Capacitance pressure sensor with high Q value and large relative variable quantity

A pressure sensor and capacitance technology, applied in the direction of fluid pressure measurement using capacitance changes, etc., can solve the problems of reduced deformation of the vibrating membrane, reduced deformation, no attention to the relative change of capacitance and Q value, etc., to achieve a large relative capacitance change Quantity, high quality factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

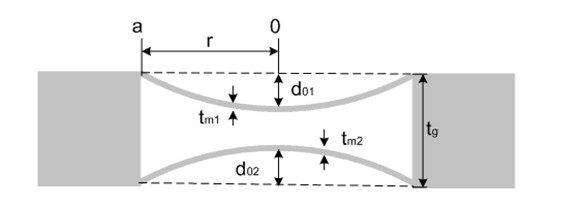

[0031] The capacitive pressure sensor of the present invention comprises a circular elastic vibrating diaphragm 1, a circular elastic vibrating diaphragm or base 2, rings 3 and 4 made of sealing materials, circular metal film electrodes 5 and 6, metal film leads in the electrodes Lines 7 and 8, outer metal film electrodes 9 and 10, and a plurality of insulating material bumps 11

[0032] The circular elastic vibrating diaphragm 1, the circular elastic vibrating diaphragm or the base 2 adopts a bonding process so that its edges are bonded to the sealing rings 3, 4 to form an elastic film fixed around the periphery, as a detection Deformable parts under pressure. Diaphragm materials include, but are not limited to, alumina ceramics.

[0033] The circular rings 3 and 4 made of the sealing material are located between the circular elastic vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com