Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2262 results about "Butylene Glycols" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

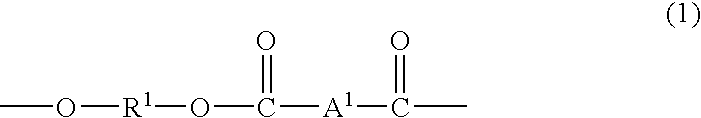

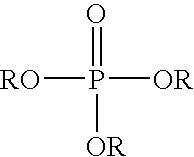

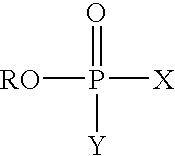

4-carbon straight chain aliphatic hydrocarbons substituted with two hydroxyl groups. The hydroxyl groups cannot be on the same carbon atom.

Transparent, oxygen-scavenging compositions containing polyesters comprising a cyclobutanediol and articles prepared therefrom

ActiveUS20060247388A1Easy to passGood active barrier propertyEnvelopes/bags making machinerySynthetic resin layered productsPolyesterPolymer science

Disclosed are oxygen-scavenging polymer compositions having high transparency and low haze comprising immiscible blends of at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol, a copolyamide or a transamidized, homogeneous blend of a least two polyamides, and a metal catalyst. The components of the immiscible blend which have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. The blends of the present invention are useful in producing shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties.

Owner:EASTMAN CHEM CO

Composite of aluminum alloy and resin composition and process for producing the same

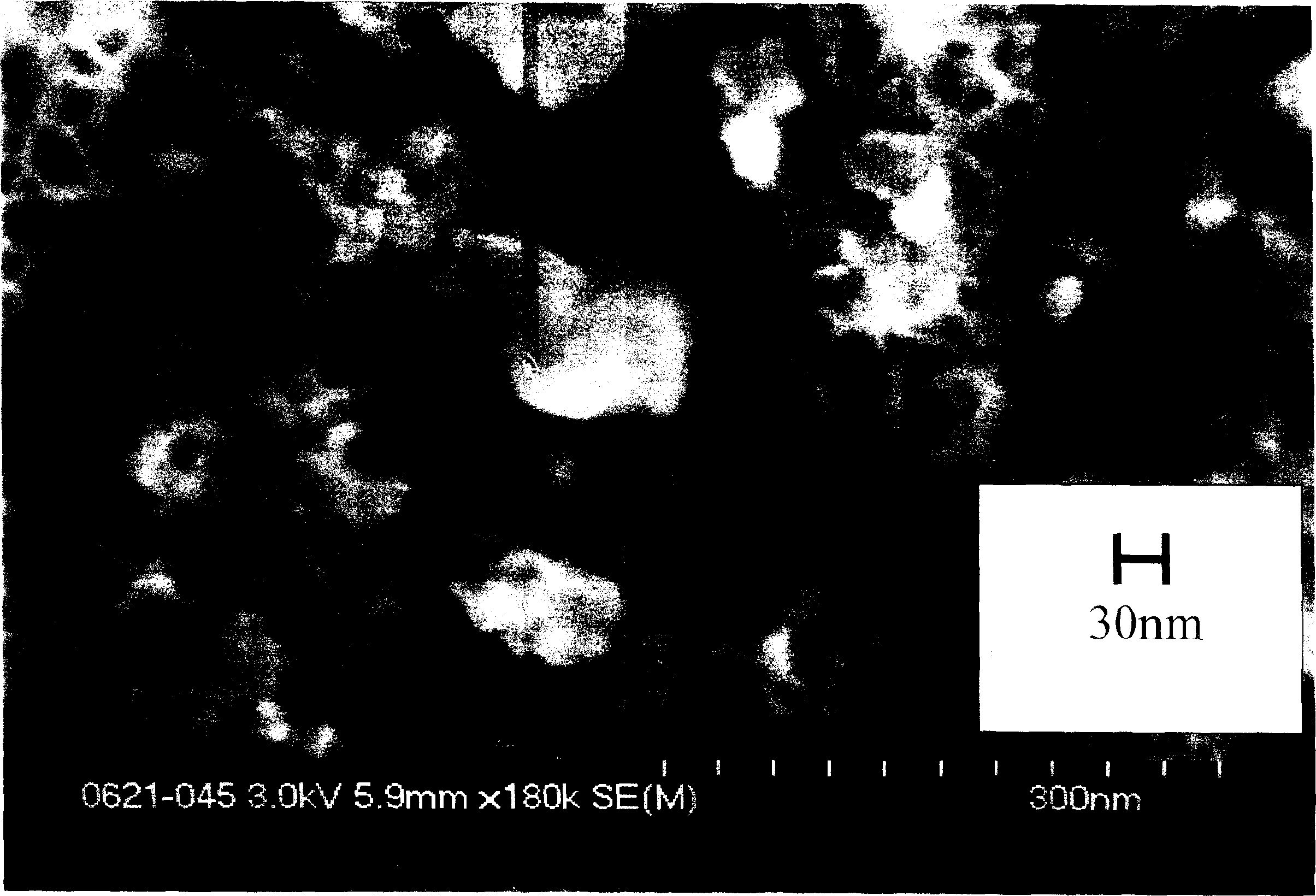

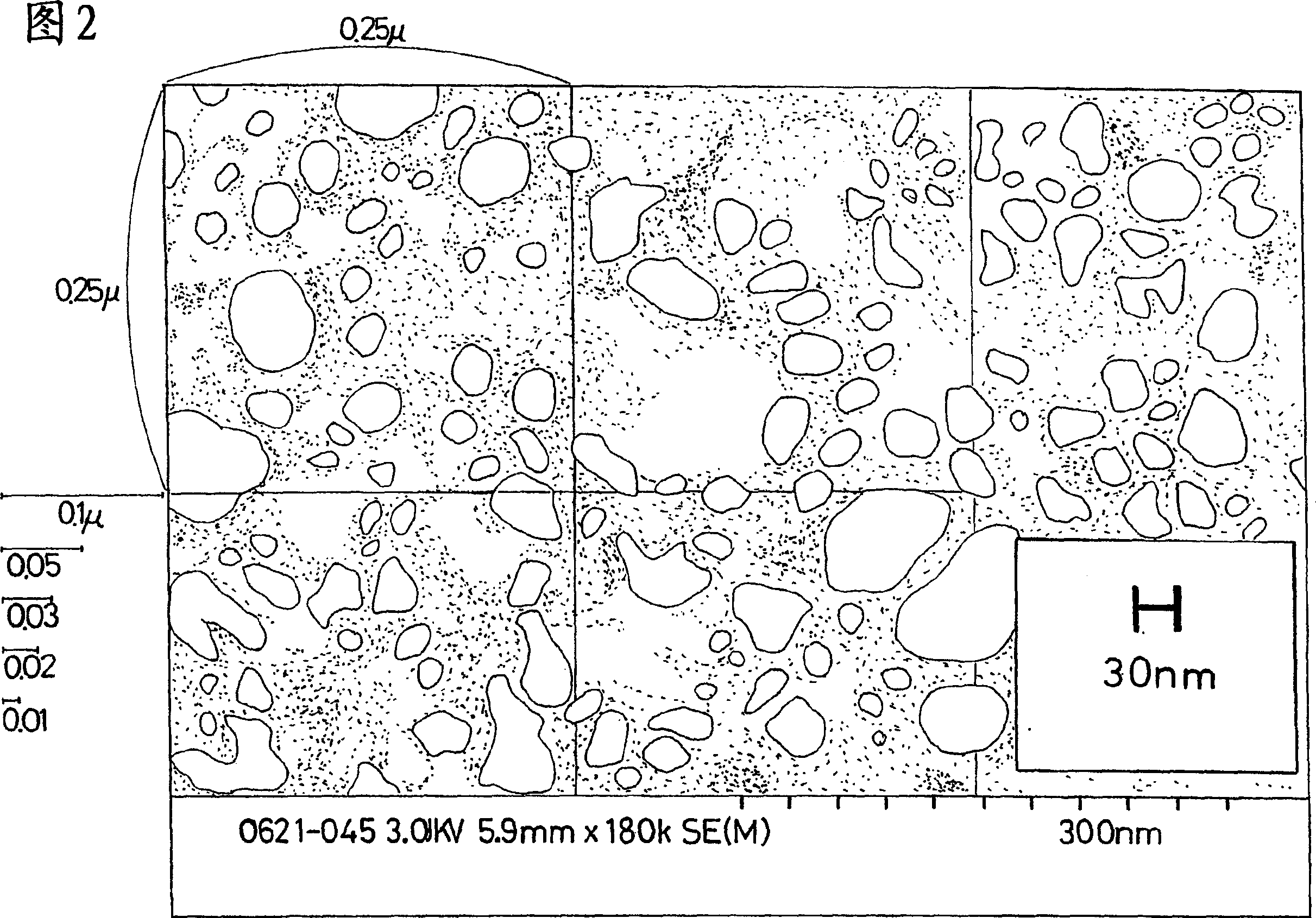

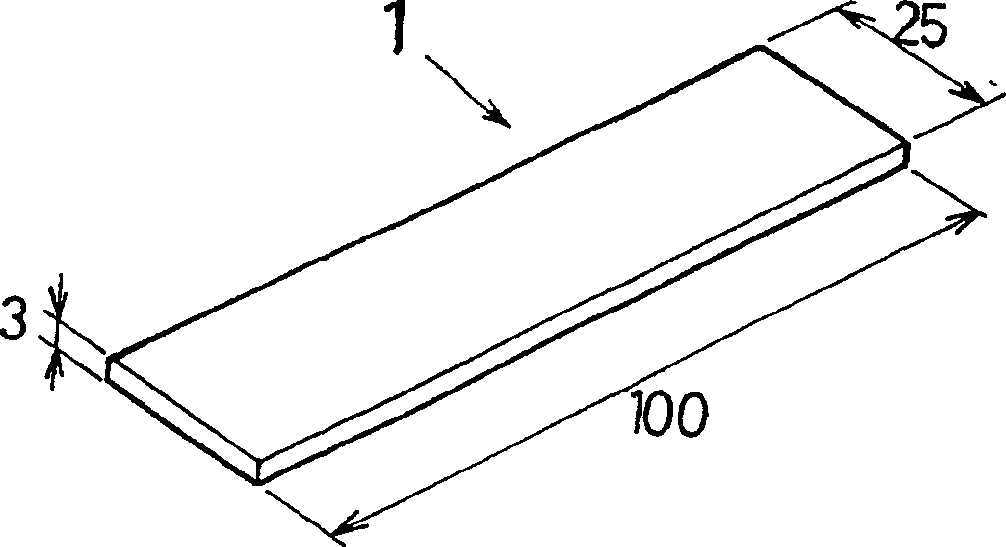

InactiveCN1717323ASynthetic resin layered productsThin material handlingPolytetramethylene terephthalateSurface roughness

The invention relates to a complex, which is characterized in that the complex consists of an aluminium alloy shape and a thermoplastic resin combination; the roughness of surface of the complex is more than 5 to 50 Mu m; the surface is provided with the aluminium alloy shape with minute recessed parts or raised parts, the diameter of which is less than 1 Mu m; the aluminium alloy shape is fixed through the recessed parts or raised parts; with the longitudinal and transverse average coefficientof linear expansion ranging from 2X<-5> DEG C<-1> to 4X<-5> DEG C<-1>, the thermoplastic resin combination is primarily made of polybutylene terephthalate resin or polyphenyl thioether; as the thermoplastic resin combination is not peeled off easily from the aluminium alloy shape, the invention has the advantages of metal enclosers and synthetic resin structures in electronic machines and electric appliances. The production efficiency is high, and the complex can be produced on large scale with shape and structure to be designed freely.

Owner:TAISEI PLAS CO LTD

Process for the preparation of transparent, shaped articles containing polyesters comprising a cyclobutanediol

ActiveUS20060235167A1Easy to passGood active barrier propertyEnvelopes/bags making machineryFilament/thread formingPolyesterPolymer science

Disclosed is a process for the preparation of shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles, having high transparency and low haze, and comprising immiscible blends of at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce shaped articles having oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

Transparent polymer blends containing polyesters comprising a cyclobutanediol and articles prepared therefrom

ActiveUS20060228507A1Improve claritySuitable for preparationEnvelopes/bags making machinerySynthetic resin layered productsPolyesterPolymer science

Disclosed are polymer compositions having high transparency and low haze comprising immiscible blends of at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. The blends of the present invention are useful in producing shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce oxygen-scavenging compositions.

Owner:EASTMAN CHEM CO

Ink for ink jet recording, ink set for ink jet recording, method for ink jet recording, ink cartridge for ink jet recording, ink jet recording apparatus and recorded article

InactiveUS20030107632A1Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksImaging qualityEngineering

An ink for ink jet recording and an ink jet recording method which realize an image quality of laser printer on a plain paper in a one-pass printing mode under conditions of a volume of an ink droplet ejected being 5 to 43 Pico liter, a velocity of an ink droplet being 6 to 20 m / sec, frequency of 1 kHz and resolution of 300 dpi or more. The ink for ink jet recording is a penetrating type ink which comprises (1) at least one humectant selected from glycerin, 1,3-butandiol, triethyleneglycol, 1,6-hexanediol, propyleneglycol, 1,5-pentanediol, diethyleneglycol, dipropyleneglycol, trimethylolpropane and trimethylolethane, (2) colorant contained in the amount of 6 % by weight or more, (3) a polyol having 8 to 11 carbon atoms and glycolether, and an anionic surfactants or non-ionic surfactants, the ink has viscosity of 5 mPa.s or more at 25° C. and a surface tension of 40 mN / m or less.

Owner:RICOH KK

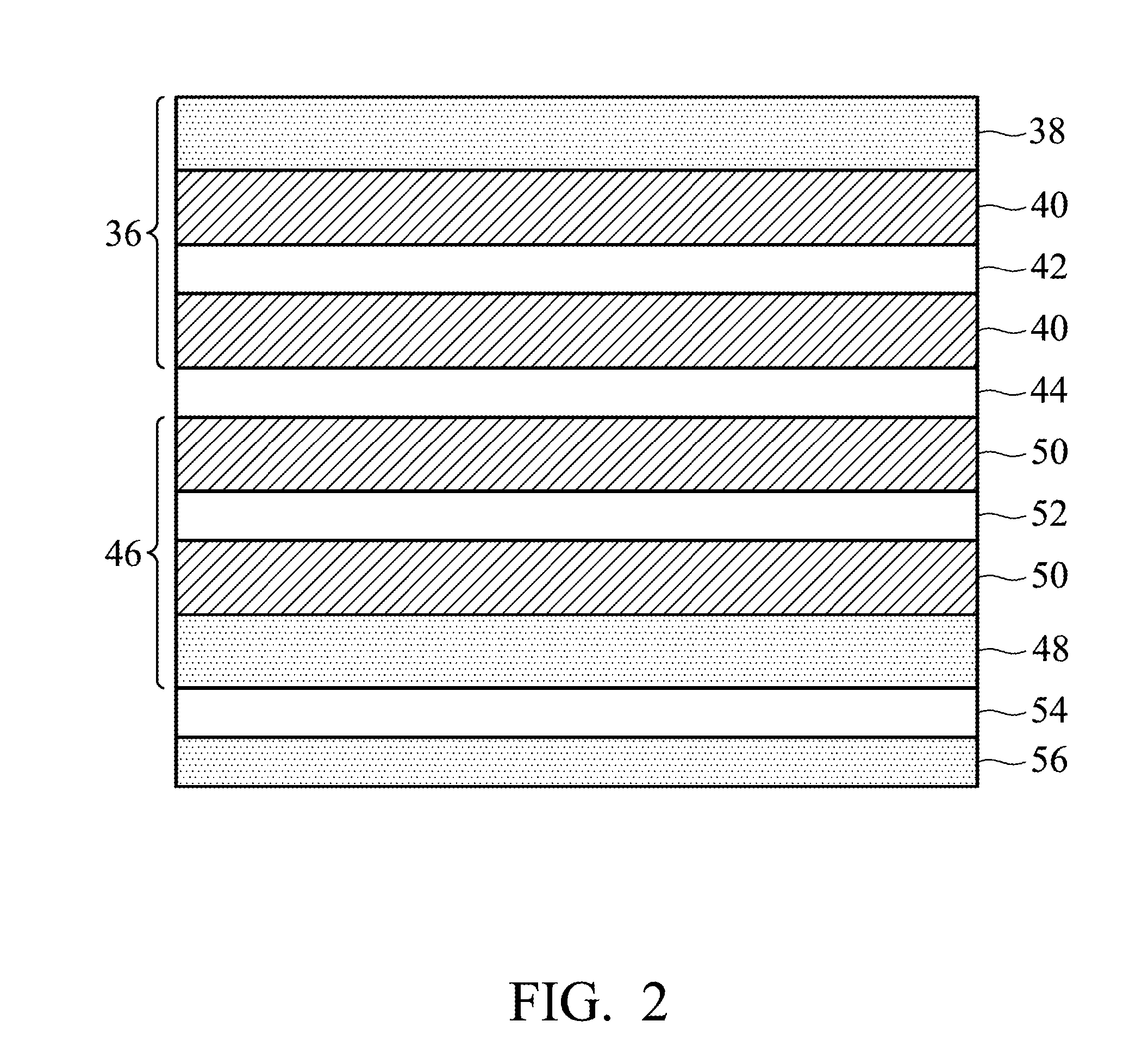

Multilayered, transparent articles containing polyesters comprising a cyclobutanediol and a process for their preparation

InactiveUS20060234073A1Easy to processImprove propertiesBottlesSynthetic resin layered productsPolyesterPolymer science

Disclosed are transparent, multilayered articles having high transparency and low haze and a process for their preparation. The multilayer articles comprise at least one layer which contains at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol and a separate layer which contains copolyamide or homogeneous blend of polyamides. The polyester component and the polyamide component have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into one or more of the layers of the article while maintaining high clarity. These articles can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into one or more layers to impart oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and moderate glass transition temperature and articles made therefrom

ActiveUS20060293495A1Easy to optimizeHigh impact strengthDialysis systemsDialysisFiberCyclohexanedimethanol

Described are polyesters comprising (a) a dicarboxylic acid component comprising terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Film(s) and/or sheet(s) comprising polyester compositions which comprise cyclobutanediol and have a certain combination of inherent viscosity and moderate glass transition temperature

ActiveUS20060293494A1Improve bindingIncrease temperatureDialysis systemsDialysisCyclohexanedimethanolCarboxylic acid

Described are film(s) and / or sheet(s) comprising polyesters comprising (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Polyester compositions containing furandicarboxylic acid or an ester thereof, and 2,2,4,4-tetramethyl-1,3-cyclobutanediol

ActiveUS20130095263A1High glass transition temperatureBottlesSynthetic resin layered productsFiberPolyester

Described are polyesters comprising (a) a dicarboxylic acid component comprising 2,5-furandicarboxylic acid residues; optionally, aromatic dicarboxylic acid residues and / or modifying aliphatic dicarboxylic acid residues and 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues. The polyesters may be manufactured into articles such as fibers, films, bottles, coatings, or sheets.

Owner:EASTMAN CHEM CO

Molding compositions containing fillers and modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

The invention relates to a composition comprising (a) from 5 to 99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and (2) has at least one residue derived from the polyethylene terephthalate component, and (b) at least 1 wt % of a filler component. In one embodiment, the invention relates to an article molded from the above-mentioned molding composition. In another embodiment, the invention relates to methods for making and methods for using the molding composition.

Owner:SHPP GLOBAL TECH BV

Elastomer blends of polyesters and copolyetheresters derived from polyethylene terephthalate, method of manufacture, and articles therefrom

A composition comprising:(1) from 50 to 99 wt % of a modified, random copolyetherester containing:(i) a modified, random polybutylene terephthalate copolymer block that is derived from a polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and combinations thereof; and that contains at least one residue derived from the polyethylene terephthalate component; and(ii) a polyalkylene oxide copolymer block that is derived from a polyethylene terephthalate component and polyalkylene oxide glycol, and contains polyalkylene oxide and at least one residue derived from the polyethylene terephthalate component; and(2) from 1 to 50 wt % of a polyester;wherein the copolyetherester, the polyester, and optionally any additives, are present in a total amount of 100 wt %.

Owner:SHPP GLOBAL TECH BV

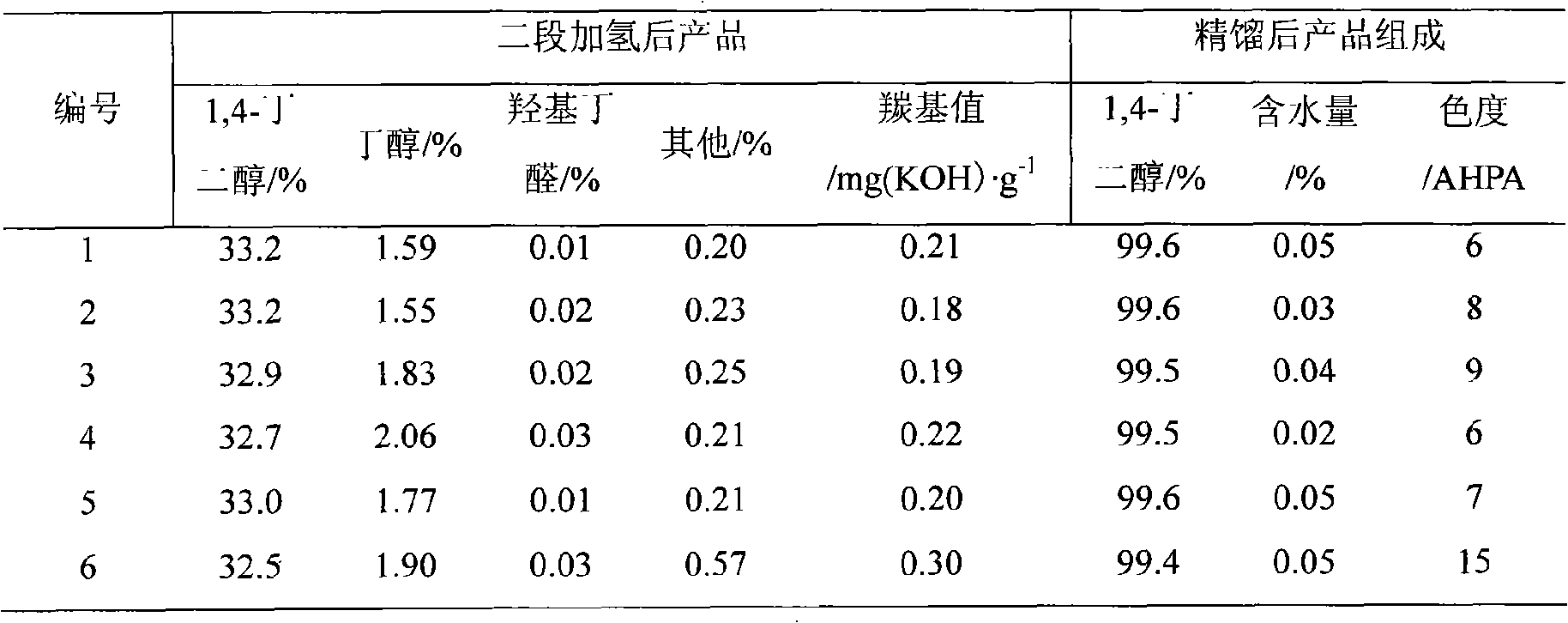

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

Scaffold for tissue engineering cartilage having outer surface layers of copolymer and ceramic material

InactiveUS6656489B1High mechanical strengthEfficient transportBiocideJoint implantsCartilageComposite scaffold

A biodegradable, biocompatible porous matrix as a scaffold for tissue engineering cartilage is formed of a copolymer of a polyalkylene glycol and an aromatic polyester such as a polyethylene glycol / polybutylene terephtalate copolymer. A ceramic coating such as a calcium phosphate coating may be provided on the scaffold by soaking the scaffold in a solution containing calcium and phosphate ions. A composite scaffold which is preferably a two-layer system may be formed having an outer surface of a layer of the porous matrix formed of the copolymer, and an outer surface of a layer of a ceramic material. The composite scaffold may be prepared by casting the copolymer on top of the ceramic material in a mould. Cells are preferably seeded on the scaffold prior to implanting, and the scaffold may contain bioactive agents that are released on degradation of the scaffold in vivo.

Owner:OCTOPLUS SCI

Preparation method of thermoplastic polyurethane elastomer

InactiveCN103059554AImprove mechanical propertiesImprove heat resistancePolyethylene glycolHydrolysis

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

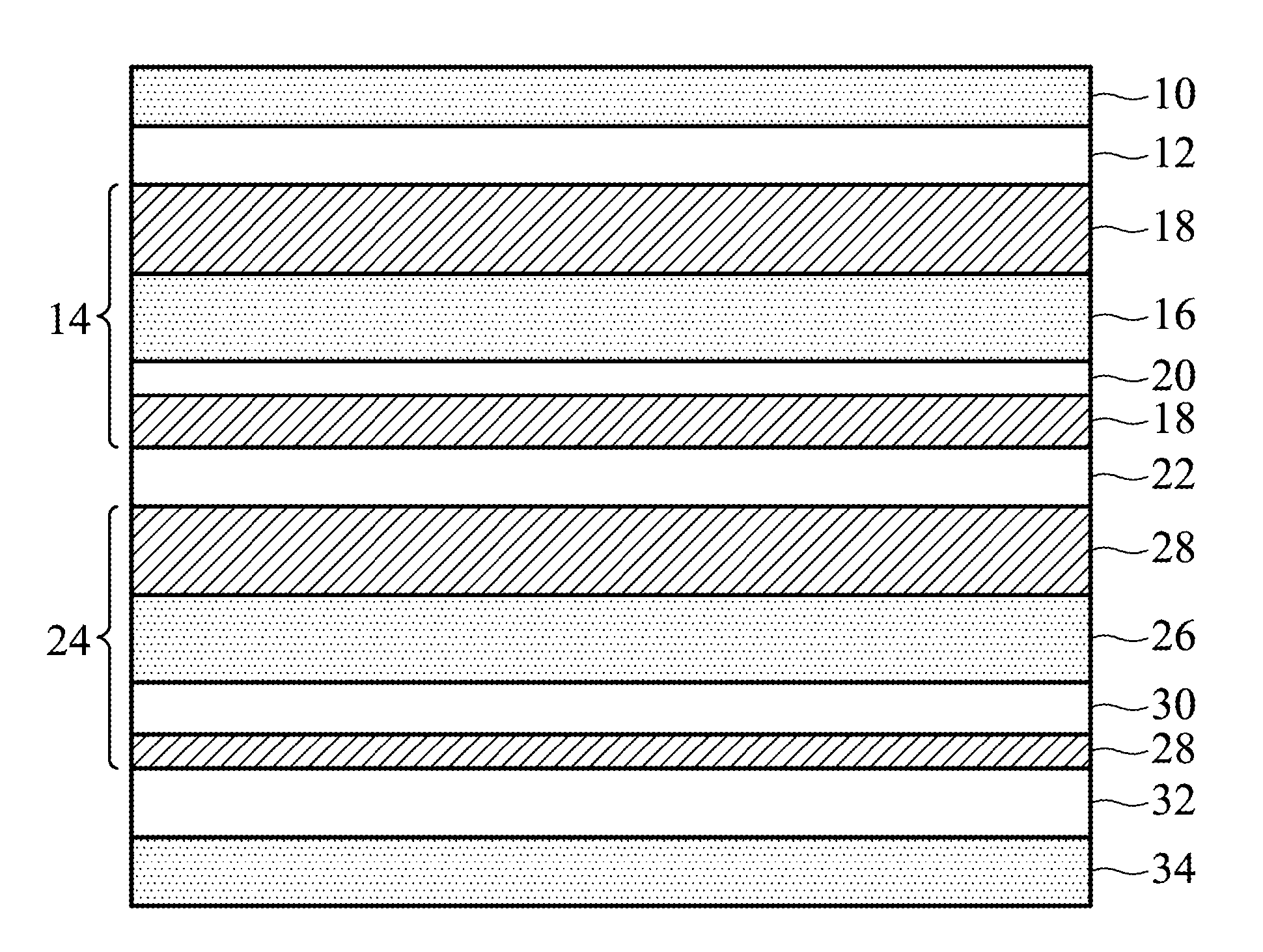

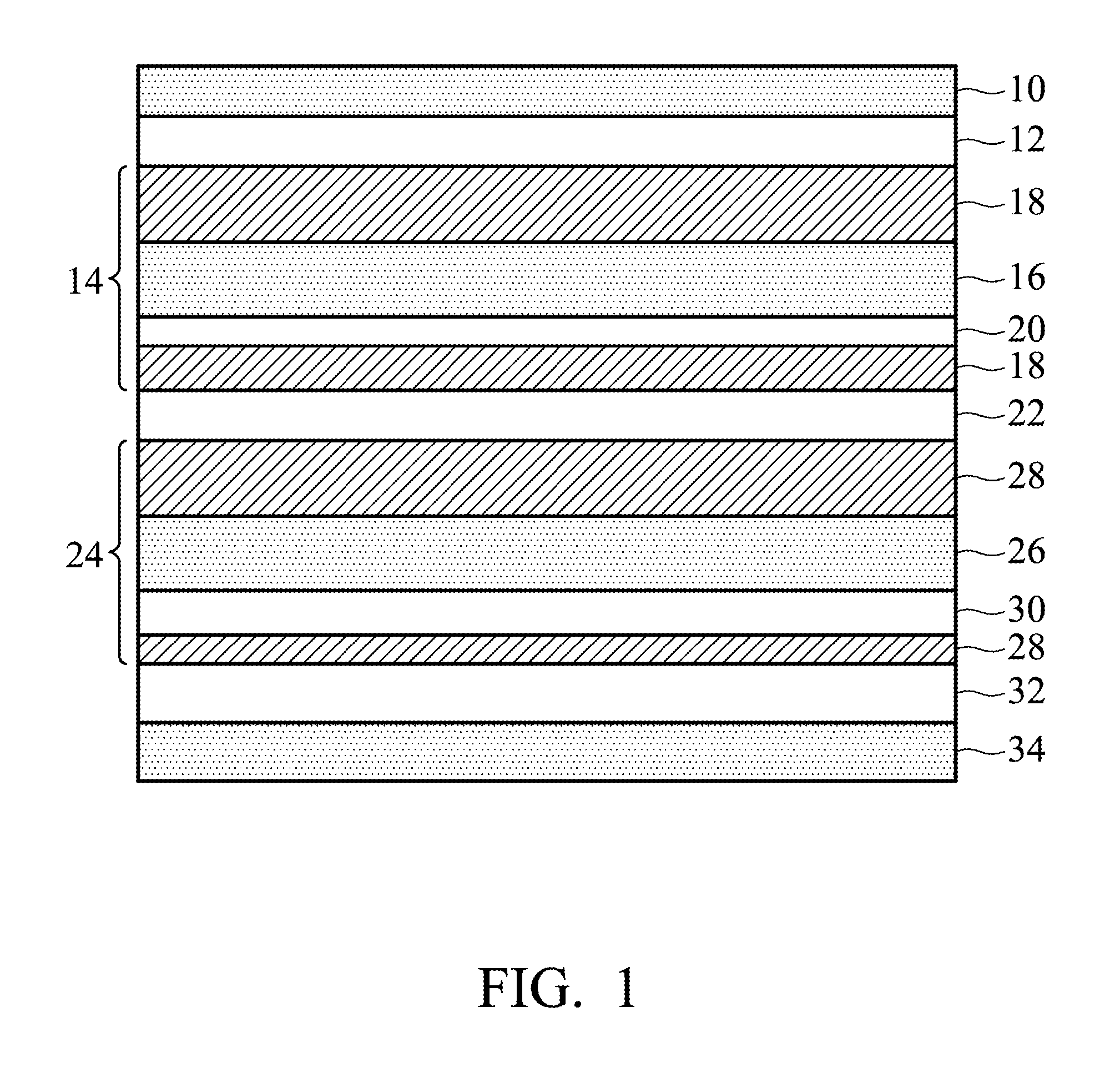

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

ActiveUS20120148785A1High gas barrierImprove adhesionSynthetic resin layered productsRecord information storageLow-density polyethyleneLinear low-density polyethylene

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

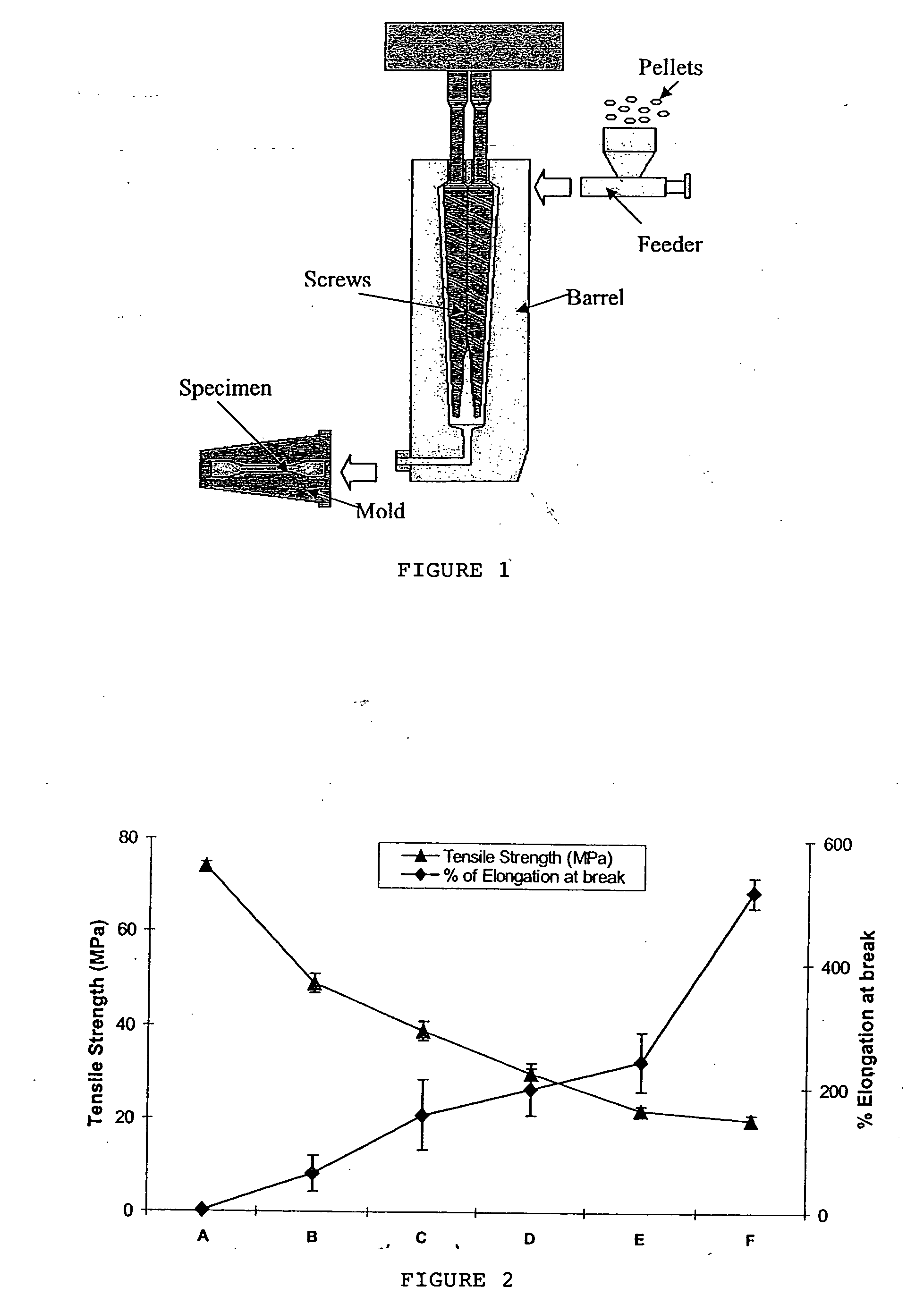

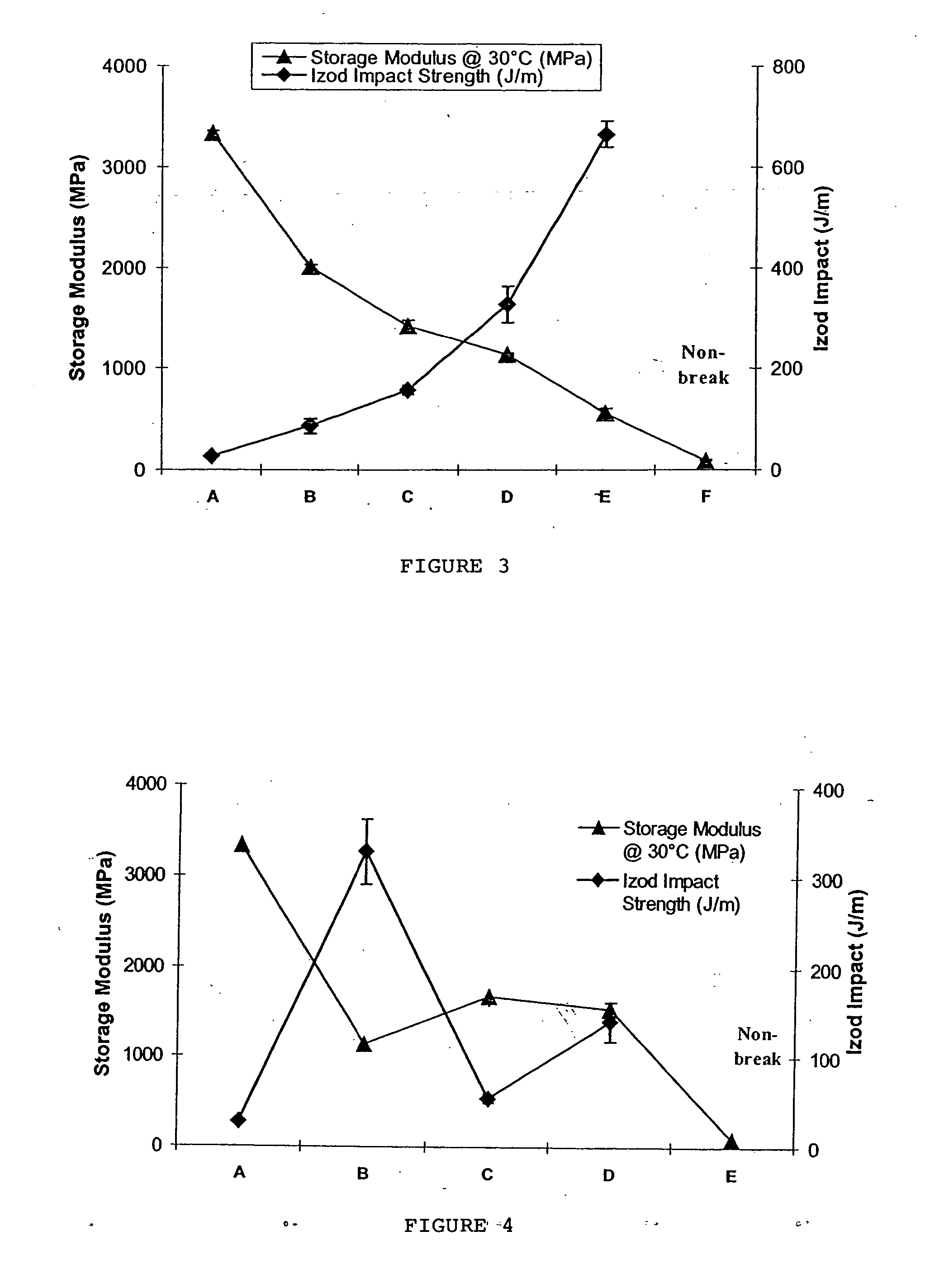

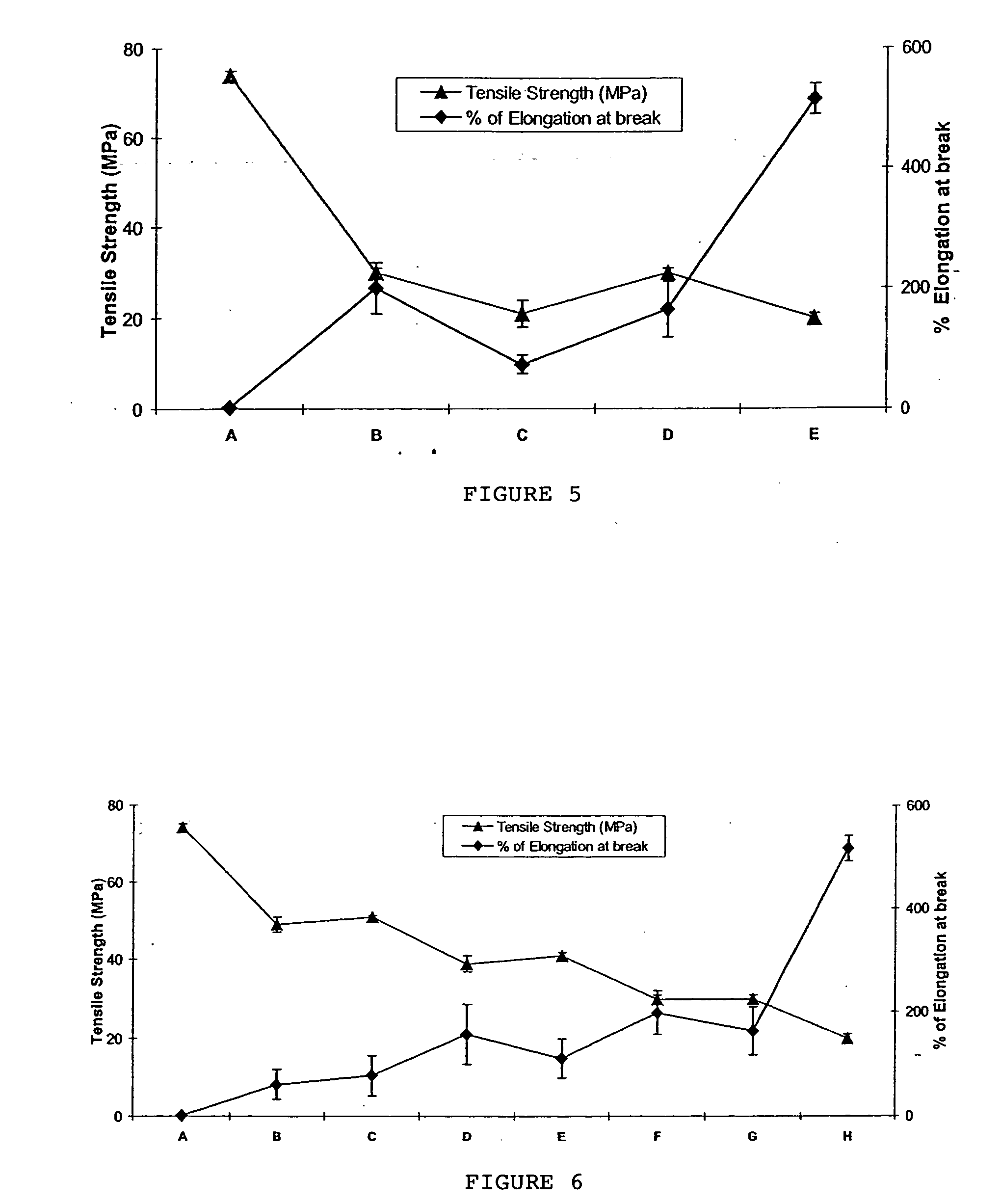

Biodegradable polymeric nanocomposite compositions particularly for packaging

Specific polymer blends of polylactic acid (PLA) and polyhydroxybutyrate (PHB) and poly-(butylenes adipate-co-terephthalate (PBAT) as a fatty acid quaternary ammonium modified clay. The blends are particularly useful for barrier packaging.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Molding compositions containing polycarbonate and modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070276069A1Reduce the amount requiredFibre treatmentPolytetramethylene terephthalatePolymer science

A molding composition comprising: (a) from 5 to 90 wt. % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and (2) has at least one residue derived from the polyethylene terephthalate component, and (b) from 5 to 90 wt. % of a polycarbonate component; and from at least 1 wt. % of an impact modifier component, wherein the modified polybutylene terephthalate random copolymer, the polycarbonate component, the impact modifier, and optionally at least one additive, have a combined weight % of 100 wt %. The invention also encompasses methods for making the composition and articles made from the composition.

Owner:SHPP GLOBAL TECH BV

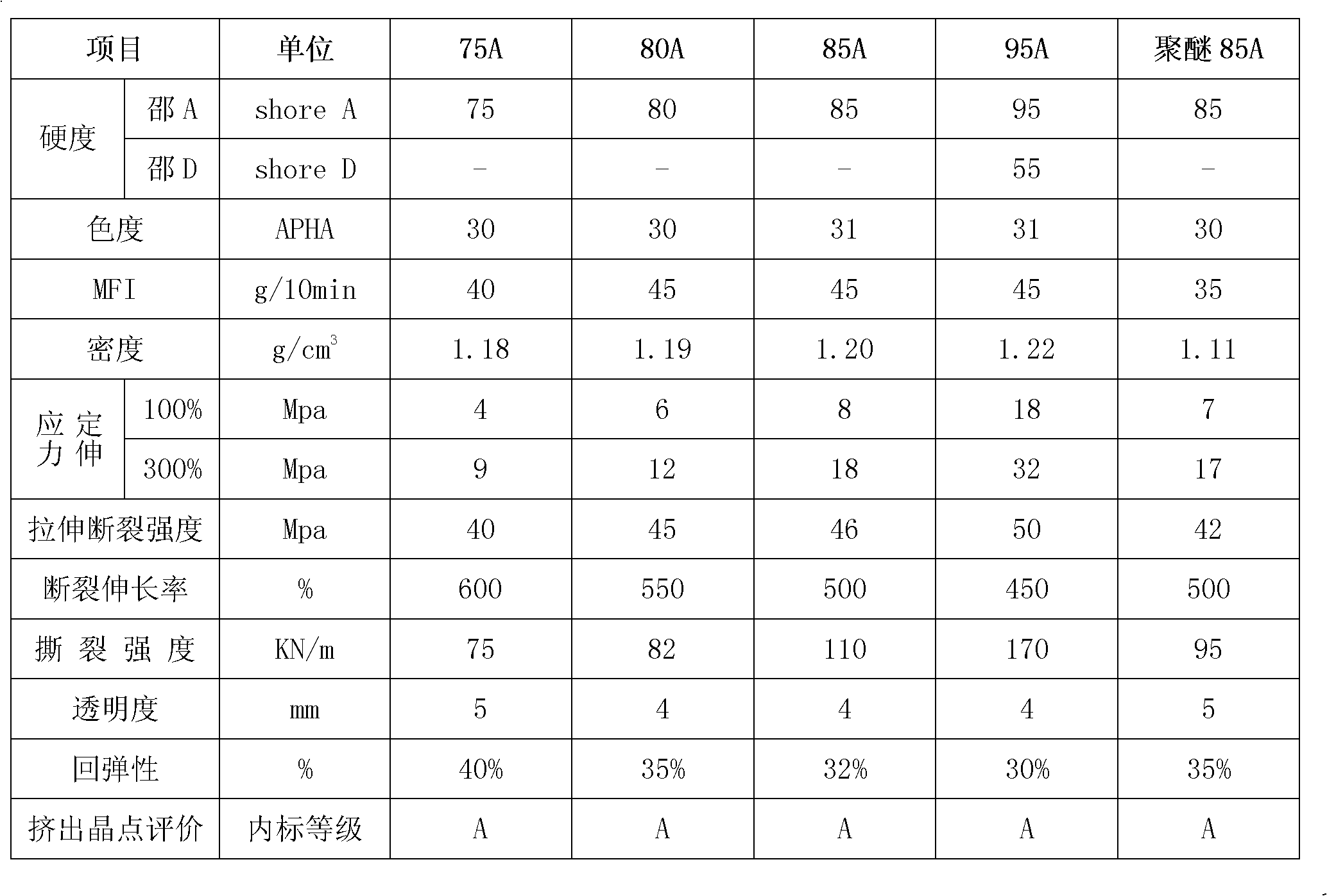

Preparation method of transparent film-grade thermoplastic polyurethane elastomer

The invention relates to the technical field of thermoplastic polyurethane elastomer (TPU), and specifically relates to a formula and a production technology of transparent film-grade TPU. According to the invention, 20-40% of diisocyanate, 45-75% of polymer polyhydric alcohol with a molecular weight of 1000-4000, 4-10% of 1,4-butylene glycol, 0.2-1% of an anti-oxidant, 0.2-1.5% of a lubricant, 0.001-0.02% of an environment-friendly catalyst, 0.2-1.0% of an ultraviolet ray absorbing agent, 0-0.8% of a hydrolysis-resisting agent, 0.1-1% of a light stabilizing agent, and 0-2% of other auxiliary agents are processed through steps such as premixing, reacting, dicing and dehydrating, and drying and curing, such that the transparent film-grade TPU is obtained. According to the invention, with the innovations on formula, equipment and technology, a defect of fisheye generation in TPU preparation processes in prior arts is solved. Factors such as a filling manner, an auxiliary agent adding manner, distributive mixing and dispersive mixing effects of an extruder, extruder retention time, and drying and curing are comprehensively considered, such that a stable product with high quality is produced.

Owner:SHANGHAI LIANJING MATERIAL ASSETAB

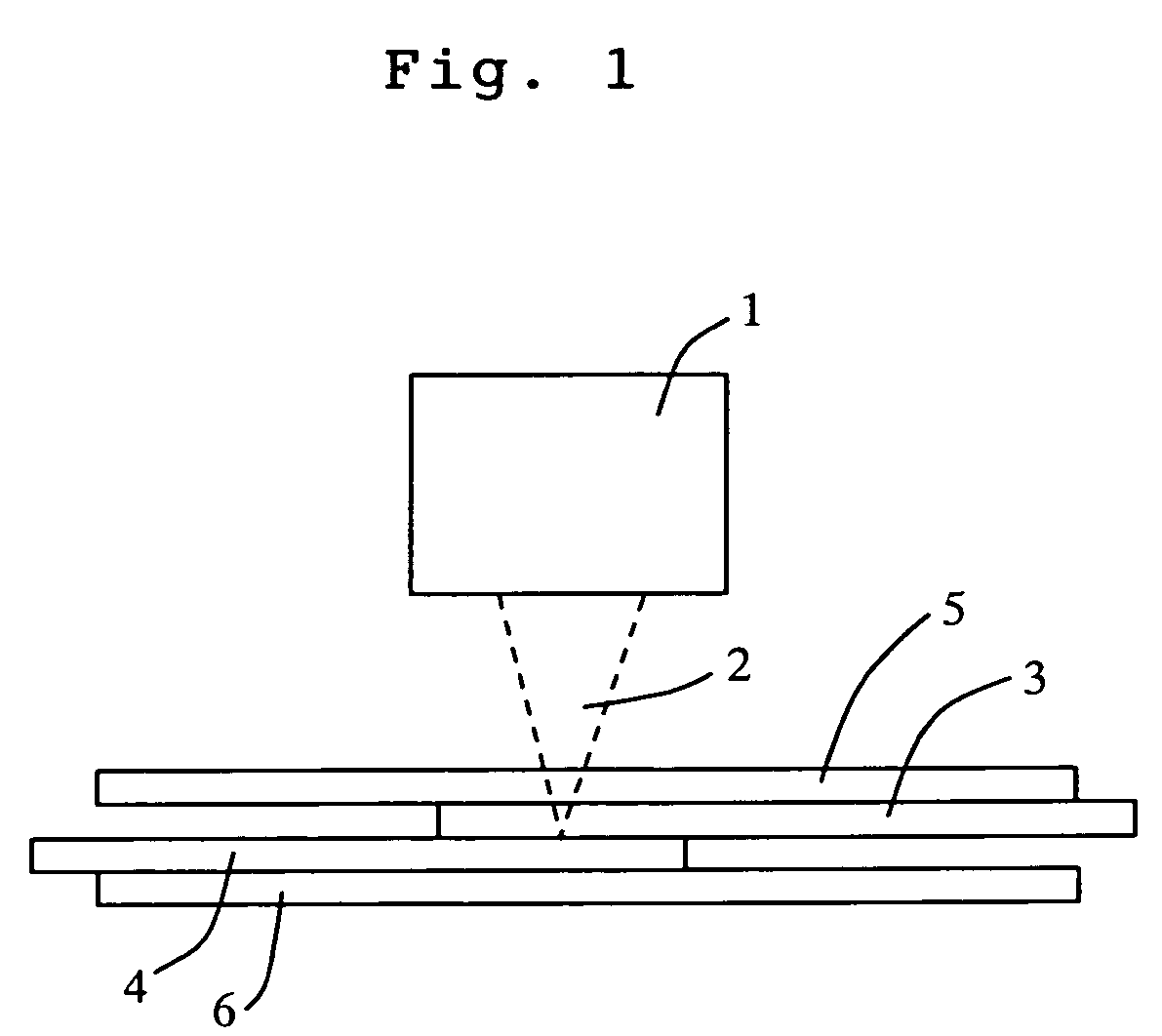

Polybutylene terephthalate resin composition for fusion bonding with laser and molded article

InactiveUS20050165176A1Improve Laser Welding PerformanceImprove welding strengthPolytetramethylene terephthalatePolymer science

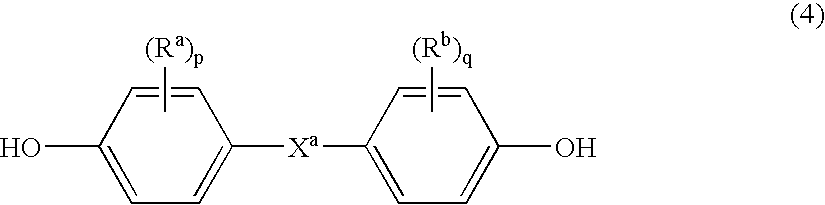

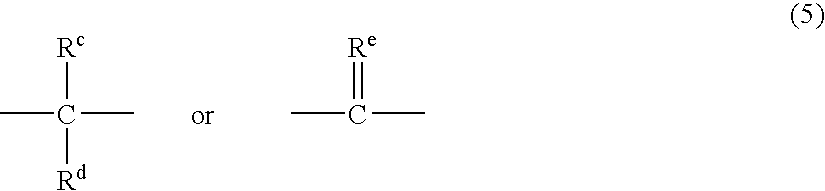

A laser weldable PBT-series resin composition comprises a polybutylene terephthalate (PBT)-series resin (A), and at least one resin (B) selected from the group consisting of a polycarbonate-series resin (b1), a styrenic resin (b2), a polyethylene terephthalate-series resin (b3) and an acrylic resin (b4). The PBT-series resin (A) may be a PBT homopolyester, or a PBT-series copolymer modified with not more than 30 mol % of a copolymerizable monomer (e.g., a bisphenol compound or an adduct thereof with an alkylene oxide, and an asymmetrical aromatic dicarboxylic acid). The ratio (weight ratio) of the resin (B) relative to the PBT-series resin (A) [the former / the latter] is about 0.1 / 1 to 1.5 / 1. The resin composition may comprise a glass fiber. The resin composition is excellent in laser weldability, and can improve in welding strength of a shaped article formed from the resin composition.

Owner:WIN TECH POLYMER LTD

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

Molding compositions containing polyalkylene terephthalates and modified polybutylene terephthalate (PBT) random copolymers derived from pet

A molding composition comprising (a) from 5 to 90 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate component selected from the group consisting of polyethylene terephthalate and polyethylene terephthalate copolymers and (2) at least one residue derived from the polyethylene terephthalate component, and (b) from 5 to 40 wt % of a polyalkylene terephthalate component; wherein the modified polybutylene terephthalate random copolymer, the polyalkylene terephthalate component, and optionally, at least one additive, have a combined weight % of 100 wt %. Methods for making the composition and articles made from the composition.

Owner:SHPP GLOBAL TECH BV

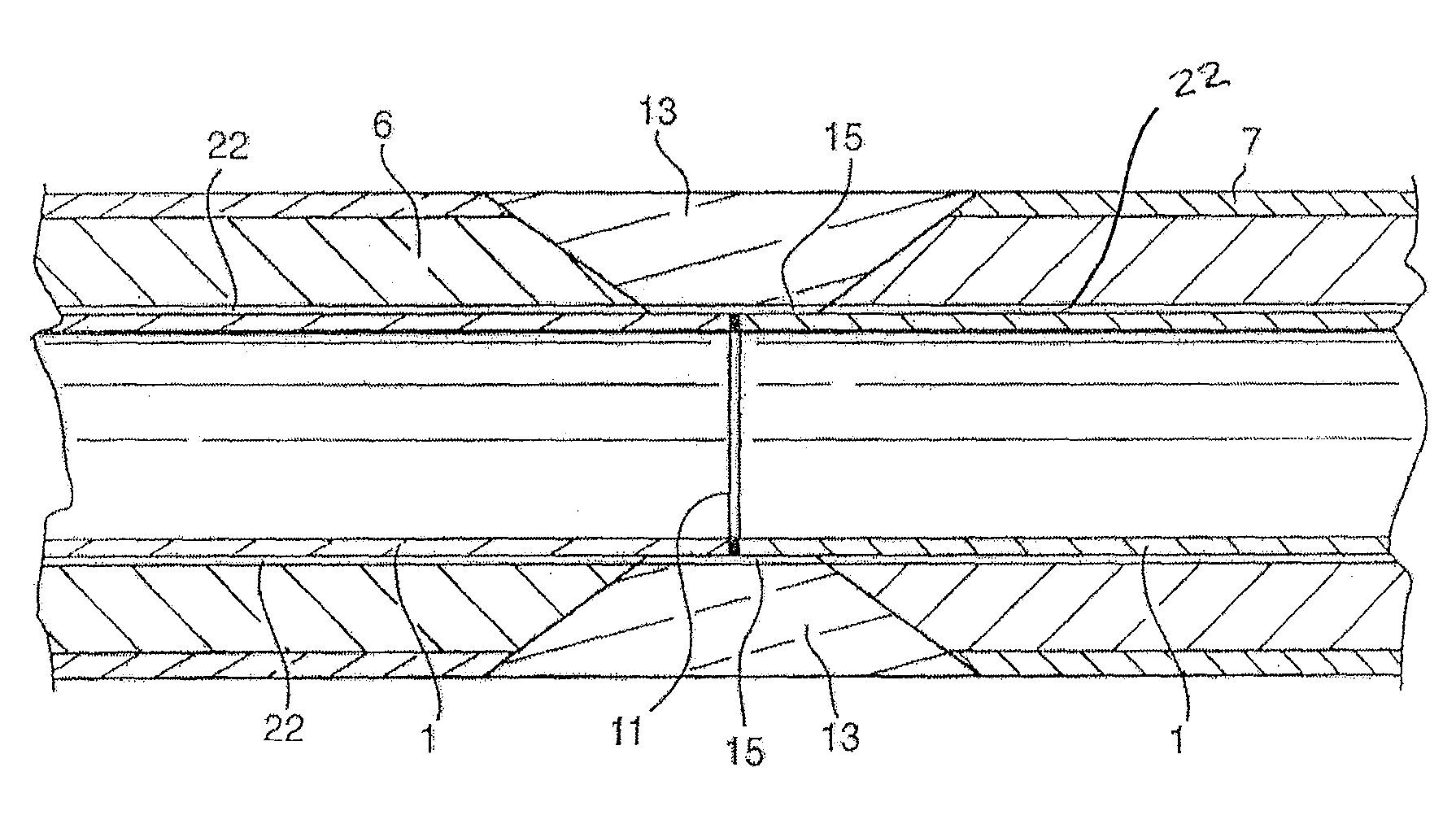

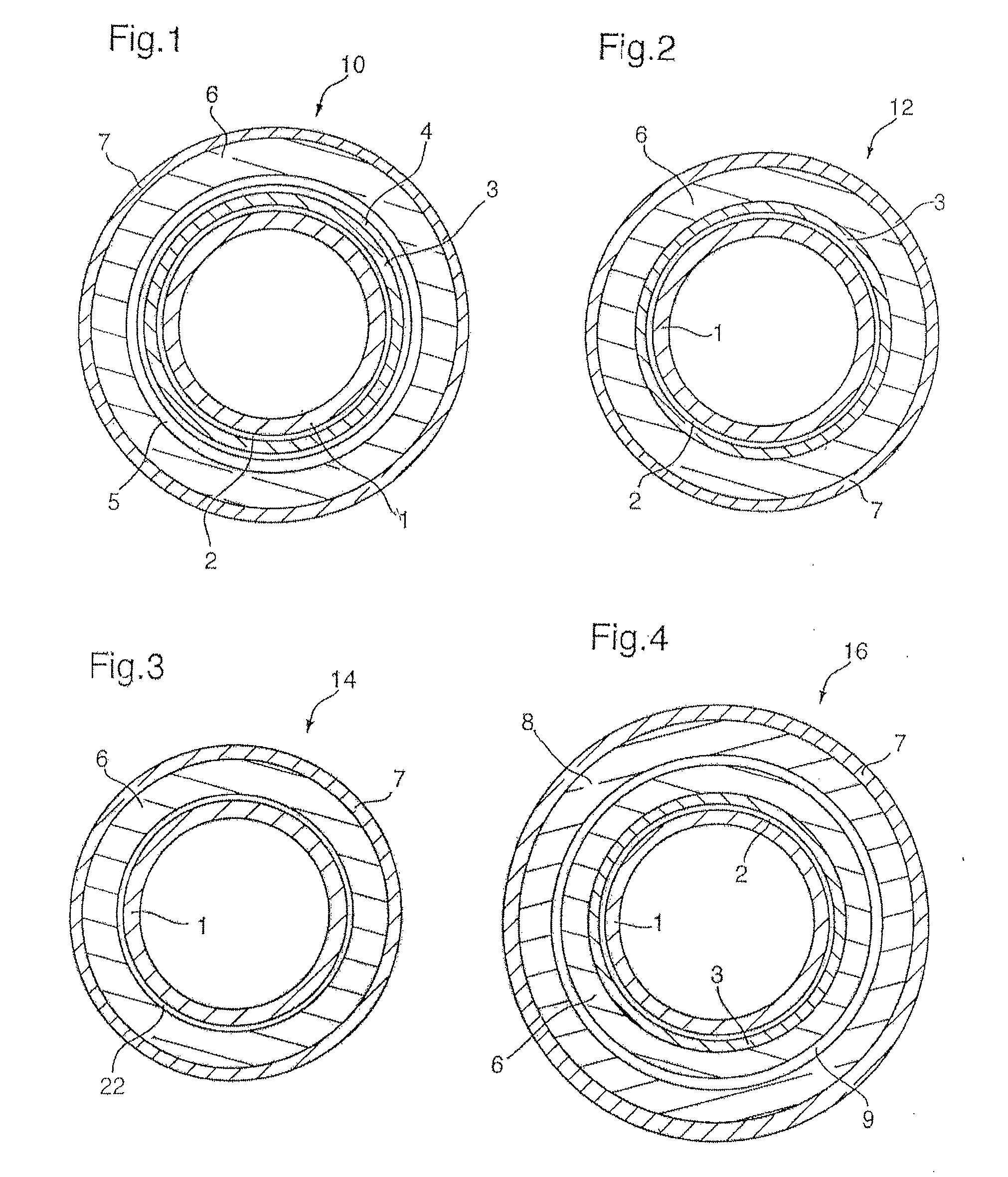

High temperature resistant insulation for pipe

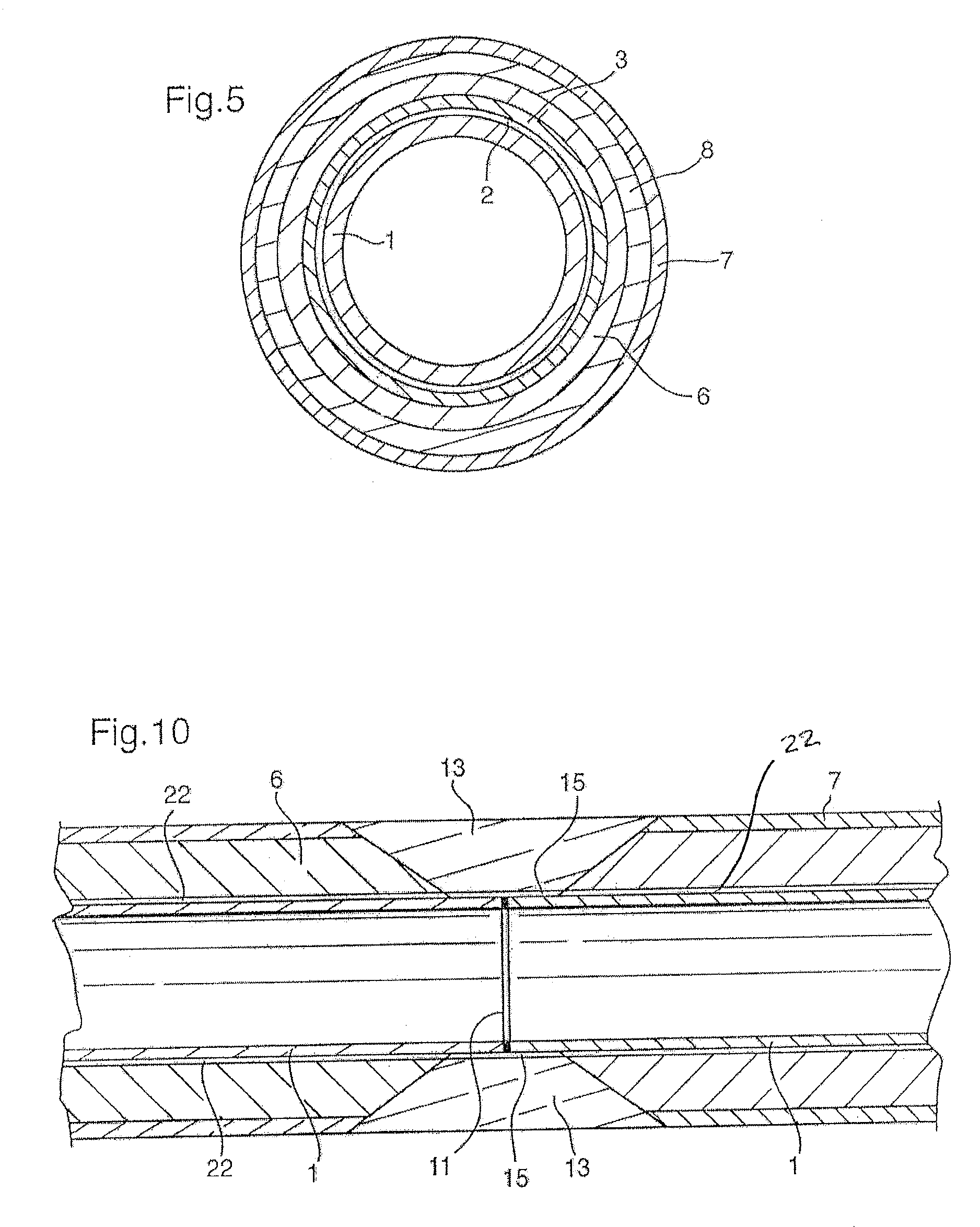

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

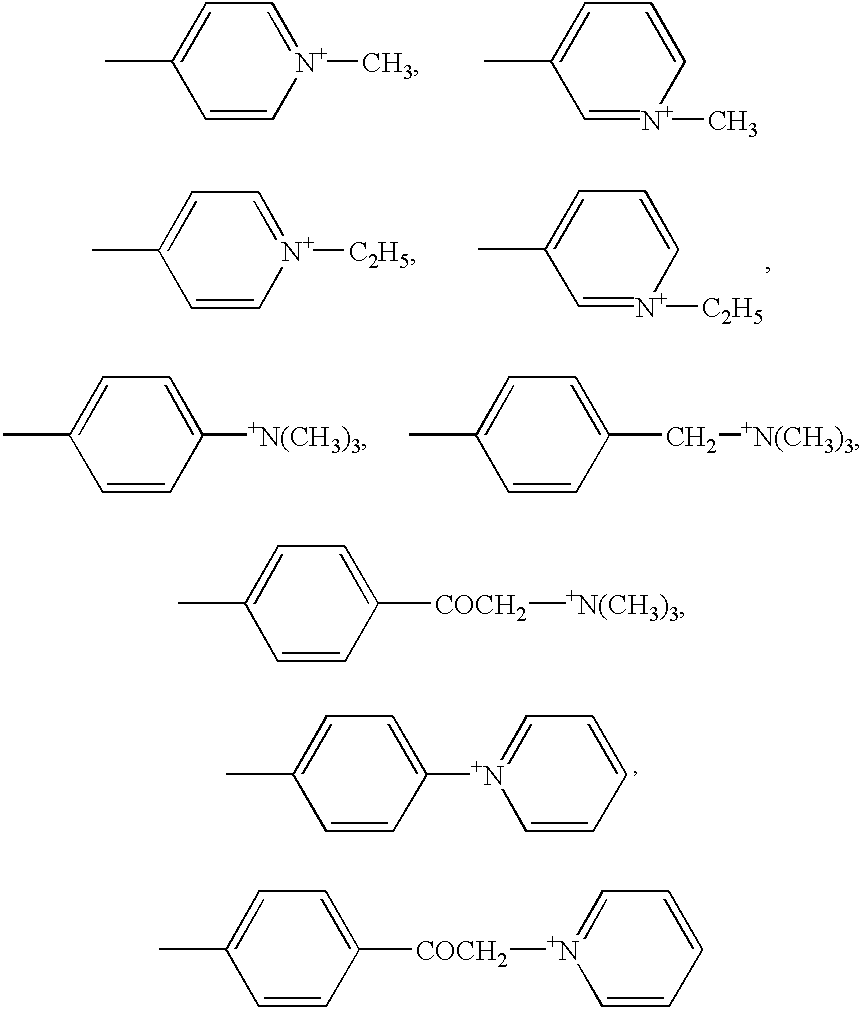

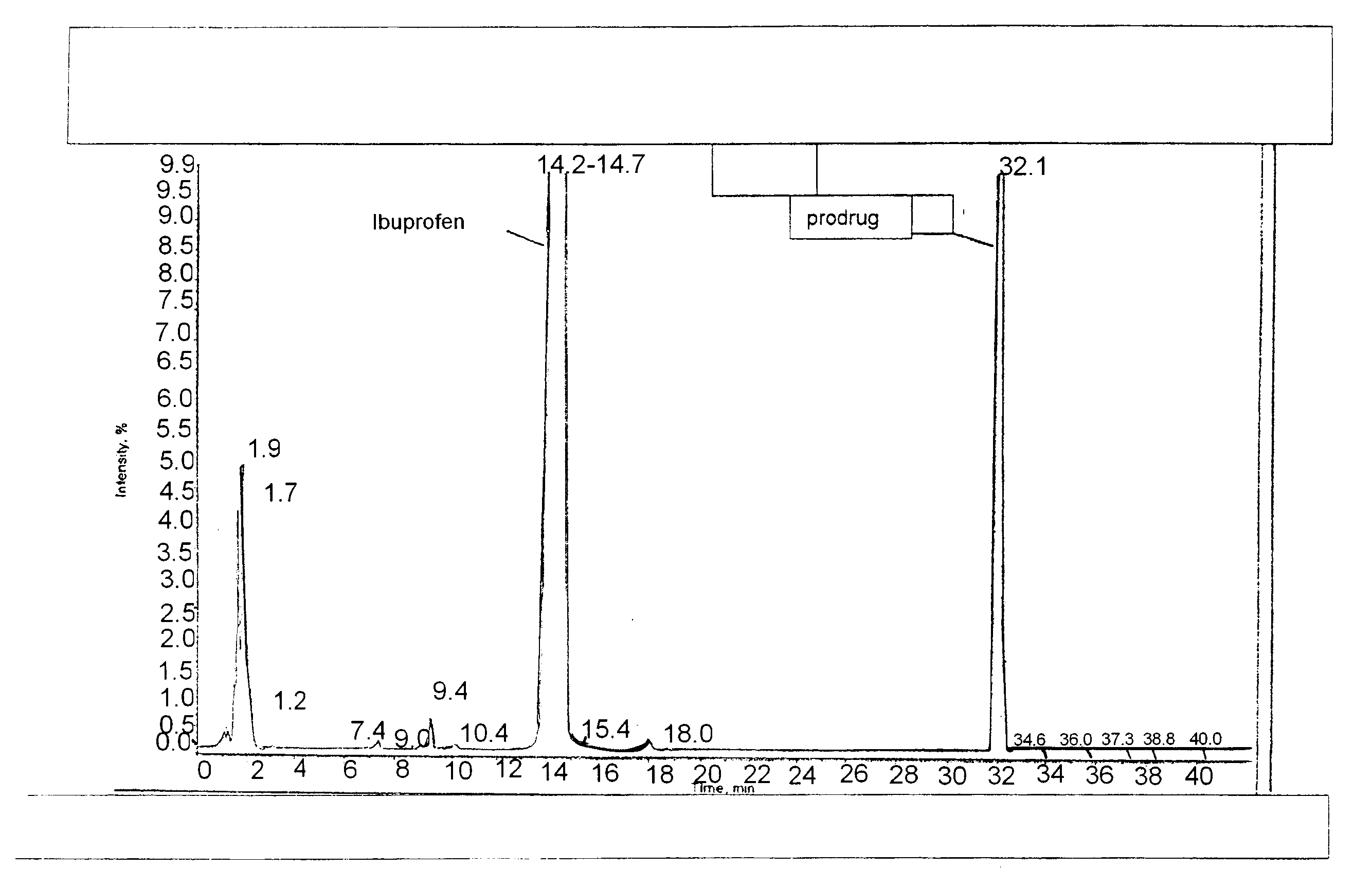

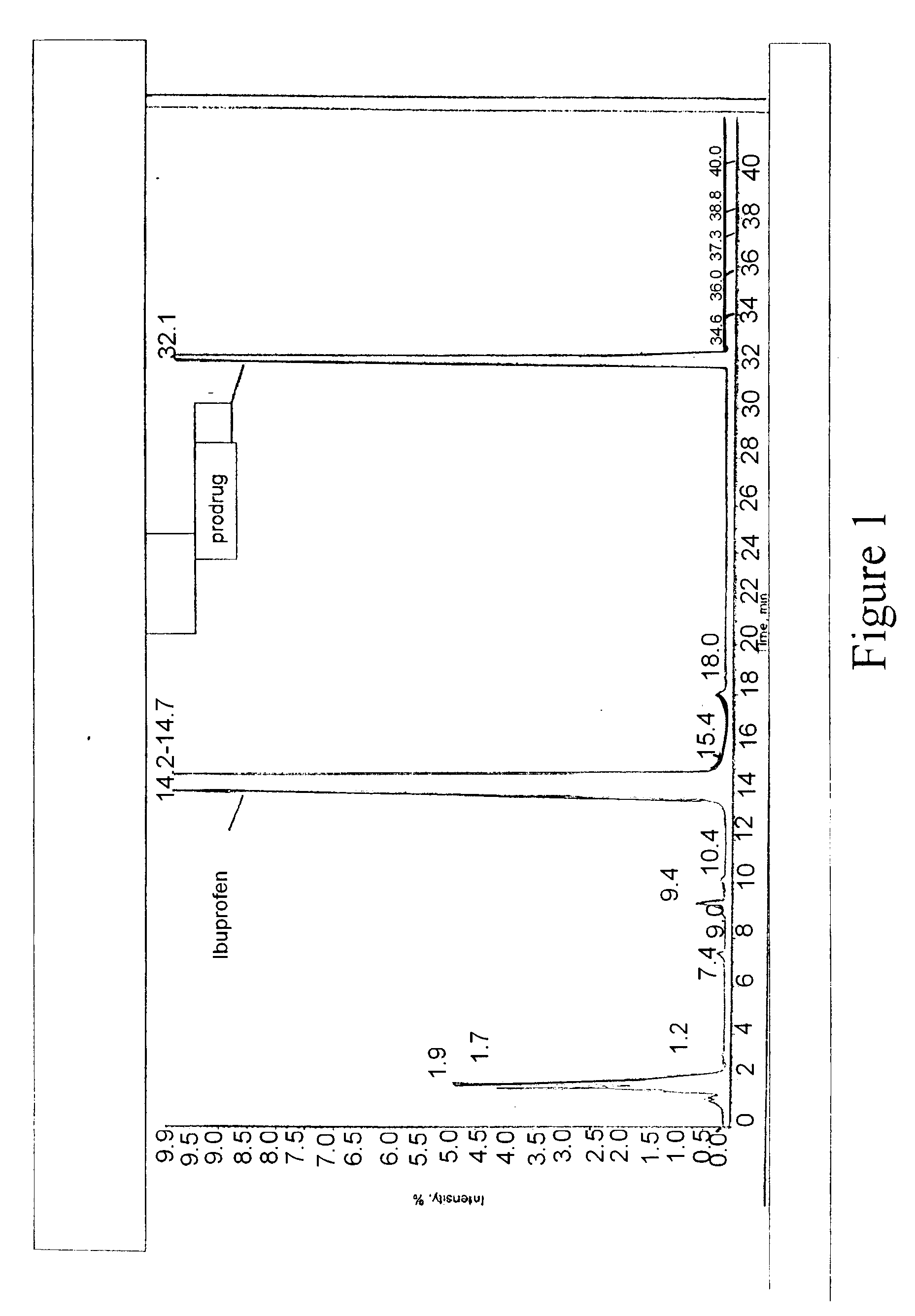

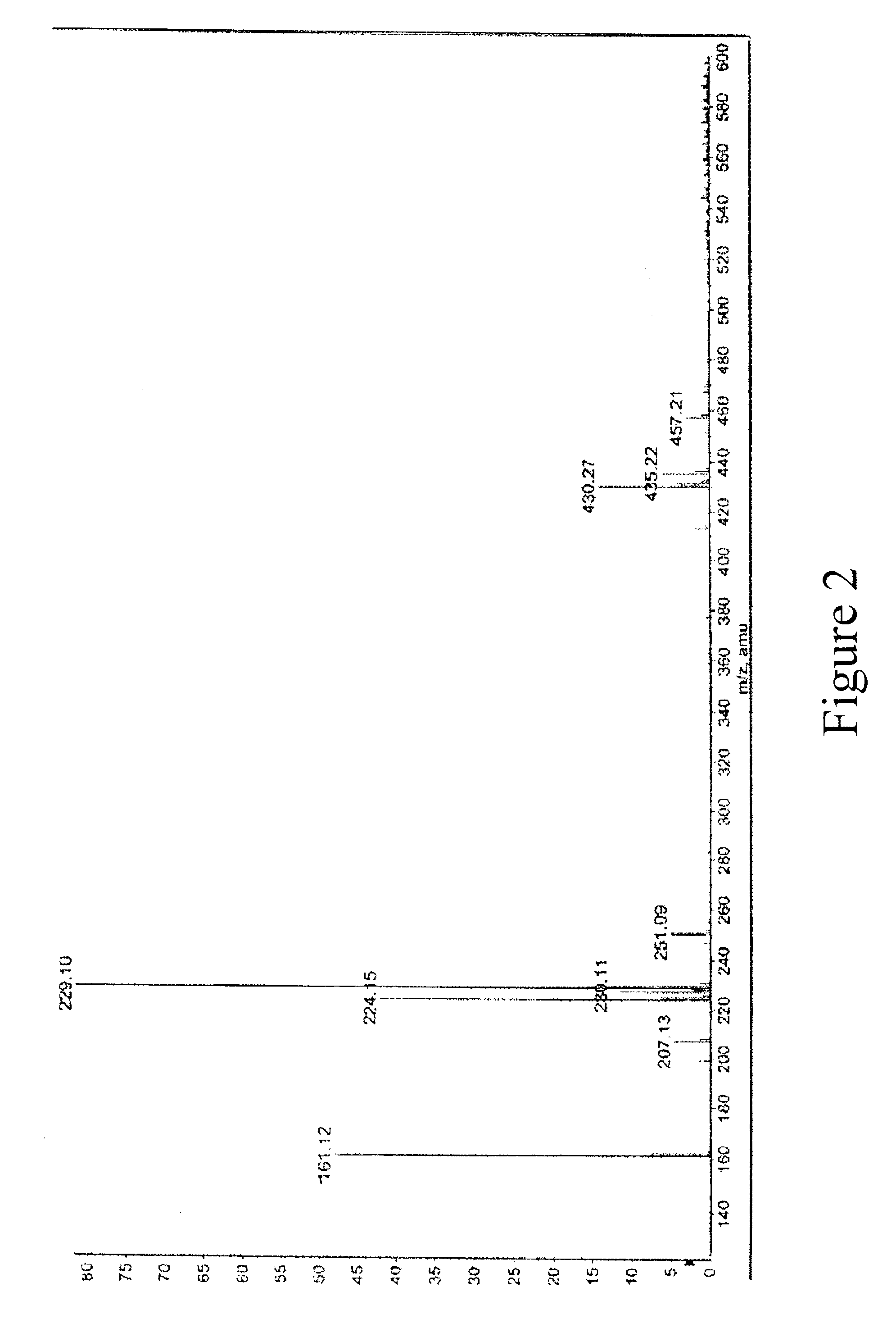

Topical Compositions

InactiveUS20080317684A1Maintain good propertiesAntibacterial agentsBiocidePolyethylene glycolEthanol

Topical compositions are disclosed that are useful for delivering a therapeutic level of an NSAID to a target within a subject having a local inflammatory disorder. A composition of the present invention comprises a Drug and a solvent system, wherein the solvent system comprises at least two solvent alcohols and wherein the solvent system is present in an amount sufficient to solubilize the Drug, the solvent system is a low alkanol system, and the composition is a single phase composition. Exemplary solvent systems are those for which one of the at least two solvent alcohols is polyethylene glycol, glycerin, butylene glycol, dipropylene glycol, propylene glycol, ethanol, isopropanol, or a derivative thereof. Optionally the local inflammatory disorder is pseudofolliculitis barbae, dermatitis, psoriasis, wounds, or sunburn.

Owner:ISW GRP INC

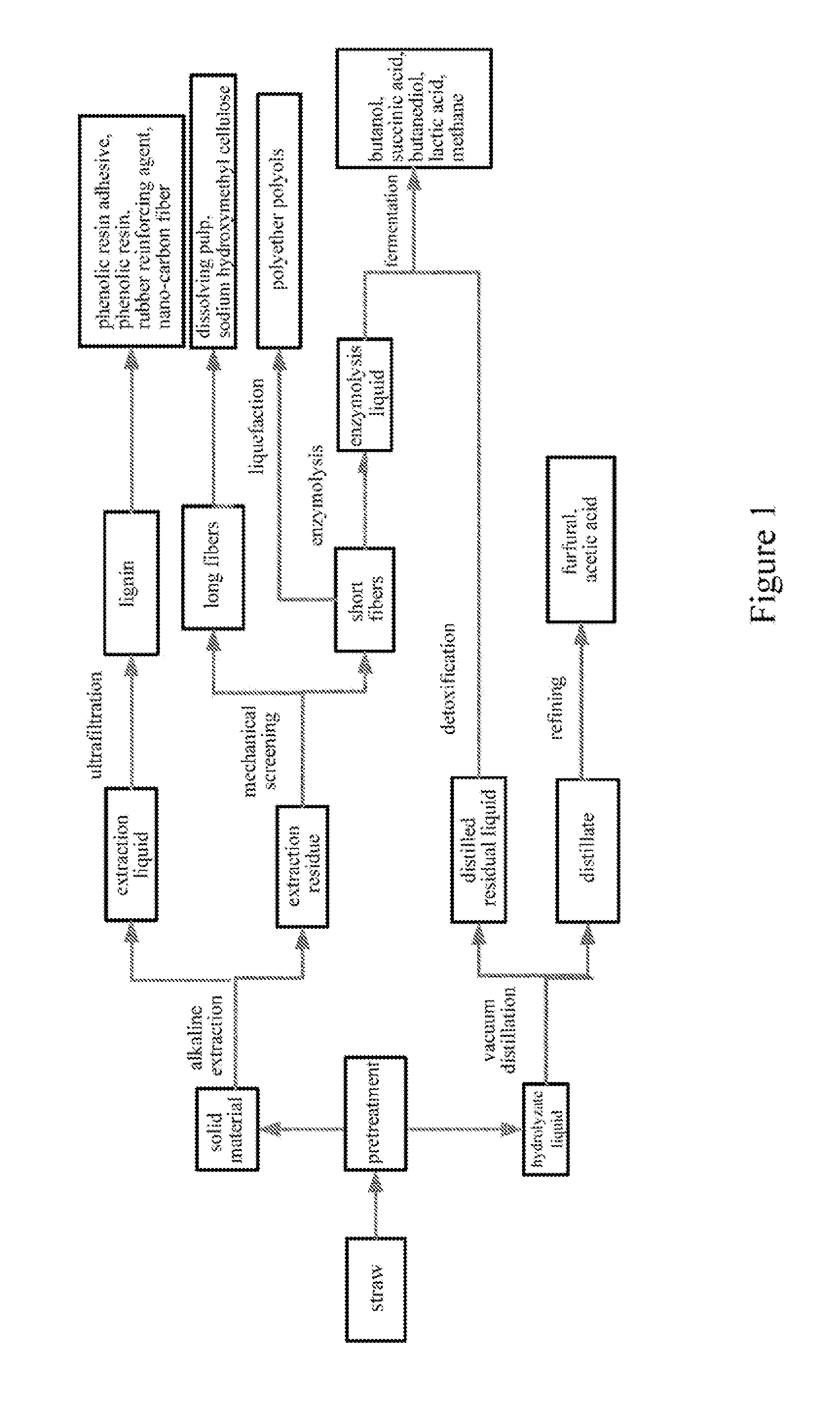

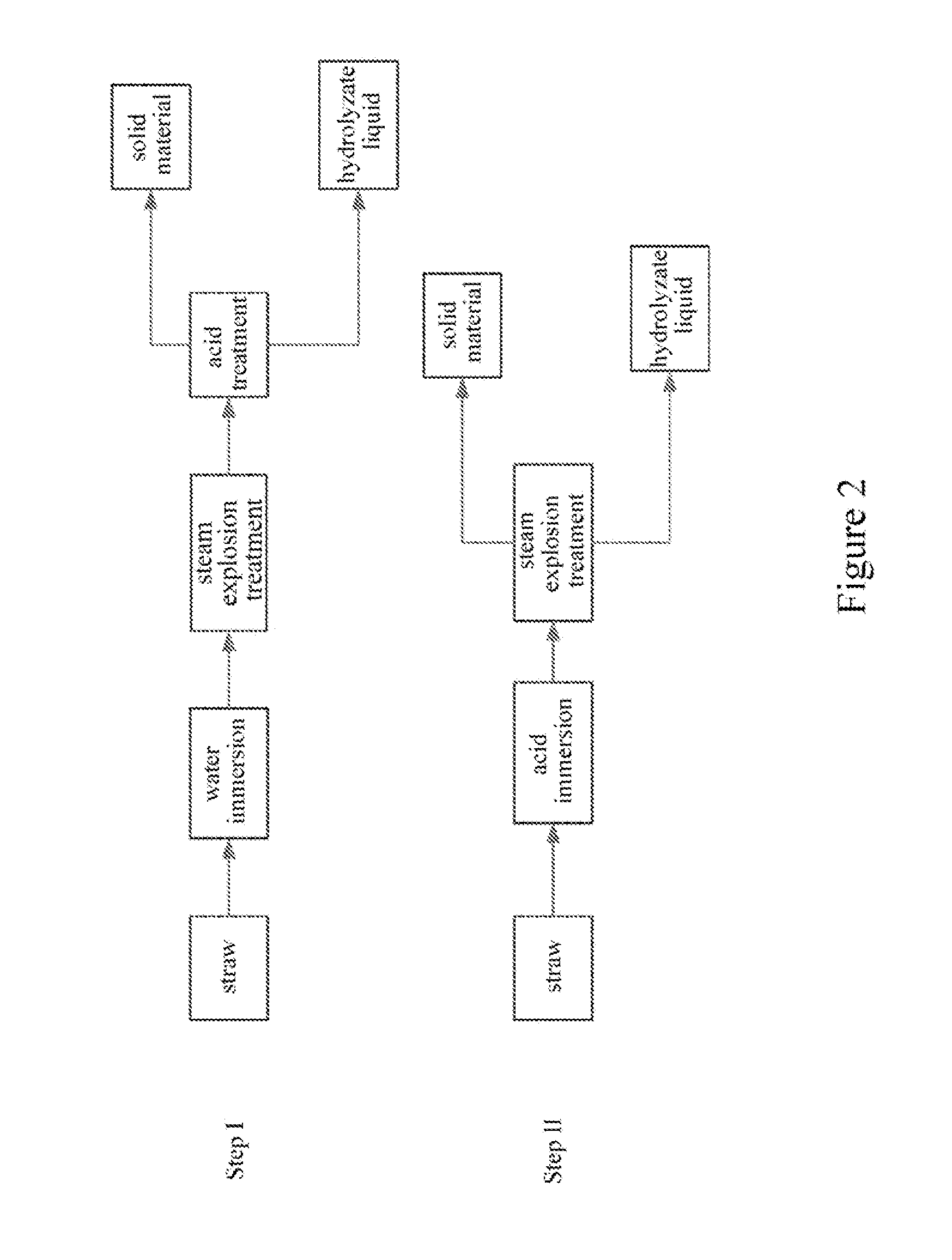

Process for producing bio-based product from straw hemicellulose and fully utilizing the components thereof

ActiveUS20130252293A1Low costHigh value utilizationPretreatment with water/steamBacteriaHigh concentrationSuccinic acid

Provided is a process for producing biomass-based product from straw hemicellulose and utilizing the components thereof thoroughly. Steam-explosion and acid-hydrolysis are combined in the pre-treatment of straw in the process, thus a higher concentration of a sugar liquid can be obtained, and furfural and acetic acid can be recovered. The hemicellulose obtained by the pre-treatment can be used directly as ferment materials for producing butanol, succinic acid, butylene glycol, lactic acid, hydrogen and firedamp, which reduces the cost of these biomass-based products. The cellulose and lignin obtained by extracting the straw with an alkaline solution can produce products, such as sodium hydroxymethyl cellulose etc. In the process, all components in the straw can be utilized thoroughly and waste and pollutant will not be produced.

Owner:HAINAN SUPER HEALTHY GRAIN CO

Multilayer composite having a barrier action

A multilayer composite comprising at least the following layers:I. a layer I of a polyamide molding composition andII. a layer II of a polyester molding composition, where the layers are firmly bonded to each other without use of an additional layer of bonding agent, wherein the polyester molding composition comprises a mixture of:a) from 80-99% by weight of a polyalkylene 2,6-naphthalate selected from the group consisting of polyethylene 2,6-naphthalate and polybutylene 2,6-naphthalate, andb) from 1-20% by weight of one or more compounds containing at least two isocyanate groups, wherein, in addition, the isocyanate groups from component IIb are present in layer II in a concentration of from 0.03-3% by weight.

Owner:DEGUSSA AG

Polyester compositions

InactiveUS6986864B2Improve impact performanceIncrease crystallization rateHollow wall articlesBeltsPolyesterPolyolefin

Disclosed are certain novel polyester compositions particularly useful for shaping or forming into containers and similar shaped articles by thermoforming procedures. The polyester compositions comprise a thermoplastic polyester, an impact modifier and a polyester crystallization rate enhancing component selected from poly(tetramethylene terephthalate) homo- and co-polymers. The polyester compositions exhibit improved crystallization rates as compared to similar compositions not including impact modifier or compositions using other types of crystallization rate enhancing components such as polyolefin-based polymers.

Owner:EASTMAN CHEM CO

Flame-retardant resin composition

ActiveUS20080167406A1Improve flame retardant performanceImprove machinabilityGroup 5/15 element organic compoundsPolytetramethylene terephthalateElastomer

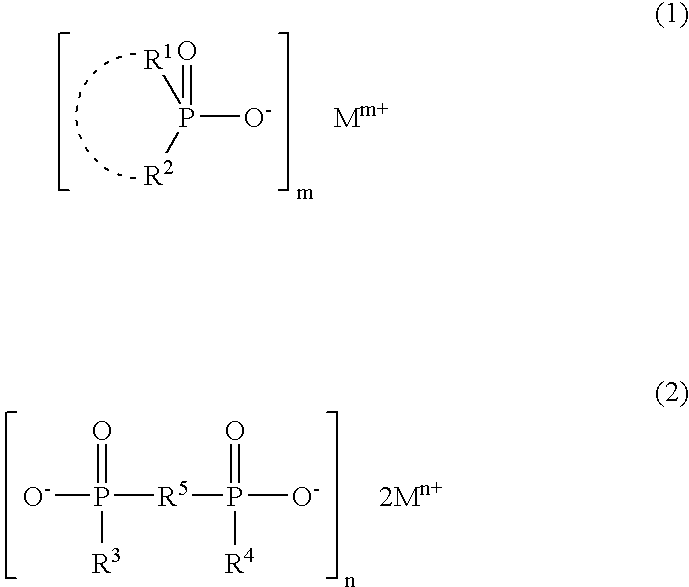

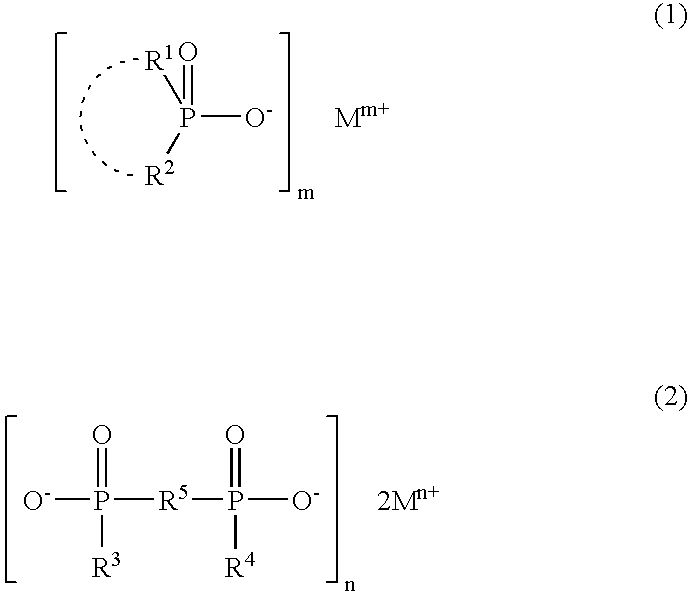

A flame-retardant resin composition comprises 25 to 150 parts by weight of (B) a thermoplastic polyester elastomer, 5 to 40 parts by weight of (C) a phosphinic acid compound comprising a salt of at least one member selected from the group consisting of a phosphinic acid, a diphosphinic acid, and a polymerized product thereof, and 0.5 to 20 parts by weight of (D) an epoxy compound, relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin. Such a flame-retardant resin composition is useful for various molded products and for covering the surface of an electric wire, or the like. The present invention provides a halogen-free flame-retardant resin composition which has a high heat resistance and a high flame retardancy and is excellent in hydrolysis resistance, abrasion resistance, and moldability (e.g., extrusion properties).

Owner:WIN TECH POLYMER LTD

Low cost bio-based full degradable film and preparation method thereof

The present invention discloses a low cost bio-based full degradable film and preparation method thereof, the ratio of each component in parts by mass of the film is as follows: 15-25 parts of a polyglycolic acid, 25-35 parts of corn starch, 35-55 parts of poly(butylene adipate-co-terephthalate), 5 parts of a compatilizer, 3.75-12.25 parts of a starch plasticizer, 0.5-0.7 part of citric acid, 0.75-1.25 parts of acetyl tributyl citrate, 0.3-0.5 part of maleic anhydride, 0.2 part of antioxidant 164, and 0.2 part of 2-(2″-hydroxyl-5″-methylphenyl)benzotriazole. The low cost bio-based full degradable film provided by the present invention has a bio-based content, which can reach 30% or more, a lower cost, and a tensile strength exceeding a traditional PE thin film, and has very important significance for solving the problem of “white pollution” and promoting the popularization and application of full biodegradable materials.

Owner:JIANGSU JINJU ALLOY MATERIAL

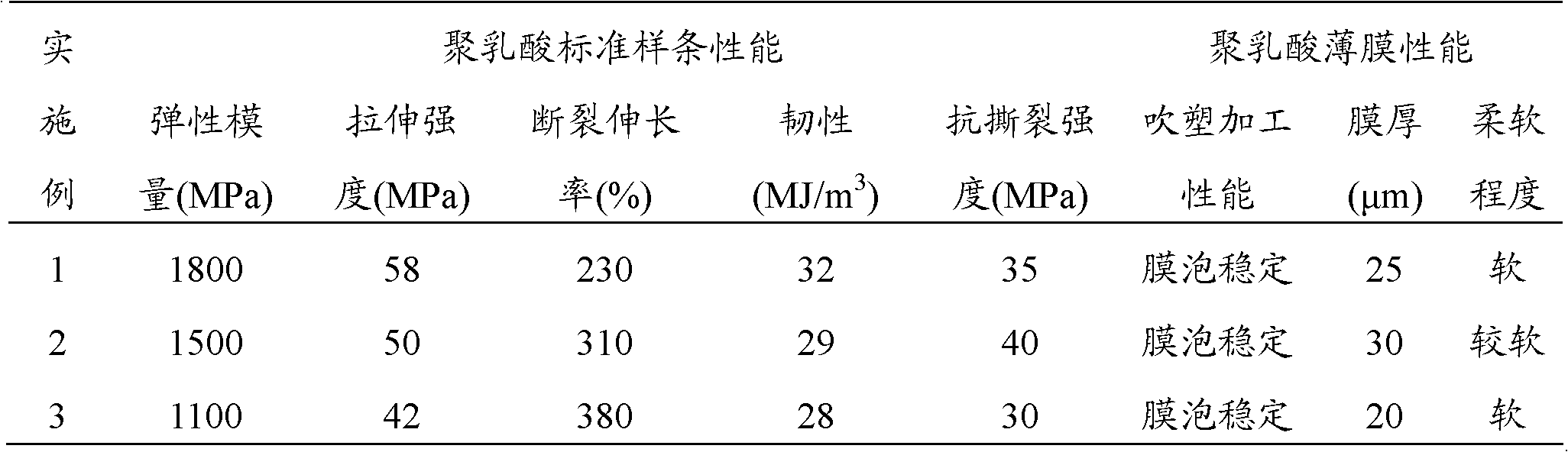

Polylactic acid composition and polylactic acid product

InactiveCN102618003AGood comprehensive mechanical propertiesImprove blow molding processabilityPlasticizerPolylactic acid

The invention provides a polylactic acid composition and a polylactic acid product. The polylactic acid composition comprises the following components by weight percent: 50 to 80 percent of polylactic acid, 0 to 35 percent of adipic acid-polybutylene terephthalate, 0 to 35 percent of poly(butylene succinate), 0.05 to 0.5 percent of peroxide, 0.05 to 0.5 percent of chain extendor and 3 to 15 percent of plasticizer, wherein the content of the adipic acid-polybutylene terephthalate and the content of the poly(butylene succinate) are not 0 percent. The mechanical properties such as melt strength, elongation at break, tenacity and anti-tear strength of the polylactic acid composition provided by the invention are improved, so that the polylactic acid composition with better comprehensive mechanical properties can be obtained, and the polylactic acid composition has more stable processability and better film forming stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com