Preparation method for PVC (Polyvinyl Chloride)/modified PBT (Polybutylece Terephthalate) lining material composite section

A technology of PVC materials and composite profiles, applied in the direction of window/door frame, leaf frame, etc., can solve the problems of easy cracking, limited use, product surface overflow, etc., achieve the effect of small creep and increase wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Example formulation:

[0022]

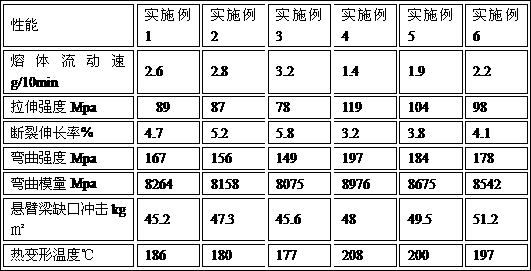

[0023] The performance index of a kind of PVC / modified PBT lining material composite profile produced by this process parameter and equipment is as follows:

[0024]

[0025] According to the above experimental data, it is shown that different material ratios can be selected to obtain PBT modified materials with different properties. Compared with Example 3, Example 4 has high rigidity, high heat distortion temperature and low elongation at break. By combining the above comparative data According to the material requirements of composite doors and windows, a formula with the closest comprehensive mechanical properties is selected as the final production formula of door and window lining material modified PBT and a new weather-resistant, low-temperature reinforced structural composite profile production process.

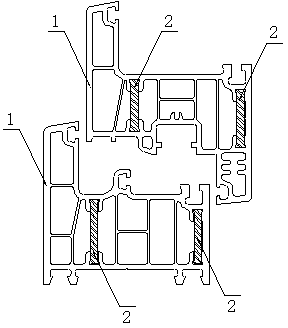

[0026] figure 1 : profile section, 1—modified PVC material, 2—modified PBT material

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com