Cutter for processing sputtering face of target material and processing method

A processing method and sputtering surface technology, which are applied to lathe cutting tools, manufacturing tools, metal processing equipment, etc., can solve problems such as difficulty in meeting product quality requirements and poor texture quality, and achieve improved roughness, improved quality, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

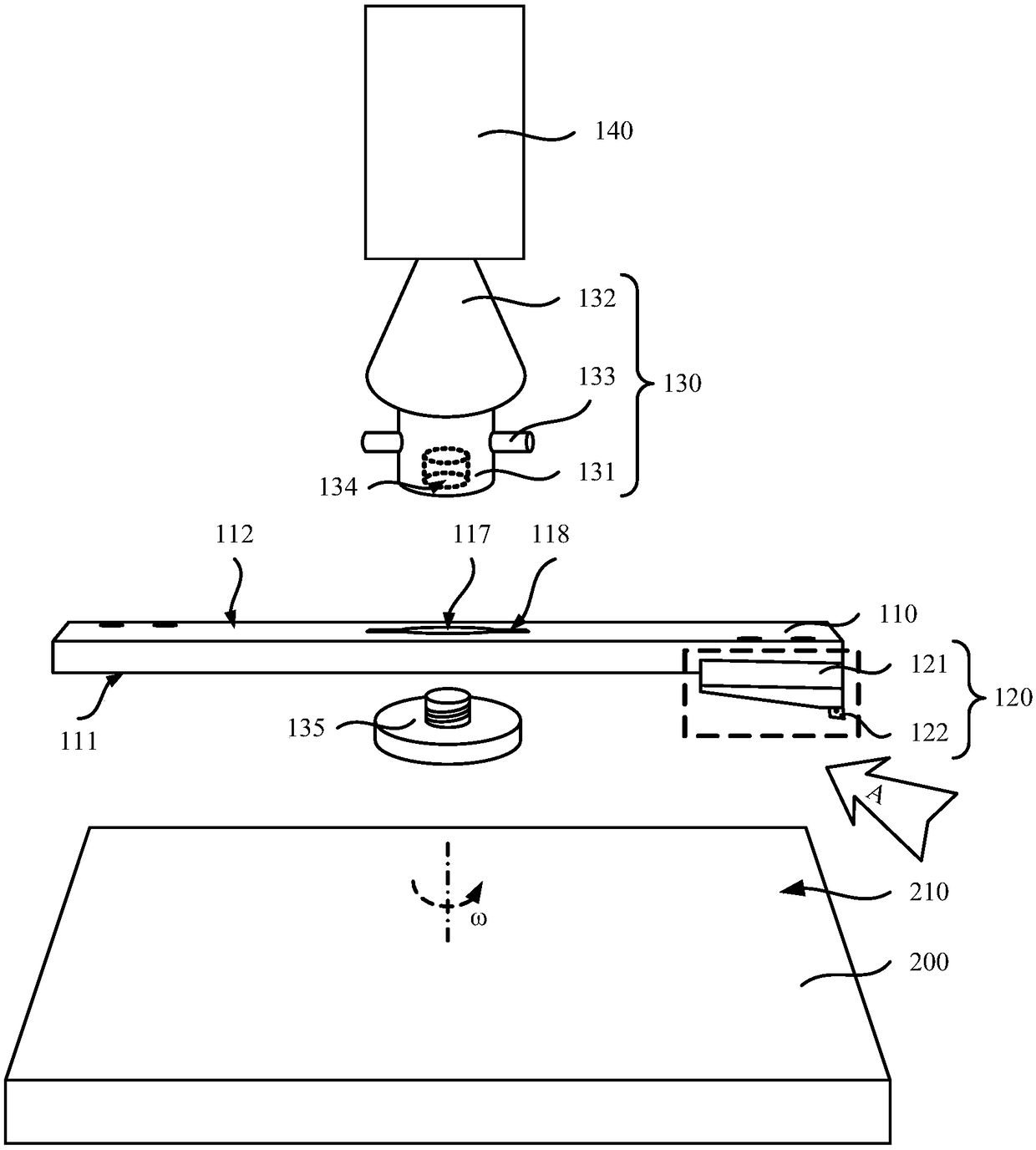

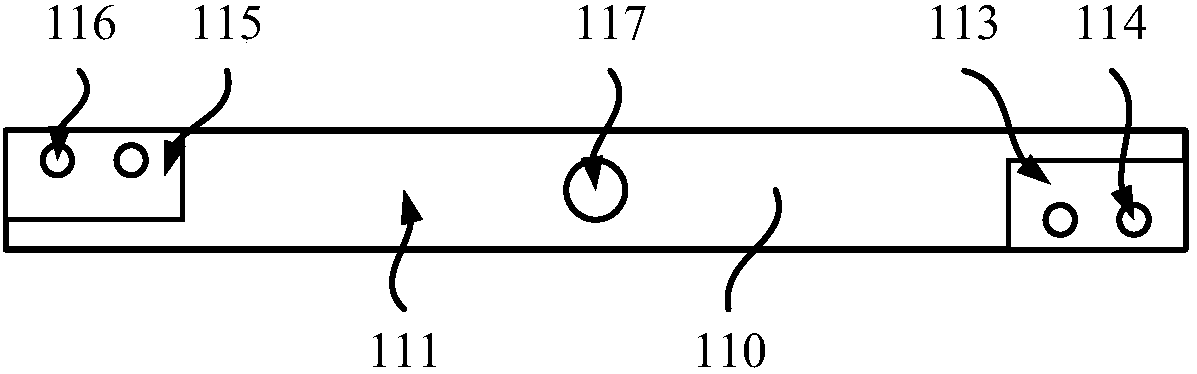

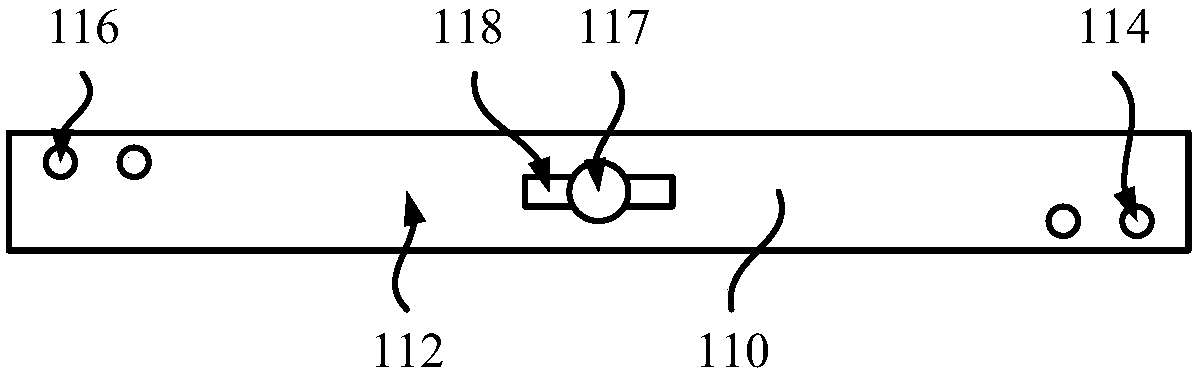

[0043] It can be seen from the background art that the quality of the texture formed on the sputtering surface of the target in the prior art is poor, and it is difficult to meet the quality requirements of the product.

[0044] In the process of machining, disc cutters are usually used for surface treatment on the surface to be processed, so as to form texture on the surface to be processed. However, the texture formed on the sputtering surface of the target by using a disc cutter is often difficult to meet the quality requirements of the sputtering surface of the target.

[0045] After research, it is found that since the disc cutter usually includes multiple cutter heads located in the same plane, when the disc cutter is used to process the sputtering surface of the target, multiple cutter heads will simultaneously cut the sputtering surface of the target, each The cutter head will form an independent pattern; while the disc cutter will not only move the entire blade body i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com