Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Less crystal point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene type optical protective film

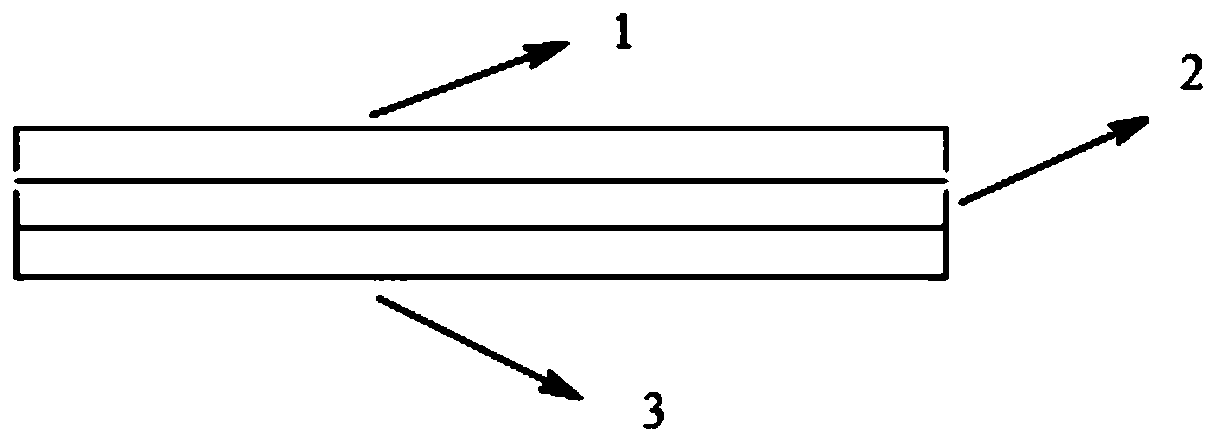

ActiveCN103336321ANo residueGood lookingSynthetic resin layered productsOptical elementsRough surfaceCentral layer

The invention provides a polypropylene type optical protective film which is composed of a smooth layer, a central layer and a self pasting layer, the total thickness ranges from 20 micrometer to 70 micrometer, the thickness of the smoothness layer accounts for 10 percent to 20 percent of the total thickness, the thickness of the central layer accounts for 40 percent to 60 percent of the total thickness, and the thickness of the self pasting layer accounts for 10 percent to 30 percent of the total thickness. The protective film provided by the invention has the characteristics of low cost, no residual glue picture, less crystal points, better appearance, no residual solvent, uniform initial viscidity, easiness in control, and the like. The polypropylene type optical protective film provided by the invention adjusts the adhesion strength by adding proper content of POP and EVA. In addition, the invention adopts propylene block copolymers as the main producing materials, so as to enable the surface of the protective film to be provided with a certain shading effect and rough surface performance, and play a role of sunscreen and pressure proofing to the substrates under protection accordingly. Comparing with general PE protective film which achieves the purpose of extinction by adding flatting agents, the protective film provided by the invention further avoids the impact of the inorganic impurities or carbide crystal points to the appearance of the protective film.

Owner:湖北慧狮塑业股份有限公司

Multilayer coextrusion paper-like liquid packaging film

PendingCN101905776AGood dispersionGood compatibilityPackage recyclingFlexible coversMultilayer membraneFood packaging

The invention provides a multilayer coextrusion paper-like liquid packaging film. In resent years, people demand more dairy products, and the demand for the packaging films of various kinds of dairy products and liquid foods increases along with the continuous development of a UHT (Ultra Heat Treated) sterilization technology. According to incomplete statistics, only the consumption of milk packaging films reaches 7200 tons / year in 2009, and because liquid foods have self characteristics, liquid packaging films which are all made from 100% plastics are impossible to adopt a biodegradable packaging material to package the liquid foods so that gigantic pressure is brought to environmental protection, and a great amount of oil resources is consumed. Therefore, the field needs a material which can be used for packaging liquid, particularly a multi-layer liquid packaging film for packaging liquid dairy products and being capable of reducing the consumption of oil resources. According to one aspect of the invention, the invention provides the multilayer film is used for packaging liquid and can greatly reduce the consumption of plastic raw materials.

Owner:刘燕

Self-adhering protecting film and application thereof in adhering protecting smooth-surfaced PC board

ActiveCN104497900AHigh glossGood flexibilityFilm/foil adhesivesLow-density polyethyleneSurface layer

The invention provides a self-adhering protecting film. The self-adhering protecting film comprises a surface layer, a core layer and an adhering layer, wherein the core layer is arranged between the surface layer and the adhering layer; the adhering layer is prepared from two of low-density polyethylene, an SEBS thermoplastic elastomer, metallocene polyethylene and a POE thermoplastic elastomer. According to the self-adhering protecting film, the core layer is prepared from two of low-density polyethylene, the SEBS thermoplastic elastomer, metallocene polyethylene and the POE thermoplastic elastomer, and therefore, the prepared self-adhering protecting film is relatively high in adhering force with an adhering object under the normal temperature; in addition, the adhering force has small change as temperature changes; when processing is performed at high temperature, the adhering force can be kept within a certain range, instead of excessively raising, and therefore, the self-adhering protecting film is easily torn without any adhesive residue under the high temperature state.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Preparation method of extinction polyvinyl chloride resin

The invention provides a preparation method of extinction polyvinyl chloride resin. The preparation method comprises the following steps: acquiring vinyl chloride monomer, deionized water, an initiator, a buffering agent, a dispersant and a matting agent which serve as reaction raw materials; performing pre-emulsification treatment on the matting agent by use of part of the dispersant; adding the vinyl chloride monomer, the deionized water, the initiator, the buffering agent and the rest dispersant into a polymerization kettle, performing polyreaction, and adding the matting agent subjected to pre-emulsification treatment during the reaction process so as to prepare the extinction polyvinyl chloride resin, wherein the matting agent is a monomer or polymer containing two or more reaction active functional groups, the dosage of the deionized water accounts for 105-200% of the weight of the vinyl chloride monomer, the dosage of the initiator accounts of 0.04-0.18% of the weight of the vinyl chloride monomer, the total dosage of the dispersant accounts for 0.04-0.15% of the weight of the vinyl chloride monomer, the dosage of the buffering agent accounts for 0.06-0.18% of the weight of the vinyl chloride monomer, and the dosage of the matting agent accounts for 0.01-8.0% of the weight of the vinyl chloride monomer. The prepared extinction polyvinyl chloride resin is fewer in crystal spot and good in extinction effect.

Owner:HANGZHOU ELECTROCHEM GROUP

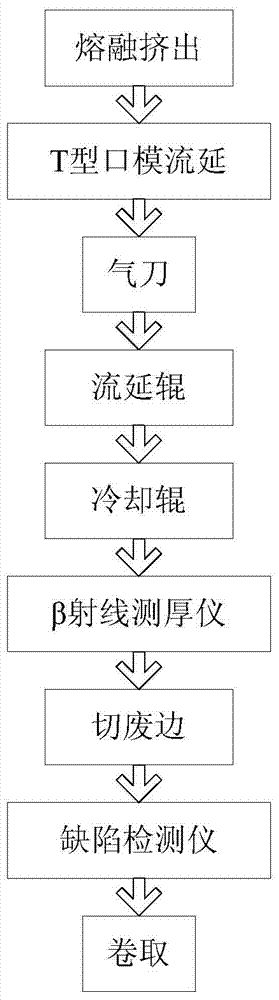

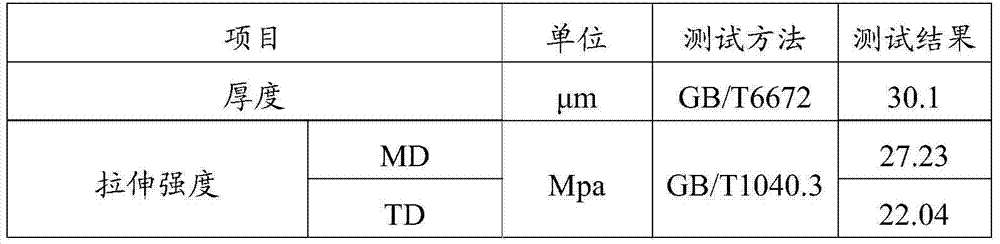

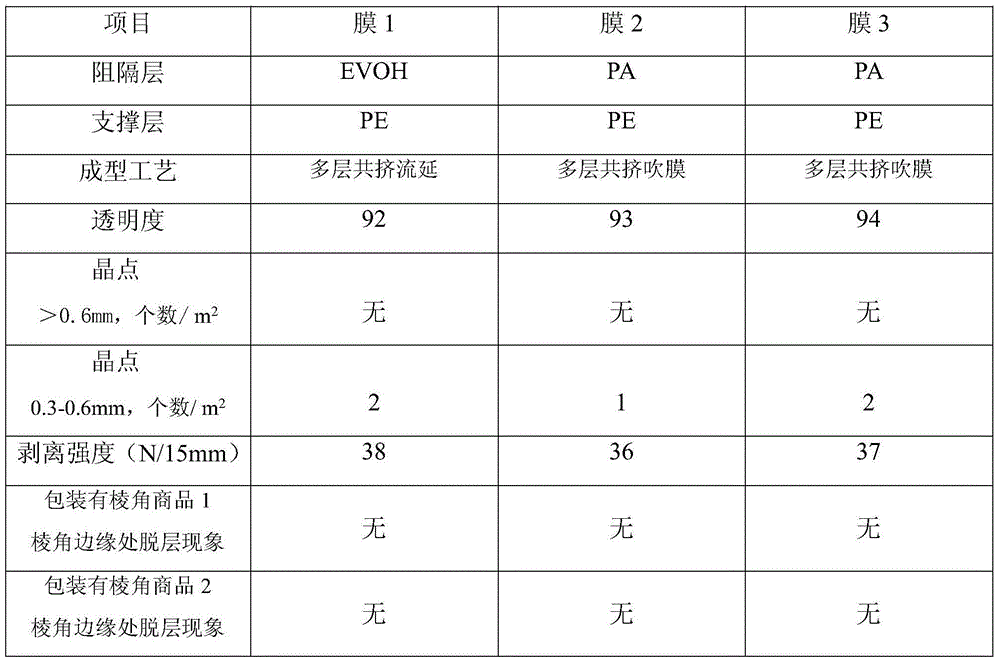

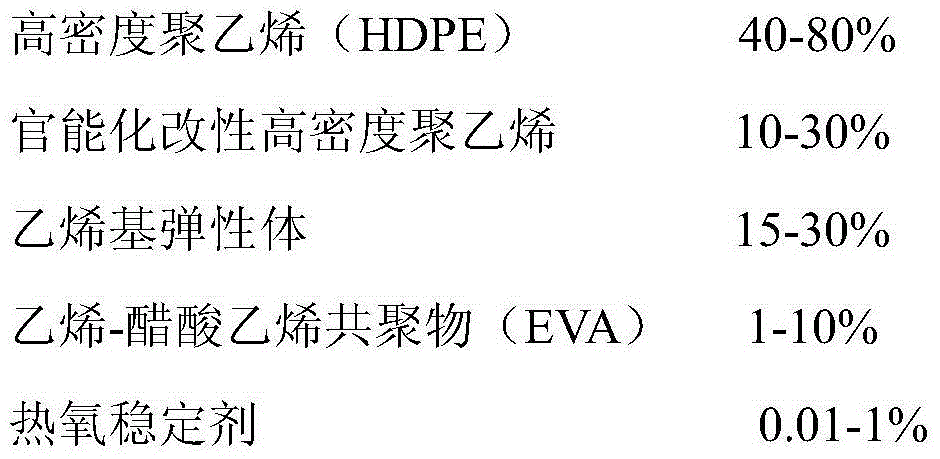

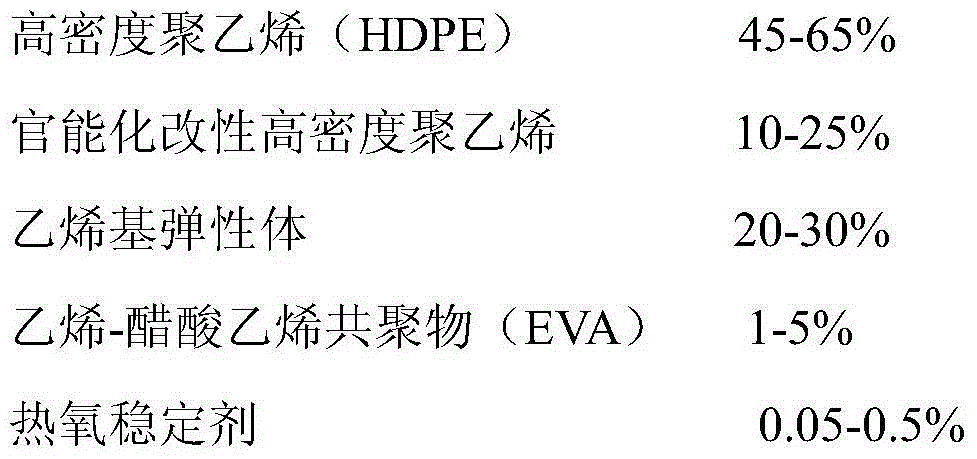

Method for preparing polyethylene type adhesive resin for multilayer co-extrusion barrier package

The invention discloses a polyethylene type adhesive resin for multilayer co-extrusion barrier package. The polyethylene type adhesive resin comprises the following formula raw materials in percentage by weight: 40-80 percent of high density polyethylene (HDPE), 10-30 percent of functionalization modified high density polyethylene, 15-30 percent of vinyl elastomer, 1-10 percent of ethylene vinyl acetate copolymer (EVA), 0.01-1 percent of hot oxygen stabilizer. The polyethylene type adhesive resin is prepared by the following steps: performing a plasticizing and blending process by adopting a twin-screw extruder, extruding, and granulating, thereby obtaining the product. The adhesive resin disclosed by the invention is used for an adhesive layer of a polyethylene (PE) / nylon (PA) or polyethylene (PE) / ethylene-vinyl alcohol copolymer (EVOH) multilayer co-extrusion barrier package film (sheet) and is excellent in processability, high in transparency, high in heat resistance and fewer in grain points, is particularly excellent in adhesive performance, and a good adhesive layer material is provided for the field of polyethylene type multilayer co-extrusion barrier package.

Owner:HEYUAN PLG MATERIALS

Multi-layer co-extruded paper-like liquid packaging film

InactiveCN102079418AGood dispersionGood compatibilityPackage recyclingFlexible coversMetallic aluminumPlastic materials

In recent years, with the increasing demand of people for dairy products and the unceasing development of ultra heat treated (UHT) sterilization technology, people need more and more packaging films of various dairy products and liquid foods. According to incomplete statistics, in 2009, the weight of the films used for only packaging milk is up to 7,200 ton (year). Because of the large amount and the characteristics of the liquid foods, and because the liquid packaging film is manufactured from 100 percent plastic raw materials or is synthesized from paper, a plastic and metal aluminum and the liquid foods cannot be packaged by a biodegradable packaging material, great pressure is put on environmental protection, at the same time, a large amount of petroleum resources is consumed, paper making puts pressure on environment and the paper, plastic and aluminum film structures cannot be recycled. Therefore, a material for packaging liquid, particularly a multi-layer liquid packaging film structure used for packaging liquid dairy products and reducing the consumption of the petroleum resources, is still needed. On the one hand, the invention provides a multi-layer film which is used for packaging liquid materials and can greatly reduce plastic materials.

Owner:JIANGSU BEST RIEL PACKAGING MATERIALS CO LTD

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Adhesive resin for barrier composite hose and preparation method and application thereof

ActiveCN104449470AEasy to prepareImprove performanceMacromolecular adhesive additivesFlexible pipesElastomerLinear low-density polyethylene

The invention discloses adhesive resin for a barrier composite hose and a preparation method and application thereof. The preparation method comprises the following steps of: firstly dissolving the following materials in parts by weight: 0.1-0.5 part of initiating agents, 1-3 parts of maleic anhydride and 0.5-1.5 parts of acrylamide into acetone, then uniformly mixing with 100 parts of PE, and carrying out reactive extrusion to obtain a maleic anhydride and acrylamide double-monomer grafted PE master batch; then carrying out blending extrusion on the following materials in parts by weight: 20-30 parts of the PE master batch, 50-70 parts of linear low density polyethylene, 10-20 parts of polyolefin elastomers, 0.05-0.15 part of fluoropolymer processing auxiliary agents and 0.2-0.5 part of antioxidants for granulation to obtain the adhesive resin for the barrier composite hose. The adhesive resin disclosed by the invention forms a transparent granule with a natural color in appearance, is stable in property and few in eutectic points and achieves the stripping strength on adhering to EVOH more than 250 N / cm. The barrier composite hose prepared by using the adhesive resin has the advantages of good adhesive property of various layers, high barrier property and smoothness of inner and outer surfaces.

Owner:合诚技术股份有限公司

Preparation method of adhesive resin for multilayer coextruded plastic composite hose

ActiveCN104356977AHigh bonding strengthMeet the needs of useNon-macromolecular adhesive additivesGraft polymer adhesivesLow-density polyethyleneElastomer

The invention discloses a preparation method of an adhesive resin for a multilayer coextruded plastic composite hose. The adhesive resin comprises the following raw materials in percentage by weight: 30%-70% of linear low density polyethylene (LLDPE), 10%-30% of functionalized modified LLDPE, 10%-30% of vinyl elastomer, 5%-20% of low density polyethylene (LDPE) and 0.01%-1% of a thermal oxidation stabilizer. The adhesive resin is prepared by extruding and pelletizing in a twin-screw extruder through a plasticizing blending process. The adhesive resin disclosed by the invention is used for the adhesive layer of the multilayer coextruded plastic composite hose of polyethylene (PE) / ethylene-vinyl alcohol copolymer (EVOH), and is excellent in processability, good in heat resistance and few in crystal points, and in particular, excellent in adhesive property; as a result, a good adhesive layer material is provided for the multilayer coextruded plastic composite hoses.

Owner:HEYUAN PLG MATERIALS

Preparation method of polypropylene type bonding resin for multi-layer coextrusion barrier packaging

ActiveCN104371597AEasy to processHigh transparencyLaminationLamination apparatusElastomerHeat resistance

The invention discloses a preparation method of polypropylene type bonding resin for multi-layer coextrusion barrier packaging. The raw materials include (by weight percent) 50% to 80% of polypropylene random copolymer, 10% to 30% of functionalized modified atactic polypropylene, 10% to 30% of propylene based elastomer, 1% to 10% of styrene block copolymer and 0.01% to 1% of thermal oxygen stabilizer. The resin is obtained in extruded and granulated manners through a double screw extruder by the plasticating and blending process. The bonding resin is applied to the bonding layers of polypropylene (PP) / Niron (PA) or polypropylene (PP) / ethylene vinyl alcohol copolymer (EVOH) multi-layer coextrusion barrier packaging films (pieces), the processing performance is fine, the transparency is high, thermal resistance is fine, fisheye is few, the bonding performance is excellent, and a good bonding layer material is provided in the field of polypropylene type multi-layer coextrusion barrier packaging.

Owner:HEYUAN PLG MATERIALS

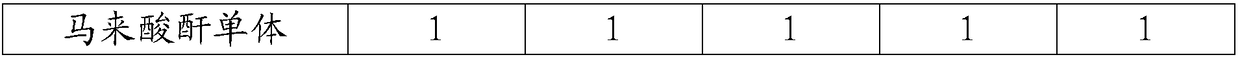

Bonding resin for aluminum-plastic board, preparation method thereof, and aluminum-plastic board

InactiveCN109321172AIncrease polarityImprove non-polaritySynthetic resin layered productsMetal layered productsUltimate tensile strengthExtrusion Granulation

The invention discloses bonding resin for an aluminum-plastic board and a preparation method thereof. The bonding resin is obtained by extrusion-granulation by a plasticizing blending process using atwin-screw extruder, and has high bonding strength, good bonding durability and film forming performance, less crystal points, and good heat and oxygen aging resistant performance, especially, by introducing HIPS, the bonding speed of the bonding resin is greatly improved, and simultaneously the bonding strength and durability are improved, so as to solve the defects of low bonding strength and poor stability caused by the untimely bonding reaction of the aluminum-plastic board in a high-speed production process, thereby greatly improving the production speed and bonding stability of the aluminum-plastic board.

Owner:HEYUAN PLG MATERIALS

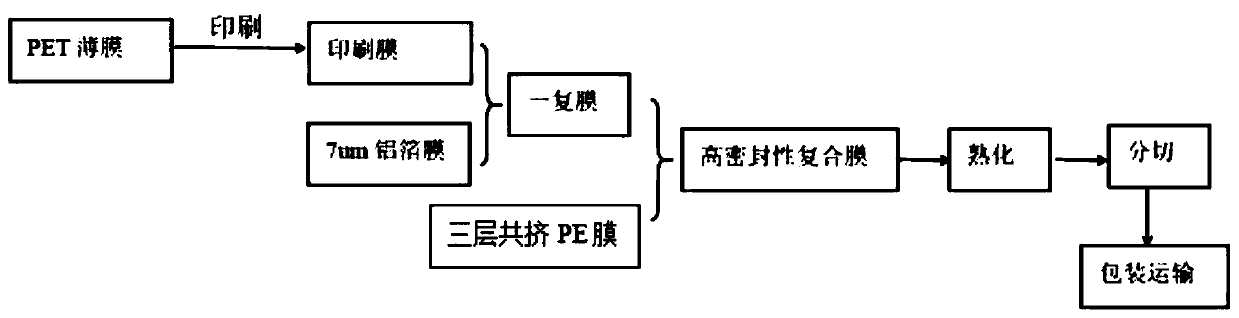

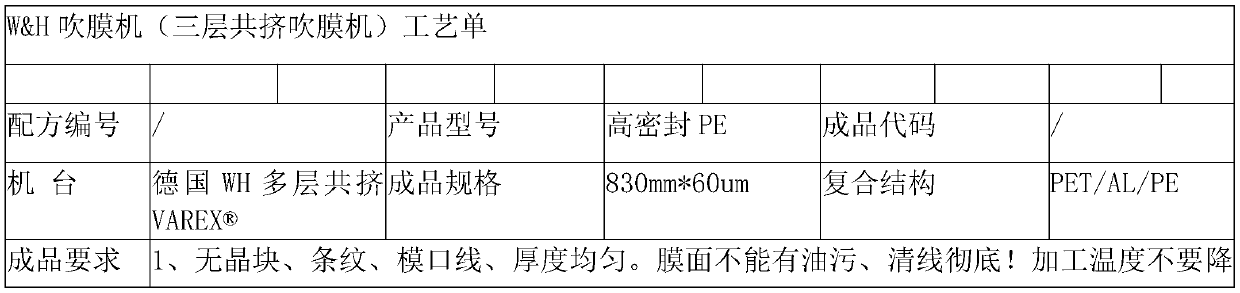

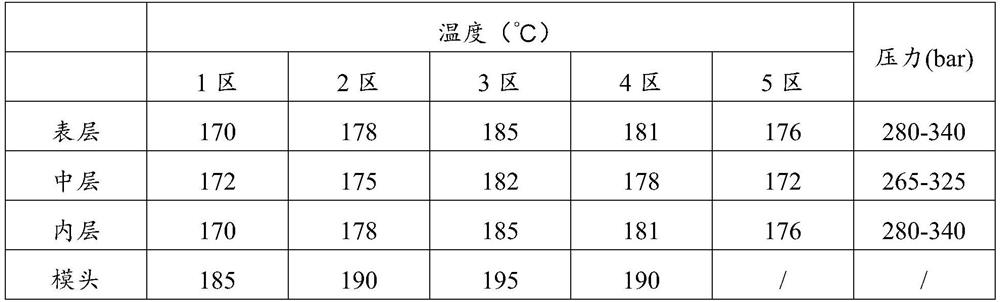

High-leakproofness multichannel packaging composite membrane and production technology thereof

ActiveCN110065270AExcellent thickness stabilityHigh heat sealing strengthFlexible coversWrappersChemistryBonding strength

The invention relates to a high-leakproofness multichannel packaging composite membrane and a production technology thereof. The composite membrane is formed by compounding a PET membrane, an aluminumfoil membrane and a three-layer co-extrusion PE membrane through an adhesive; the three-layer co-extrusion PE membrane comprises a corona layer, an intermediate layer and a heat-seal layer, wherein the corona layer comprises linear low-density polyethylene, low-density polyethylene and a fluorine-containing processing aid, the intermediate layer comprises low-density polyethylene, linear low-density polyethylene and high-density polyethylene, the heat-seal layer comprises first metallocene linear low-density polyethylene, second metallocene linear low-density polyethylene, polybutylene, a slipping agent and open masterbatches, and the melting index of the first metallocene linear low-density polyethylene is smaller than that of the second metallocene linear low-density polyethylene. The composite membrane has excellent thickness stability, the friction coefficient is 0.2-0.3, and machine running is facilitated; the heat-seal strength and heat-bonding strength are high, the membrane isresistant to negative pressure larger than or equal to 0.8 MPa, and the leakproofness is excellent; the Elmendorf tearing force is low, the thin membrane is easy to cut, and filament generation doesnot occur.

Owner:HUANGSHAN NOVEL

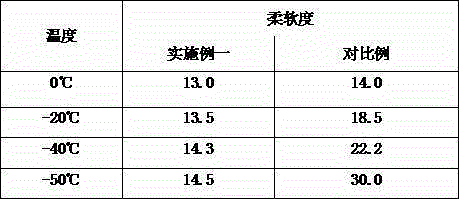

Low-temperature-resistant bidirectionally-stretched polypropylene thin film and preparation method of same

ActiveCN105235336AImprove low temperature resistanceLess crystal pointLamination ancillary operationsSynthetic resin layered productsMasterbatchPolymer science

The invention discloses a low-temperature-resistant bidirectionally-stretched polypropylene thin film and a preparation method of the same. The polypropylene thin film comprises, from exterior to interior, a low-temperature-resistant anti-adhesion layer, a low-temperature-resistant core layer and a low-temperature-resistant corona treatment layer. The low-temperature-resistant core layer is composed of 30-70% of homo-polypropylene, 10-40% of a thermoplastic elastic master batch, and 20-50% of a low-temperature-resistant master batch. The low-temperature-resistant anti-adhesion layer and the low-temperature-resistant corona treatment layer are both composed of 50-70% of copolymerized modified polypropylene, 25-40% of a low-temperature-resistant master batch and 2-10% of a SiO2 anti-adhesion agent. The polypropylene thin film has excellent low-temperature-resistant performance, has excellent use performance even at -30 DEG C, is soft, is excellent in printing performance, has excellent physical performance and is simple in preparation method.

Owner:ANHUI GUOFENG PLASTIC

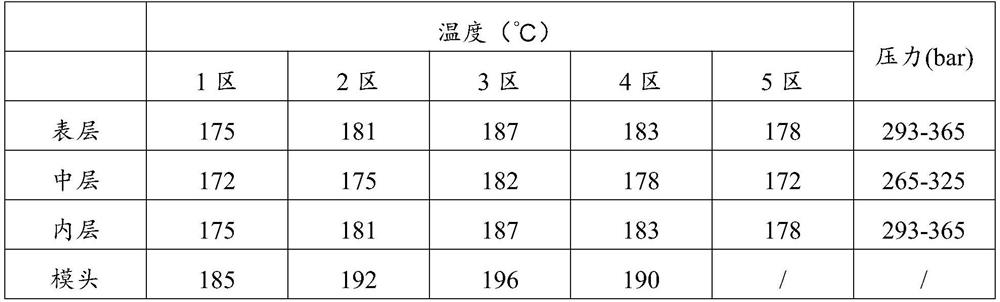

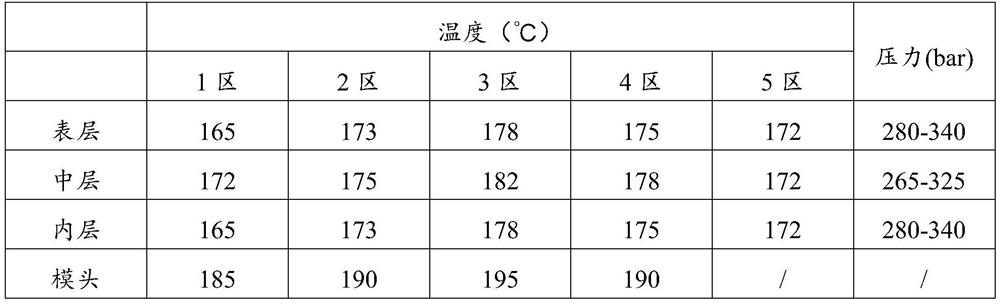

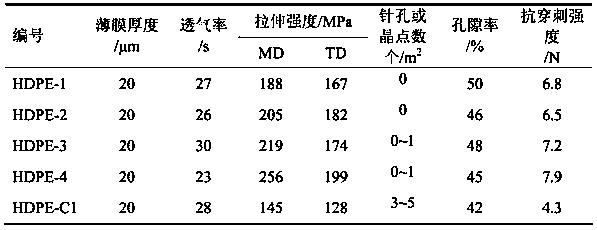

Polyethylene composite film as well as preparation method and application thereof

ActiveCN112976744AUltra-thinImprove stiffnessSynthetic resin layered productsLow-density polyethylenePolymer science

The invention belongs to the technical field of polyethylene materials, and particularly relates to a polyethylene composite film as well as a preparation method and application thereof. The polyethylene composite film provided by the invention comprises a surface layer, a middle layer and an inner layer which are sequentially bonded; the surface layer comprises first low-density polyethylene, first high-density polyethylene and a first processing aid; the middle layer comprises second low-density polyethylene, metallocene linear low-density polyethylene, second high-density polyethylene and a second processing aid; the inner layer comprises third low-density polyethylene, third high-density polyethylene and a third processing aid; and the thickness of the polyethylene composite film is 40 microns. Experimental results show that the polyethylene composite film provided by the invention has both thinning and good stiffness.

Owner:江门市华龙膜材股份有限公司

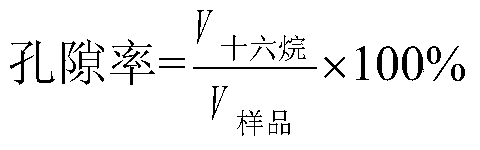

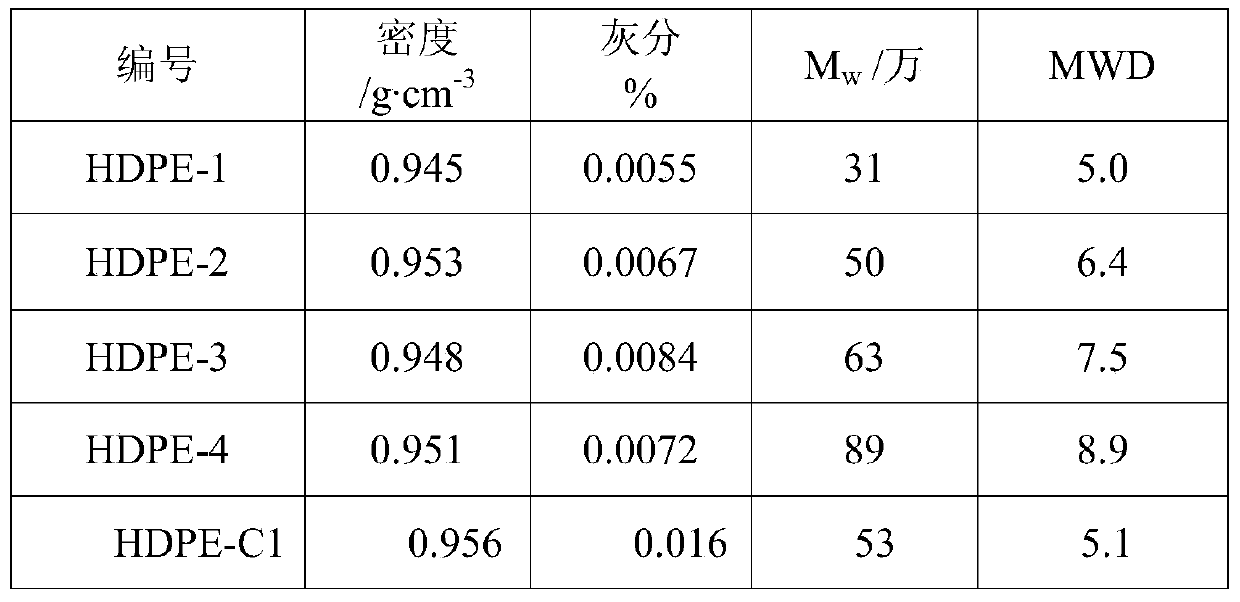

Low-ash and high-density polyethylene resin and preparation method thereof

ActiveCN105504124AUniform pore size distributionHigh tensile strengthCell component detailsBulk chemical productionLow-density polyethylenePolymer science

The present invention discloses a low-ash and high-density polyethylene resin and a preparation method thereof, wherein the weight average relative molecular mass of the low-ash and high-density polyethylene resin is 3.0*10<5>-9.0*10<5>, the relative molecular mass distribution is 5-9, the density is 0.940-0.965 g / cm<3>, and the ash content is less than 100 ppm. According to the present invention, the low-ash and high-density polyethylene resin has advantages of uniform composition, low ash, low metal impurity content, and the like; with the three-reaction kettle series connection method, the relative molecular mass, the relative molecular mass distribution and the co-polymerization monomer distribution of the polymerization product are easy to adjust, and the method can be directly used for molding of the wet lithium-ion battery separation membrane; and the molded microporous separation membrane has characteristics of uniform pore size distribution, less pinholes, less fisheye, high yield, high tensile strength, and high puncture strength.

Owner:SINOPEC YANGZI PETROCHEM +1

Transparent TPU film with barrier performance and preparation method of transparent TPU film

The invention relates to a transparent TPU film with barrier performance and a preparation method of the transparent TPU film. The transparent TPU film comprises the following components in percentage by weight: 40-60% of thermoplastic polyurethane, 2-5% of SBS, 20-30% of K adhesive, 5-8% of inorganic filler and 12-20% of barrier agent. The preparation method comprises the following concrete steps of (1) after mixing all the materials, plasticizing TPU particles by using a single-screw extruder to form a semi-finished product; (2) directly connecting the single-screw extruder to a filtering machine of calendar equipment, and carrying out impurity filtration and re-plasticization on the semi-finished product on the filtering machine of the calendar equipment; and (3) processing the plasticized semi-finished product by using four-roller molding equipment to mold the film. The TPU film prepared by using the preparation method has high transparency and favorable barrier performance, tensile strength and processability.

Owner:SUZHOU XIONGLIN NEW MATERIAL SCI & TECH CO LTD +1

Transparent blocking thermoplastic polyurethane elastomer and preparation method thereof

ActiveCN104231595AIncrease elasticityHigh transparencyPolyurethane elastomerThermoplastic polyurethane

Owner:DONGGUAN JIXIN POLYMER SCI & TECH +1

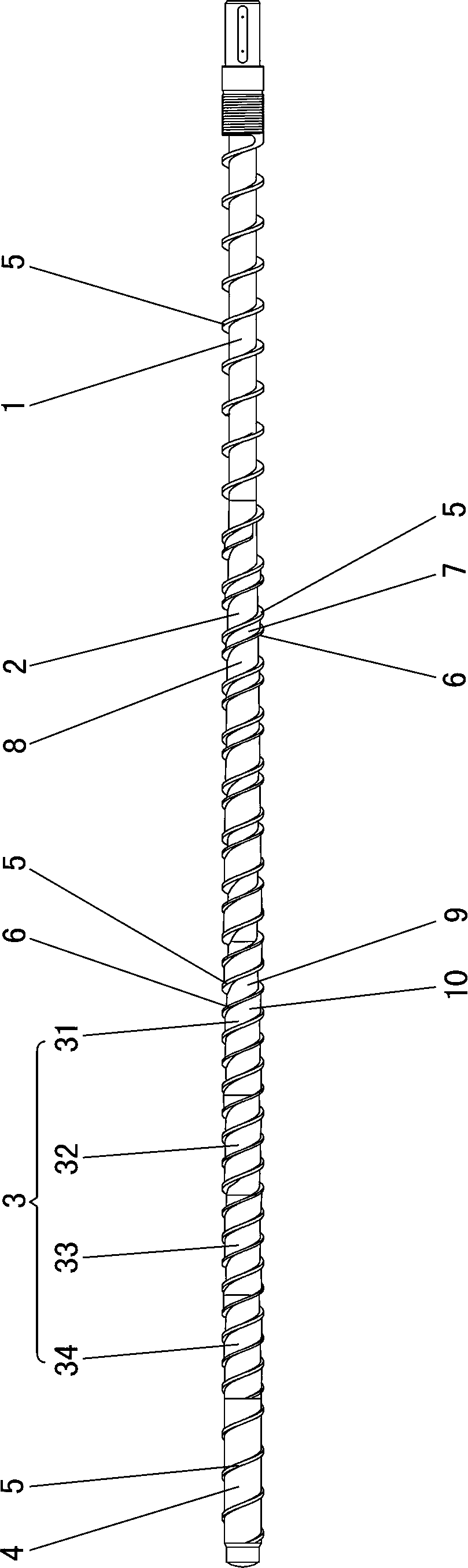

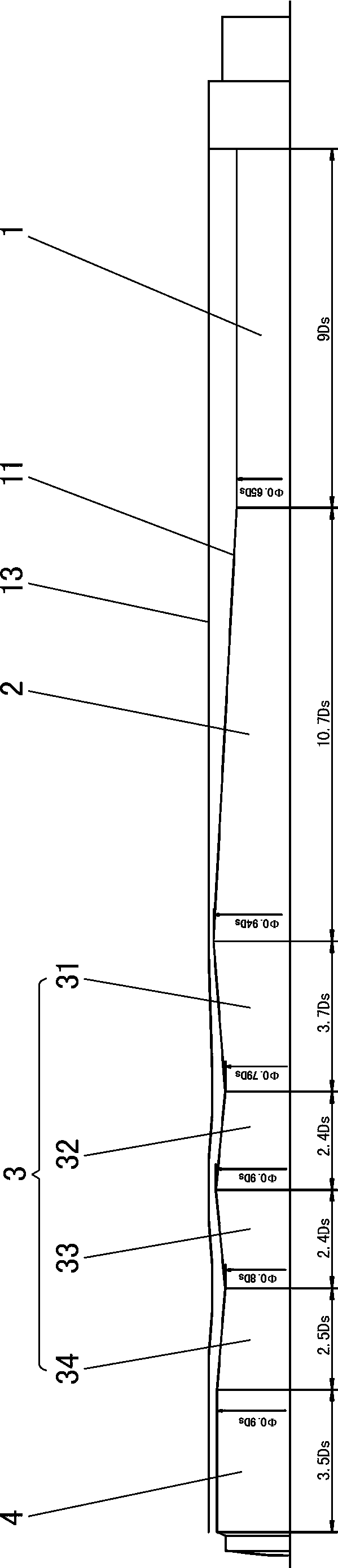

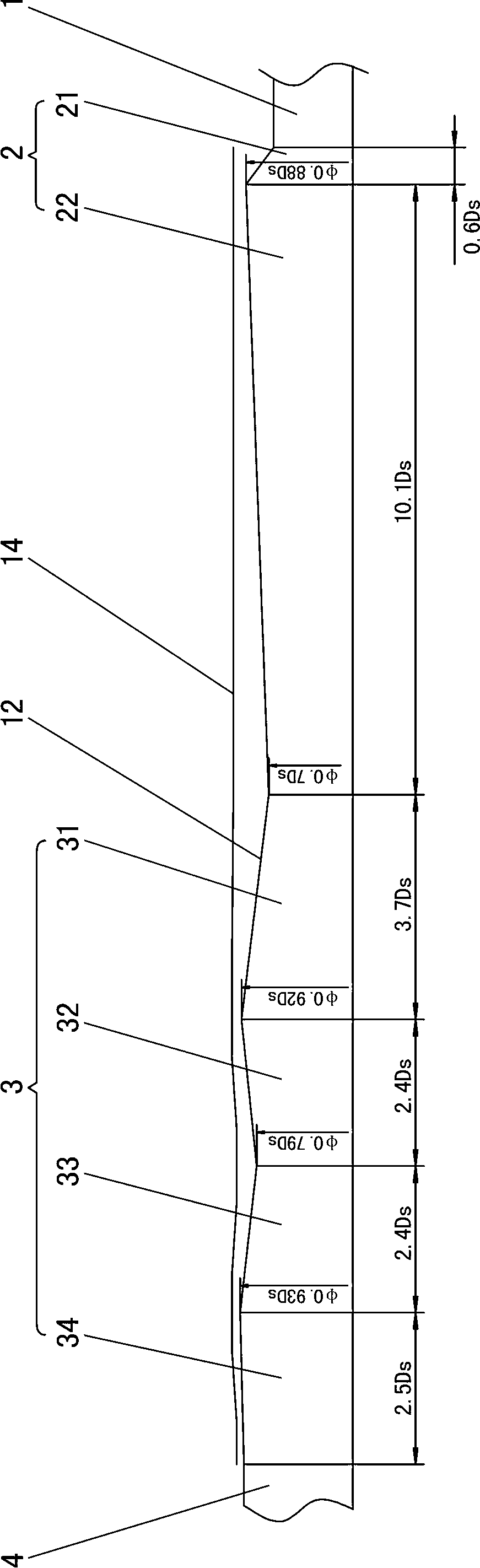

Screw rod of single screw extruder

The invention discloses a screw rod of a single screw extruder. The screw rod sequentially comprises a feeding section, a compression separation section and a metering section from front to back, wherein the feeding section is provided with a main thread, the compression separation section is provided with a main thread and an auxiliary thread, and the metering section is provided with a main thread. The screw rod is characterized in that a mixed section is arranged between the compression separation section and the metering section, is provided with main threads and auxiliary threads, and sequentially comprises a plurality of mixed subsections from front to back; the bottom diameters of the main threads on the odd mixed subsections gradually decrease from front to back, and the bottom diameters of the auxiliary threads on the odd mixed subsections gradually increase; and the bottom diameters of the main threads on the even mixed subsections gradually increase from front to back, and the bottom diameters of the auxiliary threads on the even mixed subsections gradually decrease from front to back. According to the screw rod provided by the invention, the bottom diameters of the main and auxiliary threads on the mixed change alternately, so that materials can be alternately compressed and relaxed, completely plasticized and uniformly mixed. Therefore, the plastic material extruded by the single screw extruder with the screw rod is high in viscosity, and a plastic product produced by the extruder has few crystal points and bubbles.

Owner:GUANGDONG DESIGNER MASCH CO LTD

Biaxially oriented polypropylene protecting film for base material of flexible printed circuit board and preparation method of biaxially oriented polypropylene protecting film

ActiveCN104260521ALess crystal pointLess impuritiesLamination ancillary operationsSynthetic resin layered productsLow-density polyethyleneMasterbatch

The invention discloses a biaxially oriented polypropylene protecting film for a base material of a flexible printed circuit board and a preparation method of the biaxially oriented polypropylene protecting film. The biaxially oriented polypropylene protecting film is of a three-layer structure consisting of an inner surface layer, a middle layer and an outer surface layer, wherein the middle layer comprises an antistatic master batch, a flexible master batch and homo-polypropylene; the inner surface layer comprises an anti-sticking master batch, a flexible master batch, an antistatic master batch and homo-polypropylene; the outer surface layer comprises an anti-sticking master batch, a flexible master batch and homo-polypropylene; the flexible master batch comprises an ethylene-propylene polymer, an ethylene-butylene polymer, a propylene-butylene polymer, low-density polyethylene and linear low-density polyethylene. The biaxially oriented polypropylene protecting film has the advantages of good flexibility, excellent physical performance, optical performance and printing performance, good tear resistance, low static electricity, simple processing process and the like, and the base material can be maximally protected.

Owner:ANHUI GUOFENG PLASTIC

Grafting reaction device and molten grafting reaction method

The invention discloses a grafting reaction device. The grafting reaction device comprises film casting equipment, grafting addition agent dispersion pre-reaction equipment and reactive extrusion grafting equipment, wherein the film casting equipment is used for extruding a premixed material in a mixed mode and casting the premixed material into a polymer film; the grafting addition agent dispersion pre-reaction equipment is used for dispersing grafting addition agents onto the polymer film and making the grafting addition agents have a pre-grafting reaction with the polymer film; the reactive extrusion grafting equipment is used for grafting functional monomers to a polymer molecule chain to form a graft polymer. According to the grafting reaction device, the polymer is cast to form the film, the grafting addition agents are dissolved in a dispersing agent and sprayed on the molten polymer film in a mist spray mode, the pre-grafting reaction happens to the surface of the molten polymer film, a grafting reaction is completely conducted in the reactive extrusion grafting equipment, a trace of the grafting addition agents are uniformly dispersed, the intercoupling probability of free radical active points of the polymer is lowered when the material is constantly sheared in a screw rod and an interface is updated so that the occurrence probability of crosslinking side reactions can be lowered, and the graft polymer which is high in grafting ratio, small in fisheye quantity and small in smell is obtained.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Polypropylene film used for ultra-thin type aluminum-plastic film and preparation method thereof

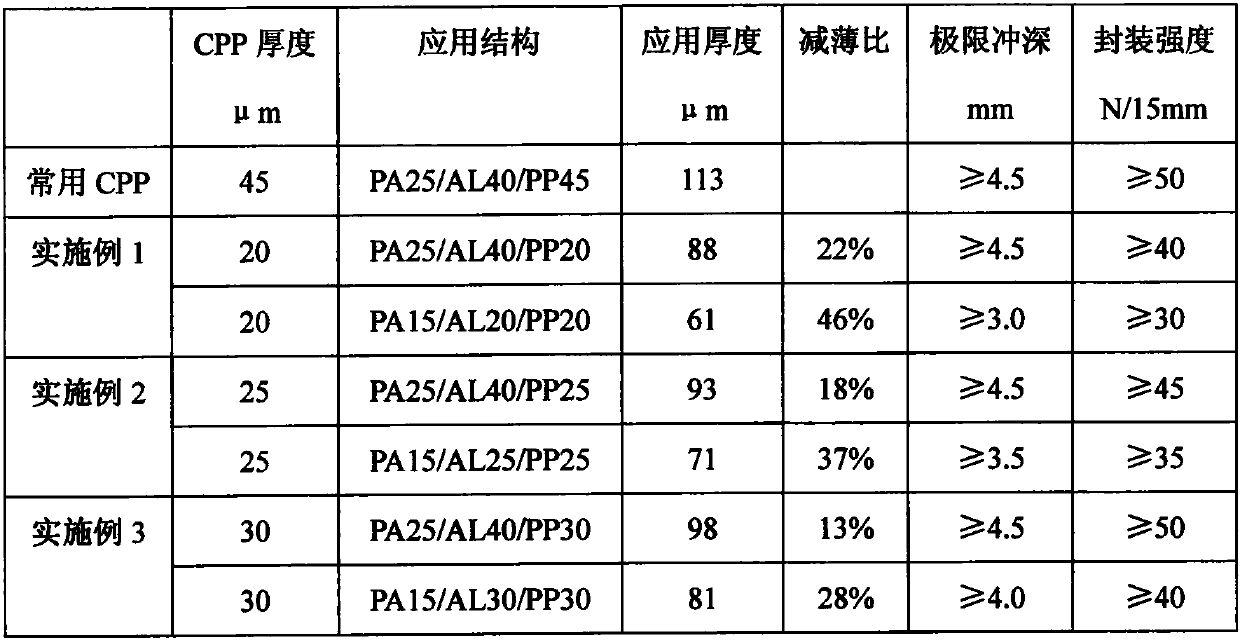

PendingCN107757032AImprove temperature resistanceLess crystal pointSynthetic resin layered productsElectrical equipmentPolymer scienceFiltration

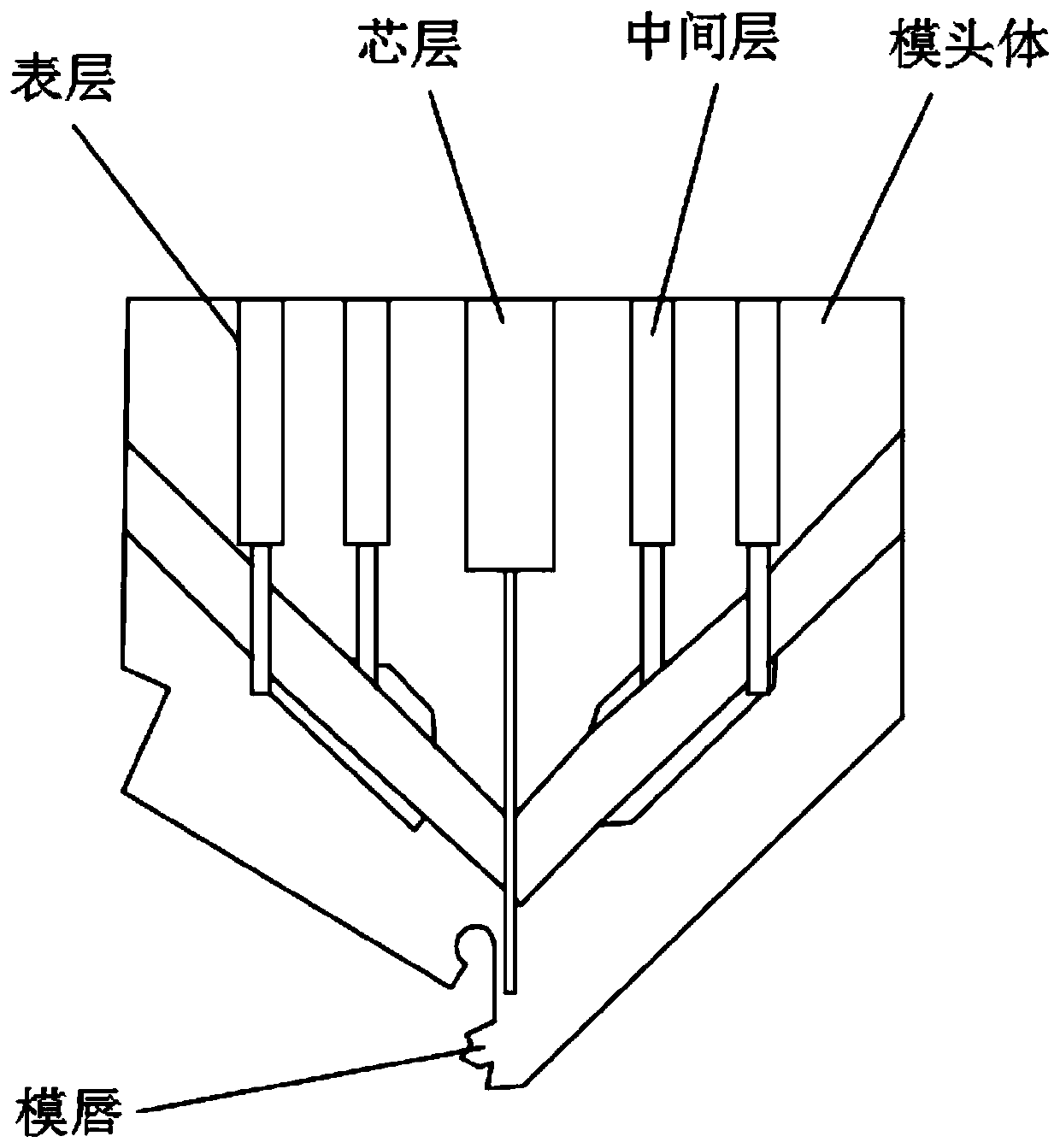

The invention provides a polypropylene film used for an ultra-thin type aluminum-plastic film. The polypropylene film comprises a polypropylene outer layer, a polypropylene core layer and a polypropylene heat-seal layer, wherein the polypropylene core layer is arranged between the polypropylene outer layer and the polypropylene heat-seal layer, and the polypropylene outer layer, the polypropylenecore layer and the polypropylene heat-seal layer are sequentially compounded together. The invention also provides a preparation method of the polypropylene film used for the ultra-thin type aluminum-plastic film. According to the preparation method, polypropylene resin of different melting points are combined, so that polypropylene has better temperature resistance; and a charging device with a vacuumizing or nitrogen sealing function and a secondary filtration technology are used, and one or more combinations of other raw materials is added, so that the produced casting polypropylene film has fewer crystal points. The casting polypropylene film is applicable to the ultra-thin type aluminum-plastic film, thinning is guaranteed, and packaging and depth scouring performances are also guaranteed at the same time.

Owner:SHANGHAI ZIJIANG NEW MATERIAL TECH CO LTD

Manufacturing process of biaxially stretched color base film for manufacture process protection of electronic products

The invention discloses a manufacturing process of a biaxially stretched color base film for manufacture process protection of electronic products, and belongs to the field of manufacturing color basefilm. The manufacturing process comprises the steps of manufacture of a color masterbatch and manufacture and production of a color film by using a five-layer biaxial stretching device, specificallythe color masterbatch is produced by using a tandem type screw extruder; and the production of the color film by using the five-layer biaxial stretching device includes the following steps: drying, extruding, casting, longitudinal stretching, transverse stretching, heat treatment and winding, specifically the step of extruding includes extruding by a main extruder and extruding by using four auxiliary extruders. the four auxiliary extruders used in the step of extruding by using the four auxiliary extruders are able to make the film surface color be uniformly distributed, less in crystal point, less in bubbles, and high in gloss; the corona surface has a uniform corona value and no corona on the back surface, and the non-corona surface has no glue; the pollutant to a main batching system of a production line is less; and products are converted quickly after production is completed.

Owner:SUQIAN GETTEL PLASTIC IND

Metallocene linear low-density polyethylene reinforced wrapping film manufacturing process

InactiveCN111805950AReduce thicknessImprove puncture resistanceSynthetic resin layered productsFlat articlesWaxLow-density polyethylene

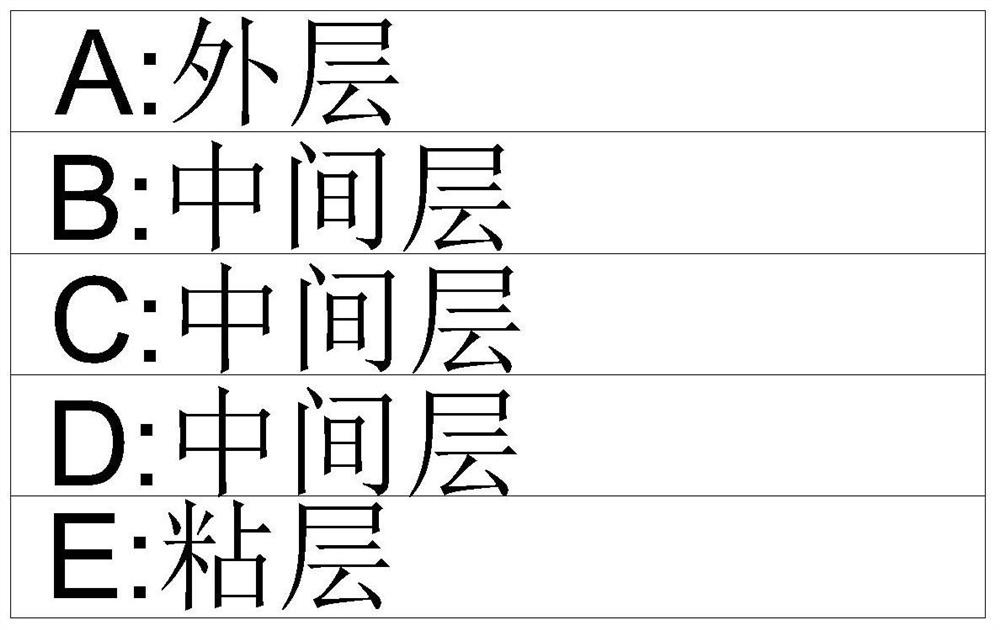

The invention relates to the technical field of wrapping films, and discloses a metallocene linear low-density polyethylene reinforced wrapping film manufacturing process. The process is characterizedin that mLLDPE-a and mLLDPE-b in a wrapping film structure are two metallocene linear low-density polyethylene with different melt indexes respectively, are used for improving the strength, and are used for adjusting melt index of blended material according to different equipment characteristics; an mLLDPE-c is metallocene linear low density polyethylene with a high viscosity mark and is used forimproving the viscosity of a finished product film, polyethylene is thermoplastic resin prepared by polymerizing ethylene and also comprises a copolymer of ethylene and a small amount of alpha-olefinin industry, and the polyethylene is odorless, nontoxic and wax-like in hand feeling, has excellent low-temperature resistance (the lowest use temperature can reach minus 100 DEG C to minus 70 DEG C)and good chemical stability, can resist erosion of most acids and alkalis (does not resist acids with oxidizing properties), is insolubility in common solvents at normal temperature, and has low water absorption and excellent electrical insulation, and the layer A is the mLLDPE-a + mLLDPE-b + LLDPE; the B layer is mLLDPE-a + mLLDPE-b + LLDPE, the C layer is mLLDPE-a + mLLDPE-b + LLDPE, the D layer is mLLDPE-a + mLLDPE-b + LLDPE, and the E layer is mLLDPE-c.

Owner:上海瑞泽丰标准技术服务有限公司

Adhering resin for high-barrier bottle and preparation method thereof

ActiveCN108178995AStable performanceLess crystal pointNon-macromolecular adhesive additivesGraft polymer adhesivesMaleic anhydridePlasticizer

The invention provides adhering resin for a high-barrier bottle and a preparation method thereof. The adhering resin is prepared from the following components of 15 to 30 parts of maleic anhydride-grafted linear low density polyethlyene master batch, 15 to 30 parts of high density polyethlyene, 15 to 30 parts of low density polyethlyene, 20 to 30 parts of POE (polyolefin elastomer), 5 to 10 partsof polylactic acid, 0.2 to 1 part of talcum powder, 0.2 to 0.5 part of antioxidant, 1 to 10 parts of plasticizer, and 2 to 6 parts of silane coupling agent. The invention further provides a preparation method of the adhering resin for the high-barrier bottle. The adhering resin for the high-barrier bottle and the preparation method have the advantages that the self color is transparent, the property is stable, and the number of crystal points is fewer; the adhering property of each layer of the prepared high-barrier property is high, the barrier property is strong, the inner surface and outersurface are smooth, the heat stability is good, and the like.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

Hot melting pressure-sensitive glue as well as preparation method and application thereof

ActiveCN109777331ANo pollutionImprove stabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesTectorial membranePlasticizer

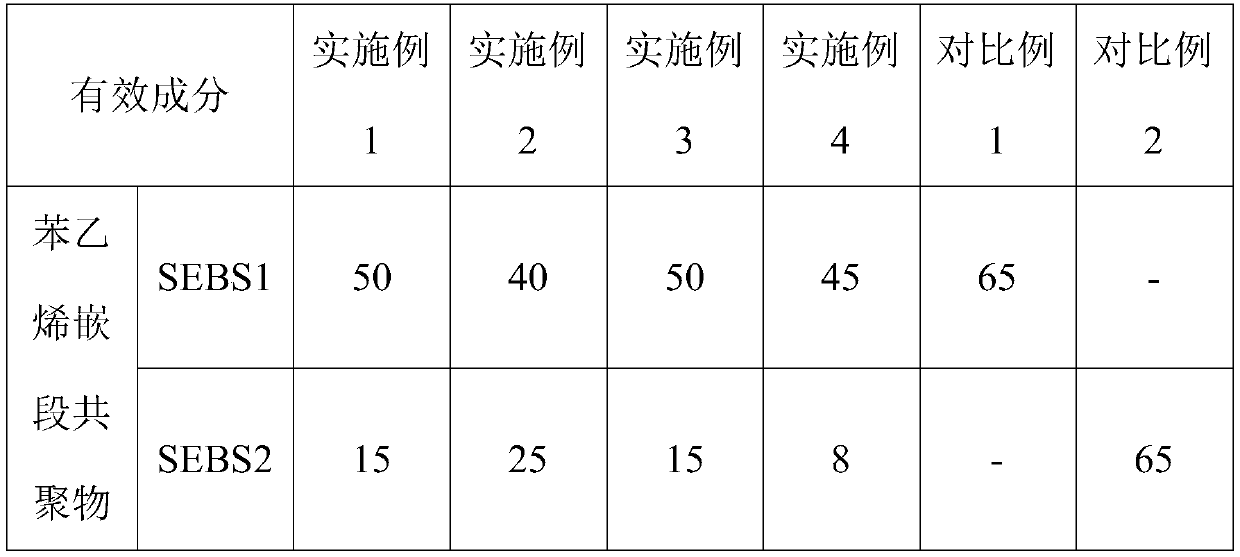

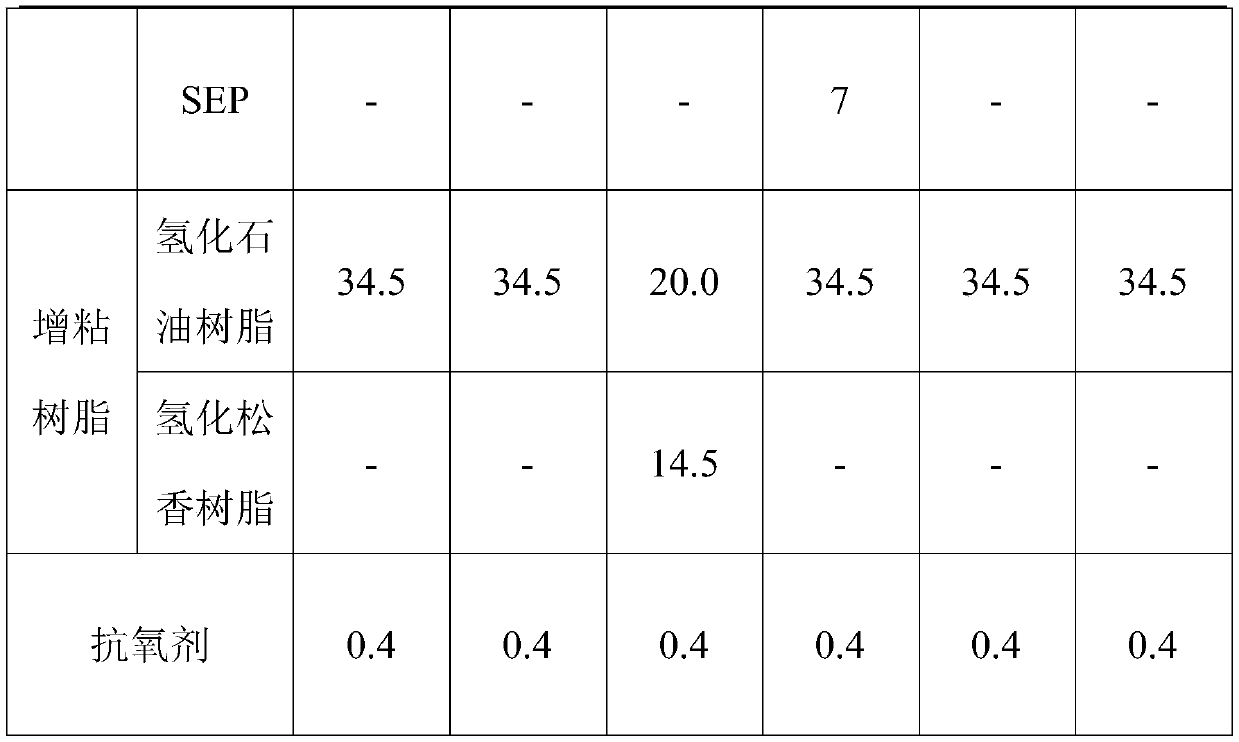

The invention discloses a hot melting pressure-sensitive glue as well as a preparation method and application thereof. The hot melting pressure-sensitive glue comprises the following effective components in parts by weight: 55-70 parts of styrene segmented copolymer, 30-45 parts of tackifying resin, and 0.1-0.5 part of an antioxidant. The preparation method comprises the following steps: mixing styrene segmented copolymer, tackifying resin and antioxidant to obtain a mixture; pelletizing the mixture in water; drying. The hot melting pressure-sensitive glue is used for preparing a protection film; the hot melting pressure-sensitive glue is free from plasticizer such as mineral oil and polybutene oil; the problems of oil separating out and smoking in processing are avoided; a die head is notinfluenced; the production can be continuously carried out; generation of three wastes in production is avoided; the environmental pollution is avoided.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

High temperature-resistant nanosized self-adhesive optical protective film and production method thereof

PendingCN109605886AImprove transmittanceStable self-adhesiveSynthetic resin layered productsFlat articlesLow-density polyethyleneElastomer

The invention relates to a high temperature-resistant nanosized self-adhesive optical protective film and a production method thereof. The self-adhesive optical protective film comprises a self-adhesive layer, an intermediate layer and an unwinding layer, wherein the self-adhesive layer comprises metallocene polyethylene elastomer resin, soft rubber resin and ternary polymerized polypropylene resin at a mass ratio of (70-80):(10-20):(5-15), the intermediate layer includes high-density polyethylene resin, linear low-density polyethylene resin and low-density polyethylene resin at a mass ratio of (25-35):(35-45):(25-40), and the unwinding layer includes block polypropylene resin and a fluorine-containing auxiliary agent at a mass ratio of (90-98):(2-10). The self-adhesive optical protectivefilm is produced in a multi-layer coextrusion tape-casting mode, and has the excellent properties of high temperature resistance, no shrinkage, repeated sticking and no precipitation.

Owner:永新股份(黄山)包装有限公司

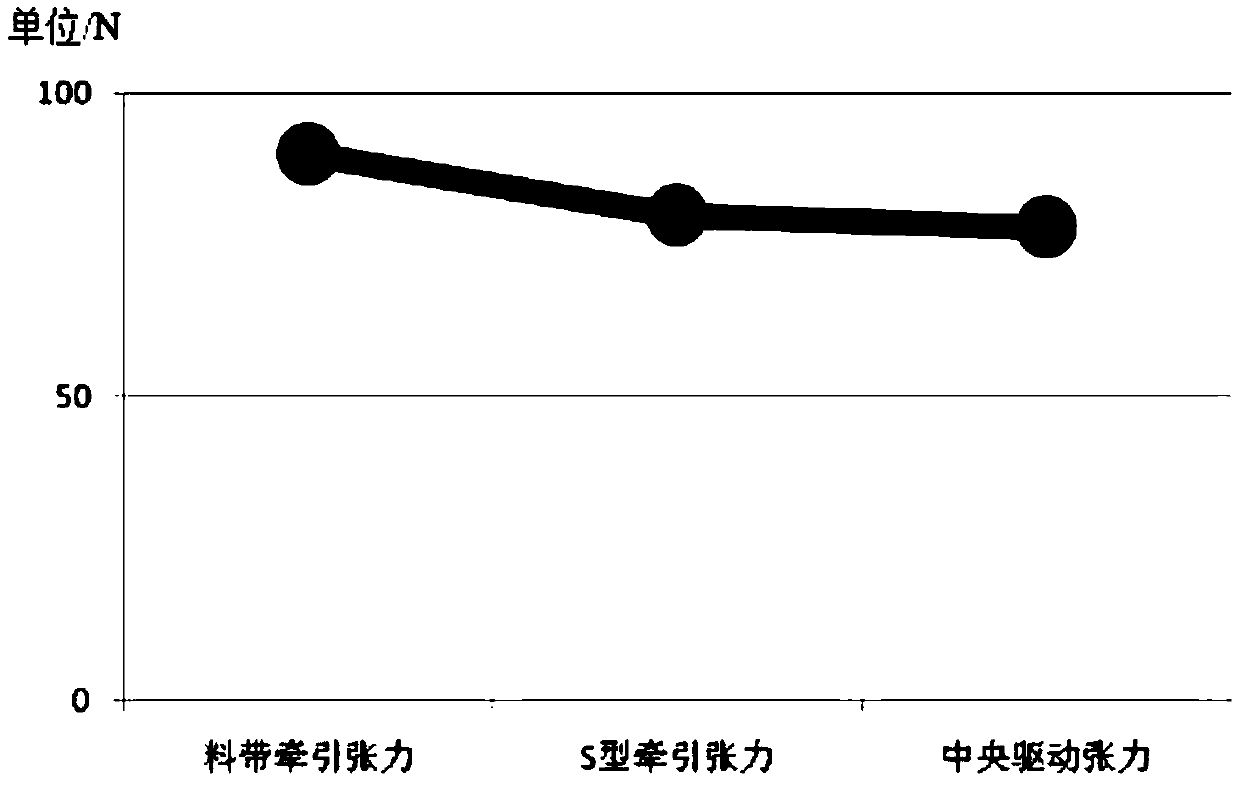

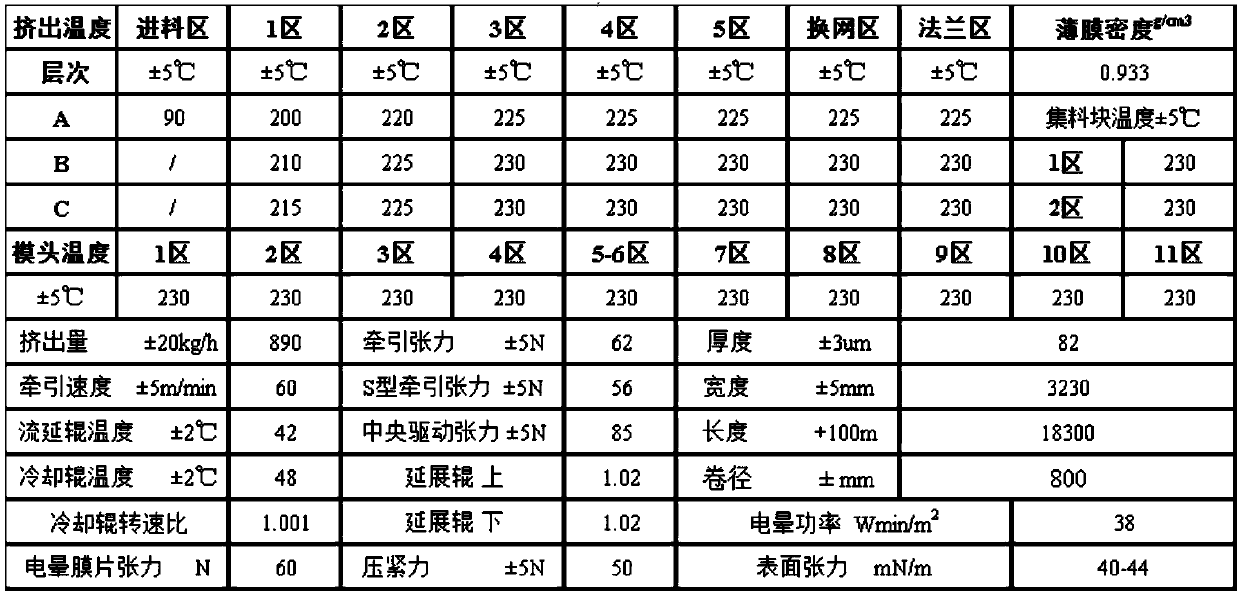

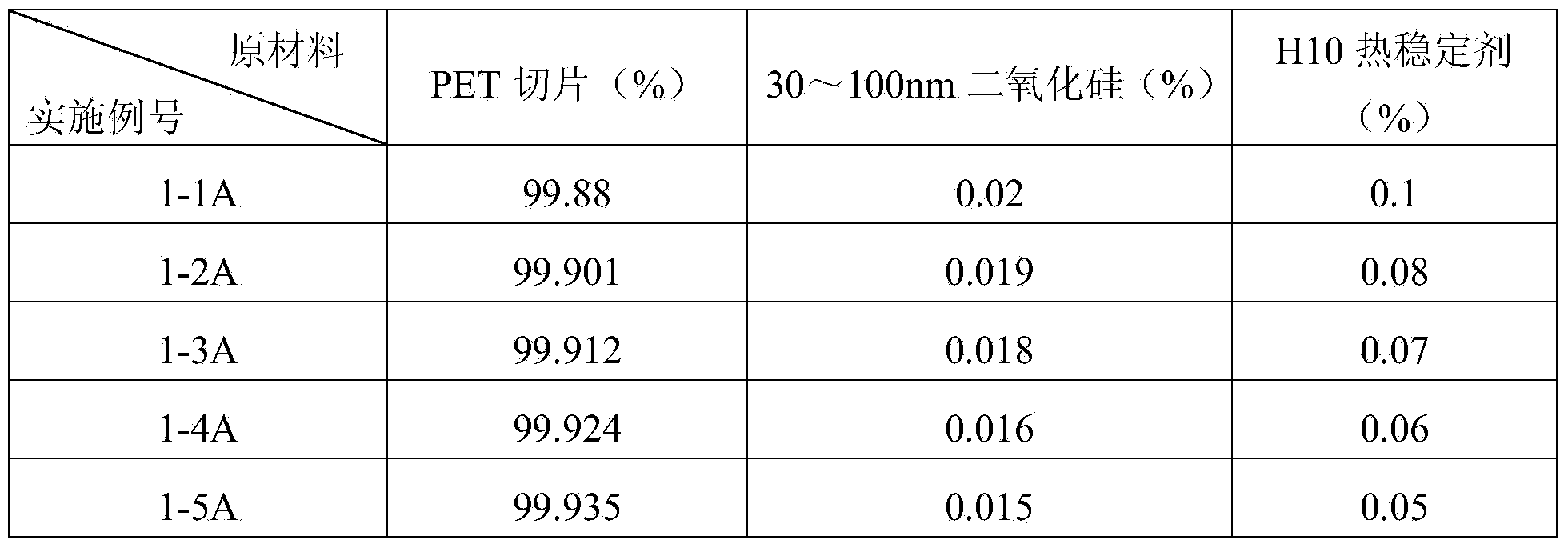

Single-face or double-face optical hardening composite membrane and preparation method thereof

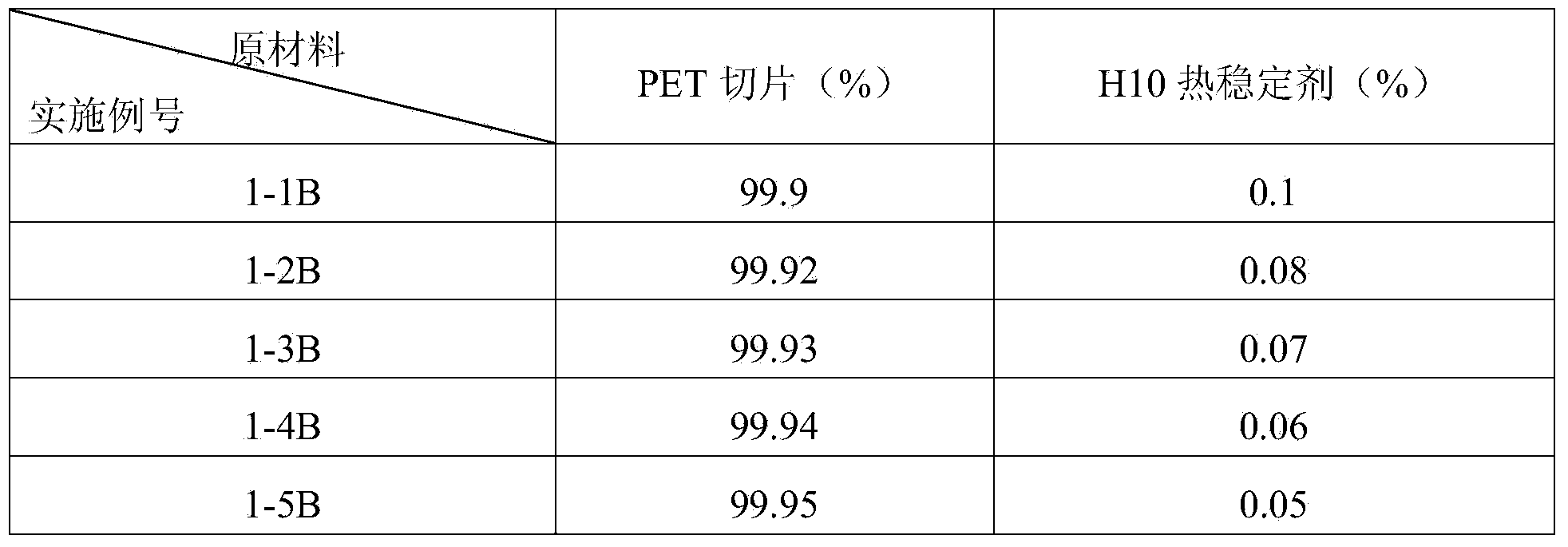

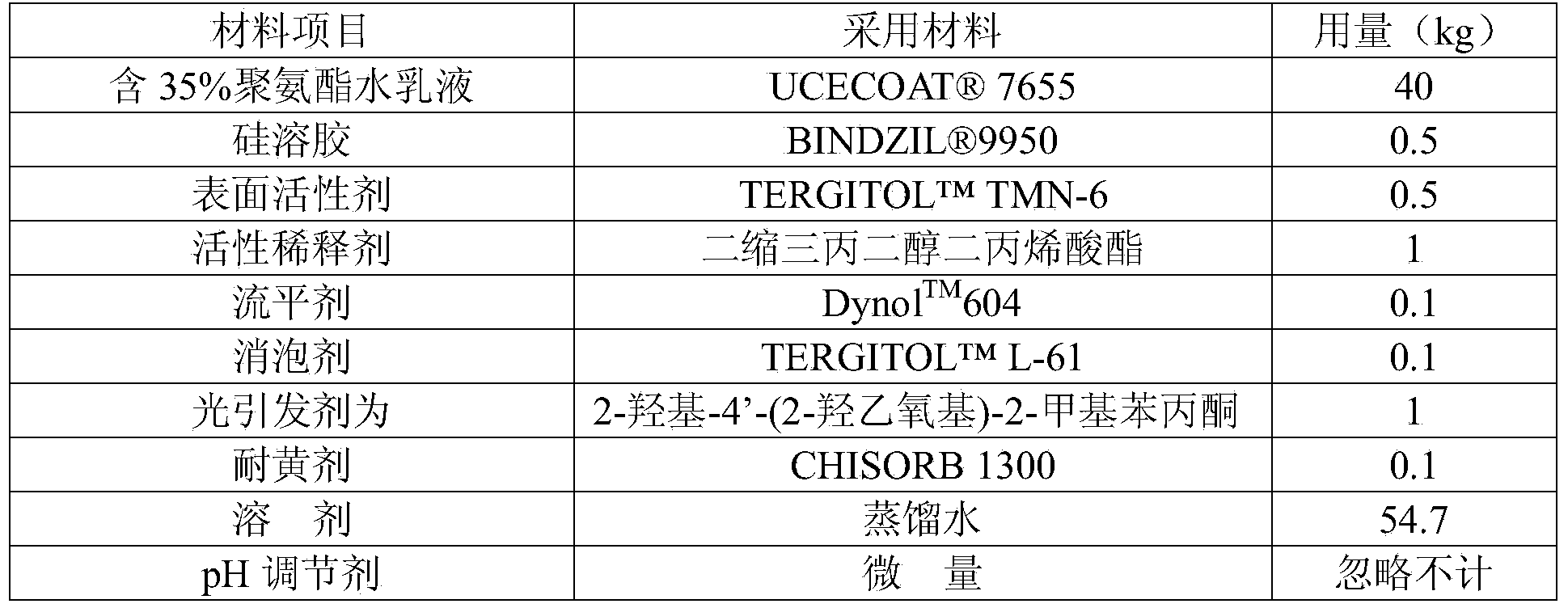

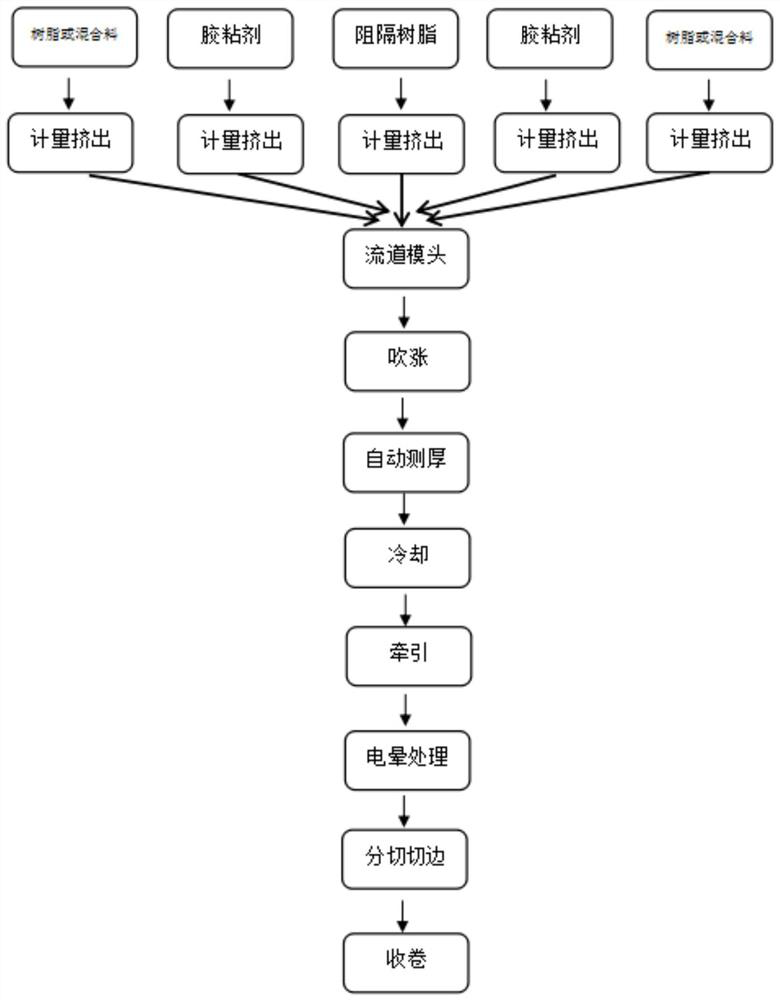

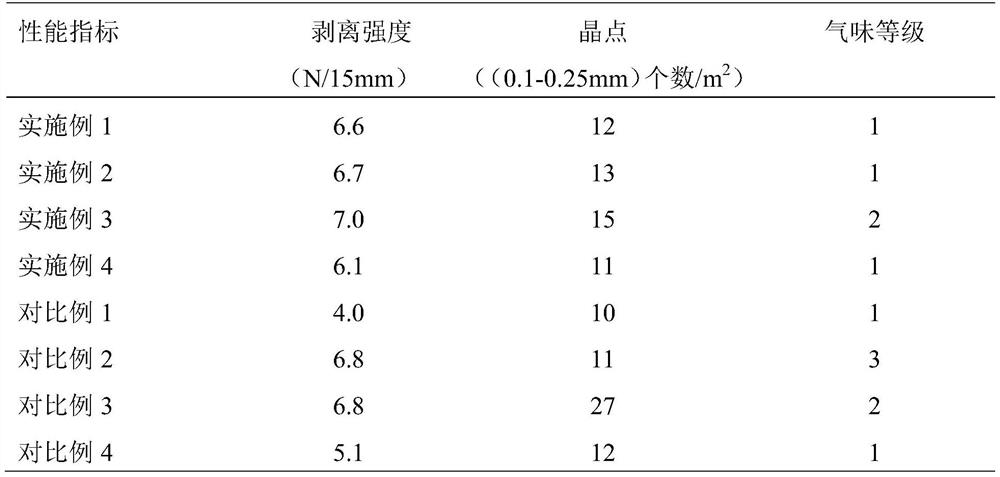

ActiveCN104228257AReduce interference rainbow patternLess crystal pointLamination ancillary operationsSynthetic resin layered productsActive agentUltraviolet lights

The invention discloses a single-face or double-face optical hardening composite membrane. The single-face or double-face optical hardening composite membrane is characterized by being composed of a base membrane and hardening resin coatings, wherein the hardening resin coatings are applied and solidified to single face or double faces of the base membrane, the base membrane is a two-way-stretched optical A-layer and B-layer composite membrane or A-layer B-layer and A-layer composite membrane, the thickness of the base membrane is 100 to 250 microns, and the thickness of each coating is 1 to 10 microns. A preparation method comprises the steps of performing melting casting and longitudinal drawing on polyester chips respectively by a No.1 extruder and a No.2 extruder so as to form blank sheets, then applying hardening resin coating liquid to the surfaces of the blank sheets, drying, horizontally drawing, performing heat setting, and solidifying by ultraviolet light so as to obtain the single-face or double-face optical hardening composite membrane, wherein the hardening resin coating liquid is composed of an aqueous emulsion containing 35% of polyurethane, nano-silica sol, a surface active agent, a flatting agent, a defoaming agent, a photoinitiator and an anti-yellowing agent. According to the single-face or double-face optical hardening composite membrane, one-step processing is adopted, and the prepared single-face or double-face optical hardening composite membrane is suitable for the field of touch displays.

Owner:四川东方绝缘材料股份有限公司

Hot melt adhesive for high-performance polypropylene barrier film as well as preparation method and application of hot melt adhesive

ActiveCN114032049AGood adhesionNo irritating smellNon-macromolecular adhesive additivesSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a hot melt adhesive for a high-performance polypropylene barrier film as well as a preparation method and application of the hot melt adhesive. The hot melt adhesive is prepared from 10 to 30 parts of maleic anhydride grafted polypropylene, 35 to 60 parts of polypropylene-random-copolymer, 0 to 20 parts of low-density polyethylene, 10 to 30 parts of metallocene polyolefin plastomer, 0 to 5 parts of PP grafted maleic anhydride wax and 0.1 to 0.5 part of antioxidant. Through component optimization, the hot melt adhesive has the characteristics of excellent bonding performance, no pungent smell and few crystal points, and solves the problems of poor bonding force, strong smell and many crystal points of the hot melt adhesive for the domestic polypropylene barrier film.

Owner:合诚技术股份有限公司

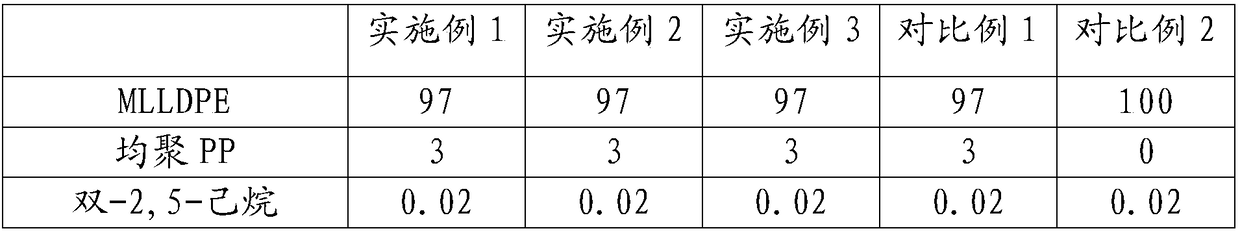

Polyethylene composition for greenhouse film and preparation method of polyethylene composition

InactiveCN108003452AFully dispersedImprove melt strengthCultivating equipmentsGreenhouseThermal insulation

The invention relates to a polyethylene composition for a greenhouse film. The polyethylene composition is prepared from the following raw materials in parts by weight: 100 parts of mLLDPE resin, 0.03to 0.05 parts of peroxide, 6 to 14 parts of maleic anhydride master batch, 0.1 to 0.5 part of antioxidant, 0.04 to 0.07 part of rheological agent, 1 to 1.5 parts of heat preserving additives, and 0.05 to 0.10 part of lubricating agents. The composition has higher melt viscosity, and the prepared greenhouse film has thermal insulation properties.

Owner:淄博赢信达知识产权咨询服务有限公司

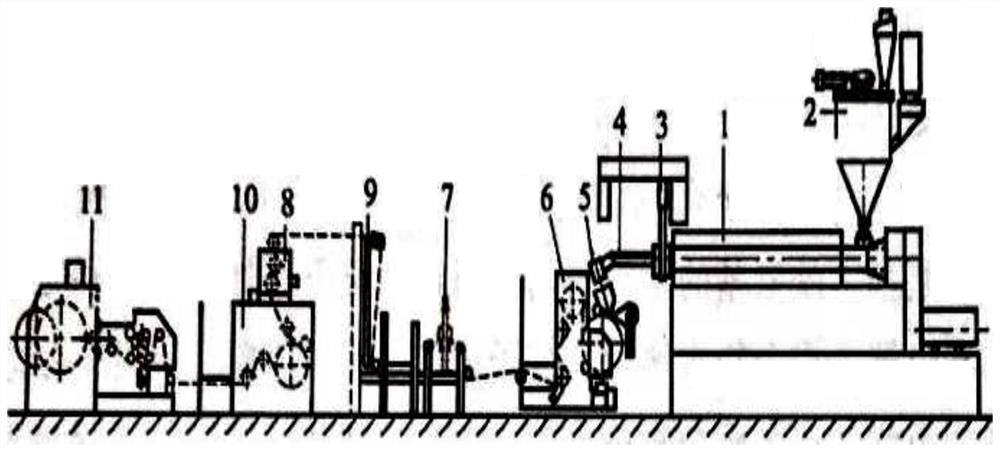

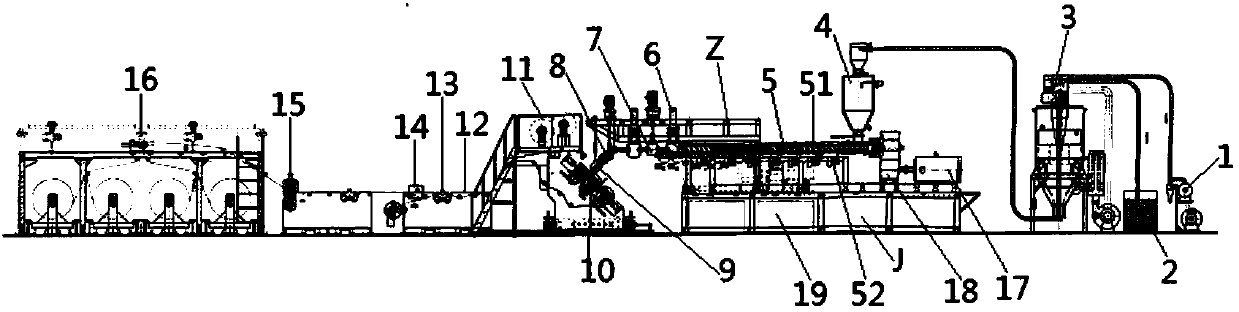

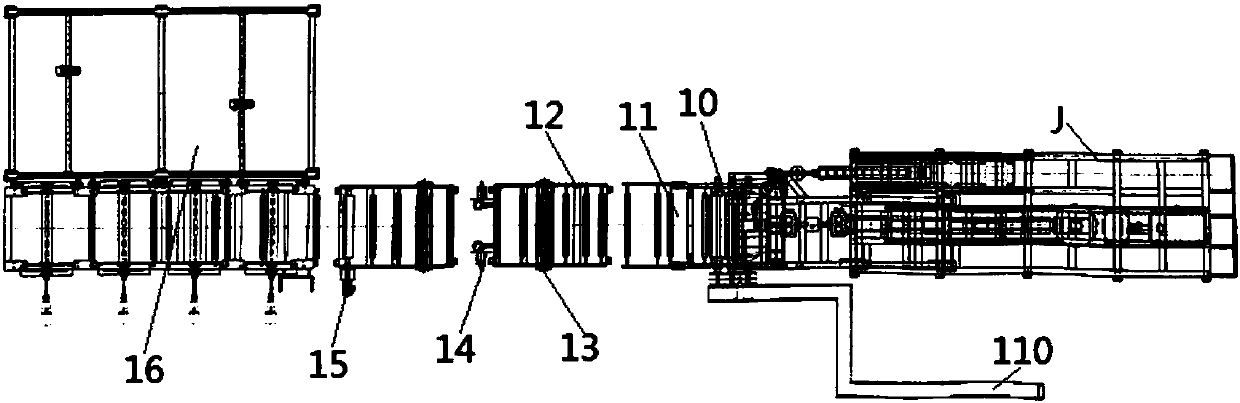

Special PET food packaging sheet extrusion production line

The invention provides a special PET food packaging sheet extrusion production line, which sequentially comprises a material feeding unit, a molding unit, a cooling trimming unit and a finished product collection unit from right to left, wherein the material feeding unit comprises a vacuum feeder, a material tank, a dryer and a material hopper, the molding unit comprises a rack, a support arm, a cylinder, a screen changer, a metering pump, a distributor, a mold, a three-roller calender and a double-working position laminating device, the cooling trimming unit comprises a cooling bracket, a round cutter device and a corona machine, the finished product collection unit comprises a drawing machine and a winding machine, the cylinder and the support arm are sequentially arranged on the rack, and the screen changer, the metering pump and the mold are sequentially arranged on the support arm. According to the present invention, the produced special PET food packaging sheet has characteristics of less crystal point, no whitening during plastic suction, neat winding and high comprehensive energy efficiency; and the production line can further be used for producing PS, PP, PE and other sheet materials.

Owner:东莞市杰伟机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com