Aluminum alloy mobile telephone shell

A technology of mobile phone casing and aluminum alloy, which is applied in the direction of telephone structure, metal material coating process, ion implantation plating, etc., can solve the problems of low strength and unsuitability of pure aluminum, so as to improve the service life, prolong the service life, and The effect of extending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

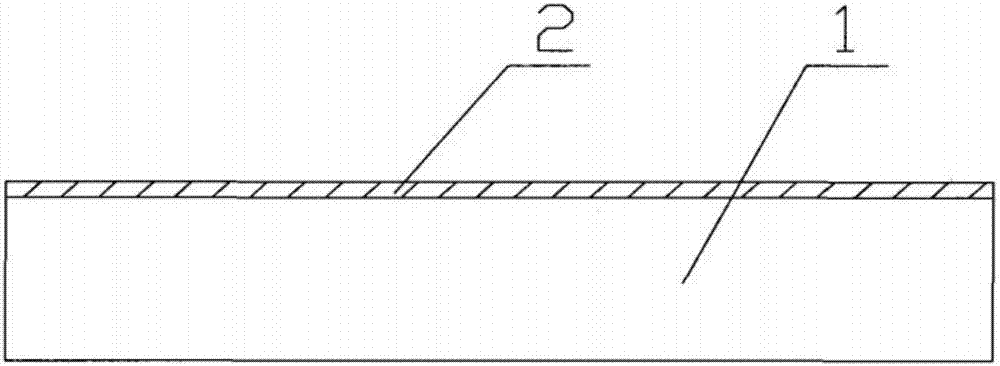

[0029] refer to figure 1 , an aluminum alloy mobile phone casing, comprising a casing body 1, the surface of the casing body 1 is vacuum-coated with a nanoscale composite film layer 2. The thickness of the shell body 1 is 0.1-0.3mm. The thickness of the nanoscale composite film layer 2 is 200-300nm. The thickness of the shell body 1 is preferably 0.2 mm, and the thickness of the nanoscale composite film layer 2 is preferably 250 nm. The nanoscale composite film layer 2 is nano silver.

[0030] The shell body is an aluminum alloy profile.

[0031] The aluminum alloy profile is characterized in that: by weight percentage, it comprises the following components: 0.1-2wt% of Fe, 0.5-3wt% of Cu, 0.01-0.1wt% of B, 0.1-1wt% of Si, 0.5-3wt% of Zn, 0.1-2wt% of Ni, 0.1-2wt% of rare earth elements, 0.1-2wt% of Mo, and the rest are aluminum and unavoidable impurities.

[0032] The rare earth elements include at least one of La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, S...

Embodiment 2

[0038] An aluminum alloy profile, characterized in that: by weight percentage, it contains the following components: 0.1wt% of Fe, 1wt% of Cu, 0.01wt% of B, 1wt% of Si, 0.5wt% of Zn, 2wt% % Ni, 1wt% rare earth elements, 1wt% Mo, and the rest is aluminum.

[0039] Among the rare earth elements is La.

[0040] The first step is to smelt each raw material in proportion at 800°C, after stirring evenly, after refining, removing slag, and degassing, after standing at 770°C for 30 minutes, cast bars in the casting machine, and then lead the cast bars into the rolling mill , the temperature of the introduction into the rolling mill is 550°C, and the temperature of the exit is 420°C, which is heated during the hot rolling process.

[0041] In the second step, the aluminum alloy strips are cold-rolled into aluminum alloy strips of different sizes on a rolling mill.

[0042] In the third step, the aluminum alloy is subjected to solution heat treatment at 500° C. for 8 hours.

Embodiment 3

[0044] An aluminum alloy profile, characterized in that: by weight percentage, it contains the following components: 1wt% of Fe, 1wt% of Cu, 0.1wt% of B, 0.5wt% of Si, 2wt% of Zn, 0.7wt% % Ni, 0.9wt% rare earth elements, 1wt% Mo, and the rest is aluminum.

[0045] The rare earth element is Nd.

[0046] The first step is to smelt all raw materials in proportion at 780°C, stir them evenly, refine, remove slag, and degas, and keep them at 750°C for 30 minutes, then cast bars in the casting machine, and then lead the cast bars into the rolling mill , the temperature of the introduction into the rolling mill is 520°C, the temperature of the exit is 400°C, and it is heated during the hot rolling process.

[0047] In the second step, the aluminum alloy strips are cold-rolled into aluminum alloy strips of different sizes on a rolling mill.

[0048] In the third step, the aluminum alloy is subjected to solution heat treatment at 510° C. for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com