Preparation method of transparent film-grade thermoplastic polyurethane elastomer

A thermoplastic polyurethane and transparent film technology, applied in the field of thermoplastic polyurethane elastomers, to achieve good high and low temperature resistance, high tensile strength and elongation at break, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

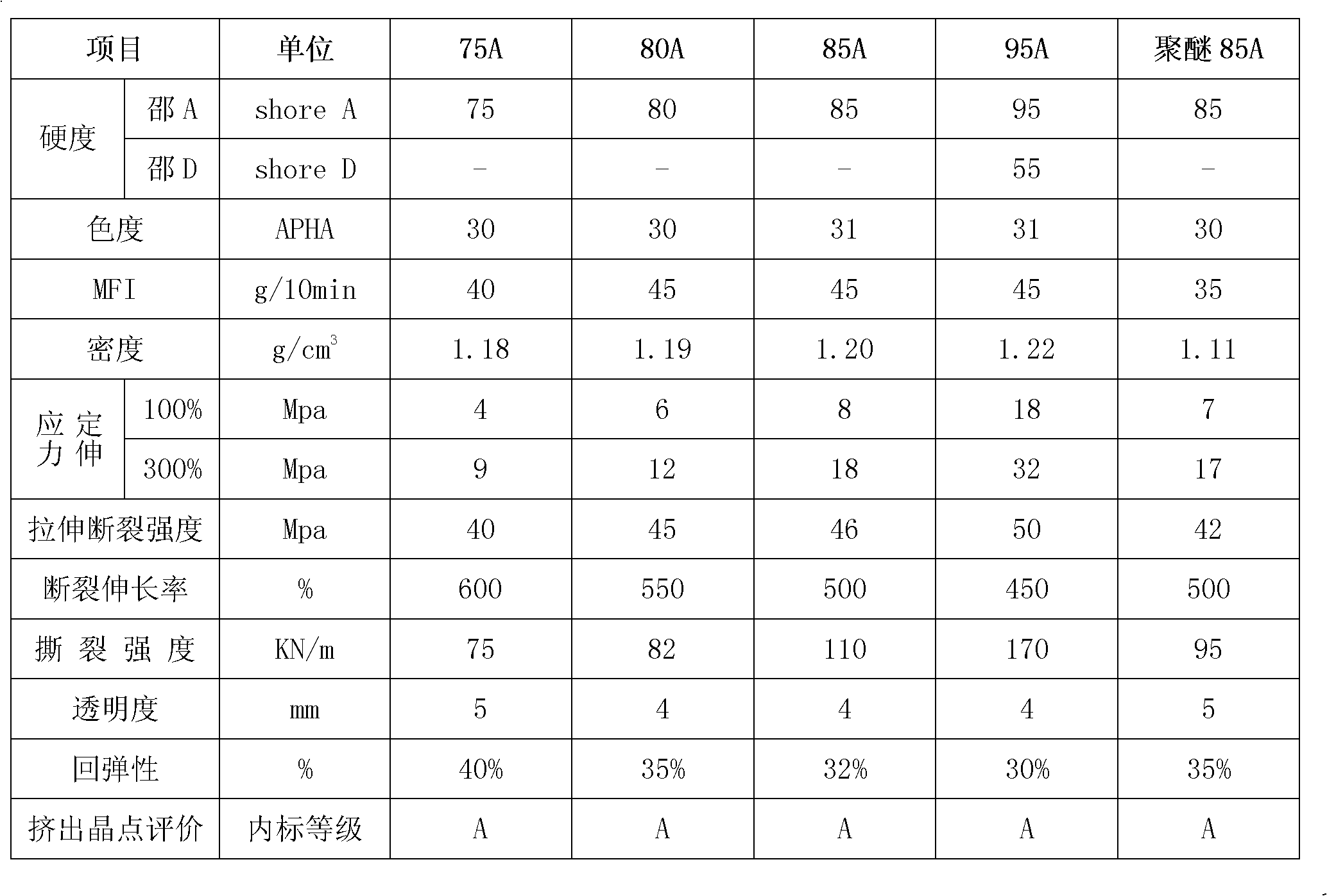

Image

Examples

Embodiment 1

[0063] Premix: 0.5% antioxidant, and 0.15% hindered amine light stabilizer, and 0.25% benzotriazole UV absorber, and 0.5% montan wax and / or erucamide wax Add slip agent and 0.01% environmental catalyst to 70% polybutylene adipate polyol (PBA, hydroxyl value 56±3mgKOH / g, acid value≤0.5mgKOH / g) with molecular weight 2000 Mix to obtain polymer polyol mixed solution,

[0064] Mixing: pouring the polymer polyol mixing solution and 22% diisocyanate into a single-screw mixing device through a mass flow meter for mixing to obtain a preliminary reaction mixture,

[0065] Reaction: pour the preliminary reaction mixture with 4.5% 1,4-butanediol into a co-rotating twin-screw continuous reaction extruder for reaction, the reaction temperature is 150-250°C, the pressure is 4-8MPa, the screw The rotation speed is between 250-350rpm, the kneading frequency is between 7-15 times / s, the length-to-diameter ratio of the screw is 48, the length of the reaction section is 1561mm, the length of the...

Embodiment 2

[0069] Premix: 0.5% antioxidant, and 0.15% hindered amine light stabilizer, and 0.25% benzotriazole UV absorber, and 0.5% montan wax and / or erucamide wax Add slip agent and 0.01% environmental protection catalyst to 67% polybutylene adipate polyol (PBA, hydroxyl value 56 ± 3mgKOH / g, acid value ≤ 0.5mgKOH / g) with a molecular weight of 2000 Mix to obtain polymer polyol mixed solution,

[0070] Mixing: pouring the polymer polyol mixed solution and 24% diisocyanate into a single-screw mixing device through a mass flow meter for mixing to obtain a preliminary reaction mixture,

[0071] Reaction: pour the preliminary reaction mixture with 5.5% 1,4-butanediol into a co-rotating twin-screw continuous reaction extruder for reaction, the reaction temperature is 150-250°C, the pressure is 4-8MPa, the screw The rotation speed is between 250-350rpm, the kneading frequency is between 7-15 times / s, the length-to-diameter ratio of the screw is 48, the length of the reaction section is 1561mm...

Embodiment 3

[0075] Premix: 0.5% antioxidant, and 0.15% hindered amine light stabilizer, and 0.25% benzotriazole UV absorber, and 0.4% montan wax and / or erucamide wax Slip agent, and 0.01% environmental protection catalyst are added to 68% polyethylene adipate butylene glycol ester polyol (PEBA, hydroxyl value 37 ± 2mgKOH / g, acid value ≤ 0.5mgKOH / g) of molecular weight 3000 ) are mixed to obtain a polymer polyol mixed solution,

[0076] Mixing: pouring the polymer polyol mixed solution and 23% diisocyanate into a single-screw mixing device through a mass flow meter for mixing to obtain a preliminary reaction mixture,

[0077] Reaction: pour the preliminary reaction mixture with 5.8% 1,4-butanediol into a co-rotating twin-screw continuous reaction extruder for reaction, the reaction temperature is 150-250°C, the pressure is 4-8MPa, the screw The rotation speed is between 250-350rpm, the kneading frequency is between 7-15 times / s, the length-to-diameter ratio of the screw is 48, the length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com