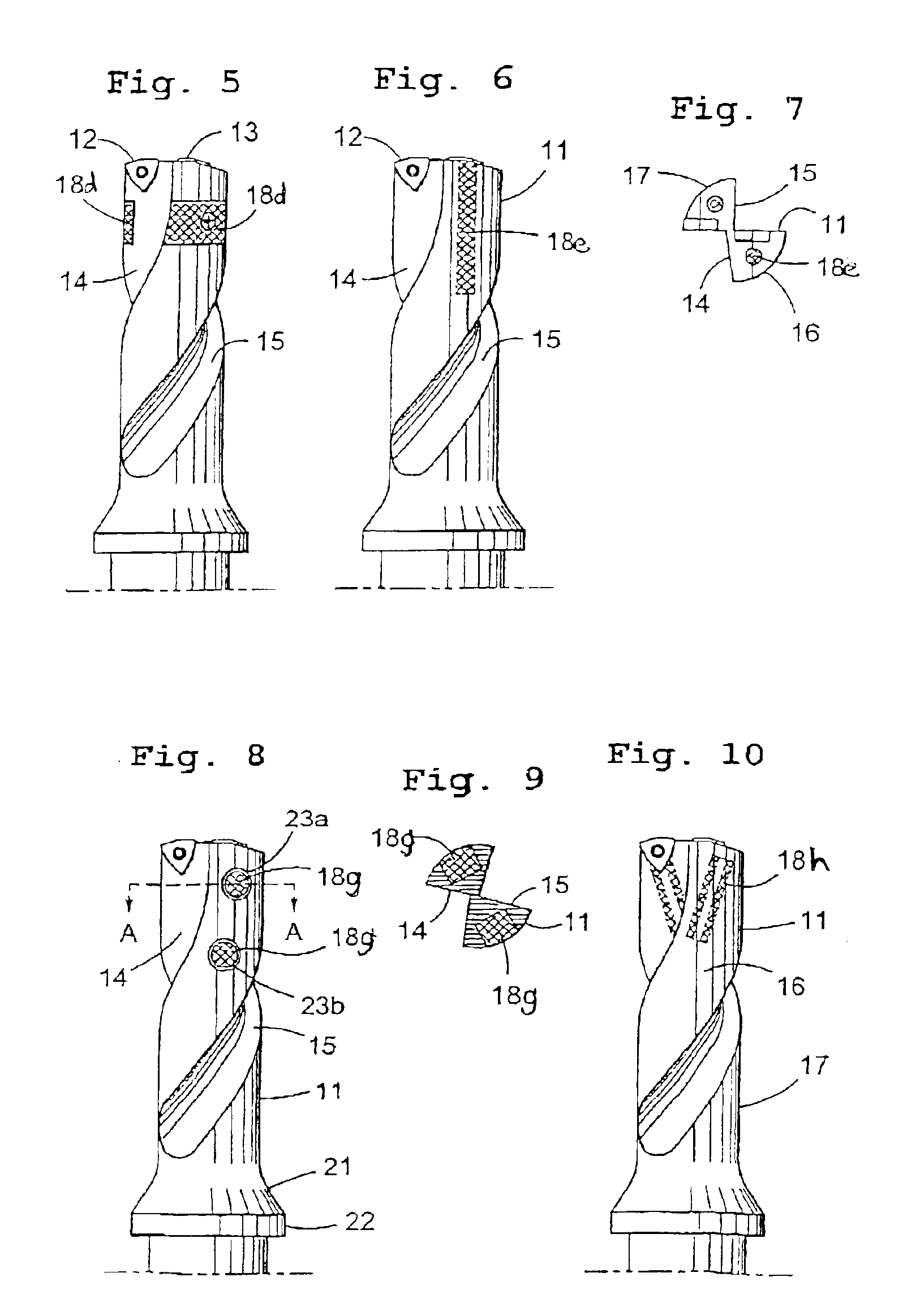

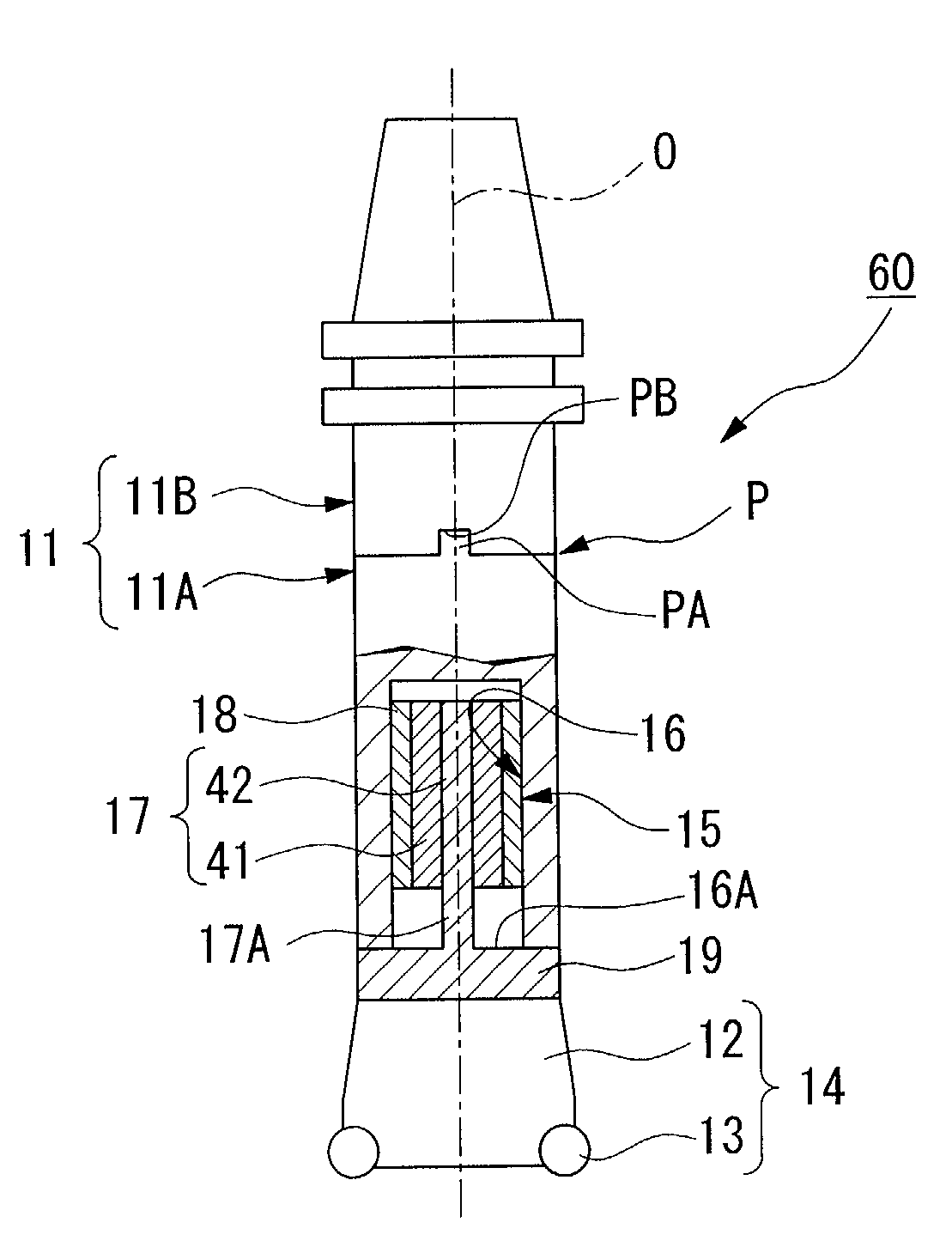

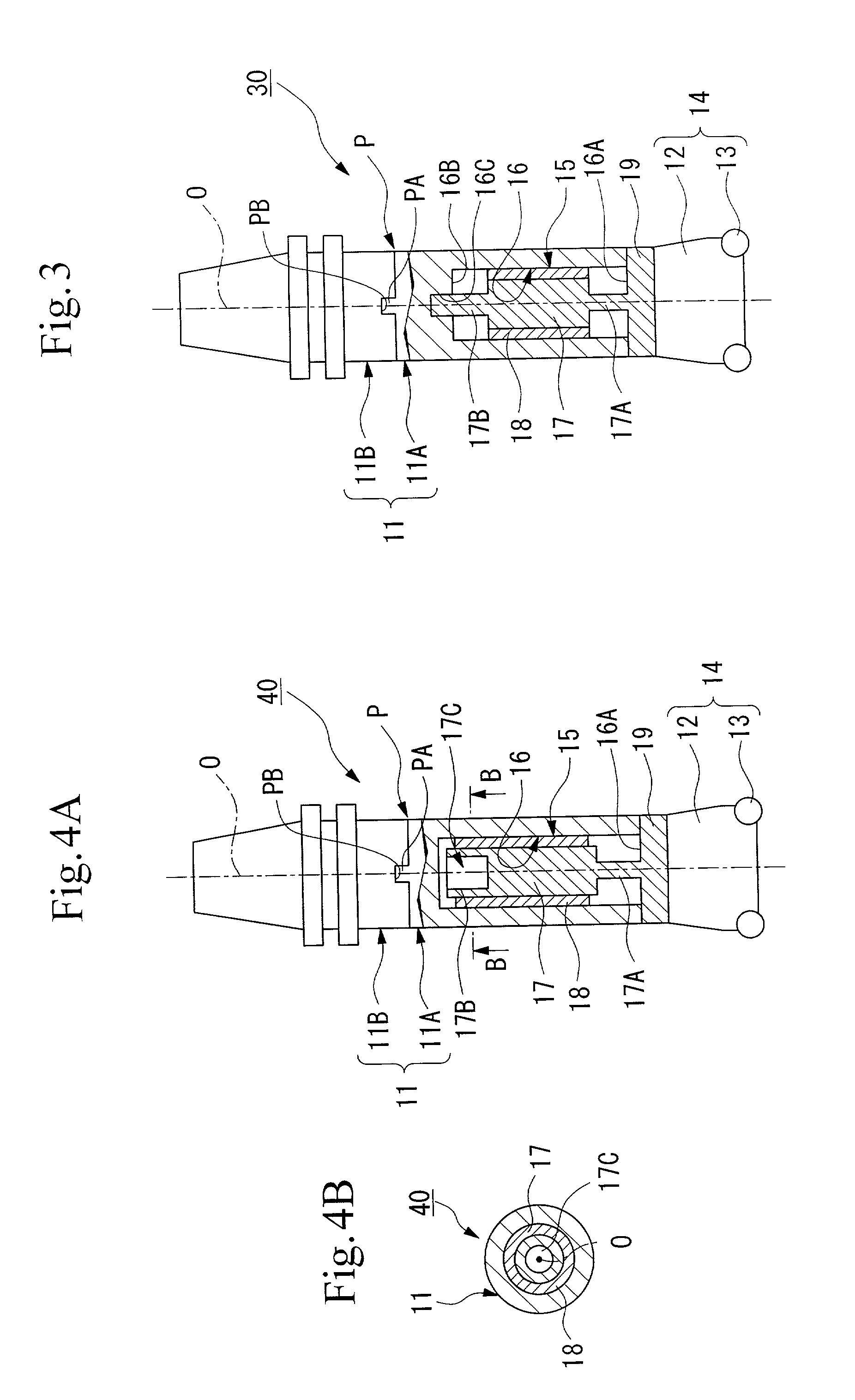

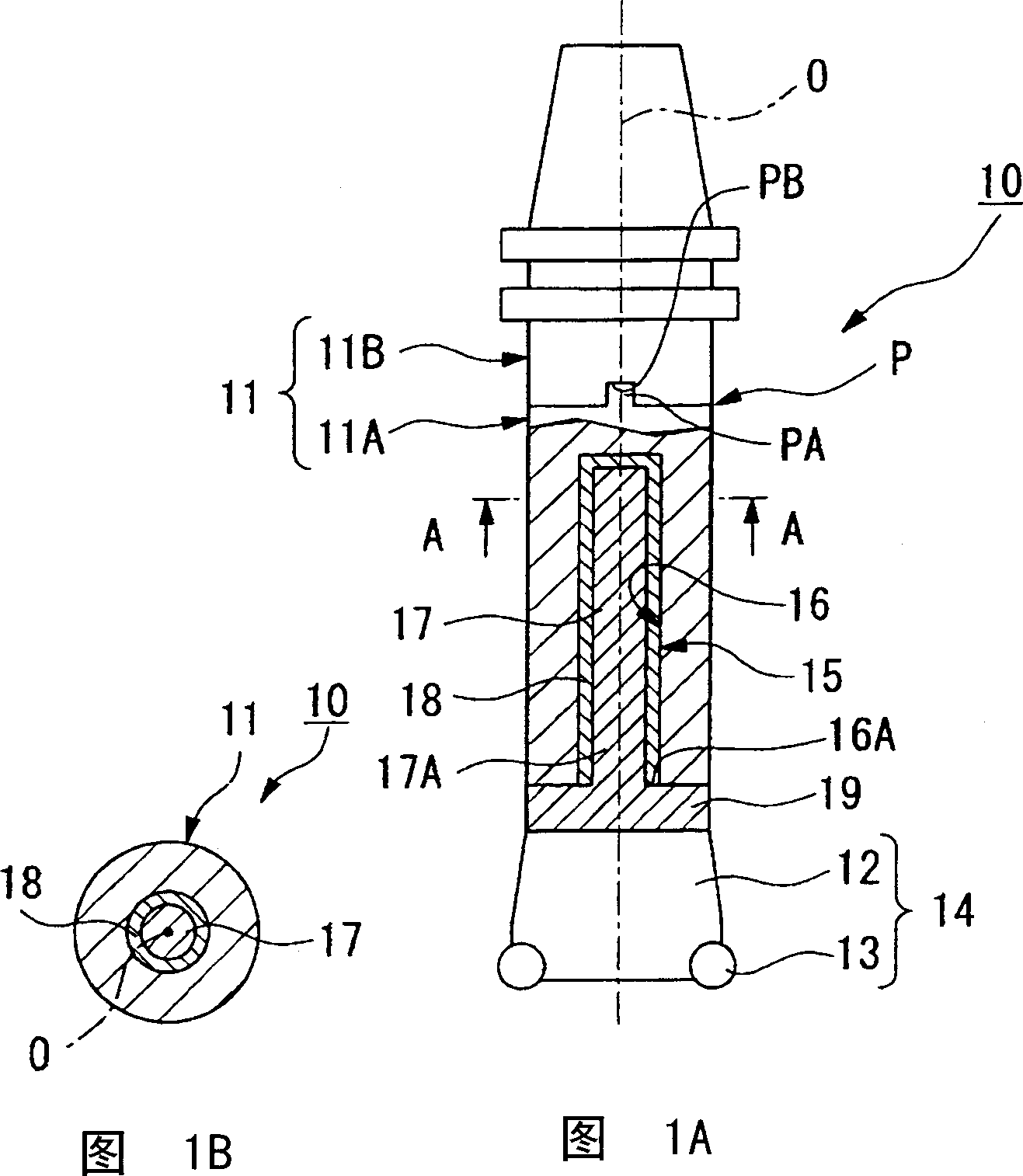

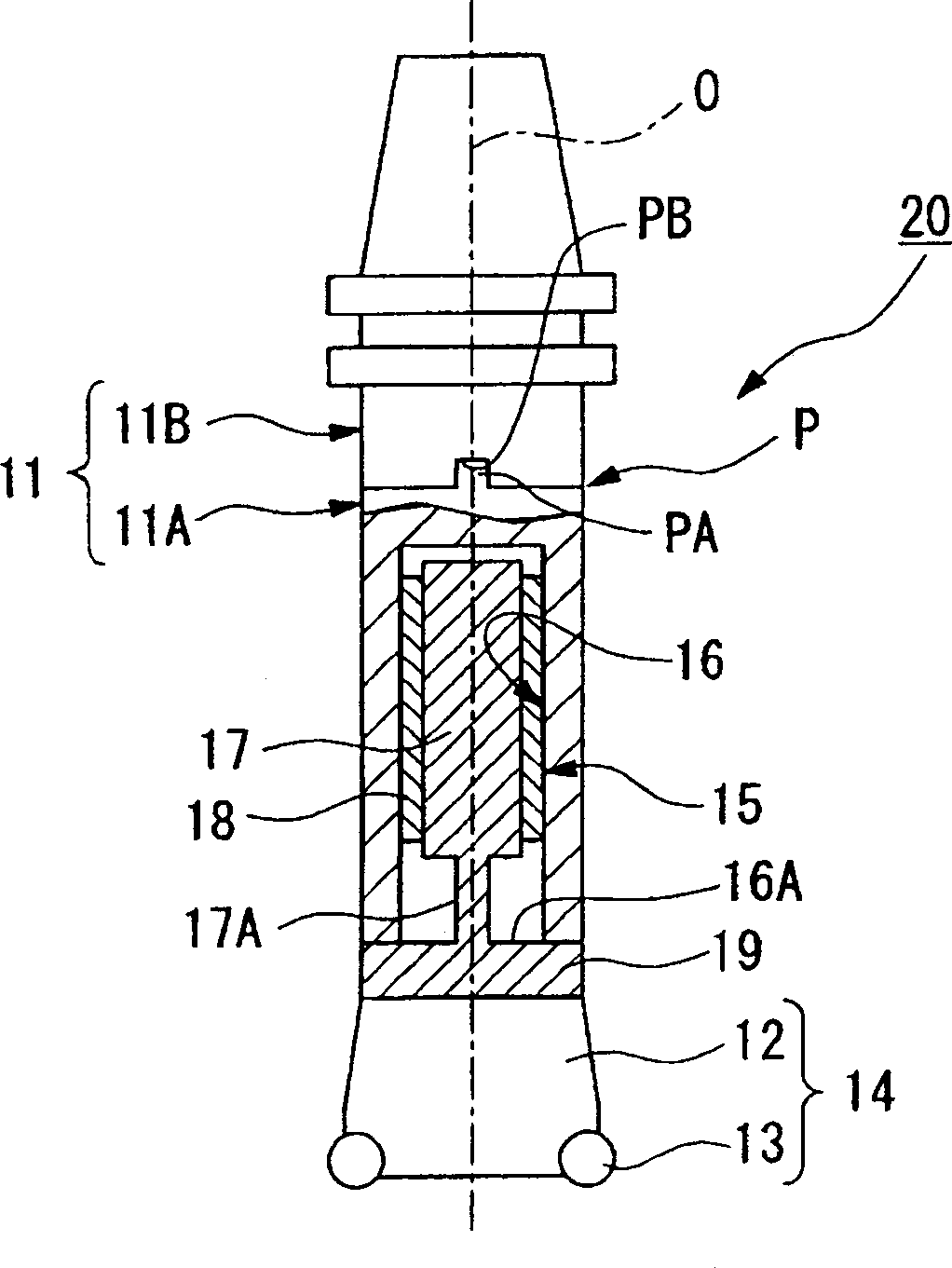

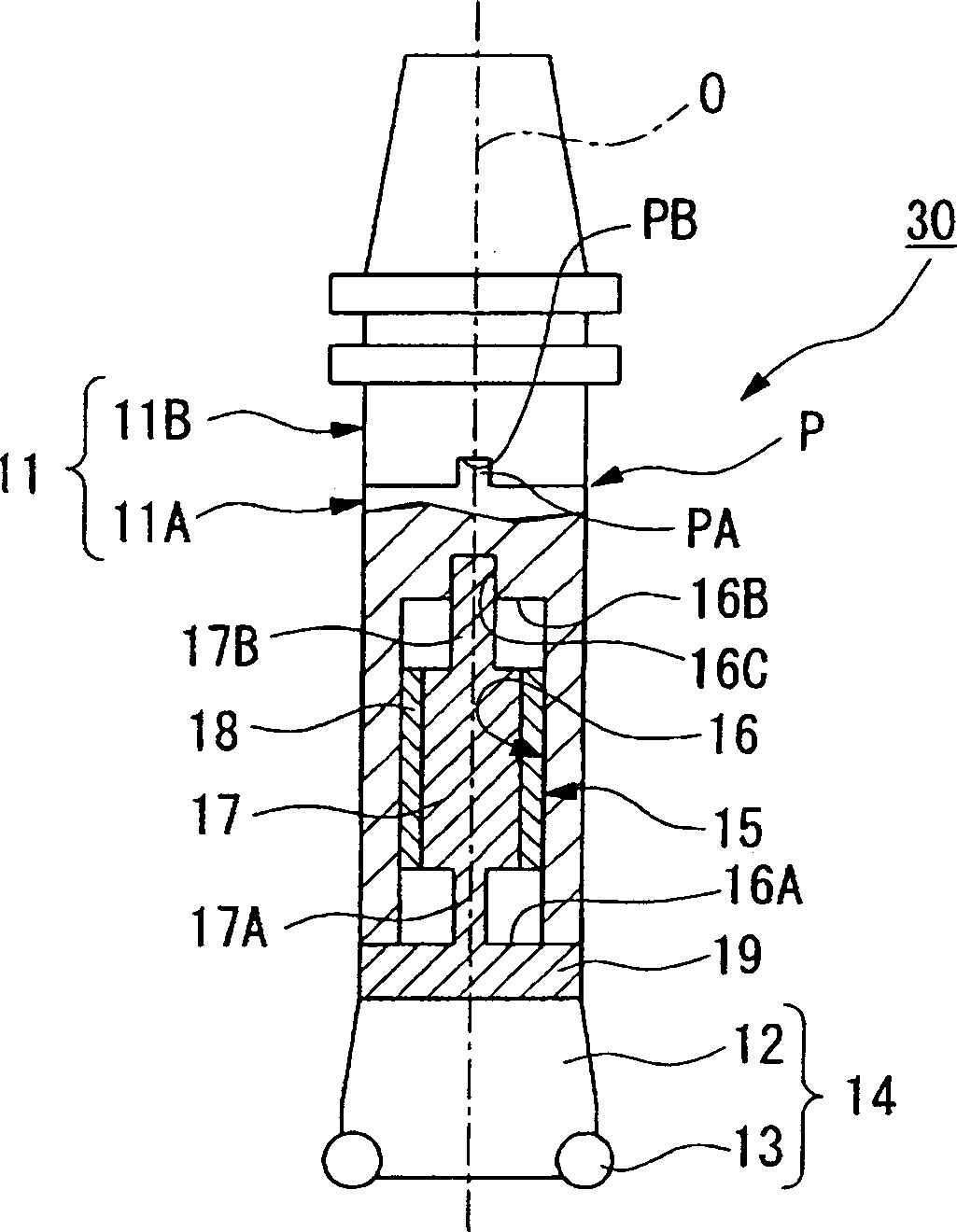

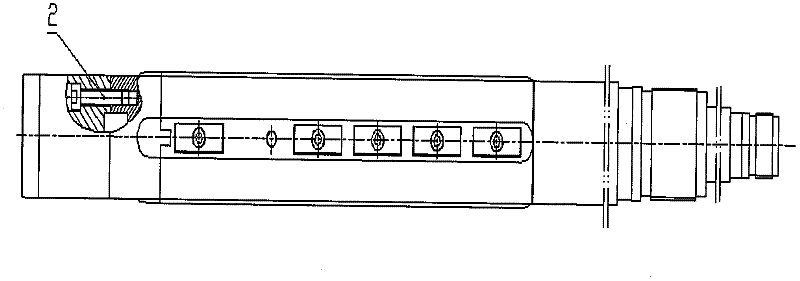

Tool having damper, cutting method using the same, and manufacturing method of impeller or guide vane of fluid machine

InactiveUS20060275090A1Easy to adjustEasy to manufactureMilling cuttersBoring barsImpellerDynamic stiffness

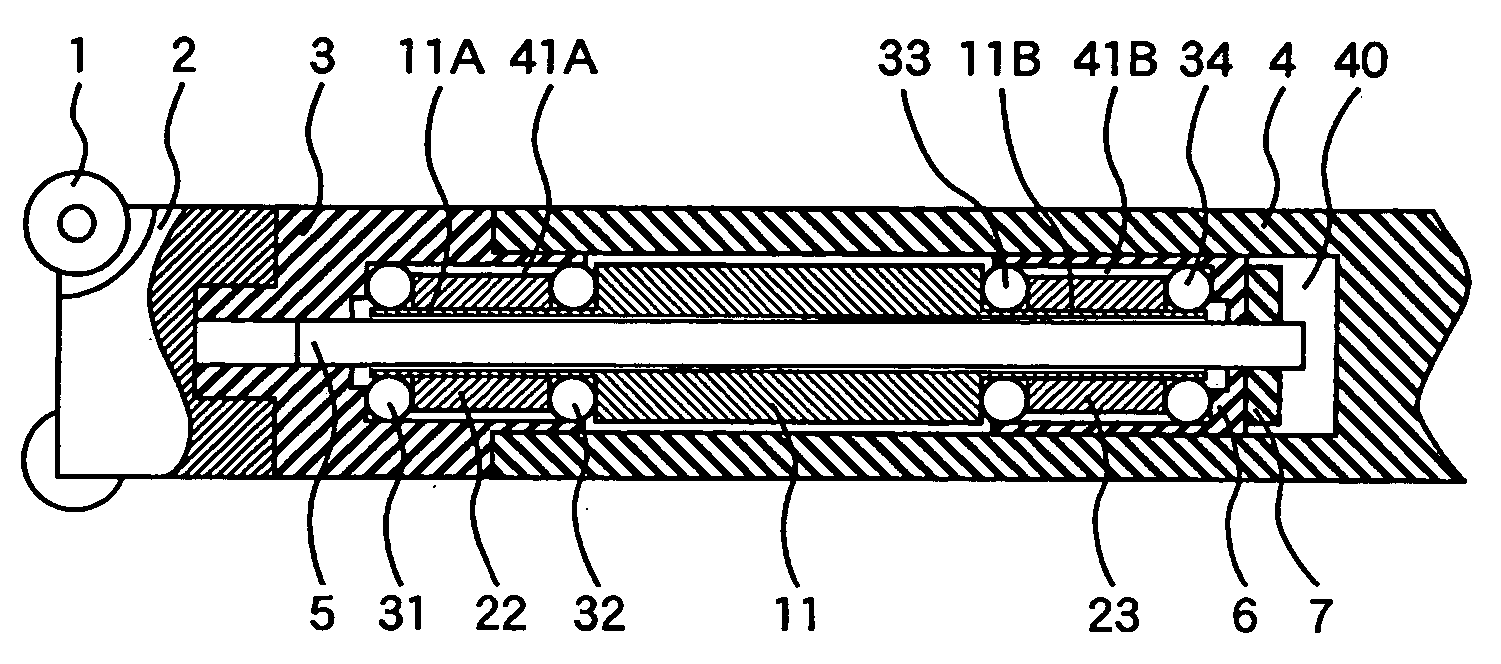

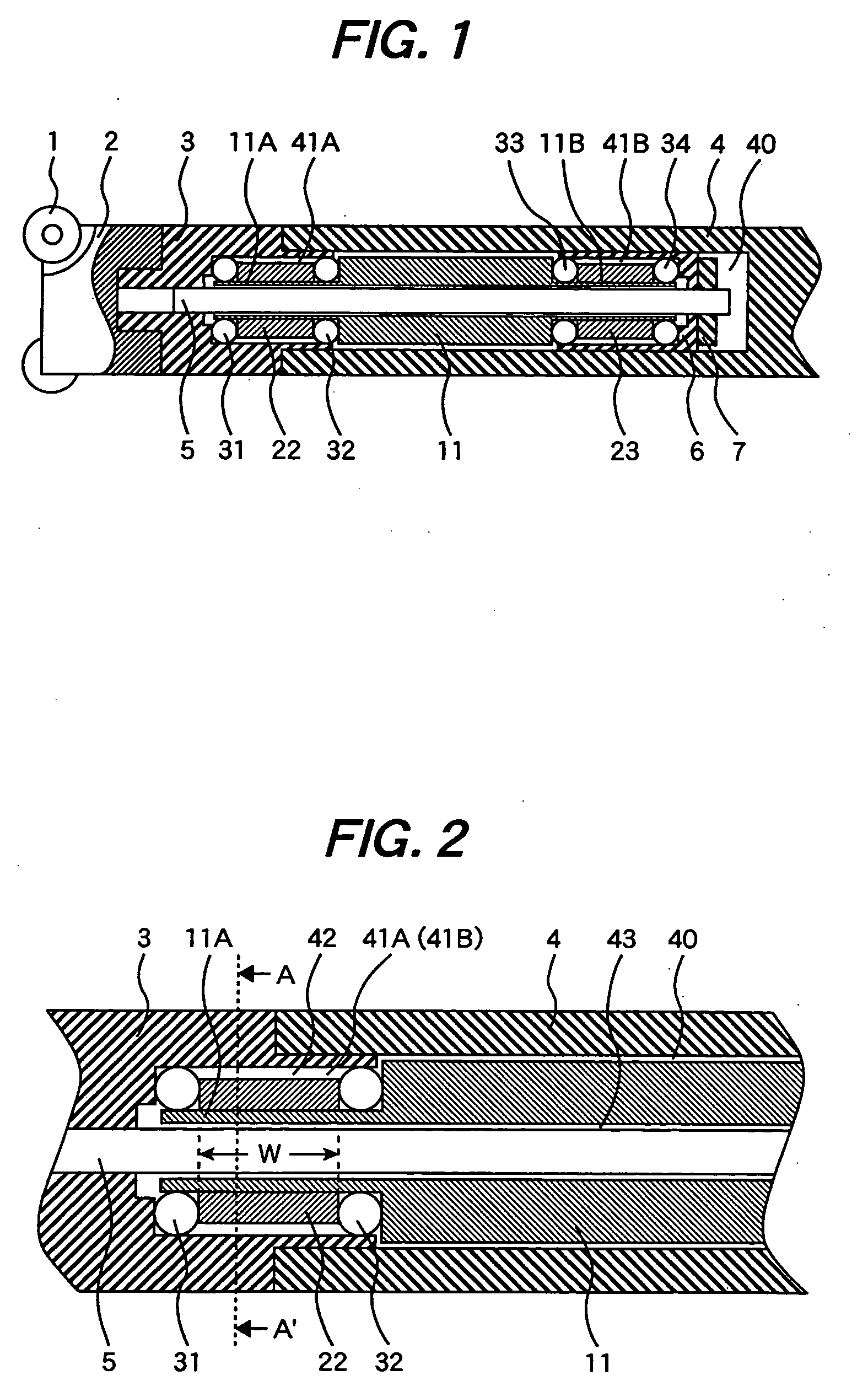

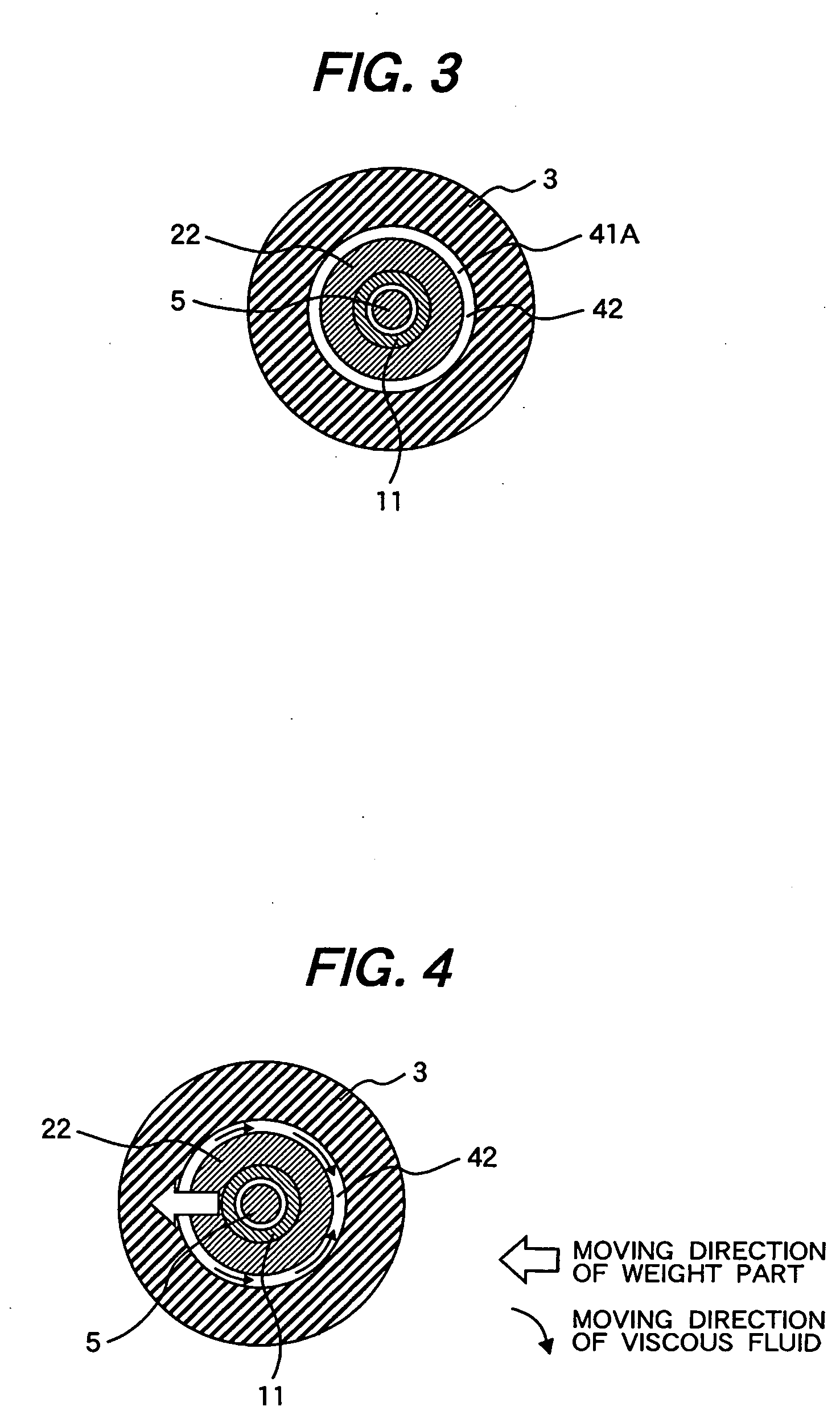

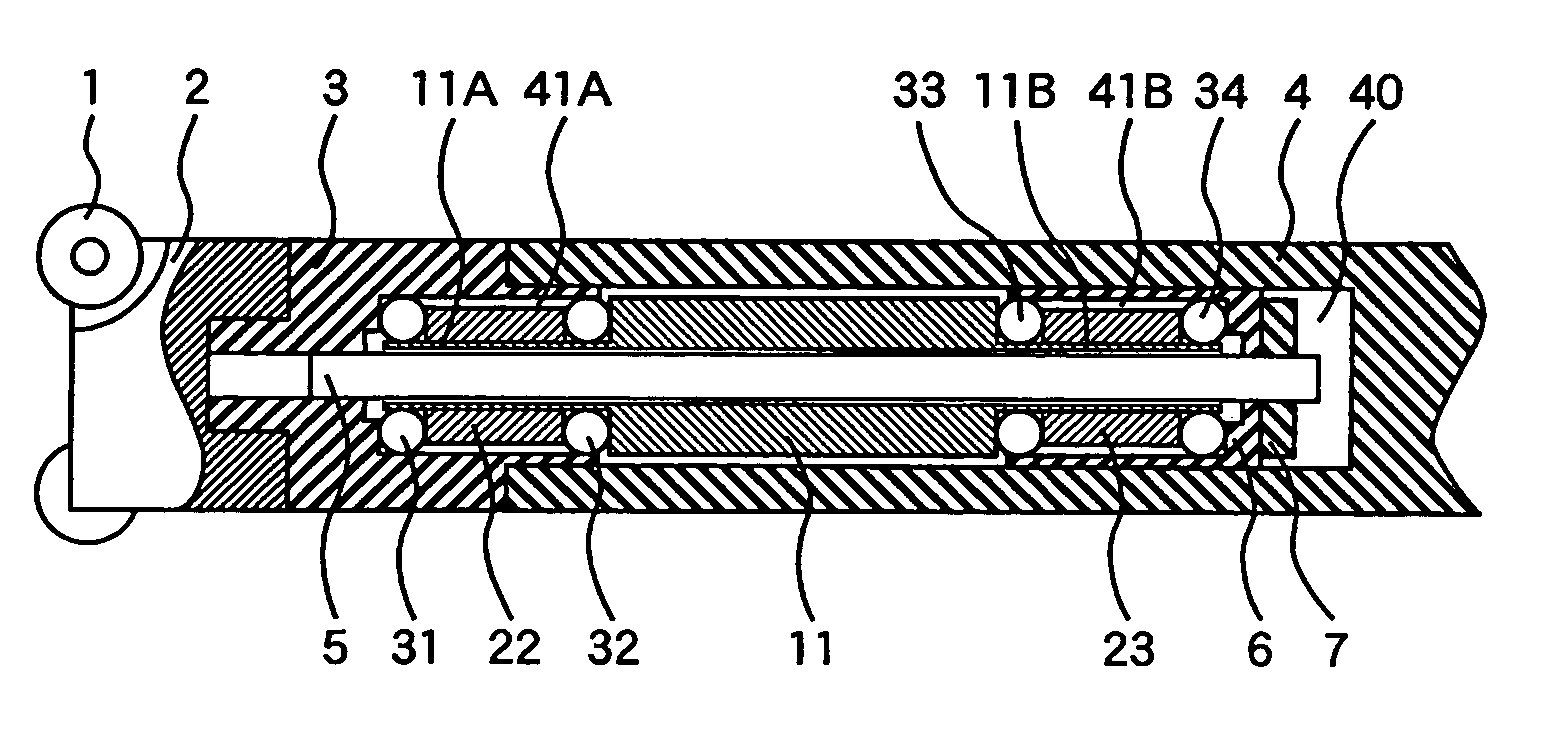

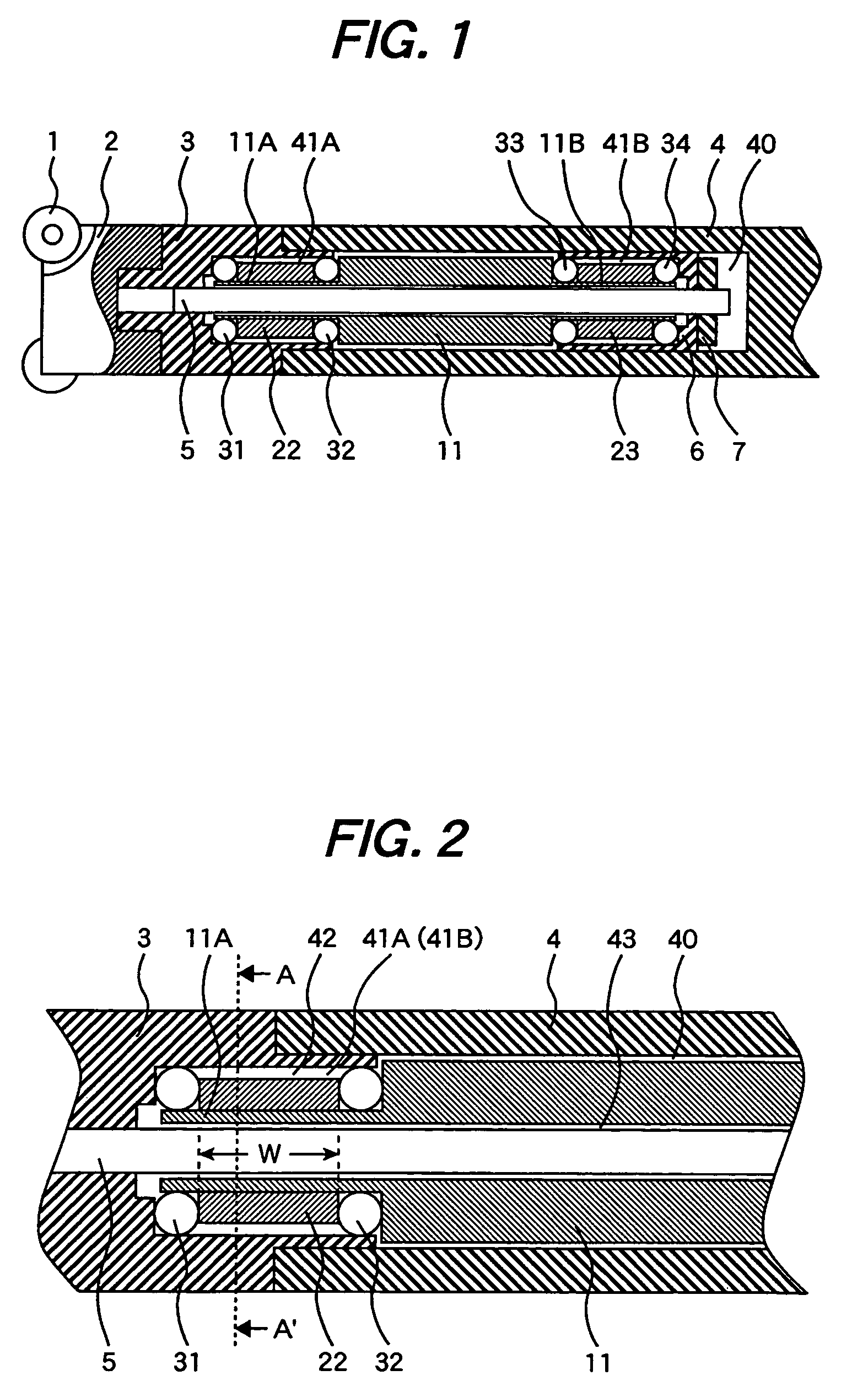

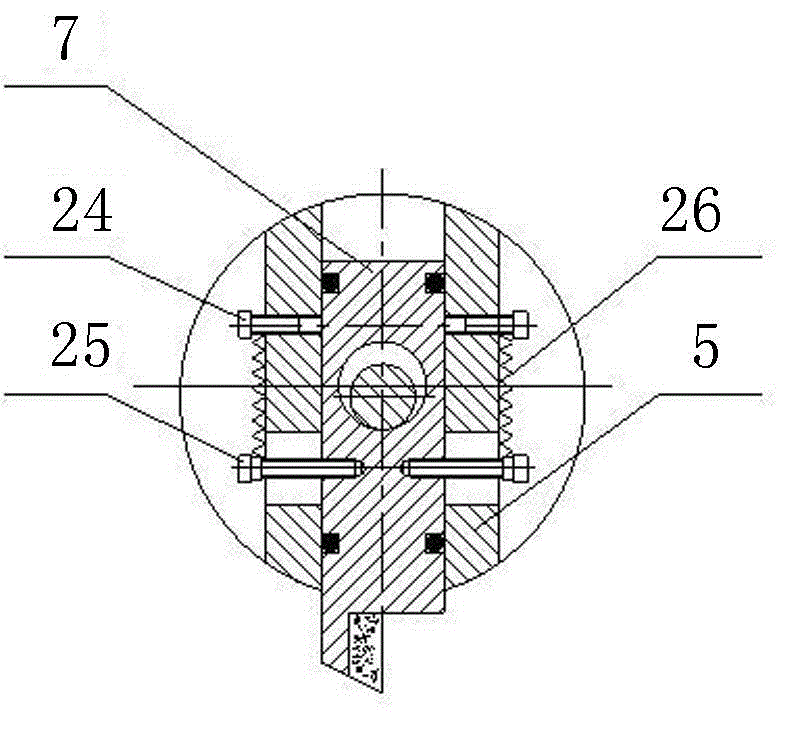

Disclosed herein is the structure of a damper that is capable of improving the degree of freedom in design to optimize the damping characteristics of the damper and is capable of allowing the damper to be easily optimized and manufactured for a wide variety of dynamic stiffness characteristics of a tool body, and a manufacturing method using the same. A plurality of ring-shaped elastic members are disposed at opposite ends of a weight part. The weight part is connected to the tool body via the elastic members. Consequently, the weight part is moved relative to the tool body. The plurality of elastic members are mounted while spacers are disposed between the elastic members, and the spacers are moved with respect to the weight part in the axial direction thereof. A viscous fluid is filled in the region surrounded by the outer circumferential surfaces of the spacers, the elastic members, and the inner surface of a hollow part of the tool body. Consequently, it is possible to damp the relative movement of the weight part with respect to the tool body.

Owner:HITACHI TOOL ENG LTD

Clamping and adjustment apparatus for a cutting tool

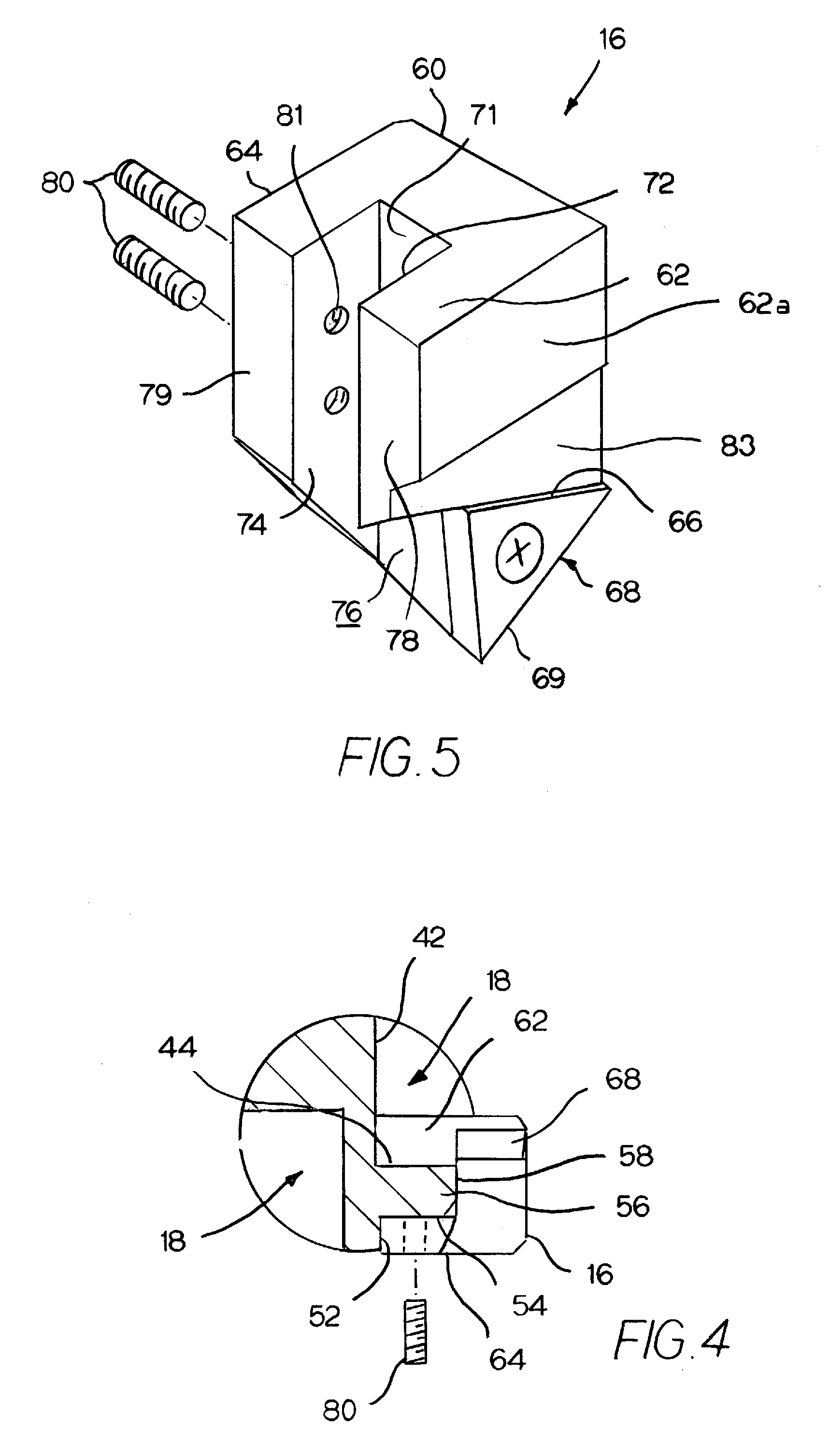

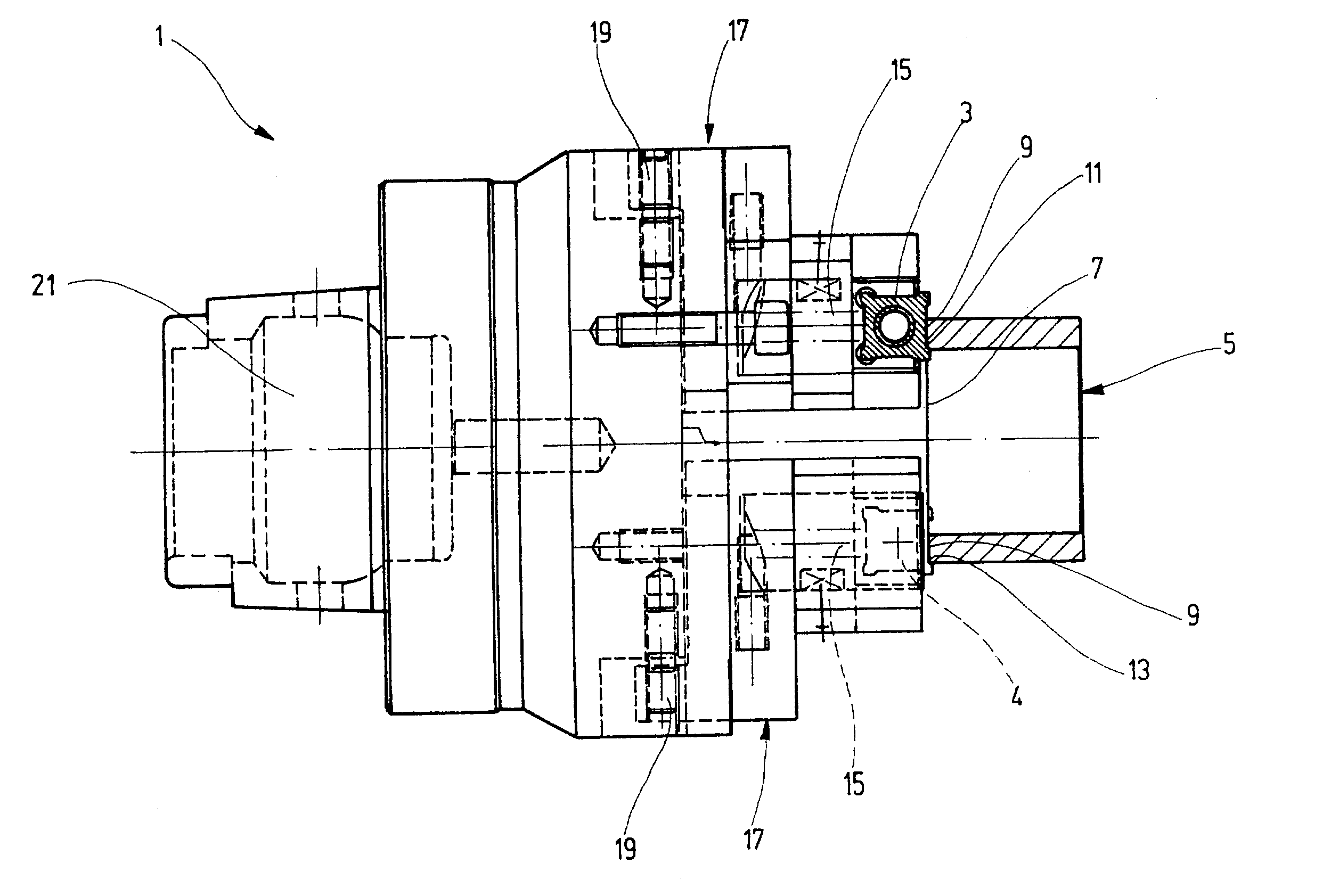

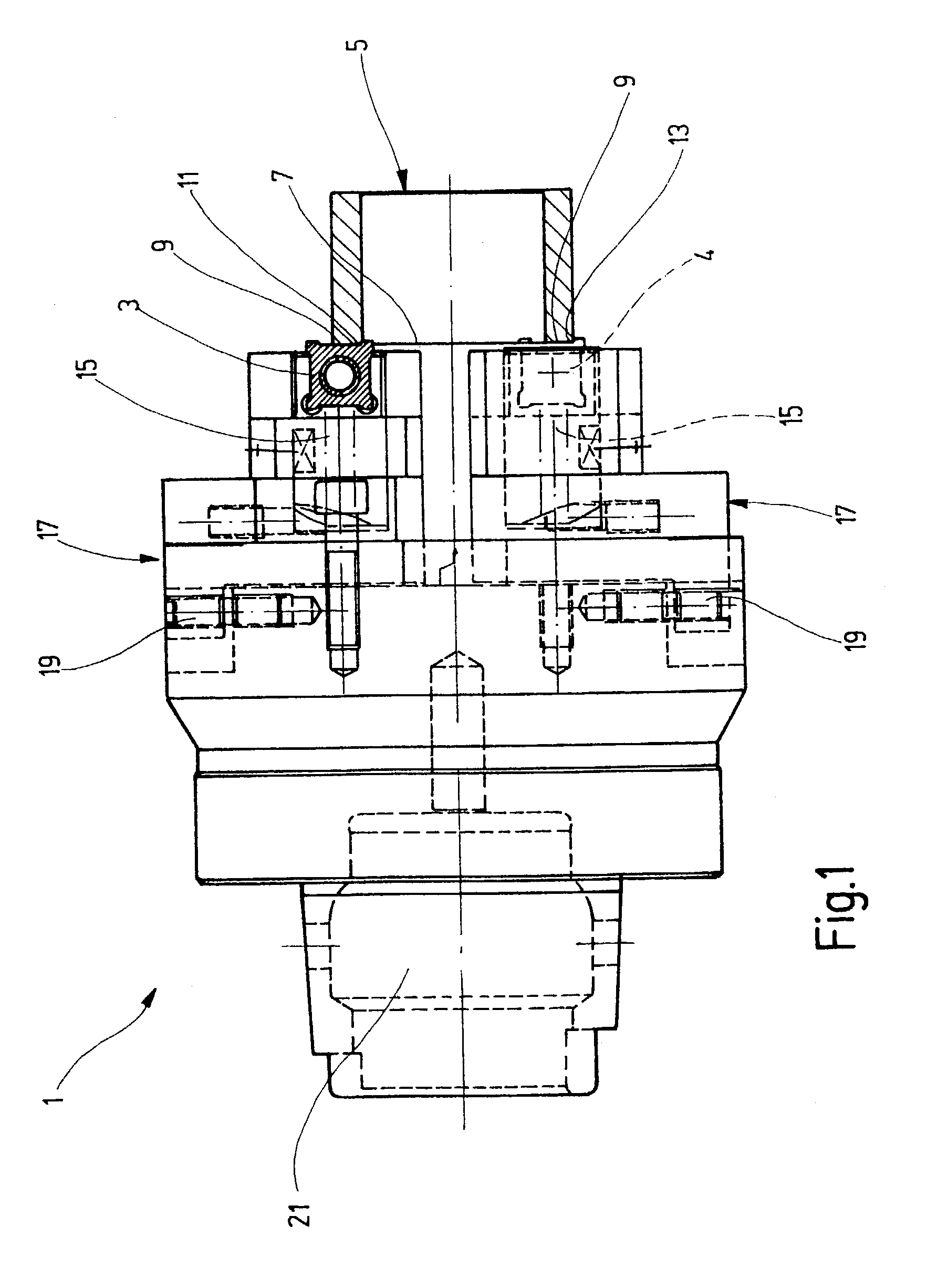

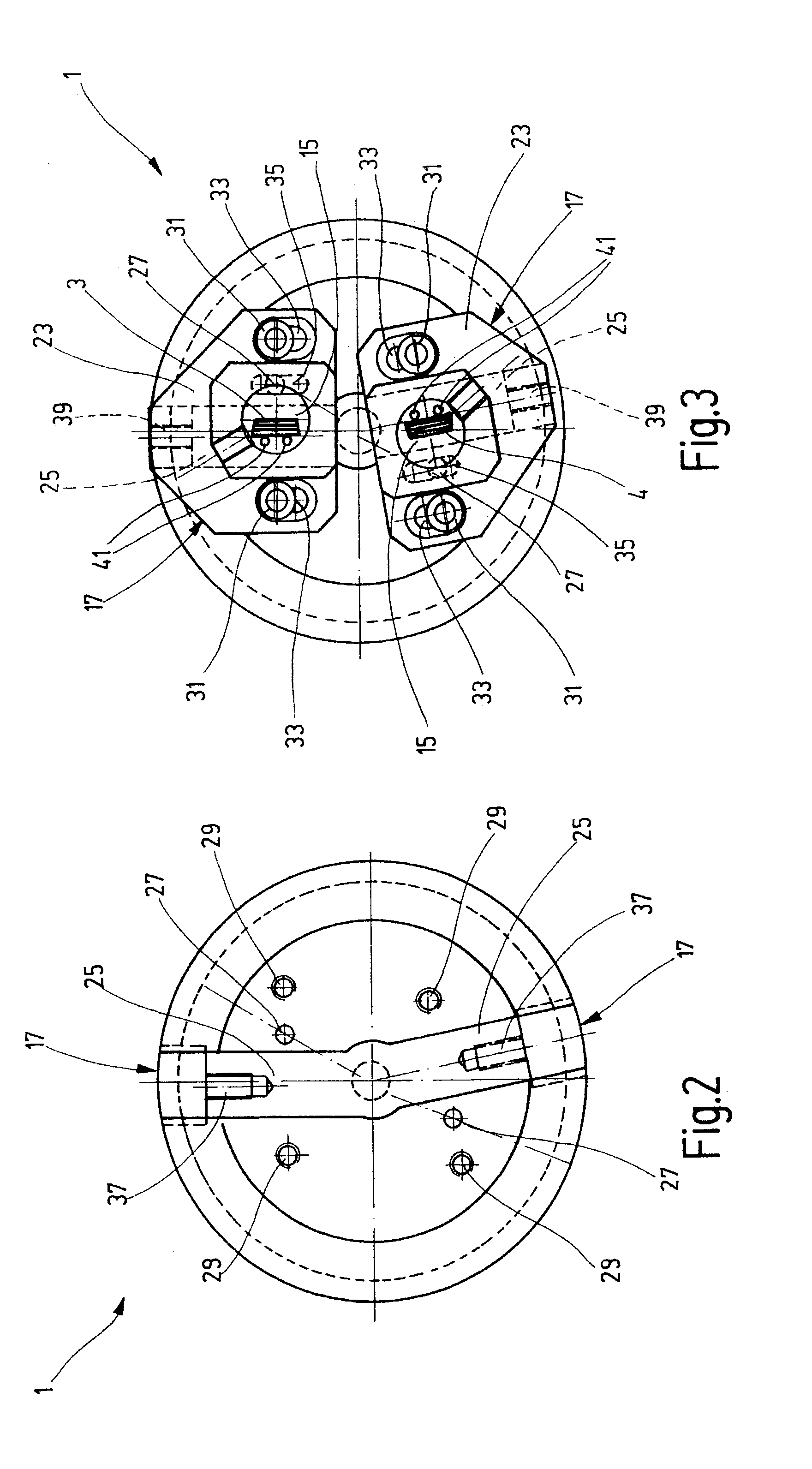

ActiveUS7014393B2Convenient ArrangementLimited rangeMilling cuttersBoring barsMechanical engineering

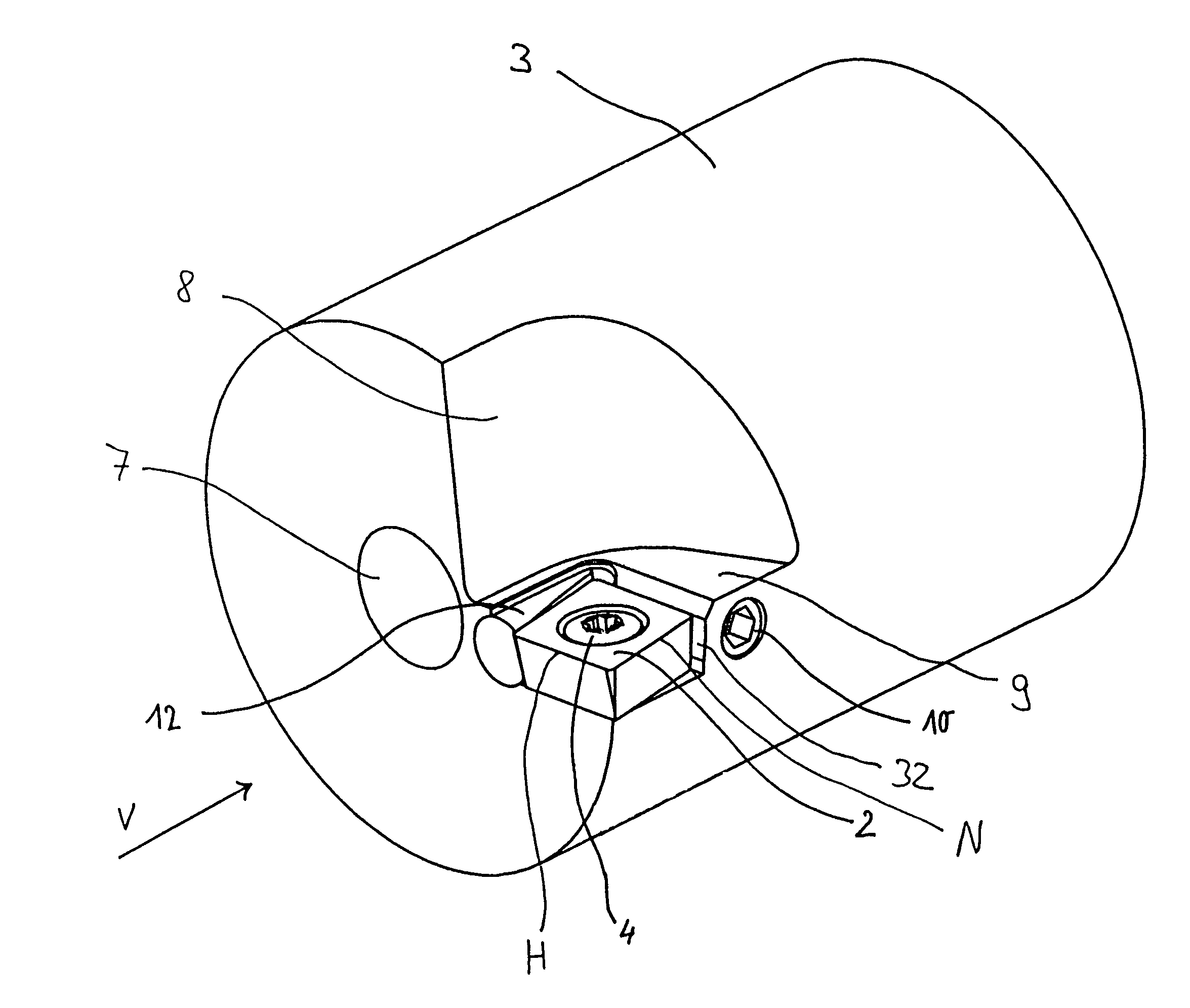

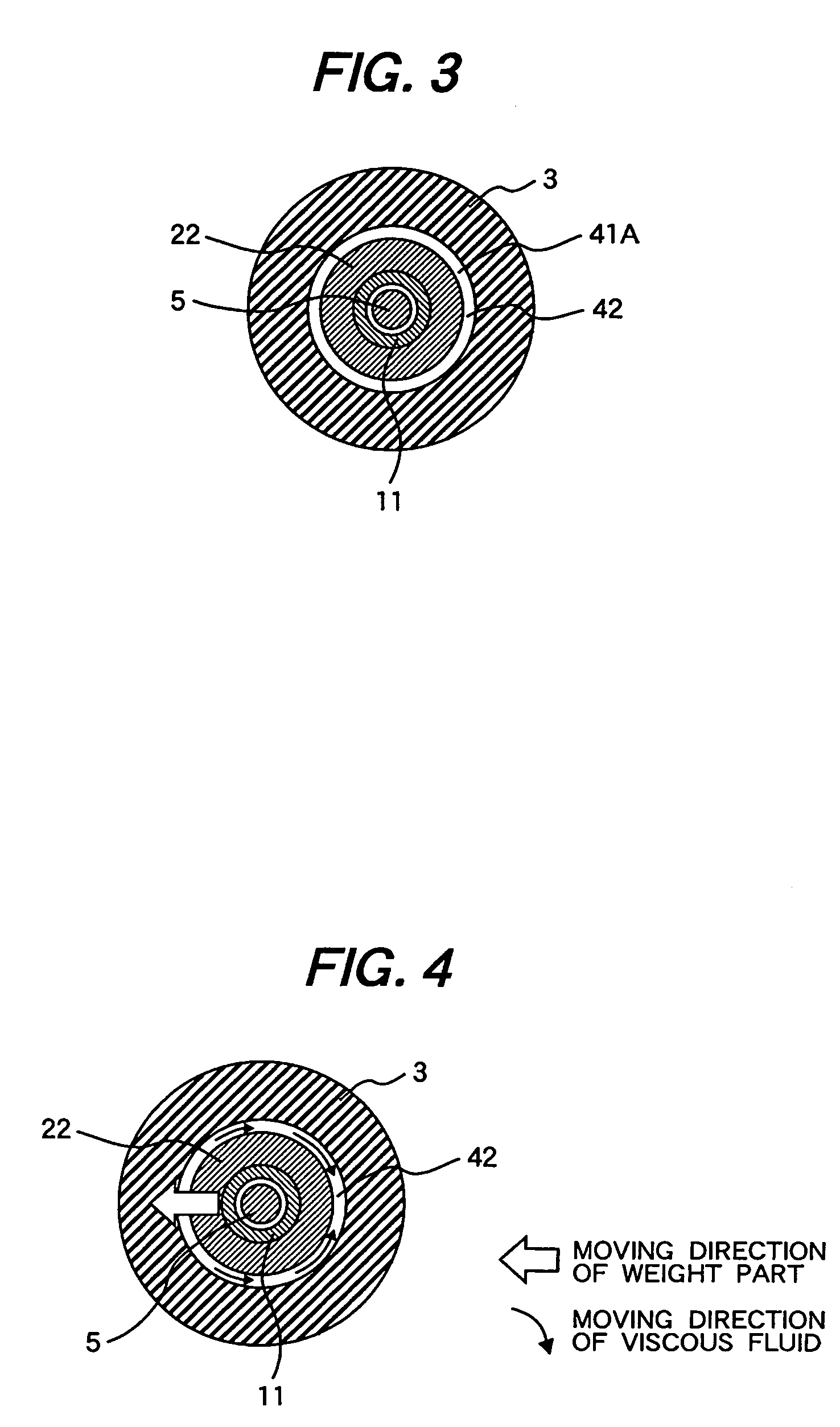

A clamping and adjustment apparatus for a cutting tool is described in which a plate-shaped cutter insert is prestressable and fastenable by means of a tension screw with its bottom surface against a seat surface such that it is supported with lateral wall sections in a positionally fixed manner on a cutter support. In order to allow precise adjustment of the cutter insert when little space is available, the clamping and adjustment apparatus has an adjustment wedge which can be actuated by means of a pressure screw in a direction (V) that extends essentially parallel to the seat surface. The adjustment wedge is accommodated in the cutter support in a form-fitted and displaceable manner. The cutter insert is supported on the adjustment wedge and can be adjusted by means of it. Moreover, a tool which is equipped with this clamping and adjustment apparatus is described as well as a tool cartridge which is used for it.

Owner:GUHRING JORG

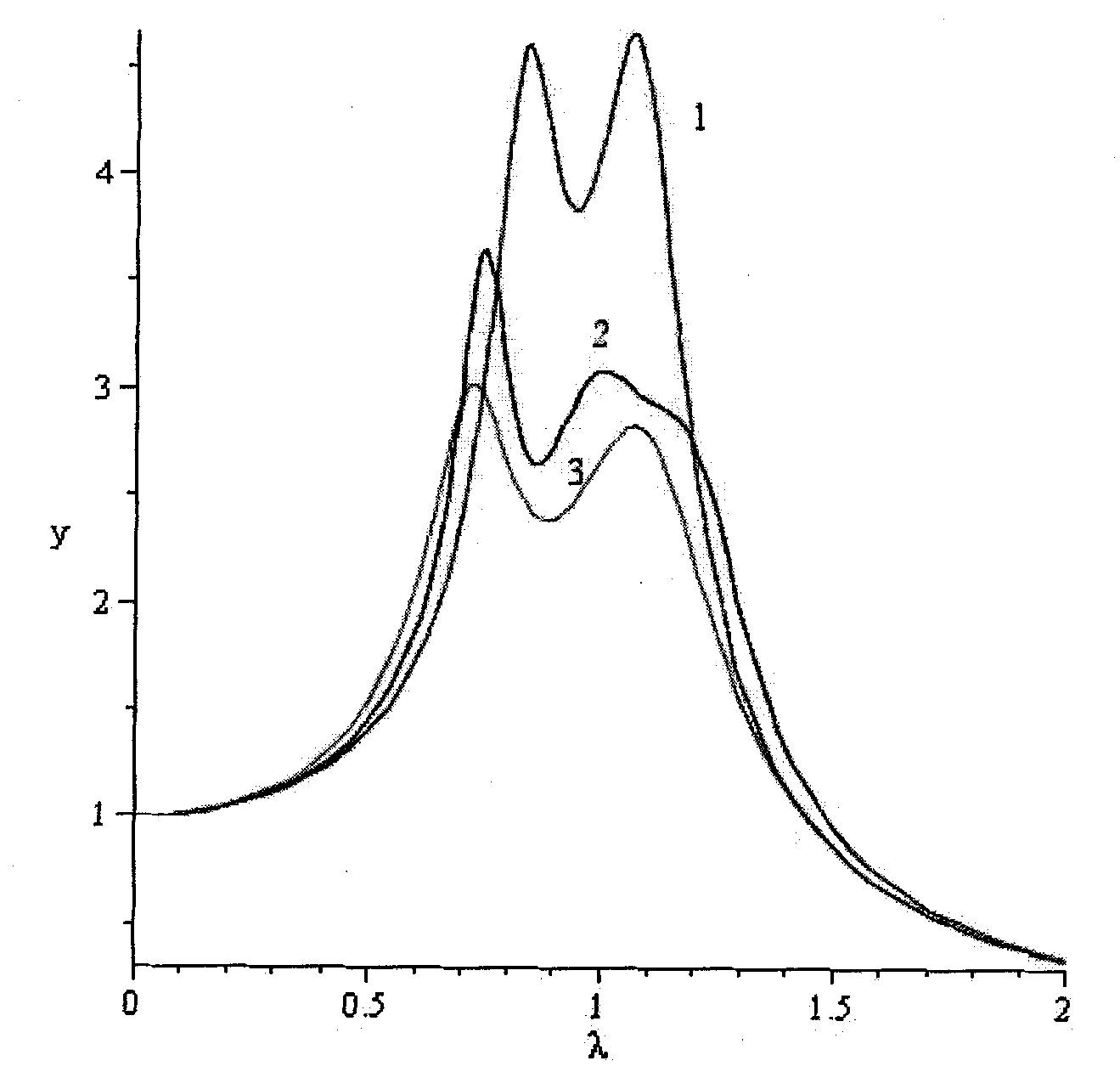

Cutting Tool Assembly and Tool Holder Therefor

A cutting tool assembly for boring and internal grooving operations includes a tool head having a removably secured cutting insert at a forward insert receiving end and a rear mating end with a male or female type tool holder coupler in the form of an engagement protrusion or cutting holder receiving pocket. The tool head is fixed to a tool holder with a front mating end having a female or male tool head coupler in the form of a tool head receiving pocket or engagement protrusion. Following assembly, at least three abutting wall surfaces and an adjacent support surface of the tool holder coupler are in contact with at least three non-coplanar abutment surfaces and an adjacent supporting surface of the tool head coupler, respectively, and a fastening screw member extends through a through bore in the tool holder coupler engaging a threaded screw bore in the tool head coupler.

Owner:ISCAR LTD

Rotatable cutting tool

A rotatable cutting tool has a shank portion for coupling to a tool driving device and a cutting portion to which is attached at least one support member for retention of a replaceable cutting element. The support member is so arranged to permit displacement of at least the portion thereof retaining the cutting element whereby the position of the cutting element relative to the body of the cutting tool may be changed by such displacement. A totally enclosed hydraulic force multiplier is mounted within an internal cavity of the cutting tool. The force multiplier is responsive to a control force to effect the displacement of the support member, the control force advantageously supplied by application of pneumatic pressure.

Owner:VALENITE

Tool having damper

InactiveUS7661912B2Improve featuresIncrease freedomMilling cuttersBoring barsDynamic stiffnessViscous flow

Owner:HITACHI TOOL ENG LTD

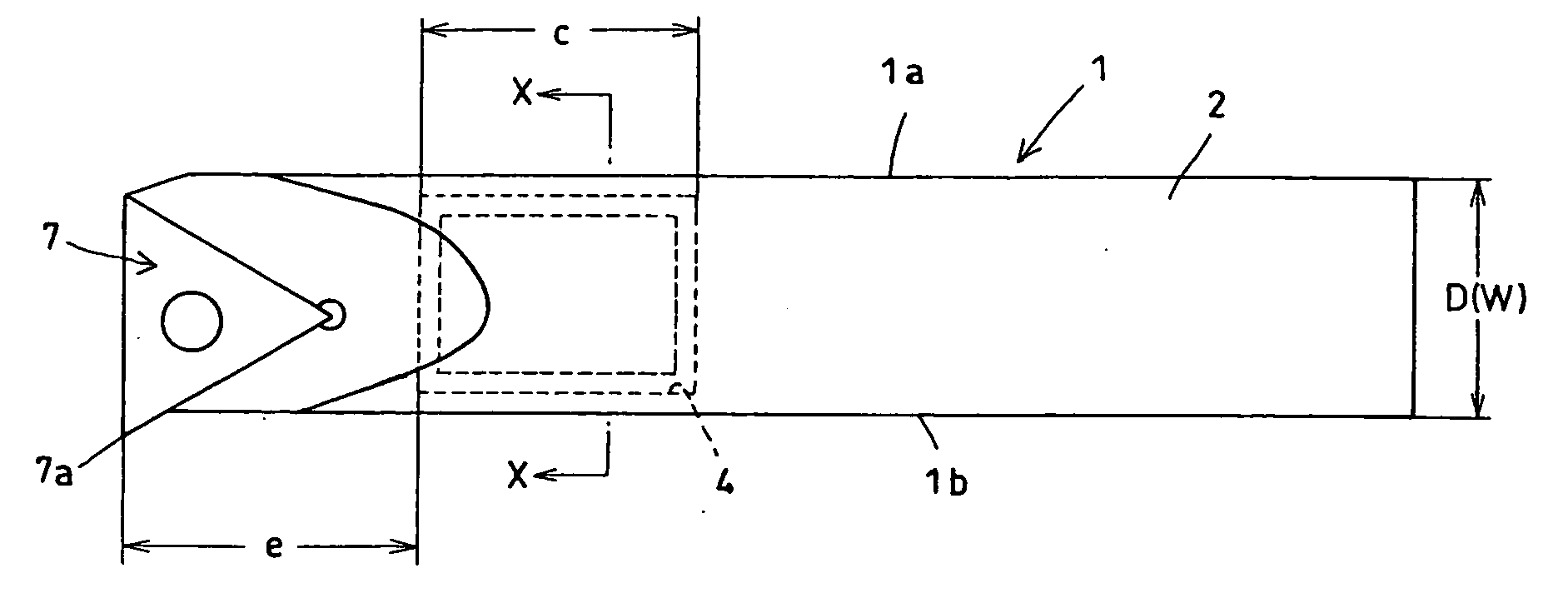

Tip-extension type deep hole boring cutter rod

The invention relates to a tip-extension type deep hole boring cutter rod. A cutter seat (3) is positioned in a cavity between a press cover (1) and a gear installing seat (5), and a screw rod (11) connected with one end of a core shaft (10); a rack (6) is installed in a slot on one end of the core shaft (10); one inner edge of a cutter installing hole needs to be coincide with the symmetric center surface of double-row teeth; a cutter (2) is positioned in the cutter installing hole, and a tip is positioned on a center line of a processed hole; and gears (4) are respectively meshed with the double-row teeth of the rack and the cutter seat. The screw rod is rotated by rotating a handle (14) on the screw rod (11) to drive the core shaft (10) to move, and then the cutter tip is extended by the transmission among a thread pair, the rack, gears and the rack. When retracting, the tip enters the end part of an inner hole of a part; and when the tip extends out, the middle of the part is processed. By adopting a guiding block (9), the rigidity of the cutter rod is ensured, and the cutter rod is provided with axial scales and circumferential scales. The tip-extension type deep hole boring cutter rod is suitable for processing deep holes on both ends of a long-shaft part, wherein the deep holes have small inner diameters at two ends, large inner diameters in the middles and larger difference of diameter sizes.

Owner:AECC AVIATION POWER CO LTD

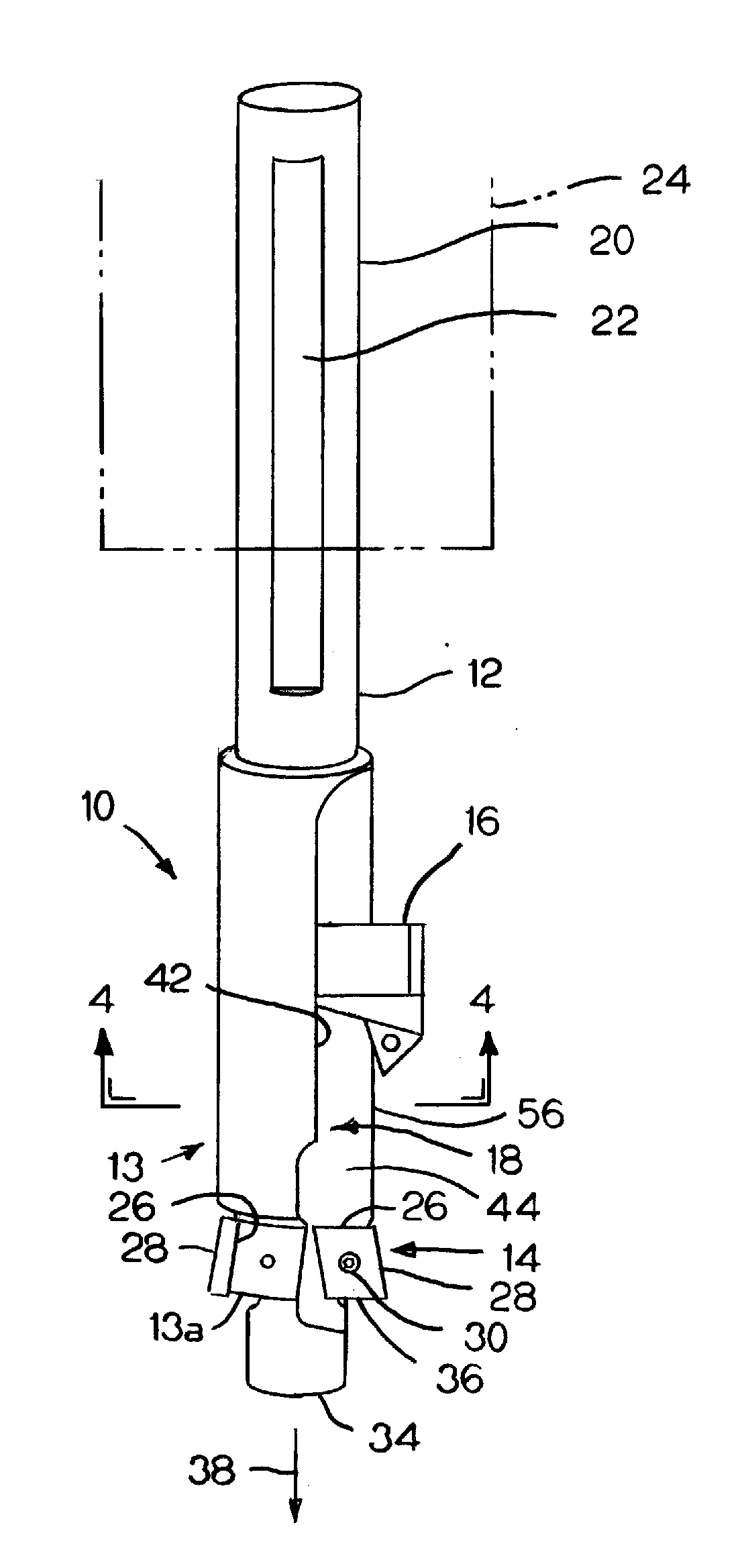

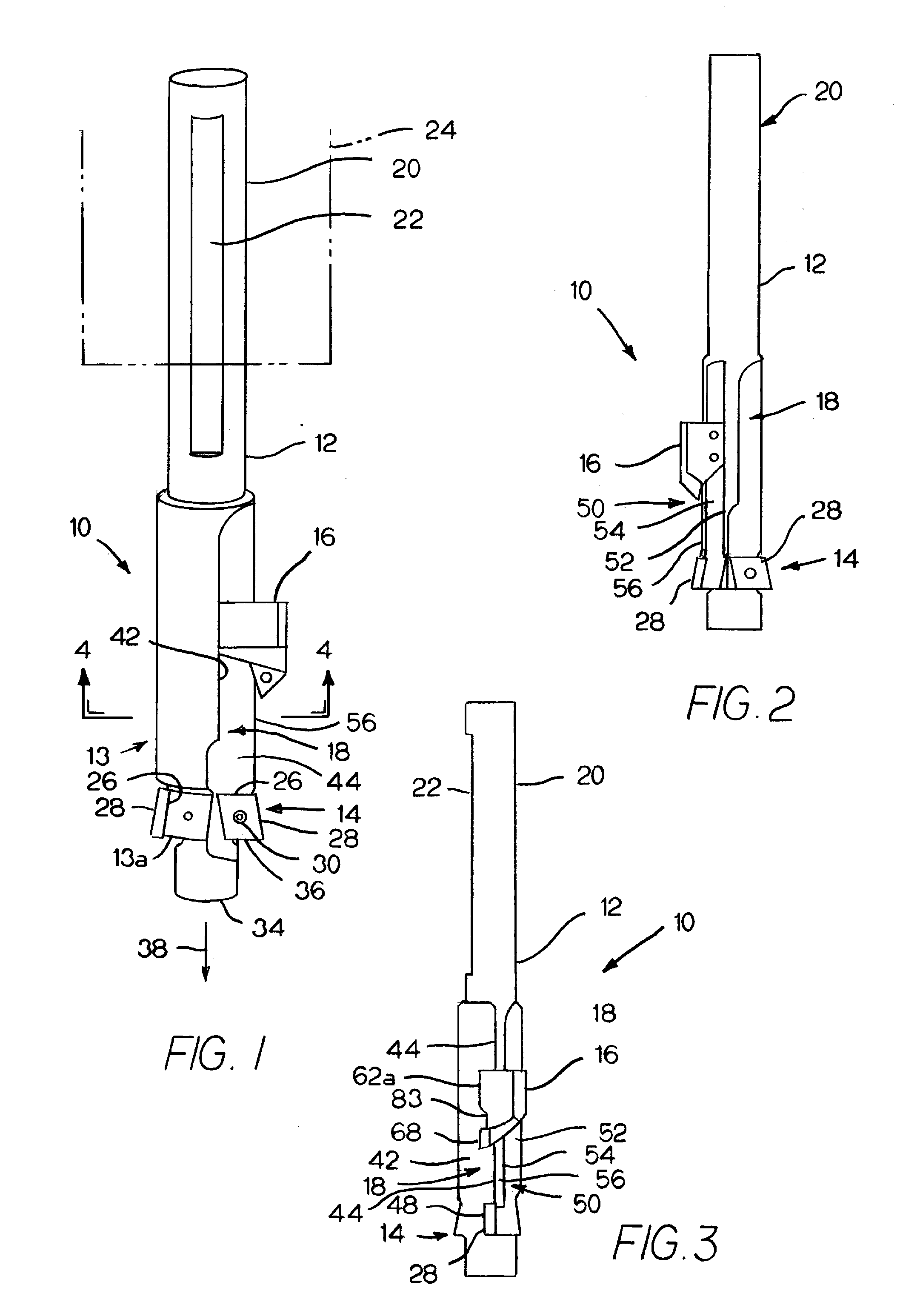

Miniature cutting insert holder

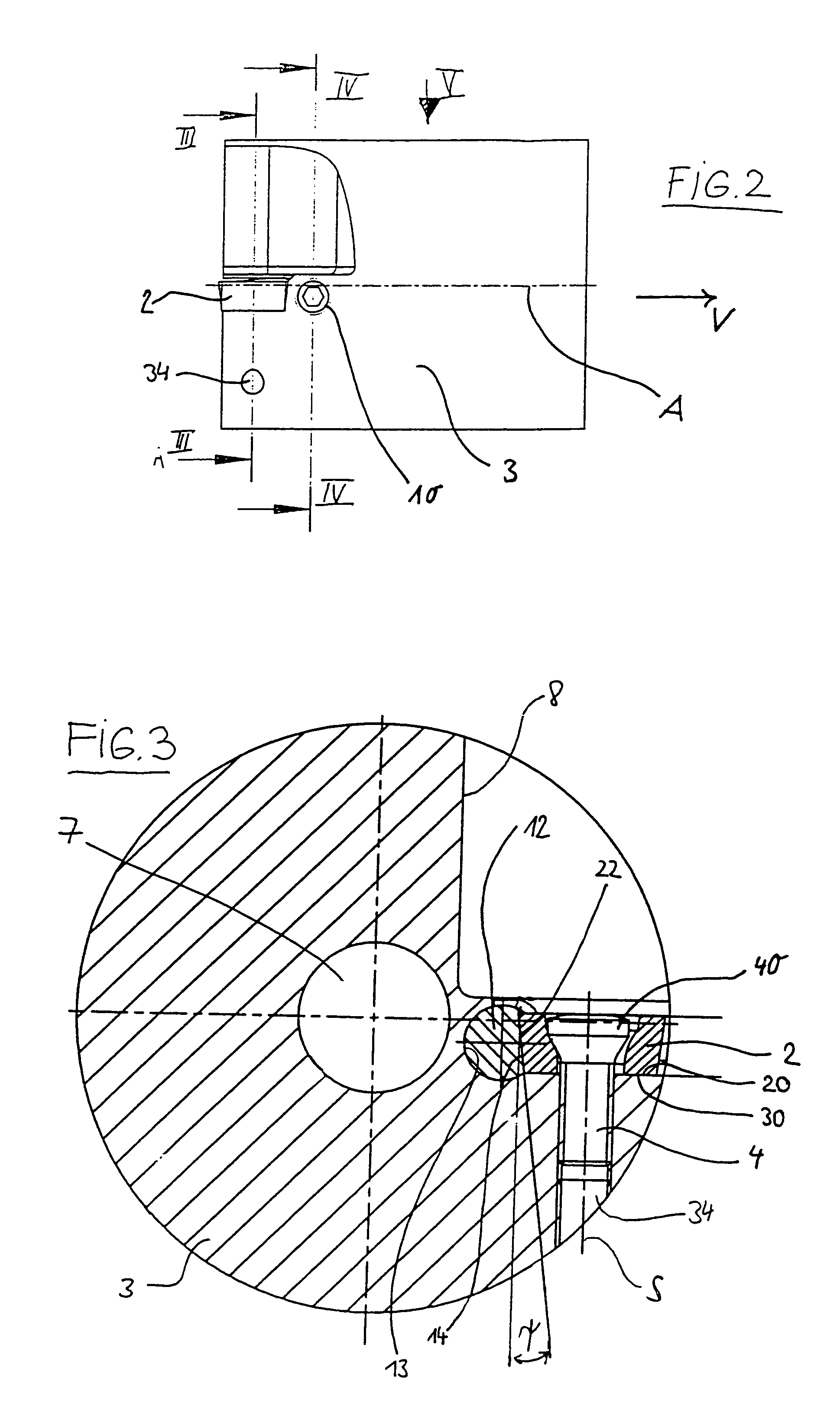

A holder (20) for a cutting insert (12), which includes a head (22) with a pocket (24) for holding the cutting insert and a bar device (26) for supporting the head, allows the use of a removable head for a miniature head and bar device that fits into a small hole in a workpiece, and allows rapid and easy replacement of the head. The head has a front part (42) of small height for holding the cutting insert and has a taller rear part (40) of the same height as the bar device. The head rear part has a screw-receiving hole (56) that extends at a downward-rearward incline (A) into a corresponding threaded hole (62) at the front of the bar device. The head and bar device respectively have a recess (70) and a projection (74) that lie around the screw-receiving holes and that align the head and bar device. A coolant passageway system (92) in the bar device provides coolant for both right and left hand heads.

Owner:VERSABAR TOOLS LLC

Vibration-dampened tool for working in metallic material

InactiveUS6929431B2Improved sound and vibration dampingLess sensitiveLathesThread cutting toolsMetallic materialsRelative motion

A drill for working in metallic materials includes a tool body having located in its front end at least one cutting insert, wherein the tool body is provided with one or several damping elements mounted such that during machining, a relative movement (i.e., sliding and / or deformation) of the tool body and the damping element is allowed to occur.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

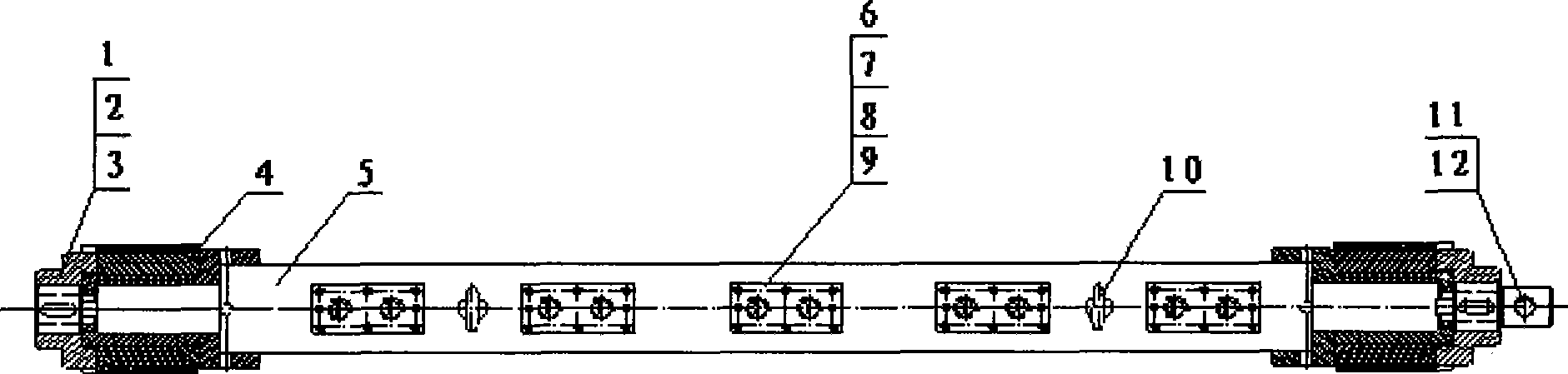

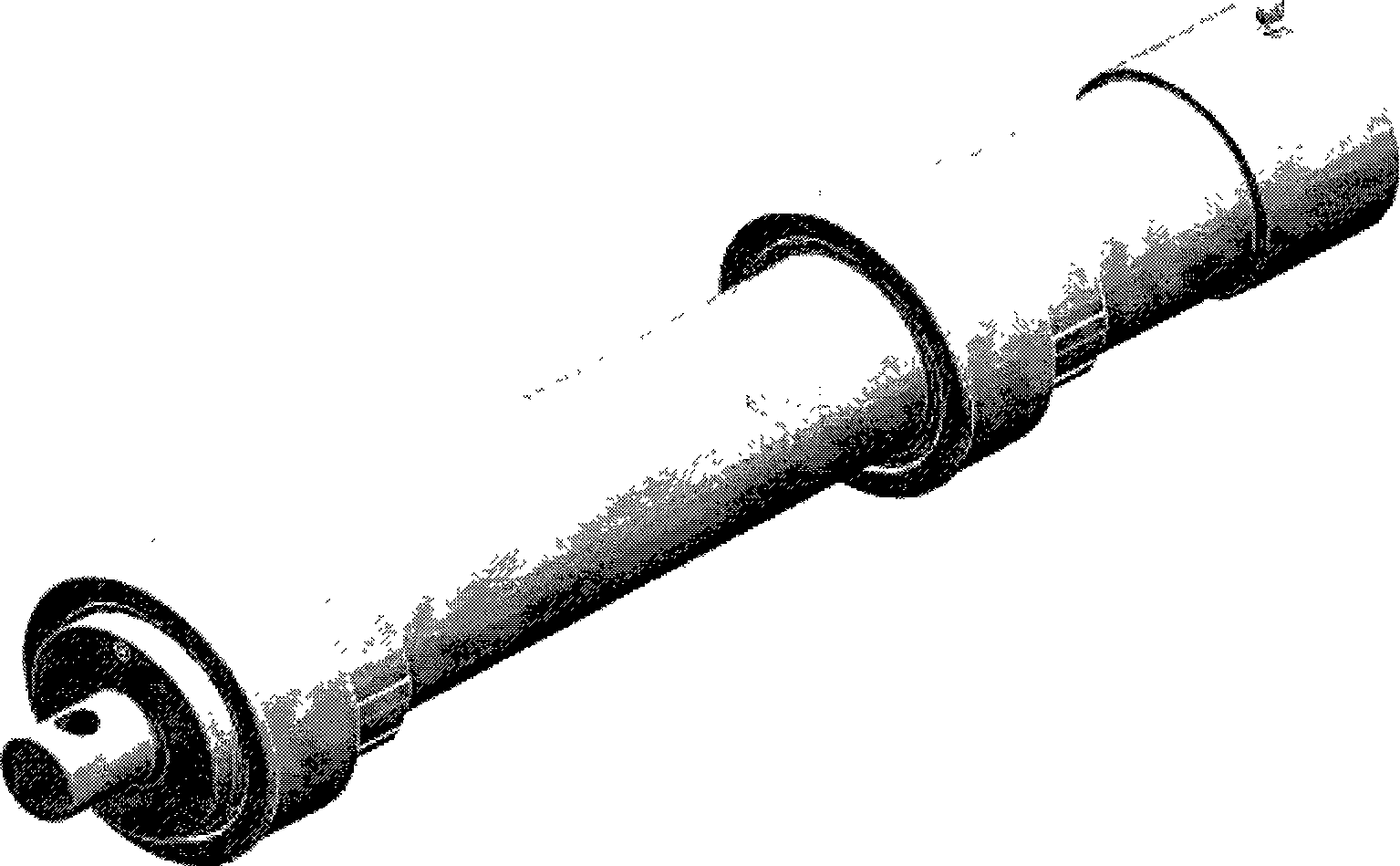

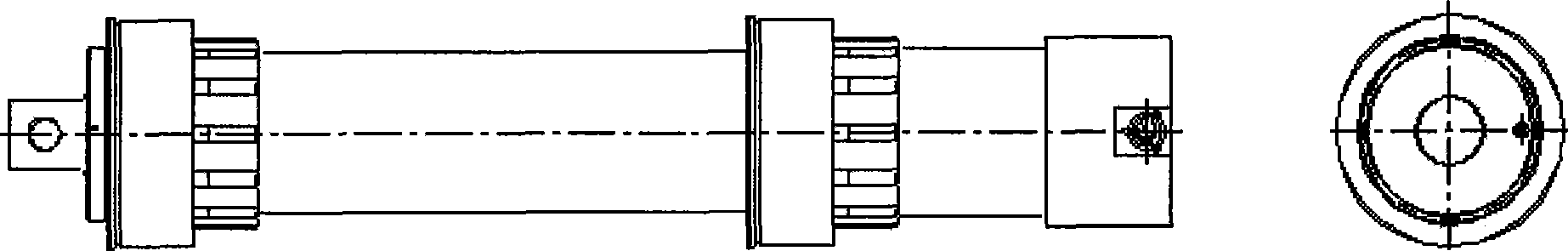

Built-in dynamical double-damping boring bar

The invention discloses a built-in dynamical double-damping boring bar for processing deep holes, which mainly comprises a bar body, an elastic locating piece and cylindrical damping blocks, wherein, a cylindrical hole cavity is designed on one end of the bar body provided with a tool bit, the two cylindrical damping blocks are axially arranged, and each cylindrical damping block is arranged at the center of the cylindrical hole cavity of the bar body through the elastic locating piece by two ends. Compared with the single-damping boring bar in the prior art, the built-in double-damping boring bar of the invention greatly improves the vibration damping property to achieve good vibration damping property, thus greatly improving boring processing conditions and enhancing the machining precision of workpieces.

Owner:SICHUAN UNIV

Guide pad

ActiveUS20130051944A1Convenient ArrangementAchieve improvementDrilling/boring measurement devicesThread cutting machinesEngineeringMechanical engineering

A guide gib (500) for a deep drilling tool of a substantially rectangular shape with a longitudinal direction (L) and a width (B) and with at least one sliding surface (540) is characterized in that at least one lubricating groove, preferably a plurality of lubricating grooves (501, 502), is / are arranged at least in the region of a contact zone of the sliding surface.

Owner:BOTEK PRAEZISIONSBOHRTECHNIK GMBH

Technological method of fine boring large-sized diesel engine cylinder porous series

InactiveCN101468402AImprove machining accuracyMeet high-precision process requirementsBoring barsBoring/drilling machinesSurface roughnessPorous system

The invention discloses a process method of a finish machining large-scale diesel engine cylinder body porous system. The process method comprises: machining two or more than two holes inside a porous system on a cylinder body by adopting self guidance of a workpiece; installing a guide sleeve on the two machined holes inside the porous system on the cylinder body as guidance; installing a float boring bar inside the guide sleeve; installing a precision boring unit and a boring cutter on the float boring bar corresponding to a to-be-machined hole; and connecting the float boring bar with a main shaft to carry out precision machining on a large-scale diesel engine cylinder body porous system hole on a horizontal boring and milling machine or a horizontal machining center. The process method makes use of a machined hole of the workpiece for guidance so as to carry out machining on the porous system with large aperture, long distance and higher requirements on size, form and position precision and surface roughness concentration; moreover, the method has high machining precision and lower process cost and can meet the requirements of high-precision process. The process method does not require special machine tool and special frock and has simple and safe operation and quick production; therefore, the method is suitable for popularization and application in the engine industry.

Owner:GUANGXI YUCHAI MASCH CO LTD

Vibration suppressing cutting tool

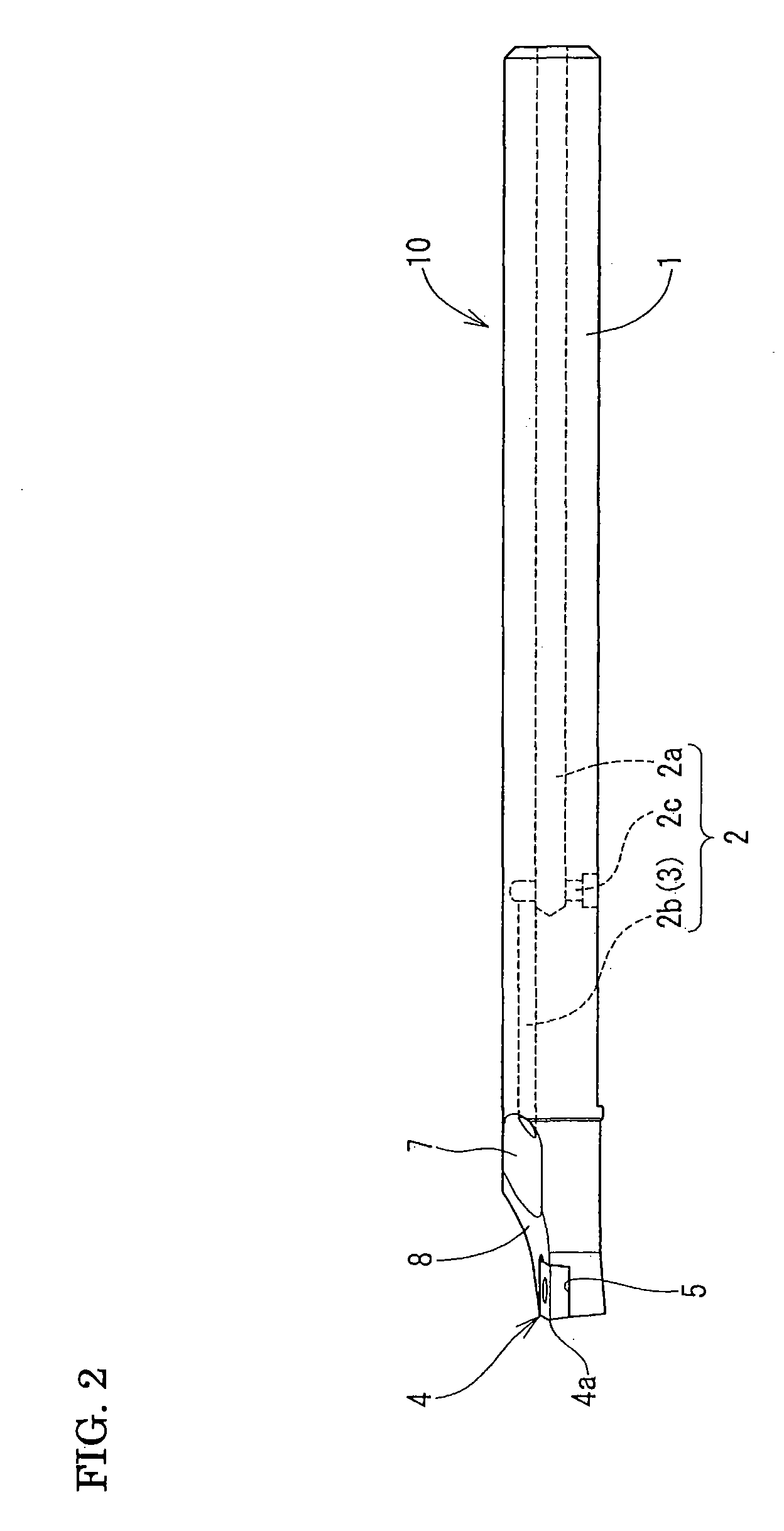

ActiveUS20070089574A1Suppress chatterReduce flutterLathesBoring barsEngineeringMechanical engineering

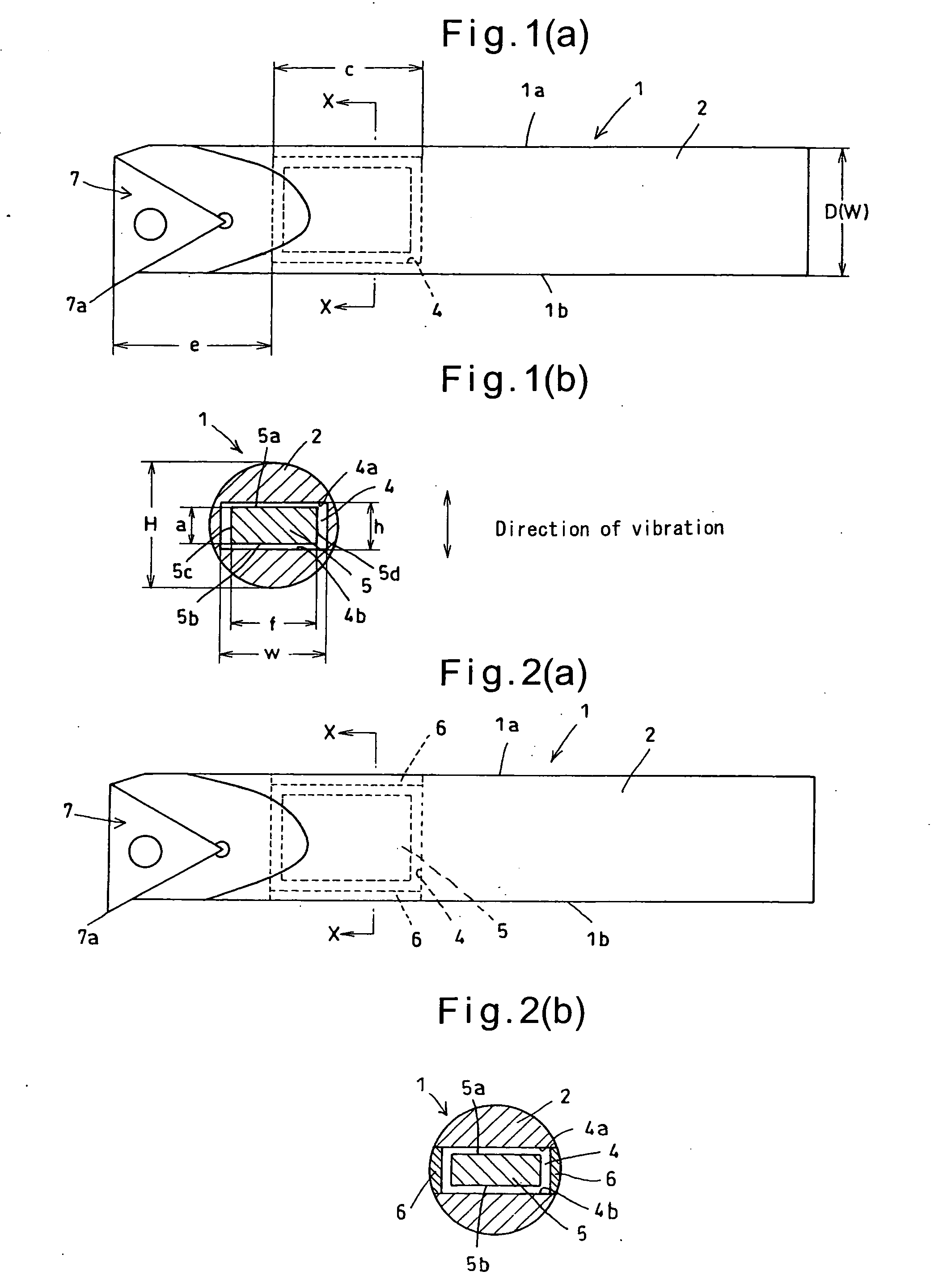

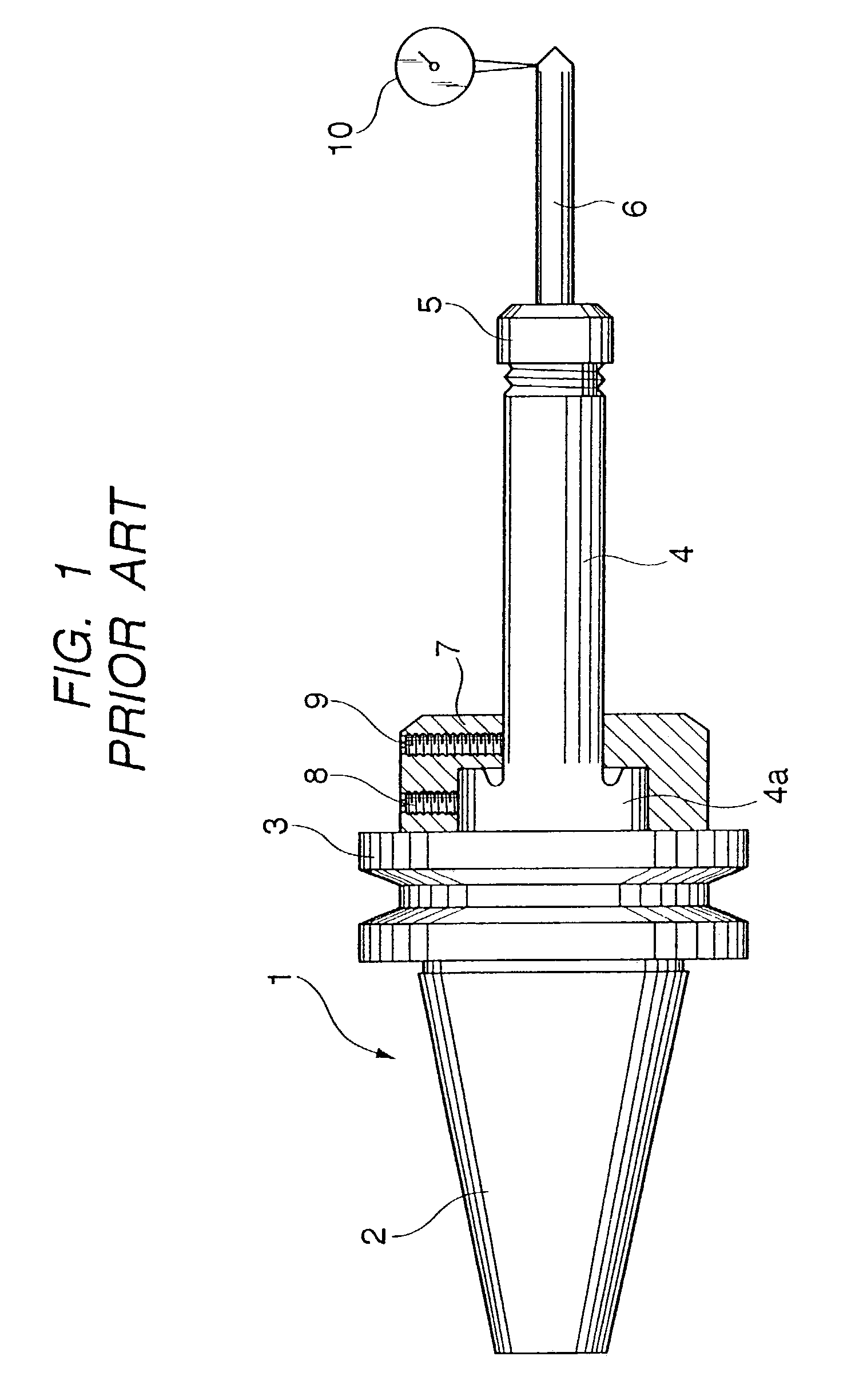

An object is to provide a vibration suppressing cutting tool which is inexpensive and can damp chattering extremely effectively, and which is simple in structure and is applicable to a wide variety of machining diameters and cutting conditions. The shank 2 of the holder 1 is formed with a pocket 4. In the pocket 4, a vibration suppressing piece 5 is received so as to be movable relative to the holder 1 and not protrudable from the pocket 4. Under kinetic energy from the holder during cutting, the vibration suppressing piece 5 alternately knocks against a pair of opposed inner wall surfaces 4a and 4b of the pocket along its surface, along a plurality of lines or on a plurality of points when the holder vibrates during cutting, thereby damping vibrations of the holder.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

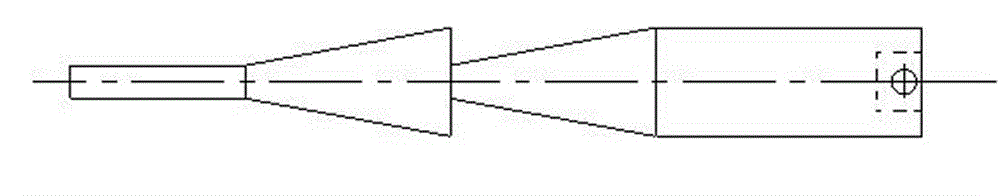

Cylindrical deep hole boring device with auxiliary supporting

ActiveCN102717118AMeet roughness quality requirementsAvoid scratchesBoring barsTool holdersMachined surfacePosition error

The invention relates to a cylindrical hole processing device, in particular to a cylindrical deep hole boring device with auxiliary supporting, which solves the problem that in the machining process of the current cylindrical hole processing device, a cutter can scratch the machined surface during returning, a boring rod is seriously deformed when a hole is deeper, and the shape and position errors of the bored hole is large. The cylindrical deep hole boring device comprises the boring rod and a boring cutter, wherein holes are formed in the axial center and the radial direction of the boring rod, and the boring cutter is installed in the radial hole of the boring rod; a double-cone core rod is arranged in the axial hole of the boring rod; two cone bodies are arranged at the front end of the double-cone core rod, and the tapers of the two cones of the two cone bodies are equal; a floating gripper is also installed on the boring rod; and a tapered hole is formed in the boring cutter, and the axis direction of the tapered hole is parallel to that of the boring rod. The cylindrical deep hole boring device has the beneficial effects that when the cutter returns, the cutter leaves the machined surface to avoid to scratch the surface; the quality requirement of the workpiece roughness is met; the shape and position errors of the bored hole is small; and the boring rod is not easily deformed.

Owner:ZHONGBEI UNIV

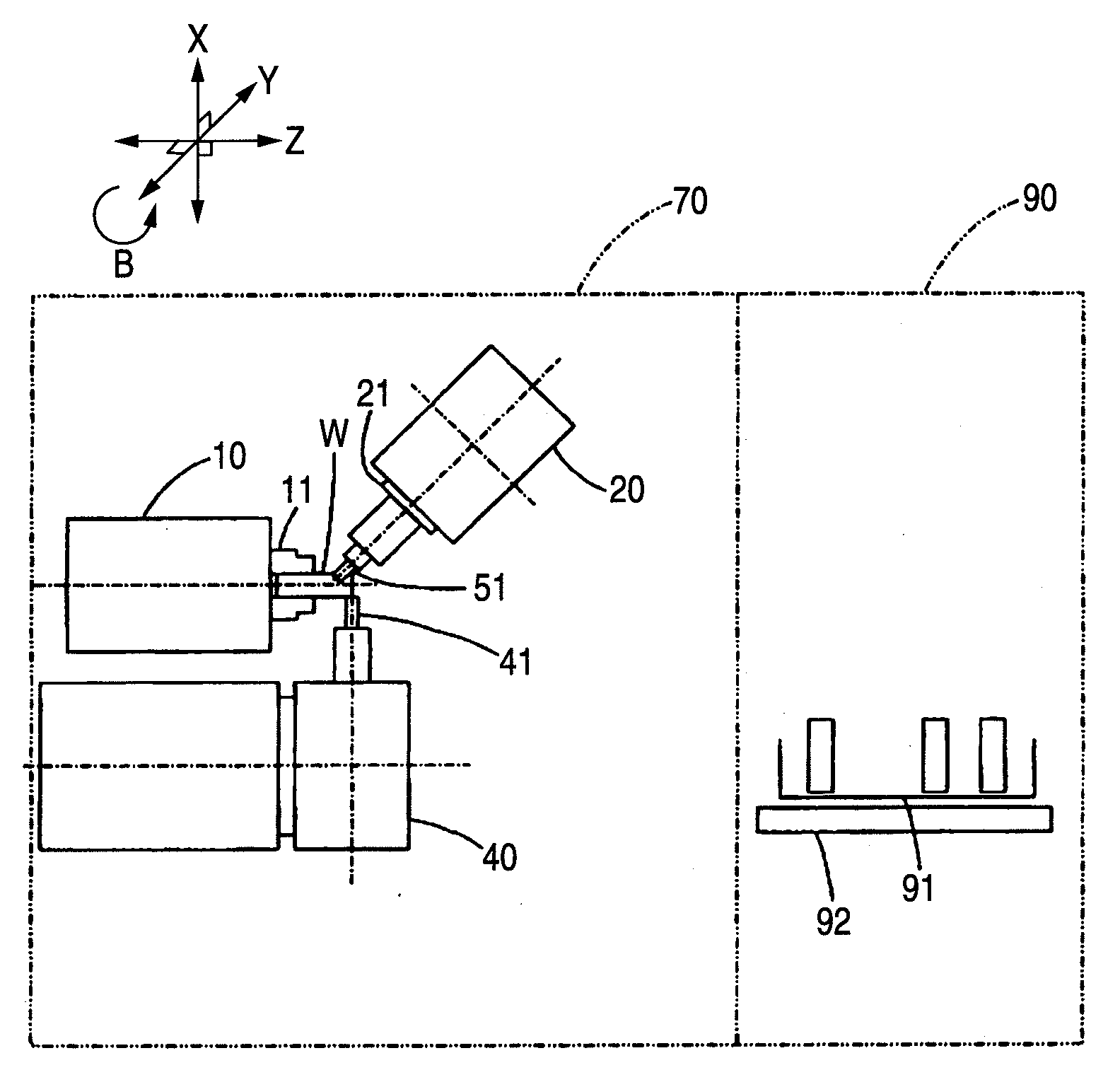

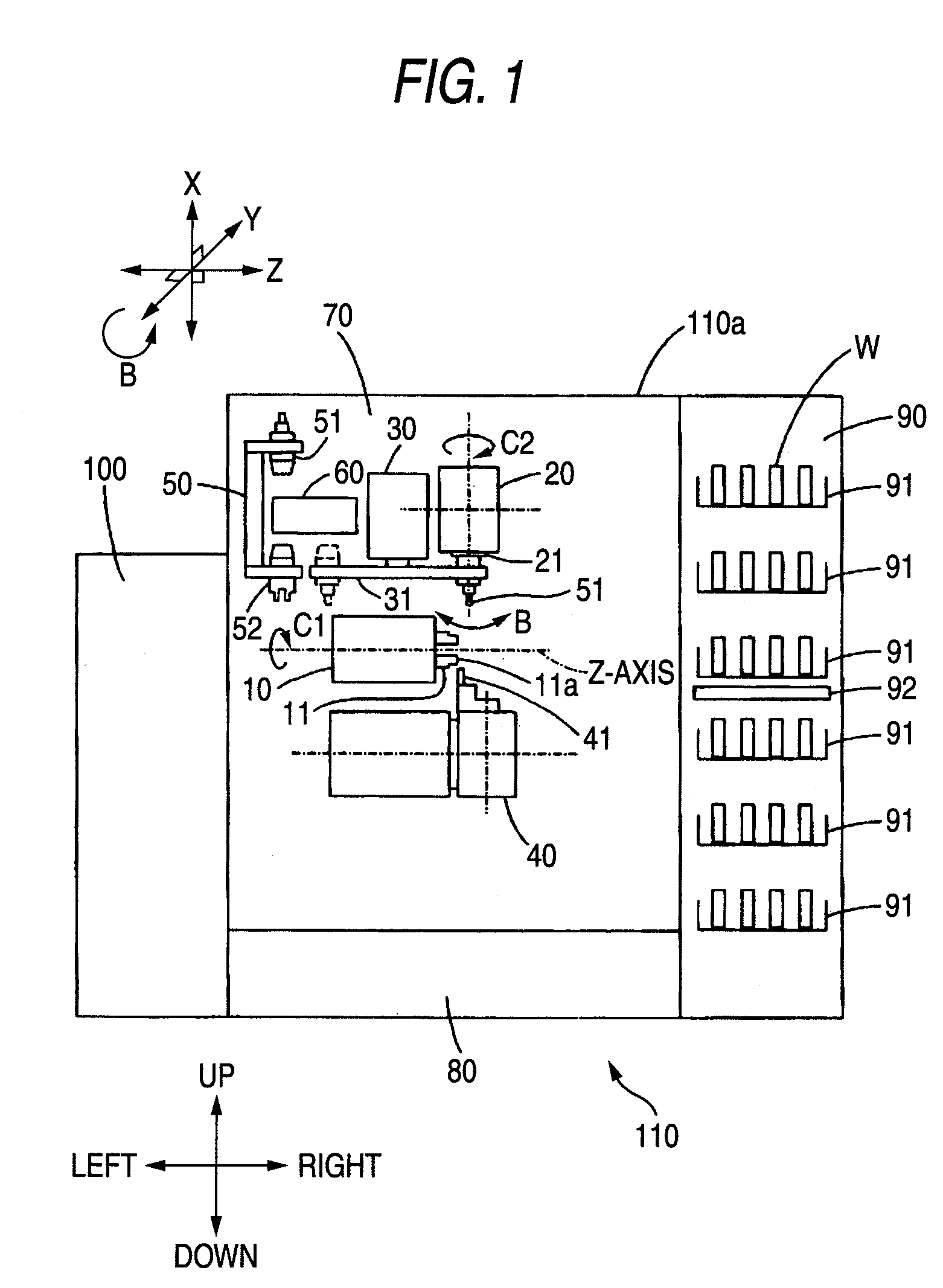

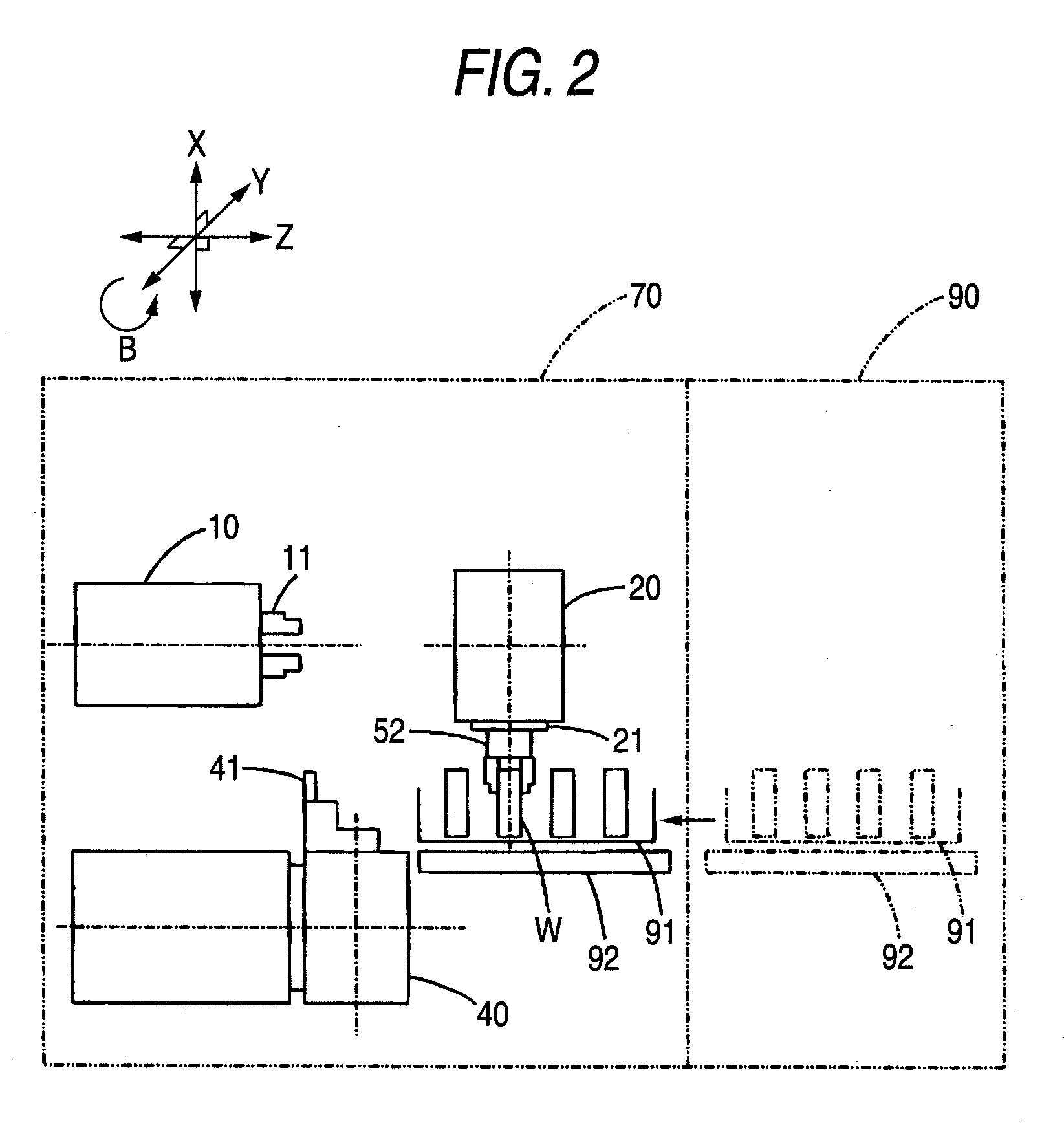

Machine tool

A machine tool includes: a main spindle adapted to be rotatable with a workpiece chucked thereby; a tool spindle capable of moving in directions of three axes perpendicular to each other and capable of pivoting about one of the axes, the axis being perpendicular to the main spindle; an automatic tool changer adapted to detachably attach a first tool and a chucking unit to the tool spindle, the first tool being used for machining the workpiece chucked by the main spindle, the chucking unit being used for chucking the workpiece; and a tool post having a second tool mounted thereon, the second tool being used for machining the workpiece chucked by the chucking unit attached to the tool spindle.

Owner:STAR MICRONICS

Boring tool with adjustable chamfer cutter

A cutting tool having a cutting portion located proximate to one end. The cutting tool including a recessed chip flute formed along the shank of the tool away from the cutting edge. The tool includes a chamfering cartridge which is clamped to the tool shank along the chip flute. The chamfering cartridge performs a chamfering or deburring operation while allowing chips from the cutting portion to pass through the flute and away from the tool and workpiece.

Owner:STOJANOVSKI DIMITRIJE

Boring tool with coolant hole

In a boring tool with a coolant hole, a spray opening of a coolant hole formed in a shank is positioned with a radial offset from the shank center toward the side on which a cutting tool is formed. The spray opening is sloped at an angle of 0 to 10 deg from an axial center of the shank toward a cutting edge. Also, the spray opening is positioned so that a distance from the cutting edge to the opening is up to three times the shank diameter.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

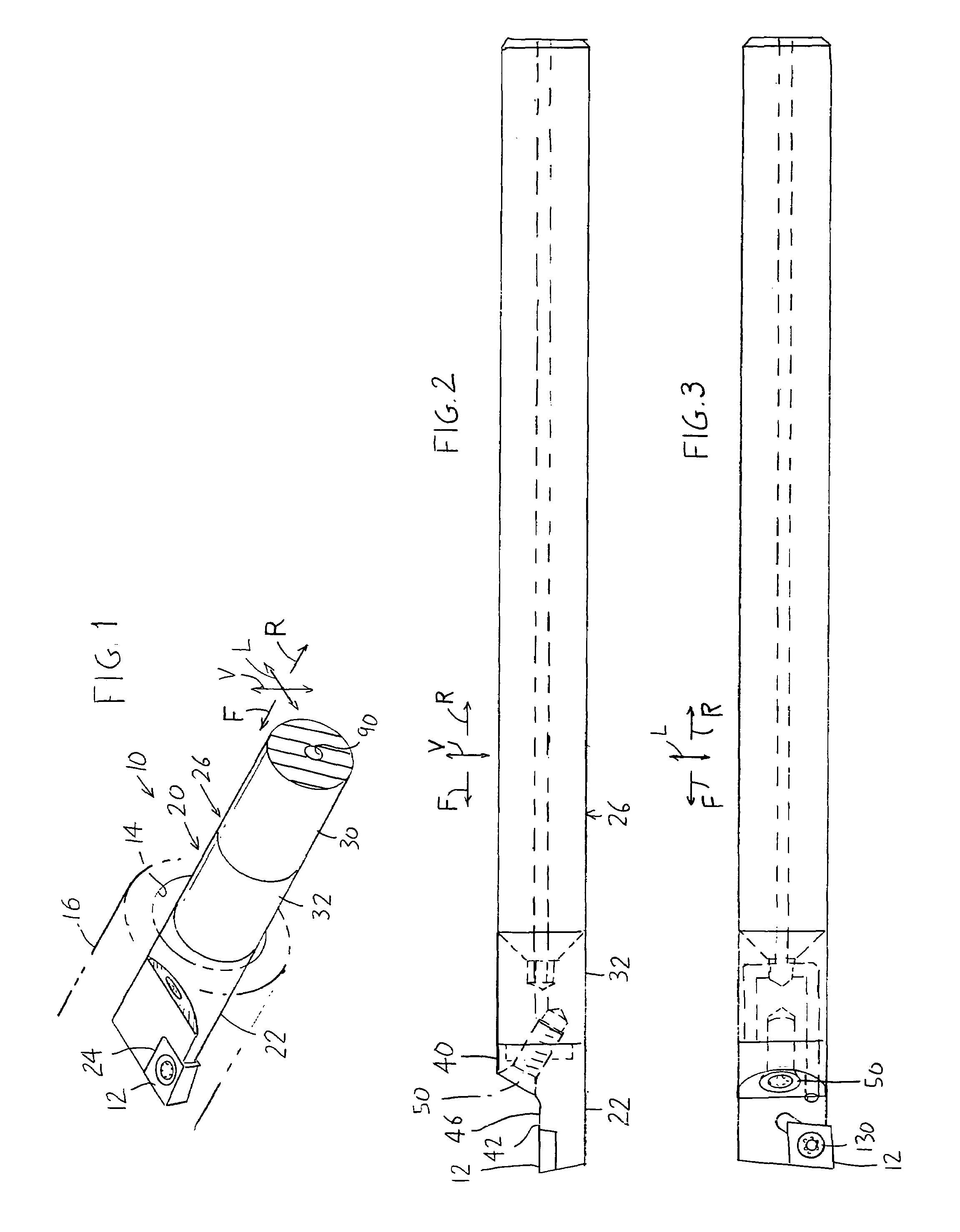

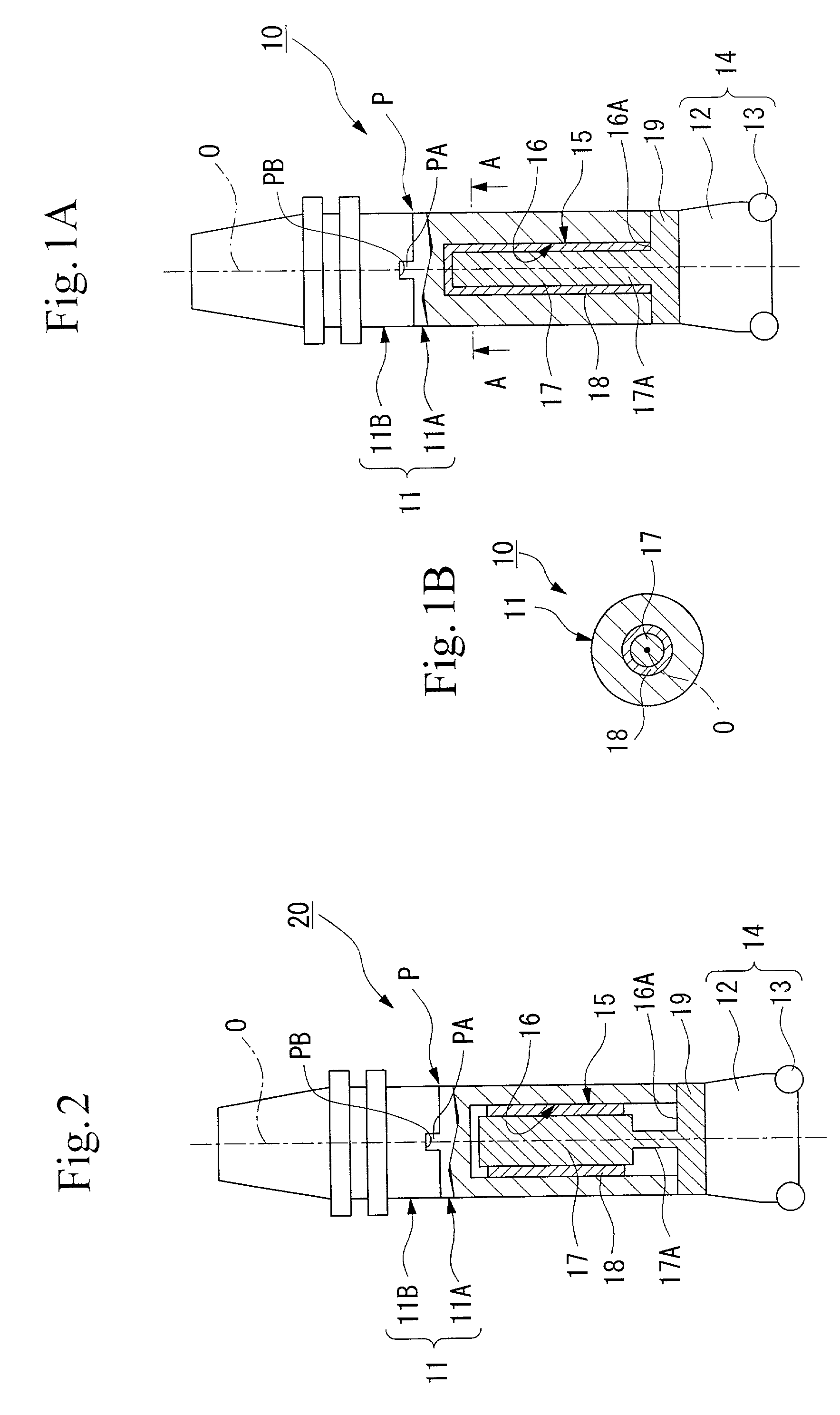

Vibration damping tool

A vibration damping tool having the following structure is provided. In the vibration damping tool, a hollow portion is formed in the interior of the distal end portion of a tool body and one end of a weight member is connected to the inner wall surface of the distal end side of this hollow portion. A gap created between the outer peripheral surface of the weight member and the inner wall surface of the hollow portion is filled with a visco-elastic body. The one end of the weight member is formed as a narrow diameter shaft portion. The tool body can be divided into two and freely removed from and reattached at a dividing surface located on the base end side of the hollow portion. A hole portion is formed inside the other end of the weight member by hollowing out the interior thereof. Chatter vibration is thus absorbed using a simple structure without there being any effects from heat generated during cutting processing.

Owner:MITSUBISHI MATERIALS CORP

Damping tools

InactiveCN1390666ASimple structureSuppress high frequency vibrationLathesBoring barsChatter vibrationEngineering

A vibration damping tool having the following structure is provided. In the vibration damping tool, a hollow portion is formed in the interior of the distal end portion of a tool body and one end of a weight member is connected to the inner wall surface of the distal end side of this hollow portion. A gap created between the outer peripheral surface of the weight member and the inner wall surface of the hollow portion is filled with a visco-elastic body. The one end of the weight member is formed as a narrow diameter shaft portion. The tool body can be divided into two and freely removed from and reattached at a dividing surface located on the base end side of the hollow portion. A hole portion is formed inside the other end of the weight member by hollowing out the interior thereof. Chatter vibration is thus absorbed using a simple structure without there being any effects from heat generated during cutting processing.

Owner:MITSUBISHI MATERIALS CORP

Method for machining a dental prosthesis

InactiveUS20120177456A1Reduce the possibilityThread cutting toolsLayered productsDenturesEngineering

A method for machining a dental prosthesis that reduces the likelihood of forming tool failure includes machining a workpiece to form a bottom surface without machining a bottom cavity of the dental prosthesis, then machining the bottom cavity and machining the top.

Owner:JUNG YUNOH +1

Intelligent vibration reduction boring bar and vibration reduction control method

The invention provides an intelligent vibration reduction boring bar and a vibration reduction control method and belongs to the field of machining. The problems that an existing passive vibration reduction boring bar has no automatic vibration reduction adjusting function, and an active vibration reduction boring bar system is large and difficult to maintain and repair are solve. According to the boring bar, a three-axis accelerator sensor, multiple cantilever vibration absorption units and a sliding base are arranged in a cavity at the front end of a cutter bar. Each cantilever vibration absorption unit comprises a mass block and a cantilever beam, wherein the two ends of the cantilever beam are fixed to the mass block and the rear end face of the cavity respectively. A data processing unit calculates acceleration data of the pointed end of a blade according to acceleration data measured by the sensor, the sliding base is controlled by a transmission unit to slide in the cavity, and accordingly the overhanging amount of the cantilever beams is changed. The method includes the steps that the data processing unit controls the sliding base to slide from one end of each cantilever beam to the other end, in the process, the data processing unit determines the slider optimal position corresponding to the minimum acceleration data at the pointed end of the blade, and a slider is controlled to slide to the position. The boring bar is used for deep hole boring.

Owner:HARBIN UNIV OF SCI & TECH

Tool holder

InactiveUS7037053B2Easy to correctForce is smallThread cutting toolsTransportation and packagingFlangeKnife holder

A tool holder is equipped with a tip run-out correction mechanism for correcting run-out of the tip of the tool. The tip run-out correction mechanism includes an annular stepped portion formed on a cylindrical support portion of a holder body; a ring member rotatably fitted onto the annular stepped portion; an eccentric cam disposed within the ring member, the eccentric cam extending radially through the ring member and being rotatable about a radially extending axis; and a pin disposed within the ring member to be movable along a direction parallel to the center axis of a flange portion of the holder body. One end of the pin is in contact with the eccentric cam, and the other end of the pin is in contact with a rear end face of a clamp sleeve which clamps a tool inserted into a chuck sleeve of the holder body. The eccentric cam is rotated so as to adjust press force that the pin applies to the rear end face of the clamp sleeve, to thereby elastically deform a base end portion of the chuck sleeve in a radial direction in such a manner that tip run-out of the tool approaches zero.

Owner:NIKKEN KOSAKUSHO WORKS LTD

Tool for machining pipe ends

InactiveUS6957936B2Avoid disadvantagesIncrease valueThread cutting toolsTransportation and packagingBlade plateEngineering

A tool for removing material or machining the end of a pipe. The tool having at least one and preferably two blade plates. Each blade plate includes a first cutter for machining an end surface of the pipe, a second cutter adjacent the first cutter for producing an internal chamfer in the pipe end and a third cutter adjacent the first cutter positioned for producing an external chamfer adjoining the end surface of the pipe end. Devices guide and permit movement of the cutters either radially or axially. The shaping of the cutter is disclosed.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

Head Replaceable Cutting Tool

InactiveUS20130142582A1Prevent rotationThread cutting toolsWood turning toolsHead surfaceBiomedical engineering

A cutting tool has a cutting head and a shank. The cutting head has a body, a head threaded portion, a first helical head surface and a second helical head surface. The shank has a cylindrical portion, a shank threaded portion, a first helical contact surface and a second helical contact surface. The head threaded portion screw-engages the shank threaded portion. The first helical head surface is parallel to the thread of the head threaded portion and the first helical contact surface is parallel to the thread of the shank threaded portion. The second helical head surface and the second helical contact surface are inclined reversely to the first helical head surface and the first helical contact surface, respectively. The first helical head surface comes into surface contact with the first helical contact surface. The second helical head surface comes into surface contact with the second helical contact surface.

Owner:TAEGUTEC

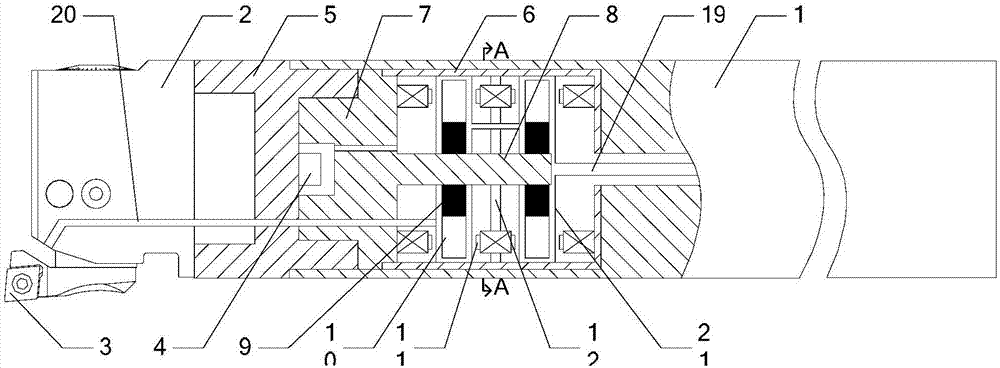

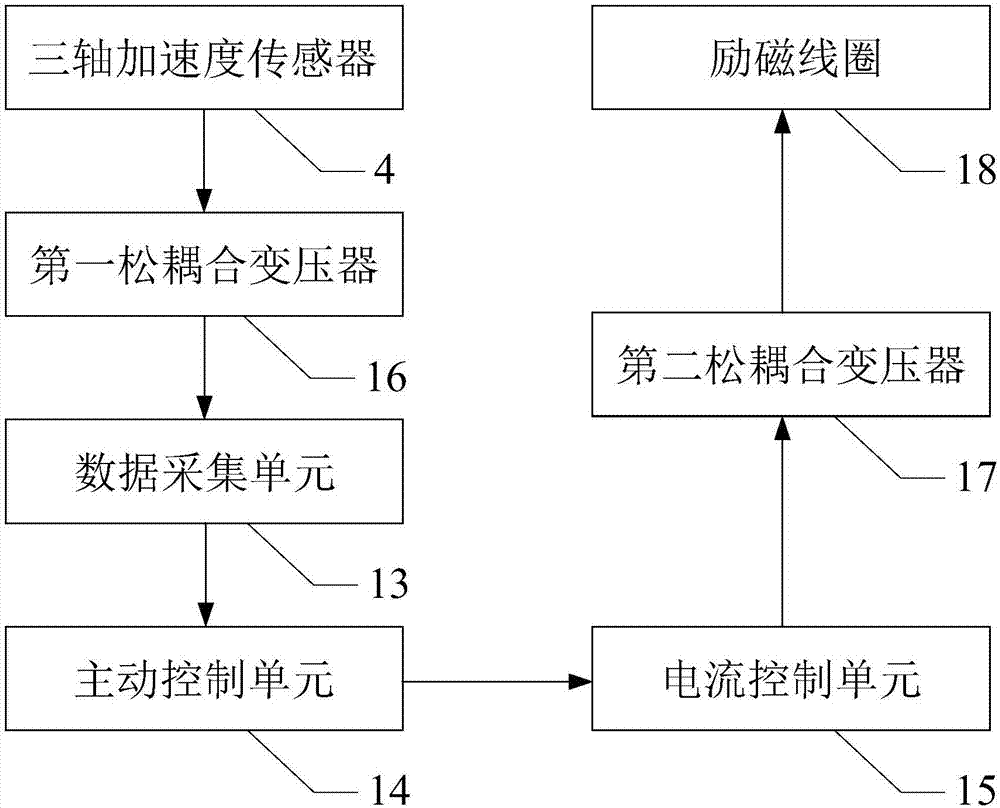

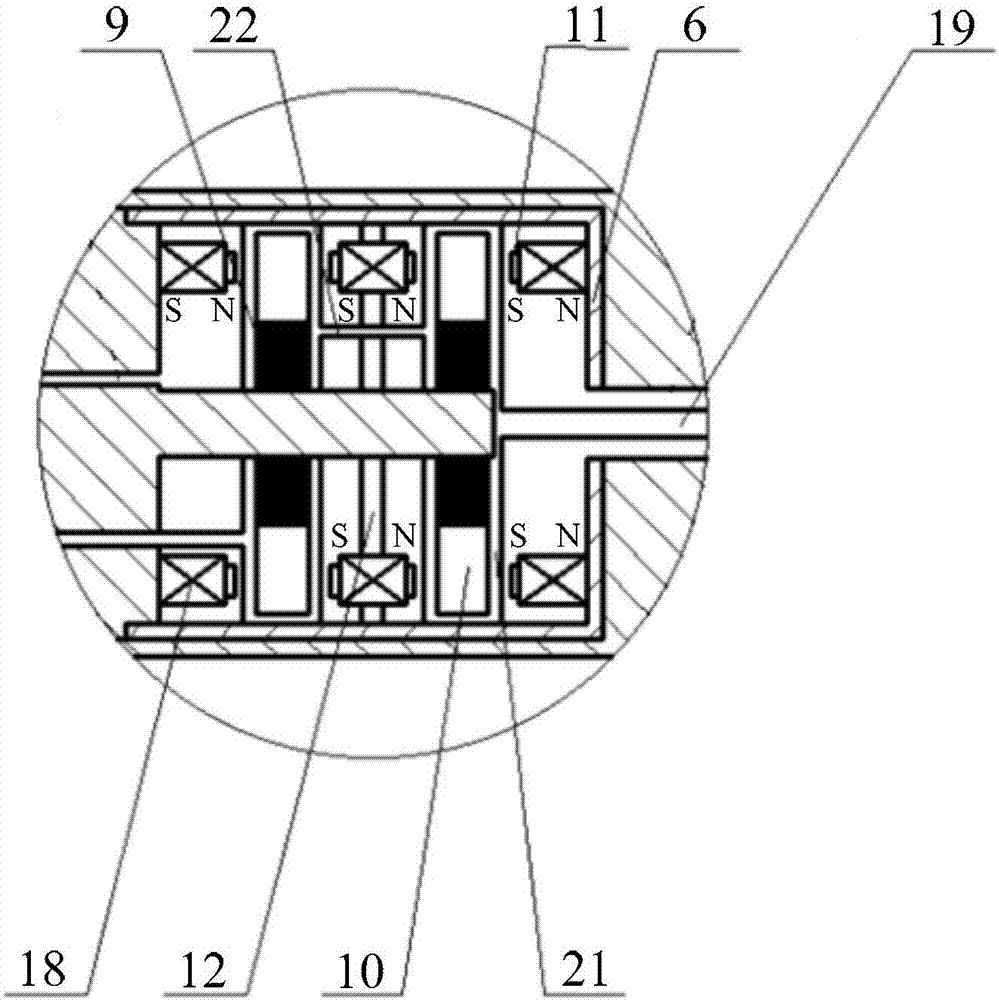

Active vibration reduction boring rod based on electromagnetic damper

InactiveCN107989958ASimple structureSolve the problem of failureNon-rotating vibration suppressionBoring barsDamping factorControl system

The invention relates to an active vibration reduction boring rod based on an electromagnetic damper, and belongs to the field of machining. The active vibration reduction boring rod based on the electromagnetic damper solves that problem that an existing active vibration reduction boring rod based on a damper is prone to failure, complex in structure and large in manufacturing difficulty. The active vibration reduction boring rod based on the electromagnetic damper comprises a rod body, the electromagnetic damper, a three-axis acceleration sensor and a control system, wherein a tool bit is arranged at the front end of the rod body, and the tool bit is used for clamping a blade; the electromagnetic damper is arranged inside the rod body. When the vibration reduction boring rod is used forboring, the three-axis acceleration sensor is used for measuring acceleration data of the rod body and sending the acceleration data to the control system, and the control system is used for adjustingthe damping coefficient of the electromagnetic damper until the acceleration data that the control system receives reaches the minimum. The active vibration reduction boring rod based on the electromagnetic damper is suitable for fine boring.

Owner:HARBIN UNIV OF SCI & TECH

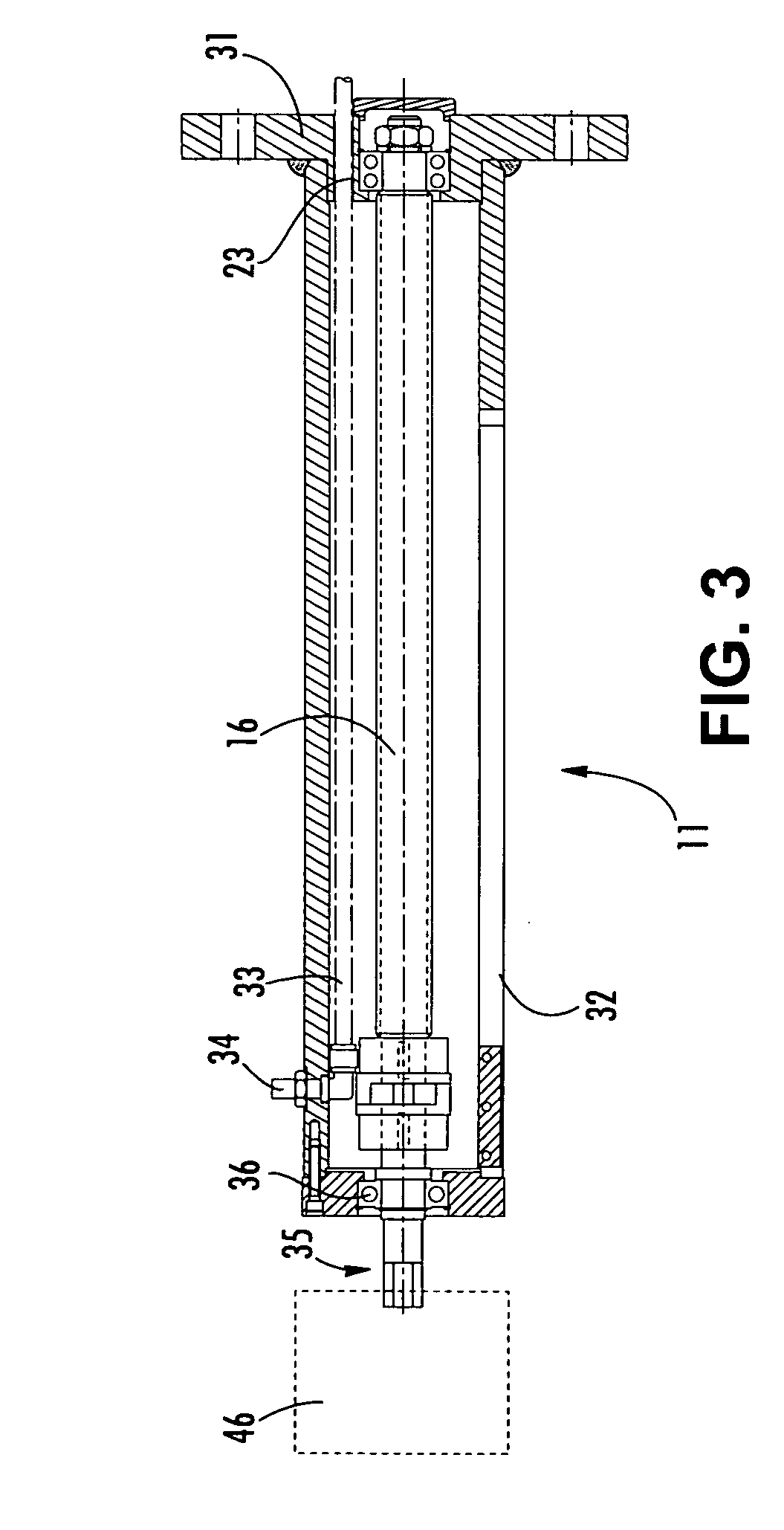

Automated boring bar

InactiveUS20050204879A1Eliminate inaccuraciesReduce dependenceBoring barsBoring headsGear systemEngineering

The present invention relates to an improved apparatus and method for machining pipe. In one aspect, the multifunction apparatus is an improved device for machining the inside diameter and outside diameter of pipe, as well as shaping the wall of pipe. In another aspect, the invention is an improved method for machining pipe. In particular, the method employs a one-to-one communication ratio between the geared components that control the position of the cutting tool in order to eliminate rounding errors associated with conventional gearing systems.

Owner:WACHS TECHN SERVICES

Reamer with clamping arrangement for adjusting cutting insert and other cutting tools with clamping arrangements for adjusting cutting inserts

InactiveUS7322777B2Avoid OverloadingIncreased bending loadThread cutting toolsTool workpiece connectionEngineeringReamer

A cutting tool with a cutting insert and a pivotable screw and nut combination for holding the cutting insert. The cutting tool also has a feed mechanism to adjust the position of at least one cutting edge of the cutting insert in the cutting tool.

Owner:KENNAMETAL INC

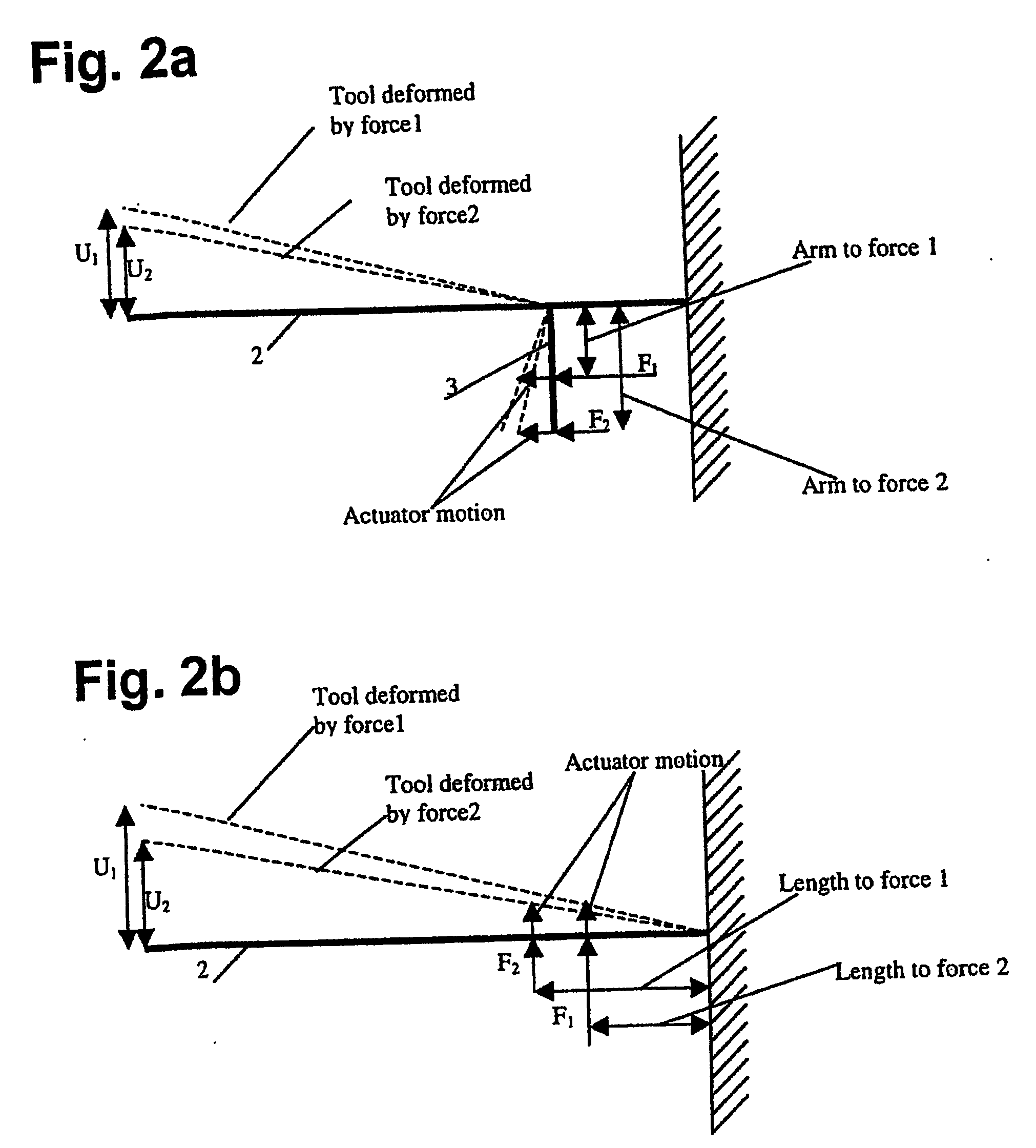

Arrangement for damping of vibrations and defection in a tool holder

The invention relates to a device for damping vibrations and / or controlling the flexion of an object (2, 10) in machining, said device comprising at least one force exchange device (7) which could be a force applying device or a damping device. A such force applying device (7) is for applying a force having a force component directed at right angles to the surface of the object and / or for applying a moment to the object (2, 10). A damping device (7) of this type is for absorbing vibrations from the object (2, 10) and is adapted to absorb a force component directed at right angles to the surface of the object or to absorb a moment from the object.

Owner:TEENESS AS

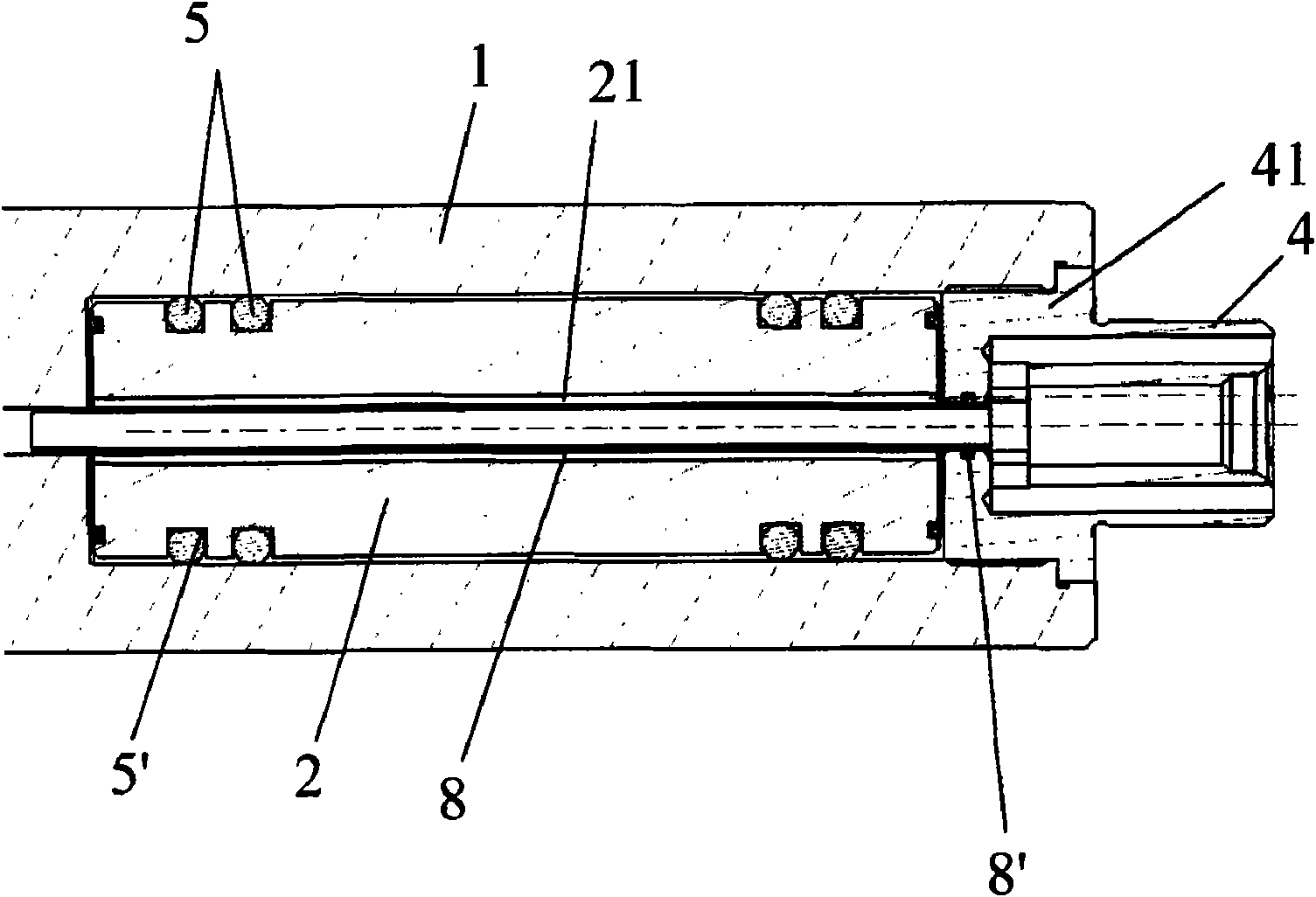

Tool holder equipped with a damping means

ActiveCN101554666AReduce vibration effectsSimple designWorkpiecesBoring barsNumerical controlDigital control

The present invention relates to a tool holder, such as a reaming head (1), or a milling arbor, provided with a damping means (2) in the form of an elongated body, which is arranged in an end compartment (3) of the tool holder (1), which compartment is of appropriate shape and size, and closed at end thereof by a body (4) for receiving a reaming head or by a milling element. Tool holder characterized in that the damping means (2) is of the type presenting only radial absorption, and is provided with at least one elastically deformable means (5), at least close to each end, where said elastically deformable means (5) extend between the envelope of the damping means (2) and the wall of the compartment (3) of the tool holder (1), and are clamped between the wall of the compartment (3) and the damping means (2), and where the ends of the damping means extend in the compartment (3) without stress. The invention is applicable more particularly in the field of accessories for machine tools, with digital control, machining centers, flexible cells and workshops.

Owner:EPB

An internal reaming tool based on continuous automatic chip removal for blind deep holes

The invention discloses an inner chambering cutter based on the continuous automatic rear chip removal of a blind deep hole, aiming to provide a special inner chambering cutter which is more favourable for processing special parts with irregular and complex curve, such as a conical surface, a sphere, a cylindrical surface and the like in the blind deep hole, the middle of each special part is big, and two ends of the part are small. The inner chambering cutter comprises a push-pull mechanism, a movable tool rest mechanism, an end cover and a cutter body, wherein the push-pull mechanism is formed by connecting a push-pull rod and a guide rail via a taper pin; a diamond coating machine clip blade is fixed on a small boring cutter body by a special sunk screw to form a movable tool rest mechanism; when the push-pull mechanism moves left and right, slope movement is carried out on the tool rest mechanism to realize the purpose that the tool rest mechanism radially moves; and the end cover is fixed on the front end of the boring cutter support body by two bolts to prevent a cutting fluid and cuttings from flowing into the inner cavity of a boring rod. The cutter body is composed of the boring cutter support body, a middle boring cutter body and a boring cutter body. The chip removal mode disclosed by the invention is rear chip removal in the external chip removal.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com