Manufacturing process of solid cold-spun forged steel piston with internal cooling oil chamber

A technology for cooling oil cavity and integral piston, applied in the field of piston manufacturing process, can solve the problems of big difference in size, high cost, high welding scrap rate, and achieve the advantages of increasing the flexibility of the skirt, which is beneficial to the gap between cylinders and the oil return. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

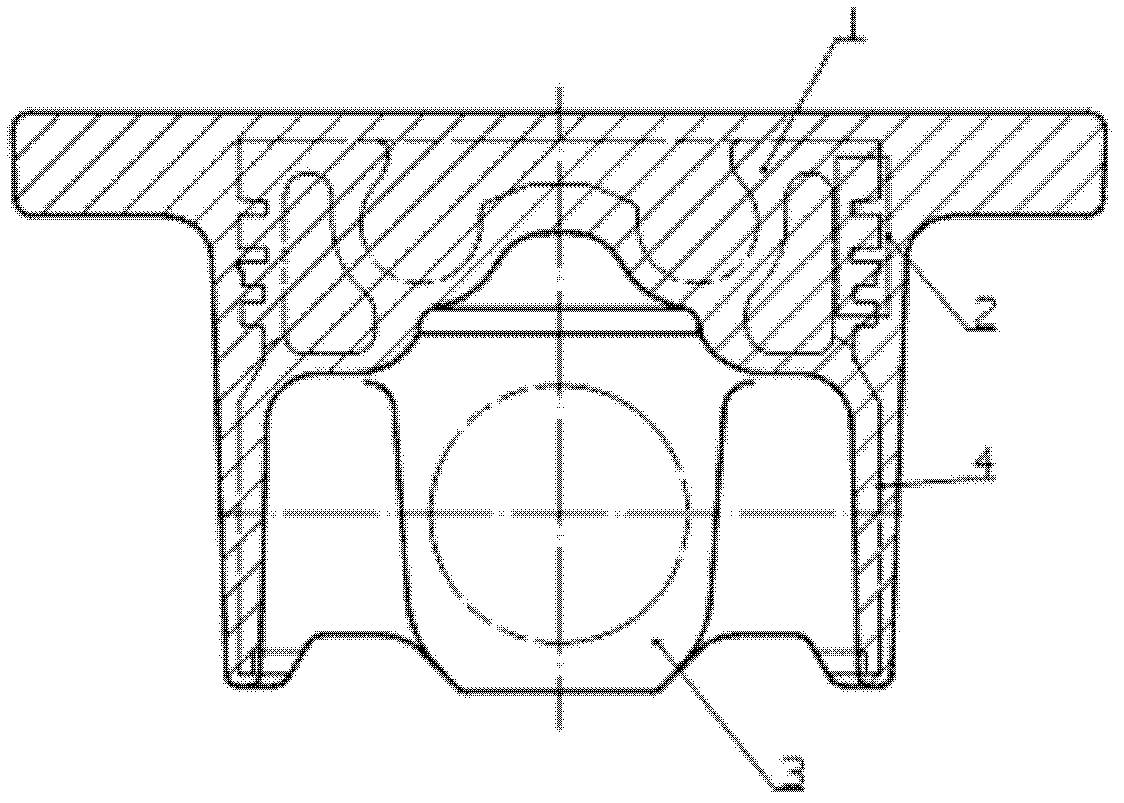

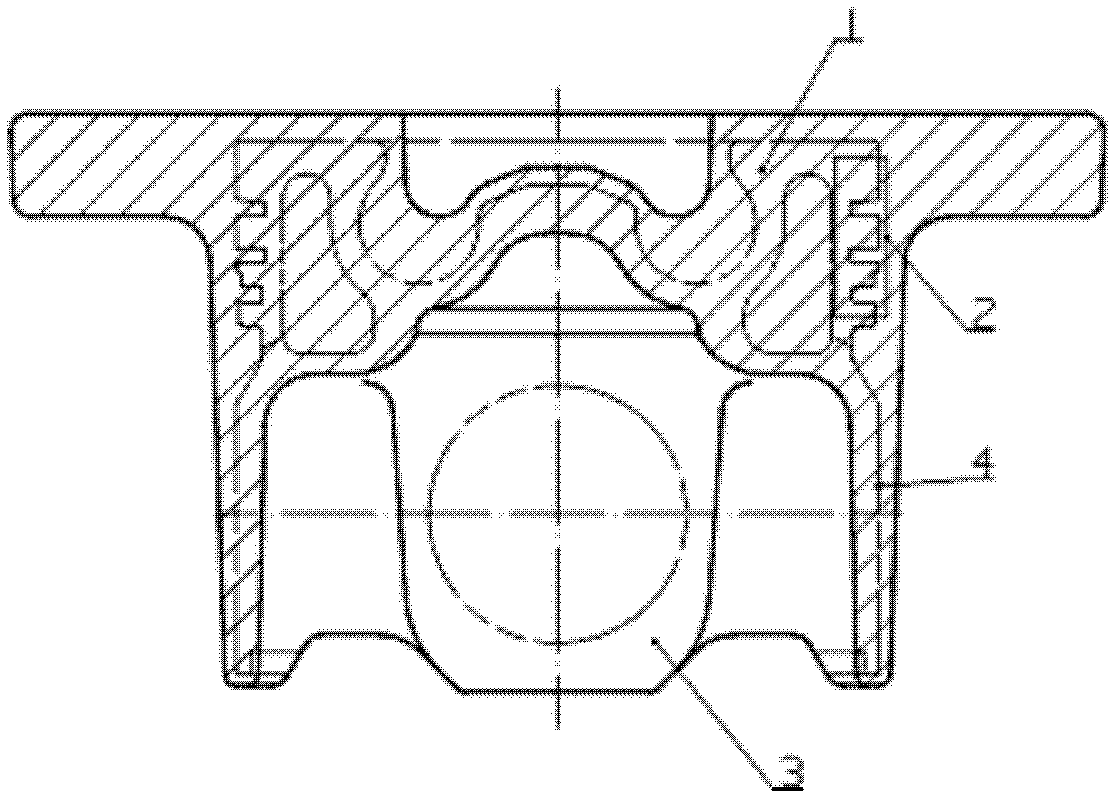

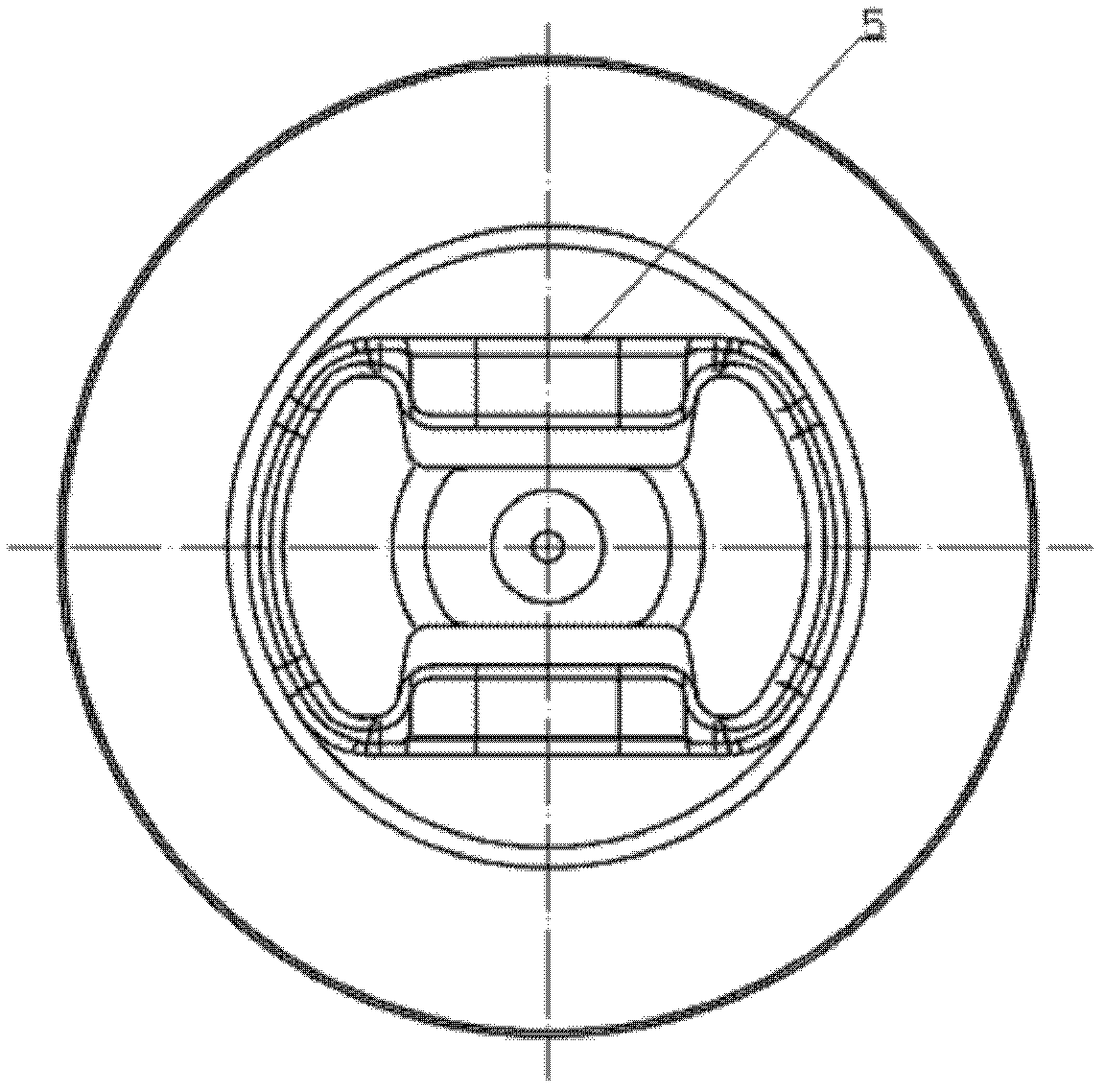

[0042] figure 1 , figure 2 with image 3 A monolithic forging blank manufactured using a hot die forging method is shown. figure 1 with figure 2 The outline of the finished piston is marked with a double dotted line, figure 2 A dimple is added to the top of the forging blank, which reduces the subsequent machining allowance. The piston blank has a piston head 1, a piston ring groove area 2, a piston pin seat 3 and a piston skirt 4. image 3 There is recessed face window 5 in piston skirt portion.

[0043] Figure 4 Shown is the semi-finished piston after mechanical roughing of the piston blank, with the dimpled top blank marked with a dotted line to outline the dimples of the blank. The inner part 6 of the inner cooling oil chamber and the shielding part 7 for blocking the inner cooling oil chamber are mechanically processed on the semi-finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com